1

FROM THE EDITOR

WE NEED TO ACT NOW!

Ian Cochran Editor, Clean Shipping International

To get to net zero emissions, what ship and equipment designs will be needed in the future? What do we need to do now – and how? These are the main questions on shipowners lips, as they strive to comprehend the sheer number of solutions being thrown at them to reach the International Maritime Organization’s (IMO) goal. The net result of all of these initiatives is to polarise the industry into separate camps, especially in the near term, until a universally accepted solution is found. Of course, impending regulations also need to be fit for purpose, as down the years, several have proved to be impracticable. Flexibility will be key going forward with a combination of technologies coming together to solve the problem. With a new fuel will come new engine designs and supply chain logistics to make it work. But as one leading shipowner said in a recent webinar: “Let’s concentrate on what is possible today.” The so called e-fuels look as though they are going to be very expensive, but with further research and development, the cost will come down – but will it be to the level of today’s options? As it has been pointed out time and time again, an importer of soya beans into China will not care about how his or her cargo is shipped, only the cost involved. In the container trades, major shippers, such as Amazon, Walmart and so on, are getting more involved in how goods are shipped, as are the major trading houses. All are claiming to be turning “green”.

PROBLEM WITH CLAUSES

One problem, recently highlighted by a leading drybulk broker, is that a standard charterparty does not include any clauses on the amount of emissions the ship involved emits, thus not declaring a carbon footprint.

C L E A N S H I P P I N G I N T E R N A T I O N A L – S p r i n g 2 0 21

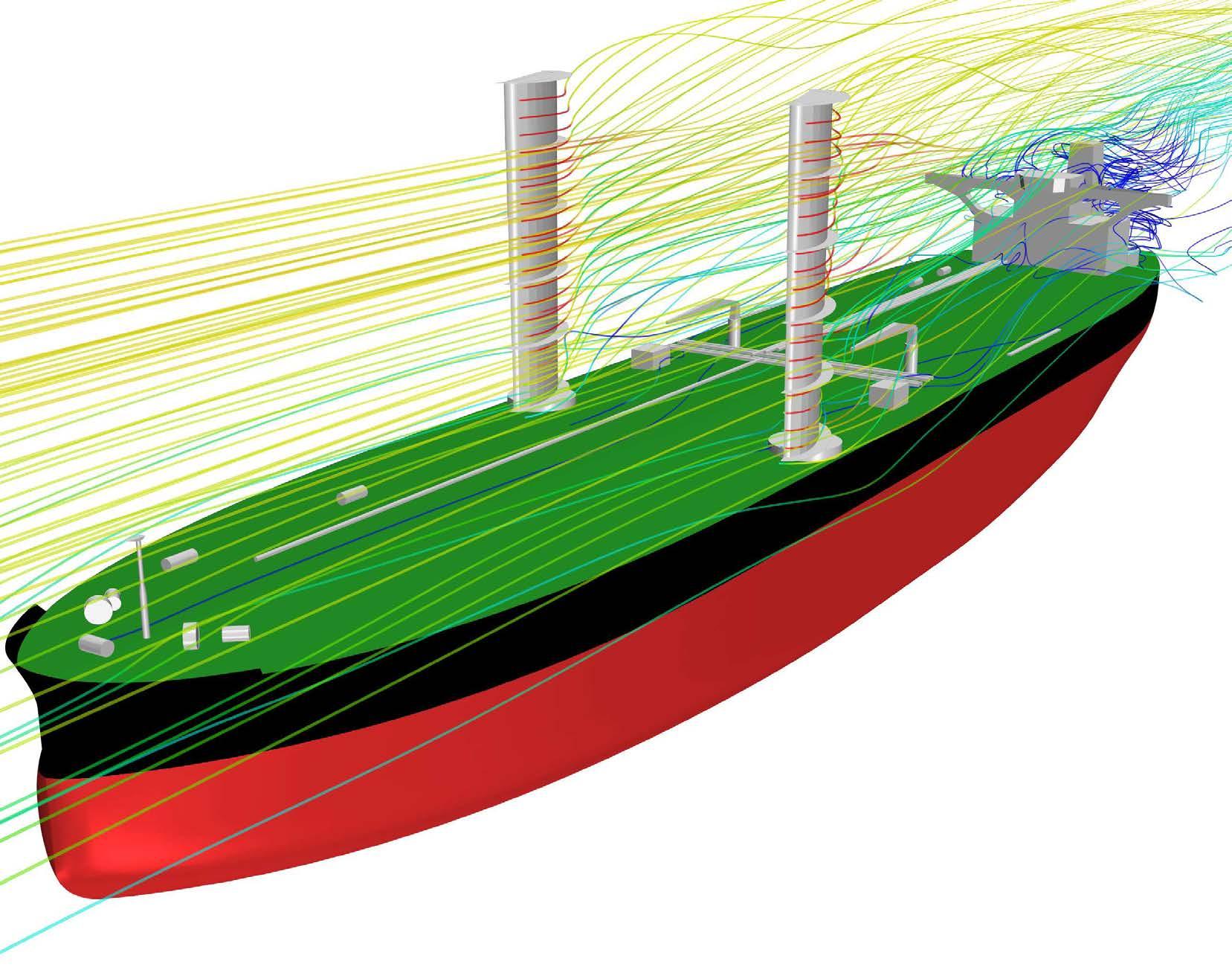

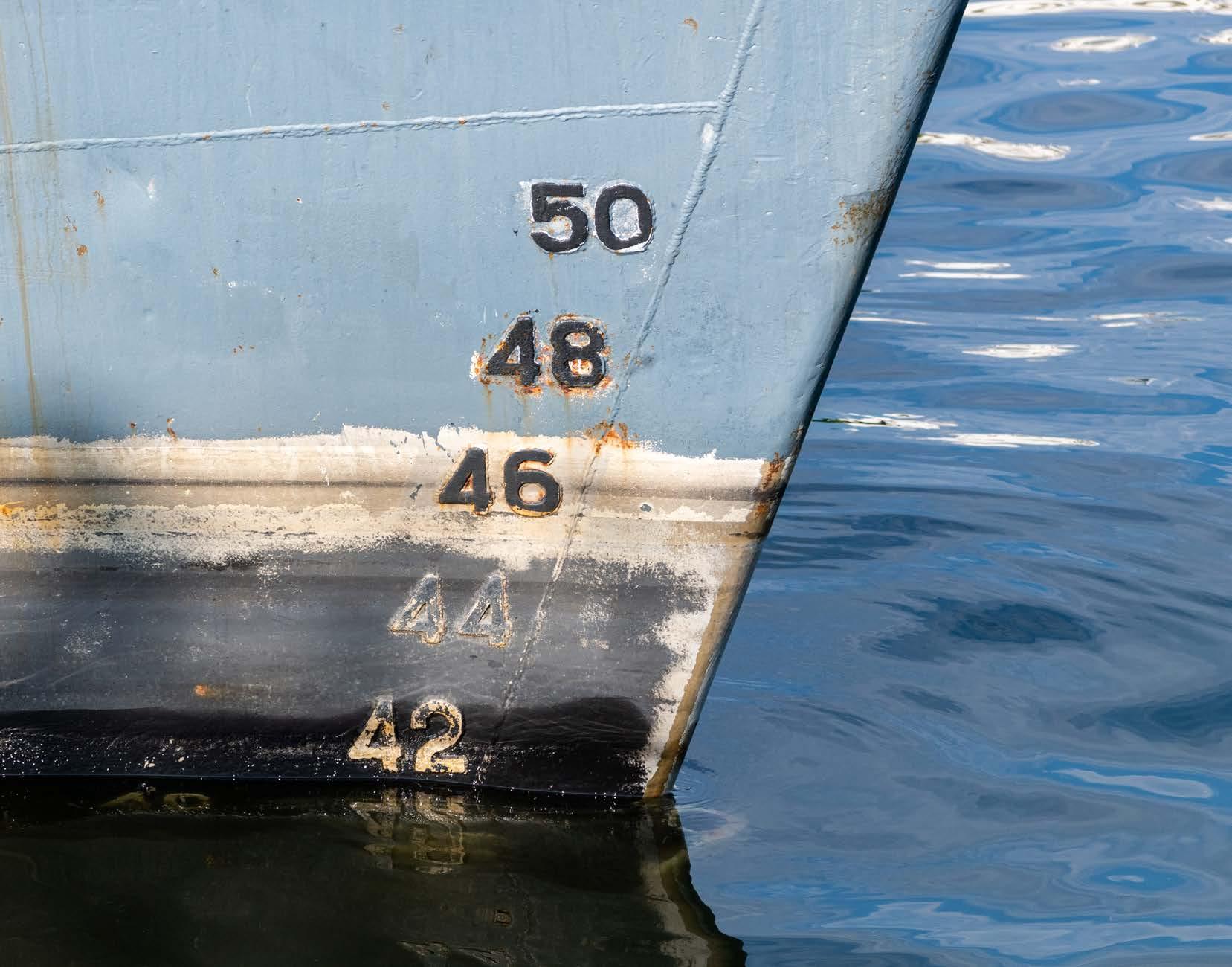

A charterparty also rarely depicts alternative fuel use, such as wind-assisted ships, although with Cargill and other major charterers becoming involved, this is gradually changing. Proper measurements still need to be developed – no measurement, no improvement, as the old saying goes. Despite the clock ticking, shipowners are still ordering standard ships with standard equipment installed, except for LNG-ready and other designs, which have proved to be expensive to retrofit. Further down the road, ammonia will need large storage space on board the vessel. A standard design is purely down to costs, as large shipyards normally offer a standard package at a set price with the owner paying for any extra add-ons, such as scrubbers. Methane, hydrogen and other alternative fuels currently doing the rounds have huge challenges ahead before they become commercially viable alternatives to what is on offer today, both technically and commercially. The bunkering and storage infrastructure of, say, hydrogen will take several years to develop – maybe not at all without a sound business case.

BIGGEST BURNERS

For example, out of the world fleet, it has been estimated that 20,000 vessels burn around 80% of the mainstream fuels. Drybulk still makes up the largest vessel sector and tends to involve tramp ships that will often not know the next destination once their current voyage is completed. World trade is forecast to double by 2050, just at the time when the shipping industry should be reaching net zero emissions. To cope with this huge demand, more ships will obviously be needed. This is only 30 years away, just over a ship’s lifecycle, so we need to be investing in new ideas, technology and designs now and ensuring they are workable both in technological and economic terms.