Boxy SpA was founded in 1969 in Remedello (Italy) and supplies solutions for the manufacturing of wire & cable used in industrial, transportation, civil, communication, and energy applications. During these 55 years, it has continuously invested in the development of new technologies and know-how to satisfy the needs of each one of these key industry applications, with the goal of global growth. Thanks to the collaboration with major wire & cable machinery manufacturers, BOXY’s solutions are in-line with the real needs of the market, guaranteeing superior productivity, efficiency, safety control of process. This communication also extends to our customers, therefore opening the road to technical innovation, which ensures growth of experience by all parties. In addition to reels and spools, we also supply accessories and equipment for their safe handling.

The quality control system is updated annually based on the most recent ISO norms, which is why BOXY has been ISO 9001:2008 certified since 1993. The attention to quality is a derivate of safety; being aware of the inherent risks due to the weight and movement of the reels, every product is subjected to critical testing to provide the safety certificate and CE marking.

We have our headquarters located in northern Italy, specifically in Remedello (BS), Italy. This strategic location gives us an excellent operational base to serve our customers everywhere in the world. Furthermore, we have a production facility in Slovakia since 1992, which allows us to meet the needs of the Eastern European market with efficiency and reliability. Our diverse geographic presence allows us to provide tailored solutions and high-quality customer service across the globe.

BOXY SpA

BOXY - RS s.r.o

076 51 Pribeník - Slovakia

25010 Remedello (BS) - Italy

Applications: – drawing – stranding/buncher – extrusion

Reel with single skin rimmed flange in pressed steel. Indicated for insulated wires, stranding copper/ alluminium wires, metallic wires and welding wires. For one way or multiple use. The BST reel can be manipulated with our handling equipment. Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Applications:

– rod breakdown

– drawing

– stranding/buncher

– armouring

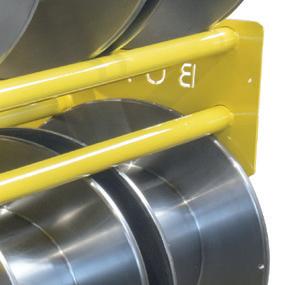

Reel with double skin rimmed flange in pressed steel and machined barrel. Dynamically balanced up to 40 m/sec and indicated for rod wire, stranding copper/aluminium wires and metallic wire. The NA reel can be manipulated with our handling equipment.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

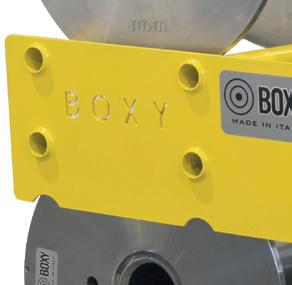

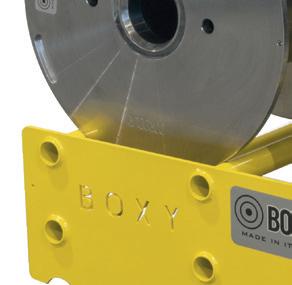

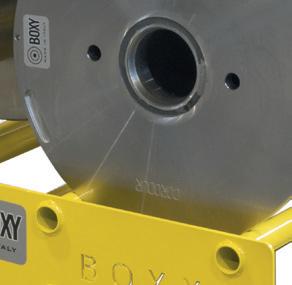

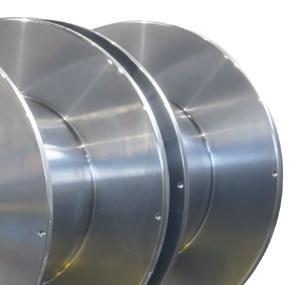

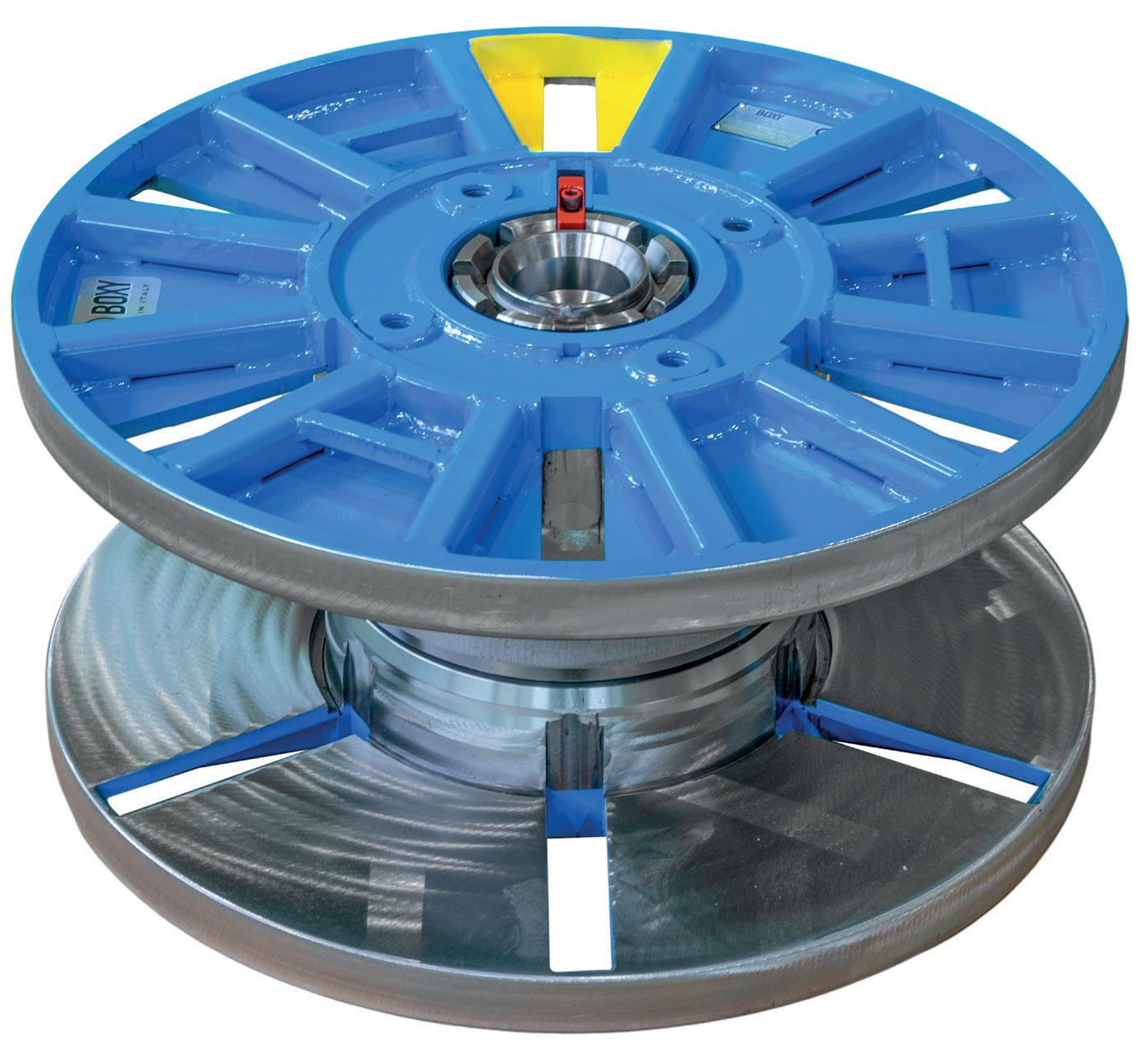

Applications:

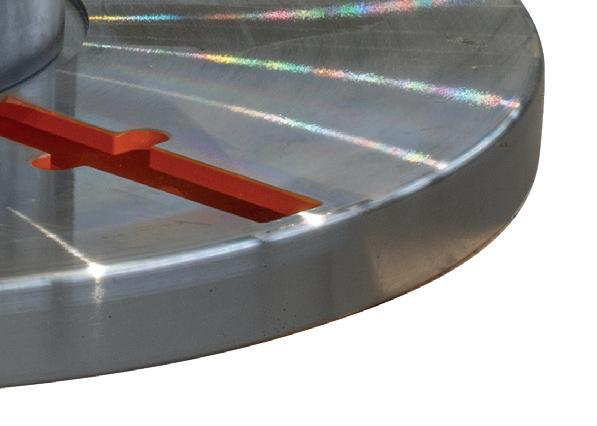

– drawing

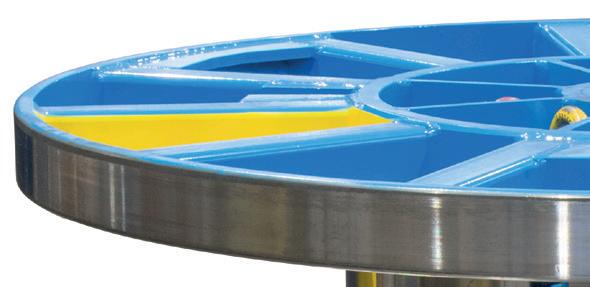

Reel with solid flange and fully machined. Dynamically balanced up to 50 m/sec and indicated for multiwire, rod wire, copper/aluminium wires and metallic wire. The BTE reel can be manipulated with our handling equipment.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Applications:

– drawing – stranding

– armouring

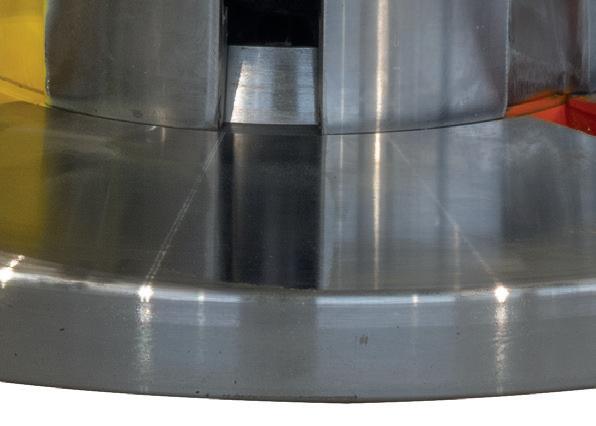

Reel with solid flange and machined barrel. Dynamically Balanced up to 35 m/sec and indicated for single and stranding steel wire, copper/aluminium wire. The BCE reel can be manipulated with our handling equipment.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

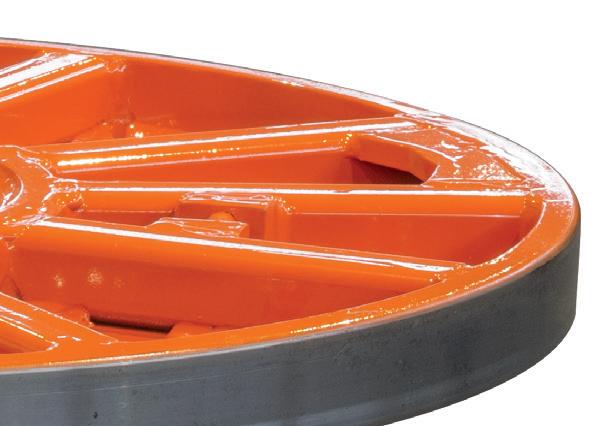

We offer 2 versions for this reel which is mainly used for the production of single steel wire: with extra stiffeners between the 2 walls that compose each flange (pict. 1) or with flanges reinforced by folds and the use of high strength material developed with an important steel producer. The BFP reel can be manipulated with our handling equipment. Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions. They are machined on the barrel. Dynamically balanced up to 35 m/sec and also indicated for copper/aluminium wire, used in drawing, galvanizing, stranding and armouring.

Applications:

– stranding

– extrusion

– armouring

– drawing

Large drum used for production process or shipment of finished product. Statically balanced and indicated for cable, rope, bare wire, coated wire and insulated wire. For one way or multiple use. The BMP reel can be manipulated with our handling equipment.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Applications:

stranding

extrusion

armouring

drawing

Large drum used for production process or shipment of finished product. Statically balanced and indicated for cable, rope, bare wire, coated wire and insulated wire. For one way or multiple use.

The BAL reel can be manipulated with our handling equipment.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Applications:

– drawing – galvanizing

Fully machined conical reel for steel, copper and aluminium wire. Suitable for static and dynamic use. The BSK reel can be manipulated with our handling equipment.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Conical reel supplied in 3 versions with different sizes: FB100 – FB120 – FB150. The FB reels can be manipolated with our handling equipment.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Conical flanges to be assembled with cardboard tube by threaded bar. Available in 2 diameters: 570 and 800. The conical flange FLK can be manipulated with our handling equipment.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Pallet for the storage of reels. Can be stored one above the other up to a maximum capacity of 12 tons.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Baskets for coils and rod wire of copper and aluminium.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

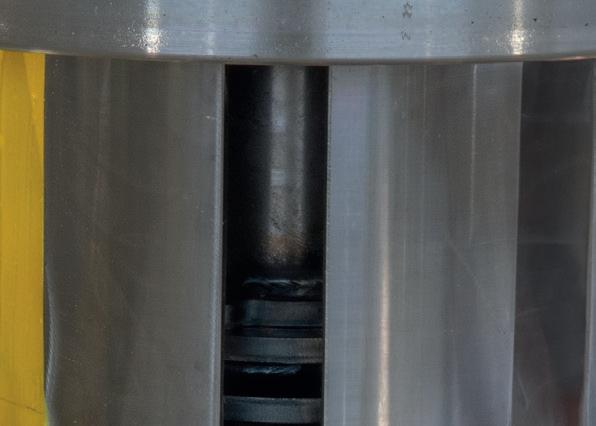

This kind of take-apart reel has a very quick opening system. Just unscrew the only screw on the top flange.

The sequence shows a full take-apart reel with the safety screw removed (pict.1), the top flange and barrel sectors collapsed to be removed from the coil (pict.2) and the coil lies on the bottom flange (pict.3).

The KOILER is machined in the winding surfaces and dynamically balanced up to 40 m/sec.

CE-certified and supplied with use and maintenance manual.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

A take-apart reel model that helps operators save a lot of time. It has an expandable barrel that allows the wire coil to be lifted and transferred once made. The sequence shows a full reel (pict.1) where the crane hooks engage in two specific positions (pict.2) so that the barrel expands and takes hold of the coil; when the coil is ready to be placed on a pallet or on the floor the hooks engage in other specific positions (pict.3) so that the barrel sectors are kept back to their position and the coil is released.

Boxy KOILER take-apart reel is also machined on the barrel and flange rims and dynamically balanced up to 40 m/sec.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

The sequence shows the opening system of this take-apart reel: the safety pin is removed (pict.1), the central screw is unscrewed (pict.2), the top flange and the collapsed barrel sectors are removed from the coil (pict.3) and the coil lies on the bottom flange (pict.4).

The BOSCO is machined in the winding surfaces and dynamically balanced up to 40 m/sec.

CE-certified and supplied with use and maintenance manual.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

The best solution to make Z2 coils. This reel is machined in the winding parts and dynamically balanced. This model has a system operated by a ring nut screwed up to the central tube (pict.1).

Once the top flange is lifted (pict.2) the coil lies on the bottom flange is ready to be removed (pict.3)

The take-apart reel of the picture is for application with a cardboard tube only – however we can also offer the option to make coils with and without a cardboard tube by using steel sectors.

The reel is machined in the winding surfaces and dynamically balanced up to 40 m/sec.

Consult the DIN 46391 / 46395 and DIN 46397 standards.

Mechanical lifting unit for coil movement and stockpiling with internal grip.

Clamping and releasing of the coil occur automatically and do not request, therefore, the intervention of an operator.

It is supplied CE marked, with an instruction and maintenance manual.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

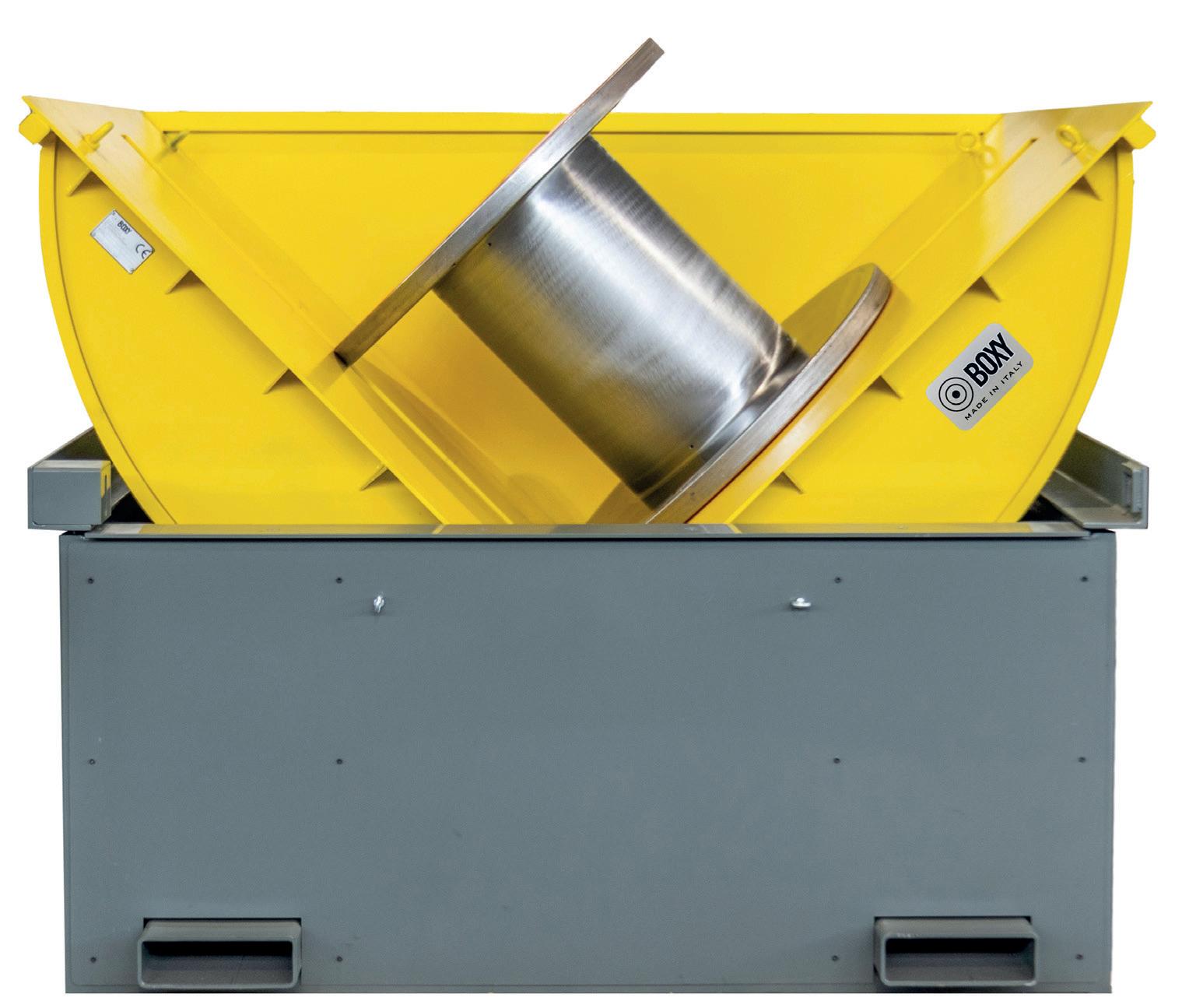

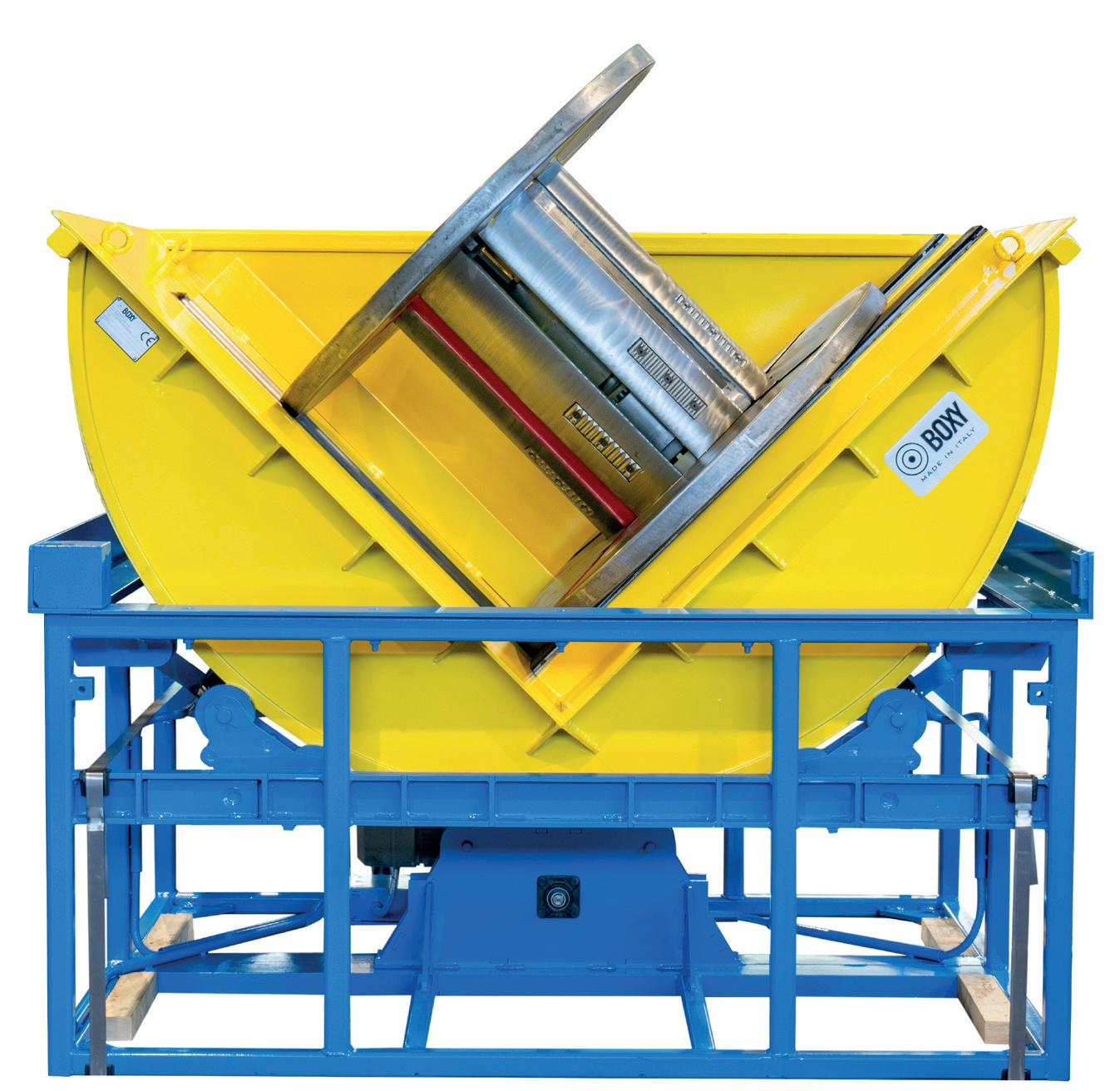

Fixed electro-mechanical tilting unit for reels and coils. It can be laid built-in in the ground with loading platform aligned with the floor. Designed and reinforced to rotate different loading range from 1 ton up to 8 tons, CE marked, with an instruction and maintenance manual.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Fixed electro-mechanical tilting unit for reels and coils. It can be laid on the floor. Designed and reinforced to rotate different loading range from 1 ton up to 8 tons, CE marked, with an instruction and maintenance manual.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

DETAIL

Internal rollers

Fixed electro-mechanical tilting unit with integrated rollers to strap a coil made by take-apart reel. Designed and reinforced to rotate different loading range from 1 ton up to 8 tons, CE marked, with an instruction and maintenance manual. Available also with motorized rollers.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Fixed electro-mechanical tilting unit with motorized and integrated rollers to strap a coil made by a take-apart reel. Available for a maximum flange diameter of 1500mm and a weight of 5.5 tons. It is supplied with a control console.

CE-certified and supplied with use and maintenance manual.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Horizontal semi-automatic lifter

Automatic lifter to handle horizontally reels with a maximum weight of 15 tons. It takes hold of the reel from the flanges. No operator intervention is necessary as the lifter takes hold and releases the reel in an automatic way. It is tailor-made to meet customer’s requirements.

CE-certified and supplied with use and maintenance manual.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Automatic lifter to handle vertically reels with a maximum of 15 tons. It takes hold of the reel from the flanges. No operator intervention is necessary as the lifter takes hold and releases the reel in an automatic way. It is tailor-made to meet the customer’s requirements.

CE-certified and supplied with use maintenance manual.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Mechanical lifting unit for reel movement and stockpiling with grip from the central hole. Clamping and releasing of the reel occur automatically and do not request the intervention of an operator.

CE-certified and supplied with use and maintenance manual.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Mechanical lifting unit for reel movement and stockpiling with grip from the central pass-through hole. Clamping and releasing of the reel occur automatically and do not request the intervention of an operator.

CE-certified and supplied with use and maintenance manual.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Manual tilter for reels with a maximum weight of Kg. 2000 and a maximum flange diameter of 1000mm. It is possible to turn a reel from horizontal (pict.1) to vertical position (pict.2) and viceversa.

Available also in other versions with different ways of taking hold of a reel – please refer to the technical features. CE-certified and supplied with use use maintenance manual.

Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.

Manual lifter to handle horizontally reels with a maximum weight of Kg.1250 and a minimum central bore diameter of 30mm. Available in any colour. It is an excellent solution to lift reels where there are no possibilities to take hold from the flanges. CE-certified and supplied with use and maintenance manual. Consult the DIN 46391 / 46395 and DIN 46397 standards or customize your dimensions.