Caterpillar C15

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017

FuelPrimingPump-RemoveandInstall

SMCS-1258-010

RemovalProcedure

NOTICE

Caremustbetakentoensurethatfluidsarecontainedduring performanceofinspection,maintenance,testing,adjusting,andrepair oftheproduct.Bepreparedtocollectthefluidwithsuitablecontainers beforeopeninganycompartmentordisassemblinganycomponent containingfluids.

RefertoSpecialPublication,NENG2500,"DealerServiceTool Catalog"fortoolsandsuppliessuitabletocollectandcontainfluidson Catproducts.

Disposeofallfluidsaccordingtolocalregulationsandmandates.

NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

1.Turnthefuelsupplytothe“OFF”position.

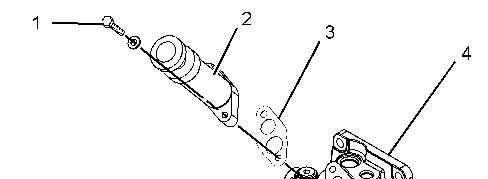

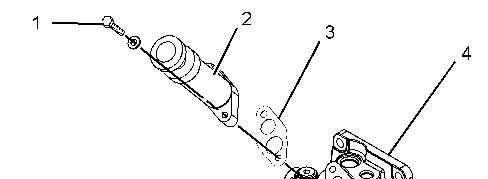

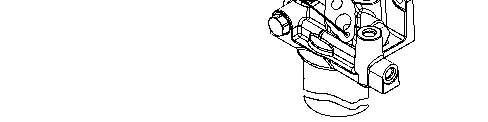

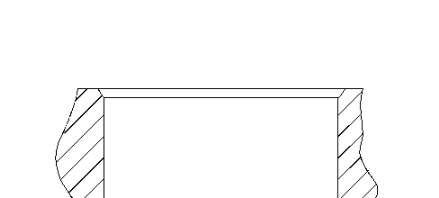

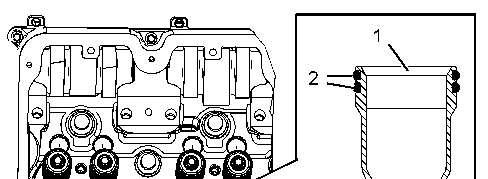

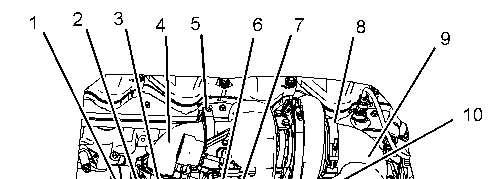

Illustration1g01075873

2.Removebolts(1).Removefuelprimingpumpassembly(2)fromfuelfilterbase(4).

3.Removegasket(3)fromthefuelprimingpumpassemblyandthefuelfilterbase.

InstallationProcedure

NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

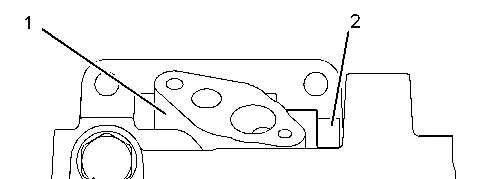

Illustration2g01075873

1.Positiongasket(3)onfuelfilterbase(4).

2.Positionfuelprimingpumpassembly(2)onthefuelfilterbaseandinstallbolts(1).Tighten theboltstoatorqueof15±3N·m(11±2lbft).

3.Turnthefuelsupplytothe“ON”position.

4.Removetheairfromthesystem.RefertoTestingandAdjusting,"FuelSystem-Prime".

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:41:16UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017 i02121646

FuelFilterBase-Remove

SMCS-1262-011

RemovalProcedure Table1

RequiredTools

ToolPartNumberPartDescriptionQty A185-3630StrapWrench1

NOTICE

Caremustbetakentoensurethatfluidsarecontainedduring performanceofinspection,maintenance,testing,adjusting,andrepair oftheproduct.Bepreparedtocollectthefluidwithsuitablecontainers beforeopeninganycompartmentordisassemblinganycomponent containingfluids.

RefertoSpecialPublication,NENG2500,"DealerServiceTool Catalog"fortoolsandsuppliessuitabletocollectandcontainfluidson Catproducts.

Disposeofallfluidsaccordingtolocalregulationsandmandates.

NOTICE

Keepallpartscleanfromcontaminants.

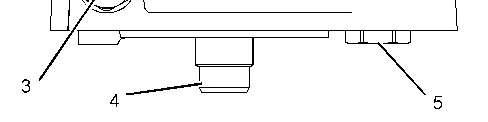

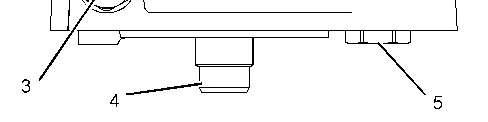

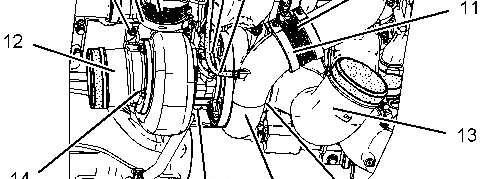

1.Turnthefuelsupplytothe“OFF”position. Illustration1g01080654

2.Disconnecthoseassembly(3)fromfuelfilterbase(4).

3.Disconnecthoseassembly(5).

4.Disconnecttubeassembly(6).

5.Disconnecttheharnessassemblyfromfuelpressuresensor(3).Removethefuelpressure sensorfromthefuelfilterbase.

6.UseTooling(A)toremovefuelfilter(7)fromfuelfilterbase(4).

7.Removebolts(1)andremovethefuelfilterbase.

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:41:47UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017

FuelFilterBase-Disassemble

SMCS-1262-015

DisassemblyProcedure

StartBy:

a.Removethefuelfilterbase.RefertoDisassemblyandAssembly,"FuelFilterBaseRemove".

NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

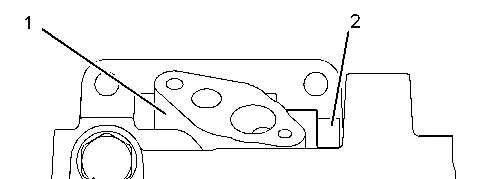

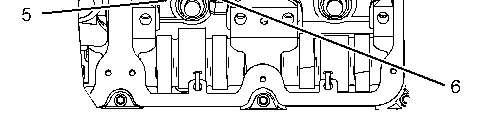

Illustration1g01063845

1.Removefuelbypassvalve(2)fromfuelfilterbaseassembly(1).RemovetheO-ringseals fromthefuelbypassvalve.

2.Removefuelcheckvalve(5)fromfuelfilterbaseassembly(1).RemovetheO-ringseals fromthefuelcheckvalve.

3.Removefitting(3)fromfuelfilterbaseassembly(1).RemovetheO-ringsealsfromthe fitting.

4.Ifnecessary,removehollowstud(4)fromfuelfilterbaseassembly(1).

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:42:02UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017

FuelFilterBase-Assemble

SMCS-1262-016

AssemblyProcedure

Table1

RequiredTools

ToolPartNumberPartDescriptionQty A155-0695ThreadLockCompound-

NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

1.InstalltheO-ringsealsonfuelbypassvalve(2).Installthefuelbypassvalveinfuelfilter baseassembly(1).

2.InstalltheO-ringsealsonfuelcheckvalve(5).Installthefuelcheckvalveinfuelfilter baseassembly(1).Tightenthefuelcheckvalvetoatorqueof28±3N·m(21±2lbft).

3.InstalltheO-ringsealsonfitting(3).Installthefittinginfuelfilterbaseassembly(1).

4.Ifnecessary,installhollowstud(4)tofuelfilterbaseassembly(1).Tightenthehollowstud toatorqueof70±15N·m(52±11lbft).

Note:ApplyTooling(A)tothefirst7.6±0.8mm(0.30±0.03inch)ofthreadsatthebase endofthetaperlockstud.

EndBy:Installthefuelfilterbase.RefertoDisassemblyandAssembly,"FuelFilterBaseInstall".

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:42:25UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017 i02121648

FuelFilterBase-Install

SMCS-1262-012

InstallationProcedure NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

1.Positionfuelfilterbase(4)onthecylinderblock.Installbolts(1).

2.Installfuelfilter(7)onthefuelfilterbase.Followthedirectionsonthefuelfilterforthe correctinstallationprocedure.Donotovertightenthefuelfilter.

3.Connecthoseassembly(3)tothefuelfilterbase.

4.Connecthoseassembly(5)tothefuelfilterbase.

5.Connecttubeassembly(6)tothefuelfilterbase.

6.Installfuelpressuresensor(3).Connecttheharnessassemblytothefuelpressuresensor.

7.Turnthefuelsupplytothe“ON”position.

8.Removetheairfromthesystem.RefertoTestingandAdjusting,"FuelSystem-Prime".

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:42:39UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017

FuelTransferPump-Remove

SMCS-1256-011

RemovalProcedure

NOTICE

Caremustbetakentoensurethatfluidsarecontainedduring performanceofinspection,maintenance,testing,adjusting,andrepair oftheproduct.Bepreparedtocollectthefluidwithsuitablecontainers beforeopeninganycompartmentordisassemblinganycomponent containingfluids.

RefertoSpecialPublication,NENG2500,"DealerServiceTool Catalog"fortoolsandsuppliessuitabletocollectandcontainfluidson Catproducts.

Disposeofallfluidsaccordingtolocalregulationsandmandates.

NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

1.Turnthefuelshutoffvalvetothe“OFF”position.

2.Disconnectthefuelsupplylineatthefueltransferpump.

3.Disconnecttubeassembly(4).

4.Removebolts(3).

5.Removefueltransferpump(1)fromfronthousing(5).

6.RemoveO-ringseal(2)fromthefueltransferpump.

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:42:56UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017

FuelTransferPump-Install

SMCS-1256-012

InstallationProcedure

NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

1.InstallO-ringseal(2)onfueltransferpump(1).LubricatetheO-ringsealwithcleanengine oil.

2.Positionthefueltransferpumponfronthousing(5).Installbolts(3).

3.Connecttubeassembly(4).

4.Connectthefuelsupplylinetothefueltransferpump.

5.Turnthefuelsupplyvalvetothe“ON”position.

6.Removetheairfromthefuelsystem.RefertoTestingandAdjusting,"FuelSystemPrime".

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:43:11UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017

ElectronicUnitInjector-Remove

SMCS-1290-011

RemovalProcedure Table1

RequiredTools

ToolPartNumberPartDescriptionQty A5F-4764PryBar1

StartBy:

a.Removethevariablevalveactuator.RefertoDisassemblyandAssembly,"ValveActuator (Variable)-Remove".

b.Removetherockerarmsandtherockerarmshaft.RefertoDisassemblyandAssembly, "RockerArmandShaft-Remove".

NOTICE

Caremustbetakentoensurethatfluidsarecontainedduring performanceofinspection,maintenance,testing,adjusting,andrepair oftheproduct.Bepreparedtocollectthefluidwithsuitablecontainers beforeopeninganycompartmentordisassemblinganycomponent containingfluids.

RefertoSpecialPublication,NENG2500,"DealerServiceTool Catalog"fortoolsandsuppliessuitabletocollectandcontainfluidson Catproducts.

Disposeofallfluidsaccordingtolocalregulationsandmandates.

NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

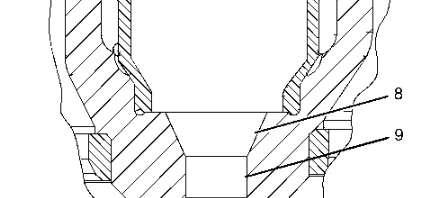

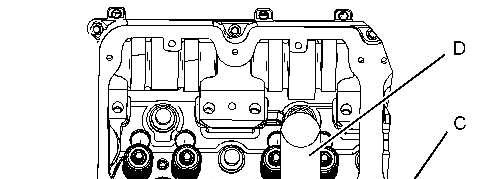

Illustration1g01076052

1.Disconnectharnessassembly(1).

2.Removebridgeassemblies(3).

NOTICE

Iftheinjectorholddownboltislooseduringtheremovalprocedure, inspecttheinjectorboreforwearanddebris.Replacetheclampand spacer.

3.Removebolt(4),spacer(5),andclamp(6).

4.Placeanidentificationmarkonelectronicunitinjector(2)forinstallationpurposes.Each electronicunitinjectormustbereinstalledintheoriginallocationinthecylinderhead.

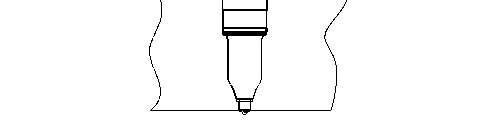

Illustration2g01076047

5.UseTooling(A)toprybeneaththebaseandfreeelectronicunitinjector(2).

6.Removetheelectronicunitinjectorfromthecylinderhead.

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:43:21UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017

ElectronicUnitInjector-Install

SMCS-1290-012 InstallationProcedure

169-7372FluidSamplingBottle1 4C-4057Tube7.9mm(0.31inch)OD1

D4C-5552LargeBoreBrush1

E4C-6774VacuumGunKit 1

F8T-7765SurfaceReconditioningPad1

G 9U-6862TaperedBrush 9U-7237BrushExtension NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

1.UseTooling(C)toremovethefuelandoilfromthecylinder.Evacuateasmuchfuelandoil aspossiblefromthecylinderbeforeinstallingtheelectronicunitinjector.Several evacuationsmaybenecessary.

2.UseTooling(D)tocleanthecarbondepositfromtheinsidetheelectronicunitinjector sleeveatLocation(Z).Tooling(E)isavailabletocleanloosematerialfromtheboreofthe electronicunitinjectorsleeveandthecylinder.

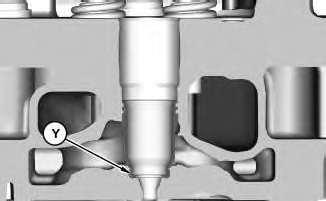

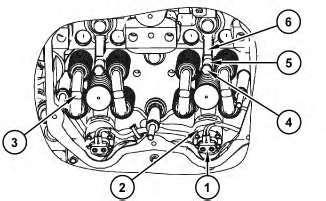

Illustration2g03722826

Sectionview.

3.UseTooling(F)tocleanthecarbonfromtheseatareaatlocation(Y)thatisinsidethe electronicunitinjectorsleeve.

Illustration3g03722522

4.UseTooling(G)tocleaninjectorseatingarea(8)andinjectortipbore(9).

Illustration4g03718585

5.UsealintfreematerialtocleanO-ringseals(7)andelectronicunitinjector(2).

6.LubricatethetoptwoO-ringseals(7)withTooling(A).Donotuseanyotherlubricant.

Note:OnceO-ringseals(7)arelubricated,installimmediately.

Note:DonotreuseO-ringseals(7).

Note:O-ringseals(7)mustbestoredproperlytopreventcontamination.

7.InstallO-ringseals(7)ontheelectronicunitinjector.

Note:CautionmustbetakentoavoidoverstretchingtheO-ringseals(7).

Illustration5g03729389

Illustration6g01135876

8.Whenyouinstallanewinjector,theE-Trimvaluemustbeprogrammedintotheengine controlmodule.Theinjectorconfirmationcodemayneedtobeprogrammedintotheengine controlmodule.E-TrimValue(X)isa12-digitalphanumericcodethatissuppliedwiththe datasheetthatcomeswiththenewinjectors.InjectorConfirmationCode(Y)isafour-digit numericcode.Bothofthecodesareonthetopofelectronicunitinjector(2).Usethe followingmenutoprogramtheE-Trimvalue.

ECMSummaryScreen

ServiceMenu

Calibration

InjectorCodeCalibration

NOTICE

Whenanelectronicunitinjectorisreplaced,thenewelectronic injectorcodemustbeprogrammedintotheengine'spersonality modulesoftwarebyusingthecalibrationmenuontheElectronic ServiceTool.Ifthenewelectronicinjectorcodeisnotentered,the characteristicsofthepreviouselectronicunitinjectorisassumed. Ifitisnotpossibletoimmediatelyreprogramtheelectronicinjector codeintothepersonalitymodulesoftware,theenginewillnotbe severelyharmed.Thenewelectronicinjectorcodeshouldbe reprogrammedasquicklyaspossibleinordertooptimizeengine performance.

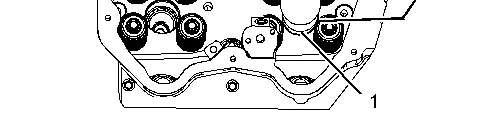

9.Assembleelectronicunitinjector(2)withtheclamp(6),spacer(5),andnewbolt(4). Positionelectronicunitinjector(2)intheinjectorbore.

Note:CautionmustbeusedtoavoiddamagingO-ringseals(7)arenotdamagedwhen positioningelectronicunitinjector(2)intheinjectorbore.

Note:Donotpushormanuallyforceelectronicunitinjectorintothebore.

10.Tightenbolt(4)toatorqueof55±10N·m(41±7lbft).Ensurethatelectronicunitinjector (2)isalignedintheborewhiletighteningbolt(4).

Note:Tightenbolt(4)ataslowanduniformrate.Ifapneumaticorelectrictoolisused, caremustbetakentoavoiddamagetotheO-ringduetoquicklyseatingtheinjector.

Note:Tighteningbolt(4)tocorrecttorquewillproperlyseatelectronicunitinjector(2).

11.Inspectareaaroundtheboreforelectronicunitinjector(2)toensurethatO-ringseals(7) werenotdamagedorextruded.

12.Installbridgeassemblies(3).

13.Connectharnessassembly(1).Tightenthenutstoatorqueof2.5±0.25N·m(22±2lbin).

EndBy:

a.Installtherockerarmsandtherockerarmshaft.

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:43:32UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017 i02169626

ElectronicUnitInjectorSleeve-Remove

SMCS-1713-011

RemovalProcedure

Table1 RequiredTools

ToolPartNumberPartDescriptionQty

A9U-6891InjectorToolGroup1

StartBy:

a.Removetheelectronicunitinjectors.RefertoDisassemblyandAssembly,"ElectronicUnit Injector-Remove".

NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

1.Drainthecoolantfromtheengine.RefertoOperationandMaintenanceManual,"Cooling SystemCoolant-Change".

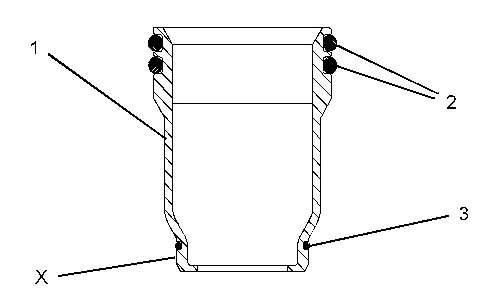

2.InstallTooling(A)inelectronicunitinjectorsleeve(1).

3.TightenthenutonTooling(A)untiltheelectronicunitinjectorsleeveispulledfreeofthe cylinderhead.

4.RemoveO-ringseals(2)andO-ringseal(3)fromelectronicunitinjectorsleeve(1).

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:43:50UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017 i02536688

ElectronicUnitInjectorSleeve-Install

SMCS-1713-012

InstallationProcedure

Table1 RequiredTools

ToolPartNumberPartDescriptionQty

9U-6862TaperedBrush1

9U-6863SmallBoreBrush1

B

9U-7244EndBrush 1

9U-7237BrushExtension1

4C-5552LargeBoreBrush1

C(1)221-9778PullerStud1

D(1)9U-7258DriverCap1

E4C-9507RetainingCompound-

(1)Partofthe9U-6891InjectorToolGroup

NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

1.UseTooling(B)tocleantheboreinthecylinderheadfortheelectronicunitinjectorsleeve.

NOTICE

Ensurethattheelectronicunitinjectorsleeveandthecylinderhead borearecompletelyfreeofoil,dirt,andsealantdebris.

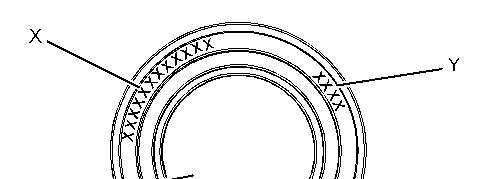

2.InstallnewO-ringseals(2)andO-ringseal(3)onelectronicunitinjectorsleeve(1).

Note:DonotapplyTooling(E)tothecylinderheadsurfaces.ApplyTooling(E)onthe electronicunitinjectorsleeveonly.

3.ApplyTooling(E)tothecontactsurfaceofelectronicunitinjectorsleeve(1)onthesurface thatisMarked"X".

4.LubricateO-ringseals(2)withcleanengineoil.

Illustration2g01076119

5.InstallTooling(C)intothethreadsofelectronicunitinjectorsleeve(1).

6.PositionTooling(C)andtheelectronicunitinjectorsleeveinthecylinderhead.Usecare nottodamagetheO-ringsealsontheelectronicunitinjectorsleeve.

7.UseTooling(D)andahammertoinstallelectronicunitinjectorsleeve(1)inthecylinder head.

NOTICE

Ensurethattheelectronicunitinjectorsleeveisproperlyseatedinthe cylinderhead.TheToolingwill"RING"whentheelectronicunit injectorsleeveisfullyseatedintheboreofthecylinderhead.

8.RemoveTooling(D)andTooling(C).UseacleantowelandremoveexcessTooling(E).

9.Fillthecoolingsystemwithcoolant.RefertoOperationandMaintenance,"Refill Capacities"forthecoolingsystemcapacity.

EndBy:

a.Installtheelectronicunitinjectors.RefertoDisassemblyandAssembly,"ElectronicUnit Injector-Install".

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:44:00UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017

Turbocharger-Remove-LowPressure

SMCS-1052-011

RemovalProcedure

NOTICE

Caremustbetakentoensurethatfluidsarecontainedduring performanceofinspection,maintenance,testing,adjusting,andrepair oftheproduct.Bepreparedtocollectthefluidwithsuitablecontainers beforeopeninganycompartmentordisassemblinganycomponent containingfluids.

RefertoSpecialPublication,NENG2500,"DealerServiceTool Catalog"fortoolsandsuppliessuitabletocollectandcontainfluidson Catproducts.

Disposeofallfluidsaccordingtolocalregulationsandmandates.

NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.

NOTICE

Failuretofollowestablishedprocedurescanleadtodamageofthe parts.

Toavoiddamagetotheparts,alwaysidentifyandmarkthepartsso thatthepartscanbeinstalledinthesamelocation.

1.Putidentificationmarksonthebellowsforalignmentandorientationduringinstallationof thebellows.

Illustration1g01076551

2.Loosenclampassembly(8).Loosenclampassembly(11).

Theendsofthebellowsareverysharp.Injurycouldoccurifthebellows arenothandledproperly.Handlethebellowsbytheconvolutions.

Note:RefertoSpecialInstruction,REHS1728,"ApplicationGuidelinefortheBellows"for additionalinformationonhandlingthebellows.

3.Removeairinletelbow(9)andbellows(10)fromtheturbochargers.

4.Loosenclampassembly(5).Loosenclampassembly(2).

Theendsofthebellowsareverysharp.Injurycouldoccurifthebellows arenothandledproperly.Handlethebellowsbytheconvolutions.

Note:RefertoSpecialInstruction,REHS1728,"ApplicationGuidelinefortheBellows"for additionalinformationonhandlingthebellows.

5.Removeduct(4)andbellows(3)fromtheturbochargers.

6.Disconnecthose(7).

7.Disconnecthoseassembly(6).

8.Disconnecthoseassembly(15).

9.Loosenclampassembly(17).Removeinletelbow(13)andtheO-ringsealfromthe turbocharger.

10.Removelocknuts(14).Removeexhaustelbow(12)andthegasketfromtheturbocharger.

11.Removelocknuts(1).

12.Useasuitableliftingdeviceinordertoremoveturbocharger(16).Theweightofthe turbochargerisapproximately29kg(65lb).

Copyright1993-2025CaterpillarInc. AllRightsReserved. PrivateNetworkForSISLicensees.

SatJul2619:44:26UTC+05302025

Product:TRUCKENGINE

Model:C15TRUCKENGINEMXS

Configuration:C15On-HighwayTruckMXS00001-UP

DisassemblyandAssembly

C15On-highwayEngines

MediaNumber-RENR9403-13PublicationDate-01/11/2017DateUpdated-29/11/2017

Turbocharger-Remove-HighPressure

SMCS-1052-011

RemovalProcedure

NOTICE

Caremustbetakentoensurethatfluidsarecontainedduring performanceofinspection,maintenance,testing,adjusting,andrepair oftheproduct.Bepreparedtocollectthefluidwithsuitablecontainers beforeopeninganycompartmentordisassemblinganycomponent containingfluids.

RefertoSpecialPublication,NENG2500,"DealerServiceTool Catalog"fortoolsandsuppliessuitabletocollectandcontainfluidson Catproducts.

Disposeofallfluidsaccordingtolocalregulationsandmandates.

NOTICE

Keepallpartscleanfromcontaminants. Contaminantsmaycauserapidwearandshortenedcomponentlife.