41

PROPULSION: LUBE OILS

Clean Shipping International spoke to leading lube oil manufacturers to find out how they will have to adapt in the future as engines switch to using renewable fuels and advanced combustion techniques

POURING OIL ON TROUBLED WATERS

Dr Luis Garcia Technology Manager – Marine & Power Engine Lubricants, Shell Global Solutions (Deutschland) GmbH

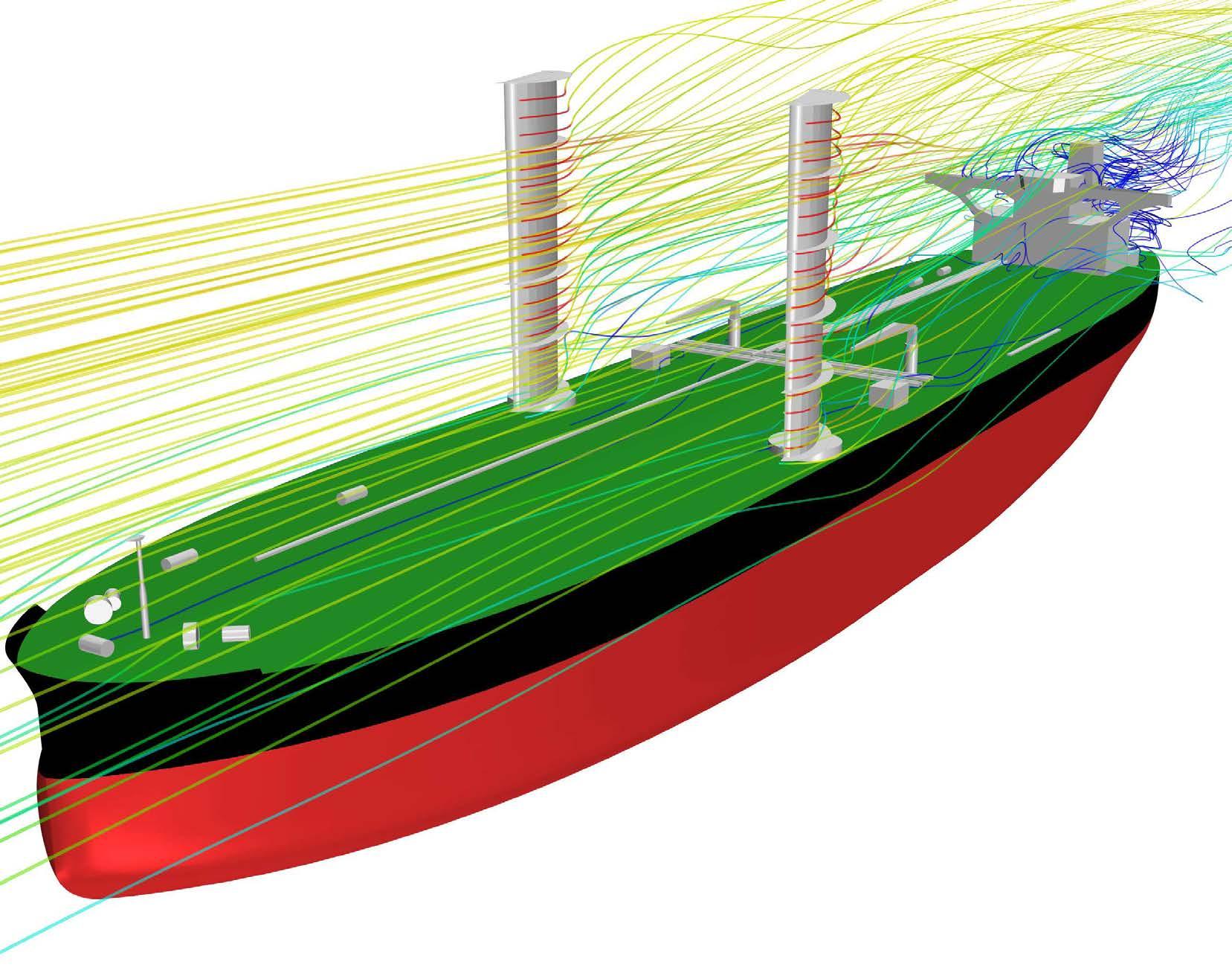

Dr Luis Garcia, Technology Manager – Marine & Power Engine Lubricants, Shell Global Solutions (Deutschland) GmbH, says that shipping is one of the harder sectors to de-carbonise and there will likely be multiple solutions across sub-sectors. Shell’s analysis points to hydrogen with fuel cells as the zero-emissions technology that has the greatest potential to help the shipping sector achieve net-zero emissions by 2050. However, a zero-emissions fuel is not likely to be available on a commercial scale globally until the 2030s. The industry must take action to reduce emissions now with solutions available today, such as advanced engine lubricants and digital optimisation technologies, he says. There is consensus in the industry that deepsea-going ships will continue to rely on the internal combustion engine for their main propulsion. However, in recent years, significant gains in fuel efficiency have been attained by engine manufacturers (OEMs) in diesel, gas and dual fuel (diesel/natural gas) marine

C L E A N S H I P P I N G I N T E R N A T I O N A L – S p r i n g 2 0 21

engines. The latest engine designs operate at higher pressures and temperatures and aim for using less lubricant per unit of power produced. This has resulted in increased performance demands for marine lubricants and in response, additive companies and lubricant suppliers are currently developing higher performing oils. As an example, MAN Energy Solutions (MES) 2-stroke division has recently introduced a two category system looking for higher performance cylinder oils and Shell and other players in the industry are currently working on developing category II oils at 40 BN level. Lubricant solutions will also need to be developed at an accelerated pace in line with shortened hardware development cycles.Typically, developing a new engine lubricant can take a few years, from laboratory studies, bench and rig testing, lab engine testing to full-size engine testing. Added to this, the engine design involved might not be entirely mature, for example, the original equipment manufacturer (OEM) could still be making the first field