How to Diagnose and Fix Common Problems in Caterpillar C15 Truck Engine: Service Manual Guide

Click Here to Download Now

Common problems in Caterpillar C15 truck engines can lead to significant downtime for truck owners, fleet managers, and diesel mechanics. The Caterpillar C15, a robust inline-6 diesel engine introduced in 1999 as an upgrade to the 3406E, powers heavy-duty trucks in applications like long-haul transport, construction, and mining. With its reputation for fuel efficiency and reliability, the C15 remains a staple, but issues such as head gasket failures, turbocharger problems, and cooling system challenges are frequent. This service manual guide

provides a detailed, step-by-step approach to diagnosing and fixing common problems in Caterpillar C15 truck engines, drawing from realworld service insights. Whether you're dealing with starting issues or power loss, this guide equips you with practical tips to restore performance and extend engine life.

Table of Contents

• Understanding the Caterpillar C15 Truck Engine

• Common Problems in Caterpillar C15 Truck Engines

• Step-by-Step Diagnosis of C15 Engine Issues

• How to Fix Common Problems: Practical Solutions

• Preventive Maintenance Tips for Caterpillar C15 Engines

• Conclusion

• FAQ

Understanding the Caterpillar C15 Truck Engine

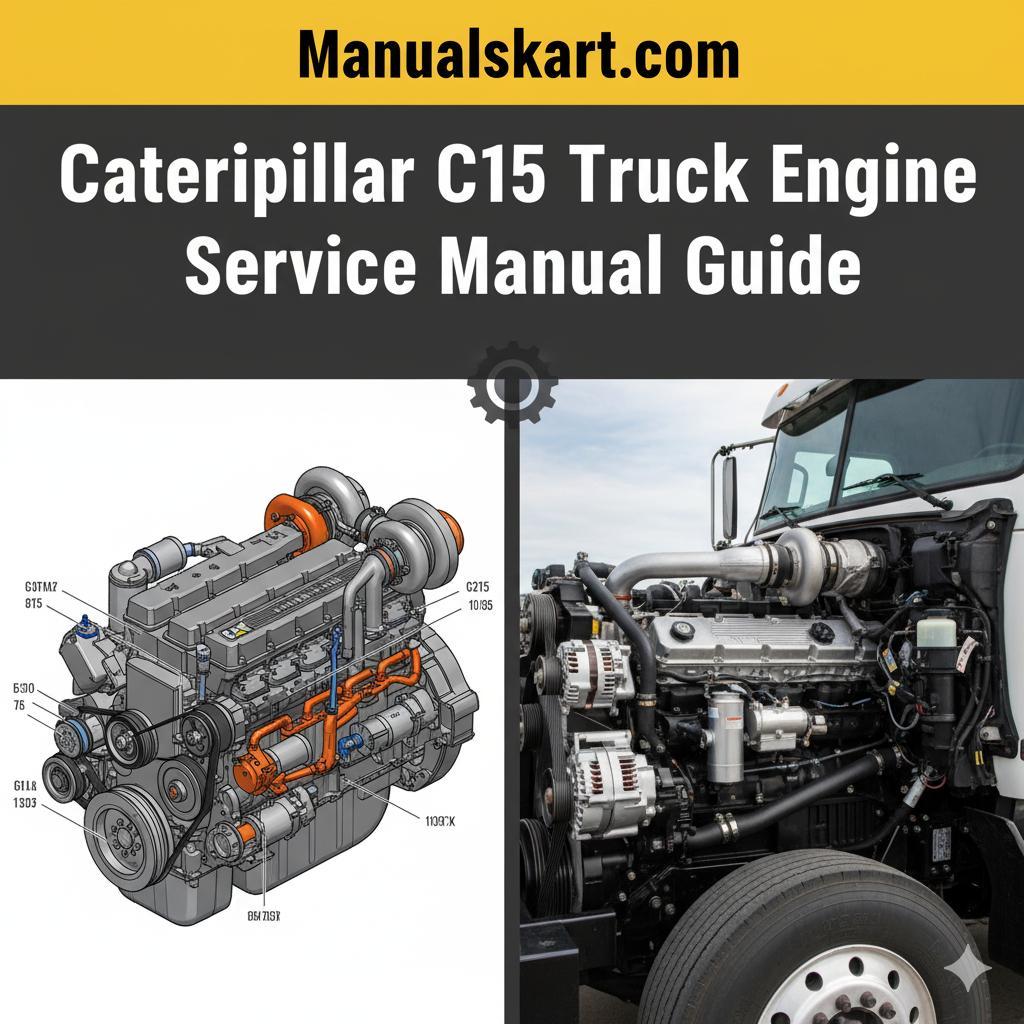

The Caterpillar C15 truck engine is a 15.2-liter inline-6, four-stroke diesel powerhouse designed for heavy-duty applications. Released in 1999, it improved upon the 3406E with stronger gaskets, enhanced seals, and better adaptability for on-highway and off-highway use.

Models like the ACERT variants incorporate advanced emissions controls, but all C15 engines share core components that can wear over time, leading to common problems in Caterpillar C15 truck engines.

Key Components and Their Functions

• Cylinder Head and Gaskets: Facilitate combustion; prone to cracking or gasket failure under high pressure.

• Turbocharger: Boosts air intake for power; bearings and fins can fail from debris or friction.

• Fuel System (Injectors and Pump): Delivers precise fuel; clogging leads to poor performance.

• Cooling System: Manages heat; leaks or restrictions cause overheating.

• ECM and Sensors: Electronic controls for timing and fuel; faults result in starting issues.

• Engine Block: Sturdy foundation; design flaws can exacerbate gasket problems.

Grasping these elements is essential for effective troubleshooting. For instance, the C15's engine block design is often cited as the root cause of head gasket issues rather than the gasket itself, highlighting the need for comprehensive inspections.

Common Problems in Caterpillar C15 Truck Engines

The C15's durability is legendary, but high-mileage use in demanding environments reveals recurring issues. Based on mechanic reports and service data, here are the most common problems in Caterpillar C15 truck engines.

Typical Issues

• Head Gasket and Cylinder Head Failures: Cracks or blown gaskets lead to coolant leaks into cylinders, causing overheating and power loss.

• Turbocharger Faults: Failed bearings cause the turbo to rub its housing, resulting in reduced boost, hot running, and debris damage to fins.

• Cooling System Challenges: Leaks, restricted flow, or faulty thermostats contribute to overheating, especially in ACERT models.

• Fuel System Problems: Clogged injectors or low fuel pressure cause starting failures, poor performance, and high consumption.

• ECM and Sensor Issues: Communication faults or weak signals prevent starting, often without check engine lights.

• Starting Difficulties: Common in older 6NZ models, linked to check valves, priming pumps, or timing sensors.

Real-World Examples

• A 2005 Peterbilt 379 with a C15 ACERT required ether to start, traced to a missing O-ring in the filter head bleeder bolt after replacing check valves twice.

• Fleet operators report intermittent low power in MXS C15s during engine braking, due to low fuel pressure (below 75-90 PSI) or boost leaks.

These problems, if unaddressed, can escalate to major repairs costing $5,000-$15,000, but early intervention keeps the C15 reliable.

Step-by-Step Diagnosis of C15 Engine Issues

Diagnosing common problems in Caterpillar C15 truck engines starts with safety: Park the truck on level ground, shut off the engine, and use protective gear. Consult the official Caterpillar service manual for model-specific codes.

Diagnostic Steps

1. Visual Inspection: Check for leaks around the head gasket, turbo housing, hoses, and cooling lines. Look for coolant residue or oil contamination.

2. Fluid Level and Condition Check: Inspect coolant, oil, and fuel levels. Milky oil indicates head gasket failure; contaminated fuel points to injector issues.

3. Scan for Codes: Use Cat ET software or an OBD scanner to read ECM codes. No light doesn't rule out sensor faults.

4. Pressure Testing: Measure fuel pressure (should be 75-90 PSI at the secondary filter plug) and boost (40 PSI normal; 30 PSI during braking signals issues).

5. Listen and Feel for Symptoms: Crank the engine for unusual noises (whining turbo) or vibrations. Test for starting with/without ether.

6. Component-Specific Tests: For turbo, check for shaft play; for cooling, pressure-test the radiator. Prime the fuel system manually to assess pump stiffness.

7. Road Test: Monitor power, boost, and temperature under load to replicate intermittent issues like low power during braking.

Tools Needed

• Cat ET diagnostic tool

• Pressure gauge kit (fuel and cooling)

• Fuel pressure test plug adapter

• Thermometer or infrared gun

• Basic wrenches and OBD scanner

This systematic approach pinpoints issues efficiently. For example, low fuel pressure without codes often indicates a regulator or filter problem in MXS models.

How to Fix Common Problems: Practical Solutions

Fixing common problems in Caterpillar C15 truck engines requires genuine parts for compatibility. Always torque to spec and retest postrepair.

Repair Strategies

• Head Gasket/Cylinder Head Fixes: Resurface or replace the head if cracked. Install upgraded fire-ring gaskets. Flush cooling system to remove debris.

• Turbocharger Repairs: Replace bearings or the entire unit if fins are damaged. Clean intake to prevent debris ingress; costs $1,500$3,000.

• Cooling System Solutions: Replace leaking hoses, thermostats, or the radiator. For ACERT coolant loss, inspect EGR lines first.

• Fuel System Overhauls: Clean or replace clogged injectors; swap fuel filters and check the regulator under the housing. Address low pressure with a new transfer pump.

• ECM/Sensor Corrections: Update software or replace faulty sensors (e.g., cam/timing). For starting issues, verify O-rings and check valves in the filter head.

• General Starting Fixes: Hand-prime until stiff; if persistent, inspect the ECM for communication faults.

DIY vs. Professional Repairs

• DIY: Fluid changes, filter replacements, and basic inspections for experienced owners.

• Professional: Head work, turbo rebuilds, or ECM programming to avoid voiding warranties.

Repairs vary: $200 for filters to $10,000 for a full head job. In deleted DPF models (post-2007), reliability improves, but monitor coolant loss carefully.

Preventive Maintenance Tips for Caterpillar C15 Engines

Routine service prevents most common problems in Caterpillar C15 truck engines, ensuring longevity beyond 500,000 miles.

Maintenance Checklist

• Change fuel and oil filters every 10,000 miles or 500 hours; use Cat-approved fluids.

• Inspect turbo and cooling hoses quarterly for wear.

• Monitor coolant levels daily; replace every 2 years to avoid contamination.

• Run diagnostics monthly with Cat ET to catch sensor issues early.

• Avoid overloading; train drivers on proper regen cycles for ACERT models.

Best Practices

• Flush the cooling system annually to prevent restrictions.

• Use high-quality fuel to minimize injector clogging.

• For older 6NZ engines, replace check valves proactively every 100,000 miles.

Mechanics and owners can join forums like Reddit's r/DieselTechs for tips, while tracking service logs helps spot trends like intermittent power loss.

Conclusion

Common problems in Caterpillar C15 truck engines, from head gasket failures to turbo issues, can be managed effectively with proper diagnosis and repairs. By understanding the engine's components, identifying symptoms like low power or starting difficulties, following step-by-step diagnostics, and implementing targeted fixes, you'll maintain peak performance. Preventive maintenance is the cornerstone of reliability, reducing downtime and costs for heavy-duty operations.

For a complete Caterpillar C15 truck engine service manual guide, visit Manualskart.com. Our platform offers downloadable PDFs with detailed diagrams, torque specs, and troubleshooting procedures tailored to your C15 model. Empower your maintenance routine— download today and keep your truck engine running strong!

FAQ

What are the most common problems in Caterpillar C15 truck engines?

Frequent issues include head gasket failures, turbocharger faults, cooling system leaks, fuel injector clogs, and starting difficulties due to sensor or valve problems.

How do I diagnose head gasket issues in a C15 engine?

Check for milky oil, coolant loss, or overheating. Perform a compression test or use Cat ET for codes; pressure-test the cooling system for confirmation.

Why does my Caterpillar C15 have low power during engine braking?

This intermittent issue often stems from low fuel pressure (below 75 PSI) or boost leaks. Test pressure at the secondary filter and inspect air piping.

Can I fix turbocharger problems on a C15 myself?

Minor inspections yes, but replacements require professional tools. Common fixes involve bearing swaps; always clean debris to prevent recurrence.

Where can I get a full Caterpillar C15 service manual?

Manualskart.com provides comprehensive C15 service manuals with repair guides, parts lists, and diagrams for all variants, including ACERT models. Click Here to Download Now