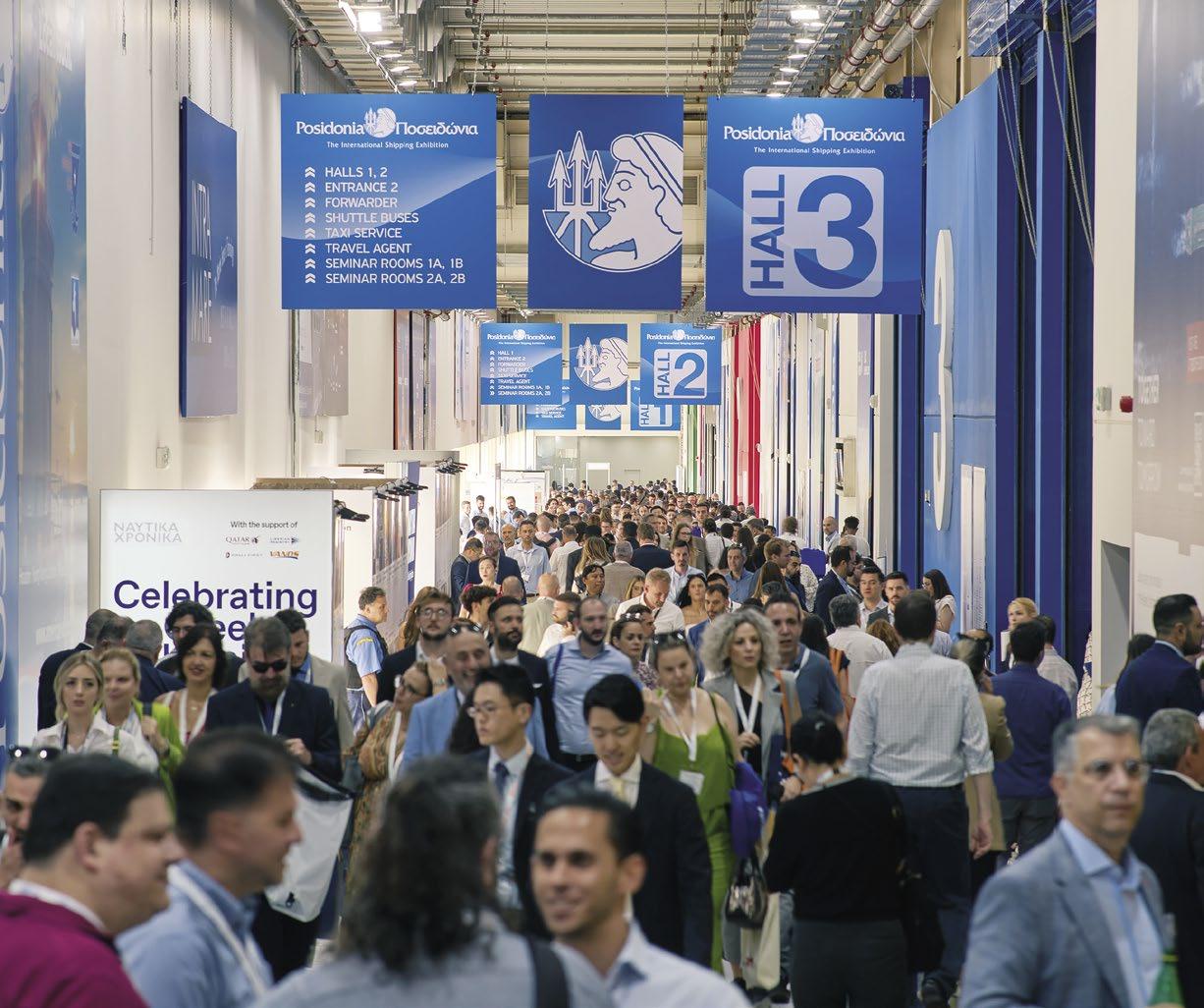

COLD COMFORT

The industry’s reaction to IMO’s NZF postponement

BLINDED TO SCIENCE

Why are some countries still ignoring the value of EGCS?

CLEAN THINKING

Which are the frontrunners in the alternative fuel race?

The industry’s reaction to IMO’s NZF postponement

Why are some countries still ignoring the value of EGCS?

Which are the frontrunners in the alternative fuel race?

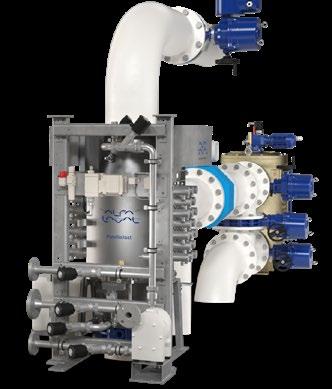

At Roodhart, we believe in solutions. Carefully considered, precisely tailored, and always made for what is truly needed. Not just any solution, but the right one. Every single time.

Through our Marine & Offshore Services department, we support the marine and offshore market with a comprehensive range of pumps, separators, electric motors, spare parts, technical support, and engineered solutions. From fleet management challenges to full turnkey engineering projects, we shape the missing piece of the puzzle and make it fit.

Founded in 1982 and overlooking the port of Rotterdam, Roodhart has grown into two specialized departments: Marine & Offshore Services and Emission Control for onshore industry. With over 120 professionals on board, we bring decades of experience to projects of every scale. From small, targeted upgrades to complex, large-scale installations.

For more than 40 years, we’ve approached every challenge with care. As a family-run business, we take the time to make considered decisions, working closely together to combine technical expertise, engineering insight, and reliable equipment into solutions that truly work. It’s about delivering what is needed and understanding the problem behind it.

This mindset is embedded in our Engineering, Procurement & Project Management (EPP) approach, built on the EPC framework. Whether it’s FPSO overhauls, offshore pump skid engineering, BWTS retrofits, or firefighting systems, we provide a complete service. Transforming an initial idea into a fully integrated, installation-ready solution.

Have questions? Or maybe just an urge to chat about the color red? We’re here for both, anytime.

Your reliable partner for pumps, spare parts and engineering services — since 1982

Samantha Robinson Editor

Clean Shipping International

Welcome to the latest edition of Clean Shipping International, packed with all the latest news, views, innovations and initiatives from across the maritime industry that support sustainable shipping.

Whether it’s sabre-rattling or sulking over peace prizes, Donald Trump continues to keep the world on its toes. It was the turn of the maritime industry to come under his spotlight late last year, when he made his opposition to the International Maritime Organization’s Net-Zero Framework very clear. We take a look at the global reaction to the ensuing postponement (page 13).

When it comes to the transition to net zero, innovations in ship design and building are helping to future proof the industry. The Sustainable Shipping Initiative offers an interesting take on this area, explaining why green steel and circular shipbuilding are an untapped pathway to net zero (page 58).

Meanwhile, according to data from Clarksons Research, orders for scrubbers – both for newbuilds and retrofits – are rising sharply, particularly in the tanker and container ship segments. However, some countries are still ignoring the science and banning their use, a topic the Clean Shipping Alliance delves into on page 20.

Elsewhere in this issue, we discover the latest frontrunners in the alternative fuels race (page 25), take a look at a pioneering ballast water treatment system (page 33), learn why companies must meet the global decarbonisation challenge head on (page 38) and examine the latest digital tools aiding decarbonisation (page 46).

Finally, turn to page 63 to discover all the not-to-be-missed industry events.

I hope you enjoy reading this issue.

“Green steel and circular shipbuilding are an untapped pathway to net zero”

Chart a clear course toward zero emissions with advanced monitoring solutions that deliver accurate, real-time insights. Our technology empowers maritime operators to track performance, optimise efficiency, and confidently navigate their sustainability journey.

Editor: Samantha Robinson sam.robinson.journalist@ gmail.com

Project Director: Jonathon Ferris jonathon.ferris@ cleanshippinginternational.com

Publisher: Bill Robinson production@ cleanshippinginternational.com

Designer: Justin Ives justindesign@live.co.uk

Published by Maritime AMC, Clean Shipping International supports Clean Shipping Initiatives.

The views expressed in Clean Shipping International are not necessarily those of Maritime AMC unless expressly stated as such and disclaim any responsibility for errors or omissions or their consequences or for advertisements contained in this magazine and has no legal responsibility to deal with them.

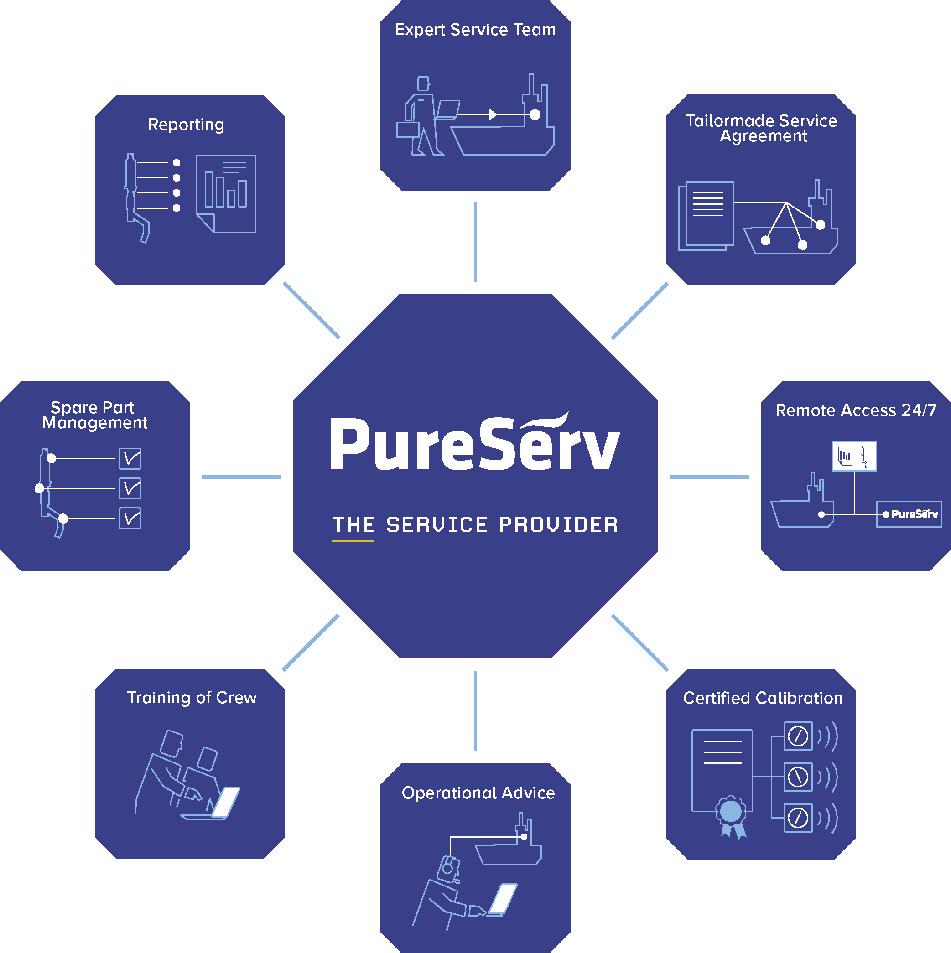

PureServ, the certified service organization of PureteQ A/S, provides maintenance and support for all brands of scrubbers and sensors worldwide. Through our sensor replacement program, you’ll receive advance notification when calibration is due. A newly calibrated sensor is delivered before the old one is returned for refurbishment — ensuring zero downtime and continuous compliance.

Note: pH sensors typically require calibration every three months, while gas analyzers are calibrated annually, depending on manufacturer requirements.

The latest high-tech tools aiding the industry’s path to

New regulations and guidelines shipowners and operators need to be aware of

to smart

how modern ship design is future proofing

Tales trawled from the world of

Don Gregory Director,

Recently in the UK, King Charles III hosted a state banquet for German President Frank-Walter Steinmeier at Windsor Castle. In his speech, he specifically highlighted the collaboration between scientists, inventors, business leaders and investors. But what struck me was that he did not mention engineers.

It got me thinking about who and what creates the wealth and the rising standards of living the world has enjoyed over the past 50 years.

Poverty certainly remains endemic in some parts of the world, but on the whole many nations and populations have been taken out of poverty and have enough to eat and have enjoyed, generation by generation, an increasing standard of living – none more so than in China, which has seen spectacular and stellar development of its nation.

The future appears different today. We hear of the rising cost of food, the rising cost of transport, the lack of affordability of housing and many of the other things we need and enjoy. Something has changed. I don’t hear of any serious research and analysis into what is the cause of this global problem.

Countries and nations can be and are destroyed by poor or bad governance. I was talking recently to a Master on a vessel I was visiting for an inspection. He said that if you look at successful and poor nations, it is always the political system that is at the root of the success or failure.

Some political systems are controlled by religion, others by a culture of nepotism; some are authoritarian and some follow a mature democratic governance. No one system always results in poor governance, but we can observe poor governance in all failing nations or nations that simply fail to pull their populations out of poverty.

So, good governance is one element of the story of what creates improving standards of living. It does not answer why that seems to be now going in reverse.

Since the Uruguay round of the World Trade Agreement, global trade has also

played a massive role in driving down poverty and increasing many nations living standards. Poorer nations have been able to gain wealth by exporting goods and raw materials. Richer nations have benefitted from the opportunity for lower cost imports while re-directing their previous activities (goods and services now being imported from abroad) to more value-added activities. Has the globalisation that has won us great leaps forward in the standard of living now reached its sell by date? In other words, the living standard gains that were had through globalisation may now be diminishing and the social impacts of globalisation may now be becoming ever more evident.

Examples include the loss of a variety of jobs and the undercutting of prices of more expensive producers in a race to the bottom of work and reward. The costs to nations includes high welfare expenditure, migration, drug addiction and more. So is the root cause of the recent sudden turnaround in the growth in the standard of living the result of globalisation having reached an end point?

It is also worth saying that, all in all, the trading world has also enjoyed more than 70 years of relative calm and order. It seems that that world order can no longer be guaranteed as we are currently observing. It does not seem obvious that threats of war and conflict would be impacting living standards yet.

But underlying the macro economics and politics, what other causes are impacting the current rise in the cost of living and the steady decline in living standards and aspirations of the next generation?

Fundamentally, humans all need to eat, be warm, be sheltered and we like to have mobility – and, of course, not forgetting good health.

There are numerous reasons why these basic needs are being eroded, but I would like to focus on the area where things are created and problems solved and which specialisms do that and which specialisms

don’t do that, but seem to be gaining policy influence to the detriment of society.

I return to the fact the King Charles mentioned scientists at his dinner speech, but did not mention engineers.

According to the UK Science Council: “A scientist is someone who systematically gathers and uses research and evidence, to make hypotheses and test them, to gain and share understanding and knowledge”. The advances due to scientists in our understanding of all aspects of our existence and our surrounds have been amazing and it continues to expand.

And some examples of sciences advances in our knowledge include:

» The mathematician Euler developed amongst a range of his discoveries the law of buckling strength (or the critical load on a strut), which defines the maximum axial compressive load that a long, slender, ideal column can support without buckling (bending laterally).

» A key application for naval architects was discovered by William Froude who systematically used dimensional analysis and scaling laws to calculate the resistance of a ship’s hull.

» Mario Molina and F Sherwood Rowland published research that demonstrated that CFCs –widely used as refrigerants and aerosol propellant – when released into the atmosphere drift into the stratosphere, where they are broken down by ultraviolet light and have been destroying the ozone layer.

Michigan Technology College says engineers “are experts in their fields, creating and innovating constantly. Engineers deal with complex systems, structures, devices and materials to fulfil functional requirements while also considering the limitations imposed by regulations, safety, cost and more.”

It goes on to say: “Engineers solve problems using mathematics, science, and technology. As a problem-solver,

every potential answer an engineer devises must be weighed against the realities of the physical world and other concerns such as public safety, a client’s requirements, regulations, available materials, and a finite budget. It takes creativity to get successfully from problem to solution, all while navigating a tangle of constraints.”

I think most importantly Michigan Technology College says: “Engineers are creative problem-solvers. There is never just one way to solve an engineering design challenge; there is no single ‘right’ answer to a problem. Engineers must accept a degree of uncertainty regarding a solution’s endpoint, and creativity helps here, too. Engineering requires a sense of vision that goes beyond constraints to ‘see’ a solution that others might miss or dismiss as farfetched.”

“Is science leading policy development at the expense of engineering and at a significant negative cost to society?”

Engineers use Euler’s laws of buckling every day to design piers to hold up buildings or the lightest possible weight steel struts to support solar panels. This use of Euler’s laws reduces cost, energy and assures safety and longevity – a contribution to the green energy revolution.

Marine engineers use Froud’s scaling laws to design more efficient hull forms which reduces energy consumption and CO2 emissions. Models can be made which can be used to measure and assess different

hull forms and speeds from which a full size ship will be constructed safe in the knowledge that the expected performance will be achieved.

As we move into science that is discovering environmental impacts, engineers have played the role of solving the identified negative effects. This has been witnessed with the phasing out of CFC refrigerant gases. These gases when initially developed gave a leap forward in refrigeration efficiency and cost.

At the beginning of the use of CFCs, it was not expected that there would be many thousands of tonnes released and their negative effect on the ozone layer. Once this was understood action was taken to solve the problem by engineers.

One solution was to minimise the leakage and losses. In hindsight this would have been the most effective solution resulting in less energy consumption than the alternative route that was taken.

Engineers had the ability along with robust controls to curtail CFC leakages and losses. Policymakers did not accept the leakage mitigation solution, which could have reduced CFC leakages faster than developing new refrigeration plant with alternative heat transfer fluids.

The Montreal protocol entered into effect in 1989, but still today there are many systems using CFCs and the leakage and losses remain significant and complete phase out is another five years away.

Humans desire mobility. Henry Ford recognised that when he developed one of the first motor vehicle assembly lines. His cars became affordable to many and the history of the automobile is rich with engineering design and improvements and has remained affordable to many until very recently.

But with the rising cost of living and decline of living standards, is there an underlying causal factor in the balance of policy influence between science and engineering? Has environmental science driven policy that has created the unaffordability?

Clearly it is not the science alone as other factors already mentioned are at

play. King Charles mentioned investors. Investors and finance play an ever more important role in development and growth. In general, investors have poor knowledge of opportunities and are influenced by such things as government policy, taxation – and following the herd.

Science, it appears, has identified that increasing levels of anthropogenic CO2 and other greenhouse gases are changing the global climate. There are some doubters as to the robustness of the science, but on the other hand there is factual and tangible evidence that the global climate is changing. So there are problems to solve.

“It appears that engineers are being ignored in the creation of policy”

I would argue they are engineering problems, which we know engineers can and have created solutions for that are cost effective, robust and long lasting, and at an acceptable cost.

But it appears that engineers are being ignored in the creation of policy and that then leads on to where investments are being made. It seems now to be a world where science is leading policymaking.

As described in the definition of a scientist, science does not take responsibility for their discoveries or convert them into added value benefit for society. Thus, they don’t take accountability for the consequences, yet policymakers believe that it is following the science that enables us to reach the solution.

Science should and must form the source of information of the identified problems to be solved and not how to solve them. The knowledge and information gained by science should

be based on sound science principles of observation and control checks.

Engineering should then lead policy development with solutions and applications.

I shall close by providing an example from the automotive industry, which has taken the brunt of policymaking to reduce CO2 emissions. Accelerating and decelerating mass is expensive and energy costly.

That is why successful passenger transport vehicles have been designed and built as light as physically possible, utilising a high energy density hydrocarbon to provide the vehicles energy.

Instead of setting out policy to reduce CO2 emissions most cost effectively and goal based, nations have instead focused on pre-conceived solutions to set policy. Hence the zero-emission passenger transport policies. The result: a vehicle with at least double the mass of the most efficient internal combustion engine vehicles with a limited range, useability and practicality. The vast expense of electric vehicles development with only a small CO2 reduction benefit has and

is being paid for by society. All those investments in electric vehicles don’t come free!

The alternative approach to reducing anthropogenic CO2 emissions that would have been engineering-led in terms of policy setting. Engineers should have led the problem solving and informed governments of best policies to encourage investment targeted at the most costeffective solutions.

It almost goes without saying the early investments should have been in static-energy consumers and high-energy consumers. Driving down energy costs and abating CO2 emissions in these sectors would have avoided higher costs, inflation and some of the consequences we are now suffering.

We must get back to sound science being tested for veracity and integrity, which informs engineering of the problems to be solved. Government then provides the policy guidance driven by engineering solutions and goals, which then hopefully directs investment to achieve those solutions and goals.

All the latest news, views and partnerships, plus a look at the global reaction to IMO’s NetZero Framework postponement

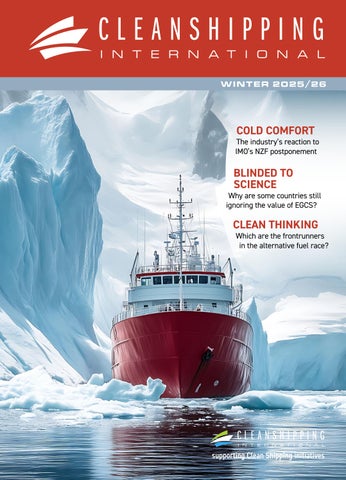

The movement to create green shipping corridors – trade routes designed to demonstrate and scale novel zero-emission fuels, vessels, and technologies – has expanded in numbers and geographic scope, according to a new progress report published by the Getting to Zero Coalition and the Global Maritime Forum.

This year’s edition, At a Crossroads: Annual Progress Report on Green Shipping Corridors 2025, identifies 25 new green corridor initiatives, expanding the global total to 84 active initiatives. Initiatives have been launched in major developing economies such as China, India, Brazil, Chile, Ghana and Kenya, reflecting the significant economic opportunities that can be seized through the development of zero-emission marine fuels and bunkering capabilities in these regions.

The news comes only a month after discussions to adopt the International Maritime Organization’s (IMO) landmark Net-Zero Framework, designed to establish a path for shipping to reach net-zero emissions by 2050, were delayed for at least one year.

“The move of major countries like China, India and Brazil into green corridors is hugely promising, as these are markets that will determine whether zero-emission shipping scales fast enough to meet global climate goals,” Jesse Fahnestock, Director of Decarbonisation at the Global Maritime Forum, says. “But even more importantly, we’re seeing recognition from these countries that green corridors are more than just environmental projects – they are strategic economic infrastructure. Countries that move early stand to gain competitive industrial and geopolitical advantages across energy, trade, and technology.”

For the first time since the report’s inception in 2022, four green shipping corridors have now reached the ‘realisation stage’, an important milestone at which the construction and/or operation of vessels, infrastructure, and/or fuel plants

takes place. However, the report cautions that many of the 84 initiatives remain stalled by a ‘feasibility wall’ created by the cost gap between conventional and zeroemission fuels – a challenge that the Net-Zero Framework, delayed until at least next October, could help overcome.

“The move of major countries like China into green corridors is hugely promising”

Despite this delay, the report warns that industry and governments should not surrender the next year to a ‘wait and see’ approach. Instead, corridors should make use of emerging policies and programmes from national governments, such as the EU’s Global Gateway initiative, H2Global and Australia’s Hydrogen Headstart programme – something that would unlock progress ahead of a global framework and put participants among the frontrunners to benefit from future IMO incentives.

“We have at least 12 months before the IMO’s Net-Zero Framework is adopted,” Fahnestock says. “That time can either be spent waiting, or used to build projects that create strategic economic advantages, generate learnings that can influence the IMO’s reward mechanism, and put participants first in line for future global rewards. Those who act now will be best positioned to benefit when regulation catches up.”

To best expand and progress green corridors, the report recommends that the industry:

» Pursue strategies to break inertia and maintain momentum, closing the cost gap and ensuring corridors are advanced enough to qualify

for first mover rewards once they’re available.

» Capitalise on the opportunity to shape IMO policy, like the reward mechanism, and be well-positioned to benefit from eventual regulation.

» Better engage those with ambitious decarbonisation goals that can help scale solutions, particularly cargo owners who may be more willing to pay a premium for cleaner fuels.

» Utilise emerging national policy and adapt it for new geographies to accelerate change and encourage industry buy-in.

» Stay true to original principles, remembering that green corridors’ greatest contribution to maritime decarbonisation comes from fostering collaboration and prioritising harder-to-deploy e-fuels over more readily available solutions.

The UK P&I Club and the TT Club have announced that they are currently engaged in discussions regarding a potential merger between the two mutual insurers.

The Clubs have worked closely together for many years through their common manager, Thomas Miller. At their meetings in November, the Boards of both Clubs agreed to explore the possibility of cementing this existing relationship through a potential merger. The merged Club would have a unique breadth of expertise across the maritime and transport industry and bring together complementary strengths to enable an enhanced and integrated service to members while meeting the evolving needs of the industry.

The strategic visions of the UK P&I and TT Clubs are closely aligned, in each case they are focused on providing exceptional service to members, delivering growth, efficiency and improving financial stability. Both Clubs are highly respected in their own markets and combining the two accelerates progress towards their shared strategic goals. The combined Club will be uniquely positioned to support its members, and the broader

maritime and transport industries, in addressing the challenges and opportunities of the future.

Discussions remain at an early stage and will continue over the coming months.

Jan Valkier, Chairman, UK P&I Club, says: “Exploring a merger with the TT Club reflects our strategic focus on achieving greater scale, diversification and sustainable growth. This merger would create a market-leading maritime and transport insurance mutual, with an exceptional service offering underpinned by enhanced financial strength. As part of our considerations, we remain committed to our membership of the International Group which is a cornerstone of our identity.”

“The TT Club and UK P&I Club already have a strong relationship and operational synergies,” Morten Engelstoft, Chairman, TT Club, says. “Combining our capabilities while preserving our successful independent brands and service offering will deliver greater value to our respective members. We are still in the early stages of our discussions and whilst no final decision has yet been made we are confident that this opportunity creates exciting prospects for both Clubs.”

European, Chinese and South Korean financiers have over half of their portfolio tied to oil and gas carriers that are most at risk of becoming stranded assets in the global rush to shift to a low-carbon energy system, a new report by UCL’s Energy Institute Shipping and Oceans Research Group suggests.

A substantial portion of ship financing is tied to fossil fuel carriers that face risks of stranding in the global shift to a low-carbon energy system. A comprehensive study by researchers at UCL (University College London) has mapped the global landscape of shipping finance and uncovers the financial arrangements and institutions behind US$378bn of maritime assets, about 30% of the global vessel fleet value.

While most financiers maintain diversified portfolios across various shipping segments, certain institutions show concentrated exposure to specific fossil fuel carrier types. Based on the identified transactions, five financiers have more than half of their shipping portfolio tied to fossil fuel carriers, including China Merchants Group and Korea Eximbank. They are followed by mostly European banks, including Standard Chartered, ABN AMRO, ING Bank, SEB, Nordea and SMBC who have over one-third of their portfolio tied to fossil fuel carriers.

BNP Paribas, the financier with the largest portfolio recorded in the dataset ($9bn), was also found to have almost a quarter of its portfolio invested in fossil fuel carriers ($2bn).

The research, which compiled data from over 3,000 financial transactions – loans, bonds, leases

“A substantial portion of ship financing is tied to fossil fuel carriers”

and equity investments – provides the first detailed assessment of which financiers and economies are most invested in vessels that transport oil and gas. To maintain a liveable planet as stated in the Paris Agreement’s climate goals, demand for these fossil fuels must decline. Vessels that transport these commodities may then be in oversupply and potentially become a ‘stranded asset’. Previous analysis identified gas carriers and oil tankers as segments that are particularly exposed to this demandside risk.

The demand for the transport of coal is also set to decline, but options to switch to carrying other cargoes that will increase in demand, such as grains, and without major conversion

costs, keeps the bulk carrier fleet at a low risk. In contrast, the young fleet of liquefied natural gas (LNG) carriers has a very high newbuild value and a purpose-specific design; repurposing to other commodities, if possible, would require high additional investments, reducing the fleet’s competitiveness and ability to generate profit.

Dr Marie Fricaudet, Senior Research Fellow at UCL Shipping and Oceans Research Group and lead author, says: “To our knowledge, this is the first attempt to map climate risk to shipping financiers’ portfolios. The results show many financiers have a substantial part of their portfolio linked to fossil fuel transportation and highlight that more transparency is needed to properly anticipate and price-in the climate risk carried by shipping financiers.”

Dr Nishatabbas Rehmatulla, Principal Research Fellow at UCL Shipping and Oceans Research Group, says: “The gaps in data highlight an urgent need for much greater transparency in shipping finance. Building this dataset from various sources, while complex and novel, underscores the current failure of disclosure in the sector. While initiatives such as the Poseidon Principles have made an attempt at this, the climate alignment scores are aggregated at the portfolio level, meaning that data cannot be traced back to individual vessels. Furthermore they provide only an annual snapshot on greenhouse gas (GHG) emissions intensity, but to really assess exposure to stranded asset risks, more forwardlooking understanding is needed.”

To date, the Poseidon Principles reporting has focused on the GHG intensity of the financed fleet and have not considered demand-side climate risk, i.e. the exposure to risks in major reconfigurations due to climate policy related energy transition.

Last month UCL Shipping & Oceans Research Group and Kuehne Climate Centre published an interactive online tool ‘Investment Risk Monitor for Fossil Fuel Carrying Ships’, (available at https://shipping-transition.org), which provides users with high-level fleet-wide estimates of the future overall supply and demand balance for

maritime transport services of different fossil fuel carrying ship types under different climate and energy scenarios. The findings show that LNG carriers in particular can be expected to be in oversupply over the next decade and thus face a risk of being written off.

Dr Tristan Smith, Professor of Energy and Transport at UCL Shipping and Oceans Research Group, says: “These risks exist regardless of the IMO’s adoption of the Net-Zero Framework. However, reflecting on the Framework being delayed, this subject has now increased in salience - regulation has not gone away, but is now more uncertain. Understanding and managing that risk will now be of greater importance than ever.”

IBIA, the International Bunker Industry Association, is evolving to effectively support shipping’s energy transition. As the industry transitions to low and zero carbon fuels such as biofuels, LNG, methanol, and ammonia, IBIA is expanding its membership and services to better represent a broader marine fuels supply chain.

As the industry continues its shift toward low- and zero-carbon fuels, IBIA is building on its existing work to address the growing need for reliable bunkering infrastructure, fuel quality standards, and safe delivery processes while remaining committed to supporting transparency, quality and availability of conventional fuels during the transitional period.

Alexander Prokopakis, Executive Director, IBIA explains: “Regulatory targets are encouraging a more sustainable future for shipping. To achieve this, the fuels landscape is evolving rapidly with inherent obstacles to overcome - IBIA’s diverse membership makes it uniquely positioned to play a central role in aiding the industry’s progress.

“The organisation will expand into a more diverse global membership, representing not only the traditional marine fuels sector, but also stakeholders across the new and emerging marine fuels supply chain. This will create more opportunities to

have their voices represented at IMO, to access educational resources, and to benefit from network engagement.”

From shipowners to next-generation fuel providers, IBIA’s membership spans the entire bunker and marine energy supply chain. Its membership extends over 70 countries, ranging across traditional and alternative marine fuels suppliers, traders, brokers, barging companies, ship owners/operators, storage companies, surveyors, port authorities, industry associations, credit reporting companies, lawyers, P&I clubs, equipment manufacturers, shipping journalists and marine consultants.

In line with IBIA’s evolution, the organisation is refreshing its logo and brand identity to represent its more diverse global membership across both the traditional marine fuels sector and new and emerging marine fuels supply chains.

Constantinos Capetanakis, Chair, IBIA Board and Star Bulk Bunker Director, says: “Since 1993, IBIA has acted as the trusted voice of the marine energy supply chain, focused on promoting transparency, quality and high standards in the purchase and delivery of marine fuels to vessels.

“As the industry evolves amid the emerging future fuels landscape, IBIA remains committed to guiding it through the supply challenges facing the marine fuels market. We recognise that, as an organisation, we too must evolve to effectively support shipping’s energy transition.”

Hornsea 3 offshore wind farm has signed a lease agreement for up to 100,000 square metres at the Port of Tyne, one of the UK’s major deep-sea ports. Hornsea 3 is being developed by Ørsted, a global leader in offshore wind energy.

The site, located at Tyne Clean Energy Park in South Shields, will be fundamental to the construction and completion of the 2.9GW Hornsea 3 Offshore Wind Farm, which, once complete, is expected to be the world’s single largest offshore wind farm.

The Denmark-headquartered company will use the site to marshal secondary steel components for the project before each unit is loaded on to the Wind Orca, a state-of-the-art jackup vessel owned by Cadeler ahead of setting off to the Hornsea 3 site

Located 160km off the Yorkshire coast, Hornsea 3 is an £8.5bn infrastructure project set to generate enough green energy to power more than three million UK homes, boosting energy security and delivering local and national economic growth through supply chain investment.

Matt Beeton, Chief Executive Officer at the Port of Tyne, says: “Ørsted’s decision to base its marshalling operations at the Port of Tyne represents a clear vote of confidence in the infrastructure, skills and capabilities we have developed at the Tyne Clean Energy Park.

“This partnership is not only about delivering clean energy – it is about securing international investment, driving economic growth and creating the highly skilled jobs that will sustain our communities for generations, anchored by our best-in-class offshore wind base.”

“The construction of Hornsea 3 will greatly improve energy security for the UK, as well as bringing investment into the local and national economy. This means home-grown clean power, skilled jobs and economic growth,”

Jason Ledden, Senior Project Director, Hornsea 3 at Ørsted, says. “Ørsted’s vision is to create a world that runs entirely on green energy and the dedication of skilled workers all over the UK, including at the Port of Tyne, will help make that happen.”

As well as partnering with the Port of Tyne for its efficient marine access to Hornsea 3, 13 metre-deep berths and 24/7 365-day operation during all tide states, Ørsted is working alongside industry-leading partners to deliver the 197 offshore wind turbines needed for the project.

Severfield, a UK structural steel contractor, and Smulders, a multidisciplinary construction firm located on the River Tyne, will fabricate and supply secondary steel components.

The International Maritime Organization’s (IMO) Marine Environment Protection Committee (MEPC) voted in October to adjourn discussions on the Net-Zero Framework for one year.

The IMO Net-Zero Framework (NZF) was approved at the MEPC 83 session in April 2025, with the aim of creating the first global carbon pricing mechanism for any industrial sector and delivering a clear path for shipping’s transition to net zero. It comprises a set of international regulations aimed at reducing greenhouse gas (GHG) emissions from ships, in line with IMO’s 2023 Strategy for Reduction of GHG Emissions from Ships. It includes two key elements: a global fuel standard and a global GHG emissions pricing mechanism. The IMO has set a target for shipping to achieve net-zero shipping by or around 2050.

However, the US made its opposition to the framework very clear in the weeks leading up to the MEPC, with President Donald Trump stating: “The United States will NOT stand for this Global Green New Scam Tax on Shipping and will not adhere to it in any way, shape or form.” The US also cautioned that countries backing the NZF could face retaliatory measures including potential tariffs, visa or portaccess restrictions.

The IMO agreed to adjourn the extraordinary session of the MEPC to consider the adoption of draft amendments to MARPOL Annex VI, including the IMO NZF.

Industry associations expressed disappointment at the MEPC outcome and the resulting delay – adoption of the framework can now only happen in late 2026 at the earliest. Leading figures from the industry lined up to express their frustration.

“We regret the postponement of the adoption of the international climate agreement for shipping. The IMO NZF

is essential to give the industry the certainty it needs and to send a strong signal to the market to produce the clean fuels necessary to get to net zero. Shipping is an international industry which requires meaningful global regulations to decarbonise. Global regulation is essential to ensure a level playing field at international level and to deliver the energy transition of international shipping. We will continue to work with our international partners to ensure an agreement on the IMO NZF can be reached”, said Sotiris Raptis, Secretary General of European Shipowners.

The European Sea Ports Organisation, meanwhile, said: “The postponement risks undermining this rare moment of convergence and weakens the credibility of international climate leadership in shipping.”

The International Chamber of Shipping (ICS) commented that the framework would have created the first global carbon pricing mechanism for any industrial sector with the aim of delivering a clear path for shipping’s transition to net zero. Thomas A Kazakos, ICS Secretary General, stated: “We are disappointed that member states have not been able to agree a way forward. Industry needs clarity to be able to make the investments needed to decarbonise the maritime sector, in line with the goals set out in the IMO GHG strategy. As an industry we will continue to work with the IMO, which is the best organisation to deliver the global regulations needed.”

Director of Decarbonisation Jesse Fahnestock at the Global Maritime Forum called the delay “a disappointing setback for shipping, but not the end of this journey. The adjournment for a full year creates serious challenges for meeting the timelines in the NetZero Framework agreed in April and will make delivery of the sector’s decarbonisation targets even more

challenging. We encourage member states that agreed on the framework in April to re-confirm their commitment to multilateralism.”

The World Shipping Council underlined the importance of using the year ahead to clarify and develop the IMO NZF. “A globally agreed framework is needed to provide a level playing field to get there. The liner industry is committed to the goal of net-zero by 2050 and has invested US$150bn in ships designed to run on green fuels. The IMO remains the right place to deliver a global solution. We are committed to continuing work with governments to deliver the necessary regulatory consistency, support renewable fuel production and infrastructure, and keep shipping’s energy transition on track,” it said.

The UK Chamber of Shipping said: “It is disappointing that an agreement could not be reached to adopt the Net Zero Framework at the IMO. As a longstanding advocate of a global carbon pricing mechanism, the UK Chamber of Shipping has consistently championed international collaboration to drive meaningful decarbonisation.”

International Association of Ports and Harbors Managing Director Patrick Verhoeven said: “This is a major setback for the maritime industry. Shipping and ports need a global framework that provides them with legal certainty to make the necessary investments in decarbonisation. Only IMO can provide such a framework. We fear it will simply open the door for more national and regional measures, which will add to an already complex regulatory patchwork resulting in unintended consequences.”

Finally, Tim Wilkins, Managing Director of INTERTANKO, saw the delay as an opportunity: “This gives us time to improve the single regulatory maritime framework to cut maritime emissions. Let’s use this opportunity to work collaboratively to tackle the ambiguities and concerns of the NZF.”

As global regulations evolve and the maritime industry accelerates toward decarbonisation, reliable scrubber operation remains key to both compliance and cost control.

PureServ, the certified global service division of PureteQ, delivers expert maintenance and digital support for all scrubber brands – helping shipowners maintain continuous MARPOL compliance while optimising system performance and fuel efficiency. PureServ’s expert team of certified marine engineers and naval architects has serviced thousands of systems across every major technology, combining deep technical know-how with practical onboard experience.

With service hubs in Europe and Asia, PureServ dispatches engineers anywhere in the world—or connects directly to ships via its secure digital platform, Internet for Remote Assistance Services (IRAS), for remote troubleshooting and guidance.

Competent crews are key to scrubber reliability. PureServ offers practical training covering the full system – from sea chest to overboard discharge. With IRAS enabling wi-fi connectivity in engine rooms, crews can receive live video support from PureteQ engineers. This handson, digitally supported training strengthens crew confidence and ensures consistent operational quality across fleets.

“No matter the brand or location, PureServ ensures your scrubber system stays compliant and operational 24/7

Every vessel operates differently. That’s why PureteQ Service Agreements are custom-built to fit the shipowner’s operational pattern and crew proficiency. Agreements typically include:

» Certified calibration and maintenance of CEMS and WMS

» Crew training, online or onboard

» Spare parts management with 24-hour dispatch

» Remote monitoring and operational guidance

» Performance reporting and optimisation

» Expert hotline support 24/7/365 Working with the PureteQ team makes scrubbing simple and provides peace of mind for owners, managers and operators. It also helps reduce costly breakdowns, enables predictive maintenance, and lowers overall OPEX.

Some type-approved components, such as gas analysers and PAH sensors, require calibration by

certified engineers to maintain MARPOL approval.

PureServ’s sensor maintenance and replacement programme ensures full compliance and zero disruption. Clients receive reminders in advance and newly calibrated sensors are shipped before the old ones are returned, eliminating operational gaps. Refurbished sensors are recalibrated and stocked for reuse, cutting lifecycle costs and environmental footprint.

PureServ’s web-based platform PureSPOT takes scrubber management into the digital era. It provides fleetwide visibility of performance and compliance, measuring fuel efficiency, and approximate carbon footprint. By assessing the scrubber’s impact on specific fuel oil consumption and comparing heavy fuel oil versus compliant-fuel scenarios, Pure-SPOT helps owners optimise performance and document savings— all while aligning with IMO EEXI and CII requirements.

“Pure-SPOT transforms scrubber data into actionable insights for compliance and cost efficiency”

IMO regulations require regular drydocking to ensure vessel safety, structural integrity, and certification. PureServ supports shipowners with pre-drydocking inspections covering pumps, fans, internal structures and compliance equipment.

The reports define clear drydocking work scopes to reduce risks, delays and extra costs.

Drydocking is also an ideal opportunity to implement retrofitting upgrades that align vessels with future environmental standards. PureteQ engineers assess system performance and advise on potential improvements to enhance energy efficiency, automation, and digital integration, helping shipowners future-proof their fleet and extend the lifecycle of installed scrubber systems.

With certified engineers, rapid spareparts logistics, and advanced digital tools, PureServ offers a true onestop solution for scrubber service, calibration and optimisation. Whether through remote assistance, onboard service, or predictive maintenance, PureServ provides the operational security and environmental integrity shipowners need in a decarbonising industry.

For more information, visit: pureteq.com service@pureteq.com spares@pureteq.com

Research shows orders for scrubbers – both for newbuilds and retrofits –rising sharply

Berge Bulk has completed the installation of a carbon capture system on board its 63,000 DWT Ultramax vessel Berge Yotei, marking a key step in its decarbonisation journey under the company’s signature Maritime Marshall Plan for decarbonisation.

The system, developed by Value Maritime, integrates carbon capture into an exhaust gas cleaning system known as the Filtree System. It is designed to capture up to 15 tonnes of CO2 per day, representing a potential 30% reduction in emissions during operations.

Unlike conventional scrubbers, the Filtree System removes both sulphur oxides and CO2 from a vessel’s exhaust. CO2 is absorbed into a reusable amine solution, which can be offloaded in port for regeneration or reuse. Potential applications include use in greenhouses, beverage production and other industrial processes – contributing to a more circular carbon economy.

“Carbon capture is a key pillar of our decarbonisation strategy. While we remain committed to optimising fleet efficiency, installing decarbonisation technology and switching to new fuels, we must also capture carbon at the same time,” says James Marshall, CEO of Berge Bulk. “We’ve been actively capturing carbon through nature-based solutions on shore for many years –now it’s time to also start capturing carbon on board.”

While regulatory frameworks such as MARPOL and the EU ETS are still evolving, Berge Bulk is already contributing practical insights into how onboard carbon capture systems can be implemented, monitored and scaled.

This pilot is part of Berge Bulk’s broader Maritime Marshall Plan – a four-pillar decarbonisation strategy focused on:

» Pillar 1 – Maintain a relentless focus on improving efficiency.

» Pillar 2 – Leverage the latest advances in maritime technology.

» Pillar 3 – Convert to new fuels.

» Pillar 4 – Invest in solutions to capture carbon through technology and nature.

Berge Bulk has also set three key decarbonisation milestones:

» Offset 100% of carbon emissions from 2025.

» Build and operate a zero-carbon vessel by 2030.

» Achieve zero-carbon emissions fleetwide by 2050.

Global shipping group Performance Shipping has announced the successful naming and delivery of its first LR2 Aframax newbuilding, M/T P. Massport, constructed at Shanghai Waigaoqiao Shipbuilding Co in the People’s Republic of China.

The M/T P. Massport, is a 114,000DWT liquefied natural gas (LNG)-ready Tier III product/crude oil tanker, the first of three LNG-ready, scrubber-fitted LR2 Aframax tankers ordered by the company and scheduled for delivery between the third quarter of 2025 and early 2026.

All three vessels have secured five-year charter contracts with Clearlake Shipping, a subsidiary of the Gunvor Group, one of the world’s largest independent commodities trading houses.

Andreas Michalopoulos, Performance’s Chief Executive Officer, says: “This marks the kick-off of a series of newbuilding tanker deliveries for Performance Shipping, which will see the addition of two further sister LR2 Aframax vessels through early 2026 and an LR1 tanker in early 2027.

Together, these modern vessels form a core part of the company’s strategic fleet expansion and renewal plan. We are proud to introduce this state-of-theart tanker to our fleet and honoured to commence this charter with Clearlake Shipping. We wholeheartedly wish the M/T P Massport and her crew fair winds and calm seas.”

According to data from Clarksons Research, orders for scrubbers – both for newbuilds and retrofits – are rising sharply, particularly in the tanker and container ship segments. As of 1 June, there were 455 tanker scrubber orders, marking a 16% increase since 1 February.

Container ships with scrubbers on order have reached 207, also showing a 16% increase.

At the same time, retrofits on existing vessels are also accelerating. Container ships are leading the trend, with 127 retrofits underway – a 25% increase since February.

Bulk carriers are close behind, with 55 retrofits scheduled – more than double the 25 recorded four months ago.

In total, there are 166 more scrubber installations planned compared to February: 107 on newbuilds and 59 through retrofits.

“Carbon capture is a key pillar of our decarbonisation strategy. We remain committed to optimising fleet efficiency”

The maritime industry operates under increasing environmental pressure, tighter emission regulations, and rising expectations for vessel uptime and reliability. For shipowners and scrubber manufacturers, this creates a clear challenge: ensuring that every exhaust gas cleaning system performs flawlessly under the toughest operational conditions. When corrosion, cracking, improper welds or material failures occur, downtime is costly, off-hire risks escalate, and reputational exposure increases. This is exactly where Ticco BV delivers unmatched value.

Ticco BV is one of the world’s most specialised companies in scrubber high-alloy welding repairs and modifications.

Based in Willemstad in the Netherlands and active worldwide, Ticco BV has built its reputation on executing the repairs that others cannot. We are the organisation that shipowners or scrubber manufacturers call when high alloy maritime scrubber welding is needed. Our welders and fitters work exclusively on high-alloy materials used in EGCS systems, including SMO254, 904L, SuperDuplex (2507), Duplex (2205), Alloy 625, Alloy 31, Titanium and other corrosionresistant grades. Good material expertise is one of the reasons our teams are deployed worldwide for complex and time-critical repairs.

We specialise in welding jobs that involve strict inspection regimes and full documentation packages. Our WPQR and WPS packages are developed for the exact material grades used by the main scrubber manufacturers, ensuring weld integrity, corrosion resistance, and long-term durability. Our engineers

deliver high-quality welds, penetration testing, visual inspections and full class-approved reporting. We work in accordance with the standards demanded by leading OEMs and yards across Europe and Asia.

In many cases we are called by shipowners, technical managers, superintendents, vessel managers and general ship repair yards for scrubber repair issues. Many shipyards subcontract their scrubber repairs to Ticco BV because they lack the highalloy welding capabilities required. Ticco BV bridges this gap and operates as the specialist supporting major scrubber brands. When weld quality matters, or when a repair must be executed right the first time, the above decision makers insist on having Ticco BV on board.

A malfunctioning scrubber is not a local issue – and neither are we.

Ticco BV provides 24/7 global response, including:

» 80% of the jobs on terminal locations

» On-board at anchorage or during sailing operations

» Worldwide deployable 24/7

» Dry-docks world wide

» Coordination with chief engineers, agents, port authorities and terminals

» Hot-work permits, logistics and launch services

» Material sourcing and emergency mobilisations

Our teams have worked in Spain, Portugal, Italy, Croatia, Malta, Nigeria, South Afrika, Dubai, Seychelles, Sri Lanka, Vietnam, China, Indonesia, Singapore, Japan, Belgium Germany, Sweden, Finland, US, Panama, Norway, Lithianua, Poland, France, Curacao, Aruba, Egypt, Turkey and dozens of other ports worldwide. Where your vessel needs us, we go.

We have executed repairs and welding works on scrubber systems from nearly all major brands, including:

» Wärtsilä

» Valmet

» Clean Marine

» Value Maritime

» Ecospray

» Yara Marine

» Pacific Green

» Mantra/Yara

» Hyundai/ HHI

» Alfa Laval

» Panasia

» CR Ocean

» VDL/AEC

» Langh Tech

» ME Production

» Pureteq

» Bilfinger

» Dupont

Each system has its own engineering philosophy, wall thicknesses, internal geometries and material combinations. Ticco BV understands the differences and the best repair methods for each design. Whether the issue concerns corroded welds, leaking joints, cracked internal structures, damaged pipes, thinning walls, or improper OEM welding, we execute the repair with precision.

1. We specialise only in scrubber repairs – not in general ship repairs

This narrow focus allows us to master the materials and corrosion mechanisms in EGCS systems at a level unmatched by multipurpose repair yards.

2. Zero tolerance for welding errors. A single pore or improper heat

input can cause galvanic or crevice corrosion inside a scrubber. Our procedures prevent these failures.

3. Short dry-dock windows demand perfection.

Our teams are trained for highpressure, zero-delay situations. We deliver on time, every time.

4. We keep vessels in service. If the repair allows, we execute work during sailing, at anchorage or in parallel with other dock operations — minimising off-hire.

5. OEMs trust us when problems become complex.

Many manufacturers contact Ticco BV directly for warranty-sensitive issues or critical repair operations.

Ticco BV welders and fitters work daily with high-alloy materials, including:

» SMO254 (UNS S31254)

» 904L (UNS N08904)

» SuperDuplex 2507

» Duplex 2205

» Inconel / Alloy 625

» C-276 (Hastelloy)

» Alloy 31

We follow the correct heat-input ranges, root gas specifications, interpass temperatures and filler metal combinations required for long-term corrosion resistance.

“Our welders are trained to recognise corrosion patterns instantly”

Scrubber systems operate in an extremely aggressive environment. Incorrect welding, material mismatch or fatigue can rapidly lead to:

• Crevice corrosion

• Galvanic corrosion

• Pitting corrosion

• Stress-corrosion cracking

• Wall thinning

• Localised erosion

• Chloride-induced attack

Our welders are trained to recognise corrosion patterns instantly. This allows us to identify root causes much faster than typical yard-based welders, ultimately reducing downtime and repair costs.

Ticco BV operates with a simple philosophy: Do it right the first time — anywhere in the world.

This approach has earned us longterm relationships with shipowners operating tankers, bulk carriers, container vessels, cruise ships, ferries, Ro-Ro vessels and PCTCs.

Our clients appreciate that we communicate clearly, deliver what we promise and take full ownership of every project — whether it concerns a minor weld correction or the reconstruction of an entire scrubber chamber.

A single failed weld can jeopardise compliance, performance and safety. Choosing the wrong welding team can cost days of off-hire, class complications and OEM disputes. This is why shipowners and OEMs choose Ticco BV.

We provide the expertise, precision, certification and reliability required to keep your exhaust gas cleaning systems fully compliant and operating flawlessly — anywhere, anytime. For more information www.ticco.nl

Captain M Kaczmarek, Chairman, Clean Shipping Alliance (CSA), looks at how to maintain scientific integrity in a fragmenting regulatory landscape

The maritime industry is still in the early stages of a complex energy transition, where technologies that deliver immediate emissions reductions must coexist with solutions that are still developing. Exhaust gas cleaning systems (EGCS), or ‘scrubbers’, have long been part of this landscape. They were incorporated into MARPOL Annex VI as an approved equivalent method for achieving sulphur compliance and EU legislation, including Directive 2016/802, continues to reflect this by permitting their use in European waters.

Today, EGCS remain in use on approximately 5,800 ships worldwide (a little under 10% of the global shipping fleet). At a time when alternative fuels are not yet scalable or globally available, the EGCS/heavy fuel oil combination continues to deliver well-to-wake CO2 advantages. Despite this clear regulatory basis and a substantial scientific evidence base showing no environmental risk, several national and regional initiatives in Europe have sought to restrict EGCS use. OSPAR members

recently voted to phase out EGCS discharges in North Atlantic ports and internal waters, while Denmark, Sweden and Finland have each initiated bans within their territorial seas.

These actions complicate route planning, add operational cost and create uncertainty for ships transiting these waters. They also take place outside the International Maritime Organization (IMO) process, conflict with existing IMO rules and lack clear justification. To date, there has never been credible evidence of environmental harm caused by EGCS operations.

“Key environmental policy decisions for EGCS in Europe are being shaped by precautionary assumptions”

Risk assessments

What unites recent restrictive initiatives is a shared set of defining characteristics; they are not grounded in robust scientific evidence and none of the OSPAR members conducted their own research or testing. Instead, they relied on a small group of studies from a single source using limited datasets and non-standard methods. Although the IMO recommends that any authority considering restrictions must first conduct an environmental risk assessment using MEPC.1/Circ.899,

none of the OSPAR states followed this guidance.

By contrast, those countries that have performed risk assessments aligned with IMO standards, notably Brazil and Japan, found negligible environmental risk and saw no basis for restrictions.

This divergence highlights a core problem: key environmental policy decisions for EGCS in Europe are being shaped by precautionary assumptions rather than empirical evidence. This conflicts with the EU’s own Science for Policy (S4P) framework, intended to support evidence-based decision-making.

Many of the studies used to justify restrictions rely on small datasets with missing or unqualified values, employ modelling scenarios that do not reflect real-world dilution, or consist largely of literature reviews rather than original sampling, and use different methods, equipment and quality standards.

What the science shows

In contrast, a large body of peerreviewed studies, national research programmes, and industry supported datasets submitted to the IMO paint a consistent picture. Detailed analysis by the Danish Environmental Protection Agency (EPA), Japan’s Ministry of Land, Infrastructure, Transport and Tourism, DNV GL/CLIA, DHI, CE Delft and research teams across Europe, North America and South America, including Brazil’s Port of Tubarão, have concluded that EGCS discharge water presents negligible environmental risk when operated in accordance with IMO guidelines.

A uniquely valuable long-term data source is Norway’s Mongstad refinery, where the same seawater EGCS discharge point has been monitored for more than 30 years. Annual benthic surveys continue to show no detectable

negative impact on local flora, fauna, or sediment chemistry.

These studies follow standardised IMO protocols and analyse large numbers of washwater samples taken from operating vessels across diverse regions. Their conclusions are consistent: EGCS discharges meet IMO discharge criteria and typically comply with major national and international water quality standards, including the EU Water Framework Directive Environmental Quality Standards and, in some cases, even World Health Organization and US Environmental Protection Agency drinking water standards.

Concerns about potential accumulation of washwater constituents in ports have also been addressed. CE Delft’s modelling indicates that even with continuous presence of multiple EGCS-fitted ships, sediment accumulation over 20 years would remain extremely low and far beneath regulatory or dredging thresholds. Similarly, whole-effluent toxicity testing by DHI, performed using internationally accepted methods, found risk characterisation ratios consistently below 1, indicating negligible risk.

Regional restrictions on EGCS create a fragmented regulatory environment that makes compliance more complex and less predictable. Instead of operating under a single globally agreed framework, ships must adapt to a patchwork of differing national rules, which complicates voyage planning, fuel management and operational procedures. For some vessels, switching fuels before entering territorial waters can take hours, increasing risk – particularly for single-engine ships, at night, in heavy traffic, or in poor weather – introducing avoidable operational, safety and cost burdens for shipowners.

There is also a broader principle at stake. The industry invested in EGCS technology in good faith based on IMO and EU endorsement, and EGCS remain explicitly recognised under the EU Sulphur Directive as an acceptable

compliance method in EU waters. Penalising early adopters – especially without scientific evidence of harm – risks deterring future investment in transitional technologies essential for decarbonisation.

This is especially relevant given EGCS’ documented well-to-wake CO2 advantages. CE Delft’s 2021 study found that refining marine gas oil (MGO) increases lifecycle CO2 emissions by 10-25%, while operating a scrubber increases CO2 output by only 1.0-1.5%.

EGCS also contribute to improved local air-quality, consistently achieving low sulphur oxide emissions and reductions in Polycyclic Aromatic Hydrocarbons (PAHs), with some studies showing additional reductions in particulate matter compared with very low sulphur fuel oil or MGO. Collectively, this performance supported the IMO’s decision to approve EGCS as an equivalent method of compliance.

“Scrubbers are a mature, wellunderstood system that contributes to improved air quality”

EGCS also enable onboard carbon capture systems (CCS), which require a cleaned exhaust stream. Several CSA members are currently testing integrated EGCS-CCS solutions at sea. However, fragmented restrictions introduce uncertainty for these next-generation technologies and risk delaying their development and associated emissionsreduction potential.

The CSA and the wider industry recognise that regulators and the public expect environmental safeguards to be robust, transparent and science-led. This is why we consistently advocate for thorough, IMO-aligned risk assessments and why we continue to gather and develop large empirical datasets, including hundreds of recent washwater measurements provided to inform ongoing GESAMP (Group of Experts on the Scientific Aspects of Marine Environmental Protection) work at the IMO.

Sound environmental regulation must be grounded in evidence, not precautionary assumptions. To date, no IMO-aligned risk assessment has identified unacceptable risks from EGCS discharge water. No credible study has demonstrated environmental harm, and decades of real-world operations have revealed no measurable impact on marine ecosystems.

For a global industry reliant on regulatory coherence, regional divergence creates uncertainty at a time when shipping needs clarity to invest, innovate, and decarbonise. Evidence-based policymaking through the IMO remains the most effective path for ensuring environmental protection while supporting technologies that deliver emission reductions today.

Scrubbers are a mature, wellunderstood system that contributes to improved air quality, supports CO2 reduction, and enables future abatement technologies – all without any demonstrated harm to the marine environment.

The Mongstad refinery’s 30-year dataset offers a clear lesson: longterm, large-scale EGCS operation can coexist with healthy marine ecosystems. What the industry now seeks is coherence in global rule-making – grounded in science, delivered through the IMO and informed by consistent, standardised local assessments by coastal states before any restrictions are adopted.

In response to mounting global pressure to reduce greenhouse gas (GHG) emissions, the International Maritime Organization (IMO) has advanced its regulatory framework by proposing a global carbon pricing mechanism for shipping. This initiative forms part of the IMO's 2023 Strategy on the Reduction of GHG Emissions from Ships, which aims to achieve net-zero emissions by around 2050. Central to this strategy is the implementation of an economic instrument, likely a levy-based carbon pricing scheme, intended to internalise the cost of carbon emissions and incentivise decarbonisation within the maritime sector.

The IMO’s carbon pricing scheme is expected to function through a mandatory GHG levy or a market-based measure (MBM), such as a cap-and-trade system. These approaches put a monetary value on CO₂ and potentially other GHG emissions, thereby encouraging ship owners and operators to invest in cleaner technologies and adopt operational efficiencies. A global scheme would also level the playing field, reducing the risk of regional fragmentation caused by disparate national or regional mechanisms like the EU Emissions Trading System (EU ETS), which began applying to shipping in 2024.

To ensure fairness and effectiveness, accurate emissions quantification is paramount. This is where Continuous Emissions Monitoring Systems (CEMS) come into play. CEMS offer realtime, direct measurement of pollutants emitted from ship exhausts, typically including CO₂, NOx, SOx, and particulate matter. Unlike fuel-use-based estimations under the existing IMO Data Collection System (DCS), CEMS provide actual emission data, which is especially valuable for verifying compliance with a carbon pricing regime.

The applicability of CEMS to the new carbon pricing scheme lies in its ability to deliver verifiable, tamper-resistant emissions data that can underpin carbon cost calculations. With CEMS, carbon charges could be based on actual CO₂ emitted rather than theoretical models or fuel consumption estimates. This approach enhances transparency and accountability, particularly for ships using variable fuel blends or operating in dynamic conditions, where standard emission factors may fall short.

Furthermore, CEMS facilitate integration with digital reporting platforms and remote verification systems, supporting the IMO’s push towards data-driven enforcement. As the industry transitions to low- and zero-carbon fuels such as biofuels, hydrogen, and ammonia, the role of CEMS becomes even more critical. These fuels present new combustion characteristics and emission profiles that may not be adequately captured by default emission factors.

However, widespread adoption of CEMS faces challenges, including high installation costs, space limitations on smaller vessels, and the need for regular calibration and maintenance. To overcome these hurdles, the IMO may consider regulatory incentives or funding schemes, especially for ships operating in developing regions.

In conclusion, the IMO’s proposed global carbon pricing scheme marks a significant milestone in aligning shipping with global climate goals. For the scheme to be effective and equitable, robust emissions monitoring is essential. CEMS, as a mature and reliable technology, can play a key role in enabling accurate emissions accounting and ensuring trust in the system. As the industry adapts to a carbon-priced future, CEMS will likely become an integral component of compliance and environmental stewardship in maritime operations.

CEMS provide real-time, direct measurements of GHGs like CO₂, NOx, SOx, and particulate matter from ship exhausts Unlike theoretical models or fuel-use-based estimates (e g , under the IMO DCS), CEMS generate actual, verifiable data, which is critical for precise carbon pricing calculations This accuracy enhances trust and credibility in the carbon pricing system

CEMS enable tamper-resistant and continuous monitoring, strengthening compliance with emissions regulations They also facilitate remote verification and integration with digital platforms, aligning with the IMO’s vision for data-driven enforcement and reduced administrative overhead

As shipping transitions to alternative fuels (biofuels, hydrogen, ammonia), standard emission factors may not accurately reflect real emissions CEMS are capable of capturing the unique combustion profiles of these fuels, making them essential for future-proof emissions monitoring

In addition to regulatory benefits, certain gases measured by CEMS, such as CO, O₂, and unburned hydrocarbons, can be used to assess the combustion efficiency of individual engines

This data helps identify suboptimal engine performance early, enabling proactive maintenance and reducing the risk of costly breakdowns or inefficiencies

Accurate emissions data make the cost of carbon transparent, incentivising shipowners to invest in:

Cleaner technologies

Fuel efficiency

Operational improvements

This accelerates the shift toward net-zero emissions by 2050

A globally harmonised monitoring standard like CEMS can help unify practices under the IMO framework, mitigating conflicts with regional systems like the EU ETS

Conclusion

Emissions monitoring through CEMS is fundamental to the success of the IMO’s carbon pricing strategy It ensures that the costs of pollution are accurately assigned, compliance is transparent and fair, and industry efforts to decarbonise are appropriately rewarded Despite some implementation challenges, CEMS represent a critical enabler of sustainable and accountable maritime operations in a carbon-constrained future

A unified voice for ethanol & methanol in maritime

Eliminates fragmented advocacy and duplication

Aligns policy, safety and technology across sectors

Builds a credible, liquid low-carbon coalition

Support IMO, ISO, EU Fit-for-55 and FuelEU

www.green-fuels.org/mema mema@green-fuels.org

Are front-runners starting to emerge in the alternative fuel race?

Lloyd’s Register (LR) has launched its new Biofuel Advisory service to help shipowners, fuel suppliers and producers adopt biofuels safely and at scale.

Biofuels are emerging as one of the most proven and reliable alternative fuel options for reducing greenhouse gas emissions from shipping. LR’s new service is designed to remove uncertainty for the industry by providing end-to-end support across the biofuel supply chain, from production and certification through to delivery and onboard use.

The initiative builds on two years of groundwork and combines LR’s energy transition advisory with the technical expertise of its Fuel Oil Bunker Analysis and Advisory Service (FOBAS). FOBAS’ experience with biofuels spans more than 20 years, during which it has collaborated with shipowners, suppliers and producers to advance safe and scalable adoption of alternative fuels.

LR has already worked with leading biofuel producers to assess the impact of regulation on market demand, supported major bunker suppliers in producing transparent documentation for buyers, and guided shipowners through the testing and operational steps needed to start using biofuels across their fleets.

James Frew, Director of Lloyd’s Register Advisory, says:“Biofuels represent an immediate and practical solution, but owners need confidence on performance, safety and compliance. Our new Biofuel Advisory service brings together technical expertise and regulatory insight to provide the industry with confidence and clarity at every stage of the biofuel supply and adoption process.”

Alfa Laval Korea has signed a memorandum of understanding (MOU) with Hanwha Ocean Ecotech, marking a significant step toward strengthening cooperation in developing safe and

reliable ammonia fuel system solutions for dual-fuel vessels.

The MOU with Hanwha Ocean Ecotech marks a strategic collaboration to leverage Alfa Laval’s technical expertise in ammonia fuel systems, together with Hanwha Ocean Ecotech’s capabilities in marine technology. The joint approach aims to secure early market opportunities and build competitive advantage in the rapidly growing field of alternative marine fuels. It includes cooperation on business co-development and project opportunities, with the ambition to deliver a pilot installation to enable future collaboration.

“Our Biofuel Advisory service brings together technical expertise and regulatory insight”

the classification society American Bureau of Shipping saw Alfa Laval contribute to the design of the entire fuel system, including the ammonia fuel supply system and fuel valves train, with Alfa Laval also adding an Aalborg ammonia dual-fuel boiler system to the project scope.

According to the latest figures from DNV’s Alternative Fuels Insight platform, 10 new orders for alternative-fuelled vessels were placed in November 2025.

All the new orders were for LNG-fuelled vessels, with six in the container segment, while the tanker segment accounted for four. 232 alternative-fuelled vessels have been ordered in the first 11 months of 2025.

This represents a 53% decrease compared with the same period last year, highlighting a general slowdown in the newbuild market. The container segment remains dominant, comprising 66% of total orders.

Alfa Laval will contribute its proven capabilities in ammonia fuel and mitigation technologies through its ammonia fuel supply system and Hanwha will apply its extensive experience in system engineering and integration.

Alfa Laval is engaged in several other key collaborations focused on ammonia as a marine fuel. It has a long-standing research and development partnership with WinGD, which has successfully tested the ammonia release mitigation system and fuel valve trains, laying a solid foundation for its commercial rollout.

Another collaboration between South Korea’s shipbuilder K Shipbuilding, Alfa Laval, WinGD and

Port of Hamburg’s Waltershofer Hafen area has been approved for the bunkering of methanol and LNG by ship-to-ship. Ships can be supplied with these alternative fuels at central container terminals Burchardkai and Predöhlkai.

With this move, the Hamburg Port Authority (HPA) is taking another important step towards more climate-friendly shipping and the implementation of energy and climate targets in the port.

The first methanol-powered vessels are already in service worldwide, as are the first ammonia-ready ships, with more on order in international shipyards.

These new vessel types require the necessary fuelling infrastructure (so-called ‘bunker-ready terminals’) to ensure the availability of alternative fuels and safeguard the port’s future competitiveness.

In close cooperation with RWE Supply & Trading and other local stakeholders, HPA has carried out a comprehensive risk assessment and developed a detailed safety concept. These joint efforts have now paved the way for the official approval of safe bunkering operations at the designated terminal locations.

By enabling methanol bunkering, the port is consolidating its role as a Sustainable Energy Hub and contributing to the implementation of agreed Green Corridor initiatives.

Wärtsilä Gas Solutions is supplying a range of systems for a new LNG bunkering vessel built at the Jiangnan Shipyard in China for Shanghai International Port Group (SIPG) Energy Shanghai Co.

The scope includes the cargo handling system, the fuel gas supply system and a boil-off gas reliquefaction system. The systems are fully integrated to ensure optimal efficiency.

The Wärtsilä equipment is scheduled for delivery to the yard during 2026, with the ship expected to be commissioned in summer 2027.

The Maritime and Port Authority of Singapore (MPA) has issued licences to supply methanol as marine fuel in the Port of Singapore from 1 January 2026, following the Call for Applications launched in March 2025. This marks an important step towards establishing methanol bunkering at scale and driving Singapore’s ambition to be a sustainable multi-fuel bunkering hub.

Licences will be awarded to Global Energy Trading, Golden Island and PetroChina International (Singapore). The three companies were selected from a total of 13 applicants through a comprehensive evaluation process that assessed supply chain reliability, operational readiness, safety systems

and the sustainability certification of the methanol to be supplied. The strong interest reflects the sector’s growing focus on lower-emission marine fuels.

The licences will be valid for a fiveyear period, from 1 January 2026 to 31 December 2030, subject to successful applicants meeting relevant licensing conditions.

The five-year period supports the early development of methanol bunkering by giving licensees sufficient scope to build capabilities, strengthen supply chains and anchor initial investments as the market develops.

Industry collaborative SEA-LNG has welcomed the EU Commission’s new Sustainable Transport Investment Plan (STIP), published last November, which represents a major milestone for the methane decarbonisation pathway.

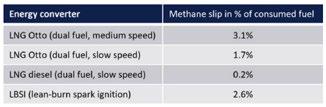

The plan explicitly recognises LNG, bio-methane and e-methane within the clean-fuel mix, noting that “LNG, with effective methane-slip mitigation technologies, can also reduce GHG emissions” and the trend of “ocean-going ships moving towards methane (LNG, bio-methane and in future e-methane)”.

In clearly recognising the methane decarbonisation pathway, the STIP reflects long-standing calls for fuel and technology neutrality, ensuring methane, biomethane and e-methane compete on equal terms with other clean fuels.