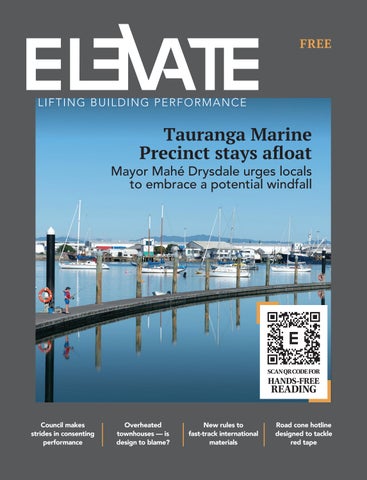

Tauranga Marine Precinct stays afloat

UNMATCHED QUALITY

Explore the pinnacle of stainless-steel fabrication with Stainless Electrical Products (S.E.P), New Zealand’s leading innovator in stainless steel Electrical solutions since 2004.

At S.E.P, we specialise in fabricating highquality stainless steel electrical enclosures powered by ABB Products

Our Extensive product line features state-ofthe-art modular distribution cabinets, IP66rated hygienic enclosures, wire mesh cable trays and robust stainless-steel cabinets designed for severe industrial conditions, all proudly NZ made.

Our versatility shines through our custom fabrication services, where we tailor solutions to fit your exact requirements, enhancing both functionality and aesthetic appeal.

Why choose S.E.P? We commit to excellence and precision in every product. Our engineering expertise ensures that each item not only meets but exceeds industry standards, providing you with lasting reliability.

From complex electrical setups to straightforward enclosures, our skilled team delivers exceptional support and meticulous attention to detail in every project

Partner with S.E.P for your stainless-steel need and beefier from a partnership that values quality, customer satisfaction and innovative solutions

In this issue of Elevate, Mayor Mahé Drysdale urges locals to embrace a marina redevelopment that could deliver jobs, industry growth, and a renewed sense of purpose for the waterfront.

While the sale has stirred debate, the focus now is firmly on turning a contested deal into a regional win. From the water’s edge, we move into the building sector, where new legislation is set to make it easier — and cheaper — to source high-quality

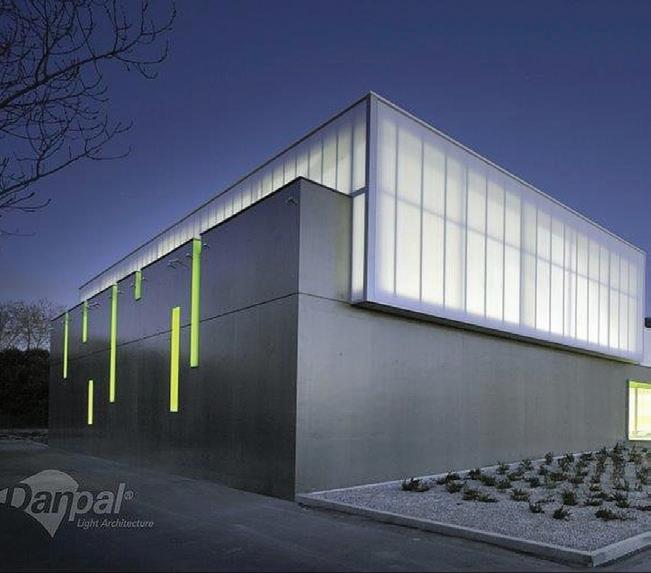

DANPALON is the complete daylighting solution offering exceptional quality of light, thermal insulation and UV protection with a rich non-industrial visual appeal. The Danpalon system offers substantial physiological and psychological benefits in all work and living spaces.

DANPALON’s performance is certified by rigorous testing from worldwide institutions. It offers a new concept in glazing providing outstanding performance and flexibility in design. Use Danpalon for roofing, facades or partitions, internally and externally.

Smarter Real Estate

Wayne Jackson is a seasoned real estate agent with 28 years of experience in both Australia and New Zealand. He holds a Full Agents Licence and approaches his daily work with enthusiasm, dedication, and a positive attitude. His commitment to excellence has made him the leading listing and sales agent in his area for several years.

Wayne recently joined Arizto to elevate his service to clients by utilizing a modern approach to real estate. This allows him to offer affordable services, leveraging the latest technology and systems to ensure success.

If you need an experienced, hardworking realtor to sell your most valuable asset, contact Wayne at 027 728 3355. He'll happily appraise your property and provide expert advice on how to achieve the best result in any given market.

Outside of his work, Wayne enjoys fishing, traveling & relaxing with his family, cooking, and gardening. Call Wayne today to take advantage of his wealth of experience and passion for real estate.

Wayne Johnson 027 728 3355

132 Onslow Street, Kawerau

231 Valley Road, Kawerau

River Road, Kawerau

Easing access to crucial materials New legislation to open the NZ market to international building products

A reform in New Zealand’s building sector is set to transform the way building materials are sourced and approved, promising greater choice, reduced costs, and improved resilience to supply chain shocks.

Passed on 2 April 2025, the Building (Overseas Building Products, Standards, and Certification Schemes) Amendment Bill aims to streamline the use of internationally certified building products by integrating them more efficiently into the local regulatory framework.

By the end of July 2025, over 12,000 essential products — including plasterboard, cladding, and insulation — will become easier to use under the new system. These reforms represent a significant step in expanding access to a broader global building products market, while ensuring compliance with the New Zealand Building Code.

Building and Construction

Minister Chris Penk says, “Builders and designers will soon be able to count on highquality products from overseas being accepted by Building Consent Authorities (BCAs), eliminating unnecessary delays and reducing project costs.

The current system has long been criticised for limited competition, high

Builders and designers will soon be able to count on high-quality products from overseas being accepted by Building Consent Authorities (BCAs), eliminating unnecessary delays and reducing project costs.

- Chris Penk, Building and Construction Minister

material costs, and sluggish productivity. The 2022 plasterboard (GIB) shortage highlighted the sector’s vulnerability to disruptions in local supply chains.

With just a handful of dominant players, the building materials market in New Zealand has lacked the flexibility and competitive pricing seen in comparable economies.

Minister Penk highlighted the gravity of the issue.

“It is unacceptable that it

costs around 50% more to build a standalone home in New Zealand than it does in Australia. Since 2019, building costs have risen over 40%, and productivity levels have remained stagnant since 1985.”

By reducing regulatory red tape and introducing recognised international certification schemes, the Government aims to bring New Zealand in line with global best practices, making building faster, more efficient, and less costly.

Making certification and compliance easier

Under the new legislation, products certified through internationally recognised standards and schemes — vetted and endorsed by the Ministry of Business, Innovation and Employment (MBIE) — must be accepted by BCAs, provided they are used as intended. These changes will reduce the burden on BCAs, builders, and designers to prove compliance, creating a more streamlined consent process.

“The Bill targets every level of the product assurance system: standards, certification schemes, and compliance pathways,” explained Suzannah Toulmin, Manager of Consenting and Practitioners Policy at MBIE. “Our goal is to deliver the greatest benefit across the entire sector.”

Key features of the reform package include:

• Recognition of overseas standards and certification schemes: Reducing duplication in compliance processes

• Building Product Specifications: Simplifying how international standards can be cited and used alongside the Building Code

• Mandatory BCA acceptance: Requiring BCAs to accept overseas-certified products recognised by MBIE, ensuring consistency and reliability.

However, the oversight of BCAs remains crucial. BCAs will still assess proposed building work to confirm that products are being used appropriately and that the final outcome meets

This Bill aims to reduce the cost of building products, strengthen our resilience to supply shortages, and give more choice to the people designing and building homes. It’s about making the system work better for everyone involved.

Building Code requirements. The core principles of safety, durability, and health remain non-negotiable.

While the immediate focus is on improving access to foreign products, the Bill is also expected to benefit local manufacturers. By enabling local products to be tested against internationally accepted standards, New Zealand-made materials could become more competitive on the global stage.

“This is not just about imports,” Chris Penk says. “It’s also about empowering local producers to meet international benchmarks, opening the door to lucrative export opportunities.”

Part of a broader reform

The Bill is one component of a comprehensive reform programme aimed at modernising New Zealand’s building and construction sector. Other measures include:

• Simplifying the process for minor variations and customisation within building consents

• Removing the building levy on projects under $65,000

• Expanding digital tools and pathways for faster approval processes.

These collective reforms are designed to tackle longstanding barriers in the sector and bring about a more agile, competitive, and efficient building system.

“This Bill aims to reduce the cost of building products, strengthen our resilience to supply shortages, and give more choice to the people designing and building homes,” Toulmin says. “It’s about making the system work better for everyone involved.”

Looking forward

With implementation just weeks away, the industry is bracing for a shift that could redefine how building work is done in New Zealand. For professionals across the construction value chain, the changes represent both a challenge and an opportunity to adapt, innovate, and build a more competitive and sustainable future.

As Chris Penk put it: “Once these changes take effect, Kiwis will be able to tap into the global building product market — and finally pay a fair price for quality construction.”

The changes target each level of the building product system and will:

• Enable recognition of overseas standards and standards certification schemes, therefore removing the need for designers, builders or Building Consent Authorities (BCAs) to verify standards

• Streamline the citing of international standards with the new Building Product Specification, which can be used with Building Code documents to show compliance with the Building Code

• Require BCAs to accept building products certified overseas and recognised by the regulator, the Ministry of Business, Innovation and Employment (MBIE).

- Suzannah Toulmin

AI meets home consent process

By Ben O’Connell

There were 33,530 new homes consented in Aotearoa in the year ended May 2025, down 3.8% compared with the year ended May 2024, according to new figures released by Stats NZ.

“The record for the annual number of new homes consented was 51,015 in the year ended May 2022. While consent numbers fell sharply after that peak, they have levelled out over the past year,” economic indicators spokesperson Michelle Feyen said.

In the year ended May 2025, 17,852 multi-unit homes were consented, an 8.6% decrease compared to the year ended May 2024. There were 15,678 standalone houses consented, representing a 2.4% increase over the same period.

The seasonally adjusted number of new homes

consented in May 2025 rose 10% compared with April 2025. This follows a seasonally adjusted drop of 15% in April 2025.

The seasonally adjusted number of new stand-alone houses consented rose 3.5% in May 2025. This follows a 5.4% fall in April 2025.

With home consent figures stabilising after earlier declines, the focus is shifting to how digital tools can streamline the consent process and support sector efficiency.

A new BRANZ research project explores this, focusing on how AI can automate processes that typically require extensive manual documentation.

The research asks building consent officers about the pain points they experience in processing applications, and where they think AI could eliminate them. Missing documents and inaccurate information are two pain points that have already been identified.

Currently, pre-submission checks by councils only

The seasonally adjusted number of new standalone houses consented rose 3.5% in May 2025. This follows a 5.4% fall in April 2025.

With home consent figures stabilising after earlier declines, the focus is shifting to how digital tools can streamline the consent process and support sector efficiency.

confirm if required documents are present, not whether they’re complete or accurate. BCOs believe that AI could improve this vetting by identifying missing elements, such as site plans, boundaries, and construction details.

BCOs are also interested in AI tools that can quickly interpret specifications, standards, and compliance data, such as NZS 3604 lintel sizes or material compatibility under E2/AS1.

Another key area is communication: BCOs want AI to help draft better Requests for Information (RFIs) by simplifying technical language, improving grammar,

and referencing relevant Building Code clauses to make requirements clearer for applicants.

“That’s a challenge in itself,” one BCO said on crafting high-quality RFI letters. “How do you communicate a reasonably technical thing in a way that can get you the answer that you need?”

BRANZ researchers are currently gathering more use cases from BCOs. They will next consult with applicants to determine which AI applications are feasible to trial and implement in the building consent process.

DESIGN & CONSTRUCT

BORED PILING

DISPLACEMENT PILING

GROUND IMPROVEMENT

CFA DOUBLE ROTARY

RETENTION PILING

BANK STABILISATION

SLIP REPAIR

DRAINAGE SOLUTIONS

FOUNDATIONS & STRUCTURES

LIMITED ACCESS PILING

OLIVIER PILES

RAMMED AGGREGATE PIERS

RAIL

ALAN LEE GROUP OF COMPANIES

– Vehicle WOF’s

– Tractor WOF’s

– Auto Repairs & Servicing

– Air Conditioning Repairs & Regas

– Automotive Parts & Accessories

– Auto Electrical Parts & Batteries

– Auto Electrical Repairs

– Hydraulic Hoses & Fittings

Our services include, but is not limited to the following:

• Air conditioning – servicing and repairs

• WOF checks and repairs

• Insurance claims

• Winz approved quotes

• Petrol servicing with quality approved and genuine parts

15 Atuaroa Avenue, Te Puke Tauranga District 3119 Bay of Plenty

¼

• Diesel servicing including DPF burn offs

• Diagnostics scanning and electronic repairs

• Spark plug and coil pack replacements

• Pre-purchase inspections

• Supply and fitting of new tyres, wheel alignments

• Brake repairs including brake drum machining, brake fluid flushing and replacement

• Suspension specialist

• Exhaust fabrication and repairs

OPEN HOURS: Monday to Friday – 8am to 5pm

Saturday WOF’s by appoinment

Accredited Bosch Service Agents

ALAN LEE GROUP OF COMPANIES

OVERVIEW

Our business was established in 1983 operating from Queen Street Te Puke in the Tauranga District BOP. Prior to this, Alan Lee, an experienced Te Puke mechanic, was employed by two local garages and the major tractor workshop. In 1988 we moved to Atuaroa Ave where extensions to the premises were started in 2000.

Family owned and operated, now run by Alan’s daughter and son in law. This group of companies has a low profile – one that provides honest service with a smile!

To keep up with technology we are members of the Bosch Dealer Association. We are recognised by Bosch as Electronic Fuel Injection and ABS Braking Systems Specialists.

– Auto Repairs & Servicing

The services and products that we can provide through our three companies are many and varied. We have the ability and equipment to service all makes and models of cars, tractors, light trucks and forklifts. – Vehicle WOF’s – Tractor WOF’s

– Air Conditioning Repairs & Regas

– Automotive Parts & Accessories

– Auto Electrical Parts & Batteries

– Auto Electrical Repairs

– Hydraulic Hoses & Fittings

Complete hose and hydraulics had been running in Te Puke since 2001. We can service all hydraulic machinery on agricultural, horticultural and commercial machinery. Our on-site vehicle is able to to reach you in your time of need, so you can get up and running as soon as possible

We offer a 24/7 service, give us a call and we will be there.

In addition to on-site servicing, we offer a while-you-wait service at our workshop (15 Atuaroa Ave, Te Puke) with a large stock on hand and capable staff on site at all times, we will help you out.

In addition to hose repairs and replacements, full plumb up jobs and servicing we also are fully equipped to repair, replace or supply your hydraulic rams.

Tauranga Mayor Mahé Drysdale has called for locals to look ahead and consider the potential, positive impact of the Marine Precinct.

The precinct’s sale was confirmed in April after the High Court dismissed an injunction to prevent it, and in light of this decision, Mayor Drysdale is urging the community to focus on the potential benefits the redevelopment can bring.

The Precinct’s new owners plan to transform the site into a purpose-built facility designed to serve the marine sector. Their vision includes creating new employment opportunities and boosting economic activity, which Drysdale sees as a win for the broader Tauranga region.

Since taking office in August 2024, Drysdale says he has made it his priority to understand the details of the sale and ensure it delivers the

Tauranga Marine Precinct stays afloat

Mayor

Mahé Drysdale urges locals to embrace a potential windfall

best outcomes for residents.

“Over the past nine months, I’ve listened to stakeholders and reviewed the deal. I’ve been openly critical of the commercial terms and would not have supported the sale as it was originally negotiated,” he says.

However, he acknowledged that the current Council must honour agreements made by their predecessors. “We’ve inherited this deal. While I may not like it, our responsibility now is to fulfil the legal obligations and focus on future benefits.”

The Marine Precinct, originally envisioned as a hub for the marine industry, struggled to reach its potential and has reportedly cost Tauranga ratepayers around $1.5 million annually in losses. Drysdale noted that the High Court found the legal basis for challenging the sale to be “weak,” and any attempt to overturn it could have exposed the Council and ratepayers to additional costly litigation.

The precinct’s sale was confirmed in April after the High Court dismissed an injunction to prevent it, and in light of this decision, Mayor Drysdale is urging the community to focus on the potential benefits the redevelopment can bring.

Now that the legal hurdles have largely been cleared, the mayor is encouraging the city to move forward and support the development. “It’s time to embrace the vision of the new owners,” he said. “Their success will ultimately benefit Tauranga, both in terms of jobs and economic growth.”

While the sale has been finalised, legal action continues. Pacific 7, one of the parties opposing the sale, has confirmed it will pursue further court proceedings, including an amended application for a stay, a request for leave to appeal, and a continuation of its judicial review.

In response, the Council held an Extraordinary Meeting

on 9 May 2025, where the majority voted to oppose Pacific 7’s latest legal efforts. The Council also reserved the right to seek reimbursement of legal costs incurred since the High Court’s 11 April judgment.

Mayor Drysdale said the city cannot afford to continue spending ratepayer money on a case that has already been rejected multiple times.

“It’s not financially responsible to keep fighting a losing battle,” he stated. “With the sale complete, we must now focus on securing the best possible outcome for the marine industry and our wider community.”

Excellence in pump & electrical solutions

Pump & Electrical Services Ltd, based in the heart of Waikato, is your premier destination for a comprehensive range of pump and electrical services tailored for domestic, lifestyle, farm, and industrial needs.

Founded in Hamilton in 1988, Pump & Electrical’s experienced team will work with you to determine your precise requirements and then provide you with exactly what you need.

At Pump & Electrical Services, the business ethic has been built on providing quality service, and they have successfully forged many long-lasting partnerships with their clients.

Their expertise extends to their milking systems, water treatment and pool and spa care, ensuring your operations run smoothly and efficiently. With a strong reputation built on quality products, exceptional services, and unparalleled expertise, Pump & Electrical stands ready to exceed your expectations.

From installation and maintenance to repairs and consultations, Pump & Electrical’s dedicated team leverages years of experience to provide solutions that not only meet but surpass your requirements. Whether you’re facing challenges with water boring, trenching, or irrigation or require sophisticated water filtration and treatment

solutions, Pump & Electrical is equipped to assist.

Their commitment to quality and customer satisfaction shines through in every project, ensuring you receive the best possible service and outcomes. Located in Hamilton, with services extending throughout the Waikato region, they are your reliable partner for all pump and electrical needs.

Get in touch with the team today at 0274 387 931 or come visit their showroom to view the great range of water pumps and other products they have to offer at 25 Lincoln St, Frankton, Hamilton.

The Waikato Pump Specialists

With over 20 years of experience in earthmoving and general contracting, Crimpy’s Contracting brings a commitment to honesty, integrity, and quality work to every project.

Equipped with a bobcat, truck, and excavator, we have the tools and expertise to handle a wide range of projects, always treating each site with the care and respect we would give our own property.

No work, no workers Infrastructure delays trigger national skills shortage

Infrastructure delays are driving hundreds of engineers to lose their jobs and leave the country, resulting in a skills shortage, according to Richard Templer, Chief Executive of Engineering New Zealand.

“In 2023, the government spent approximately $17 billion on infrastructure, and in 2024, the government spent about $3 billion on infrastructure, so that is $14 billion less.”

Richard says that this has resulted in a significant lack of work, among other factors, which has led to a massive loss of jobs.

“Engineering consultancy firms have lost 1200 people in the last 12 months, and they are heading overseas, because that is where the work is and that is where the jobs are.”

Richard adds that when the infrastructure work starts being produced more steadily, there will not be enough engineers, and there aren’t enough engineers coming in and graduating to fill the space left by those leaving the profession or retiring.

“An example of this shortage is the fact that Massey University is downsizing significantly its engineering

spending more on the new classrooms, we need Kainga Ora building social housing, we need the government to lead, and then local governments to follow.”

In order to have a stable, longterm infrastructure outlook, Richard believes it needs a bipartisan approach. “You need Labour and National to agree on, you know, what the 80% of projects are that they agree need to happen? What are the big water projects, roading projects, power projects, transport projects that must happen.”

Once these projects are in the pipeline and agreed upon, Richard says the profession will then have long-term visibility on what is needed and can start building the necessary capability.

In 2023, the government spent approximately $17 billion on infrastructure, and in 2024, the government spent about $3 billion on infrastructure, so that is $14 billion less.

Richard says that this has resulted in a significant lack of work, among other factors, which has led to a massive loss of jobs.

school, and that’s simply because there weren’t enough students coming through to take up positions.”

The previous government and the current government have indicated that there is an infrastructure deficit of approximately $100 billion. But Richard says credit has to be given to the Minister

of Infrastructure as “we need that work to start getting out there, and he has recognised this, and is encouraging the government agencies to do that.

“We need things like the Dunedin Hospital project underway, we need the ferries project underway, we need the Ministry of Education

If current trends continue, a big risk that could occur is that currently, there are 147 projects in the fast-track consenting bill, which Richard says 140 plus of those need engineering input.

“So when that bill goes through, and those current projects come on stream, if the current trends continue, there’s not going to be engineers to do the design, and there’s not going to be people capable of doing the build and the construction.”

Richard adds that while engineers are heading overseas, many within the infrastructure sector are as well, “as in the people who drive the bulldozers, swing

However, while the brain drain and delays in the sector have been a cause for concern, these types of things do tend to be cyclic.

“You get a dip, it’s always followed by a raise, and talking with industry people, they’re starting to see a lift.

the hammers, and that sort of thing, they have headed overseas to find work or find other places to work.

People will not be here to do it, which means we will have delays and increases in costs.”

However, while the brain drain and delays in the sector have been a cause for concern, these types of things do tend to be cyclic.

“You get a dip, it’s always followed by a raise, and talking with industry people, they’re starting to see a lift.”

Richard thinks that, ironically, there will be a shortage of engineers in two or three years.

“You know, there will always be a lag on it, it may take, you know, six months, may take 18 months, but things will start to pick up, and that’s because there is so much infrastructure that needs replacement, needs building.”

While the infrastructure delays are impacting engineers, it is also having a large effect on a much wider group of people.

“You’ve got professional engineers doing the design work, but there are a lot more people involved in the actual construction, and that’s where a really big number of people have been impacted.

“That’s why, when we’re talking to the government about this, we are talking about those people, not just engineers, because it is preserving the jobs for all of those people that is really important.”

Richard Templer Chief Executive of

Hire & Services

• Party Hire, chillers, roasters, crockery & cutlery

• Marquees, porta-loos & porta-showers

• Bouncy Castles & Candy Floss Machine

• Mini buses & cars

• Furniture trucks & crane trucks

• Trailers, horse floats & tow dollys

• Scissor lift & cherry picker

• Temporary security fencing

• Industrial & contracting

Specialist Services

• Engineering

• Hydraulic hoses

• Ride-ons, mowers, chainsaws and small motors

• Pumps and water filters

• Exhaust & radiator repairs

Marquee & Party Hire

We have a huge range of hire equipment available. From party hire to building, plumbing and engineering, we have it all.... well, almost all!

07 315 6515

Administration@LHEopotiki.co.nz 021 114 6693 (After Hours)

www.lheopotiki.co.nz

Marquee Hire

Road cone hotline tackles red tape

By Ben Kennedy

It’s a scene many Kiwis know too well — an empty road flanked by endless rows of bright orange cones, seemingly without purpose or workers in sight.

That frustration, once shared in private grumbles and online memes, now has an official outlet: a government-backed hotline for reporting excessive road cone use.

Unveiled at a post-Cabinet press conference this week, Prime Minister Christopher Luxon and Workplace Relations and Safety Minister Brooke van Velden announced the initiative as part of a wider

overhaul of New Zealand’s health and safety regulations.

Dubbed a “real issue” by Luxon, the sea of road cones has become symbolic of what the government sees as overregulation and bureaucratic inefficiency.

“You can drive around this country at different times of the day, and you’ve got whole roads shut down, no one is doing any work, and the cones are frankly just clogging up the joint,” Luxon said yesterday. “It’s just symptomatic, frankly, of a country that is not getting things built.”

The new hotline will allow the public to report what officials are calling “overzealous” or unnecessary deployments of road cones. While the exact operational details are still

You can drive around this country at different times of the day, and you’ve got whole roads shut down, no one is doing any work, and the cones are frankly just clogging up the joint,” Luxon said yesterday. “It’s just symptomatic, frankly, of a country that is not getting things built.

being finalised, van Velden confirmed that WorkSafe will be tasked with managing the complaints and providing guidance when instances of overcompliance are identified.

“Having WorkSafe focus on this will be a culture shift for the agency, but it signifies the broader direction this Government is taking with the health and safety system,” van

Velden said. She added that the overuse of cones was brought up at nearly every public meeting during her recent travels across the country. Luxon and van Velden were joined in the initiative by Transport Minister Chris Bishop, who will oversee the role of the New Zealand Transport Agency (NZTA) in the cone review effort.

The bigger picture

While the cone hotline has captured public attention, it is just one component of a broader regulatory reset. Cabinet has approved changes to the Health and Safety at Work Act that will narrow its focus to serious risks — those that could cause death, serious injury, or illness — particularly for low-risk, small businesses.

“For example, a small clothing shop would still need to provide first aid, emergency plans, and basic facilities — such as suitable lighting — but wouldn’t need to have a psychosocial harm policy in place,” van Velden said.

According to the government, these changes are meant to reduce “tick-box” compliance and eliminate redundant paperwork that confuses employers and employees alike. Luxon argued that such well-intentioned rules had often spiralled into impractical expectations.

“We’ve got signs that are actually there to warn you about hot water taps, we’ve got signs to say please hold on to the handrail ... that is where

While the government frames the reforms as common-sense deregulation, reactions from stakeholders have been mixed. The Retail NZ chief executive Carolyn Young welcomed the changes, saying they would remove a “huge burden” from the country’s 27,000 small retailers.

we have jumped the shark and it’s gone mad,” Luxon said.

The reforms are expected to be introduced to Parliament by the end of the year, with changes coming into effect in early 2026 if passed.

The public reacts

While the government frames the reforms as commonsense deregulation, reactions from stakeholders have been mixed. The Retail NZ chief executive Carolyn Young welcomed the changes, saying they would remove a “huge burden” from the country’s 27,000 small retailers.

However, safety experts were less impressed. Mike Cosman, chair of the Institute of Safety Management, criticised the

reforms for failing to address New Zealand’s high rate of workplace fatalities — between 50 and 70 deaths annually, more than four times the rate in the UK.

“The reforms are focused instead on costs to businesses of prevention and not the much greater costs of harm,” Cosman said. “This seems to be looking through the wrong end of the telescope to us.”

He also criticised the government for ignoring recommendations from experts, unions, and high-risk industries provided last October.

While the hotline may strike some as trivial, the government insists it’s about more than just traffic cones.

Van Velden said it represents a cultural shift in how regulation is approached, shifting focus to high-impact risks and away from bureaucratic formalities.

“There is a sentiment that road workers are annoying,” she said, before Luxon interjected, clarifying, “Road cones are annoying.”

In that spirit, the hotline might be the beginning of a broader public reckoning with how New Zealand manages both risk and responsibility.

Feel safe & secure with the best security systems & electrical provider.

NOWOPENINTAUPO

EXPERTISE & DEDI

To provide exceptional service and deliver on our promises, we need a strong team.

We achieve this by adhering to our core values and promoting personal development, allowing our team members to advance within the company.

OUR TEAM IS THE BACKBONE OF OUR SUCCESS

INNOVATORS IN THE INDUSTRY

Our continual investment in advanced scaffolding technologies and methods keeps our team at the cutting edge of the industry.

TRAINING & PERSONAL DEVELOPMENT

We provide regular training to keep our team updated with the latest industry skills and knowledge.

The risks of working on roofs

WorkSafe is urging businesses whose employees work at height to take the risks seriously after a tragic workplace accident left a Wellington man permanently injured.

The incident, which happened in April 2023, has prompted renewed scrutiny over the safety practices of companies working on rooftops and in other elevated environments.

The accident occurred when 38-year-old Josh Bowles, a relatively new employee at a commercial cleaning company called Prowash, fell six metres from a wet rooftop in central Wellington. The roof was slippery from both rain and cleaning chemicals, and Mr Bowles, who had only been in the job for two months, had no prior experience working at height. He also hadn’t

Wherever possible, edge protection—such as guardrails, scaffolding, or temporary barriers—should be installed to prevent falls. These passive systems are the most reliable because they don’t depend on individual decisions or quick reactions.

received any formal training on how to safely use harnesses, roof anchors, or other fallprevention equipment. Tragically, the consequences were severe. Mr Bowles suffered a traumatic brain injury, multiple broken bones, and spent more than half a year in hospital recovering. He continues to live with chronic pain and has been unable to return to work. He is also a father of five, adding a heavy emotional and financial toll to his ongoing recovery.

A subsequent investigation by WorkSafe revealed serious gaps in Prowash’s health and safety procedures.

Although some limited edge protection was in place, it was clearly inadequate for the job. In situations like this, where edge protection alone isn’t enough, a well-maintained and properly used harness system should have served as a backup. But the company failed to provide it. Even if such a system had been available, Mr Bowles wasn’t trained in how to use it, highlighting a broader failure in staff preparation and risk management.

Adding to the concern, Prowash was unable to produce any documentation outlining how it planned to

manage risks in this kind of environment. No written safety procedures, hazard identification processes, or formal risk assessments were provided to WorkSafe investigators. The absence of basic workplace safety planning suggested a systemic disregard for the health and well-being of workers, particularly in hazardous conditions such as cleaning a rain-soaked iron roof treated with chemical products.

“This was a preventable fall which has permanently impacted a young father’s quality of life and job prospects,” said WorkSafe principal inspector Paul Budd. “Falls from height are one of the most well-understood risks in the workplace, and there is simply no excuse for not having robust safety systems in place.” According to WorkSafe, the best protection against falls isn’t reliant on workers making quick decisions under pressure—it’s about eliminating risk through proper planning and physical safeguards. “The most

effective controls are those that don’t rely on active judgment by workers,” Budd said. “This includes things like scaffolding and edge protection. If someone slips or loses their balance, there should be something physically there to stop them from falling.”

Mr Bowles’ fall happened during poor weather, but the job continued despite the obvious risks. Budd emphasised that when conditions make a job too dangerous, businesses have a responsibility to delay the work until it’s safe to proceed. “There’s never a good reason to push forward with hazardous work when the weather or other factors increase the danger,” he said. “Stopping work to keep someone safe is always the right call.”

WorkSafe’s message is clear: employers must take responsibility for their workers’ safety, not only by complying with regulations, but by actively identifying hazards and responding to them before someone gets hurt. “Where businesses fail to manage risk, we will take action,” Budd said. “This isn’t just about legal compliance; it’s about influencing the culture of workplace safety in New Zealand. Every worker deserves to go home at the end of the day in one piece.”

Josh Bowles and his family are now facing a long road ahead. His story stands as a stark reminder of the human cost of neglecting basic safety practices. While no regulation can turn back time, WorkSafe hopes that strong enforcement and real accountability will prevent others from enduring the same hardship.

Preventing falls from roofs isn’t complex, but it does require a clear, consistent commitment

WorkSafe’s message is clear: employers must take responsibility for their workers’ safety, not only by complying with regulations, but by actively identifying hazards and responding to them before someone gets hurt. Where businesses fail to manage risk, we will take action.

This isn’t just about legal compliance; it’s about influencing the culture of workplace safety in New Zealand. Every worker deserves to go home at the end of the day in one piece.

to safety—one that starts long before anyone climbs a ladder. The most effective way to protect workers at height is to eliminate the risk. Still, when that’s not possible, there are well-established safeguards every employer should have in place.

Every job involving height should begin with a detailed risk assessment. What are the hazards specific to this job and this site? Is the roof pitched or flat? Are there skylights or fragile surfaces? Will the work be done in wet or windy conditions? These aren’t minor questions—they should guide decisions about equipment, timing, and worker responsibilities.

Written safety plans should be standard. These documents help ensure nothing is overlooked and can also be used to brief workers so they know exactly what the risks are and how to stay safe. Plans should be site-specific, updated regularly, and shared in full with everyone on the job.

Wherever possible, edge protection—such as guardrails, scaffolding, or temporary barriers—should be installed to prevent falls. These passive systems are the most reliable because they don’t depend on individual decisions or

quick reactions. If edge protection can’t be installed, a harness system becomes essential. But a harness alone is not enough. Workers must be trained to use the equipment correctly, understand where and how to anchor themselves, and know how to inspect their gear for wear and tear. Equipment should be checked before every use and stored properly to ensure it stays in good condition.

Josh Bowles’ fall was made worse by the fact that he hadn’t been trained to work at height or use fall protection systems. No one, regardless of their level of experience, should be sent onto a roof without the proper knowledge and confidence to work safely. Training should cover not only the “how” of the job, but also the “why” behind safety protocols. When people understand the reasons behind the rules, they’re more likely to follow them.

Training should be ongoing, too. It’s not a one-off induction or a box to tick. As gear, work environments, and standards change, so should the training. Employers s hould keep records of who’s been trained, when, and in what.

Weather is one of the most unpredictable hazards on any work site. Wet roofs, strong winds, and low visibility all increase the likelihood of slips, trips, and falls. WorkSafe is clear: it’s better to delay a job than to push ahead in unsafe conditions. No deadline is worth a life-altering injury.

Before work begins, the forecast should be checked. If conditions worsen throughout the day, supervisors should be prepared to pause or postpone the job. Having clear procedures for stopping work can save lives and protect businesses from liability.

Ultimately, health and safety should be viewed as a dynamic system, not a static checklist. After each job, teams should take time to review what went well and what could be improved. Were there any close calls? Were all procedures followed correctly? This kind of reflection helps build a culture of accountability and improvement.

Businesses should also conduct regular audits of their safety systems, checking whether policies are up to date, whether equipment is being maintained, and whether workers feel confident and supported. Safety should be built into the way a business operates, rather than being treated as an afterthought.

By following these principles, businesses can protect their workers and prevent the kind of tragedy that changed Josh Bowles’ life. Falls from height are often sudden, but the systems to prevent them are well known. What’s needed now is for every employer to take those systems seriously— and act before it’s too late.

ALAN LEE GROUP OF COMPANIES

– Vehicle WOF’s

– Tractor WOF’s

– Auto Repairs & Servicing

– Air Conditioning Repairs & Regas

– Automotive Parts & Accessories

– Auto Electrical Parts & Batteries

– Auto Electrical Repairs

– Hydraulic Hoses & Fittings

AUTO ONE BOP LTD

Stockists of a Comprehensive Range of Automotive and Auto Electrical Parts and Accessories

• Auto electrical parts, local parts distributor of bulbs, headlights, drive lamps, LED lamps, sealed and semi-sealed beams, sensors, spark plugs, trailer lights, trailer parts, ignition parts, cables and wiring parts, drive belts and pulleys, automotive belts and kits, batteries and accessories

• Automotive chemicals, cooling fluids/coolants, cleaners, Chemz, Cyclo, CRC, CRC Shine

• Engine oil and fuel additives, air flitration, oil and fuel filters, lubrication gear, bushes

• Lucas oil agent

• Exit trax - agent (Vehicle recovery boards)

• Oils: Gulf Western, Valvoline, Shell and access to many other brands

• Safety equipment, seat belts

• Aftermarket headlights and tail lamps

• Tools – King Tony, SP Tools

• Car seat covers and mats, automotive paints, car care products – Megulars, Rain-X, sickers, roof racks

• Trailers parts, Couplings and jockey wheels, tiedowns

• Engine and head repair units, turbo charger parts, parts washing equipment, piping and hangovers, radiator caps and thermostats

• Exhaust Parts, Mufflers, Resonators, Tube and Bends

• Gear knobs, gauges, steering wheels and covers, suspension arms and joints

• Car audio, Aerials, speakers and accessories

• Automotive braking equipment, brake pads, shoes, actuators, discs and drums

• Windscreen wipes

• Tyres and Mag wheels

Fast-tracking development

Tauranga City Council makes strides in consenting performance

The Tauranga City Council reports promising progress in improving its consenting processes for the 2024/25 financial year, while acknowledging that further work remains to be done.

As the city continues to grow despite national economic pressures, the Council is focused on streamlining the building and resource consent process to make it faster, more efficient, and easier for applicants.

A report presented at the City Delivery Committee meeting in June highlighted encouraging developments. While application volumes have decreased slightly compared to the previous year, they have remained steady overall, a positive indicator that development in Tauranga is still progressing.

Deputy Mayor and Chair of the City Delivery Committee, Jen Scoular, praised the efforts made so far and emphasised the importance of continued improvement. “The team has worked hard to refine processes, and it’s good to see tangible results,” she says. “Going forward, we’ve asked staff to continue streamlining the process, so that applying for consent is simpler and faster for our community.”

One of the key initiatives includes piloting a “reference consent” system for simple,

These reforms could take away some of the risk-averse culture we’re seeing in the industry,” Jen says. “While we are moving in the right direction, we know consenting will remain a key area of focus as we continue adapting to change.

The Council remains committed to delivering high-quality service to residents and businesses while ensuring that Tauranga’s built environment continues to evolve in a way that supports both growth and community needs.

repeatable building designs. This system enables the Council to pre-approve standard building models, thereby reducing processing times for these types of applications. Not only will this cut wait times for applicants, but it will also free up staff resources to focus on more complex and timeconsuming projects.

Council staff have also been tasked with deepening their engagement with the local construction industry. By collaborating more closely with developers and builders, the Council aims to identify

common issues and process bottlenecks that slow down the application process. Additionally, benchmarking against other councils is being conducted to establish performance targets and identify areas for further improvement.

Jen noted that the Council’s recent performance builds on strong past achievements. In 2023, Tauranga City Council received its best Building Control Authority audit result in over a decade. Now, staff are preparing for the next IANZ (International Accreditation New Zealand)

audit scheduled for September 2025, with the aim of further improving on that record.

However, challenges remain, particularly as new legislative reforms take effect. Changes to the Building Act and Resource Management Act, currently being proposed by the central government, are expected to alter how consents are processed. Some low-risk activities may no longer require consents at all, potentially reducing red tape and allowing the Council to focus on more critical tasks.

“These reforms could take away some of the risk-averse culture we’re seeing in the industry,” Jen says. “While we are moving in the right direction, we know consenting will remain a key area of focus as we continue adapting to change.”

The Council remains committed to delivering highquality service to residents and businesses while ensuring that Tauranga’s built environment continues to evolve in a way that supports both growth and community needs.

AI to improve timber worker

A major leap forward in worker safety is taking shape in the timber manufacturing industry with the introduction of AIpowered hazard detection, thanks to a nearly half-milliondollar agreement between WorkSafe New Zealand and Claymark, the country’s largest manufacturer and exporter of premium pine products.

This initiative comes in response to a workplace tragedy where a worker lost two fingers due to unsafe machinery at Claymark’s Rotorua factory in February 2023.

Following a WorkSafe investigation into the incident, it was found that the machine involved wasn’t properly guarded, and the company’s maintenance systems were inadequate. Additionally, the worker hadn’t received the necessary training or supervision. This tragic event highlighted the need for a stronger approach to health and safety in the timber industry, leading Claymark to commit to improving its safety protocols.

Now, Claymark has entered into an enforceable undertaking (EU) with WorkSafe, a binding agreement that will make sure the company takes the right steps to fix its shortcomings. As part of the EU, Claymark is investing $481,000 in a range of safety initiatives, including the development

The highlight of Claymark’s safety plan is the use of CCTV systems combined with AI capabilities. These systems will actively monitor workers’ surroundings and alert them to any potential safety risks before they turn into serious issues.

and deployment of innovative AI technology designed to detect hazards in real-time.

The highlight of Claymark’s safety plan is the use of CCTV systems combined with AI capabilities. These systems will actively monitor workers’ surroundings and alert them to any potential safety risks before they turn into serious issues. This tech aims to prevent accidents by providing an extra layer of awareness that workers or supervisors might otherwise miss.

In addition to rolling out AI systems, Claymark will offer up

to 15 trials of the technology to other businesses in the wood manufacturing sector, encouraging broader use of smarter safety solutions across the industry. The company is also introducing microlearning tools and interactive safety displays in break rooms to continuously educate workers on health and safety.

Claymark’s efforts go beyond just meeting regulations — they reflect a well-rounded approach to workplace safety, focusing both on technology and employee engagement. The company has also committed to offering reparation to the injured

worker and collaborating with local communities and schools to raise awareness about safe practices in wood manufacturing.

Along with the technological upgrades, Claymark is working with the Central North Island Wood Council (CNIWC) and other industry groups to share their safety learnings and help build a stronger culture of health and safety within the timber sector. The company aims to create a workplace where workers feel supported, informed, and ready to tackle safety challenges.

Alongside the AI surveillance systems, Claymark is modernising its approach to worker training. The company is investing in online, interactive training modules that can be customised for different roles within the factory. These flexible modules will allow workers to complete safety training at their own pace, making sure they are fully prepared to recognise and deal with potential hazards.

“We’re excited to see Claymark lead the way with AI innovation, which could benefit the wider timber processing sector,” said Tracey Conlon, WorkSafe’s Head of Regulatory Services. “Agreements like this are all about turning a negative event into an opportunity for positive change.”

Paul Pedersen, Claymark’s executive director, echoed this commitment, saying that the company’s focus on safety goes beyond just meeting the rules. “This is about creating a workplace where our people feel informed, supported, and

safe. Claymark is committed to continuous improvement and working with others to build a safer, stronger future for our people, our industry, and our communities.”

For Claymark, this isn’t just a regulatory response — it’s a personal commitment to ensuring that no worker faces the same risks again. The company recognizes that workplace safety is a constant journey, requiring ongoing attention, adaptation, and innovation.

The worker who lost two fingers in the incident has been deeply affected by the accident. After undergoing three surgeries and facing a long recovery, he continues to adapt to life with a permanent injury. While the injury has changed his life in significant

ways — including his ability to play music, a passion he’s had for years — he remains hopeful about the future and thankful for the support from his family and Claymark.

In his statement, the worker expressed appreciation for Claymark’s efforts to improve safety, saying, “I’m really grateful for Claymark’s commitment to improving workplace safety, especially the initiatives outlined in this agreement. I’ve seen these changes firsthand. While my future looks different than I imagined, I’m determined to keep moving forward, one day at a time.”

As Claymark leads the way in using AI technology and improving safety practices, it sets an example for the timber manufacturing industry and

other high-risk sectors to follow. By combining cuttingedge technology with a focus on worker well-being, Claymark is paving the way for a safer, smarter, and more sustainable future in the workplace.

This partnership between WorkSafe and Claymark shows how businesses can turn a serious incident into a chance for meaningful change. By prioritizing worker safety through innovative solutions like AI and fostering a culture of continuous improvement, the timber industry is taking big steps toward reducing accidents and improving safety for workers nationwide.

As Claymark leads the way in using AI technology and improving safety practices, it sets an example for the timber manufacturing industry and other high-risk sectors to follow. By combining cutting-edge technology with a focus on worker well-being, Claymark is paving the way for a safer, smarter, and more sustainable future in the workplace.

Carbon-storing construction materials

Researchers say new building materials could cut global CO₂ emissions in half

By Jonathan Taylor

A recent study by U.S. researchers suggests that replacing conventional building materials with carbon-storing alternatives could remove up to 16.6 billion tonnes of carbon dioxide (CO₂) from the atmosphere annually—about half of the human-caused CO₂ emissions recorded in 2021.

These alternatives include concrete infused with carbon-capturing aggregates and bricks made from biobased materials.

Experts in New Zealand say the findings present a promising opportunity, especially considering the country’s natural resources and existing industries. Associate Professor David Dempsey from the University of Canterbury notes that carbon removal through construction materials could become a significant part of climate change mitigation strategies.

A major contributor would be concrete that incorporates CO 2 -absorbing minerals, such as dunite rock, which is abundant in regions like Nelson and Southland. However, he emphasises the need for high-purity CO 2 sources, such as emissions from biomass boilers, and for

thorough testing to ensure the durability and safety of these new materials.

Dempsey adds that New Zealand’s robust forestry sector gives it another edge, especially in substituting traditional materials with timber-based alternatives. But to capitalize on this, he says, regulatory support is essential.

Policies must acknowledge the carbon embodied in building materials, possibly by incorporating it into the Emissions Trading Scheme. He also cautions that storage is only as permanent as the building’s lifespan—CO2 stored in materials could eventually be released if not properly managed after demolition.

Professor Suzanne Wilkinson from Auckland University of Technology echoes the

potential but highlights significant industry barriers. The construction sector is cautious by nature and driven largely by cost, time, quality, and safety.

She points out that even if carbon-storing materials are certified and effective, they may not be adopted if they are more expensive, require new training, or complicate supply chains.

Overcoming these obstacles, she suggests, would require educating clients, introducing supportive legislation, or adjusting taxes and trade policies to make new materials more viable.

Diego Elustondo of Scion adds another layer to the conversation, emphasising the long-standing carbon benefits of wood-based materials.

He cautions that the paper may overstate the benefits of experimental masonry materials, which are not yet commercially viable, while downplaying the proven performance and sustainability of timber.

He points to Scion’s timberbased building in Rotorua, which stores 418 tonnes of CO 2, as a real-world example of how forestry products can contribute to climate goals.

Together, these expert insights underscore that while material innovation offers real promise, practical, policy, and industry-level changes are critical to unlocking its full potential.

Too hot to handle

By Jamie Quinn

Before we know it, summer will be back, and so will the heatwaves, restless nights, and soaring indoor temperatures.

For many New Zealanders, especially those living in modern townhouses, the warmer months don’t just bring beach days and barbecues. They bring heat, intense, sometimes overwhelming heat that turns living spaces into sweltering ovens.

Recent data from the Building Research Association of New Zealand (BRANZ) backs up what many of us already feel: New Zealand homes can get seriously hot in summer. According to a survey conducted during the 2023/24 summer, a whopping 70% of people said their homes were warmer than they wanted at least some of the time. And interestingly, it wasn’t just in the country’s traditionally warmer regions. Wellingtonians reported higher rates of discomfort

According to a survey conducted during the 2023/24 summer, a whopping 70% of people said their homes were warmer than they wanted at least some of the time. And interestingly, it wasn’t just in the country’s traditionally warmer regions.

than Aucklanders, despite recorded temperatures in their homes being actually lower. That suggests that design, layout, and ventilation — rather than outdoor temperatures alone — play a major role in how hot a home feels.

That brings us to townhouses. Compact, efficient, and often more affordable than standalone homes, townhouses are an increasingly popular housing choice, especially in urban centres like Christchurch, which now has the highest concentration of townhouses in the country. According to a recent report, townhouses now make up around 24% of Christchurch’s

housing stock. But alongside their rapid rise in popularity has come a growing concern: they might just be too good at trapping heat.

In December, just as the heat started to ramp up, a Christchurch townhouse resident went public with concerns after recording bedroom temperatures that hit an unbelievable 50 degrees Celsius. While this might be an extreme case, it’s not an isolated experience. Across the country, townhouse dwellers are reporting indoor heat levels that are not just uncomfortable but potentially unsafe.

What’s causing the issue?

A lot of it comes down to design. Many townhouses are built with energy efficiency and affordability in mind, but this often means compromises are made, particularly in terms of airflow and insulation. High-density housing tends to have less exterior wall space, which can restrict cross-ventilation. That means fewer windows to open, and less opportunity for natural breezes to pass through. Add to that the growing trend of smaller outdoor areas, darker roofing materials, and tightly packed developments that reflect heat between walls, and it’s easy to see how things heat up quickly.

Then there’s glazing. Floor-to-ceiling windows and sliding doors might look sleek and modern, but they also act like magnifying glasses in the summer sun. Without adequate shading or tinting, they can turn a room into a greenhouse by mid-afternoon. And if a townhouse has a north or west-facing orientation, it’s

likely to soak up the worst of the afternoon sun.

There is also a growing reliance on heat pumps, not for heating, but for cooling. Traditionally, many Kiwi homes were focused on staying warm through the winter, with heat pumps installed for those chilly months. But in recent years, that’s flipped. One Auckland installer recently described the industry shift as moving from a winter heating business to a summer cooling business. Today, nearly half of all heat pump installations in summer are reportedly going into high-density housing like townhouses.

But not everyone has a heat pump. And not every heat pump is enough to counteract the poor design

decisions that trap heat in the first place.

So what can be done?

The good news is that conversations are beginning to shift. The government is reviewing ventilation rules, with a particular focus on the needs of residents in highdensity housing. As it stands, current building standards don’t always guarantee that new homes will stay cool in summer, particularly those with limited passive airflow or inadequate insulation against heat.

For homeowners and renters, there are also some practical changes that can help make a difference. Installing thermal curtains or blinds, adding exterior shading like awnings, and opting

for lighter roofing materials during re-roofing can all help reduce indoor temperatures. In some cases, retrofitting ventilation systems or upgrading insulation can be a worthwhile investment.

But the larger solution lies in how we approach housing at a design level. If townhouses are going to be a long-term part of New Zealand’s housing future, as seems likely, then they need to be built to cope with New Zealand’s increasingly extreme weather patterns. That means smarter window placement, better cross-ventilation, higherperformance glazing, and materials that reflect heat rather than absorb it.

A well-designed townhouse should be comfortable all

The good news is that conversations are beginning to shift. The government is reviewing ventilation rules, with a particular focus on the needs of residents in highdensity housing.

year round, not just in winter. As the climate continues to change, and our cities grow taller and denser, we must take heat seriously, not as an afterthought. Because a bedroom shouldn’t feel like a sauna before sunrise, clearly, something needs to change.

Best practices for demolition safety in New Zealand

Even though demolition is necessary for urban growth, there will always be serious safety concerns. Specific safety regulations must be met in New Zealand to protect both employees and the public.

From careful planning to actual demolition, a number of steps are involved to ensure compliance with safety standards, highlighting the importance of an organised strategy to manage the risks associated with demolition.

Site assessment and hazard identification

A thorough site evaluation is a must before any demolition work starts. This stage helps in locating possible dangers like asbestos or other hazardous materials. In order to plan the safe removal and disposal of potentially dangerous items and avoid any health concerns to demolition workers and the surrounding community, it is important to know what you are working with.

Personal protective equipment (PPE)

The use of appropriate personal protective equipment is non-negotiable. Helmets, safety glasses, gloves, and other equipment tailored to the site’s hazards should be worn by employees. This gear is essential for lowering the chance of injuries and minimising exposure to dangerous substances.

Training and emergency preparedness

It is important that all demolition workers receive extensive instructions. This covers training on emergency response procedures and the safe use of demolition equipment. Workers can greatly lower the risk of accidents and guarantee a ready response in the event of an incident by being prepared to manage unforeseen circumstances.

Legal compliance and permits

Getting the required demolition permits is only one aspect of following the

law. It also entails abiding by safety and environmental requirements, which are intended to safeguard the public and employees. Verifying that all demolition operations are carried out in line with regional and national regulations ensures accountability and safety.

Health, safety and environmental (HSE) plans

It matters to create a specific Health, Safety, and Environmental (HSE) plan for every demolition project. These plans describe how to safely dismantle structures and manage garbage, while also addressing the particular challenges of each site. Effective HSE strategies are needed for reducing the negative impacts on the environment and protecting everyone’s health and safety.

Effective communication

It is essential to maintain constant and transparent communication throughout the process. It guarantees that everyone on the team

is always informed about ht procedure and any changes to the plan throughout the process Misunderstandings that can result in safety breaches are preventable with the use of effective communication.

Continuous monitoring and review

To maintain high safety standards, safety measures should be monitored and reviewed often. This ongoing evaluation means that strategies can be modified if needed and emphasises the importance of safety throughout the process of the demolition project.

To make sure your project runs smoothly, seek advice from professionals or visit Chemcare’s website for more information if you are unsure how to keep yourself or others safe when doing demolition work. They may be able to help you with everything from health and safety procedures and the actual demolition job to pre-demolition inspections and demolition techniques. www.chemcare.co.nz

Can infrastructure pay for itself?

NZ Infrastructure Commission explores the possibilities

New research from the New Zealand Infrastructure Commission is examining whether public infrastructure investments, such as roads, schools, hospitals, and water systems, can eventually generate enough revenue to cover their own costs.

Peter Nunns, General Manager of Strategy at the Commission, said that while the social and economic benefits of infrastructure are well understood, how these projects are paid for remains less clear. He noted that all infrastructure must be funded somehow, but the mechanisms for doing so are not always straightforward.

The challenge of funding new infrastructure

One common method of funding new infrastructure is through higher user charges or increased tax rates. However, according to a recent Ipsos

survey, although many New Zealanders support increased infrastructure investment, few are willing to pay more through taxes or charges to make it happen.

An alternative approach is to invest in infrastructure projects that indirectly generate revenue—by stimulating economic activity or increasing usage, for example—leading to higher returns from existing taxes, rates, or user fees. The Commission’s latest report, Paying it back: An examination of the fiscal returns of public infrastructure investment, explores when and how this model is viable.

When infrastructure pays for itself

According to the report, projects that are cost-effective and serve a large population are more likely to recover their costs through increased revenue. Prioritising high-value projects can enhance New Zealand’s ability to invest in future infrastructure needs. However, the threshold for a project to fully pay for itself is extremely high. Nunns explained that the government typically only captures a small portion of the economic value created through infrastructure investments.

For a transport project to break even fiscally, it must deliver social and economic benefits at least five to nine times greater than its cost to generate enough new tax revenue.

The report also highlights that incremental infrastructure expansion—adding to networks bit by bit as demand grows—tends to deliver better fiscal returns. In contrast, large-scale “big bang” developments often fail to produce enough revenue and must be subsidised from general taxation, potentially at the expense of other critical services like healthcare and education.

Insights from local councils

One of the report’s case studies looked at seven large or rapidly growing urban councils over 25 years. It assessed how much each spent on infrastructure to accommodate population growth, including both construction and maintenance costs.

The findings showed mixed outcomes. Some councils managed to recover their costs through increased rates revenue and development contributions from new buildings. Others, however, spent more than they gained.

The report also highlights that incremental infrastructure expansion—adding to networks bit by bit as demand grows—tends to deliver better fiscal returns. In contrast, large-scale “big bang” developments often fail to produce enough revenue and must be subsidised from general taxation, potentially at the expense of other critical services like healthcare and education.

Councils that scaled infrastructure growth in step with population increases were significantly more likely to break even or generate a surplus over the 25-year timeframe.

Beyond the bottom line

While revenue generation is an important consideration, Nunns stressed that the core purpose of public infrastructure is to improve community wellbeing, not necessarily to be profitable. However, with the dual pressures of an ageing population and slowing productivity growth straining public finances, fiscal sustainability will need to become a more prominent consideration in infrastructure planning.

Report highlights and case studies

The Paying it Back report includes three detailed case studies to illustrate how different types of infrastructure investments perform financially:

Local government infrastructure (2007–2031):

This case study analyses infrastructure investment across seven councils— Auckland, Hamilton, Tauranga, Wellington, Christchurch, QueenstownLakes, and Dunedin—to assess long-term fiscal impacts of populationdriven growth.

Major transport projects:

The study evaluates the fiscal returns from four significant transport initiatives:

• Ōtaki to north of Levin (O2NL) motorway

• Pūhoi to Warkworth motorway

• Warkworth to Wellsford motorway

• Auckland’s City Rail Link (CRL)

Value capture scenarios:

A hypothetical analysis tests the effectiveness of a value capture levy—a tool that collects a portion of increased property values resulting from infrastructure improvements. Different project characteristics and population densities were modelled to assess the impact on revenue recovery.

Key takeaways

The report outlines four key lessons for boosting revenue from infrastructure investments:

• High-quality, costeffective projects serving more users tend to generate stronger fiscal returns

• The threshold for a project to fully pay for itself is high

• Incremental growth in infrastructure often yields better financial outcomes than large-scale projects

• Attaching dedicated revenue streams, such as levies or targeted rates, can significantly improve fiscal sustainability.

As New Zealand continues to grapple with infrastructure needs amid fiscal constraints, these findings provide valuable guidance for decisionmakers looking to balance public benefit with economic reality.

We are a team of talented professionals who work alongside their clients every step of the way on each project. We apply artistic engineering and construction skills to design commercial buildings and bespoke residential homes.

End of an eyesore Government clears the way to demolish controversial building

The long-running standoff over Wellington’s Gordon Wilson Flats is finally coming to an end, with the Government announcing it will remove the building’s heritage protection to enable its demolition.

Housing and RMA Reform Minister Chris Bishop confirmed in a press release published in June of this year that Cabinet has approved a legislative amendment that will clear the way for the derelict structure to be torn down. The move comes after more than a decade of legal and planning that have prevented progress on the site.

“The Gordon Wilson Flats were used as social housing until 2012, when an engineer’s report showed the building

Housing and RMA Reform Minister Chris Bishop confirmed in a press release published in June of this year that Cabinet has approved a legislative amendment that will clear the way for the derelict structure to be torn down. The move comes after more than a decade of legal and planning that have prevented progress on the site.

was so unsafe that large slabs of the concrete exterior could come off in an earthquake or even a strong wind,” Chris Bishop said in a press release. “The building has sat vacant since then, becoming more dangerous and more of an eyesore every year.”

Once used for state rental housing, the 11-storey building overlooking The Terrace has become a symbol of what the Government describes as a failed planning system that prioritises heritage preservation at the

expense of common sense and safety.

“There has been attempt after attempt to deal with the Gordon Wilson Flat since 2012, all of which have failed,” Bishop said. “The flats sit as an ugly scar on the Wellington skyline, emblematic of a failed planning system that prioritises preservation of heritage, no matter the economic cost.”

The amendment, to be added to the upcoming Consenting and Other

Resource Management System Amendments Bill, will remove the flats’ protected heritage status and make their demolition a permitted activity under the Resource Management Act. This means no resource consent will be required for its removal.

“Cities shouldn’t be museums,” Bishop said. “The Wellington City Council wants the Gordon Wilson Flats demolished, the University (the current owner) wants them demolished, and the people of Wellington want them demolished too.”

A heritage building with a troubled history Constructed in 1959 and named after government architect Gordon Wilson, the building was once a prime example of modernist architecture and public housing. It was added to the Wellington District Plan

heritage list in 1995 and later granted Category 1 heritage status by Heritage New Zealand.

However, after safety concerns forced its evacuation in 2012, the building fell into disrepair. Despite several efforts by Victoria University, which brought the building in 2014 and now owns the property, to demolish or repurpose the structure, heritage protections repeatedly blocked progress. While critics have argued for the cultural and architectural value of preserving the site, the Government maintains that the current situation is unsustainable.

What is a heritage building, and why do they matter?

Heritage buildings are formally recognised structures that carry cultural,

historical, architectural, or social value. They serve as physical reminders of a city’s evolution, representing the craftsmanship, styles, and stories of past generations. In New Zealand, heritage recognition is managed at both national and local levels, with varying degrees of protection that can prevent demolition or restrict modifications.

Supporters of heritage conservation argue that such buildings enrich urban identity, create community pride, and can be opportunities for education, tourism, and adaptive reuse. But, maintaining heritage buildings can also be costly and complex, especially when they are in disrepair or pose safety risks.

In the case of Gordon Wilson Flats, the Government has

concluded that demolition is the only logical path forward.

What happens next?

The legislation is expected to pass in the middle of this year. Once in effect, Victoria University will still need to obtain a demolition consent under the Building Act, which covers factors like asbestos removal, sediment control, and site safety. However, they will no longer be required to undergo the RMA consent process for demolishing a heritage structure.

The University has not yet released detailed plans for the site’s future, but previous discussions have included the possibility of student housing or teaching facilities. As Wellington prepares to say goodbye to a once-iconic, now crumbling piece of architecture, the

debate between heritage preservation and practical urban development still continues.

Supporters of heritage conservation argue that such buildings enrich urban identity, create community pride, and can be opportunities for education, tourism, and adaptive reuse. But, maintaining heritage buildings can also be costly and complex, especially when they are in disrepair or pose safety risks.

LOOKING FOR STAFF? LAUNCH YOUR SEARCH WITH US!

Use the most cost effective and easiest job site in New Zealand. Now with a new and improved website making things even easier, ensuring you get quality applicants, every time!

Purchase 1 ad (for 1 month) for $157+gst or unlimited ads for 12 months for $1597+gst

100% money back guarantee if you don’t think it’s the best money you’ve spent all year, plus we’ll give you another 12 months free!

Include your company profile so applicants can see why they want to work for you! (once again, other companies charge for this)

Delivering projects to the highest standards across the whole range of scaffolding requirements.

Scaffolding Bay of Plenty, clients who select a company with strong repute are generally rewarded with exemplary service. Summit Scaffolding Waikato and the Bay of Plenty are one such company, and its team are consistently aiming to maintain and improve their positive standing in the industry.

Relying on positive client feedback and peer respect gleaned from jobs well done isn’t enough, however. Competition is fierce, and to that end, Summit Scaffolding work hard to give good value with good communication; a stance evidenced by an extensive list of projects completed to date. Aiding and enabling this success are Summit’s management team who are fully focussed on delivering clear and safety–centric interactions in the office, onsite, and with customers.