Keeping People SAFER And Products FLOWING

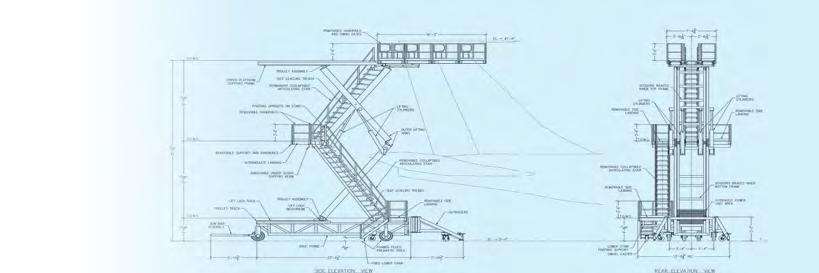

Length: 1,600 feet long

Capacity: Access up to 52 rail cars at one time.

Existing Infrastructure: None - complete greenfield project

What Carbis Solutions Supplied: Design engineering for the entire system including, an access integrated pipe rack, fall protection, spill containment, loading hoses, etc. We also coordinated the installation and taught an operator safety training course.

When planning any project there are parameters that combine to make your job unique. Whether you are facing time constraints, obstructions, a tight budget, or regulatory limitations, our Carbis Solutions Experts can work with you to design the ideal solution for your situation. We will ask a lot of questions to help formulate the right solution for you.

As you browse through this catalog, please think of the images as jumping off points for your own projects. Each of the jobs you see here was bound by its own limitations and depicts the choices made by our customers. We have presented you with an overview of equipment and ideas to stimulate your project goals.

The crash box railing on a liquid tank car is not a handrail system. At only 30 inches high it does not adequately protect workers from falling over the top of the railing as they work.

There is no mid rail on a crash box which results in a gap larger than the 19” maximum allowed by OSHA for elevated work surfaces. Operators can easily slide under the railing.

Ladder openings in the crash box provide a major fall hazard as there is nothing to prevent an operator from falling through this opening.

The ladders on a liquid rail car are extremely difficult to climb, especially when burdened by tools or inclement weather.

Improving Safety While Increasing Throughput

Potential Issues with a 12” [1’-0”] Deep Safety Cage Application for Railcars:

• The 12” deep cage is designed only to supplement the height of the railcar crash box rails to 42”. The gap beneath the crash box rail normally exceeds 19”.

• Due to varying crash box dimensions (length & width), there is a potential for a horizontal gap larger than 12” on the sides of the cage. Furthermore, there is also potential for the cage to land over the top of the railcar dome depending on the configuration causing a misalignment with railcar access opening and therefore interfering with hatches inside the crash box.

• Dimensional fall gaps, as mentioned above, are listed in OSHA 1910 Subpart D - Walking-Working Surfaces.

By

enclosing the entire crash box, Carbis Solutions can help protect your operators completely within our guardrail system, thereby eliminating gaps over, under, and around the crash box.

A 12” safety cage brings the crash box railing up to a 42” handrail height.

A 12” safety cage brings the crash box railing up to a 42” handrail height.

Our

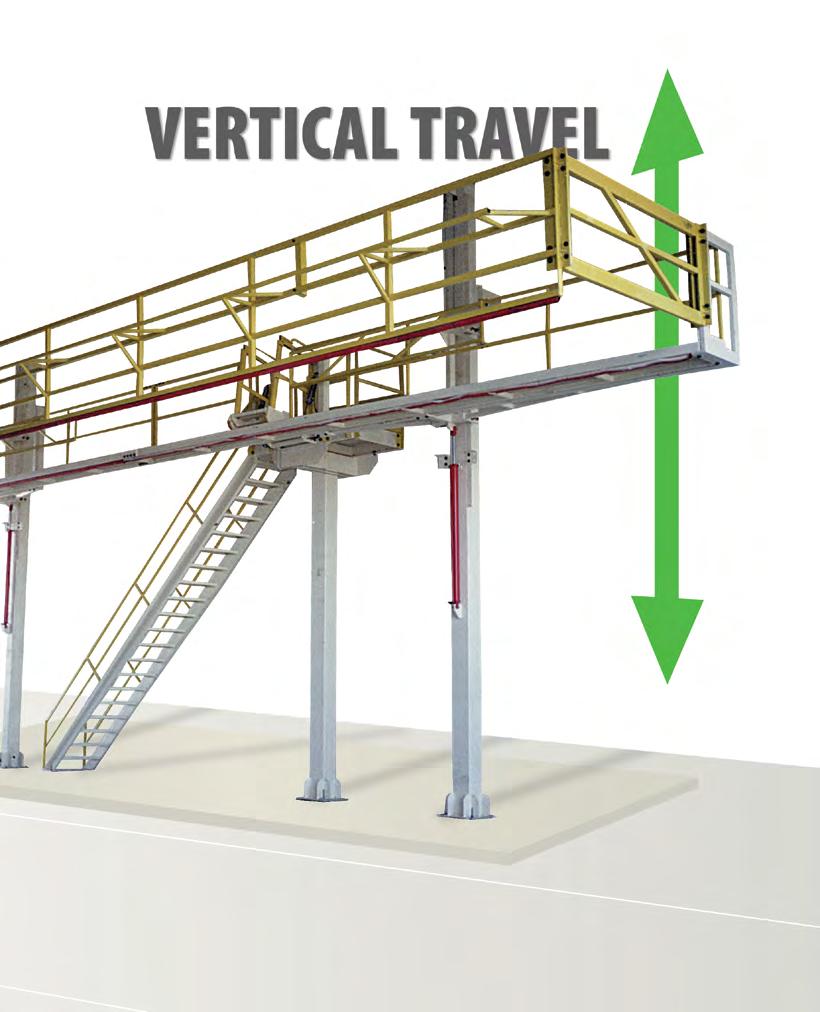

Carbis Solutions can help design and supply all of the equipment for your complete rail system to increase your throughput, protect your operators, and serve your needs for years to come.

Lighting, safety showers, canopies, and operator sheds are all available to make your solution work for you.

access racks provide efficient access to at-height work areas.

Tracking gangways allow the operator to adjust the access point to accommodate minor mis-spotting.

access racks provide efficient access to at-height work areas.

Tracking gangways allow the operator to adjust the access point to accommodate minor mis-spotting.

When a railcar is in the wrong position, safety equipment can be an obstacle rather than a tool. Ask us about how we can help keep your workers safer and products flowing.

Comments we hear from operators:

“As long as I do my job the boss doesn’t care about safety.”

“I can work around the problem if the railcar is not exactly right. I’ve done it hundred times.”

Railcar loading and unloading is dangerous when employees don’t understand proper railcar fall prevention techniques. Mis-spotted railcars and improper orientation may force employees to engage in activities that they normally wouldn’t, such as climbing over railings or having to leave the fall prevention enclosure.

“Once it’s in position I’m not going to move it.”

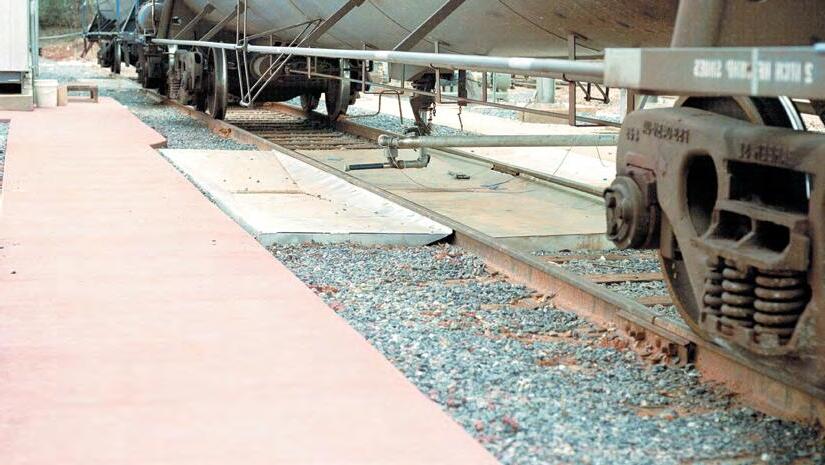

We can build your custom spill pan solution. Carbis Solutions spill pans can be any specific length or provide end-to-end pans that are continuous in coverage. Railcar pan systems include one center and two side pans linked with a cross drain for full width coverage. A center pan only system with a drain, that is between the rails is used in staging, storage, or in areas that connections are along the center belly of the car. We use heavy-gauge metal pans because they are stronger and last longer.

• Galvanized

• Stainless steel

• Aluminium

Your facility is a busy place, and the last thing you want to worry about is spill compliance. With spill pans from Carbis Solutions, you do not have to fret about environmental compliance during the material handling process.

If metal pans do not meet your requirements, we offer a composite materials as well. All the fasteners in these systems are made of stainless steel to maximize resistance to corrosion, and the gaskets are made of neoprene rubber, unless another material is requested.

Facilities meeting the criteria outlined by the EPA must develop and implement an SPCC plan to prevent oil spills. As detailed by the SPCC rule, the following tactics or precautions help prevent environmental damage and protect public health from an oil spill.

• Using the appropriate containers for storing certain oils (e.g. storing gasoline in a flammable liquids’ container)

• Providing overfill prevention for your oil storage containers by using a high-level alarm or audible vent

• Using the appropriate secondary containment, like a dike or a remote, for bulk storage containers

• Utilizing general secondary containment, like drip pans or curbing, to catch oil spill at transfer points between mobile refuelers and tanker trucks

• Periodically visually inspecting aboveground pipes and leak testing buried pipes and containers (Note: Document these inspections in the SPCC plan)

Facilities risk contaminating the environment, harming employees, and incurring significant costs for clean-up should a spill occur without an SPCC plan in place. Facility owners and operators without an SPCC plan face fines from the EPA of up to $27,500 per day for non-compliance.

Access Railcars Faster And Safer

Unit shown depicts a similar application to our Redi-Rack, but customized due to our client’s unique application. Whether a standard solution, or a one of a kind creation, we are here to help.

• Inspecting / Sampling Product

• Opening Hatch For Loading

• Connecting Hoses

Rack Options Page 43

Dry Bulk Railcar Safety Solutions

• Opening / Closing Hatches

• Sampling

• Checking Seals

• Can Be Equipped With Additional Fall Protection

A false sense of security can lead to injuries - or worse. By installing tracking gangways, workers can overcome minor mis-spotting issues without loss of time or having to move the truck.

How are you handling this life-threatening issue at your facility?

This issue occurs because:

■ You have the wrong equipment

■ The truck is mis-spotted

■ The equipment is damaged

■ The driver is not trained properly

Comments we hear from drivers:

“I’m not repositioning my truck. I can handle the cage covering the hatch.”

I’m not going to fall... I know what I am doing.”

“This is the way I have always done it.”

“I don’t have time for that!”

You can have the absolute best solution in place, but if the truck is not accurately spotted, it will not work.

Contact us about how to handle this problem.

“Short cuts make long delays.”

J.R.R. Tolkien

Access Trucks Faster And Safer

Canopy

Loading Arm

Pipe Rack

Installation and/or

Installation

Supervision

Foundation Design

Lighting

Safety Cages

Tracking Gangway

Tracking Guardrails

Access Rack

No matter your requirements, Carbis Solutions can help! We can help with anything from the initial design all the way to finalization, erection drawings and even operator training. Carbis Solutions will be with you every step of the way.

There’s no one-size-fits-all solution when it comes to fall prevention equipment. To ensure a safer work environment it’s critical to work with a trusted vendor that can design a solution to fit your exact needs.

For even greater flexibility, this unit is available with flip-up floor panels. The flip-up panels allow workers to access the hatch openings below the deck without ever setting foot on the truck, further increasing operator safety.

Full truck enclosures from Carbis Solutions afford workers easy access to all areas of the truck surface without the need for a lanyard system or a return to the work platform. This allows workers the flexibility to perform their job from any spot on the truck.

Access Trucks Faster and Safer

• Available in a variety of materials for the harshest environmental challenges.

• Customizable to meet dimensional needs.

• An affordable solution for keeping workers safer while working atop trucks.

In the case of liquid product movement, it usually takes the form of drive-offs and impact damage. Often operators will continue to utilize damaged equipment to get the job done – putting themselves at risk. In this photo, it is obvious that the cage shown has taken such an impact. Continuing to utilize damaged equipment endangers your workers, your process, and your plant. In the event of an impact incident, contact Carbis Solutions EVEN IF the equipment seems fine. A Carbis Solutions Representative will walk you through how to evaluate for hidden damage and help you get back up and running smoothly.

Accidental drive-offs are expensive for your business and dangerous for your workers. At Carbis Solutions, we offer drive-off protection solutions to help reduce the risk of accidents in your facility.

You spend thousands of dollars purchasing the very best access equipment, plus many man-hours researching your options. Then, in a few seconds, an accidental drive-off can take your loading rack out of action!

Our drive-off prevention barriers offers a cost effective way of preventing trucks leaving loading spots with costly access equipment not in the stored position. By establishing a barrier in front of the truck your loading rack you can help avoid premature drive-offs.

One of the major benefits of Carbis warning lights is they offer a simple, yet highly effective way to alert your drivers when equipment is not ready for a drive-off. By implementing a warning light system at your loading rack you can help avoid premature drive-offs. Warning lights can be added to any of our fall prevention systems to warn drivers when equipment is not in the stored position before they drive away.

At many job sites, moving a single shovelful of dirt involves careful planning, permits and can be very expensive. The new Foundationless Loading Rack from Carbis Solutions, can get your system up and running without ever lifting a shovel.

The all new Redi-Rack® represents an innovative twist on the simple loading rack. By combining our most requested additions into a simple ergonomic design we can provide an out of the box solution to even the most difficult loading challenges.

Carbis Solutions designed the Redi Rack® to accommodate pre-selected components reducing the engineering time and getting you moving product sooner rather than later. Each system can be customized to include a safety shower, eye wash station, loading arm supports, grounding, vehicle type and support style so that your system meets your specific needs today and in the future.

For customers with soil removal challenges, we now offer an aboveground foundation solution to minimize construction risk. Using our “foundationless” solution you gain all of the traditional loading and unloading freedom without having to move potentially contaminated soil.

All of the Redi-Rack® component systems are shipped in as few pieces as possible to get you up and moving product quickly.

There are two foundation options with our flexible system. Where soil integrity must be maintained, we now offer “The Rock”, an above-ground foundation alternative which provides full support for the without the need for a traditional footer.

Any combination of gangways and cages can be used to access your vehicles to facilitate your operation.

The Redi-Rack® is configured to support our complete line of loading arms, allowing you to move product quickly and easily.

With our optional safety shower/ eye wash station, personnel can remove hazardous chemicals from their skin, clothes, and eyes quickly to minimize injury.

Protect personnel and plant operations with optional static grounding for loading and unloading operations.

Power Gangway

Pneumatic or hydraulically operated equipment available to suit your application needs.

Single or double-sided canopies available for traditionally footed systems. Not available for “foundationless” systems.

Whether you need traditional halogen lighting or traffic signals, we’ve got you covered!

Drive-off protection available. Whether you need barrier gates, traffic lights, or lane indicator monitors, we can keep you moving.

The REDI-RACK® offers an economical solution for safely accessing the tops of single hatch tanker trucks and liquid rail cars. With a minimal footprint layout, the REDI-RACK® is a great design for existing sites with real estate constraints, sites with a traffic flow concern, or a greenfield location. Available in single or doublesided systems, the REDI-RACK® offers multiple configurable safety solutions with a competitive price and delivery.

Affordable, efficient, and easy to use. The Redi-Rack® from Carbis Solutions is the ideal workhorse for the cement and asphalt industry.

Access Trucks Faster And More Safely

• Inspecting / sampling product

• Opening hatch for loading

• Connecting hoses

Complete Loading Station

■ Loading arms

■ Safety cage

■ Static grounding

■ Eye wash station

■ Lighting

Loading Rack Safety Assessments offer in-depth analysis and insight into whether your equipment is still doing the job that you need it to do.

The equipment that was installed to handle a specific process or loading operation is often less than ideal when servicing new vehicles or new product lines. Whether it is a transition to ISOtainers or an addition of a new line of chemicals, we can help you figure out how to bring your loading rack into line with your current needs.

Whether you need a hazard analysis of a particular spot, or of your entire operation, our team of fall protection specialists can help you to get the most out of your loading rack equipment, increasing safety and throughput.

We will be happy to work with you to spot the areas that most need your attention and help you put together a plan to optimize your operation. We are committed to being your partner as we work together to keep your people safer and your products flowing.

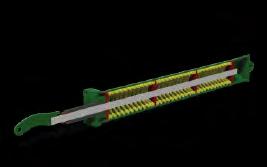

Primarily used for hopper car and hopper truck access, the flat ramp style gangway has a working range of 15 degrees above to 15 degrees below horizontal.

Spring adjustment - simply turn with a wrench to fine tune where the ramp sits when in working position.

Rubber bumpers provides vehicle protection

Aggressive tread helps ensure footing even in the worst environments

Typically used on rail and hopper cars where the access point is consistent.

The telescoping flat ramp gangway affords operators the ability to overcome the gaps which may be left by narrower rail cars and/or crash boxes.

Spring adjustment — simply turn with a wrench to fine tune where the ramp sits when in working position.

Telescopic handrails

Aggressive tread helps ensure footing even in the worst environments

Typically used on rail cars where vehicle height is constant but crash box dimensions may vary.

Telescoping extension ramp

Folding stairs from Carbis Solutions give your operators safer access to vehicles of all height configurations. The design features a selflevelling tread capability that provides level access to the tops of a variety of trucks heights. Talk to us about how we can help you exceed regulatory fall prevention requirements.

Spring adjustment - simply turn with a wrench to fine tune where the ramp sits when in working position.

Rubber bumpers provides vehicle protection

Aggressive tread helps ensure footing even in the worst environments

Typically used on chemical trucks, hopper trucks and isotainers where the height may vary

Wide gangways allow easy access to offset crash boxes and accommodate slight variations in truck and rail spotting. Cage openings can also be modified to create an articulating enclosure style system to protect your workers while maintaining flexibility.

How do you prevent drivers compromising their safety at your facility?

All too often, operators solve obstruction issues by lifting the cage out of the way, resulting in a fall risk. The Carbis LRD “lift resist device” as part of a truck spotting plan will keep your workers safer as they do their jobs.

Carbis Solutions utilizes either spread footings or pile foundations and can provide complete requirements and drawings. All foundations require a minimum soil bearing pressure of 2000 psf and have a minimum 24” of cover, unless otherwise specified.

Keep your work area safer, dry, and shaded with a canopy.

Extreme hot or cold weather conditions are brutal on your employees and may lead to exhaustion, dehydration, stress and more.

Canopy systems from Carbis Solutions deflect some of the heat from the sun and also provide protection from rain, snow, and sleet. A canopy helps keep workers, equipment, and products drier, meaning less contamination, slips, falls, and accidents.

From design to implementation and beyond, you can count on Carbis Solutions to work with you to develop your ideal solution. We strategically partner with contractors across the country to create turnkey solutions to keep your project running smoothly so you can focus on other things.

Flatbed Tarping Is A Hazardous ActivityKeep Drivers Safer At Your Facility With Our Flatbed Tarping Solutions.

Flatbed safety is often overlooked. Is this happening at your facility?

Manual platform and swing gates (Flatbed) – A manual platform combined with safety swing gates closes off dangerous openings along the length of the truck while affording workers the ability to access every point on the load. Fitted with self-closing springs, the gates keep workers protected even when their hands aren’t free.

With an overhead tarping solution, operators stay safely on the ground while the load is protected.

Scan QR code with your phone

Access Trucks Faster And More Safely

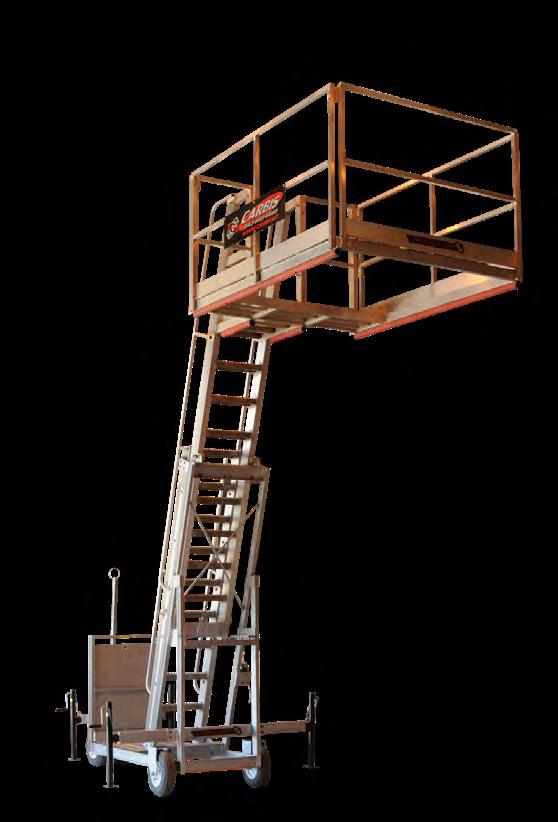

The TC-10 Mobile Access and Fall Protection system is a multi-vehicle mobile powerhouse. Whether you are loading, sampling, or transloading railcars, hopper truck, or tanks, there is a model designed for your application.

1.800.845.2387

Freestanding Truck Access Platform

Protective padding to help prevent damage to the vehicle

Combination tow bar/steering mechanism for easy unit positioning

Forklift tubes - pick up the unit and take to new location.

Ideal unpaved facilities

Features

• Counterweighted so that the unit is self-supporting

• Available in side mount

Four jacks for levelling the base

Large 16” diameter foam filled wheels

• Unique wheel design allows for a tighter turning radius and easier manoeuvrability to simplify spotting

When a loading spot goes down at your facility, the mobile platform functions to get you back up and running reducing downtime and lost revenue.

Vehicle-Supported Truck Access Platform

Protective padding to help prevent damage to the vehicle

Handle grips for easy unit positioning

8” swivel caster with brake for quick manoeuvrability

• Ideal for facilities with limited storage space

Two jacks for levelling the base

Large 16” diameter foam filled wheels

• Unique wheel design allows for a tighter turning radius and easier manoeuvrability to simplify spotting

Reliable safety solution for tank trucks at an affordable price. Our most manoeuvrable model, the TTX is a portable powerhouse of aluminium and galvanized steel construction. Whether you are sampling syrup in Sacramento or testing tankers in Tucson – this unit is easy to roll up, climb up, get it done, and get it done safely and efficiently.

By purchasing your arms and your loading equipment from the same supplier, you can rest in the knowledge that your equipment works together seamlessly from Day 1.

At Carbis Solutions, we serve many industries, providing loading/unloading systems for safer and more efficient handling of all types of liquids.

USA Manufactured and Assembled All assembly and components are made and produced in the USA. Easy

$$$ $$$ 30 $$$ 30

Maintain

Less Down-Time

HAZARDOUS

We Have Loading Arms That Can Withstand The Toughest Chemicals!

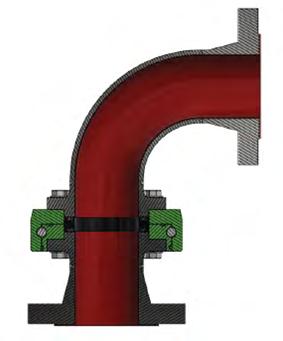

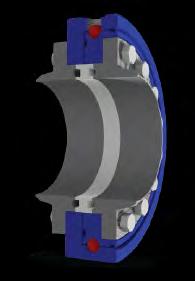

The Excel loading XL-1.0 PTFE lined swivel joint is designed for use in the most hazardous environments and was developed to meet a need of chemical manufacturers to keep their operators safer when working with these exceptionally dangerous chemicals. Manufactured by Excel Loading Arms and distributed exclusively through Carbis Solutions, the XL-1.0 is a game changer.

• Specifically designed for use in the most hazardous applications

• Domestically manufactured

• Fast & easy in-field seal replacement

• 100% PTFE-lined OR Alloy C276 Wetted Parts

• Available in Dual Seal Option

• Flame Hardened Ball Races

All areas of the arm that encounter product are lined with PTFE / ECTFE.

Special hardened ball raceway enhances longevity, provides ease of maintenance, as well as allows the swivel to manoeuvre easily under both mechanical and hydraulic loads.

Ratings — Chemical Effect

A = Excellent

B = Good — Minor Effect, slight corrosion or discoloration

C = Fair — Moderate Effect, not recommended swelling may occur

D = Severe Effect, not recommended for ANY use

All data based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

All loading arms sold by Carbis Solutions are hydrostatically tested before shipment to verify the strength and integrity of the arm.

All Carbis loading arms ship pre-assembled up to the limit of the freight carrier to get you up and running quickly, minimizing downtime.

Our swivels are designed for high durability and ease of maintenance. They are manufactured to the highest quality and safety standards in the industry.

Our swivels meet the industry’s highest standards in the oil and gas, food, and chemical industries. With precision machining and finishes, they provide high-pressure sealing for nearly all media.

Improved performance and durability — special hardened ball races enhance longevity and ease of maintenance, making the swivel easy to manoeuvre under various mechanical and hydraulic loads.

Our swivels are made entirely from domestic products to ensure quality and traceability for each swivel component.

The precision tolerances and corrosion resistant seal faces assure a tight seal as well as low-maintenance design.

Our split flange design provides minimal maintenance. No welding is required to replace swivels in line. Seals are accessible without removing ball bearings. The ability to ship an entire swivel or any component allows ultimate flexibility and minimizes downtime.

The PFS spring assembly is designed for safety and ease of use. Manufactured to the highest quality and safety standards in the industry, make the PFS your preferred choice of spring assembly.

Our spring assembly is designed for safe adjustment and reliability in the field. Our spring cylinder is completely enclosed which brings an extra level of safety to the spring assembly.

The PFS Spring Assembly has two adjustment points, one adjustment point on the arm brackets for larger adjustments, and one on the lead screw for fine tuning.

PFS spring assembly is made entirely from 100% Domestic products. This helps to ensure quality from each component of the assembly.

As part of the Carbis Solutions commitment to safety and quality, each loading arm you purchase from us has been hydrostatically tested for strength and leaks prior to shipping. No other loading arm on the market has this as a standard.

In-field replacement and adjustment services available, as well as factory refurbishment and rebuild services.

Our completely enclosed spring cylinder design eliminates many risks associated with traditional springs. Allows for maximum adjustment while keeping the operator safe.

Before a Carbis loading arm is shipped, it is assembled as much as possible so that when it arrives at your door it is ready for service quickly. Typically, a team can have their new arm up and running in a matter of just a few hours for a smooth, efficient loading process.

Easily adjusted with a standard wrench, no special tools required.

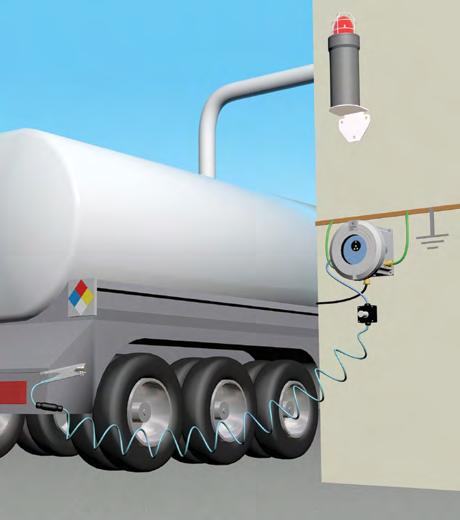

Protect personnel, product, and terminals with proven static grounding systems from Carbis Solutions

The Earth-Rite RTR™ is the most advanced Road Tanker Grounding (Earthing) System for protecting personnel and plant assets from static hazards during road tanker loading and offloading operations.

• Explosion-proof control enclosure incorporating intrinsically safe static ground monitoring interface module

• Ground connection junction box with clamp stowage point and quick release connector

• Heavy-duty stainless steel universal grounding clamp with Hytrel™ extendible cable and quick connectors

The Earth-Rite RTR includes

■ Explosion Proof Control Enclosure incorporating Intrinsically Safe Static Ground Monitoring Electronics.

■ Ground Connection Junction Box with Clamp Stowage Point and Quick Release Connector.

■ Heavy Duty Stainless Steel Universal Grounding Clamp with Hytrel™ Extendible Cable and Quick Connectors.

Tank Truck Recognition

Confirms RTR clamp is connected to tank truck and not other grounded/ungrounded objects

Positive Ground Recognition

Confirms RTR clamp is connected to tank truck and not other grounded/ungrounded objects

Ground Connection Monitoring

Confirms clamp connection and ground connection are good throughout transfer process by ensuring connection resistance does not rise above 10 ohms

The Rite PLUS™ provides positive verification of static ground (earth) connections on a wide range of industrial plant equipment, including rail cars, drums, containers, and other conductive equipment.

Whenever flammable liquids or powders are transferred, or wherever there is a risk of conductive plant items becoming isolated from ground within hazardous locations, effective grounding and bonding is necessary to ensure safe dissipation of static electricity to prevent fires and explosions which can be ignited by static. When connected to a tanker truck or other conductive equipment, the intrinsically safe monitoring circuit verifies a low resistance connection and dissipation path to ground. Good connection is confirmed by pulsing LED indicators, releasing a pair of voltage-free output contacts and enabling the transfer of product to start.

• Explosion-proof (XP/Ex d) controller with intrinsically safe monitoring module

• Universal grounding clampTM with 10m (32 ft) of 2 conductor hytreTM protected cable

• Ground connection junction box with stowage pin for universal grounding clamp

The Earth-Rite RTR includes

■ Ex(d) / XP Controller with Intrinsically Safe Monitoring Circuit. or

■ HAZLOC approved static dissipative GRP controller with Intrinsically Safe Monitoring Circuit.

■ Ground Connection Junction Box with Clamp Stowage Point and Quick Release Connector.

■ Universal Grounding Clamp with various lengths of 2 conductor Cen-Stat protected Cable.

■ Flexible HAZLOC installation options.

This system confirms safe, low-resistance static dissipation path (< 10 ohms) from tanker, drum, etc. to a designated ground point.

Meets requirements of NFPA 77, API RP 2003, and CENELEC CLC/TR: 50404 recommended best practice on controlling static electricity in hazardous areas

Universal grounding clampTM suits all common tankers, drums, conductive plant equipment

Every unit supplied with full installation and operating manual

Easy to install, operate, and maintain

Ground connection junction box simplifies IS field wiring, system set-up, and repairs in hazardous atmospheres

Made from 100% welded steel - Carbis Solutions shelters are stronger and more durable than the competition.

With the integral strength of welded galvanized steel construction, our steel buildings withstand the jarring and vibrations often present at an industrial site. Since an industrial booth will never be pampered, we provide a tough polyurethane paint finish over the galvanized steel panels to resist the corrosion caused by abrasive and toxic chemicals and continuous exposure to the elements.

Booth design may also include features such as removable access panels, double doors, and blank wall panels for mounting equipment. Impact resistant polycarbonate windows, transformers, three phase electrical panels, explosion proof electrical devices, sound deadening, and even blast and fire retardant construction. Positive pressure and other ventilation equipment are also available.

Carbis Solutions specializes in designing customized access systems to meet specific needs. Whether you need fixed or telescoping systems, we will work with you to keep your products and people moving smoothly.

Manufactured of marine-grade aluminium, our barge access systems fight corrosion while moving your people safely and efficiently.

At Carbis Solutions, we understand that changing tides and variations in ship dimensions can make accessing your ship difficult. Let our team help you turn the tide on difficult access situations.

The Carbis Solutions engineering team knows the ins-and-outs of safe access and egress, and they can design a custom gangway for your unique application. Marine access systems often require custom fitting to docks and around existing obstructions. Our marine access specialists stand ready to address your access needs.

Available in 20” to 40” lengths, our GW100 bowed truss gangways will get you on board with ease. Designed of 6000 series marine grade aluminium alloy, these workhorses afford a distributed load of 2,000lb. The twofoot-wide deck plate walk surface features a slip-resistant coating and cleats for better traction and added safety.

Available options:

• Curved tread models available

• Available with rope or aluminium handrails to suit your application

• Dockside rollers allow for variations in tide and float

The Carbis Solutions marine boarding ladder’s lightweight aluminium construction and 1-1/4” serrated rungs make this little ladder a sizable safety advocate while still offering a 500 lb. work load! The open truss construction reduces weight and wind resistance while the heavyduty swivel safety shoes with thick rubber treads improve footing on many surfaces. This unit also features a heavy-duty 1-1/2” aluminium Tee extrusion rail construction for enhanced strength and rigidity!

The rugged durability of our GW500 straight truss gangway allows you dependable access when you need it. With it’s equal height trusses and its marinegrade aluminium alloy construction, it can handle a distributed load capacity of 2000 lbs! Its 24” wide aluminium deck plate features a slip-resistant coating and aluminium angle cleats for better traction and added safety.

Available options:

• Rope or aluminium handrail to suit your particular application

• Curved tread mode available

• Available with 5-1/2” rollers on dock side, allowing for variations in ship’s float.

Our SGW series gangway is a simple, economical, and lightweight solution to ship access for you or your crew. With a distributed load capacity of 750 pounds, this portable powerhouse can run with the big dogs. The 28”-wide perforated deck walking surface features angled cleats for better traction and added safety.

ADAPTIVE.

Build what you want, where you need it. PORTABLE.

Fits through most doorways, elevators, and stairwells. SIMPLE.

Construct your configuration using common hand tools.

PRE-ENGINEERED.

Off-the-shelf components saves on engineering costs.

OSHA COMPLIANT.

Components feature OSHA compliant walk-surface, railings, and stairs.

Bolt-Together Construction

Matching Hole Patterns, Make Construction A Breeze!

TO BUILD EXACTLY WHAT YOU NEED

Meets all current OSHA/ANSI requirements

Lightweight: does not require the use of a forklift or other heavy machinery

• Assemble easily on-site

• Durable construction

• Multitude of configurations

No-slip steps and deck

• Light weight makes moving pieces easy

• Provides stability and safe access

• No-slip steps and deck

Putting together a platform system is no longer a harrowing process. A few simple tools and a two-man crew can have your new platform up and running in a couple hours. Our modular platform systems can round corners, ride elevators, and be carried upstairs. Made of lightweight marine-grade aluminium and available in various sizes and configurations, each component works together to lift you up without letting you down.

When processes change or equipment moves, our modular platform system can move with you as it easily comes apart and can be reassembled wherever you need it.

We provide, installation, relocation, and modification services through our network of qualified installers. We offer a wide range of capabilities, including relocating equipment, installing a single platform, erecting new, existing, or unique equipment, and modifying & maintaining loading systems for petrochemical or industrial manufacturing applications.

With teams located around the country, we can get your equipment installed, maintained, and running at top efficiency quickly and without the hassles of scheduling your in-house team. Whether you are installing a simple crossover or a complete loading system, our team can get you up and operational fast!

Aggressive tread helps ensure footing even in the worst environments

• Aluminium or steel constructions to meet your needs.

• Available fully welded/assembled or separate bolt-together pieces to save on freight costs.

Choosing between welded or bolt-together construction is simple. Bolt together units are ideal in areas where the unit must be moved up stairs, in elevators, and around narrow corners. The tradeoff is that when it is in place it must be bolted together. For most configurations, this is a simple process that can be completed in a couple of hours. In situations where a crane or lift can be used to place a welded unit in location, the welded solution is the better option. Simply place the finished unit in its usage location and it is ready to go.

• 45o step slope and 11-3/4” deep steps provide easy access.

• Constructed of 1” square steel tubing for durability and long service life.

• Platform height is designed to reduce tripping hazards.

• Walk-through back is standard.

• 4” x 4” skid pads on front provide a sturdy base.

• 8” Tilt-N-Roll wheels allow easy one-person repositioning.

• 300 lb. capacity.

• Lightweight, all aluminium construction allows easy moving or repositioning (steel option also available).

• Ladder hooks into slots on trailer for support.

• Left side handrail is standard (right side rails available upon request).

• 3” x 3” heavy-duty skid pads provide a secure base on most surfaces.

• 300 lb. capacity.

675 Series

Super Heavy-Duty Aluminium Process Workstands

Solid channel side rail construction for superior strength.

Specifications

• Type 1A, 500 lb. load capacity.

• Customized heights available.

• Extra heavy-duty aluminium skid plate feet protect side rails and provide a large contact area with the supporting surface.

• 270 slope with 10” risers and 6” deep step allows easier climbing and descent.

• 30” high handrail for added safety.

• 30” - 120” workstands ship fully assembled | 130” and 140” ship knocked down or bolt together to reduce freight costs.

Extra-large 20” X 20” slip-resistant coated platform adds utility and maximizes comfort for extended fixed height work.

5” Tilt-N-Roll casters allow easy positioning and put all feet on the floor for climbing.

Specifications

• 500 lb. load capacity.

• Large 12” X 18” embossed platform for easy access and added comfort.

• Flared legs provide a wide tipresistant base for added safety.

Solid brace provides superior strength.

Specifications

• 500 lb. load capacity.

• 27o stair slope for easy climbing.

• Optional Tilt-N-Roll casters for easy repositioning and transporting.

• Available with or without handrail

Large 12” x 16” platform provides a comfortable work surface on which to stand for extended periods of time.

6” deep slip-resistant steps for added comfort and safety while climbing and working.

• Large 14” x 17” embossed platform provides a comfortable, slip-resistant work surface on which to stand.

• Tool holes in top for added convenience.

• 2-sided

• Tool holes in top for added convenience.

• Exceeds OSHA requirements.

• Certified and tested to a 500 lb. load capacity.

• Aluminium ladders - marine-grade aluminium alloy for maximum strength.

• Fibreglass ladders - Non-conductive, full channel fibreglass rail design adds extra safety when working around electricity.

• 4” deep slip-resistant ribbed steps for a more comfortable work surface.

• Large 1-1/2” wide aluminium angle feet with thick rubber tread.

• All components are field repairable, which increases ladder life cycle and reduces costs.

• Tool holes in top for added convenience.

Double-Front Stepladders •

• Tool holes in top for added convenience.

• 2-sided

Platform Ladders

• Large 14” x 17” embossed platform helps provide a comfortable, slip-resistant work surface on which to stand.

• Exceeds OSHA requirements.

• Certified and tested to a 500 lb. load capacity.

• 1-1/4” OD slip-resistant serrated aluminium rungs.

• Large aluminium swivel safety shoes with thick rubber treads may be used in either tread or spike down position for improved traction.

• All components are field repairable which increases ladder life cycle and reduces costs.

Specifications

• Oversized 7” x 15” steps offer generous standing area, reducing fatigue when working at fixed heights for extended periods of time

Specifications

• Oversized 13-1/2” x 15” slip-resistant diamond tread platform provides a comfortable standing area

• 30” high handrail provides an extra level of safety

Specifications

• Designed for internal tank inspection and cleaning

• Aluminium marine grade construction with field replaceable parts.

• Standard swivel safety shoes and over shoes facilitate safe entry into tank cars through narrow access hatches.

• For internal tank inspection and cleaning.

• All components are field repairable which increases ladder life cycle and reduces costs.

• Light weight and super rigid.

Specifications

• Designed for service/cleaning of chemical and smokestacks or any difficult-to-reach areas requiring variable height access.

• Sections can be combined to provide the desired length; ladder must be laterally supported every 30’

• Aluminium construction reduces weight and resists corrosion.

• 16” wide to facilitate ease of handling and access through hatches and manholes.

Every day, workers around the world climb ladders to great heights to get their job done. Working at height is hazardous and requires constant attention to safety. A fall can happen at any time and on any structure during the climb going up or down.

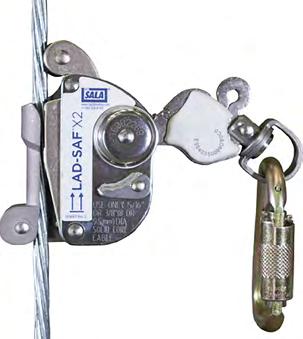

Part of a permanently installed ladder safety system, the Lad-Saf X2 Detachable Cable Sleeve with dual independent locking systems is a portable connection device that connects the worker’s harness to the ladder cable and glides freely up or down the cable as the worker climbs. Once attached, the sleeve does not require any further handling by the climber. It is designed to work with many different styles and lengths of ladders on structures like wind turbines, communication towers, buildings, water towers and more.

Fast and easy scanning of RFID tag improves management of the safety equipment inspection process.

A more manoeuvrable swivel provides the user with increased mobility while climbing.

Automatically follows the climber during ascent or descent.

One-handed attachment or removal from the cable delivers fast, easy and safe connections. Can be attached anywhere along the cable for added versatility.

In the event of a fall, the sleeve is designed to lock onto the cable and arrest the fall, and to remain locked until the worker can regain his footing or be rescued. Even if the first means of locking is compromised, the second will still engage to arrest the fall.

Deploys in the event of a fall, limits the maximum fall arrest force to 1,350 lbs. (6 kN) or less, and shows the device must be taken out of service.

Compact and lightweight stainless steel construction stands up to harsh environments.

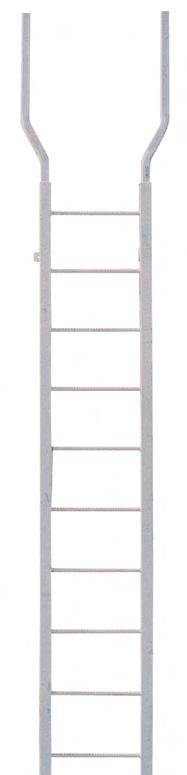

Ladders are available with either a flared or non-flared top.

Holdout brackets are standard. One pair per 10’ for steel ladders and one pair per 6’ for aluminium ladders.

Material choices include: aluminium, galvanized, primed, mill, painted, stainless steel and fibreglass depending on environmental requirements.

All Carbis Solutions ladders meet or exceed OSHA standards. Additional industry standards can be met upon request.

Can be customized to your specification although some may require additional charges.

All ladders are shipped fully assembled for quick, easy installation.

Galvanized models in stock for immediate shipment

Spring-loaded gate closes automatically to help prevent inadvertent backing out of opening.

Flared walk-through allows easy, safe access to and from buildings or tanks.

To be used with offset cage ladders

6’ high panel guards the first five rungs to help prevent unauthorized access.

Heavy-duty butt hinges allow the cover to be easily swung to the side for ladder access. Locking clasp allows the use of a padlock to secure cover.

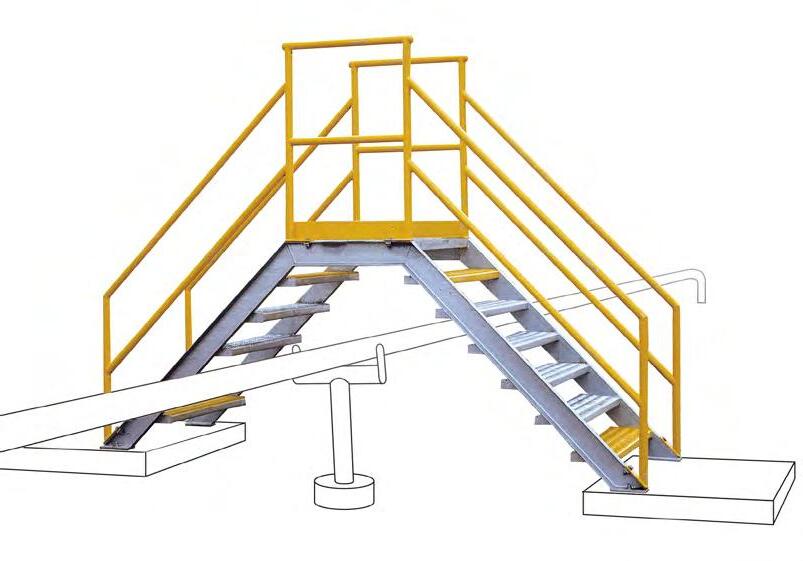

At Carbis Solutions, we offer OSHA compliant stairs and stair towers made from galvanized steel, which stands up to industrial use and various weather conditions.

Stair towers can provide excellent fall prevention with mid rails, top rails and narrow gaps between steps.

Customers come to us with unique applications all the time. Whether you need to access the engine of your airplane or the rotor on your chopper – we can work with you to keep your people safer and your processes flowing smoothly.

No aircraft? No problem! We have designed ladders for many applications – there is no job too big or too small, for us!

Specifications

500 lb. load capacity. Access from both sides. Approved for use on aircraft meeting and/or exceeding all OSHA and ANSI codes and standards. Lightweight yet durable aluminium construction with casters for added mobility. Drain holes on the platform and treads prevent pooling liquids.

We will then work with our team of engineers to design your vision.

Once approved, our manufacturing team brings your imagination to life.

T-REX (Tail Rotodome Extension) is taking the E-3 Maintenance personnel to higher places. Based upon the idea of combining several types of access stands into one stand which can be deployable in under two hours. Carbis Solutions has developed the first motorized stair accessible modular stand of its kind. T-REX.

Carbis Solutions can develop and implement a training program to train employees and operators to use the equipment at your facility. Whether you want us to train a large classroom group or a “train the trainer” small group – we can design the program around your needs,

Training programs include hazard awareness, maintenance, and the proper operation of your equipment incorporating your procedures and guidelines. We can conduct this training either on-site or online. We can also tie in to your existing employee training protocol in many situations.