Packaging solutions inspired by the extraordinary

Packaging solutions inspired by the extraordinary

Index ABOUT MARCHESINI GROUP ................................................. 4 KEYPOINT ............................................................................... 5 Turboemulsifiers homogenizer ........................................... 6 Mixers & melters ................................................................. 11 Cleaning systems ................................................................ 13 Tableting ............................................................................... 16 OUR COMPANIES

We at Marchesini Group are proud leaders in manufacturing and integrating complete lines since 1974.

To complete the range of production machines for the pharmaceutical industry, the Group companies Dott. Bonapace and Dumek allow Marchesini Group to supply processing machines for different types of products such as solids, capsules, tablets and creamy products.

Continuous improvement of existing solutions and research of new products and processes is the base of our philosophy for the design of solutions able to satisfy customers’ needs.

4

Keypoint

Biplanetary mixer for maximum homogenization efficiency

Ergonomic design

System for integrated and optimized heating and cooling, to maximize energy savings

Efficiency and Accuracy

Water consumption optimization during washing

User Friendly solutions

5

Turboemulsifiers homogenizer

TURBOEMULSIFIERS HOMOGENIZER

Vacuum overpressure

PHARMA-MEK | OPENABLE & TILTABLE

Featured Model PHARMA-MEK 2000

Vacuum turboemulsifiers suitable for processing liquid and creamy products.

VESSEL

• Openable lid

• Tilting vessel up to 3000

• Parts in direct contact with product in AISI 316 stainless steel

TEMPERATURE MANAGEMENT

• Vessel with inner jacket filled with water/thermic fluids for heating and cooling

• Smart temperature control system (patented) for temperature CURVE DESIGN

• Additional insulation jacket

VACUUM

• Vacuum circuit with visual passage and liquid ring pump

EQUIPMENT OF THE VESSEL

• Funnel on the lid for auxiliary substances loading

• Sight-port equipped with glass-wiper and light-port with momentary light on the lid

• TriClamp connections on the lid

• Membrane valves on the lid

MIXER

• Slow coaxial mixing system (counter-rotating)

• Mixing blade with optimized profile for the vertical movement of product, including PTFE scrapers

• Variable speed of the Mixer through inverter

TURBINE

• Homogenizing turbine - rotor/stator typeat the bottom of the vessel

• Variable speed of the turbine through inverter

VESSEL UNLOADING

• Piston valve for the product unloading, placed at the bottom of the vessel

RANGE 25-3000 litres

SUPPORTING STRUCTURE

• AISI 304 stainless steel supporting structure with anti-vibration/self-levelling and adjustable support feet

OPERATOR PANEL

• TOUCH SCREEN operator panel with Siemens PLC

• Digital visualization of the process parameters

• Function for the continuous recording of process parameters: trends and datalogger (D-SCRIBA)

• CFR 21

7

8

TURBOEMULSIFIERS

Vacuum overpressure

PHARMA-MEK | OPENABLE

Vacuum turboemulsifiers suitable for processing liquid and creamy products.

VESSEL

• Openable lid

• Static vessel

• Parts in direct contact with product in AISI 316 stainless steel (optional)

DUAL TECHNOLOGY

• Internal recirculation in combination with external recirculation

TEMPERATURE MANAGEMENT

• Vessel with inner jacket filled with water/thermic fluids for heating and cooling

• Smart temperature control system (patented) for temperature CURVE DESIGN

• Additional insulation jacket

VACUUM

• Vacuum circuit with visual passage and liquid ring pump

EQUIPMENT OF THE VESSEL

• Funnel on the lid for auxiliary substances loading

• Sight-port equipped with glass-wiper and light-port with momentary light on the lid

• TriClamp connections on the lid

• Membrane valves on the lid

MIXER

• Slow coaxial mixing system (counter-rotating)

• Mixing blade with optimized profile for the vertical movement of product, including PTFE scrapers

• Variable speed of the Mixer through inverter

TURBINE

• Homogenizing turbine - rotor/stator typeat the bottom of the vessel

• Variable speed of the turbine through inverter

RANGE 600-5000 litres with intermediate capacities

VESSEL UNLOADING

• Piston valve for the product unloading, placed at the bottom of the vessel

SUPPORTING STRUCTURE

• AISI 304 stainless steel supporting structure with anti-vibration/self-levelling and adjustable support feet

OPERATOR PANEL

• TOUCH SCREEN operator panel with Siemens PLC

• Digital visualization of the process parameters

• Function for the continuous recording of process parameters: trends and datalogger (D-SCRIBA)

Featured Model PHARMA-MEK 1000 HOMOGENIZER

• CFR 21

TURBOEMULSIFIERS

Vacuum overpressure

PHARMA-FIX

| FIXED LID & VESSEL

Featured Model PHARMA-FIX 1000

Vacuum turboemulsifiers suitable for processing liquid and creamy products.

VESSEL

• Fixed vessel with fixed lid

• Parts in direct contact with product in AISI 316 stainless steel (optional)

DUAL TECHNOLOGY

• Internal recirculation in combination with external recirculation

TEMPERATURE MANAGEMENT

• Vessel with inner jacket filled with water/thermic fluids for heating and cooling

• Smart temperature control system (patented) for temperature CURVE DESIGN

• Additional insulation jacket

VACUUM

• Vacuum circuit with visual passage and liquid ring pump

EQUIPMENT OF THE VESSEL

• Funnel on the lid for auxiliary substances loading

• Sight-port equipped with glass-wiper and light-port with momentary light on the lid

• TriClamp connections on the lid

• Membrane valves on the lid

MIXER

• Slow coaxial mixing system (counter-rotating)

• Mixing blade with optimized profile for the vertical movement of product, including PTFE scrapers

• Variable speed of the Mixer through inverter

TURBINE

• Homogenizing turbine - rotor/stator type - at the bottom of the vessel

• Variable speed of the turbine through inverter

RANGE

25-20000 litres with intermediate capacities

VESSEL UNLOADING

• Piston valve for the product unloading, placed at the bottom of the vessel

SUPPORTING STRUCTURE

• AISI 304 stainless steel supporting structure with anti-vibration/self-levelling and adjustable support feet

OPERATOR PANEL

• TOUCH SCREEN operator panel with Siemens PLC

• Digital visualization of the process parameters

• Function for the continuous recording of process parameters: trends and datalogger (D-SCRIBA)

• CFR 21

HOMOGENIZER

9

TURBOEMULSIFIERS

Atmospheric pressure

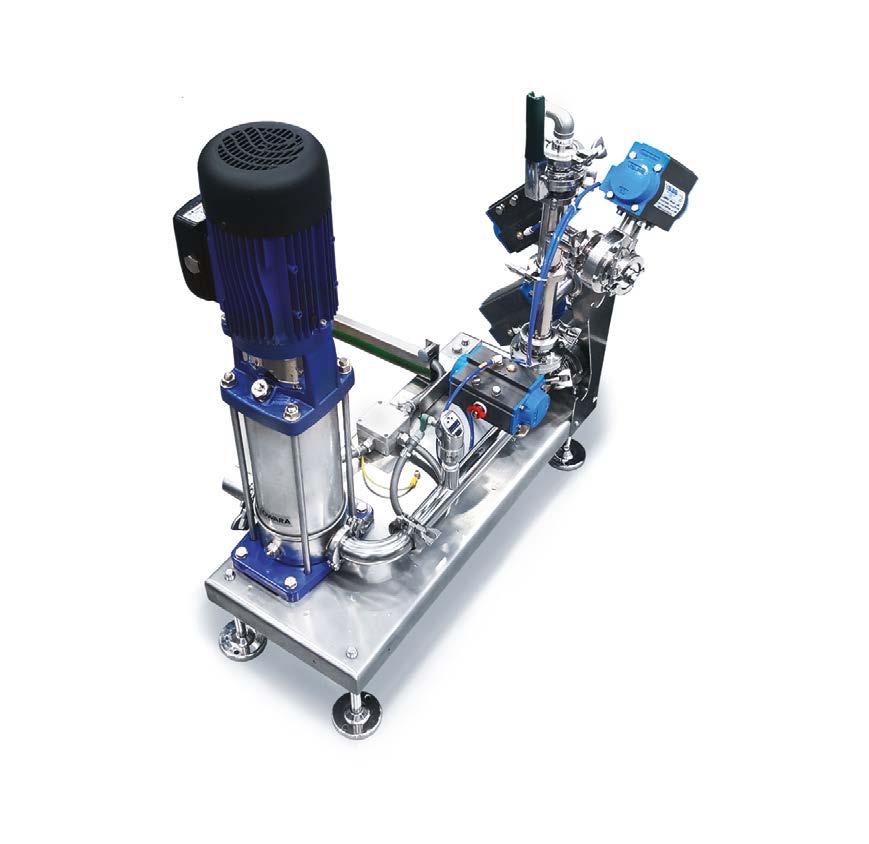

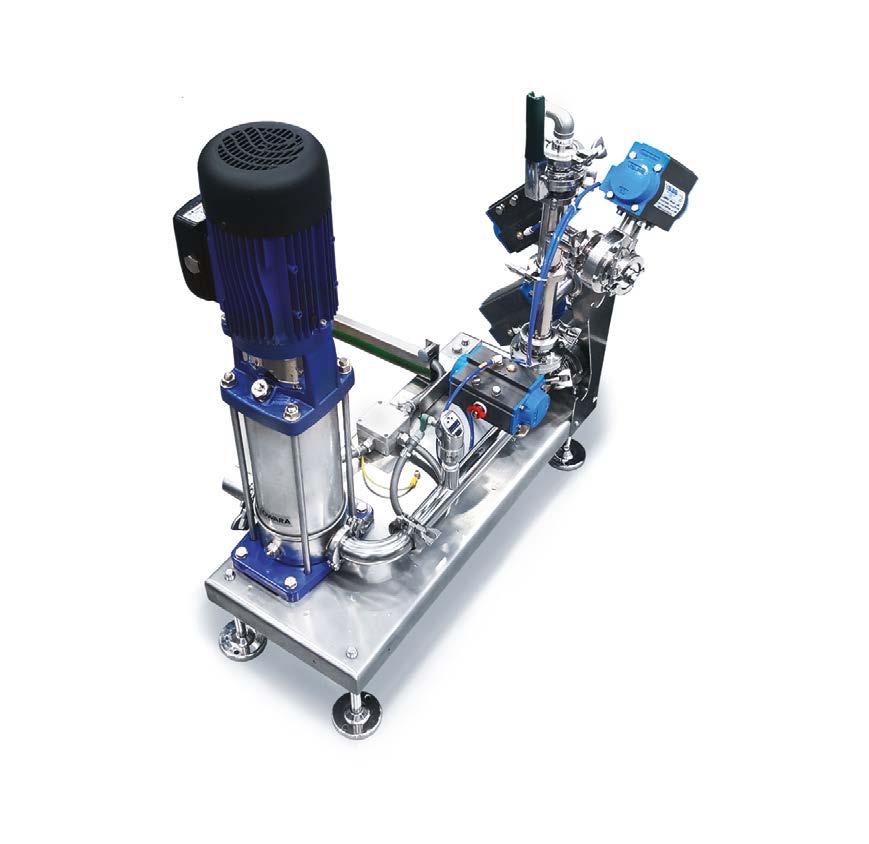

MIXER & MELTER HOMOGENIZER

Featured Model MELTER 50 + HOMOGENIZER

Melter and Mixer equipped with additional homogenizer conceived originally as machines for the preparation and heating of water or oil phases, when equipped with an adequate mixing system are turned into real preparation unit for products that do not require vacuum processing.

VESSEL

• Stainless steel vessel

• Vessel with inner jacket filled with water/thermic fluids

• Outer insulating jacket

• Vessel equipped with homogenizing unit on the bottom (otional)

TEMPERATURE MANAGEMENT

• Thermoregulation of the product

VESSEL UNLOADING

• Inclined bottom with a side-discharging valve

STRUCTURE

• Supporting frame on wheels or on feet

• Lid in two parts with one openable side

• Parts in direct contact with product in AISI 316 stainless steel

RANGE 10-5000 litres

HOMOGENIZER

10

Mixers & melters

Atmospheric pressure

MIXER & MELTER

Featured Model MELTER 1000

Turboemulsifier ancillary units for heating the oil/water phase or, when equipped with an adequate mixing system, a processing unit suitable for some creamy products, which do not require sophisticated emulsifier functions.

VESSEL

• Stainless steel vessel

• Vessel with inner jacket filled with water/thermic fluids

• Vessel can be equipped with: slow stirrer anchor shaped and/or fast mixer helix+Cowles

TEMPERATURE MANAGEMENT

• Thermoregulation of the product

• Outer insulating jacket

VESSEL UNLOADING

• Inclined bottom with a side-discharging valve

STRUCTURE

• Control panel fixed to the vessel

• Lid in two parts with one openable side

• Parts in direct contact with product in AISI 316 stainless steel

RANGE 10-5000 litres

MIXERS & MELTERS

12

Cleaning systems

Cleaning systems

SEMI-AUTOMATIC CIP

Featured Model SEMI-AUTOMATIC CIP

Standalone or Integrated systems to manage the machine washing in a semi-automatic mode by setting the duration of the washing phases.

• N° 2 automatic water loading valves

• N° 1 Automatic valve connected to the manual valve positionned on the bottom of the vessel (optional)

CLEANING SYSTEMS

14

Cleaning systems FULLY AUTOMATIC CIP

Featured Model FULLY AUTOMATIC CIP

Standalone fully automatic CIP fixed system to manage the washing in a fully automatic mode.

• Main skid featuring

• N° 2 dosing pumps for detergents

• N° 2 water storage vessels

• Steam exchanger for the water heating

• System self-cleaning

CLEANING SYSTEMS

15

Tableting

Tablet pressing

CPR-6 SE

Featured Model CPR-6 SE

Bench top tablet press machine for small batches, designed for pharmacies, hospitals, universities and also R&Ds, in a word everywhere a small batch is needed.

• Solution for formulation development phase

• Medium and high containment (isolator) solution

• Standard punches type B or D

• Dedicated software for supporting analysis of the data

TABLETING

to 2.500 tabs / h 17

OUTPUT Up

Tablet pressing

CPR-18 SE

Featured Model CPR-18 SE

A bench top rotary tablet press machine for R&D applications, clinical testing and small production batches (laboratory batches).

• Three different turrets available

• Medium and high containment (isolator) solutions

• Flexible and compact solution

• Dedicated software for supporting analysis of the data

TABLETING

OUTPUT

to 18.000 tabs / h 18

Up

Tablet pressing CPR-22

Featured Model CPR-22

Ideal for pharmaceutical and nutraceutical industries.

• Three different turrets available

• Solution for medium production batches

• Dedicated software for supporting analysis of the data

• Medium and high containment (isolator) solution

• 3 different discharge chute available (production, sampling, discarded, )

• Solution for nutraceutical products

OUTPUT

Up to 36.000 tabs / h

TABLETING

19

Tablet pressing

CPR-22 DOUBLE LAYER

Featured Model CPR-22

DOUBLE LAYER

New solution for pharmaceutical and nutraceutical applications.

• Three different turrets available

• Dedicated software for supporting analysis of the data

• First layer sampling

• Robust design

• Medium and high containment (isolator) solution

OUTPUT

Up to 36.000 tabs / h

TABLETING

20

The technical specifications given in this catalogue are subject to change without prior notice or liability.

Size range may vary in accordance with the different applications.

The Marchesini Group constantly updates its products to meet market needs.

Marchesini Group S.p.A.

Via Nazionale 100 • 40065 Pianoro BO ITALY

T +39 051 047 9111 sales@marchesini.com marchesini.com

MARCHESINI GROUP

INSPIRED BY THE EXTRAORDINARY

Packaging solutions inspired by the extraordinary

Packaging solutions inspired by the extraordinary