We produce machines and lines for the processing and packaging of cosmetic products. We are committed to responding promptly to every type of request - from laboratories and small businesses to extensive companies - in order to fulfill our common purpose: filling the world with beauty.

Vibrotech, now part of Marchesini Group Beauty, produces a wide range of feeding and orientation systems for the cosmetic market.

and internally design technologies that can be customized according to di erent needs leads Vibrotech to enter into various partnerships, including the one with the Marchesini Group which will prove to be strategic.

In 2017 the Group finalized the partial acquisition of Vibrotech, launching a common growth strategy in terms of industry 4.0.

With almost 50 employees including designers, electronics and specialized technicians, the Tuscany company, in addition to producing traditional vibrating and mechanical feeding systems, is now able to supply the customer with innovative and robotic feeding and orientation systems, designed in-house and customizable according to di erent needs.

Vibrotech feeding systems can handle a wide range of cosmetic solutions such as: bottles, brushes, caps, dispensers, droppers, eyeshadows, ferrules, jars, pumps, scrapers, stems, vials, glass products from tray.

Featured Model SNAIL

Snail is a vibratory feeding system which, thanks to circular containers and linear guides, is adaptable to multiple products such as ferrules, caps, stems, dispensers, pumps, vials, and brushes.

• Ability to configure machine layout according to needs: size, materials and external finish.

• Meet high production requirements while also ensuring rapid changeover.

• Careful handling of scratch-sensitive products.

• It is possible to supply circular vibrator or the complete self-managing feeding unit (fixed stand, cabin, linear accumulation, hopper, electrical system).

OUTPUT

Up to 300 pcm

Tracks: 1 or multiple

Position: variable

PRODUCT RANGE

Product diameter: 5mm - 100mm

Product height: 5mm -150mm

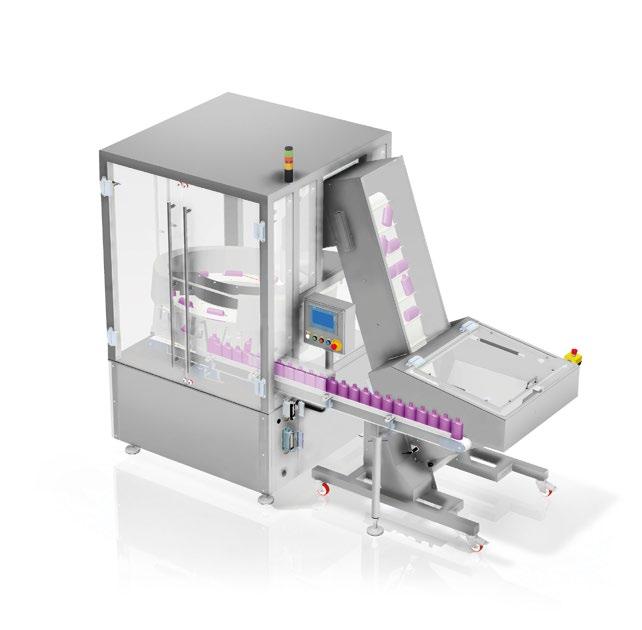

Carousel is a combined feeding system that is vibrating and mechanical type. It is suitable for handling brushes.

• It is suitable for products with unfavorable barycenters, which cannot be oriented by conventional vibrating feeding systems.

• The vibrating bowl has the function of hopper and pre-orientation. The mechanical part is responsible for completing the sorting.

• High production rates.

• Careful handling of scratch-sensitive products.

• The feeding unit is self-managing and supplied complete on an independent base.

• An hopper can be integrated to increase system autonomy.

Up to 200 pcm

Tracks: 1

Position: vertical axis with brush face down

PRODUCT RANGE

Product diameter: 10mm - 30mm

Product height: 50mm - 130mm

to prevent scratches on products and to handle products with rubber details

Featured Model ALVEOLAR SYSTEM

The alveolar system is a type of mechanical feeder adaptable to handle various forms of product such as dispensers, pumps, caps and jars.

• It consists of interchangeable sectors in the form of alveoli with a variety of shapes depending on the product to be selected.

• Fast and adjustment-free rapid changeover.

• Selections by a small number of air blows.

• The feeding unit is self-contained and supplied complete on an independent base.

• Possibility of integrating counting system.

OUTPUT

Up to 300 pcm

Tracks: 1

Position: vertical axis

PRODUCT RANGE

Product diameter: 15mm - 100mm

Product height: 15mm - 200mm

MECHANICAL

Featured Model TRESOR 1000

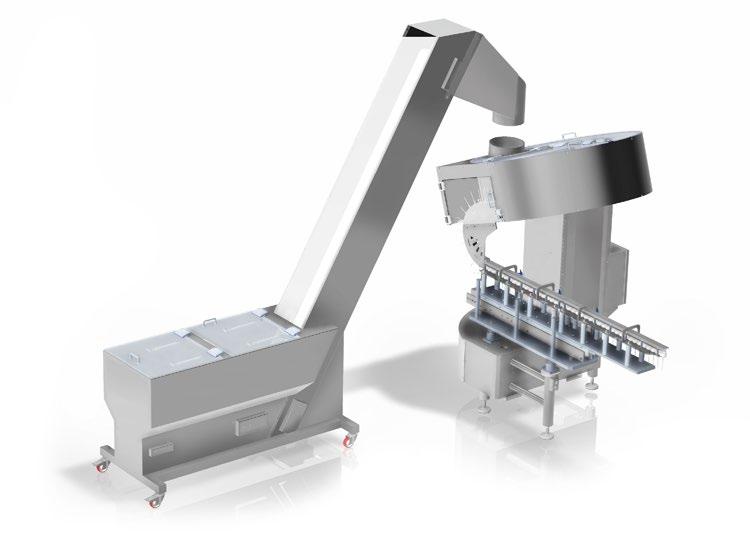

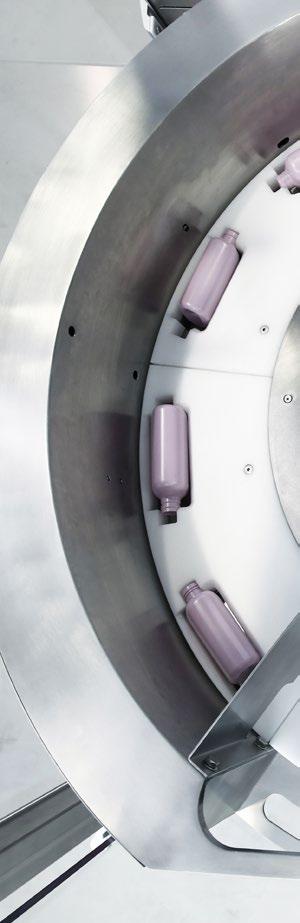

Tresor mechanical feeding system is designed primarily for feeding bottles of all sizes. It consists of circular unscrambler and linear belt conveyor.

• Its versatility and ease of changeover enable it to handle a wide range of bottle sizes.

• High production rates.

• It is suitable for products with unfavorable barycenters.

• Estimated size changeover in 15 minutes.

• Possibility of integration: inkjet printing station, cleaning station.

Up to 600 pcm

Tracks: 1

Position: vertical axis

Product diameter: 15mm - 200mm

Product height: 35mm - 400mm

OUTPUT

• Bottles capacity 10ml: up to 120 pcm

• Bottles capacity 200ml: up to 60 pcm

OUTPUT

• Bottles capacity 10ml: up to 220 pcm

• Bottles capacity 500ml: up to 70 pcm

OUTPUT

• Bottles capacity 10ml: up to 280 pcm

• Bottles capacity 1000ml: up to 120 pcm

OUTPUT

• Bottles capacity 10ml: up to 600 pcm

• Bottles capacity 1000ml: up to 220 pcm

Featured Model TRESOR G1200

Tresor G mechanical feeding system is designed primarily for feeding bottles of all sizes.

• Bottles handled in godet are: not suitable for accumulation, that need to maintain a radial phasing.

• Composed of circular unscrambler and linear belt conveyor.

OUTPUT

Up to 200 pcm

Tracks: 1

Position: vertical axis

PRODUCT RANGE

Product diameter: 15mm - 200mm

Product height: 35mm - 400mm

• Its versatility and ease of changeover allow a wide range of different bottle sizes to be handled.

• High production rates.

• It is suitable for products with unfavorable barycenters.

• Estimated size changeover in 20 minutes.

• Possibility of integration: inkjet printing station, cleaning station (carried out on an external station).

OUTPUT

• Bottles capacity 10ml: up to 120 pcm

• Bottles capacity 200ml: up to 60 pcm

OUTPUT

• Bottles capacity 10ml: up to 150 pcm

• Bottles capacity 1000ml: up to 80 pcm

OUTPUT

• Bottles capacity 10ml: up to 200 pcm

• Bottles capacity 1000ml: up to 100 pcm

The Tresor G bottles unscrambler is also capable of operating the direct insertion of products into pucks/godets.

Godets are standard holders that allow individual products to be positioned with fixed spacing and stability, even at high feeding rate. Product handling with godets is suitable for certain delicate, unstable, fragile cosmetic products with special shapes and unfavourable centres of gravity.

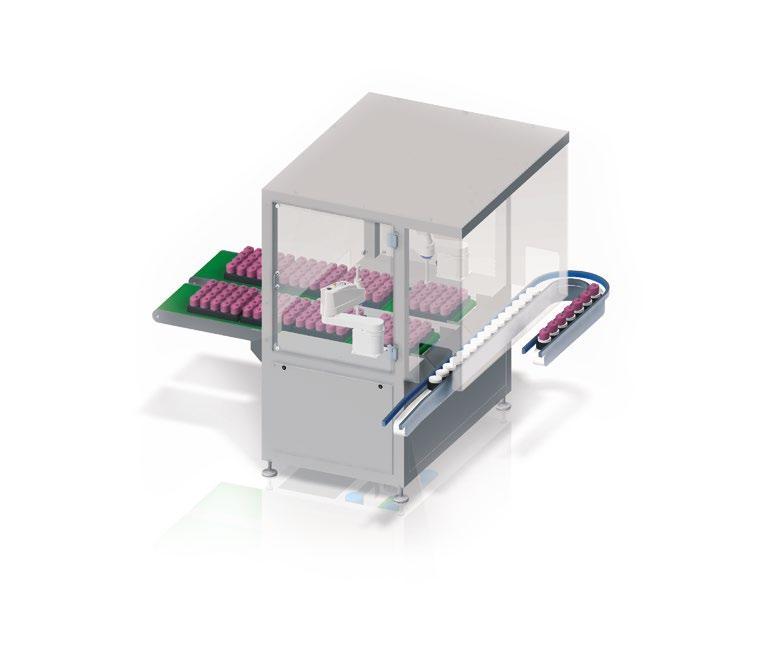

Vega is a robotic feeding system for handling tray products such as dispensers, caps, bottles or other products in both plastic and glass.

• The operator manually loads full trays and the trays are unloaded and collected outside the system.

• Dedicated software processes the images captured by the camera and sends the robot the coordinates of the products that can be picked from the tray.

Up to 40-60 ppm

Tracks: 1

Position: variable depending on the product

Product diameter: 20mm - 120mm

Product height: 20mm - 120mm

• Radial orientation of products.

• Bottles can be deposited on a conveyor belt or in godets.

• Caps can be deposited directly into the filled bottle.

• The station is designed to accommodate 2 Scara robots.

Featured Model TPR50

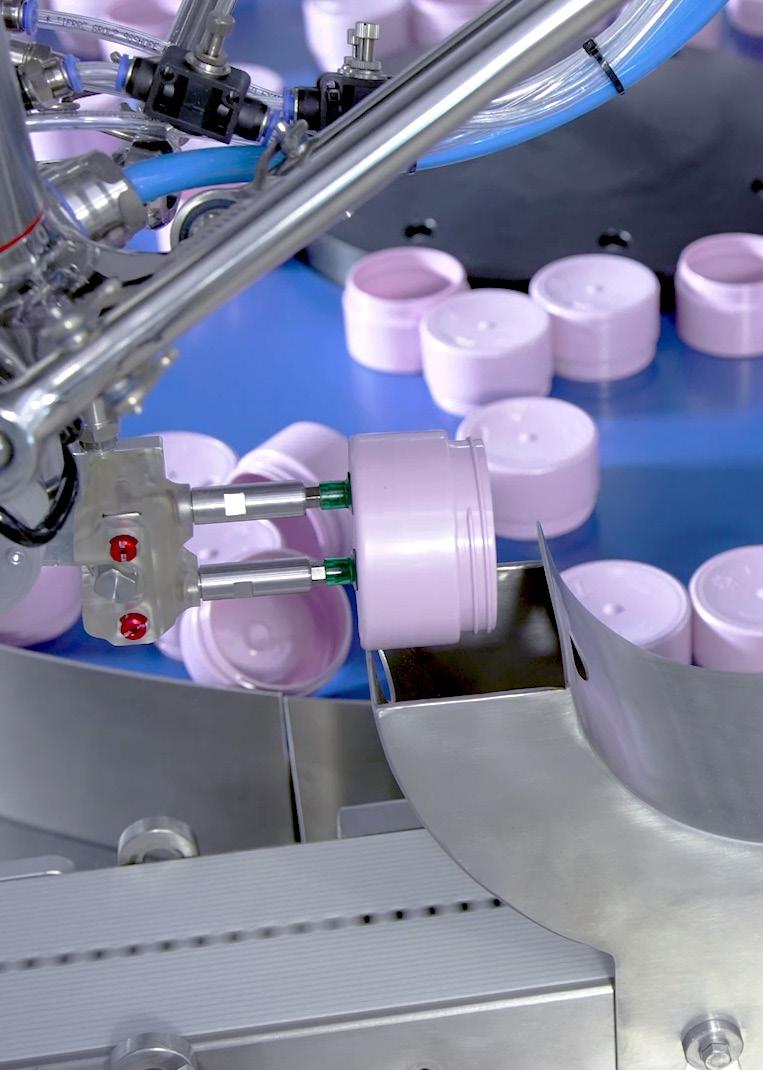

Vibroflex TPR is a flexible feeding system for handling tray products equipped with a robot, vision system, vibrating hopper, and vibrating plate that can process multiple products such as bottles, brushes and caps, and stems of all kinds.

• The hopper doses the products on the plate and is designed not to overload the vibrating platform, which operates the product handling.

• The vision system processes the images captured by the camera and send the coordinates of the pickable products to the robot.

• The robot pick up the products and deposit them oriented toward the destination. The station is prepared to accommodate different types of robots (anthropomorphic, SCARA, Delta) and from different producers.

• It is suitable for products with unfavorable barycenters.

• Handling of delicate products sensitive to scratches, possibility of distinction by internal details, and possibility of discarding nonconforming products.

• The system features ultrarapid format changeover managed by software.

• Possibility of inserting caps or brushes directly on already filled bottles.

• Possibility of using multiple stations to increase production rates.

OUTPUT

Up to 30 pcm deposit in pre-filled bottle

Up to 40 pcm deposit on accumulation guide

Up to 50 pcm double pick-up with deposit on accumulation guide

PRODUCT RANGE

Product diameter: 10mm - 100mm

Product height: 10mm - 150mm

Featured Model PEGASO

Pegaso is a robotic feeding system for handling bulk products. It can process different types of products such as bottles, jars, tubes, caps, brushes, flexible and delicate packaging products in different materials, excluding glass objects.

• The system consists of a rotating sorting disc, a belt (or vibrating) hopper that doses the products onto the rotating disc, a vision system that detects the products to be picked, and a Scara-type robot that picks up the products and deposits them at the outlet.

• High efficiency: all products loaded on the sorting disc are brought to the output without recycling with secondary systems.

• Gentle product handling: the system avoids repeated stresses on the products and thus their damage. It is therefore particularly suitable for delicate cosmetic packaging.

• Functional design and compact footprint.

• Format changeover time with zero mechanical parts for similar products.

• Robot gripper format changeover only for different products.

• Optional extras that can be integrated: deposit of products in godet and automatic emptying of products onto the disc.

Up to 40 pcm

Tracks: 1

Position: variable depending on product

Product diameter: 20mm - 120mm

Product height: 20mm - 200mm

Prism 60 is a robotic feeding system for handling bulk products. It can process different product types such as bottles, jars, tubes, caps, brushes, flexible and delicate packaging products in different materials, excluding glass objects.

system that detects the products to be picked, and a Delta-type robot that picks up the products and deposits them at the outlet.

• High efficiency: all products loaded on the sorting disc are brought to the exit without recycling with secondary systems.

OUTPUT

Up to 60 pcm

Tracks: 1

Position: variable depending on product

PRODUCT RANGE

Product diameter: 20mm - 120mm

Product height: 20mm - 250mm

suitable for delicate cosmetic packaging.

• Functional design and compact footprint.

• Format changeover time zero without mechanical parts for similar products.

• Robot gripper format changeover only for different product.

• Optional extras that can be integrated: deposit of products in godet and automatic emptying of products onto the disc.

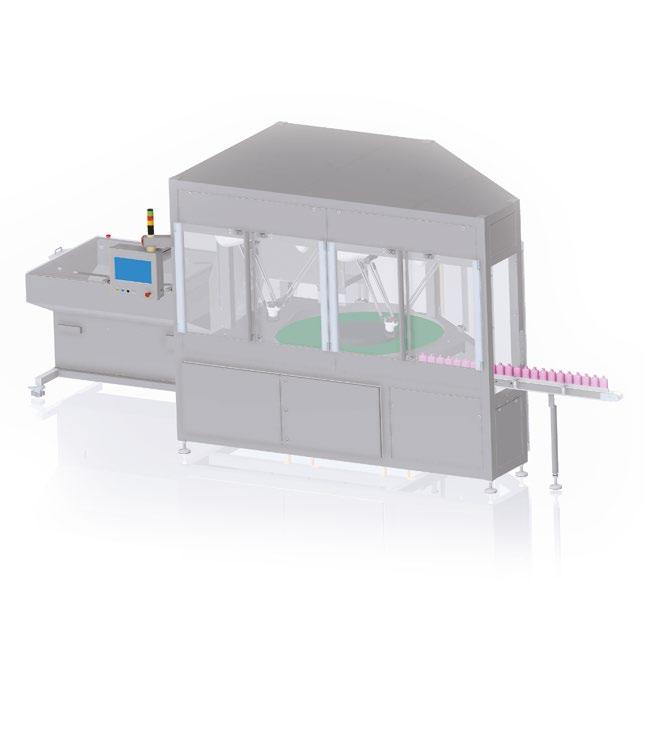

Featured Model PRISM 120

Prism 120 is a robotic feeding system for handling bulk products. It can process different types of products such as bottles, jars, tubes, caps, brushes, flexible and delicate packaging products in different materials, excluding glassware.

• The system consists of a rotating sorting disc, a belt (or vibrating) hopper that doses the products onto the rotating disc, a vision system that detects the products to be picked, and two Delta-type robots that pick up the products and deposit them at the output.

• High efficiency: all products loaded on the sorting disc are brought to the exit without being recycled by secondary systems.

OUTPUT

Up to 120 pcm

Tracks: 1

Position: variable depending on product

PRODUCT RANGE

Product diameter: 20mm - 120mm

Product height: 20mm - 250mm

• Gentle product handling: the system avoids repetitive strain on the products and thus damage to them. It is therefore particularly suitable for delicate cosmetic packaging.

• Functional design and compact footprint.

• Format changeover time zero without mechanical parts for similar products.

• Robot gripper format changeover only for different products.

• Optional extras that can be integrated: deposit of products in godet and automatic emptying of products onto the disc.

Our project engineers are at customer’s disposal to carry out special projects too meet customer satisfactions.

The technical specifications given in this catalogue are subject to change without prior notice or liability. Size range may vary in accordance with the di erent applications. Vibrotech constantly updates its products to meet market needs.

Vibrotech S.r.l.

Via Achille Pacini, 107 • 56031 Bientina Pi

ITALY

T +39 0587 734 310 sales@vibrotech.it vibrotech.it

MARCHESINI GROUP BEAUTY

LET’S FILL OUR WORLD WITH BEAUTY