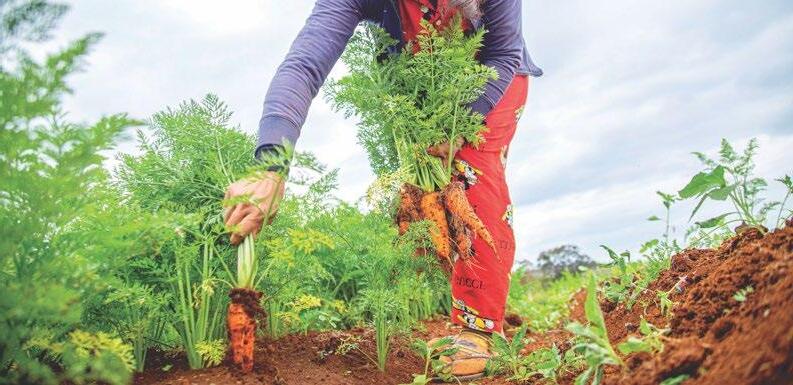

Food insecurities are a concern for most nations and a ticking time bomb that needs to be addressed effectively with sustainable solutions. With economies now looking forward to increasing food security and creating more employment through farming, it is a good move to invest in farming.

Society relies on farmers, and never is it more apparent than when supermarket shelves run empty. Perhaps this is a case of not appreciating something until it is no longer there, but I hope for all our sakes that we do not get to that point. The old adage: “If you’ve eaten today, thank a farmer”, rings as true in modern times as it did hundreds of years ago. Society simply cannot survive without food, and food is produced by farmers.

Ministry of Agriculture, Livestock, Fisheries and Co-operatives Cabinet Secretary, Mithika Linturi, recently revealed that the Zambian government has agreed to offer Kenyan farmers land for largescale farming in Zambia.

Their talks centred on improving agricultural production in both countries, especially in Kenya since the country is still facing the effects of the prolonged drought. Kenyan farmers will in turn be required to export their yields back to Kenya in order to boost the country’s food supply and security.

Some more good news, on the other hand, for Zambian residents is that Zambia is set to benefit from a recent project where solar-powered water pumps are being installed by Beyond the Grid Fund

The main objective of stubble cultivation is to thoroughly mix the crop residue and soil. LEMKEN has the right solution for farmers to cultivate African soil. Read more on page 2.

for Africa (BGFA). Projects like these, involving solar power, can scale up energy access in rural and peri-urban areas, enhance productive energy use, and help make off-grid energy products more affordable in Zambia.

I think more than ever we need to realise that standing together will take everyone much further than constantly working against one another.

A little support goes a long way, and I hope that the world soon realises that we can do without private jets, but we cannot do without farmers.

We are looking forward to attending the AgriTech Zambia expo this year, and I am sure that farmers and role players in the agriculture sector will make full use of this opportunity.

These events and expos are so important where farmers and suppliers can meet and greet, make contact and chat, because one thing remains a fact: the people must eat, farmers must provide food, and for that they need only the best technology and advice going forward.

Please contact me to tell me what you would like to read about, and to share your story and your thoughts. I would like to work together, and not against.

Until next time, enjoy the read.

ProAgri greetings

Bianca Henning

bianca@proagri.co.za

LEMKEN: The best long-term investment for your farm

John Deere AME: Meet the New S440 series combine

Choose Senter360 for local quality

Catfish farming offers an alternative in Zambia

Make money with layers by keeping your production up- Part 2

Processing of condiments 28: Pickled asparagus

Goat breeds part 1: African meat breeds

Farming with nature: Drought mitigation

Fruit production part 4: Prickly Pears

Farm management and planning Part 1

Controlling Salmonella in laying enterprises

Beekeeping part 9: Obtaining a beehive

The lastest in agricultural technology from around the world

Producing fibre crops can boost the economy

Africa climate crisis

Editor Bianca Henning >

Reporters

Benine Ackermann >

Maryna Steyn >

Natasha Pansegrouw>

Specialist Writer

Annemarie Bremner >

+27 82-326-2572

bianca@proagri.co.za

+27 73-105-6938

benine@proagri.co.za

+27 82-261-9177

maryna@proagri.co.za

+27 81-736-4236 natasha@proagri.co.za

+27 82-320-3642 annemarie@proagri.co.za

Senior Production Manager

Zainab Pandor >

+26 (0)97-769-9786 zainab@proagri.co.za

Client Relations Manager

Carin Swartz >

Marketing Manager

Diane Grobler >

Marketing

Xander Pieterse >

Johan Swartz >

Tiny Smith >

Lynette van Tonder >

Creative Director

Christiaan Joubert >

Design

Michelle Kruger & Enquiries

Engela Botha >

+27 84-233-0123

carin@proagri.co.za

+27 82-555-6866

diane@proagri.co.za

+27 79-524-0934

xander@proagri.co.za

+27 71-599-9417

johan@proagri.co.za

+27 82-698-3353

tiny@proagri.co.za

+27 74-694-4422

lynette@proagri.co.za

+27 72-419-3990

christiaan@proagri.co.za

Jamie-Lee Tromp

+27 12-803-0782

engela@proagri.co.za

Distribution and subscription

Nita Volmer-van Zyl >

Accounts

Ronel Schluter >

Business Manager

George Grobler

+27 79-515-8708

nita@proagri.co.za

+27 12-803-0782

accounts@proagri.co.za

by Bianca Henning

by Bianca Henning

Choosing quality agricultural equipment and a reputable supplier offers many valuable benefits for your farming operation.

Du Preez Landgoed is a family farming operation located in the Northwest Province of South Africa, between Lichtenburg and Koster. André du Preez (junior) is the third-generation farmer and he has always been passionate about farming. He and his brother, Waldo, run the farm, and one can see that their vast amount of dedication, patience and effort to achieve success over the years has paid off.

“At the end of 2015, I joined my father on the farm,” André says. “Farming has always been my passion, and taking forward what my father and grandfather have built up over the years, is an incredible honour.”

André and Waldo, his younger brother, work together like a well-oiled machine, to ensure that they get the best out of every planting season. They mainly grow soya beans, sunflowers, sorghum, sugar beans, and maize, some on dryland and some under irrigation.

André explains: “Waldo is responsible for the planting process, ensuring that the seeds are in the soil, whereafter I do the crop care, ensuring that the crops grow well.”

“Every aspect of our farm is planned carefully, before, during and after

every season. The agriculture industry has radically transformed over the past 50 years. When I think back to how my grandfather farmed, compared to how we do things today, there is a huge transformation. Agriculture is a constantly growing industry, offering so many opportunities, and tackling these opportunities requires that the next

generation brings fresh thinking and innovative solutions,” André adds.

“All the years we ploughed our lands, until we realised that the process of ploughing is not the most effective way

LEMKEN results: Perfect and solid-standing maize.

After LEMKEN has proved itself on the Du Preez farm, they caught the family's attention again at NAMPO with the Karat 9. Since they also plant a fair amount of maize, they faced the challenge of managing maize residue after harvesting season year after year.

• Conservation of soil moisture, and improved water infiltration

• Better seed germination resulting in better yields and more tonnes harvested

• Uniformity in fields for better lime and fertiliser application

of going forward,” André admits.

“Our journey with LEMKEN started in 2015, with a 6-metre Rubin 12. I still remember it like yesterday. It was during wheat harvesting season, and we desperately needed a soil cultivator,” says André.

“Our need was to do one cultivation and plant as soon as possible thereafter, and as we all know, wheat residue management is a big headache for most farmers. Many farmers burn it; however we believe in building up our soil, therefore, we try to work everything that we can back into our soil to build up the organic content of our soil.

“Our answer was LEMKEN. Blackie from LEMKEN suggested and demonstrated the 6-metre Rubin 12 to us on the farm, and since the machine started working on our fields, we haven’t looked back to anything else.”

After the 6-metre Rubin 12 proved itself on the Du Preez farm, it was like love at first sight. Over the years, as their farming operation expanded, they traded the 6-metre Rubin 12 in for a 9,5-metre. Now even more hectares can be cultivated per day in less time.

Apart from the need for better soil cultivation, we also wanted to improve our wheat planting methods. Back in the day, we always planted our wheat with a spreader, which wasn’t effective enough compared to the price of seed and the number of hectares we planted. Not only were the seeds placed unequally in the soil, but we also wasted approximately 30% of the seed with the spreading method, which had a ripple effect on the growth of our yields as well as the tonnes harvested,” André adds.

He elaborates: “At that time, it was crucial for us to make some changes to our wheat planting method. Our need was to plant more precisely and effectively. In 2016, we were in the market for a precision air seeder, and once again Blackie came up with the perfect solution when he recommended the LEMKEN Solitair 12 planter. The planter was demonstrated at a farmer nearby, and when we saw with our own eyes

“The need for one stubble cultivation and reconsolidating our soil after maize harvesting arose once again. After we saw the LEMKEN Karat 9 at NAMPO, it was demonstrated at a farmer’s day in the area, which made our decision much easier. We realised that this is the next step in taking our farming operation forward, getting more done with less. After the Rubin 12 and Karat 9 have done their bit, our fields are

• Less waiting time before planting André adds: “LEMKEN is 100% behind the farmer. You can always rely on them and if there are any problems or queries, they will sort it out immediately. For us, service which includes the performance and value adding of the equipment as well as after-sale service is of utmost importance, and LEMKEN ticks all those boxes.”

To cultivate and prepare more than 3 000 hectares of land, you cannot mess around with something that does not do the job correctly, effectively and timely.

André concludes: “There is no need for us to consider any other imple -

ready for the next season, creating an even and perfect seedbed.”

The Karat 9 replaced the work of ploughing and ripping on the Du Preez farm, with much less power requirement on the tractors. “So, we save fuel and time, and when the Karat has done the job, there is a firm and perfect seedbed,” André states.

André highlights the biggest advantages of LEMKEN on their farm:

• Service and support from the LEMKEN team (including the availability of spare parts)

• Minimal maintenance and breakages on the machines

• Minimal soil cultivation, resulting in less soil compaction

• Saving time and fuel

• Better management of weeds

• Reconsolidation of soil

ments than LEMKEN. We realised that investing in high-quality farm equipment helped us produce better crops, get better yields and ultimately conserve our soil for future production. All the LEMKEN equipment work in perfect harmony on our farm. I would highly recommend LEMKEN to any farmer, because with LEMKEN you are making an investment for the long term. I invite any farmer interested in LEMKEN equipment to our farm, to see with their own eyes what difference LEMKEN can make.”

For more information on LEMKEN’s implements, contact Karel Munnik on (+27)82-412-2577 or k.munnik@ lemken.com; or Blackie Swart on (+27)82-404-9651, or b.swart@lemken.com, or visit www.lemken.com.

what it could do, we knew that this was the answer to our challenges.”A proud father and son moment when ProAgri visited the Du Preez family in 2018: André du Preez, senior and junior with their LEMKEN Solitair 12 precision planter, before the Du Preez brothers took over from their father.

John Deere AME is introducing the S440 combine harvester to the Africa and Middle East Markets. This new addition to the John Deere combine line-up is an excellent choice for farmers looking for a compact, more cost effective but still technologically advanced combine. This machine is a Class 4 combine but is packed with most of the features and technology of the larger John Deere S-Series combine harvesters and is designed to achieve all the desired qualities: efficiency, reliability, grain sample quality, and harvesting technology.

Compared to the larger John Deere Harvesters in the market, the S440 consists of a smaller framework and engine capacity. Still, there is no doubt about the performance of this machine. It is equipped with the proven John Deere 6-cylinder, 6,8-litre Tier-3 engine, equipped with an isochronous governor, which assists with maintaining rotation even during peak power demand without the operator's intervention.

With 175 kW rated power and 191 kW peak power, it maintains material processing efficiency during the entire harvest operation to achieve higher performance.

The S440 is a rotor combine equipped with the John Deere-designed TriStream rotor, measuring 61 cm by 313 cm. “This feature ensures the efficient harvest of maize, soya beans, wheat, canola, rice, sorghum, and many other grains while reducing fuel and power consumption and providing effective threshing and grain separation,” says Jacques van den Berg, Tactical Marketer at John Deere AME. “The system features the Dyna Flow Plus cleaning system which ensures even material distribution over the entire length of the sieves by using side hill deflectors.”

The combine's automatic ground adjustment controls, or Active Terrain Adjust™, limit grain loss to a minimum when harvesting on inclines and slopes. The system achieves this by automati-

cally adjusting the fan speed and opening or closing the chaffers and sieves depending on the angle of the combine.

“When it comes to quality, John Deere has not compromised in the design of the S440 and included a range of technological features in the standard package,” Jacques explains. “Farmers can expect to benefit from a versatile corner post display, a lateral tilt feeder house, moisture and yield sensors, Active Terrain Adjust™, and in-cab adjustment of all settings.” Additionally, the standard package includes an industry-leading JDLink™ Connectivity subscription.

“For farmers who desire even more advanced technology solutions, John Deere offers factory-installed premium options such as the Starfire™ 7000 Receiver and Gen 4 touchscreen equipped with Auto-Track™ and Row-Sense™ functionalities” he says.

The JDLink™ subscription allows for the secure wireless transfer of harvest data and yield maps (generated by the Receiver and Gen4 Display) directly to the farmer's cell phone and the cloudbased John Deere Operations Centre™ precision farming solution. Furthermore, the 24/7 remote display access and service advisor remote capabilities provide customers an extra edge and greater peace of mind.

Specifications and optional extras: Customisable features of the S440 John Deere has combined the potent 6,8-litre engine with a 3-speed hydrostatic transmission and a 65-kW feeder house reverser. The S440 Combine also features a 6 500-litre grain tank and a 5,5-metre unloading auger that can unload at a rate of 65 litres per second while harvesting.

Farmers can choose between a stand-

ard or premium dual-speed discharge chopping beater paired with twin spreading discs for residue management.

For the farmer looking for more traction and stability, dual front wheels or a powered rear axle for four-wheel drive can be factory installed.

A deluxe cab with ample space provides operators with all the features needed to ensure productive and comfortable hours behind the controls.

An air-suspended operator seat, tiltable steering column, air conditioning, a mini cooler, radio, sun visors, and an instructor seat provide a pleasant working environment.

The S440 Harvester can accommodate a wide range of front-end equipment options. It can be fitted with six, and eight-row headers for maize harvesting, while the combine can handle rigid and flex platforms up to 25 feet in size for small grains.

During 2022, John Deere extensively tested the S440 harvester in South Africa, harvesting every type of grain over a wide geographical area. The compact combine exceeded expectations with its impressive versatility and performance under various harvesting conditions, delivering excellent grain quality, efficiency, and fuel consumption.

Based on the positive test results, John Deere AME is confident that the S440 Combine will prove to be capable, affordable, and popular option for grain farmers in the African and Middle East markets.

AtSENTER360 we are proud to not only supply products, but build long-term relations with our clients by delivering a package of high-quality products and excellent service. The SENTER360 centre pivot, manufactured since 1994, is known for its excellent quality and strength above industry standards. We have been part of the irrigation industry for more than 25 years and have interests in South Africa, Africa and in the rest of the world.

AtSENTER360 we are proud to not only supply products, but build long-term relations with our clients by delivering a package of high-quality products and excellent service. The SENTER360 centre pivot, manufactured since 1994, is known for its excellent quality and strength above industry standards. We have been part of the irrigation industry for more than 25 years and have interests in South Africa, Africa and in the rest of the world.

We are passionate about our centre pivots. We do not only build a tough, extremely strong structure but also give attention to small details to make a big difference in your everyday life.

We are passionate about our centre pivots. We do not only build a tough, extremely strong structure but also give attention to small details to make a big difference in your everyday life.

SENTER360 tower trusses are manufactured from pipe and not angle iron as is commonly used by other brands. The advantage of the lighter and structurally stronger material enables us to use two more sets of trusses per tower than is possible with angle iron trusses, ensuring an exceptionally strong structure. An added advantage of the pipe truss structure is its aerodynamic superiority above angle iron as a structural material. That is the reason why a SENTER360 machine can withstand a windstorm of 158 km hour (actual field data) without any damage. This claim is borne out by the fact that no SENTER360 was blown over in the recent storms (the only brand not to topple over).

SENTER360 tower trusses are manufactured from pipe and not angle iron as is commonly used by other brands. The advantage of the lighter and structurally stronger material enables us to use two more sets of trusses per tower than is possible with angle iron trusses, ensuring an exceptionally strong structure. An added advantage of the pipe truss structure is its aerodynamic superiority above angle iron as a structural material. That is the reason why a SENTER360 machine can withstand a windstorm of 158 km hour (actual field data) without any damage. This claim is borne out by the fact that no SENTER360 was blown over in the recent storms (the only brand not to topple over).

Firstly, the pipe structure, but also the standard long base beams, sturdy tower supports, stabilizing rods, diagonals, and a low centre of gravity, all contribute to the exceptional stability.

Firstly, the pipe structure, but also the standard long base beams, sturdy tower supports, stabilizing rods, diagonals, and a low centre of gravity, all contribute to the exceptional stability.

• feedback when the machine stops

and stop feedback communication.

• direct water application adjustment

• feedback when the machine stops

and stop feedback communication.

Last sprinkler solutions

• direct water application adjustment

• showing the position of the pivot

• low pressure stopping and pressure starting

• showing the position of the pivot

• low pressure stopping and pressure starting

• part circle and sector adjustment with variable water application per sector

• part circle and sector adjustment with variable water application per sector

• sector control of the end water cannon

• sector control of the end water cannon

• auto-reverse with variable water application on return

• auto-reverse with variable water application on return

• pre-programmable scheduling options

• and many more!

• pre-programmable scheduling options

• and many more!

All new and old** SENTER360 panels can be controlled by your cell phone*, tablet*, computer or base station by adding a simple plug-in communication unit of your choice, such as GPRS/cell network, Wi Fi, or radio unit.

Last

One of the common problems with centre pivot irrigators is the regular blockage of the last nozzle. We have solved this problem in a simple innovative way, constantly keeping the last nozzle clean throughout the irrigation cycle.

One of the common problems with centre pivot irrigators is the regular blockage of the last nozzle. We have solved this problem in a simple innovative way, constantly keeping the last nozzle clean throughout the irrigation cycle.

SENTER360 centre pivots are equipped as standard with high quality, high performance Komet Twister sprinklers operating at 10 psi (0,7 bar) or optional 6 psi (0,42 bar), mounted on drop pipes. This top-quality product ensures outstanding water distribution, even in trying climatic conditions.

SENTER360 centre pivots are equipped as standard with high quality, high performance Komet Twister sprinklers operating at 10 psi (0,7 bar) or optional 6 psi (0,42 bar), mounted on drop pipes. This top-quality product ensures outstanding water distribution, even in trying climatic conditions.

The same modular principals used throughout the entire SENTER360 design is also visible in our control panel design. Our entry level control panel is similar in functionality to the top panels of most other brands.

The same modular principals used throughout the entire SENTER360 design is also visible in our control panel design. Our entry level control panel is similar in functionality to the top panels of most other brands.

Standard functions include:

• on/ off

Standard functions include:

• on/ off

All new and old** SENTER360 panels can be controlled by your cell phone*, tablet*, computer or base station by adding a simple plug-in communication unit of your choice, such as GPRS/cell network, Wi Fi, or radio unit.

Full pump control, VSD control and feedback are also available on the same system. New panels have full function internet controls, record keeping, and graphs.

Full pump control, VSD control and feedback are also available on the same system. New panels have full function internet controls, record keeping, and graphs.

*Android, IOS and other **Older panel controls are limited to on/off, direct water adjustment, run

*Android, IOS and other

**Older panel controls are limited to on/off, direct water adjustment, run

The standard drivetrain of a SENTER360 centre pivot is made up of heavy-duty wheel gearboxes, driven by a 0,56 kW (40:1) motor gearbox combination (30:1 and others are optional.) An optional five-year extended warranty is available (T’s and C’s apply).

The standard drivetrain of a SENTER360 centre pivot is made up of heavy-duty wheel gearboxes, driven by a 0,56 kW (40:1) motor gearbox combination (30:1 and others are optional.) An optional five-year extended warranty is available (T’s and C’s apply).

by Robert Kanyembo, Aquaculture Expert, Novatek

by Robert Kanyembo, Aquaculture Expert, Novatek

Oreochromis andersonii (three spotted bream), Oreochromis tanganyicae (Mpende), and Cryptodon rendalii (redbreasted bream).

Due to this government intervention, the drive to sustainable aquaculture and fisheries, local species protection, and building climate resilient systems, it may be worthwhile to diversify.

Catfish is an attractive option. There is a huge government drive to promote fish farming in Zambia through various economic empowerment projects such as Citizens Economic Empowerment Commission (CEEC) through Aqua-fund and Constituency Development Funds (CDF).

Therefore, Novatek Animal Feeds Zambia decided to introduce a solution to farmers choosing catfish as the future of aquaculture. The introduction of catfish feeds for various age ranges, from hatchery to grow-outs, is a game changer.

Novatek Animal Feeds embraces the diversity that should be reflected in fish farming and the great opportunity catfish brings in an industry dominated by tilapia. The monoculture scenario in the fish industry has evolved because most have never thought outside the box of tilapia and understand the advantage in both growth and survival that catfish has over tilapia. The other deterring factor was the unavailability of catfish feeds and fingerlings.

Fish farming in Sub-Saharan Africa has been dominated by the cichlids commonly known as tilapias. Of the tilapias, the genus, Oreochromis has been the most cultured species in aquaculture in Zambia. It can be regarded as a monoculture species, soughtafter for its great growth and ease of management in aquaculture systems that include ponds, cages, and recirculating aquaculture systems (RAS). Most fish feeds are in line with at least the tilapia fish farmer’s needs.

In fact, catfish is much easier to culture and raise due to its ability to breathe both with its lungs and gills. They are from the Clarius genus and Claridae family which include Clarias gariepinus and Clarias ngamensis. They can stay in an aquaculture system with-

out dissolved oxygen and still survive.

Water quality in fish farming is one of the most challenging parameters to manage and one that is mostly responsible for mortalities in aquaculture systems. In comparison with tilapias, catfish can handle poor water quality, grow faster, has more meat, and is probably a good return on investment as well.

In Zambia, not all tilapias are allowed to be grown or cultured everywhere. Species like Oreochromis niloticus are not allowed by law to be cultured on the Northern circuit that include Luapula, Northern, Muchinga, part of Eastern, North-Western and Western Provinces due to its invasiveness against our local species such as Oreachromis machrochir (green-headed bream),

Those that had ventured into it found it expensive to import the feeds, especially from West Africa where catfish is more commonly farmed and consumed. Novatek Animal Feeds can now cushion this gap by producing catfish feeds locally and with the quality that Zambian farmers expect from Novatek.

The different catfish feed ranges with feeding guidelines can be seen in the table below. Novatek Animal Feeds Zambia also has the expertise required to assist you with your catfish best farming practices and help you grow into prosperity.

Novatek Animal Feeds urges you to look at catfish as a viable fish farming venture that has no restrictions over growing areas, shows better growth, survival rates, and export opportunities especially into the Congo. Farmers in the Northern Provinces who are forbidden by law to culture Oreochromis niloticus and are well positioned to export into the DRC, are taking up this Novatek propelled initiative to venture into catfish culture.

Novatek Animal Feeds Zambia promotes diversity in fish farming; contact us today and we shall be on hand to assist you. For more information, send an e-mail to Robert Kanyembo, Novatek National Sales Manager, on salesmanager@ novatek.co.zm, or contact him on +26-097-1252-522. Visit the website at www.novatekfeeds.com

table should be used as a feeding guideline only. Adjustments should be made depending on the type of production system and environmental conditions on the farm. Feeding behaviour should be observed and feeding rates adjusted accordingly.

Hens are sensitive to day length, and particularly to the direction in which day length is changing, when it comes to laying eggs. Declining day lengths discourage egg production. It is not unusual for a flock owner to have hens go out of production during winter months because the days are shorter.

A layer farmer can avoid this problem and maintain egg production year-round by using artificial lighting to give hens a long day length no matter what the season. Even in the middle of winter, if chickens are given at least 14 hours of daylight, they will lay every day except during moulting.

Moulting is the process of shedding and renewing feathers. It occurs once a year, usually during the change in season from summer to winter months as the day length starts to decline.

When hens have been in production for many months, they tend to cease laying eggs in order to allow a complete rest of the reproductive system as well as to revamp or replenish their body reserves. The process takes about a month.

It is a very important process but

can have a negative effect on the profits of the layer farmer especially if the hens all moult at the same time. However, if artificial lighting is provided, a hen may moult at any time of year and not in synchrony with other hens. If this happens, she should return to lay in a few short weeks without disrupting production too much.

A hen can live for many years. Much as in other species, an ageing hen eventually will lose her ability to be reproductively active and stop producing eggs. Birds that have gone out of production due to age must be culled promptly to prevent losses. These birds are sold as ex-layers to be used for meat.

Many poultry diseases affect egg production. Often the birds will show symptoms of illness, but sometimes they will not. If a disease is suspected, it is important to consult a poultry veterinarian without delay. A timely diagnosis may allow effective treatment for some diseases and a speedy diagnosis may prevent losses of whole flocks on a layer farm.

A number of bacterial diseases, viral diseases and even syndromes may have a negative effect on egg production and quality. They may cause a drop in numbers of eggs produced and also cause abnormalities in egg shells, and consequently lead to production losses. Let us look at some of these diseases and syndromes and how best to prevent them:

Bacterial diseases such as septicaemic disease, chronic respiratory disease, and colibacillosis will result in a substantial drop in egg production and may lead to poor quality eggs with abnormalities. Practicing proper biosecurity and sanitation may help prevent these and other bacterial diseases.

Viral diseases such as infectious bronchitis (IB), egg drop syndrome (EDS), swollen head syndrome, avian influenza and Newcastle disease will all result in a partial to complete drop in egg production. Egg quality is also affected with thin-shelled eggs. Prevent these viral diseases by following a recommended complete vaccination plan.

Syndromes – Both fatty liver haemorrhagic syndrome (FLHS) and cage layer osteoporosis will affect egg production to some degree. While restricted feeding may be a solution for FLHS, adequate nutrition helps to reduce cage layer osteoporosis.

In conclusion, keeping a high and persistent production is the way to achieve success in poultry layer farming. The farmer must keep his birds healthy, well fed on nutritious feed, and also be able to provide and maintain an environment conducive to promote egg production.

“Remember, more eggs more money!”Hen shedding feathers during moulting process. Eggs showing signs of abnormalities due to disease infestation.

Asparagus is preserved by the addition of salt and acid in a suitable container that may or may not be pasteurised. Asparagus is usually pickled as whole spears, alone or with the addition of other minor ingredients. Spices can also be used. The spices are usually in concentrated extract form and may include ginger, pimento, black pepper, chillies, cloves, and coriander.

1. Harvesting of asparagus

Harvesting season lasts for 2 to 3 months as the stems emerge in spring. Asparagus are harvested by hand when the correct size and colour has been achieved. This is done by cutting the stem with a sharp knife 3 to 5 cm below the soil surface at a length of approximately 20 cm. Asparagus is transported in an upright position from the field to processing plants as quickly as possible because it soon becomes tough and loses its sweetness. Once the harvesting season is over, the stems are allowed to grow to nourish the underground rhizomes for the next year’s crop.

2. Sorting

The stalks are spread on flat tables where the loose debris such as sticks and stones, are removed. Any damaged, shrunken or broken stalks are also removed.

3. Cleaning and washing

The product is washed in large water baths filled with potable water to remove all unwanted soil, dirt, or plant rests adhering to the surface of the product. The wash water must be regularly changed to minimise the chance of any contamination spreading. The water may be still or agitated. A highpressure water spray can be used to agitate the water to ensure that all surfaces are cleaned. The stalks are then stored in cold water tanks until processing begins.

Trimming is the deliberate removal of unwanted or unfit fractions of a food product while sorting is done to select the best suitable raw materials for manufacturing the value-added end product. Any damaged or immature sections must be removed. The quality of the product and adherence to pre-set quality standards (colour,

shape, and size) must be controlled by careful inspection.

5. Blanching (optional)

Blanching is a short heating process, immersion in hot or boiling water or steam, whereby food products are heated to a certain temperature that is high enough to inactivate the enzymes responsible for undesirable changes in colour and flavour.

Blanching must be done as soon as possible after preparation and immediately before processing. Enzymes start to break down tissues after harvesting and these waste products can be an ideal growth medium for micro-organisms, which may change the taste and flavour of the product – both advantageously and disadvantageously. Heat treatment prevents enzymatic and microbiological deterioration by inactivating the enzymes and killing plant tissue.

Blanching also has other advantages:

• Improving the colour of the finished product;

• Improved the texture of the final product;

• Blanching cleans the product and reduces the microbial load of the cells;

• Removal of gasses in the intercellular spaces that could cause oxidation of the product and that could lower the vacuum of the sealed container.

The disadvantage of blanching is the loss of nutritive value due to water-soluble vitamins dissolving

Asparagus (Image Source: blog.myskin.com)

in the blanching water. This can be contained by a short exposure time. During commercial blanching processes the products are heated as quickly as possible to the required temperature and then cooled as quickly as possible to minimise the softening of the tissue and loss of nutrients.

Water blanching:

This is the traditional form of blanching where the product is kept in warm water (60 to 85 °C for 2 to 5 minutes) for the required

time and then cooled. Retorts can be used. Some solutes leach from the product into the scald liquor, which should be allowed to build up because this minimises the leaching losses.

Reel blanchers/rotary water blancher: this is one of the simplest blanchers. It consists of a screw conveyor moving through a trough filled with hot water, heated by steam coils or direct steam injection, contained within a perforated rotating cylinder enclosed in a cylindrical shell. The speed of the conveyor and the temperature of the water controls the retention time in the warm water as well as the cooling of the product; two blanchers can also be used in series.

Water spray blancher: this consists of a three-stage blancher where the hottest water is used in the middle stage, collected and re-sprayed towards both ends of the blancher – material is warmed towards the centre and then progressively cooled.

Tubular blancher: the product is conveyed through a long tube for a specified time by pumped water, heated by steam injection. Cooling occurs naturally by evaporation and the product is washed in potable water to reduce the microbial contamination and to remove concentrated blancher liquid.

Steam blanching: The advantage of this process is the decrease in the leaching of soluble from the vegetables with increased retention of nutrients. The use of steam blanchers enhances storage life of the final product as there is no need for handling between blanching and subsequent phases. The steam blancher consists of a wire belt, moving through a steam-box or a sealed steam tunnel, which is heated by steam, followed by a deep layer holding zone and a cooling zone. A helical screw can also convey the heaped vegetable pieces along a covered trough into which steam is injected through perforation on the wall and the hollow screw shaft.

Individual quick blanching is a variations on steam blanchers were a thin layer of the product spread on a wire belt moves through a steam box. The product is exposed to sufficient heat to inactivate the enzymes penetrating halfway through the product. The product is then put on a slow moving belt and allowed to reach equilibrium until all parts have received the same heat treatment.

Vacuum steam blanching: End-over-end conical double-jacketed cookers are used. The products are loaded into the cooker and slowly rotated. The pressure is lowered to 10 kPa. The vacuum is broken with saturated steam and

atmospheric pressure is applied for one minute. The product is then cooled by lowering the pressure in the container. The advantage of this method is the rapid heating of the product, resulting in a firmer texture. This is a very efficient and waste effective process.

Microwave blanching: Heat for blanching is generated within the food by subjecting it to high frequency radiation. There is no leaching of solutes and flavour and nutritive losses are kept to a minimum. This process however has a high initial cost.

6. Brining

Brining is the addition of dry salt or a salt solution, usually sodium chloride, to food products. The asparagus can be packed directly into a brine with a 8 to 13% salt concentration. The brine may be slightly acidified with lactic acid. The asparagus should be covered with brine and is left overnight. The brine is then removed by draining. Draining aims at removing excess free moisture from a product by gravitational force to obtain partial drying of the product surface.

7. Rinsing

The salt content of the final product will be too high if the asparagus are packed directly into the acid liquor. It can be briefly rinsed in water and allowed to drain thoroughly.

8. Filling of pickled asparagus

The asparagus is packed into suitable containers (retail containers) with a packaging liquor. The packing liquor is made from natural or distilled malt vinegar, spirit vinegar, acetic acid or any desired combination according the final product requirements. Spices can also be added. The spices are usually in concentrated extract form and may include ginger, pimento, black pepper, chillies, cloves, and coriander. The final acidity of the product will depend on the acidity of the packing liquor and on the ration of asparagus to liquor. The liquor can also be added to the asparagus in bulk and allowed to stand for a few days be-

fore repacking into jars. This minimises the effect of minor variations in asparagus-to-liquor ration on the equilibrium acidity of the finished pack. The asparagus may be kept tightly covered under refrigerated conditions for several months.

9. Pasteurisation (Optional)

The product may be pasteurised to further extend the storage life by creating a commercial sterile product.

A commercially sterilised product is a product:

• That is processed in such a way as to reduce the number or activity (or both) of viable micro-organisms to such as extent that none are detectable, and

• In which no spoilage or toxicity of microbial origin is detectable under normal, non-refrigerated conditions of storage, distribution, and handling.

Pasteurised products are products which are heat treated in a container to a minimum centre temperature of 66 °C for a specified time. Pasteurisation is not often performed as it tends to soften the asparagus. Sulphur dioxide (preservative) can be used, close topping-up with liquor so as to minimise the volume of the headspace. Effective hermetically sealed closure and optional vacuumisation during capping will overcome any problems experienced.

In some instances, the firm texture is not as important and low acid pasteurised packs, which may include apple or onion, are used. The time of exposure needed to destroy spoilage organisms and pathogens is dependant on the type of product, container size, and type of retort. In acidic foods retorts may be vertical or horisontal. Horisontal retorts are easier to load and unload. The retort is closed and steam is pumped into the closed container. The time/ temperature combination depends on the processing time/temperature required.

10. Cooling

After heating, the product is cooled, first in the retort when cold water is used to replace the hot water, and then the product is removed from the retort and allowed to cool further.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.

Goats are one of the oldest domesticated animal species in the world and have been used for centuries for their meat, milk, and fibre. In recent years, the popularity of goat meat has grown exponentially, and with it, the number of different meat goat breeds. While there are many breeds of goats, some are better suited for meat production than others.

ing projects. Boer goat hides are also known for their beautiful colouring, with a variety of shades ranging from white to brown to black.

This breed has horns, lopped ears, and a variety of colours. As a result of its browsing ability and low impact on grass cover, the Boer goat is being used very successfully in South Africa in conjunction with cattle. The ewes do not need pampering and can produce enough milk

By Natasha Pansegrouw

By Natasha Pansegrouw

to raise kids that mature early and have a weaning rate of over 160%.

Exceptional members of this breed can gain more than 200 g per day in the feedlot, although a daily growth rate of 150 to 170 g is more typical. The ovulation rate for Boer goats ranges from one to four eggs per ewe, with an average of 1,7.

The average rate of kidding is 200%. There is a rapid maturation rate, occurring in rams at around six months and does at around ten to twelve months. Furthermore, the Boer goat has a long breeding season, allowing for three pregnancies every two years.

The Kalahari goat is a hardy, dual-purpose breed of goat that originated

The Boer goat is an incredibly versatile breed of goat that is highly sought after for its meat, milk, and hide production. They are known for their resistance to disease, with a low incidence of common goat diseases such as pneumonia and enterotoxemia.

The Boer goat is a large, sturdy animal with a white body and distinctive brown head. Boer goats are known for their high fertility rates and fast growth, with rams reaching up to 135 kilogrammes and does up to 100 kilogrammes. They have excellent meat quality, with a high fat content and a mild, sweet flavour and high milk production, with does producing up to eight litres of milk per day.

Boer goats are also valued for their hides, which are used to make leather goods. The hides are highly sought after for their durability and strength, making them ideal for a variety of leatherwork-

in the Kalahari desert in Southern Africa. The Kalahari goat is a mediumsized animal, with a short, glossy coat that is usually white or light brown in color. The breed is known for its hardiness and adaptability, which makes it well-suited to a variety of climates and environments.

The Kalahari goat is an excellent choice for small-scale farmers looking for a hardy and productive breed of goat. The breed has a high fertility rate, with does producing up to three kids per year. It is known for its excellent mothering ability, being very protective of its young.

Does can produce up to two litres of milk per day, making them an excellent choice for small-scale dairy operations. The milk is high in butterfat and protein, making it ideal for cheese and yoghurt production.

The breed has good meat quality, with lean, mild-flavoured meat that is highly sought after by consumers.

The red colour of Kalahari Red goats' coats is their most distinguishing physical feature. Animals that are white or very light red are not desirable because they are easier to spot by predators in their natural environments.

They have developed protective herding instincts. The Kalahari Red is distinguished by its long, flappy ears. There are small, sloping horns on top of their heads, just above the ears. Rams can weigh up to 115 kilogrammes, while does can weigh up to 75 kilogrammes; their build is similar to the well-liked South African Boer goat.

If you are looking to improve the resilience and meat production of your goat herd, Kalahari Reds make a great crossbreed. Rams should be physically larger than does, and their neck skin should be looser.

The Savannah goat is a unique breed of goat that is known for its hardiness and adaptability. It is a medium-sized goat with a short, thick coat and a long, straight face. The Savannah goat is a hardy breed, able to survive in a variety of climates and environments. It is also a very productive breed, producing high-quality meat and milk rich in butterfat and protein.

The Savannah goat was bred in South Africa in the late 1950s by Cilliers and Sons, near the Vaal River,

by crossing several breeds of goats. The most common breeds used in the development of the Savannah goat are Spanish, Angora, and Nubian goats. The Savannah goat was bred to be a hardy and productive breed, and it has proved to be just that.

The Savanna goat is prized for its meat because it is a large, muscular breed. In most cases, their coats will be white because that colour is the result of a dominant allele. However, they have black pigmentation on their skin, horns, and hooves for protection from the sun.

Savanna goats are known for their high rates of fertility, mothering ability, milk production, twin births, and overall healthy offspring development. Rams can weigh up to 90 kilogrammes, while does can weigh up to 60 kilogrammes.

References

Goat Farming in South Africa (2022). Available at: https://southafrica.co.za/goat-breeds-in-southafrica.html

Breeds of Livestock, Department of Animal Science (1996). Available at: http://afs.okstate.edu/breeds/ goats

In the face of an extreme drought that has devastated large parts of the Karoo, including the Klein Karoo, it is important for farmers to learn how to mitigate the extreme conditions exacerbated by climate change, and to save their natural pasture.

A workshop where these mitigating principles were discussed, was presented by Sarah Cromhout of the Herding Academy, in conjunction with Dr Chavoux Luyt of the Cape Leopard Trust.

Seven participants, including commercial farmer, Herman van der Walt, conservationist, Louis Jordaan, Tembelihle Mjamba from CapeNature, Jan Jordaan of the National Wool Growers Association (NWGA), and smallholders Bridget Lloyd, Sally Adams, and Sue Harris, attended the workshop at Bella de Karoo guest house between Oudtshoorn and Calitzdorp.

The Herding Academy is a holistic

by Tisha Steynlearning centre where the ancient skill of herding animals is applied within a holistic decision-making framework to regenerate the landscape and bridge the socio-economic and cultural barriers between humans and wildlife throughout Southern Africa.

The Academy, which is based in Graaff Reinet in the Eastern Cape, endeavours to revive the skills of herding livestock to mimic the effect of migratory wild herds of antelope that once roamed the land, to the benefit of the ecosystem.

The CATHSETA-accredited courses are presented by trained professionals and herders who provide practical holistic insight to landowners and student employees, and provide practical herding training to rural and communal stock farmers through short courses.

The course outline usually focuses on teaching both theory and practice to address the ever-changing environmental and social challenges.

The course is based on the approach of Allan Savory, the father of regenerative farming, who states: “No individual parts exist in nature, but only wholes, and these form and shape each other.”

Holism includes four aspects: a holistic approach, the brittleness of the landscape, the predator-prey connection, and time. All the parts of the farming system and nature are closely related and every decision that is made has an influence on something else.

Ecosystems, which include farming systems, are rated on a scale of brittle to average or normal. When the ecosystem is brittle, it is subjected to erratic rainfall and an unpredictable climate. When it is normal, there is little variation between the years and seasons, high biodiversity, and predictable climate.

It is crucial to understand the brittleness scale of land, which indicates the way it responds to different influences, such as the annual humidity, or the lack thereof, throughout the year. A dry landscape is more brittle or fragile and may deteriorate far quicker than a resilient landscape where the annual rainfall is higher, and the veld responds quicker.

In brittle systems, the duration of grazing and the mowing effect thereof is more important than the number of animals grazing it. This must be managed to prevent overgrazing.

Plants and animals evolve together, and it is necessary to understand the predator-prey connection to the health of the land in brittle environments. In more brittle environments pack-hunting predators result in large herbivores moving in herds.

Prey-predator interaction has an important influence on naturally brittle systems, and the interaction can be used to mimic the mowing (grazing) and trampling (hoof action) effect of a herd.

Time, and not the number of animals in the landscape, governs the health of the rangeland. Plants need time to recover once they have been disturbed by grazing and the hoof action of the animals grazing it.

“Eco-processes form part of ecoliteracy, which is how we read the landscape,” says Sarah. “These are also linked to each other and cannot be looked at individually.”

Four eco-processes are fundamental to all ecosystems: the water cycle, mineral cycle, community dynamics, and energy flow.

• The water or hydrological cycle refers to the movement of water from the atmosphere to the soil or oceans and through plant and animal life before it returns to the atmosphere.

• The mineral cycle refers to the movement of minerals from the soil to the plants growing in it, to the animals that eat the plants, and back into the soil again.

• Community dynamics, or succession, is the constant state of flux within a biological community. This includes the ever-changing composition of a landscape, the elements in the micro-environment, and the interplay of plant and animal species.

• Energy flow refers to the sun’s energy that allows green plants to

grow through photosynthesis into the food that fuels all life.

The context should include these four processes and how the farmer wants these processes to look on his land.

“Good management means we base our decisions on the context. The tools available to us depend on human creativity, money, and labour,” says Sarah.

A context description is fundamental to managing complexity as it shapes and informs decision-making toward a preferred future outcome. All conflict has a common origin, which includes that which is being managed, the people involved, the aim of the action, what we need to understand to manage, and what resource base and money are available to do it.

Management tools for effective impact on the veld include:

• technology,

• resting of the veld,

• biodiversity, namely the variety of living organisms in an ecosystem,

• a grazing plan for the pruning effect and hoof action of a herd, and

• fire with controlled burns and a fire plan.

The main principles of drought management include:

For grazing, it is important to know the critical dates such as the changes of seasons so as to know when the veld is ready to be utilised.

It is crucial to adjust the stocking rate to the carrying capacity, even if

it involves reducing herds to breeding animals during a lengthy drought.

It is equally important to use longer rest periods for the veld to allow it to recover completely. Rather combine herds to reduce the grazing period of a veld, especially if the veld is more brittle due to drought.

Plan, and replan cash flow, as well as stock flow. It is essential to estimate in advance whether feed will be available, and plan destocking in time. “Never, ever drought feed,” she says.

It is important to plan long-term water availability to take care of the land to the best of your ability. Also, ensure that your farming includes various income streams compatible with risk. “One must manage for a healthy, diverse, and perennial pasture.”

Bridget Lloyd farms Meatmaster sheep on a smallholding of 18 ha at Noll’s Halt about 30 km from Uniondale.

“Everything revolves around grazing for the sheep,” says Bridget. “I have been trying to do it regeneratively with no artificial fertilisers, pesticides, using mixed cover crops rather than monocrops. I use minimal tillage and restore the veld – no-till planters are costly, and I can’t afford them. But I am already seeing a difference!”

According to Bridget, she has been following the Herding Academy ‘from afar’, but their executive land management courses were too expensive to attend. “I booked as soon as I saw the workshop advertisement. I have heard

some of the information presented by following the Academy, reading articles, watching videos and documentaries, and YouTube clips. But I will most definitely benefit from the workshop as it makes the information more tangible having it explained with concrete examples.

“Being on a smallholding makes it more challenging than on a large farm, but I have already been walking around, looking at what I can apply and use and adapt for my circumstances.”

She will be interested in joining future workshops. “I took two friends along and they are also interested. I would also take Aubrey, the guy who works part-time on my farm, as I think he would also benefit.”

The next workshop on the management of problem-causing animals, such as jackal, caracal, and leopard, takes place on 19 April at Bella de Karoo. Advance booking is advised. Course cost: R200. Book in advance at capeleopard. org.za/shop/events

by Maryna Steyn

by Maryna Steyn

The cactus- or prickly pear is an interesting kind of vegetation. It is a cactus that is both a vegetable and a fruit because the fleshy pads are considered a vegetable and the parts that develop the seeds are the fruits. On top of that, the plant is increasing in popularity due to its multiple uses and low input costs.

Opuntia ficus-indica is the most common variety that grows in Southern Africa. Originally it was imported from Mexico during the 1700s to create living fences for farms in the Western Cape. A farmer from Graaff-Reinet brought two pads to Cape Town and cultivated cactus pears on his farm. In the 1850s, Sekwati, the Pedi ruler, started using it as livestock fences as well.

However, due to how easily the plant grows, it quickly became a pest and infested many areas. It is estimated that by the 1930’s, over a million hectares of natural veld in the Karoo and Eastern Cape were taken over by this cactus.

Luckily, today, innovative growers have found many uses for prickly pears. We eat the fruits when they are in season, but also harvest the oil which has many health benefits. The pads are also used as livestock feed as well as for human consumption. This usually only extends to the young leaf pads (cladodes) that are picked before they reach 15 cm in length.

The plant has bright flowers ranging from yellow to red. The pears have a thick green skin, which changes colour as the fruit ripens. Depending on the variety you grow, this colour can be orange, red, or purple. When the fruits are peeled, the inner flesh also differs in colour from green to purple. It tastes sweet and has hard seeds in the middle. The fruits are used in jam,

The colour of ripened prickly pears varies depending on the variant planted. (Source: Mali Maeder on Pexels)

jelly, soup, juice, or eaten as is.

The plant reaches up to 5 m in height when it is fully grown, and features a thick, woody trunk. What looks like huge leaves are actually stems. Stems are covered in a thin layer of wax and often found with spines. Varieties that are spineless have been selected to grow commercially as they are easier to harvest and handle.

More than hundred varieties are available, depending on which you are able to obtain in your area.

One of the reasons why prickly pears have become a popular crop is the fact that they fare so well in dry climates. They require well drained soil and can survive on rainwater alone once their roots have been established. As with

Blooms can differ in colour depending on the variety you are cultivating.

most drought-tolerant plants, prickly pears’ roots suffer when they are waterlogged. Soil ph should be neutral, ranging from 6,0 to 7,5.

It is important that these plants receive full sun. Warm temperatures are ideal for these cacti, but the good news is that they adapt well to extreme temperatures.

When propagating the prickly pear, you can use seeds, but using pads (cladodes) works best.

Prepare the soil bed by ripping the field. You can lay out rows 5 m apart, and plants can be positioned between 5 to 2 m apart, depending on the density you are looking for. If you are not planning on using tractors or machinery between the rows, you can make

the rows narrower.

Plant the specimens during spring and early summer. This ensures that they are well established before winter. Place the pads upright in the soil. Take care if your cultivar has spines, as these can stick into your skin. Use tongs instead of your hands. Make sure to find out if you are legally allowed to propagate the plant in your area. In South Africa, for instance, it is illegal to propagate the prickly pear with spines, but spineless varieties are allowed.

Your plants will start to bear fruit after 18 months. After four years you can expect a full harvest. Harvesting is labour intensive. In the southern parts of Africa, harvesting season ranges from early December to late April.

Once they have been planted, they need to be watered every two or three weeks until their roots have established properly. You do not need to invest in a permanent irrigation system. After a year, the cacti have reached maturity. This means that they can now store water well and thus have an increased frost tolerance.

Cactus pears do not need to be fer-

tilised in the first two years of their life. You can add a bit of manure at the base of every plant. Thereafter, a thorough soil analysis will indicate what fertiliser you need, but it has been noted that prickly pears respond well to nitrogen-rich fertilisers.

In prickly pear orchards, farmers only have weed problems where perennial grasses grow between the cacti. Too much grass makes it difficult to access the plants and long grass can block out

neal (Dactylopius coccus), a beetle, in 1913 and cactoblastis (Cactoblastis cactorum), a moth, in 1924 for biological control. This backfired because the insects also attacked cultivated crops.

The cochineal beetle is soft and red, covered by a white wax coating.

The cactus moth lays its eggs on the pads. When the eggs hatch, the larvae bore into the cladodes, feeding off them until the plant eventually dies.

To control these infestations, you will need to take a combined approach by removing some of the bugs by hand if it is a small infestation, or using chemicals. Electric insect traps can be used to attract moths. If you do not have access to pesticides, the beetle can be controlled by using a mixture of dish soap and water sprayed onto the cactus.

Cladodes that have been damaged should be cut off. Either destroy them, or feed them to livestock.

Sources

9 amazing prickly pear cactus facts! (2019) Balcony Garden Web. Available at https://balconygardenweb.com/prickly-pearcactus-facts/.

Brown, J. (202AD) Why prickly pears are suddenly a hot crop in SA, News24. Available at https:// www.news24.com/news24/biarchive/cactus-pear-farming-insouth-africa-2020-3.

Coleman, A. (2023) Cactus pear: One crop, three profitable markets, Farmer's Weekly. Available at https://www.farmersweekly. co.za/crops/field-crops/cactuspear-one-crop-three-profitablemarkets/.

Gordon, A. (2022) 13 edible prickly pear varieties and taste profile, luv2garden.com. Available at https://luv2garden.com/prickypear-cactus-varieties/.

Grant, B.L. (2021) Growing prickly pear - plants in the home garden, Gardening Know How. Available at https://www.gardeningknowhow.com/ornamental/ cacti-succulents/prickly-pear/ growing-prickly-pear.htm.

sunlight to smaller plants. Herbicides can assist with controlling the grass, or you can use a hoe. Take care not to damage the shallow roots of the cactus when hoeing.

There are two insects that are harmful to the prickly pear. Because the plants originated from Mexico, the South African government imported cochi-

Klein, H. (2014) Prickly pear (Opuntia ficus-indica) (Cactaceae), Agricultural Research Council. Available at https://www. arc.agric.za/arc-ppri/Pages/Prickly-pear.aspx.

Kriel, G. (2023) Cactus Pear Production in South Africa, South Africa Online. Available at https:// southafrica.co.za/cactus-pearproduction-in-south-africa.html.

Planning is one of the most important aspects of managing any business. This is especially true for farms and agribusinesses due to their complexity and the inherent uncertainties (such as weather and commodity prices) associated with agriculture. It is essential that farm managers take time to adequately plan for all aspects of their businesses. Farm families are encouraged to adopt a whole farm planning approach as they develop strategies for the future success of their businesses.

Every landowner and every tenant farmer in this country owes it to himself and the future generations to protect and utilise the natural agricultural resources, namely soil, vegetation, water, and water resources, in such a way to ensure sustainable production. This is also known as optimal resource utilisation.

The following three requirements give an indication of what optimal resource utilisation actually means:

• The natural resources should be utilised in such a way that it will be retained, conserved and even improved.

• The farming practices must be in harmony with the nature of the natural resources.

• The utilisation of the resources must be economical.

It should be the objective and ideal of every farmer to comply with these requirements.

To fulfil the ideal of optimal resource utilisation, the farmer has several aids at his disposal. One of the physical aids that can be applied to utilise the natural resources optimally, is farm planning.

Where crop farming is of no importance, farm planning will be about the provision of facilities for good veld management and also to prevent and to combat erosion.

On a properly planned farm, veld management can be administered in such a way that the physiological needs of plants will be taken into consideration, which can lead to a good and vigorous veld cover.

Farm planning makes it possible to protect the soil and water resources and these protected resources furnish economic benefits in the long run because sustainable production will be possible. Increased financial results can even be obtained in the short run, because the provision of the necessary

facilities makes it possible for better veld management as well as better utilisation of the veld.

Farm planning is a concept that can be interpreted in different ways. It varies from the provision of the minimum facilities to implement the most primitive form of veld management to the provision of sufficient facilities to implement veld management with all the herds on the farm to the highest standard.

As an example, it was assumed that most of the farms in the Northern Cape in South Africa are already planned. A study showed that it varies from totally incomplete to complete according to the present norms of the Department of Agriculture. Many farmers are satisfied that their farms are planned, but according to farm size and grazing capacity, they have only half of the camps that they really need.

Several matters have to be considered when starting with farm planning.

Fences, both primary and secondary, are used to separate grazing areas for livestock. (Source: Pixabay by Bruno /Germany)

It is essential that the existing fences should be identified on an aerial photograph or map of the farm. Use this map to indicate the different veld types that are found on the farm and also how effectively these veld types are separated by the existing fences.

Veld types should be separated because animals utilise the different veld types in different ways and therefore each veld type should be managed according to its own requirements. When the different veld types are indicated on the farm map, it should be used as a framework for further planning. Primary fences separate different veld types and secondary fences subdivide the specific veld type into smaller camps.

It sometimes happens in practice that problems are encountered to separate veld types on a specific farm.

incorporated in a larger camp with palatable grazing, but not vice versa. Remember that the farm plan only gives an indication of where the fence should be constructed, but in the actual construction the fence must be placed as close as possible to the transition line.

It sometimes happens that different veld types alternate over a short distance. Such heterogeneous veld should be separated from more homogeneous veld and should then be treated according to the most vulnerable veld type in that camp.

Sometimes the position of a certain veld type in respect of water sources is very difficult to separate from other veld types because of the cost impli-

Here are

examples: Fences were constructed without taking the separation of veld types in account. The problem can be solved by removing that fence and reconstructing it in the correct place, but farmers are usually not willing to do that because of the cost implications.

Each veld type should be managed differently because animals use them differently. (Source: Pixabay by Lynn Greyling)

It is not always practical to separate veld types effectively, but it is essential to put a fence as close as possible to the transition between veld types. A small portion of unpalatable grazing might be

cations to supply water to that camp. The value of that specific veld and its vulnerability should be compared to the cost of supplying water.

Make provision for sufficient camps for all the herds on the farm to administer good veld management. Determine the number of herds on the farm as well as the extent to which the number varies from time to time. The herd number varies considerably, but with herd sizes of around 50 LSUs (large stock units, namely cattle) veld and stock management will be reasonably simple.

For sustainable production, landowners should protect and use soil, vegetation, water, and water resources responsibly. Your livestock should not deplete all the natural resources in each pasture. (Source: Pixabay))

In next month's edition of Farm management and planning part 2, we shall look at camp sizes, how to determine it, veld management, and the cost and financing of farm planning. Stay tuned for more.

Article supplied

In our previous article we discussed what happens when Salmonella pullorum (SP) and Salmonella gallinarum (SG) enter layer enterprises. We saw that, whilst SP affects mainly replacement pullets, SG may infect birds of all ages; both SP and SG are able to cause considerable economic losses. We also learned that SG and SP cannot be completely eliminated from an infected flock, and consequently the disease will periodically recur. Based on those premises, it was agreed that the main objective should be to be to keep layer flocks free of SG and SP by implementing an appropriate prevention program.

In this article we will further discuss different prevention strategies and the reasons behind each one of them. The reader should remember that a salmonellosis prevention program should be implemented with the help of a veterinary professional. Therefore, contact your vet before making any changes in biosecurity and/or vaccination programs.

One of the main problems observed in flocks infected by SG or SP is that the infection keeps coming back. Such recurrence responds to the ability of salmonella to escape the immune system of the birds by “hiding” inside a specific immune cell, the macrophage. One of the functions of macrophages is to trap pathogens and destroy them. However, SG and SP can avoid destruction and remain “dormant” inside such cells.

When certain factors depress the bird’s immune system, the dormant salmonella becomes active again, multiplies, and gets shed into the environment by carrier chickens. As a consequence, the amount of salmonella in the environment increases, infecting new birds and restarting the cycle of disease.

Therefore, when SG or SP are diagnosed in a flock, a proportion of the birds will be infected for life. In such conditions, the management of the flock becomes very difficult, and the losses due to mortality and drop in production are usually important and recurrent.

Protection against SG and SP infection is achieved by implementing a combination of measures targeting the chicken, the environment, and the bacterium. In the following sections we discuss a list of possible control measures. You should work in collaboration with your veterinary advisor to create a prevention plan that suits the situation at your farm.

Get pullets from reputable sources: All main Zambian hatcheries have successfully established robust salmonella prevention programs in their breeder flocks. The main suppliers of pointof-lay birds are also working together with their vet consultants to keep their farms free from SG and SP. Buying birds from reliable sources reduces the risk of infection.

• Do not mix flocks of different age and/or different origin. Multi-age farms always present a

higher risk, since SG and SP can pass from older to younger birds.

• Implement a good cleaning, disinfection, and down-time program between flocks. Salmonella can remain in the environment for prolonged periods, so it is important that houses are properly prepared for the arrival of new flocks. Discuss a cleaning, disinfection, and down-time program with your vet. Such programs should not only focus on the correct choice and application of cleaning agents and disinfectants. They should also include the laboratory verification that such procedures have been successfully conducted (by bacteria cultures from samples taken from different areas in the poultry house).

• Reduce the exposure of your birds to potential sources of salmonella. Keep the facilities free of rats, since they can help spreading SG and SP. Use bait boxes placed in strategic points of the farm. Keep weekly control of the bait boxes, re-

cording their location and the level of activity observed in each one of them. Rodents are highly intelligent animals, so they can learn to avoid these traps. If your records show that rats have not been visiting a given bait box, it is time to change it to a new location.

• Control insects. Darkling beetles and flies, for example, are known for being vectors of foodborne pathogens, including salmonella.

• Avoid contact with wild birds by making your poultry houses bird-proof.

• Source your feed from reliable feed mills. Currently, the main feed mills in Zambia conduct salmonella monitoring and control programs. Also, keep your feed shed free from rodents, insects, and other pests.

• Offer safe drinking water. Evaluate the levels of bacteria in water periodically, including salmonella, using a reliable laboratory. Chlorination of water is a good preventative tool.

• Reduce the chances of SG and SP entering your farm on shoes, clothing, and vehicles. Implementation of measures such as compulsory showering and changing of clothes, application of an inside and outside boot system, proper disinfection of incoming vehicles, restriction in the number of visitors and incoming vehicles, and disinfection of incoming instruments, can be of significant help.

• Dispose manure and mortalities appropriately; both are potential sources of infection. Your vet will recommend the most appropriate ways to do it.

To assess the success of your salmonella control program, you can implement periodical environmental sampling for culture, detection, and typing of salmonella. In automated poultry houses, different surfaces such as feeders, feed hoppers, and conveyor belts may be swabbed. When birds are kept on the floor, litter samples may be taken by walking throughout the house with special boot covers. Farm workers can also be sampled for salmonella detection. Your vet will be able to explain this in more depth.

Yes, vaccination plays an important role in preventing SG and SP infections. However, as mentioned before, we cannot expect good protection if their application is not supported by proper biosecurity and management measures.

Phibro has created an integral control program against SG, SP, and other salmonella serovars, based on the administration of the live vaccine Phivax SLE (in early in life), followed by the inoculation of an inactivated vaccine (Salmin Plus) later in rearing (Table 1).

Salmin Plus is Phibro’s latest salmonella inactivated vaccine. It contains one strain of Salmonella typhimurium (from salmonella serogroup B), two strains of Salmonella enteritidis (from serogroup D), and one strain of Salmonella infantis (from serogroup C). This is the first vaccine in the market to include a strain of the serogroup C, increasing the spectrum of protection.

Salmin Plus helps to prevent verti-

cal and horizontal transmission of salmonella from group B, C, and D among birds, thus protecting the final consumer (humans) from food borne salmonellosis produced when bacteria of such serogroups contaminates food products. Furthermore, since Salmonella enteritidis belongs to serogroup D together with SG and SP, Salmin Plus can also cross-protect the birds against SG and SP.

Finally, Salmin Plus has been developed using advanced vaccine technology. Its novel adjuvant produces minor tissue damage in comparison with other water-in-oil inactivated vaccines. As a result, it can be injected intramuscularly without major inflammation or post-vaccine reactions. This makes vaccine application much easier and quicker than with inactivated vaccines that need subcutaneous application.

As usual, please consult your veterinarian about the vaccination strategy that best fits the situation at your farm.

part 9:

by Tisha Steyn

by Tisha Steyn

In the previous eight chapters, we provided a wealth of information on various aspects of beekeeping. But to keep bees, you will need a hive. There are various ways to get one.

Beehives are usually made of wood and will last a long time if you take good care of them. A sturdy, wellmaintained beehive will provide a safe home for the bee queen to lay thousands of eggs, which will be nursed by a team of female bees until they too become adult bees that can go out foraging for nectar and pollen.

In South Africa, the Langstroth hive is preferred. The key innovation responsible for the hive's design was the discovery of bee space, which refers to a gap size of about 9 mm in which bees would not build a comb or fill it with propolis.

This bee space makes it possible for the modern beekeeper to examine his bees in their hive without destroying combs or baby bee larvae and eggs. Another advantage of this type of hive is that it can be extended by adding more super boxes on top to produce more honey. A disadvantage is that the boxes can be very heavy and difficult to move around.

A hive consists of several parts, each with its own function. It has a brood chamber, which is a deep box on a base and is fitted with either eight or ten vertical wooden frames. Each frame needs a sheet of wax foundation or at least starter strips of foundation that are covered with wax to assist the bees to start building the cells.

One or more super chambers can be added on top of the brood chamber. The super chamber, which is shallower than the brood chamber, also includes eight or ten frames. You can add more super chambers on top. The cells on these frames will be filled with honey. Once the full cells are capped with wax, the honey is mature and can be harvested.