WINDOW OF OPPORTUNITY

Alternative fuels jostle for prime position in the race to net zero

TURNING POINTS

Why rotor sails are becoming the popular propulsion choice

TECH TALK

Next-generation digital platforms take shipping to another level

supporting Clean Shipping initiatives SPRING 2024

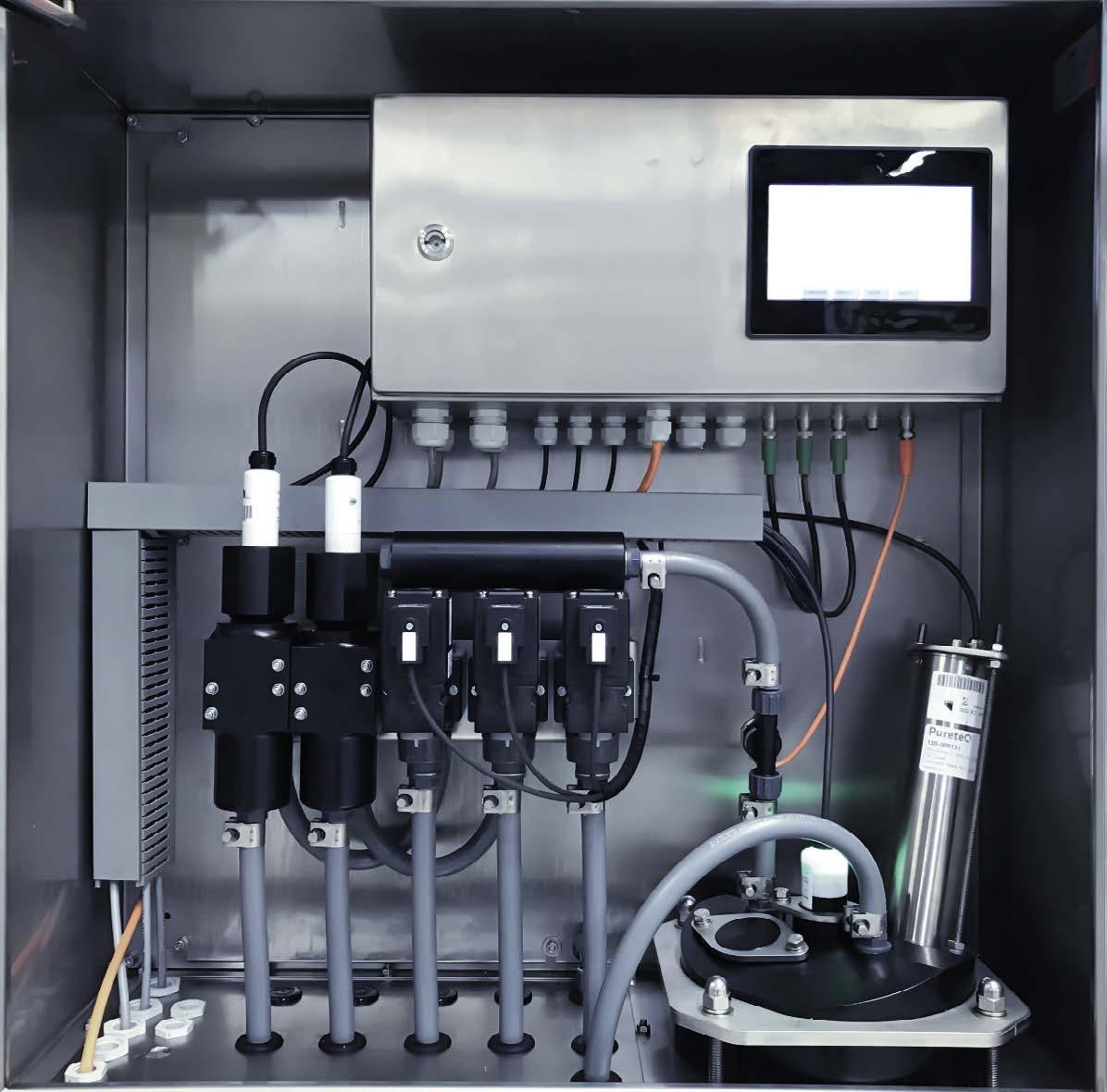

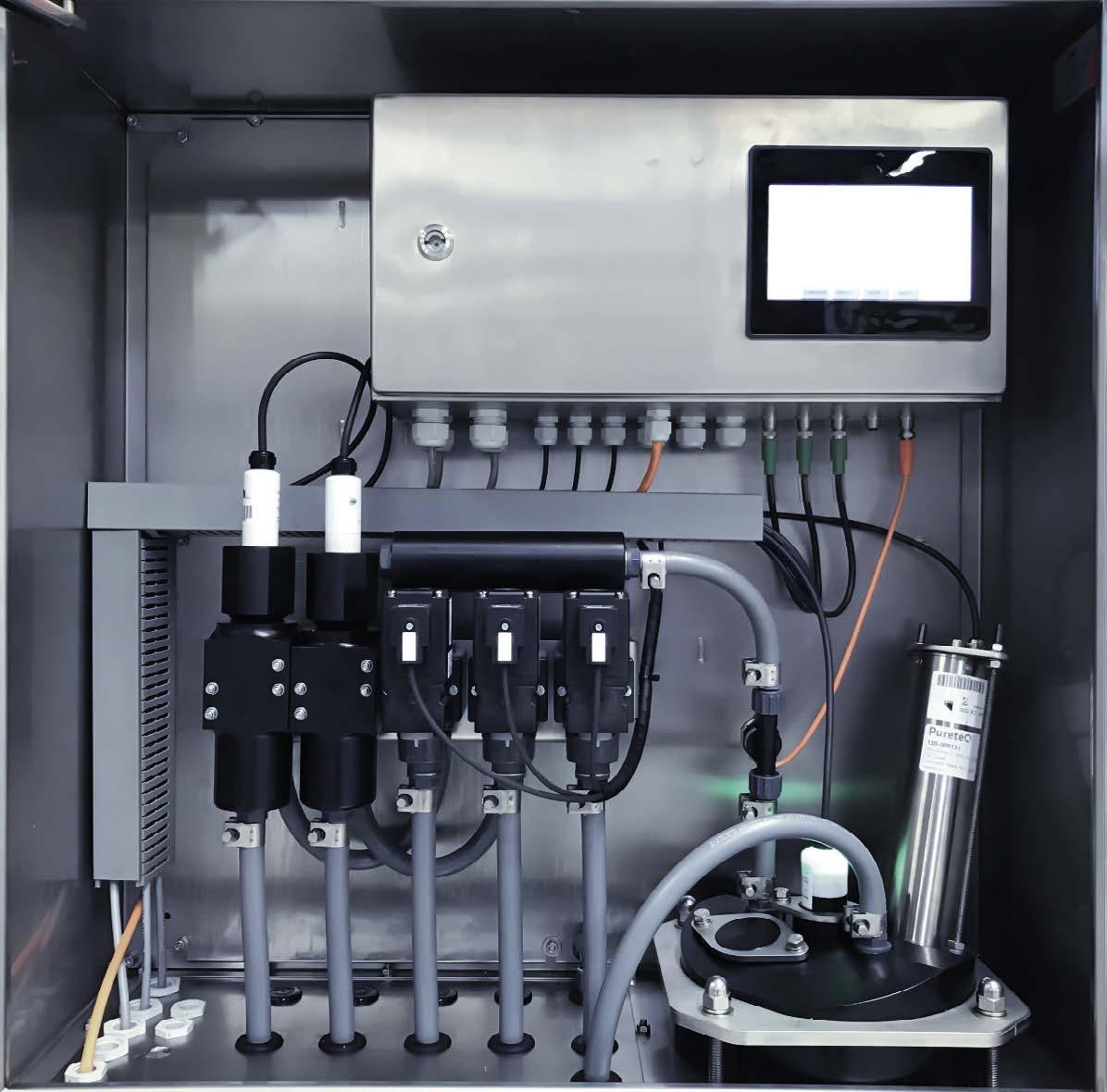

maritime scrubbers including a state-of-theart control system with remote accessibility and an energy optimisation programme.

The PureteQ WMS013 Water Monitoring System is designed for simple installation and operation with only one central monitoring cabinet, reducing sensor maintenance costs significantly. The control system and related software ease retrofitting to any existing EGCS/EGR.

WWW.PURETEQ.COM

Sandra Speares Editor, Clean Shipping International

Sandra Speares Editor, Clean Shipping International

TEAMING UP TO TACKLE CHANGE

Teamwork continues to be the most important approach when dealing with new environmental regulations and procedures, and there have been a number of alliances formed between industry members exploring solutions to the challenges.

As the next deadline for ballast water compliance looms in September, industry players are urging companies and organisations to get on with putting measures in place rather than waiting until the last minute – or passing the deadline and then trying to take retrospective measures, an approach the maritime industry has adopted in the past.

In this edition of Clean Shipping International, we take an in-depth look at how the industry is meeting environmental requirements. For example, exhaust gas cleaning systems – scrubbers – continue to be a popular solution – although combination systems linking different measures that can be run in tandem, are also popular.

What role governments will play in ensuring an environmentally friendly approach does not prove to be a liability will also be key –as well as the amount of assistance governments are prepared to provide to ensure the industry gets things right.

Efforts being made to meet environmental deadlines do not end with the ships themselves, though, and issues such as effective procedures being in place at ports to supply vessels with alternatives fuels, as well as follow and promote eco-friendly practices, are also vital to the smooth running of the wider industry. There is plenty of healthy rivalry in the alternative fuels market between the different products available – or those that will be available in the future when the right infrastructure is there to deal with them.

While moves towards greener practices continue, what impact these may make on the safe running of ships also remains a consideration – green does not necessarily mean safe and user friendly. Training is going to be a key consideration when implementing any new approach to fuel use. There have been enough accidents in the past – despite crews being informed of the impact of dangerous practices.

Ensuring that masters and crew are up to speed with any new measures is of the utmost importance. It is often the case that shore-side personnel fail to remember that crews are at the sharp end when it comes to implementation and will have to personally face the consequences of any flag state action for non-compliance following a deadline.

As ever, wIth all these changes going on in the industry, crew happiness and motivation continue to be key issues – not least when it comes to ensuring that communications between ship and shore remain good at all times and crews do not become isolated.

Meanwhile, innovative technological solutions to improve the industry’s chances of meeting the legislative deadlines are also to be found in this issue. As ever, new technological approaches are very important and can provide the solution to many of the problems facing the industry as the next wave of deadlines approaches.

We hope you enjoy this latest edition of Clean Shipping International

FROM THE EDITOR CLEAN SHIPPING INTERNATIONAL – Spring 2024 1

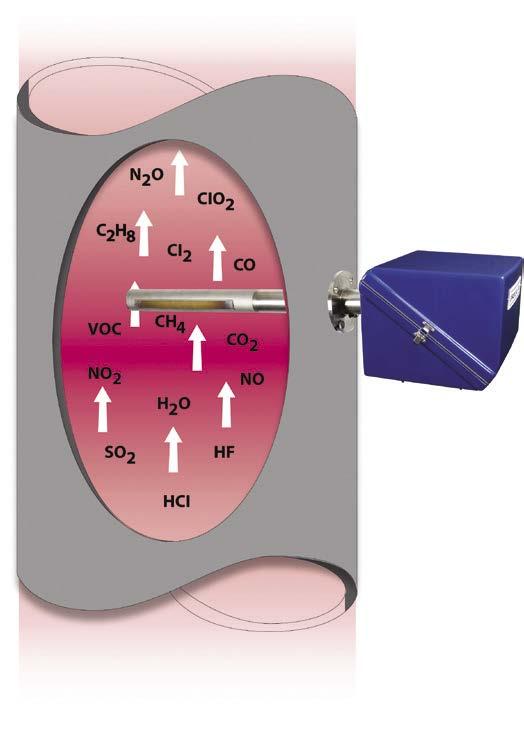

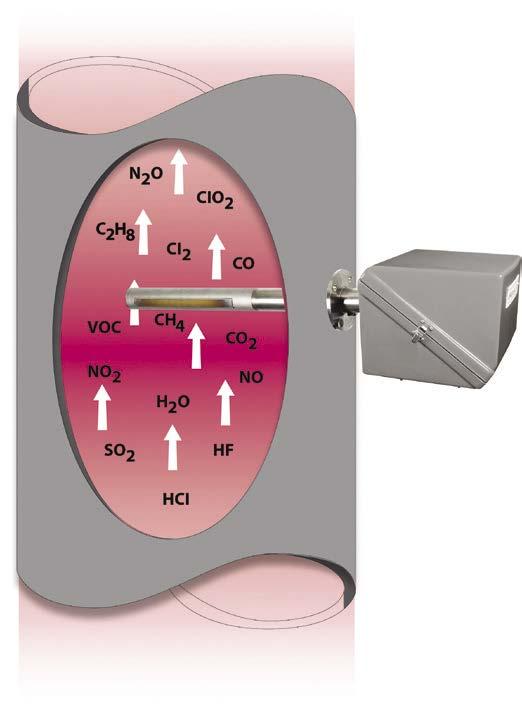

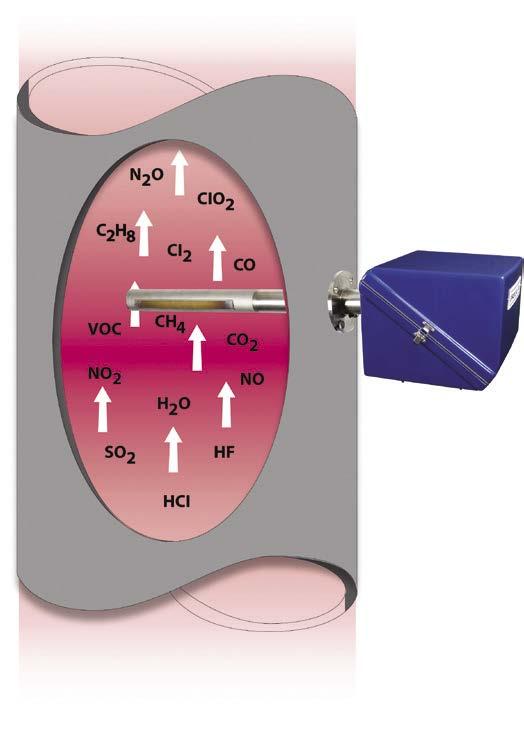

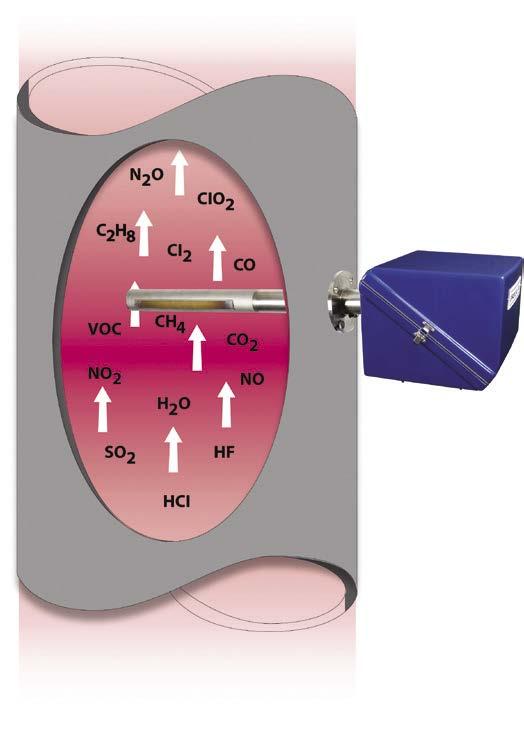

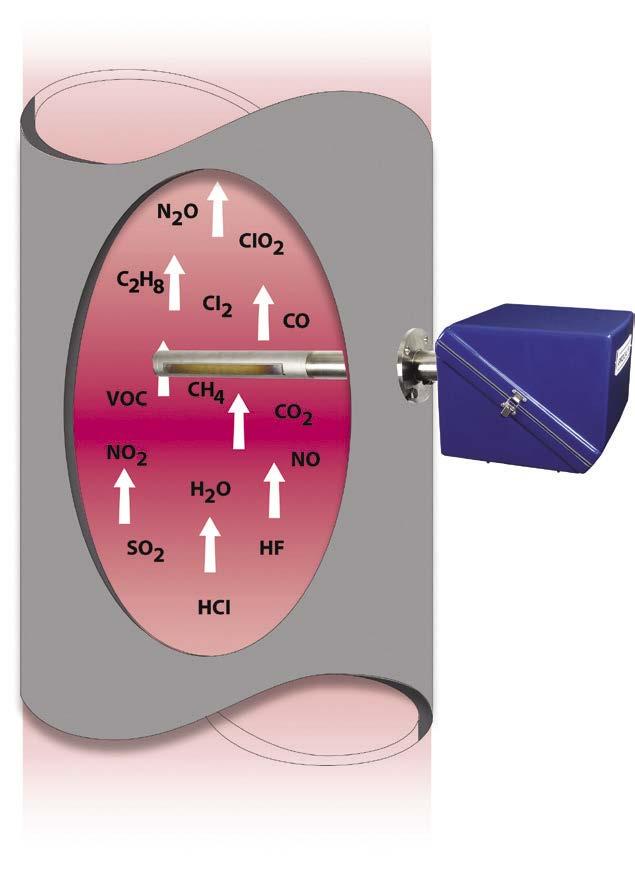

Marine Emissions Monitoring and Testing Service

Protea manufacture the equipment and supply qualified engineers to carry out the on board testing.

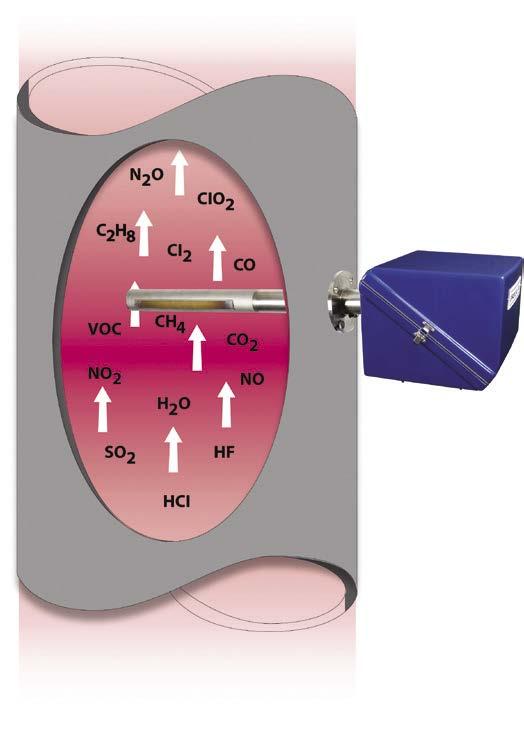

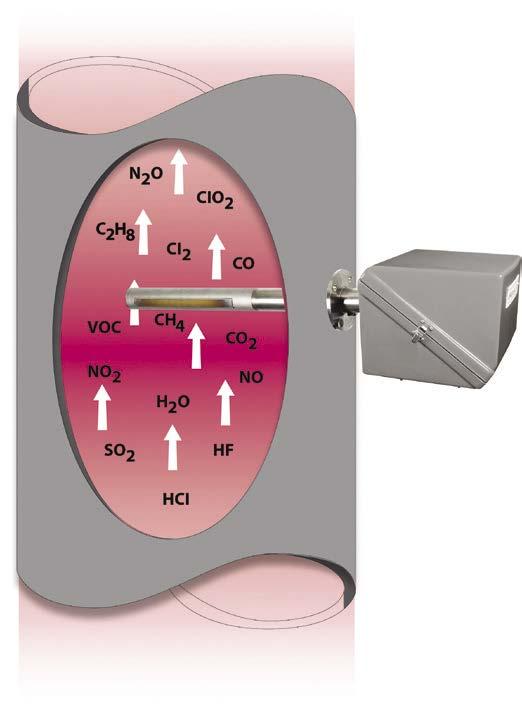

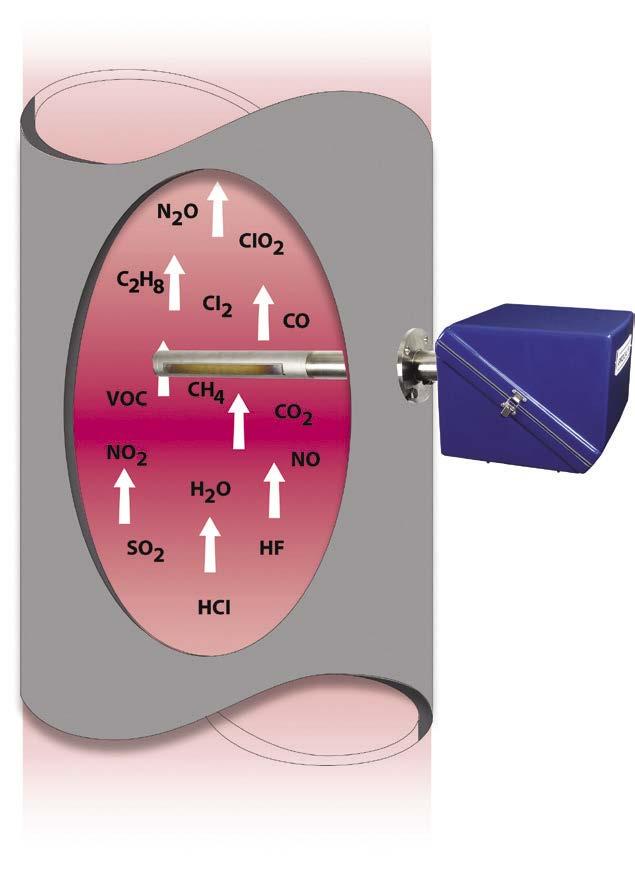

Emissions Testing using the latest Protea Transportable FTIR

• Know your ship gaseous emissions

• Verify your continous emission monitoring system

• Verify your Exhaust Gas Cleaning Systems (EGCS) performance

• Data contributes to engine efficiency checks

• Emissions Testing Continuous Emission Monitoring System

Approvals

UK Maritime and Coastguard Agency

European Commission Directive 2008/67/EC of 30th

June 2008, amending Council Directive 96/98/EC on marine equipment (4th Amendment) Annex 2, A2/2.1On board NOx monitoring and recording devices, MARPOL 73/78

Annex VI regulation 13 and the NOx Technical Code.

ATEX Protea P2000

Certficate Number:

Baseefa 18 ATEX 0060X

Markings: II 2 G Exdb IIBT* Gb

T6 Ta -20˚C – +40˚C

T4 Ta -20˚C – +60˚C

IEC Protea P2000

Certificate Number:

IECEx BAS 18.0040x

Certificate of Design Assessment Protea P2000

RINA Rules for the Classification of Ships - Part C “Machinery, Systems and Fire Protection”, Chapter 3, Section 6, Tab.1 and IMO Res. MEPC.259(68) Chapter 6 “Emission Testing” as well as the relevant requirements of Revised MARPOL Annex VI and NOx Technical Code 2008.

Lloyd’s Register - Type Approval Certificate

Protea P2000

LR Rules & Regulations for the classification of ships (July 2014) LR Test Spec No.1 (2015)

Markings: Ex db IIB T*Gb

IMO Resolution MEPC 184(59) - 2009 Guidelines for exhaust gas cleaning systems

IMO NOx Technical Code (2008)

International Association of Classification Societies

Concerning Electrical InstallationsIACS E10 Test Specification for Type

MCERTS Performance Standards for Continuous Emission Monitoring Systems Product Conformity Certificate No: Sira MC 050060/12 Sub-Brand

MCERTS Protea P2000

www.protea.ltd.uk

+44 (0)1270 872000 sales@protea.ltd.uk

Advanced Emissions Monitoring ATEX US EPA 40 CFR Part 60 & 75 Compliant European EN14181 QAL 3 Compliant Tel: +44 (0) 1733 232495 www.procal.com www.parker.com ACWn for windows Span Gas Instrument Air (Zero) Stack Gas Sub-Brand Advanced Emissions Monitoring ATEX US EPA 40 CFR Part 60 & 75 Compliant European EN14181 QAL 3 Compliant Tel: +44 (0) 1733 232495 www.procal.com www.parker.com ACWn for windows Span Gas Instrument Air (Zero) Stack Gas Sub-Brand Advanced Emissions Monitoring ATEX US EPA 40 CFR Part & 75 Compliant European EN14181 QAL 3 Compliant Tel: +44 (0) 1733 232495 www.procal.com www.parker.com ACWn for windows Span Gas Instrument Air (Zero) Stack Gas Protea Analyser Control Unit Sub-Brand Advanced Emissions Monitoring ATEX US EPA 40 CFR Part 60 & 75 Compliant European EN14181 QAL 3 Compliant Tel: +44 (0) 1733 232495 www.procal.com www.parker.com ACWn for windows Span Gas Instrument Air (Zero) Stack Gas

Editor: Sandra Speares speares1@aol.com Project Director: Jonathon Ferris jonathon.ferris@ cleanshippinginternational.com Sub-editor: Samantha Robinson sam.robinson.journalist@ gmail.com Publisher: Bill Robinson publisher@ cleanshippinginternational.com Designer: Justin Ives justindesign@live.co.uk Published by Maritime AMC, Clean Shipping International supports Clean Shipping Initiatives. The views expressed in Clean Shipping International are not necessarily those of Maritime AMC unless expressly stated as such and disclaim any responsibility for errors or omissions or their consequences or for advertisements contained in this magazine and has no legal responsibility to deal with them. Distributed to the members of CLEANSHIPPINGALLIANCE2020 cleanshippinginternational.com

Sandra Speares on why teamwork is the best way to tackle industry challenges 07

All the latest news and views from across the globe 16

An increasing number of shipowners are installing exhaust gas cleaning systems as a solution to the challenges of environmental regulation 23

Ship performance can be drastically improved with today’s state-of-the-art hull coatings, which undergo rigorous testing to achieve high standards

In an advisory risk review, Marine Mutual is warning that shipowners need to be aware of a looming BWM Convention deadline 28

The debate continues on which alternative fuels will be most effective going forward. We look at some of the approaches and viewpoints 36 TECHNOLOGY

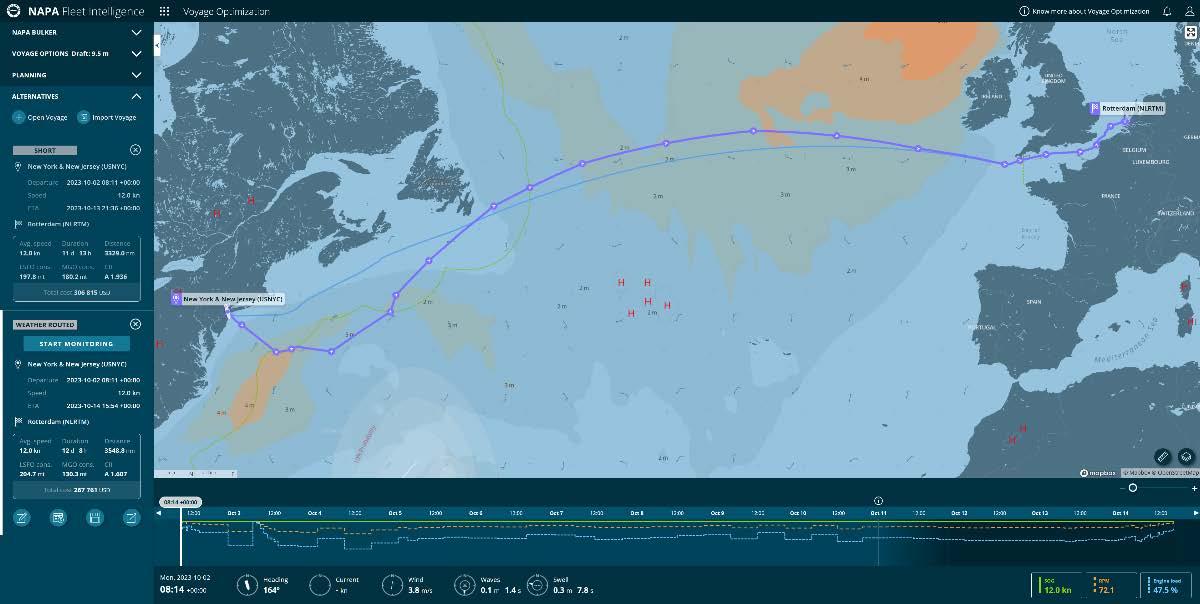

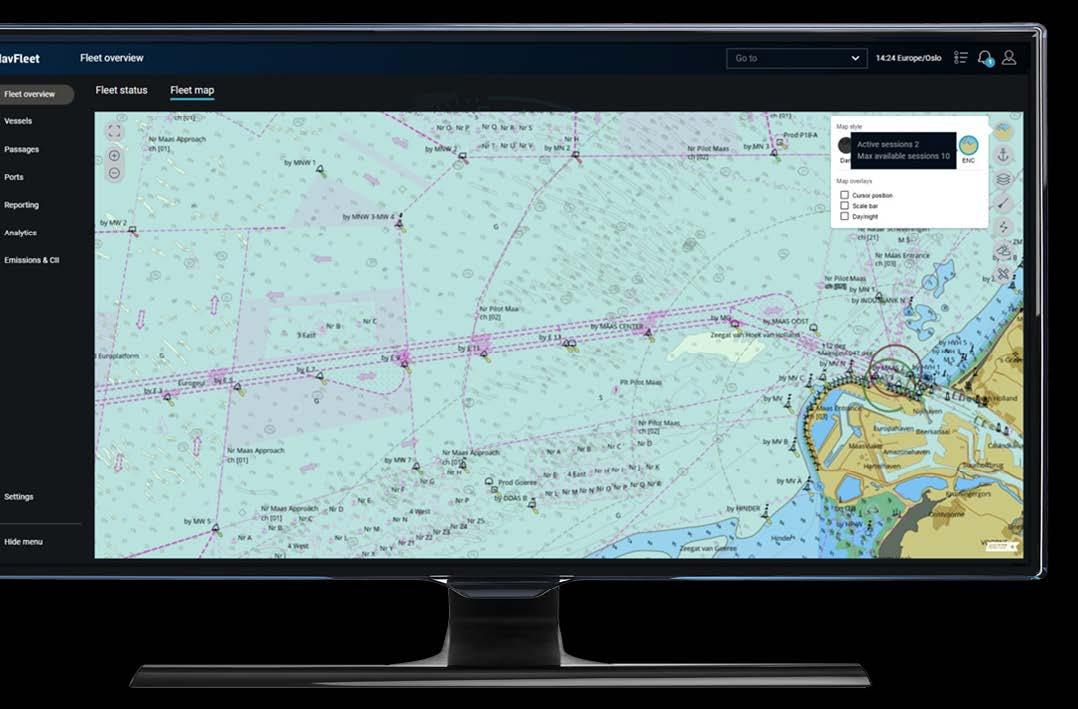

Information technology provides ever-increasing solutions to tackle environmental issues, as well as ensuring maximum efficiency of operations and safety of crew 48

A number of new designs and innovations have been revealed that improve efficiency as well as providing greener options 52

Developments in the Red Sea and other flash points are increasing fears over piracy and war risks 58 REGULATION

As swathes of environmental regulation affecting the maritime industry continue, companies warn that more preparation is needed to comply 62

Classification societies continue to guide shipowners on their net-zero journey

CLEAN SHIPPING INTERNATIONAL – Spring 2024

5

THE EDITOR

» p23 » p52 » p48 » p62

01 FROM

WELCOME Don Gregory, Director, Exhaust Gas Cleaning Systems Association 10 NEWS ROUND-UP

EGCS

MARINE COATINGS

26 BALLAST WATER TREATMENT

FUELS

ALTERNATIVE

PROPULSION

SAFETY

CLASSIFICATION

danfoss-ixa.com Scan QR code Discover more In situ SO2/CO2 CEMS: Cost-effective Continuous Emission Monitoring System Introducing the Danfoss IXA MES 1002, a revolutionary solution designed to make emission monitoring effortless for maritime operations. Our compact In situ CEMS offers real-time measurements of SO2/CO2 directly in the exhaust pipe, ensuring fast and accurate results with minimal intervention. Where Compliance Meets Innovation • Effortless Single-Unit Installation (only compressed air, data cable, and power) • Longest Calibration Interval in the market - 2 years exchange service program • Zero Drift Technology, no on-board service technician required • DNV Type Approval Certification Contact us today to learn more about our innovative solutions. MES 1002 SO2/CO2 Analyzer What If Scrubber Compliance Could Be Effortless? Compliance with MEPC.340(77) and MEPC.259(68) MARPOL Contact us: ixa @danfoss.com

Don Gregory Director, Exhaust Gas Cleaning Systems Association

Don Gregory Director, Exhaust Gas Cleaning Systems Association

THE FUTURE OF SCRUBBERS

I was recently asked by a member of the Exhaust Gas Cleaning Systems Association (EGCSA) if there was a future for exhaust gas cleaning systems? He was of the view that there would be no installations after about 2030.

In my opinion, the end of exhaust gas cleaning would be tantamount to concluding air quality no longer matters. The impacts of particulate and gaseous compounds on asthma, cardiovascular diseases and human health in general would no longer be of interest to governments and regulatory organisations.

The other presumption is that propulsion and heating on board ships will continue to be provided by combustion of fuel –whatever that fuel happens to be.

Before looking into the future of exhaust gas cleaning systems (EGCS), let us first consider the situation in 2024.

The introduction of EGCS as an alternative compliance method to the cap on the sulphur content of marine fuel enabled the International Maritime Organization (IMO) to agree at MEPC 70 to the 2020 date of entry into force of MARPOL Annex VI regulation 14. That date (2020) was five years ahead of the alternative date of 2025. The earlier date was agreed on the basis that there would be sufficient fuel available.

Consultants CE Delft had been commissioned to study the availability of lower sulphur fuel. Its report assessed a number of measures when concluding that there would indeed be sufficient low-sulphur fuel available. The key to that conclusion was that a significant portion of the fleet with high fuel consumption rates would fit EGCS and continue to use high-sulphur fuel oil (HSFO). The study also concluded that between 5,000 and 6,000 ships would fit EGCS and that group of high-consumption vessels would represent about 30% of global marine bunker demand.

In 2010, consultants Purvin and Gertz reported in a study commissioned by the EU

that in the event of a global marine sulphur cap that some 35% of global marine bunkers would be HSFO, used by ships retrofitted with EGCS.

Both the Purvin & Gertz report and the CE Delft report have proved to be correct, with more than 6,000 ships today operating EGCS. A recent email statement by Sea Intelligence reported that the containership market had reached savings of $13Bn through use of lower cost HSFO and EGCS. These vessels with high fuel consumption have enabled the re-growth of the supply of HSFO to around 30% of the total global marine bunker supplies.

I have heard statements at IMO that the large savings made by vessels fitted with EGCS has meant that the investment has been paid off and the operators are enjoying huge additional profits. This may well be true.

Transportation by sea is a key component in the world economy. Just like increased cost of energy partially creating the cost-ofliving crisis, the cost of transport, the cost of raw materials, the cost of manufacturing, and so on, all contribute.

Lowering the costs of transportation while still achieving improving environmental standards is really the only sustainable route to a global acceptance for reducing CO2 emissions. Loss of standards of living through higher costs driven by environmental regulations that often do not show any environmental benefit will, at some point, become unacceptable. So, the key to successful transition to lower greenhouse gas (GHG) emissions is one that ensures increased living standards and improves the environment.

Another CE Delft study commissioned by Alfa Laval and other European EGCS designers assessed the CO2 footprint of bunker fuels from extraction (the oil well) to propulsion (the propeller wake). The study concluded the there is a considerable amount of additional energy expended

WELCOME CLEAN SHIPPING INTERNATIONAL – Spring 2024 7

Your Trusted Partner

The Maritime Association Management Company (Maritime AMC) provides comprehensive secretariat services for trade associations operating across all sectors of the global maritime and offshore industries.

When it comes to entrusting the management of your association to a specialist services provider, we are your ideal partner.

Whether your association is a fledgling or established entity, Maritime AMC has the expertise to ensure growth, develop your association and influence regulatory and media agendas on behalf of your membership.

Our directors have extensive maritime industry and trade association expertise, with demonstrable successes in association governance, publishing, conference production and communications. We speak your language and understand the maritime world.

Maritime AMC currently provides full secretariat services to the Association of Bulk Terminal Operators (ABTO) and previously to the Clean Shipping Alliance 2020 (CSA 2020).

AMC Ltd 35 Beacon Drive, Newton Abbot

1GG

+44 (0) 1626 681103

info@maritimeamc.com

www.maritimeamc.com Maritime

TQ12

T.

E.

to produce a marine gas oil when compared with a residual fuel. In fact, the additional energy is in the range of between 10% and 20%. This means that using EGCS simply reduces the wellto-wake CO2 footprint since 2020 by at least 10%. This is a real and permanent CO2 reduction benefit, estimated to be in excess of 0.5bn tonnes of CO2 between 2020 and 2024.

A research article of the interaction of exhaust gases on human tissues was published by PLOS ONE in 2016. A leading researcher and contributor to the article, Dr Ralf Zimmermann of the University of Rostock, stated that regulating sulphur oxide (SOx) emissions was a poor decision on the part of IMO.

DRIVING FORCE

The driving force for reducing sulphur emissions was initiated in the 1990s by Scandinavian states, on the grounds of acid rain. However, the main contributor to acid raid was land-based sources and not ships. Dr Zimmermann believed that the IMO should have had a focus on particulate matter, which is damaging to human health.

Some of the University’s research identified that the exhaust gas from marine gas oil combustion resulted in a stronger adverse effect on human tissue than that of exhaust gases from HSFO after scrubbing. The studies were intended to replicate the human ingestion of gases deep into the respiratory system.

It is therefore probably likely that the new blends of very low sulphur fuel oil and ultra low sulphur fuel oil will have even more adverse reactions. If this is the case, then the 2020 regulation that capped fuel sulphur content may be having an unexpected and more detrimental effects on human health in ports and harbours.

To date, the IMO has only partially regulated emissions of SOx and nitrous oxides and has completely failed to regulate the many other emissions, gaseous, condensables and solids, discharged into the air from combustion plant exhausts on board ships. Of these discharges the two key elements that affect

climate change are black carbon (BC) and CO2

BC has been discussed ad nauseum for more than 10 years at IMO. The latest progress, if that is what it can be called, is a set of documents in which ships can set out plans to reduce BC emissions. It remains an unregulated emission.

CO2 has been dealt with in a number of ways, of which perhaps the most effective has been to reduce fuel consumption. This has had the double benefit of reducing operating costs. A win all round. There are limits to what further reductions can be achieved with propulsion and hull design and operation.

Alternative fuels are hyped as the next-step solutions. But as ever these are not ‘silver bullet’ solutions.

Biofuels come with a range of operating risks and are significantly more expensive than current fossil fuels. The consequences of 300Mt of biofuel serving the marine bunker market in terms of environmental damage is only considered as fringe prohibitions of certain sourcing, but with no real teeth to ensure adequate enforcement.

Methanol-ready ships make a great headline – but below the headlines there is a paucity of commitment peppered with a lot of aspiration. These are multi-fuel investments that may never be operated with nethanol before the ships go for scrap!

At MEPC 81, IMO seems to have at last accepted the principle of on board carbon capture (OBCC). In fact, the Intersessional Greenhouse Gas Working Group (WG) asked that the topic be put in the hands of the Air Pollution WG.

OBCC could enable a reduction in CO2 emissions by 40% by 2030 –and might even possibly reach 50% reduction. Being at last acknowledged as a possible route to significant CO2 reduction, it still is a challenge in a time frame of only six years to 2030.

The capturing of CO2 is a mature technology already used for decades in the oil and chemical sector. However, on board ship the challenge will be storage. Every tonne of fuel burned

creates about 3.2 tonne of CO2. It is a gas, so in addition to the mass challenge, there is a volume challenge.

Land-based technology for storage is mature and should be able to be ported to shipboard applications dependent upon space constraints and energy requirements.

Where do EGCS fit into an OBCC solution to reducing GHG emissions from shipping?

The most common Carbon Capture systems utilise amines, which readily dissolve CO2. The CO2 is later released from solution and the amine recycled to capture more CO2. It is critical that the solvent liquid is not polluted with soot, oil and other compounds and solids. In other words, pre-treatment of the exhaust gas is required.

Conventional wet or dry EGCS technology is effective in removing SOx, but is only partially effective in removing fine and ultra fine particulate matter and other pollutant compounds.

THE SOLUTION NEEDED

Advanced gas cleaning (AGC) technology provides the solution needed. The earliest marine application of AGC was through an EU-funded project in 2011. Known as the DEECON project, a €4M programme over three years demonstrated that using a wet electrostatic gas cleaning system reduced the water consumption to 20% of normal EGCS systems and produced extremely high efficiency removal of soluble gases and solids from a diesel engine exhaust.

The pollutants were more concentrated in the process water and therefore easier to remove and the smaller volumes of water reduced the capital cost and the operating cost of the AGC system.

The AGC system will be essential in the application of OBCC. The AGC technology has now been trialled on board a ship in the Baltic Sea and also on board a ship in the Mediterranean Sea.

Readers can make their own conclusions regarding the future of scrubbers – albeit that AGC is the evolution to gas cleaning and recycling.

WELCOME CLEAN SHIPPING INTERNATIONAL – Spring 2024 9

Maritime issues are top of the agenda across Europe, with new regulations taking effect – but the industry is advancing towards its net-zero ambitions

GLOBAL NEWS ROUND UP

UK freight forwarders have welcomed the news that the UK’s Competition and Markets Authority (CMA) will not recommend to the Secretary of State for Business and Trade that the current Consortia Block Exemption Regulation (CBER) be replaced by a UK equivalent when it expires on 25 April 2024.

The CMA conducted a robust analysis of the deep sea container shippingmarket, investigating several scenarios, and concluded in November 2023 that the conditions did not warrant the continued existence of a CBER for UK maritime movements – the same view had already been reached by the European Commission.

Second opinions were invited by the CMA and the British International Freight Association (BIFA) did provide some additional information to support its original arguments. The CMA has now upheld its original decision concluding that selfassessment is the best and most effective way for shipping lines to co-operate.

Steve Parker, director general of BIFA

says: “The decision confirms the provisional recommendation made by the CMA in November 2023 and is a sensible conclusion to the ongoing container market public consultation that has been conducted by the CMA since the start of last year.”

In the recent past, the UK’s main trade association for freight forwarding and logistics companies has said that its members are extremely concerned that practices undertaken by container shipping lines, as well as easements and exemptions provided to them, have been distorting the operations of the free market to the detriment of international trade, businesses and consumers.

“While this regulatory change, if implemented, will not end shipping line consortia and alliances, it will allow greater and ongoing scrutiny of such arrangements; and ensure that the lines will be subject fully to competition law. That will be welcomed by BIFA and its members and we call on the Secretary of State for Business and Trade to uphold the Agency’s decision.”

NEWS CLEAN SHIPPING INTERNATIONAL – Spring 2024 10

MARINE MEETING MAKES PROGRESS

Environmental issues have topped the agenda at the International Maritime Organization (IMO) recently where new guidance was agreed on several different issues.

Meeting from 19-23 February, 2024 at IMO’s headquarters in London, IMO’s Sub-Committee on Pollution Prevention and Response (PPR 11) made progress in a number of areas, for submission to the Marine Environment Protection Committee for approval. These included:

» the safe transport of plastic pellets by sea

» best practices for cutting Black Carbon emissions from ships operating in or near the Arctic

» reducing risks of use and carriage for use of heavy fuel oil (HFO) as fuel by ships in Arctic waters

» developing local contingency plans for spills or pollution involving oil or hazardous and noxious substances

» controlling nitrogen oxide emissions.

INDUSTRY ADVANCES TOWARDS TARGETS

In an insight piece by Lloyd’s Register (LR) (tinyurl.com/ CSI-LloydsInsight), the class society says that the industry is closely evaluating ordering, fuel and technology options now that there is greater clarity on global emissions reduction targets, carbon pricing and performance measures.

After a year in which decarbonisation regulations were agreed to be sharpened at both International Maritime Organization (IMO) and European Union (EU) level, the maritime industry advanced significantly towards meeting its long-range emissions targets in 2023, according to LR’s analysis of vessel ordering, technology and fuel developments.

At MEPC 80 in July, the IMO agreed a revised greenhouse gas (GHG) emissions reduction strategy with an ultimate goal of phasing out GHG emissions by or around 2050. The first ‘indicative checkpoint’ on that path will be 2030, by which time the IMO strategy calls for a 20%, striving for 30%, reduction in total emissions (based on 2008 numbers) as well as zero- or near-zero carbon fuel use representing 5%, striving for 10%, of total shipping energy use.

Last year also saw the entry into force of new rules facilitating shipping’s inclusion in the EU Emissions Trading System (ETS) – under which emissions on voyages to, from and between ports in the European Economic Area (EEA) will be subject to carbon pricing from 2024 – and FuelEU

Maritime, placing financial penalties on ships using EEA ports if they fail to meet stepped energy intensity reduction targets from 2025. Analysis from LR in March showed the quickly mounting costs these measures will impose on fleets, as well as some of the innovative strategies that will be needed for owners to reduce their exposure.

With the combination of global emissions reduction targets, carbon pricing and performance measures now in place, the dynamics of ship ordering, technology development and fuel supply are shifting rapidly. With just 27 methanol-capable vessels currently in service, 143 new construction orders were placed in 2023, which including previous orders will take the methanol-capable fleet to 227, according to data from Clarksons.

MORE ON ADMINISTERING AUTHORITIES

Since 1 January 2024, the maritime sector has been included in the EU Emissions Trading System (ETS). For shipping companies to be able to report annual emissions as per EU ETS requirements, an administering member state must be appointed. This member state is known as the shipping company’s Administering Authority (AA).

The European Commission has now published Implementing Decision 2024/411. This lists the attributed AA for shipping companies based on information available in THETIS-MRV and the European Union maritime information and exchange system (SafeSeaNet) on 20 November 2023.

For any non-EU registered shipping companies not included in the above list, which own ships that have made a voyage to a European Economic Area (EEA) port since 1 January 2024 and fall into the scope of EU ETS, or which have had responsibility for ETS compliance contractually mandated to them as the ISM DOC holder, the AA shall be (as per EU 2023/2599) either:

The member state from which the first voyage by one of their ships in scope of EU ETS started or finished; or

In the instance where two or more member states had the equal highest number of port calls by their ships in scope of ETS, the AA will be first port call to the member state with the joint highest port calls in scope of ETS.

More information is available on LR’s ETS website pages on ETS, including maritime operator holding account s and the Union Registry, as well as key compliance dates. Vist: lr.org

SUSTAINABILITY REVOLVES AROUND SAFETY

Future sustainability of the sometimes fragile global supply chain must revolve around a fundamental safety culture throughout all operators and organisation involved, according to International freight and cargo handling insurer TT Club.

“The importance of culture within an organisation, particularly where safety is concerned cannot be underestimated,” says TT’s logistics risk manager Josh Finch. “Safety is everybody’s responsibility and everybody has a voice in safety matters. A strong safety culture will positively impact safety performance.”

In an increasingly risk-intense global supply environment, a greater emphasis on safety will help avoid critical incidents

NEWS CLEAN SHIPPING INTERNATIONAL – Spring 2024 11

IMO’s Sub-Committee on Pollution Prevention and Response (PPR 11)

such as fire, cargo damage and vessel loss, which further exacerbate shortages, congestion and human suffering. This message pervades the loss prevention work of TT and is exemplified in a wide variety of studies and reports published in the insurer’s latest review of current and on-going risk trends – A Year in Focus

“TT has recently witnessed a renewed focus and commitment towards loss prevention activities, with additional emphasis placed on the Club’s mission statement to make the industry safer, more secure and more sustainable,” comments loss prevention managing director Mike Yarwood. “Greater safety goes hand-in-hand with enhanced security and consequently sustainability. TT’s mutual ethos demands that we guide those we insure – and indeed the wider industry – in all aspects of risk through the container transport and global logistics supply chain. Via our latest Year in Focus we aim to add to the large cannon of knowledge and guidance.”

AMBREY AND INCHCAPE JOIN FORCES

Ambrey and Inchcape Shipping Services (ISS) have announced a strategic partnership aimed at transforming safety and security in the maritime sector. This groundbreaking collaboration combines cutting-edge technology, global presence, and unmatched expertise to enhance safety measures and drive improved commercial outcomes for the industry.

Through this partnership, Ambrey and Inchcape will jointly offer a comprehensive range of proven and accredited services via Inchcape’s dedicated Survey and Inspection Department, led by vice president Chris Greenwood, including citadel inspections, ship security assessments, anti-piracy ship security assessments, ship security plan reviews, and port security assessments on various projects worldwide. This synergy will enable the maritime industry to bolster safety protocols, enhance operational efficiency, and address potential risks.

DECARBONISATION GROWTH AT NEWPORT

Associated British Ports (ABP) recently announced ambitious plans for the Port of Newport, to support a new era of green growth for the port and the city of Newport.

The company’s ambitions for the Port of Newport are to build on its classic port business to become a cleanmanufacturing and logistics growth cluster, ready for the next industrial age.

ABP’s plans centre around renewable energy, including a focus on harnessing wind and solar sources, linked to hydrogen electrolysis and e-fuels manufacturing plants. It is hoped that these facilities, along with carbon capture and heat networks, will underpin next-generation manufacturing and logistics, attracting a new cluster of businesses looking to future-proof their operations.

Development at the port will also be connected to the rail network and marine logistics, with the ambition of hundreds of highly productive jobs created at the resulting Newport clean growth hub. This will create benefits right across the city and beyond.

While the plan includes innovations to support businesses to future-proof and meet net zero targets, the classic port role will remain. ABP will also be investing in reconfigured access, new cargo-handling equipment, high-efficiency warehousing and ready-to-go development sites, and all with cutting-edge IT.

Ashley Curnow, divisional port manager, ABP, comments: “This masterplan is a bold step towards a sustainable future. Newport has a history of reinvention, and we are embarking on a journey to position both the port and the city of Newport as key players in the evolution towards a decarbonised economy.

“The masterplan foresees a decade-long investment boom, which will help provide superb service to customers, as well as delivering ABP’s commitment, as set out in our sustainability strategy – Ready for Tomorrow – to get our own operations to net zero by 2040.”

CAMPAIGN GROUP CALLS FOR GREEN FOCUS

The announcement of the EU’s plan to reduce its emissions by 90% by 2040 marked a historic day for the climate. But, the announcement makes no mention of a phase-out of oil and gas, even though this is imperative to meet the target, says campaigning lobby group Transport and Environment (T&E) lobby group.

Last December, the COP28 agreement committed to transition away from fossil fuels. The EU played an essential role in getting this language adopted, stating clearly it would get rid of unabated fossil fuels. Yet the Commission’s new communication still projects 46m tonnes of oil equivalent (Mtoe) of unabated oil and gas generation, which it says will mostly be used for long distance transport in 2050. That would be enough to continue powering 900,000 transatlantic flights, adding a needless 140m tonnes of CO2 in the atmosphere, the group says.

“The EU has shown the world how you can turn real climate ambition into powerful industrial policy. Industry players at home and outside of Europe can turn to the EU for production and sales of green tech, as they can be assured of a growing market and predictable demand. But this headline goal will fall flat if it doesn’t come hand in hand with a phase out of fossil fuels and new laws cracking down on the oil majors. Europe will desperately try to meet a 2040 goal whilst still feeding on fossil fuels. But you simply can’t outrun a bad diet”, Sofie Defour, climate director at T&E, explains.

“The flaws and loopholes in the text are all fixable. The EU shouldn’t undermine its own effort to slash millions of tonnes of CO2 by caving into the pressure of a handful of polluting industries. It’s time to put an end to uncontrolled growth and profit of transport’s biggest polluters and instead focus on helping them go green by 2040,” Defour concludes.

GAC OPENS SOUTH KOREAN OFFICE

GAC Group, a leading provider of shipping, logistics and marine services in the Asia-Pacific market, has opened its first office in Seoul in a strategic move which underscores its commitment to strengthening operations to serve the growing, dynamic South Korean market.

NEWS CLEAN SHIPPING INTERNATIONAL – Spring 2024 12

South Korea’s shipping industry accounts for more than 10% of global maritime trade. Exports from the country are set to rise by 7.9% in 2024 to reach US$680bn, according to forecasts by the Korea International Trade Association, while imports are expected to grow 3.3% in the same period.

“We see great potential for growth in the Korean market and are committed to expanding our services while seeking synergies with our operations in the region,” says Daniel Nordberg, GAC’s group vice president – Asia Pacific & Indian Subcontinent.

South Korea is looking to tap into renewable offshore wind energy to meet its net-zero targets. It aims to install 14.3 GW of offshore wind by 2030, which is expected to attract a large amount of investment in South Korea’s supply chain to bolster its renewable efforts over the coming years, GAC says.

While the company’s core focus is on ship agency and related shipping services, including dry docking support, husbandry and crew change services, the new office also enables it to respond to presents exciting opportunities arising in the renewable energy field, particular offshore wind energy.

ABP FILM SNAPS UP AWARD

The Voyage, a sustainability film created by Associated British Ports (ABP) in collaboration with creative agency, Polar Media, has won Bronze in the ‘Best Animation’ category at London’s prestigious Lens Awards.

Created by ABP, the UK’s largest port operator, the film helps tell the story of ABP’s sustainability journey and celebrates the launch of the company’s first ever sustainability strategy ‘Ready for Tomorrow’. With a female protagonist, the film invites audiences to see the world through the eyes of a woman who progresses through different stages of her life and maritime career, whilst witnessing and helping deliver various green energy infrastructure projects enabled by ABP’s ports.

She travels from Immingham up on the Humber, where she sees the growth of green hydrogen and carbon capture and storage to Port Talbot in Wales, where the exciting floating offshore wind industry is in bloom. Along the way, she meets different animals from a seal to kittiwakes, all serving as a reminder that industrial progress needs to go hand in hand with protecting biodiversity to create a sustainable future.

CLEAN SHIPPING INTERNATIONAL – Spring 2024 NEWS 13

dphilibert @croceanx.com BUILT TO SCRUB ENGINE EMISSIONS CROE® MARINE SCRUBBERS CR Ocean Engineering • Six Campus Dr Parsippany, NJ 07054 USA 2024_CROE_CleanShippingInternational_HalfPgAdvert.indd 1 2/8/24 8:55 AM

DANFOSS IXA: LEADING MARITIME EMISSIONS MANAGEMENT

In today’s maritime sector, the imperative to reduce emissions and enhance sustainability is essential. Danfoss IXA, a subsidiary of the Danfoss Group, is pioneering solutions that revolutionise emissions management in the industry, with a focus on advanced analyzers for precise environmental monitoring.

MES 1002 SO 2/ CO 2 ANALYZER

One such groundbreaking analyzer is the MES 1002, designed specifically for scrubber applications. This SO2/ CO2 analyzer is a testament to Danfoss IXA’s commitment to innovation and addressing industry-specific needs. Highlighting its features:

» Longest calibration intervaltwo-year exchange service programme: The MES 1002 has the longest calibration interval in its class, with a convenient two-year exchange service programme.

» Continuous reference spectra setting – no on-board service technician required: With innovative zero drift technology, the MES 1002 eliminates the need for an on-board service technician. This advanced feature ensures accurate and stable measurements over time, providing peace of mind to operators and streamlining maintenance processes.

» DNV type approval certification: The MES 1002 holds DNV type approval certification, confirming its compliance with industry standards and regulations. This prestigious certification underscores the analyser’s reliability, accuracy, and suitability for maritime applications.

» Effortless single-unit installation: Installation of the MES 1002 is effortless thanks to its singleunit design. This streamlined installation process saves time and resources, allowing vessel operators to quickly integrate the analyser into their emissions management system.

Pioneering solutions that revolutionise emissions management

COMPANY PROFILE CLEAN SHIPPING INTERNATIONAL – Spring 2024 14

You can request tailored training or webinars for you and your team, designed to enhance your understanding and utilisation of Danfoss IXA’s advanced analyzers and solutions. Visit our training portal at: https://danfoss-ixa.com/training/

EMISSIONS COMPLIANCE

Danfoss IXA’s analysers are engineered to meet the rigorous demands of emissions compliance regulations, offering accurate measurements of pollutants such as nitrogen oxides, sulphur oxides, and carbon dioxide (CO2). By providing real-time data on emissions levels, operators can ensure adherence to regulatory requirements and proactively address any deviations.

INDUSTRY COLLABORATION

Danfoss IXA actively collaborates with industry stakeholders and regulatory bodies to drive innovation and shape sustainable practices within the maritime sector.

Through partnerships and knowledge-sharing initiatives, the company contributes to the development of industry standards and best practices for emissions monitoring.

ABOUT DANFOSS IXA:

Danfoss IXA, an innovative force within the Danfoss Group since April 2009, leads the way in the maritime industry in cutting-edge exhaust emission monitoring solutions.

We develop state-of-the-art exhaust emission monitoring solutions to the maritime industry.

Danfoss IXA is dedicated to creating a more sustainable shipping industry.

For more information, visit: danfoss-ixa.com

Contact us: ixa@danfoss.com

Cutting-edge exhaust emission monitoring solutions

COMPANY PROFILE CLEAN SHIPPING INTERNATIONAL – Spring 2024 15

MEETING THE CHANGES

As the industry aims to ensure it is up to date with new environmental demands, an increasing number of shipowners are installing scrubbers as a solution to the challenges

What role will exhaust gas abatement systems have as the industry moves towards decarbonisation during the coming years? Wärtsilä exhaust treatment’s director, sales, Kashif Javaid, recently gave his views on the benefits of scrubbers going forward, stressing the importance of using multiple technologies to tackle the issues, including carbon capture and storage (CCS)ready scrubbers in tandem with CCS units going forward.

Scrubbers have always been one means of attempting to balance compliance with new regulations and profitability and Javaid says it is critical to ensure that existing ships are dealt with during the path to decarbonisation. “It will be too expensive and logistically unfeasible to recycle and replace the current merchant fleet wholesale, and many vessels built 10 years ago may have to last through to 2035 or possibly beyond, dealing with considerable regulatory change in the interim period,” he says in an opinion piece on the Wärtsilä website.

The solution, he believes, is to adopt proven technology that can be used for the existing fleet over the next few years, and avoid scrapping vessels that still have a working life ahead of them but need to be compliant with new regulation.

“Favourable economics towards scrubbers create a strong case for implementing a retrofit strategy. As has been well documented, shipowners who invested in scrubbers prior to the 2020 global sulphur cap are enjoying a competitive advantage. There are few signs that this will abate, with payback models demonstrating currently that returns can be made in months, which creates a huge driver for continual uptake of exhaust gas abatement solutions,” he says.

Also, he says: “Beyond tackling sulphur oxides, scrubbers have now become a platform from which multiple technologies are working together in the stack and throughout the exhaust chain. This includes tackling nitrogen oxide emissions by adding selective catalytic reduction systems or exhaust gas recirculation systems to ensure

EXHAUST GAS CLEANING SYSTEMS CLEAN SHIPPING INTERNATIONAL – Spring 2024 16

compliance with MARPOL Tier III requirements. In addition, scrubbers can reduce particulate matter 2.5 levels below even standard landbased requirements and a filter can be applied to capture microplastics.

“Most excitingly, scrubbers can now provide the basis of carbon capture and storage systems – underlining the modern scrubber’s position as a multiuse technology platform,” he says.

“With the International Maritime Organisation’s carbon dioxide (CO2) reduction timelines set for 2030 and 2050, and the European Union’s Emissions Trading System putting a price on CO2 from ships from 2024, low-carbon, alternative fuels will represent only a small single digit fraction of the global fleet’s fuel of choice over the next decade.”

SCRUBBERS IN ACTION

Leading tanker shipping company Stena Bulk has recently announced the latest expansion of its fleet with new long-term charter agreements for four state-of-the-art newbuild eco medium range (MR) tankers.

Two of the vessels, Stena Continent and Stena Conquest, will be delivered from Hyundai Mipo by the end of 2025. Two further eco MR tankers, Stena Contender and Stena Concept, will follow in 2026. All vessels are set to use the South Korean yard’s latest eighth generation MR tanker design, which has been recognised for its efficiency performance.

The tankers will have top-of-theline fuel consumption, consuming just 15 metric tons of fuel per day when laden at 13 knots. This efficiency will help to underpin Stena Bulk’s commitment to environmental sustainability while maintaining optimal performance. The vessels are also scrubber fitted to ensure global sulphur cap compliance.

Stena Convoy and Stena Conductor were delivered in 2022 to a South Korean yard and chartered from a Japanese owner, like these new additions to the Stena Bulk fleet. When they were delivered, Stena Convoy and Stena Conductor became the most fuel-efficient MR tankers at sea, the company claims.

Taking six long-term charters in total from Japan into the Stena

Bulk fleet underscores the country’s importance to the organisation’s longterm and flexible fleet strategy.

Erik Hånell, president and CEO of Stena Bulk, comments: “Our long-term fleet expansion strategy always requires us to act flexibly and intelligently with the best interests of our customers at the forefront. The current landscape of costly short-term time charters means we need to think differently, which is why we are proud to sign these four long-term newbuild charter deals.

The sustainability performance of these vessels will help to underpin our sustainability strategy

“The market-leading sustainability performance of these vessels will help to underpin our sustainability strategy, but the stability that these long-term deals afford will create assurance for our customers globally.

“We look forward to continuing to work pragmatically in the coming months and years, leaving no stone unturned in our pursuit to create a truly market leading tanker fleet.”

INSIGHT INTO MARKET

Bosson Research has recently published Global Ship Exhaust Gas Cleaning System Market, which is available for purchase.

The global ship exhaust gas cleaning system market size was estimated at $5,274.04m in 2023 and is projected to reach $9,343.28m by 2029, exhibiting a compound annual growth rate of 10% during the forecast period.

This report provides an insight into the global ship exhaust gas cleaning system market, covering all its essential aspects.

This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, strengths, weaknesses, opportunities and threats analysis, Porter’s five forces analysis, value chain analysis, and so on.

The analysis considers the competition within the industries and looks at strategies for the competitive environment to enhance the potential profit.

The report structure focuses on the competitive landscape of the global ship exhaust gas cleaning system market, this report introduces in extensive detail the market share, market performance, product situation, operation situation, and so on of the main industry players, which helps the readers in the industry to identify the main competitors and the competition pattern of the market.

The research report includes specific segments by region (country), manufacturers, type and application. Market segmentation creates subsets of a market based on product type, end-user or application, geographic, and other factors.

By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies.

Market segments can power product development cycles by informing how you create product offerings for different segments.

The report costs $3,000 and is available from: bossonresearch.com.

EXHAUST GAS CLEANING SYSTEMS CLEAN SHIPPING INTERNATIONAL – Spring 2024 17

Erik Hånell, President & CEO of Stena Bulk

PURETEQ: SCRUBBERS’ CRUCIAL ROLE IN GREEN FUEL TRANSITION

The scrubber market is experiencing a resurgence due to uncertainties surrounding the availability of green fuel.

Predicting the type of fuel that will power ships has become nearly impossible, leading renowned shipowners to seek secure capacities. However, only a fraction of the needed capacity appears to be available in the foreseeable future. In the interim, ships must prioritise securing their seaborn logistics.

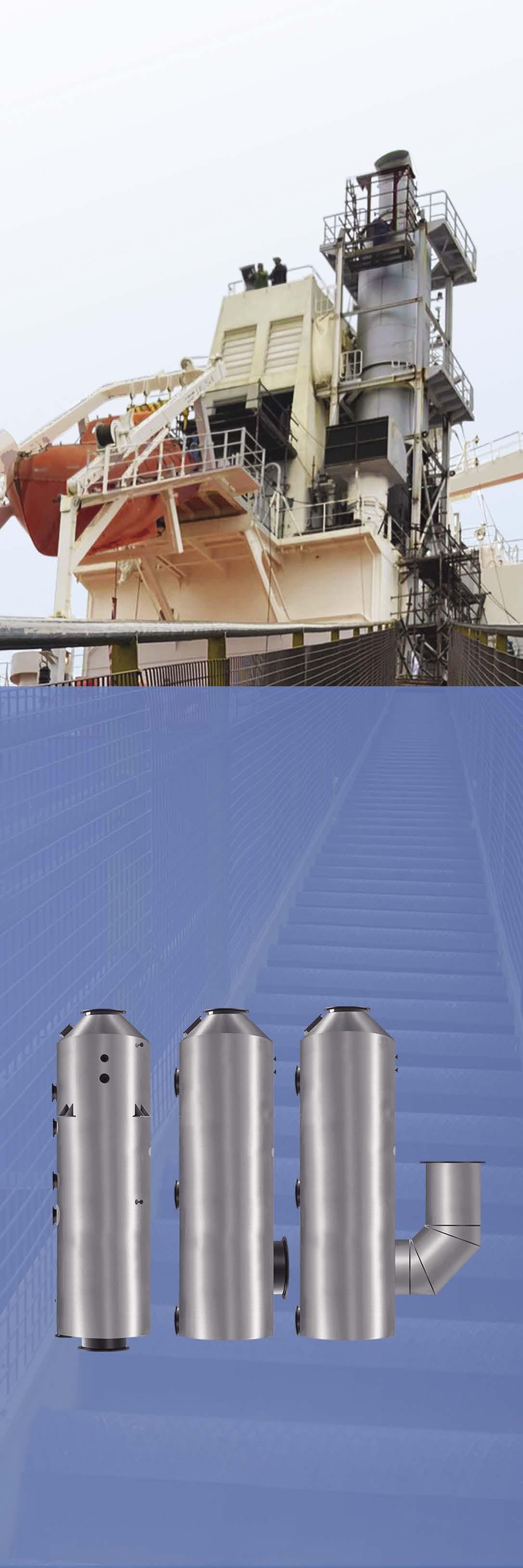

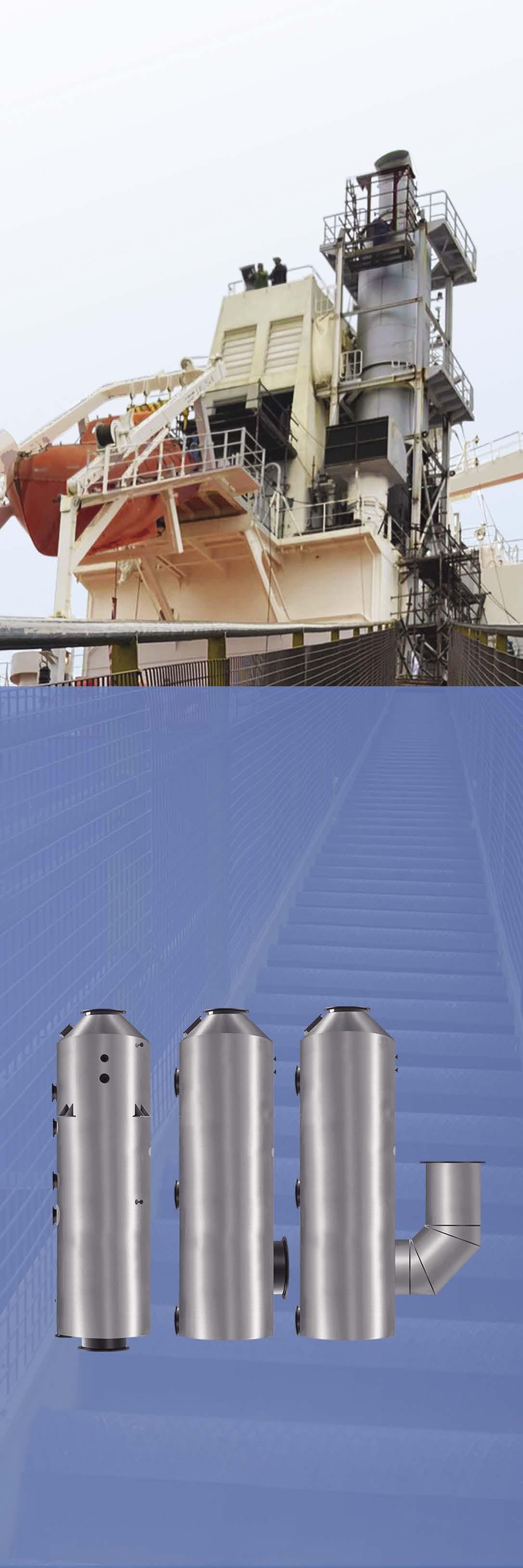

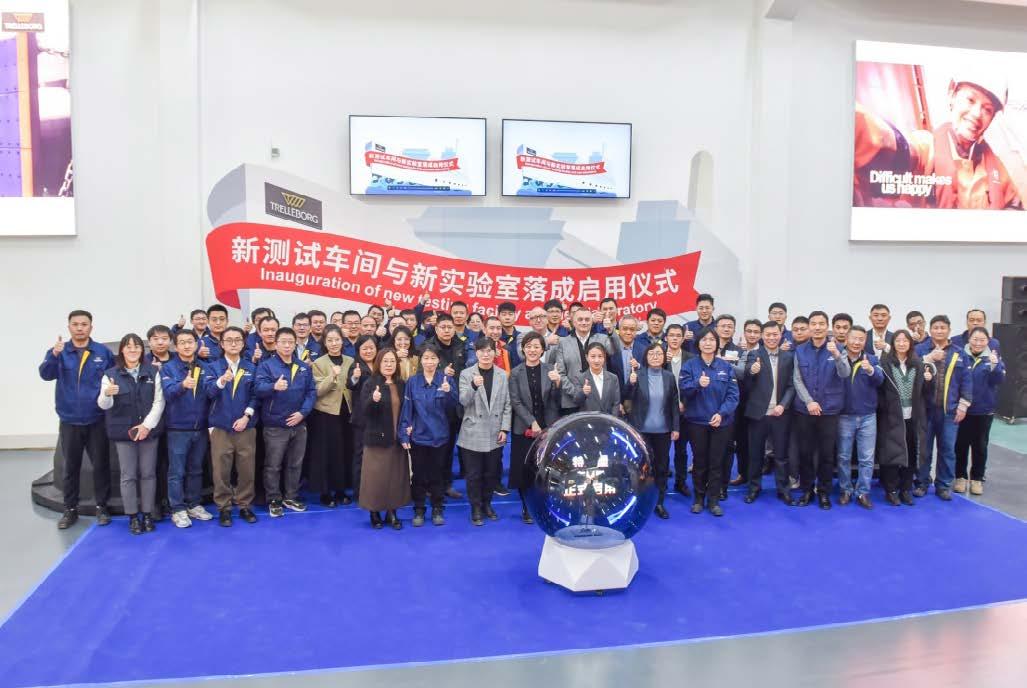

Taking advantage of the competitive situation in the scrubber market is MT Maritime and MTM Shipmanagement, which have successfully completed the installation and commissioning of their second scrubber from PureteQ on their vessel, the MTM New York

This step follows the successful installation and commissioning of the

company’s first hybrid-ready scrubber system from PureteQ on the MTM New Orleans a few months ago. The second installation was carried out under the continued stewardship of the shipowner’s representative and technical director, Prashant Lokhande, at the same Chengxi Ship Building and Repair yard in China.

PURETEQ HIGHLY RECOMMENDED

Lokhande, managing this project, recommended PureteQ as the scrubber system maker and project partner based on several crucial selection criteria: the system had to be optimised for fast installation to minimise shipyard time; be the most energy-efficient on the market; possess an advanced control system with real-time remote access and onboard

analytics; requiring minimum changes, if any, to the existing vessel structure; and offer professional and costeffective service and spares throughout the asset’s lifespan.

Quality was absolutely paramount, considering that a scrubber is a significant investment meant to outlast the vessel. The system design also needed to be suitable for upgrade to a hybrid/closedloop system to meet more stringent legislations expected in the future, and aftersales service had to be available globally to ensure compliance and optimisation.

The final requirement was reasonable CAPEX and minimum inservice OPEX cost projected over the first 10 years of the system’s life.

The chosen scrubber from PureteQ fulfilled all the above requirements.

A SIMPLE SOLUTION TO A GLOBAL CHALLENGE

COMPANY PROFILE CLEAN SHIPPING INTERNATIONAL – Spring 2024 18

Deck house where sensitive equipment and PureteQ’s outdoor U-type scrubber tower are placed

INCREASING ENERGY EFFICIENCY

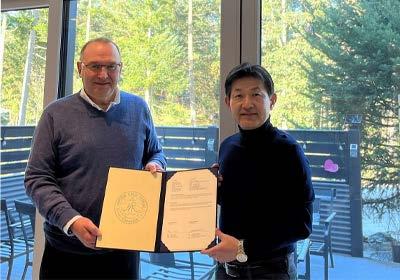

PureteQ’s scrubber system was issued a type approval certificate from Class NK and commended for its automated control and monitoring systems that reduce the need for human intervention to the bare minimum.

Installation of these scrubber systems will not only reduce fuel costs, but also substantially reduce the emission of carbon particulate matter and black carbon, also emitting less CO2 well-to-wake as a side benefit. The PureteQ system is partly carbon capture ready and may thus be upgraded later if feasible and infrastructure for captured carbon is made available at major trading ports on a worldwide basis.

“It is early days,” says Lokhande. “Assessment needs more time in service. However, both scrubber systems are performing as intended, and operations have been trouble-free. While a few glitches did occur during installation, commissioning and final certification post-commissioning went well. Overall, the owner’s choice of PureteQ as makers has proved to be satisfactory.”

MTM New York is presently at sea between Singapore and Porto De Suape in Brazil with the scrubber in operation and saving fuel costs for the owner.

Anders Skibdal, CEO of PureteQ, is proud of being selected by MTM Shipmanagement and looks ahead to possible more retrofits: “We look forward to collaborating with MTM Shipmanagement in the future, not least to help them increase their ships’ energy efficiency and thereby minimise their carbon footprint.”

For more information, contact:

Anders Skibdal, CEO PureteQ Group A/S

Tel: + 45 4017 1400

Email: anders@pureteq.com pureteq.com

COMPANY PROFILE CLEAN SHIPPING INTERNATIONAL – Spring 2024 19

Installation of PureteQ scrubber tower

PureteQ’s maritime scrubber systems can support ships of any size or trade pattern and now come as onboard carbon-capture-ready scrubbers

CR OCEAN: LEADING THE INDUSTRY TOWARDS A SUSTAINABLE FUTURE

CR Ocean Engineering LLC (also known as CROE®) is a leading air pollution reduction technology supplier, offering a full range of systems customised to clients’ specific needs. With its roots dating back to 1917, CROE is the marine-focused entity of one of the oldest and most reputable air pollution control companies in the world. Its core team is based at the company’s global headquarters in New Jersey, US, with shops and sales offices located across the globe.

In January 2020, a stricter new MARPOL Annex VI compliance ceiling came into effect, limiting a maximum sulphur content of 0.5% in marine fuels globally, as part of the race against time to reduce the shipping industry’s

emissions. This came five years after an even stricter MARPOL Annex VI 0.1% sulphur regulation came into effect for areas of the Baltic, North Sea and English Channel. The 0.1S regulation will then expand to the Mediterranean in May 2025. To prepare for these regulations, in 2013 CROE began offering its proven state-of-theart scrubbing system to the shipping industry.

This scrubbing system is a lowcost, highly reliable alternate to the premium costs of high sulphur fuel. With a CROE scrubbing system, shipowners can continue using the lower cost high-sulphur fuel oil even in Environmental Controlled Areas (ECAs).

CROE has no doubt helped to introduce scrubbing technology to the shipping industry. About 10% of all ships sailing the seas currently rely on scrubbers, some retrofitted and others installed in new builds. CROE believes that the best and most expeditious way to achieve lasting environmental benefit is when both a shipowner and the environment gain from the process.

The CROE scrubbing system is designed to be lighter, smaller, more efficient and more cost effective than most competing scrubbing systems. It requires low backpressure, has an all-metal construction, requires no bypass, replaces the silencer and can run dry without concerns. A complete washwater treatment system is also

COMPANY PROFILE CLEAN SHIPPING INTERNATIONAL – Spring 2024 20

Nick Confuorto, Senior Advisor

provided by CROE as part of the scrubbing system.

From bulk carriers travelling the Great Lakes in North America to cruise ships, cargo vessels, RoRos and ferries in Europe, CROE scrubbers are meeting exhaust emissions challenges and providing healthy ROI for their clients.

CROE’s scrubbing systems are available in three standard configurations, customisable to a ship’s requirements: open loop (seawater), closed loop (freshwater) or hybrid configurations (able to switch from one configuration to the other on demand).

» Open-loop (hybrid ready): oncethrough scrubber using sea-water

» Closed-loop: a recirculating scrubber using seawater (or freshwater) with caustic

» Hybrid: a combination of both designs for maximum flexibility.

CROE scrubbers normally replace the silencers. They are small, have a compact configuration, have flexibility of design and are one of the most reliable in the industry. They can be installed inside or outside the ship’s funnel.

Some of the features of CROE’s scrubbing systems include:

» Option of bottom entry I-Type, side entry L-Type or our U-Type entry designs to better fit any funnel configuration and simplify engine

exhaust gas duct, with or without a bypass. The CROE system can also be installed outside the funnel, if that is preferred, to maximise pre-assembly and expedite the installation.

» Strategically configured exhaust gas inlet and scrubber drainage to eliminate any potential water backflow to the engine.

» Eliminated circulation water storage from the bottom of scrubber vessel to reduce weight at the higher elevations, improving stability.

» Alloy construction (external and internal) to extend the life of the system and to allow the exhaust gas to travel through the scrubber system at high temperatures in case of dry-run conditions without a bypass.

» Used proprietary internals designed specifically to increase contact area with lower liquid flows to save on typical pumping costs associated with some scrubber designs.

» Optional proprietary CausticAssist™ feature for open-loop assist operating in low-alkalinity areas.

Over many installations in operation, CROE’s design has proved to be very reliable and effective for all clients. In addition to its long-established scrubbing systems, CROE’S research and development department is actively developing technological solutions in the areas of fine particulate controls, black carbon reduction and CO2 capture/sequestration.

The new world of decarbonisation will open many opportunities for environmental companies such as CROE. Scrubbing CO2 from the ship engine’s exhaust gas is going to become a common occurrence and we are getting ready to be a major player in that sector.

Totally committed to clients, CROE is currently analysing the track record of our established scrubbers, how they have been working and what the ship crews think about our systems.

As artificial intelligence gains acceptance as an industry tool, CROE will be there alongside the science. It is presently investigating how to possibly use that tool to the industry’s advantage.

CR Ocean Engineering LLC is a member of the Exhaust Gas Cleaning Systems Association (EGCSA)

For more information, contact: Dominique Philibert, President & COO

Tel: +1 (973) 455-0005 ext. 123

Email: dphilibert@croceanx.com croceanx.com

COMPANY PROFILE CLEAN SHIPPING INTERNATIONAL – Spring 2024 21

Paint your way to energy efficiency

High-performance hull coatings are one of the single most impactful ways to improve the energy efficiency of a vessel – and one of the simplest and fastest ways to maintain a good CII rating as well as increase the reference speed for the purpose of EEXI.

With over 4,000 vessel applications, the Hempaguard® range of hull coatings is one of the most trusted solutions on the market and the only one that offers you patented high performance silicone-hydrogel ActiGuard® technology.

The result is an exceptionally low hull roughness and a very long-lasting antifouling effect. It not only leads to an immediate speed increase, resulting in fuel savings of up to 20 per cent over a 5-year period, it also ensures a very low average speed loss down to 1.2 per cent and one of the shortest payback periods possible.

Combine Hempaguard with SeamFlow, the first ever application weldfairing system to maximise your benefits on bunker savings and energy efficiency of your vessels.

hempel.com/markets/marine/cii

TAKING COVER

Hull coatings have a key role to play in improving ship performance and saving fuel, resulting in emissions savings. However there have been concerns about how such coatings interact with other products and processes used during hull cleaning operations.

Independent laboratory testing has confirmed there is no decrease in the thickness of hull coatings from the use of Shipshave’s In-Transit Cleaning of Hulls (ITCH) solution, thereby addressing a key industry concern over adoption of the innovative system.

The Endures laboratory in the Netherlands was enlisted by Norwegian technology developer Shipshave to perform thorough tests to investigate the impact on the thickness and roughness of anti-fouling coatings from repeated brushing with the ITCH system.

A number of coated panels treated with two main anti-fouling coatings – selfpolishing copolymers (SPC) and fouling release coatings (FRC) – from three

Ship performance can be drastically improved with today’s state-of-theart hull coatings, which undergo rigorous testing to achieve high standards

suppliers were exposed to natural sea water over a two-month period and then subjected to a test simulating one year of monthly proactive cleaning, with the layer thickness and surface roughness of the coating measured before, during and after cleaning. Testing was carried out using four different brushes with varying fibre thickness at different angles on the ITCH system.

The semi-autonomous hull-cleaning robot, which can be deployed by a ship’s crew from a portable winch mounted on the forecastle deck, swipes up and down the hull underwater in transit using hydrodynamic energy to remain attached to the hull.

The newly published test report concluded that “no decrease in coating thickness could be found for all brush types used on all coatings” and therefore that “the ITCH can be used as a tool to remove fouling as it does not influence or reduce the coating thickness”.

The testing did show some increase in surface roughness, with no further increase after initial brushing, but the

COATINGS CLEAN SHIPPING INTERNATIONAL – Spring 2024 23

resulting roughness was still well within what is considered acceptable for a well-performing, freshly coated hull. Consequently, the “increase in roughness is neglectable from a hydrodynamical point of view”, according to the report.

The report confirms that proactive cleaning using the ITCH can be performed without any adverse effects to the hull coating, based on rigorous design parameters for the tests.

The positive impact from proactive hull cleaning has been verified in reallife usage of the system that supports test findings from the laboratory.

As well as reduced fuel costs and emissions, the solution is able to cut hull inspection and maintenance costs, and ease CII compliance without structural modifications, as well as limit the transfer of invasive species between different ports.

Shipshave’s CEO Åge Højmark says the results from the lab tests mirroring real-world conditions corroborate the actual operating experience reported by clients in using the technology. “This consistency between lab results and field performance validates our claims and reinforces customer confidence in our product,” he says.

“Confirmation from a third party that the ITCH has a negligible effect on fresh hull coatings directly addresses the industry’s concerns regarding impact on the coating. The Endures report will both allay industry scepticism and bolster the already strong trust we have established in the market, encouraging wider adoption of the system,” he adds.

NIPPON’S NEW PRESIDENT

Nippon Paint Marine, the world’s first manufacturer of biocide-free marine coatings, has announced the appointment of Gladys Goh as its president, effective immediately.

As president of Nippon Paint Marine Group, Gladys Goh is the first female and foreign national to lead a principal operating company in Japan. With a history of over 140 years, the marine division is the founding business for the Nippon Paint Holdings Group, a global leader and pioneer in marine paint and coatings.

She joined Nippon Paint Malaysia in 2006, driving the brand to become Malaysia’s top coatings provider and subsequently led expansion into new markets. She concurrently serves as senior vice-president, strategic innovation and marketing at NIPSEA Group.

The hull coatings market is experiencing strong, sustained growth as a result of increased regulations, the drive to meet decarbonisation targets and the impending costs of future fuels in line with shipping’s energy transition. These factors are generating a surge in the uptake of proven clean technologies that reduce fuel consumption and emissions and increase operational efficiencies, of which advanced hull coatings are the most widely used and available technology within the market.

Nippon Paint Marine Coatings works with customers across 30 countries in Asia, Europe, the Middle East, North America, and South America. Its products have been applied to more

than 40,000 vessels, from tankers and container ships to cruise liners and yachts.

Commenting on her appointment, Gladys Goh says: “I’m honoured to have been appointed as president of the Nippon Paint Marine Group, and I am also proud to be able to reflect and represent the diversity of talent within the business. My vision for growth is to deliver a multiplying effect that will drive this, enhancing our people’s capabilities, optimising operational efficiency and delivering greater value to our customers.”

Over the course of 2024, Nippon Paint Marine plans to launch several new products , including expanding its leading antifouling solution, FASTAR (See case study, right), to incorporate Hydrogel ‘water-trapping’ technology for both ocean-going and coastalrange vessels. It is also focusing on developing low volatile organic compounds (VOC) in both antifouling and anticorrosion coatings to meet regulatory compliances and regional VOC requirements, especially in key markets such as China and South Korea. Lowering VOC emissions helps protect the health of individuals working at shipyards and contributes to the overall sustainability of the marine industry.

Nippon Paint Marine will also strengthen its cargo hold and cargo tank solutions, including offering methanol-resistant coatings in line with the industry’s increased use of methanol as a viable new fuel to meet decarbonisation targets. In 2024, the company will further expand its supply points, to include North America and South Africa, following the acquisition of new locations in Australia, Egypt, and Gibraltar last year.

Case study: FASTAR

Nippon Paint Marine’s antifouling products A-LF-Sea and FASTAR have delivered up to 8% fuel and emissions savings for Taiwanese shipping company WAN HAI Lines, according to the company.

Reducing fuel consumption and emissions is a key priority for WAN HAI and the wider container shipping sector, as it looks to drive increased

COATINGS CLEAN SHIPPING INTERNATIONAL – Spring 2024 24

Shipshave’s CEO Åge Højmark (Credit: Shipshave)

Gladys Goh

operational efficiencies to comply with more stringent industry regulations, including carbon intensity indicator, Energy Efficiency Existing Index and mitigate shipping’s price on carbon following its inclusion in the EU Emissions Trading System, as well as reaching future targets for global greenhouse gas emissions reduction.

WAN HAI has worked with Nippon Paint Marine for seven years, beginning with the application of the high-end antifouling coating A-LF-Sea to 20 vessels within its fleet. Performance analysis conducted in 2019 showed that the product delivered up to 8% fuel and emissions reduction compared to conventional coatings.

A-LF-Sea is a super low-friction coating system that uses Nippon Paint Marine’s patented Hydrogel watertrapping technology, resulting in a smoother hull which reduces a vessel’s hydrodynamic drag. This results in lower fuel consumption – as less power is needed to maintain the same speed – reducing the cost of operating the vessel, as well as emissions.

In 2021, WAN HAI began applying Nippon Paint Marine’s next-generation antifouling coating, FASTAR, to generate further fuel efficiencies and help contribute towards CII ratings for its fleet. FASTAR has now been applied to 10 vessels across WAN HAI’s global fleet. The vessels are currently undergoing performance analysis to determine options for generating additional fuel and emissions saving benefits going forward.

FASTAR is Nippon Paint Marine’s fourth generation antifouling system, with self-polishing and self-smoothing capabilities. FASTAR builds upon the company’s patented Hydrogel watertrapping technology, using nanobinder technology to deliver precise, predictable antifouling performance, reducing fuel consumption and emissions, as well as improving drydock efficiency.

WAN HAI is now also considering extending this partnership to explore the use of Nippon Paint Marine’s Aquaterras solution, the world’s first completely biocide-free and proven self-polishing underwater foul-

resistant paint, which can reduce fuel consumption by up to 10%.

“We have been very impressed with the performance of both A-LF-Sea and FASTAR. Both coatings have enabled us to achieve significant fuel and emissions savings, which aligns with WAN HAI’s corporate and sustainability goals to comply with environmental regulations as well as supporting the industry in meeting global decarbonisation targets,” says a WAN HAI spokesperson.

“Improving efficiency across our entire fleet is critical to driving more sustainable, commercial and competitive operations and Nippon Paint Marine’s coating technology has played an integral role in enabling us to achieve this.”

“Helping our customers meet the challenge of accelerating the path to decarbonisation and wider sustainability is a key focus for us. We are proud to have enabled WAN HAI to achieve fuel savings of up to 8% that have a significant and positive impact on their environmental footprint and bottom line,” says Adrian Hwang, deputy general manager at Nippon Paint Marine.

Nippon Paint Marine has applied products using its Hydrogel lowfriction antifouling coatings to more than 4,000 vessels to date, reducing fuel costs and emissions by up to 8% compared with other makers’ top-ofthe-range silyl-acrylate SPC systems without Hydrogel.

AI INNOVATIONS

Revolutionary software co-developed by AkzoNobel’s Powder Coatings business and coatingAI is using artificial intelligence to help customers improve the application process and reduce their carbon footprint.

The industry-first technology, called Flightpath, optimises equipment settings to reduce defects and overspray and improve powder consumption – helping to reduce costs, avoid rework and save time and energy.

The AI-based software has been in development for two years and an exclusivity agreement has just been signed by both parties – who joined

forces after first crossing paths during AkzoNobel’s Paint the Future start-up challenge in 2021.

“We’re delighted to team up with coatingAI and strengthen our technical service capabilities,” says Remco Maassen van den Brink, Marketing Director of AkzoNobel’s Powder Coatings business. “We proactively look for ways to support customers in becoming more sustainable in their operations and this will significantly improve our ability to help them get better results – while contributing to our own ambition of halving carbon emissions across the value chain by 2030.”

Marlon Boldrini, CEO of coatingAI, adds: “The collaboration with AkzoNobel has helped to accelerate our vision since day one. Our solution, built on the power of artificial intelligence and AkzoNobel’s technical expertise, will not only increase efficiency for their customers, but also drive greater sustainability within the powder coatings industry.”

The software enables customers to optimise equipment settings such as gun motion and achieve more uniform, consistent coverage with fewer flaws – all thanks to the AIpowered recommendations. The software doesn’t require complex integration and, as conditions change, it continually adapts its recommended parameters.

“Collaborating with a startup like coatingAI – who are pushing boundaries to transform the coatings industry – means we can accelerate our own powder revolution and provide services like no other,” adds Maassen van den Brink. “It’s the latest example of how we constantly innovate and look for new ways to offer customers the most progressive and sustainable solutions.”

Earlier this year, the company’s powder coatings business was the first in the industry to launch an openly accessible online energy savings calculator for all users of powder coatings. It helps customers better understand how even making small changes in the coatings process can have a big impact in terms of becoming more energy efficient.

COATINGS CLEAN SHIPPING INTERNATIONAL – Spring 2024 25

Marine Mutual is warning that shipowners need to be aware of a looming BWM Convention deadline

STAY AHEAD OF THE CURVE

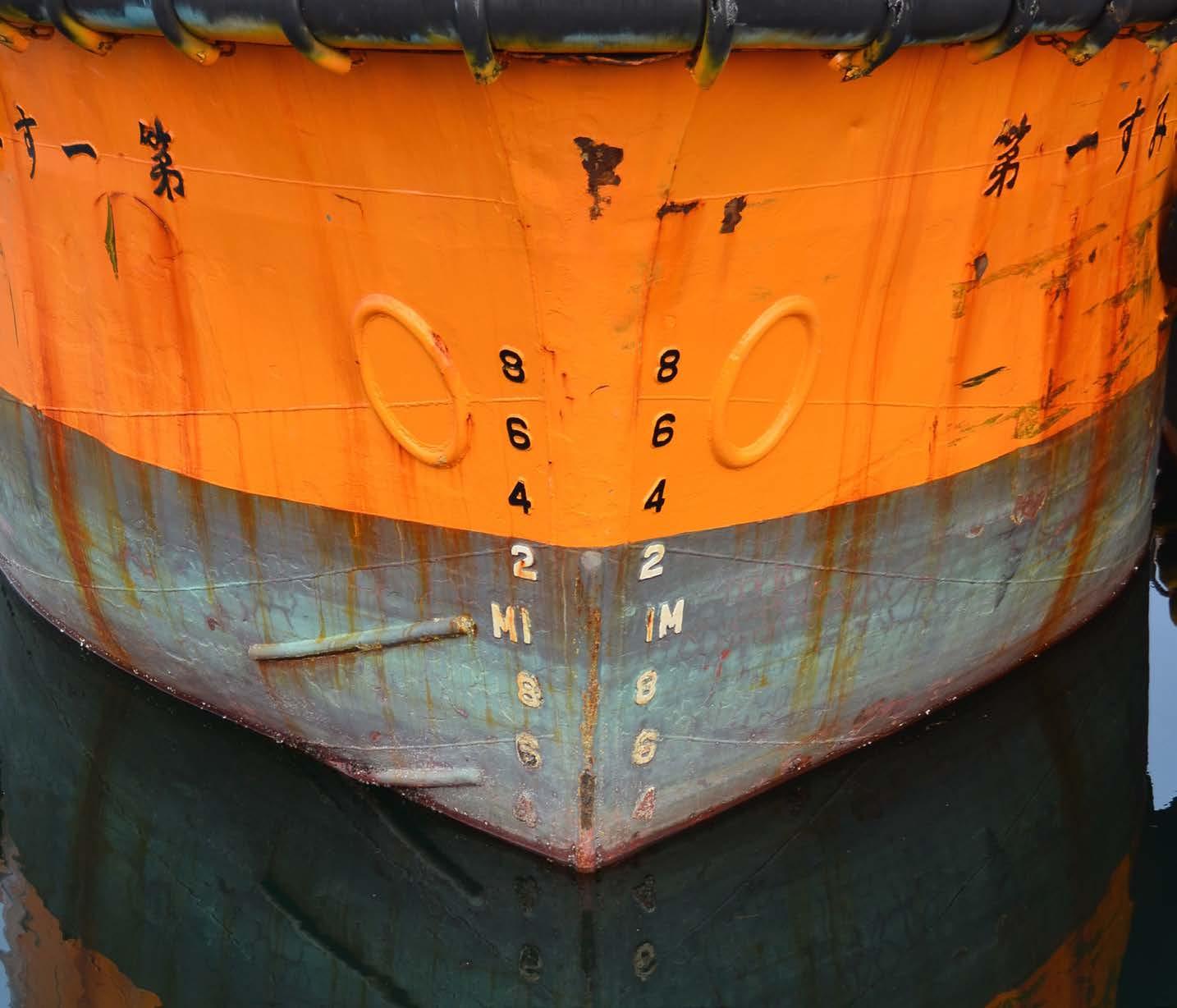

The next deadline in the Ballast Water Management (BWM) Convention is the D-2 ballast treatment deadline on 8 September this year and companies will need several months to ensure that they meet requirements or may face trading problems.

As the Marine Mutual explains to members in an advisory risk review online, the Convention’s first stage ballast water exchange requirement (Regulation D-1) came into force in 2017. The second stage (Regulation D-2), which ends the ballast water exchange process and obligates ballast water treatment instead, becomes mandatory on 8 September this year.

“Members will be aware that ballast water can contain many aquatic species which may later become invasive and harmful when released, unmanaged, into a new marine location at a distant load port,” Marine Mutual says. “The BWM Convention was created to prevent global sea and river water contamination and associated

ecological dangers, and public health issues. Regulation D-1 required all ships (over 400 GT and engaged in international trade) built before 2017 to exchange their water ballast while at sea (preferably more than 200 nautical miles from land) and for all vessels built during or after 2017 to be fitted with a Regulation D-2 ballast water treatment (filtering and disinfection) system.

“Vessels built before 2017 and permitted to use a D-1 ballast exchange process were later required to retrofit D-2 ballast treatment systems no later than their next International Oil Pollution Plan (IOPP) Certificate survey. MARPOL Annex 1 provides that IOPP certificates are valid for five years. Accordingly, all vessels built before 2017 were originally intended to have been D-2 retrofitted by 2022.

“The original 2022 D-2 compliance deadline failed, due primarily to the covid-19 pandemic shortage of International Maritime Organization (IMO) approved system

BALLAST WATER TREATMENT SYSTEMS CLEAN SHIPPING INTERNATIONAL – Spring 2024 26

equipment and shipyard capacity for installation. The IMO then agreed a two-year extension to 8 September 2024. However, despite this extension and likely due to the high cost of D-2 equipment and installation (the ICS ‘Treating Ships’ Ballast Water’ webpage estimates the cost as being between $1m- 5m per vessel), there appears to be a significant number of BWM Convention regulated vessels which have not yet been certified as D-2 compliant.”

Marine Mutual sums up the requirements of BMWD-2 as follows:

» All BWM regulated vessels built during or after 2017 must currently carry a BWM D-2 Certificate to confirm that an approved ballast water treatment system is installed on board and tested.

» All BWM regulated vessels built before 2017 must currently carry a BWM Certificate to confirm compliance with the BWM D-1 ballast water exchange standard. If the vessel has been subsequently retrofitted with a D-2 ballast water treatment system, a BWM Certificate is required which confirms a D-2 system is installed on board and tested such that it can be used on

and after 8 September 2024.

» All BWM vessels must carry an approved BWM Plan and up-to-date Record Book.

The mutual tells members to check the BWM certification for all their BWM regulated vessels. “If any of your vessels are still operating with BWM D-1 ballast water exchange only Certificates, then it is important that priority plans be made for D-2 ballast treatment systems to be installed and tested to flag state BWM D-2 requirements well before 8 September 2024.”

Plan preparation should include communications with flag state authorities for vessels and their RO to confirm BWM D2 requirements as well as with the vessels’ Class society, IMO/ BWM approved ballast water treatment system suppliers and shipyards to organise D2 system equipment purchase and installation as soon as possible.

“It is essential that masters and all crew involved in ballasting, deballasting and the operation of BWM treatment systems receive comprehensive training relating to BWM Convention requirements, the operation and maintenance of the of

the installed system and the sampling of ballast water in accordance with the IMO Guidelines for Ballast Water Sampling (G2).

“Additionally, members should ensure that their masters and crews fully understand the content of the IMO Guidelines for Port State Control

Under the BWM Convention. This IMO resolution details the PSC sampling and testing process (which should follow the aforesaid G2 Guidelines) and the circumstances that may lead to vessel detention or banning.

“Members should also direct their masters and crew to the IMO’s compilation of all BWM mandatory instruments and guidelines as listed in the IMO Guidelines and Guidance Documents related to the BMW Convention 2004 (as updated to Aug 2023). Particular attention should be given to BWM.2/Circ.20 Guidance to ensure safe handling and storage of chemicals and preparations used to treat ballast water and the development and implementation SMS safety procedures.”

The mutual says that “It seems unlikely that the IMO will grant any further time extension. Accordingly, MM members who operate vessels built before 2017 that are regulated by the BWM Convention and have not yet been retrofitted to D-2 ballast treatment standards should take priority action to avoid anticipated equipment supply and installation bottlenecks.

“If not accomplished by the due date, it seems likely that vessels will be detained.

“In addition to ensuring that all BWM regulated vessels (built both before and after 2017) are fully BWM D-2 ballast treatment equipment compliant, Members must also ensure full compliance with IMO/BWM Guidelines on system operation, ballast testing, crew training and safety.

“Members are therefore encouraged to bring this Risk Bulletin to the attention of their DPAs, ship managers and Masters. Members should also ensure that all shipboard and management office SMS manuals and procedures are updated to incorporate all BWM Convention and related crew safety requirements.”

BALLAST WATER TREATMENT SYSTEMS CLEAN SHIPPING INTERNATIONAL – Spring 2024 27

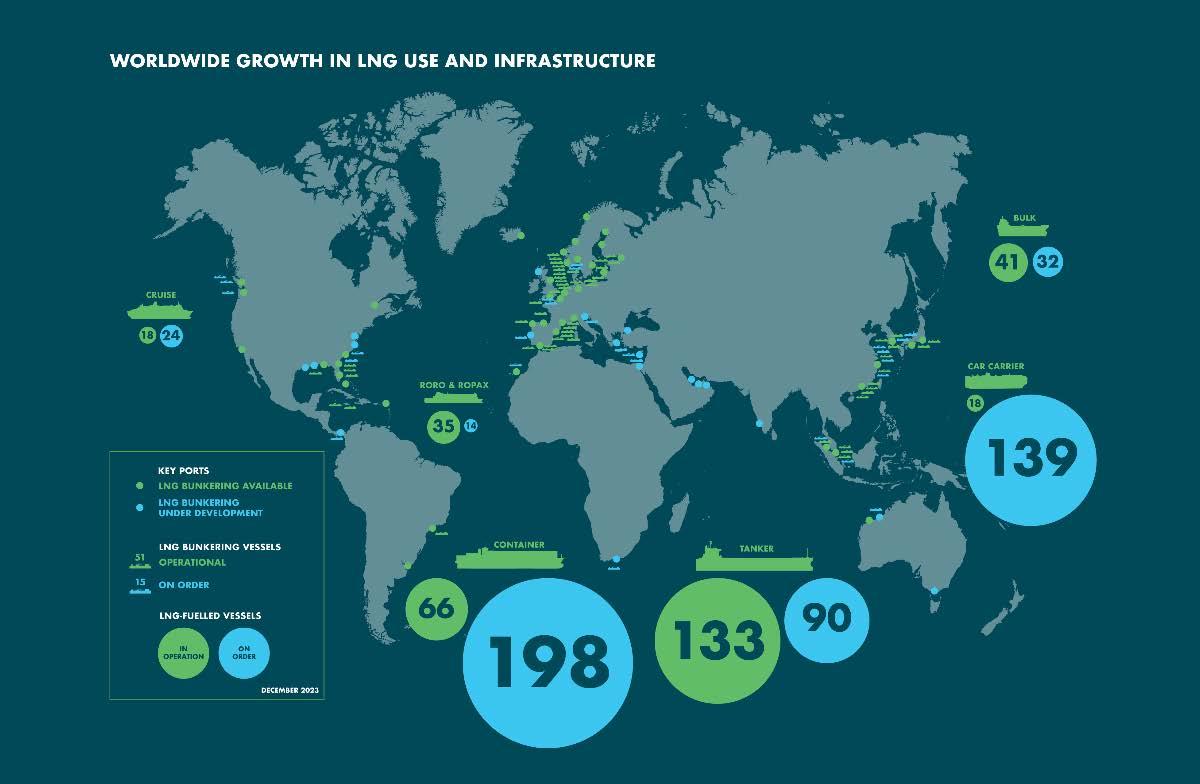

FUEL FOR THOUGHT