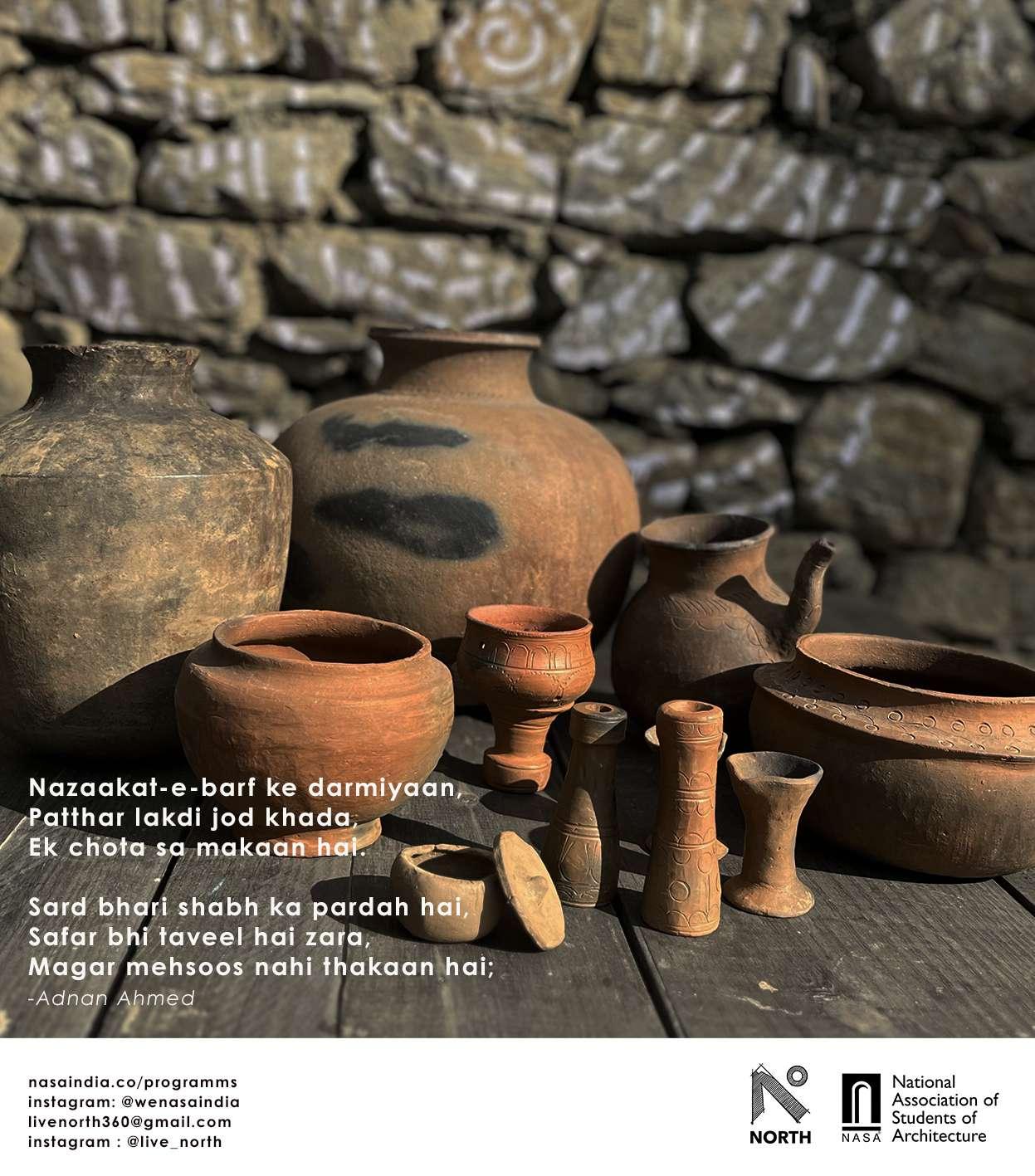

MITTI KA MATKA

FARYADI: In a quest to find what is lost;

NASA INDIA X NORTH

‘All the birds have flown up and gone, a lonely cloud floating leisurely by, we - you and I, looking at each other, only the mountains and I.’

- Li Bai

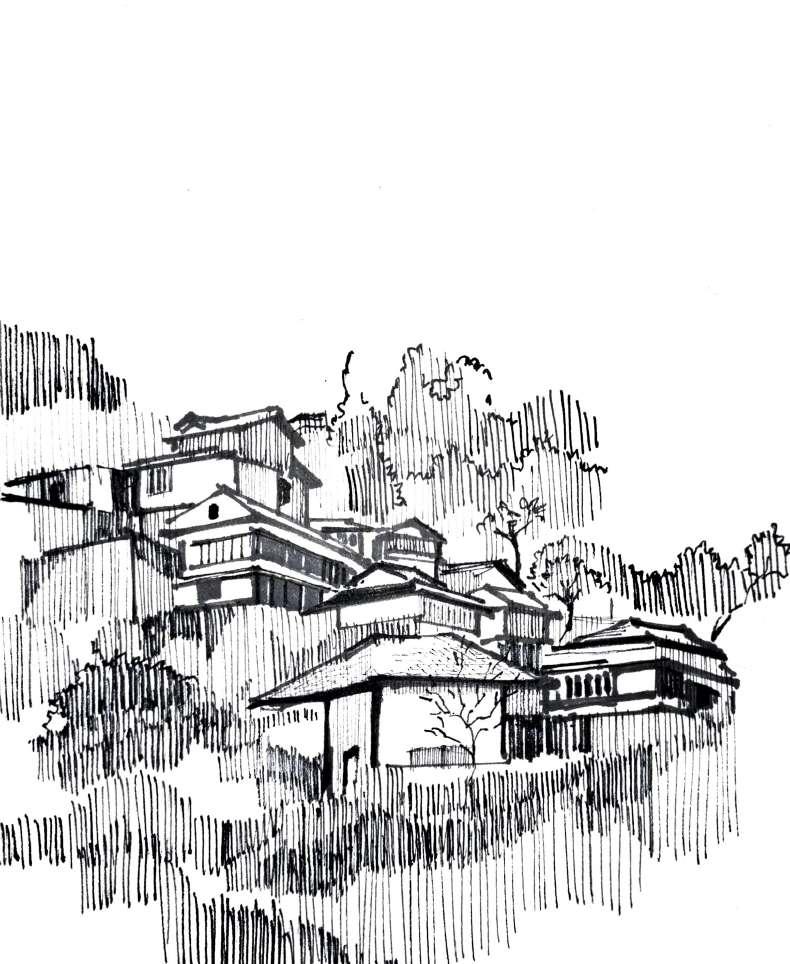

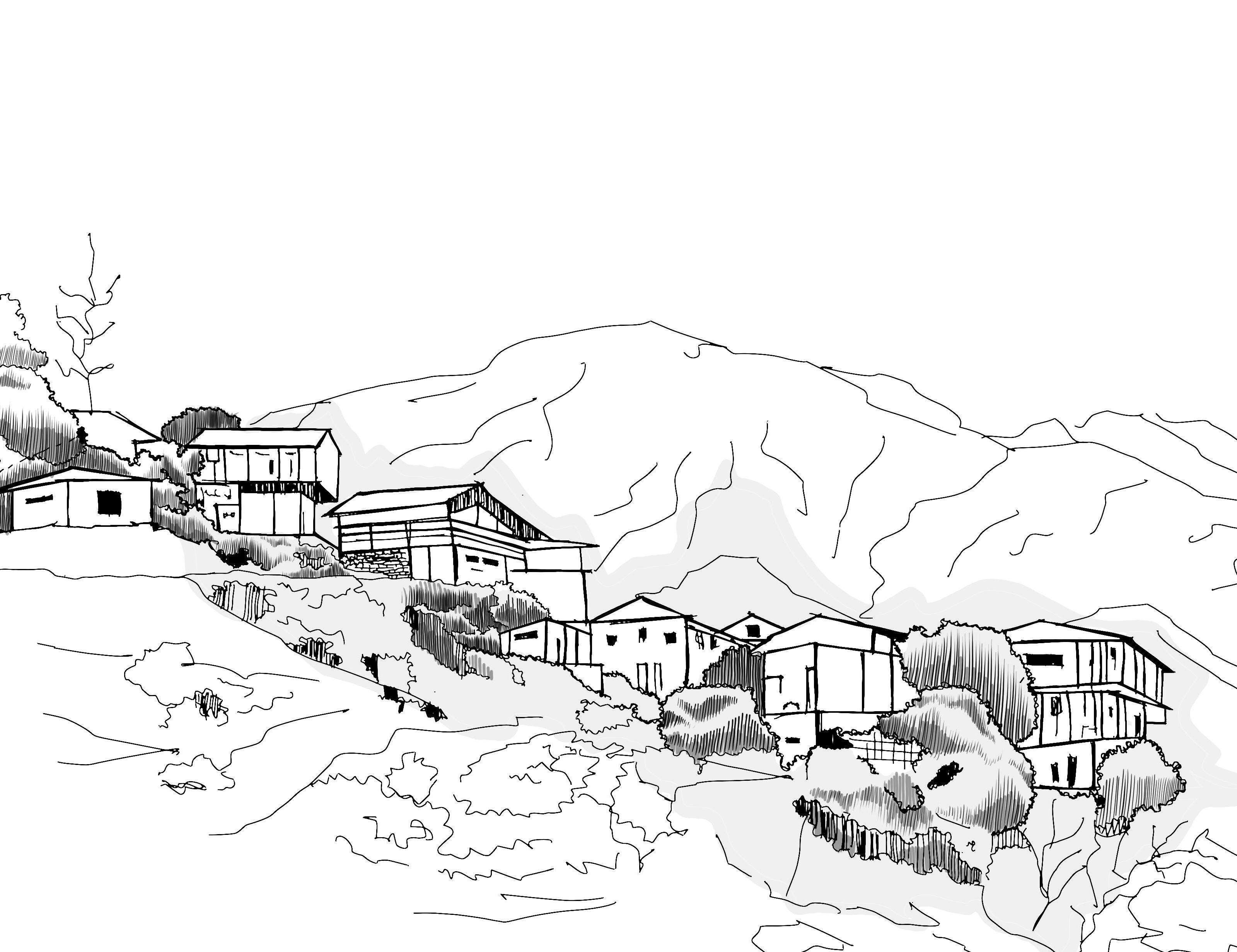

Nestled away from the busy city life, is a small nagar of Naggar, in the foot of the mountains, covered in mist, the sky is the limit, and I’m not ready to let go, yet;

- Maryam Afeefa Mehkri

Preface

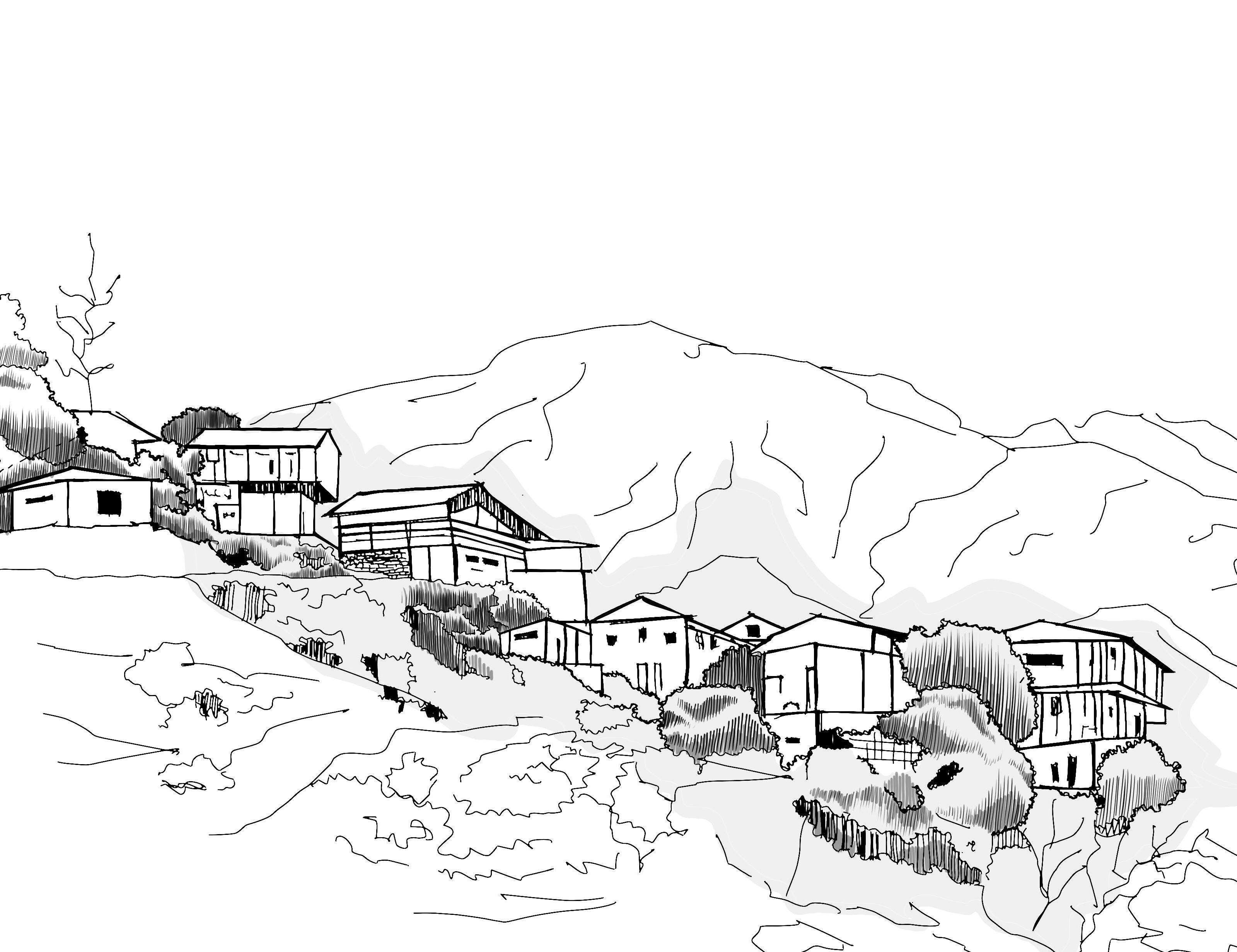

Clad in snow and draped in heritage, where life seems perfect, rests a small village called Faryadi. holding desperately onto familiar ground and culture, the people over here stand in direct contrast with societies fast paced transition towards modernity.

As future architects, we not only move towards change but also offer a simultaneous attempt to preserve our roots. It now becomes our responsibility to protect the traditions and cultures that are being tested by time and changing mindsets. Therefore we have come together, in a collaboration with NASA India and LIVE NORTH to contribute, learn and conserve what is lost.

Acknowledgement

We, as NASA India students, would like to express our admiration and gratitude to Ar. Rahul Bhushan and the entire team at Naggar, for sharing their experience and knowledge pertaining to vernacular building methods and craft documentation; lighting in us a spark of enthusiasm which helped us compile this research booklet to the best of our abilities.

We would also like to extend our appreciation to craftsmen Durga Das and Mangaram and the entire village of Faryadi for supporting us in documenting their craft and lifestyle through their stories and live demonstrations. A powerful source of knowledge is experience, this escapade was made better for us by the warm hospitality of the people of Naggar.

TABLE OF CONTENTS The Project 1 - 11 27 - 33 37 12 - 13 34 38 - 39 14 - 25 35 40 The Raw Materials The Tools The Process Transfer of Knowledge The Products Glossary Credits Conclusion

Objective

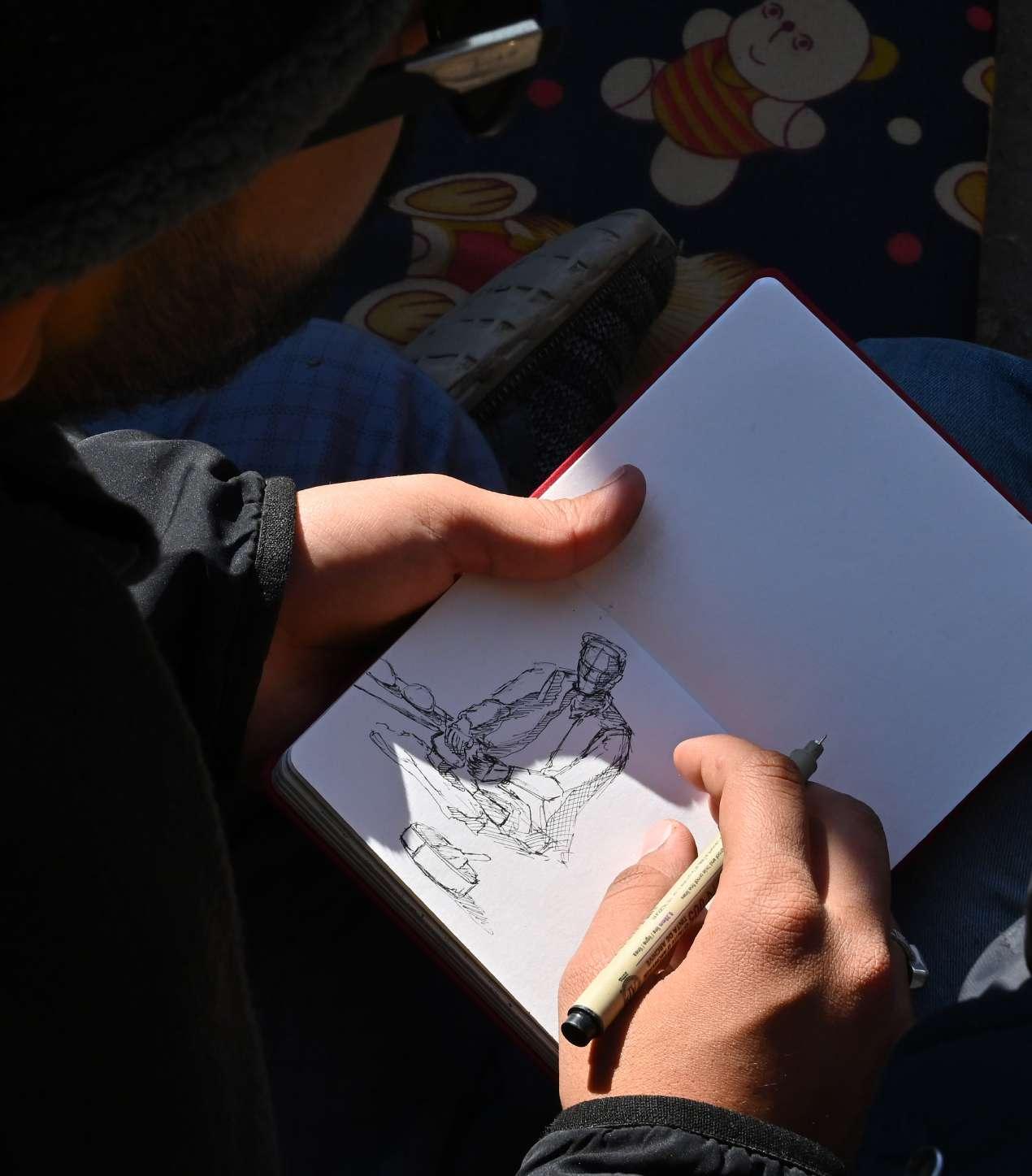

This workshop is to help participants understand the life and culture of this small world that exists among the mountains. to learn to resonate with the stories, beliefs, songs, and their craft.Meticulously documenting the unique craft of pottery in Faryadi, a village hidden away in Tirthan Valley, through interviews, videos, photo documentation, and sketching The overall documentation concentrates on bringing awareness to the forgotten art of pot carving and appreciating its makers, the craftsmen

THE PROJECT

NASA INDIA x The NORTH

The largest architectural student body in the world, NASA India in collaboration with LIVE NORTH, a studio in naggar that works towards the benefit of local artisans, their craft and overall wellbeing, hosted the Summer Winter School Program for himalayan architecture & craftsmanship in three batches.

It was an attempt to expose young minds to wood working and carving, and metal works through site visits and hands on experience. The aim of the programme was to provoke architecture students from different parts of india, to understand local communities and realise the opportunities that they could avail through the imparted professional skills.

NASA INDIA

National Association of Students of Architecture, India

NORTH

Himachal Pradesh

Craftsmanship and Design Innovation Institute, Naggar

Workshop Plan

The secondary aim was a series of lectures on sustainability, himalayan architecture, creative design thinking, natural building, and revitalization of the indigenous building system ‘kathkuni’.

The initial batch interviewed the locals of Faryadi village, a settlement harboured amidst the calm yet lively himalayan valley. the lost craft of pottery without a wheel was witnessed in person, studied and documented with the aim of reviving the lost art form.

Associate Collaborators

THE CRAFT

With a ton of unanswered questions, began the quest to understand the people of FARYADI - the `potter’s village” and their origin, we set out to interact with the villagers to understand the history in the words of the sthanivasi (localites).

The villagers, Giri-Sthanivasis (localities from the mountains), learnt various ways of living and made themselves a life in the valleys. The locals claimed that their origins went back to the Kangra Kingdom and as per records, during the early 1900s, the village came under the Kullu KIngdom. The localites continued by sharing that the village had the buzurghs (the elderly ancestors) who were once known as the kalakars (craftsmen), introduced their skill which transitioned over generations. The profound skill sets were never taught by any specific gurus but were instead a pride that only specific families carried.

The distinct feature of this art form included the use of a spinning bowl instead of the conventional pottery wheel. The use of pottery wheel was considered inauspicious, as it was believed that using the thread was equivalent to cutting their bonds with the Gods. Instead of the wheel, the craftsmen used a spinning bowl known as a koshya, with a cushion made out of cloth that spins on a marble inserted on a base-plate known as the phatta.

3

Despite being a unique kala (art form), it has lost its prominence over the course of time due to various reasons, one of them being the high risk this potmaking process carries. This process of pot-making involved heavy labor for transporting chikni mitti (clay soil) from places like Brelga and Belida since it required refined fresh clay that didn’t contain any moisture. Once the pots were made, they needed to be burnt in a bhatta (kiln) overnight and the potters often carried the risk of waking up to broken pots in the kiln. In addition to this, the crafts were never valued in the market and that’s what has caused the kala to recede to the point of extinction, where fewer than few villagers possess the required skill set to practice this kala.

Seeking for answers, we have realized we have yet another quest and a set of unanswered questions waiting for us all. The questions aren’t directed to just us but to every reader who has come across this report and traveled along with our story. The most important question still stands - Who is responsible for the dying art? Who takes the blame for this? The modernization or the industrialization? Our ignorance towards such art forms? Or ignorance of the government bodies?

5

LOCATION

The primary purpose of the documentation was to discover and highlight the significance of lost crafts.

How do I reach Faryadi?

The most practical way to get to the village is by road.

From Naggar

84 km, 2 hr 30 min

From Manali

102 km, 2 hr 42 min

From Kullu

64 km, 1 hr 53 min

Via air : Bhuntur airport is the closest to Faryadi.

32 km from Naggar

52 km from Faryadi

51 km from Manali.

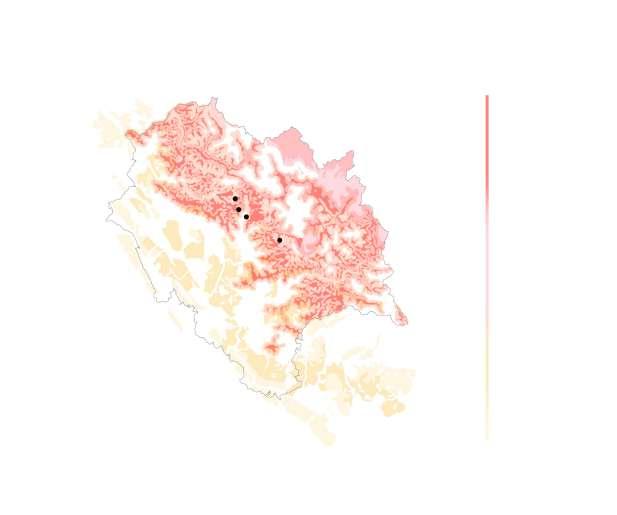

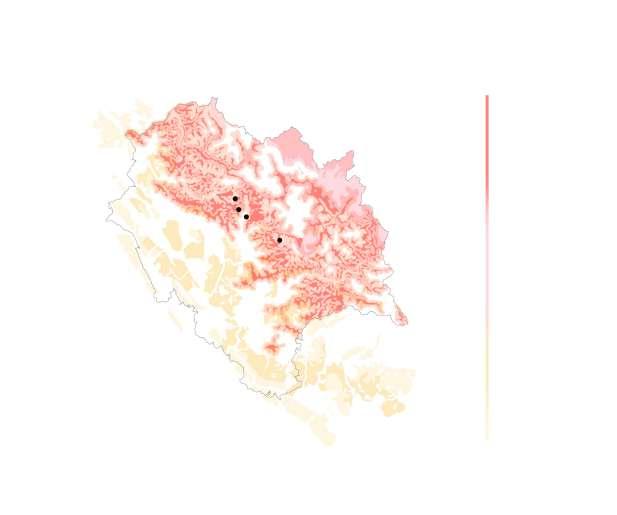

2500 1500 - 2500 1000 - 1500 250 - 1000 Manali Kullu Mohal Bhuntur Aut Banjar Bajaura

Naggar

Faryadi

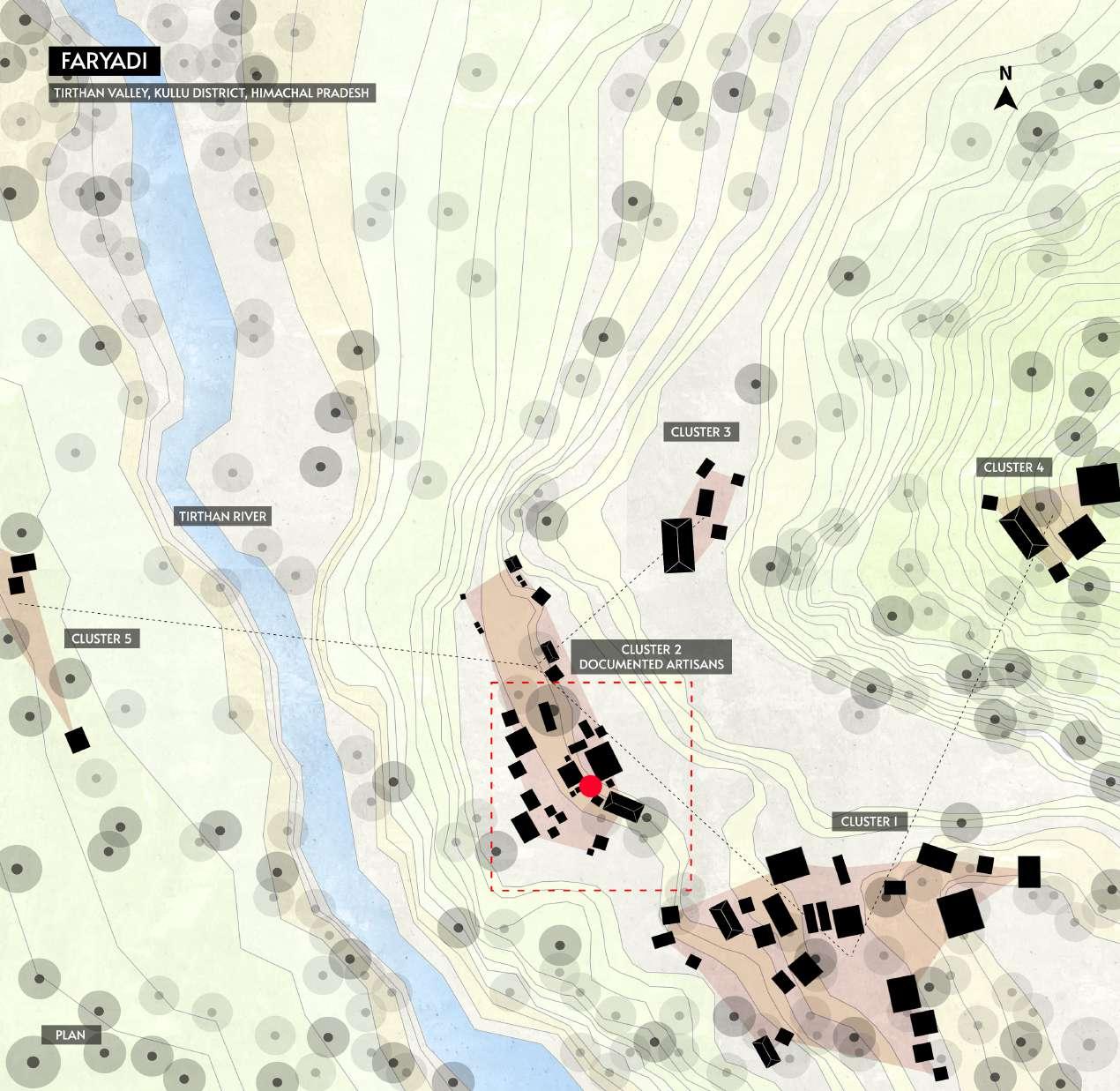

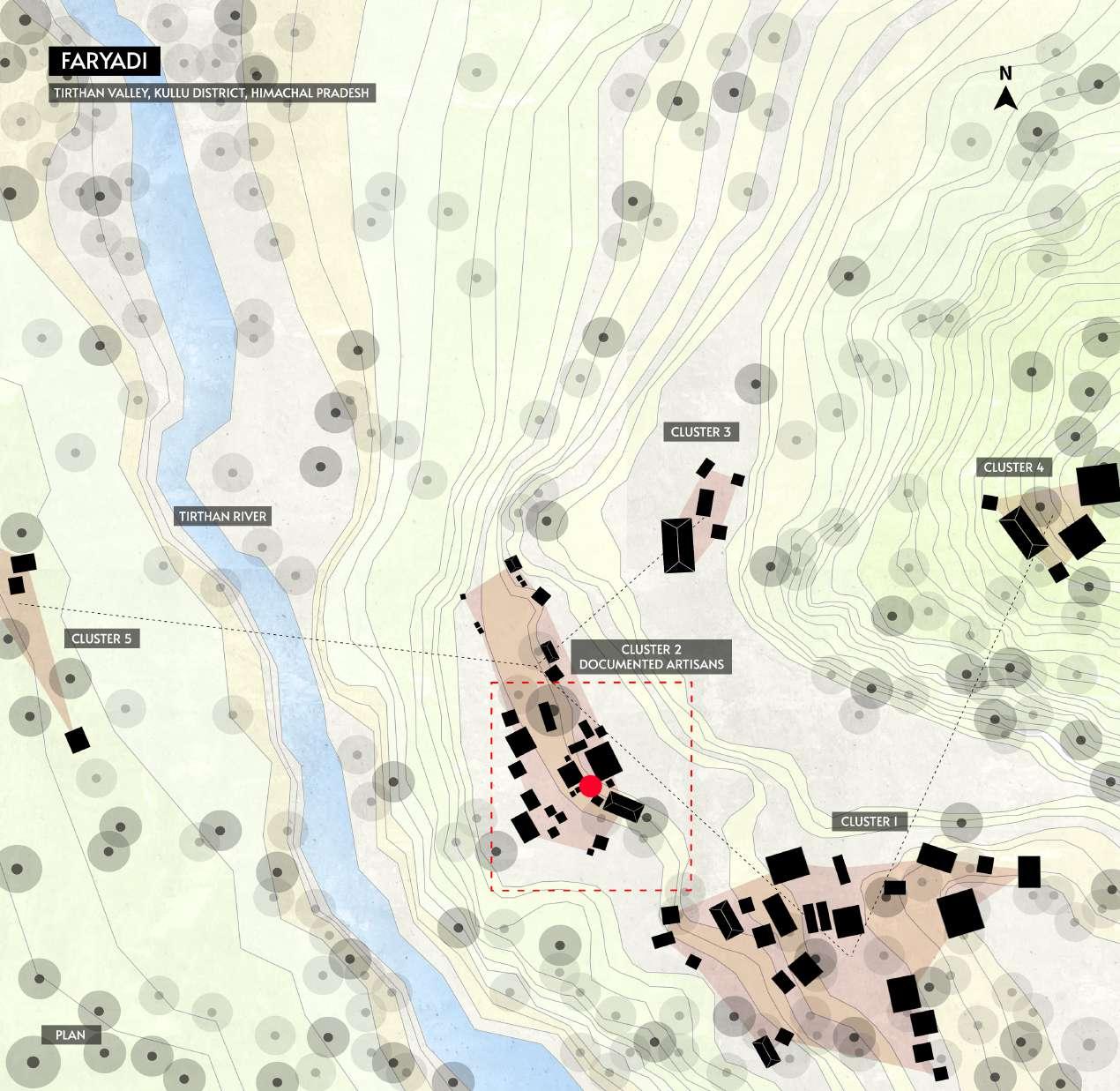

The site plan above illustrates the picturesque village of Faryadi nestled in the Tirthan Valley. The village is divided into five distinct housing clusters, as depicted on the map. The red-marked cluster 2 played host to the potters’ demonstration, where they expertly presented their craftsmanship in pottery-making.

7

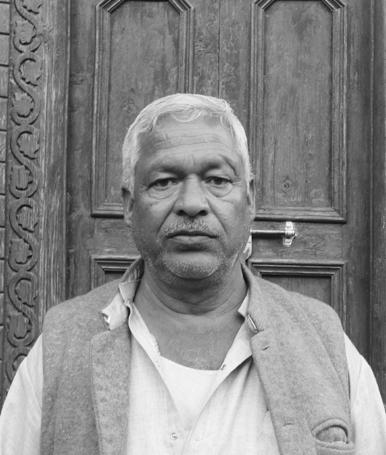

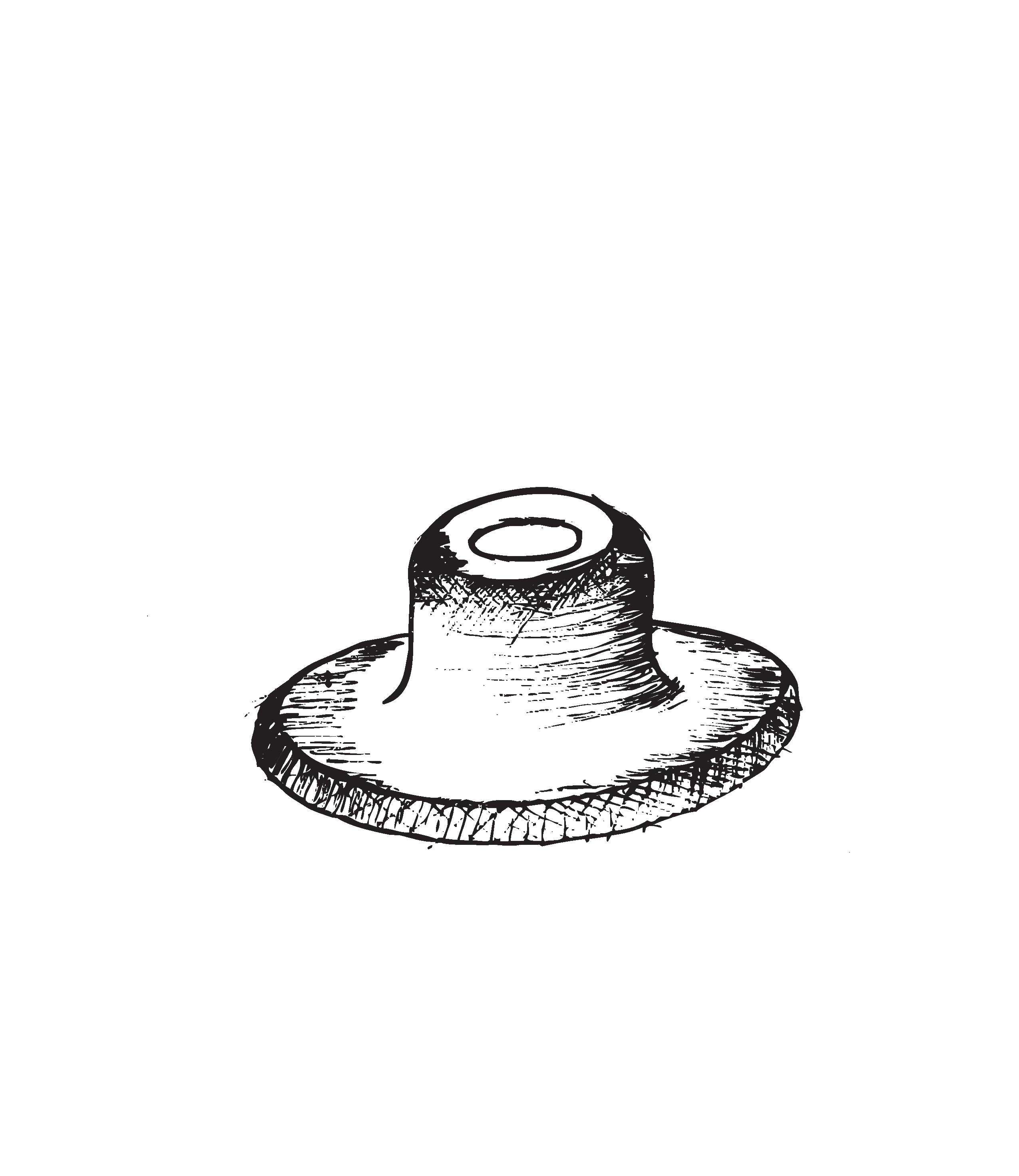

THE CRAFTSMEN OUR MENTOR

RAHUL BHUSHAN

Creative Director / Founder NORTH

Naggar, Himachal Pradesh, India

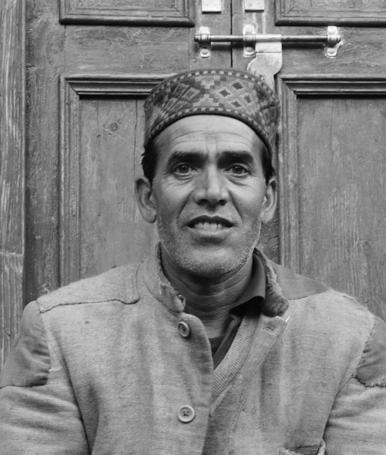

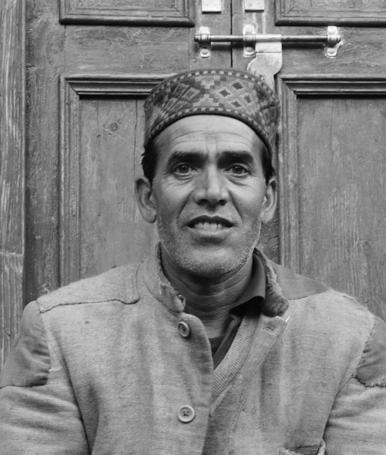

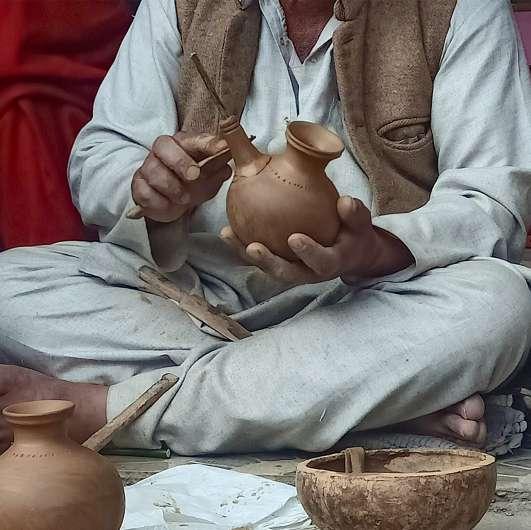

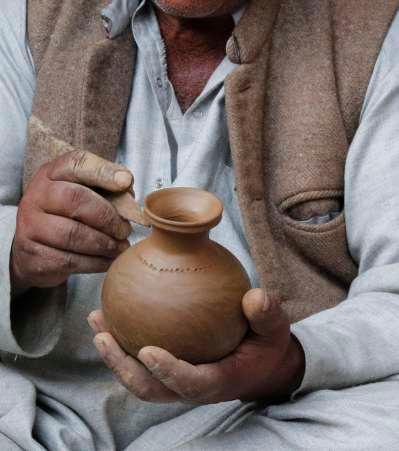

Durga Das

Age: 60 yrs.

Type of Craft: Pottery

Experience: Over 40 yrs.

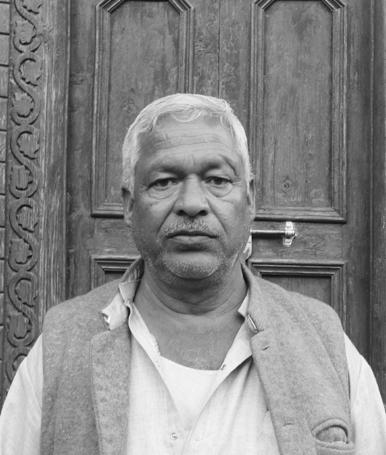

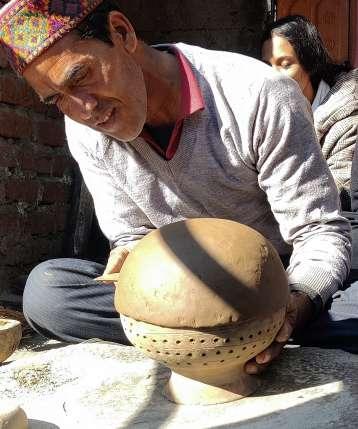

Mange Ram

Age: 46 yrs.

Type of Craft: Pottery

Experience: Over 25 yrs.

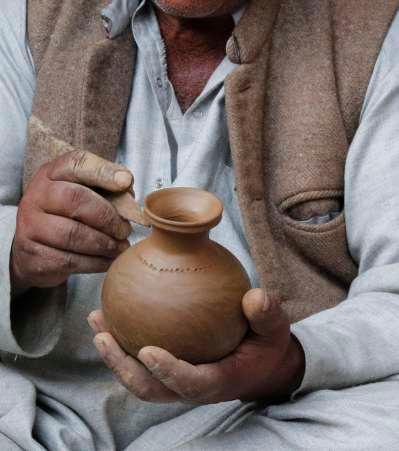

The leader of the household, according to their traditional beliefs, primarily engages in the pottery craft while other family members labour concurrently. The males are usually tasked with the collection of clay, while the females are assigned with clearing, drying, sifting, grinding, moulding, etc. In their opinion and experience of 45 years in this craft, improper clay preparation can cause pots to crumble quickly even before they are baked.

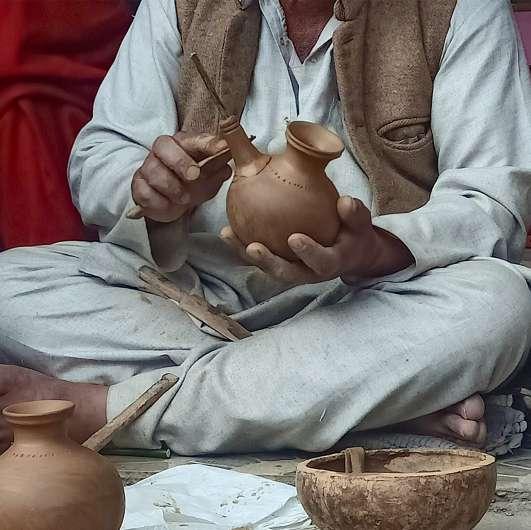

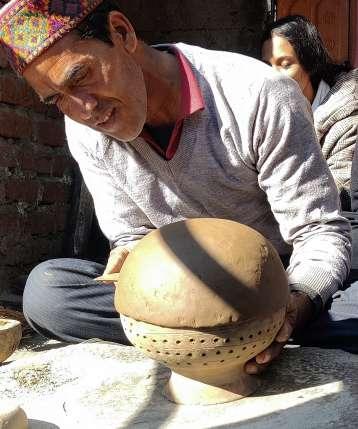

What sets this ancient craft apart is the non-usage of rotating wheels that are often used to make pottery. The fact that pots or any other craft are made in parts separately being joined to form a single piece is another distinctive feature of this pottery system.

Potters beat the clay with a wooden plank from the outside while placing one hand within the clay to form it into the desired forms. These wooden planks come in a variety of sizes and shapes to suit the needs of various pots. Once a pot is given it’s beautiful form, it is dried in the sun before being stacked and stored in the kiln.

It takes about a week for the products to bake. following which, they are put up for sales at fairs and festivals that happen in the village. Potters occasionally also sell their goods to the middleman for resale.

9

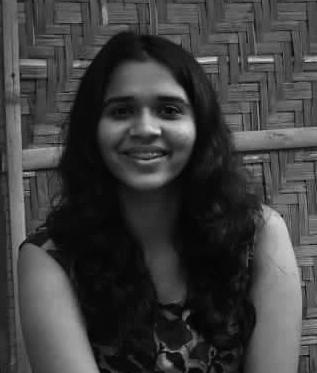

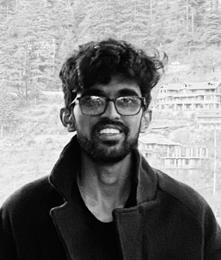

THE TEAM

11

Sanjana Cherukupalli

Divyansh Gupta Programs Head, NASA India

Shravani Narvekar

Ram Pinlodi

Sathiyashree Shankar

Mayank Choudhari

Ruthvik Pulluri

K. Anjana Nandan Aman Arora

M. Varun Rao

Keerthana S.

Shaik Umaruddin

K. Lokesh Kumar

Akshitha Pannala

Vedanti Kashid

E. Indu Manasa

Maheedhar Kotapati

Maryam Afeefa Mehkri Adnan Ahmed

Clay

Local resources are necessary for making traditional pottery, including firewood for fuel, other wooden tools, and clay as the main ingredient. In order to make pottery, clay, a form of dirt, is required as the cheapest and most important raw ingredient. The village uses red clay, or "lal-matta“ or “chikni mitti” as it is known locally, to make pots. They gather clayey dirt from villages called Brelga and Beheda at times, about -2 kilometres from the village. According to potters, the clay in this region is soft and malleable, making it simple to blend and shape. Since there is no pakka trail and many people carry clay on their backs, the area is fairly far away and challenging to approach.

This increases the overall cost and makes the process highly time-consuming and expensive. They excavate the earth to a depth of 1-3 metres and gather the clay to obtain the desired quality. The type of soil (red soil), according to the potters, is only found in this region of the valley.

Water

It is used to mix and mould clay into various shapes quickly and easily. Tirthan river: source

Wood

The main fuel used in baking kilns is made of wood. All of the local potters use the Kail (Pinus wallichiana) and Chil (Pinus roxburghii) forests specifically for baking. When baking, layers of grasses and teetne (pine tree cones) are also used.

13

हलचल क्यों आज इतनी है

नया सा जोश और नयी आवाज़ें भी

आँखों मई उत्साह है इनके

और हाथो मई मेरी प्रकृति

टूट रहा हु मई फिरसे

बात रहा है आकार मेरा

महसूस नहीं ज़ुल्म इन हाथो मई लेकिन

रख रहे है ख़याल मेरा

न धुआँ है न मचिनी है न

A new morning, a new morale new spirits, new voices that i feel a new excitement, a new experience; brimming in their eyes, exploring parts of me

Today I’m breaking down, form altered is what i see devoid of pain, their actions kind; Someone is taking care of me

No smoke, no machine, their doings hardly wrecking me out soil and wood - an earthy combination an attempt to decorate me!

एक

सा बनाया है उसके चारो तरफ लकड़ी भी पहनाई है

फिर चादर एक मिटटी की मेरे जिस्म पे उड़ाई है

सूख के टूट गए थे पत्ते जो

उनका नया घर एक बसाया है

नज़रअंदाज़ करके सर्दी मेरी

एक गुलदस्ता

A cozy, warm wooden house, perched atop me; adorned with protective planks filled with the love of mama earth, to enrich what was desolate and blank

draping me ever so tenderly with love and care, with dry and fallen leaves bracing my cold, chilly terrain; tracing a flowerbed out of me

for I’m breaking down, again,

my form being altered is what i see devoid of pain, yet their actions kind Atleast, Someone is taking care of me.

- Adnan Ahmed

लिहाज़ मई इनके दर्द पीला मेरी ही मिटटी है और मेरे ही पेड़ लौटा के मुझे सजा रहे

कठघरे

मुझमे बनाया है आज टूट रहा हु मई फिरसे आज फिर बात रहा है आकार मेरा मगर महसूस नहीं ज़ुल्म इन हाथो मई आखिर कोई तोह रख रहा है ख़याल मेरा

THE TOOLS

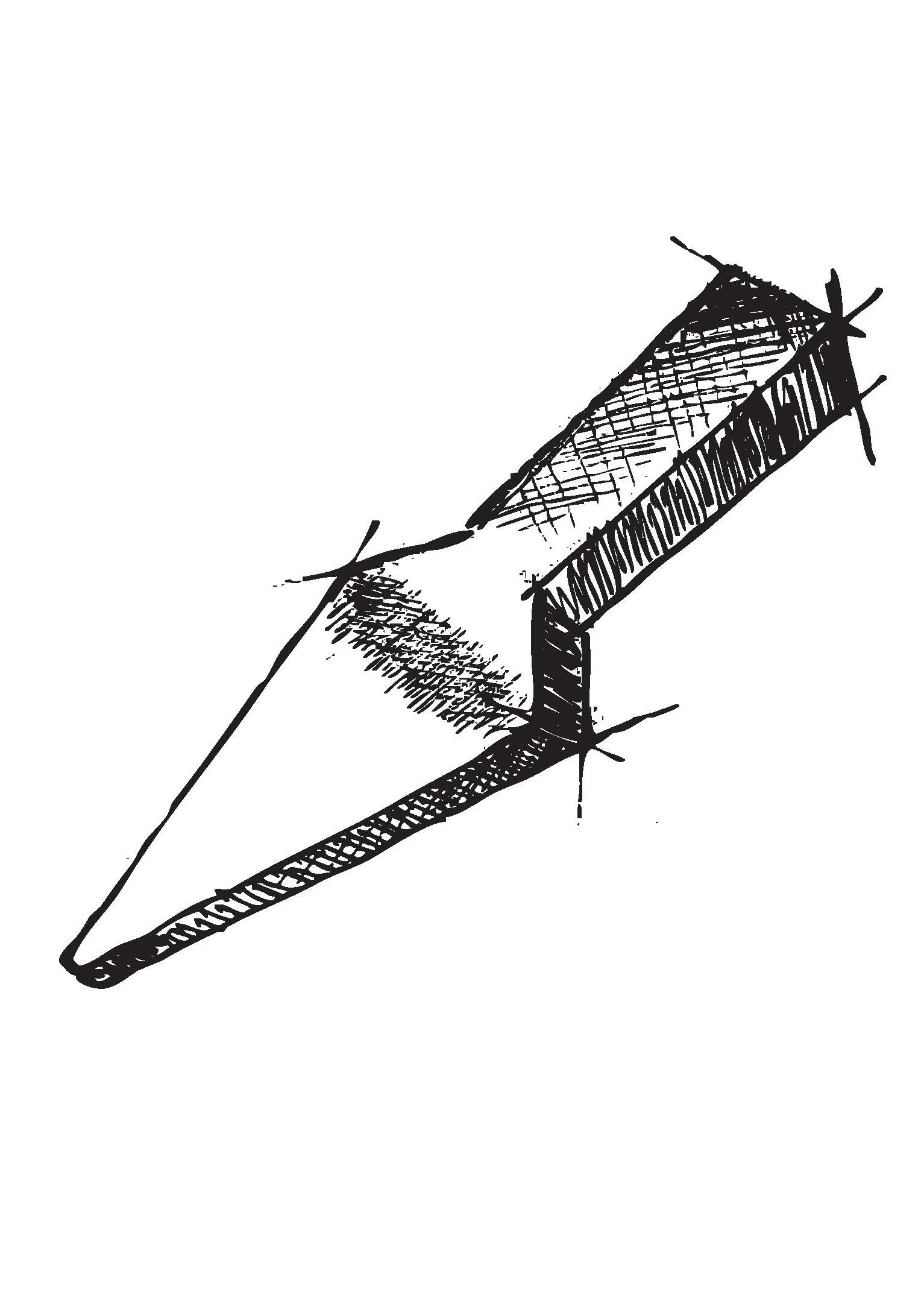

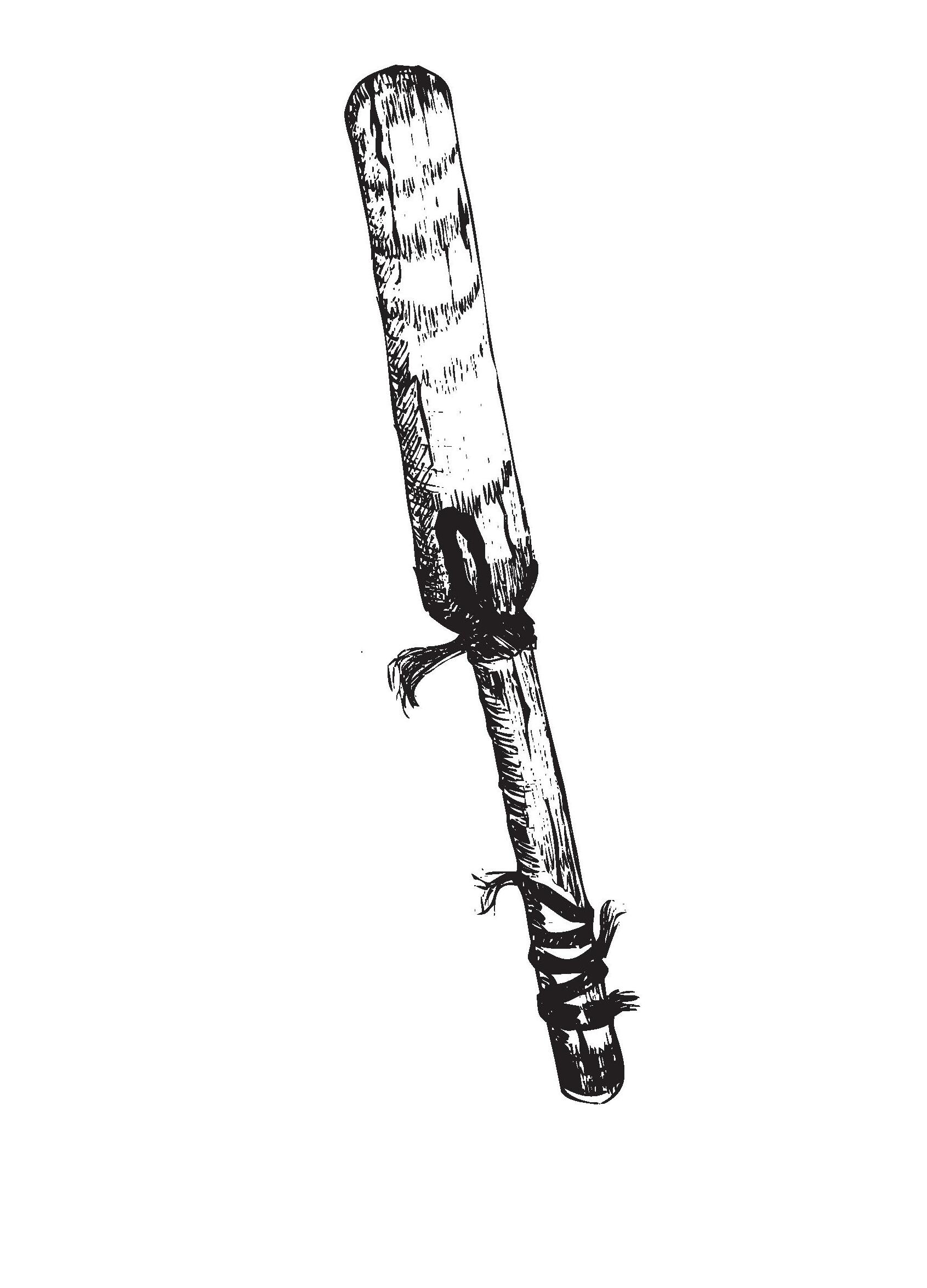

Material Used: Rikhal Wood

Tool used by potters for flattening and smoothing the edges of their ceramics in order to attach other parts of the clay together is a smoothing tool, such as a Kunddhru, which is a flat and smooth stone. This tool is used in conjunction with a softfaced hammer and is used to compress and flatten the edges of the pottery, creating a smooth surface and allowing the pottery to be attached to another piece.

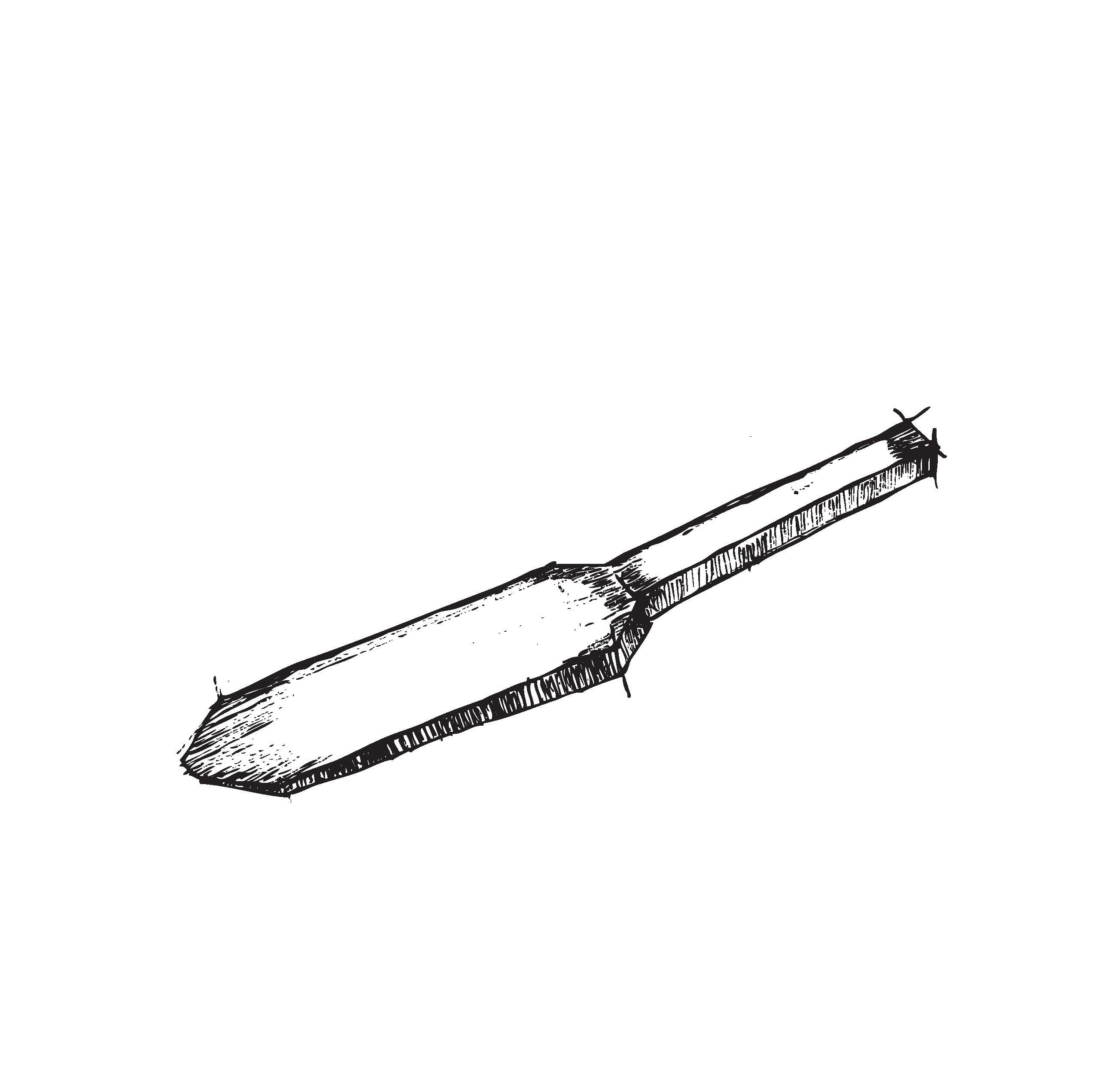

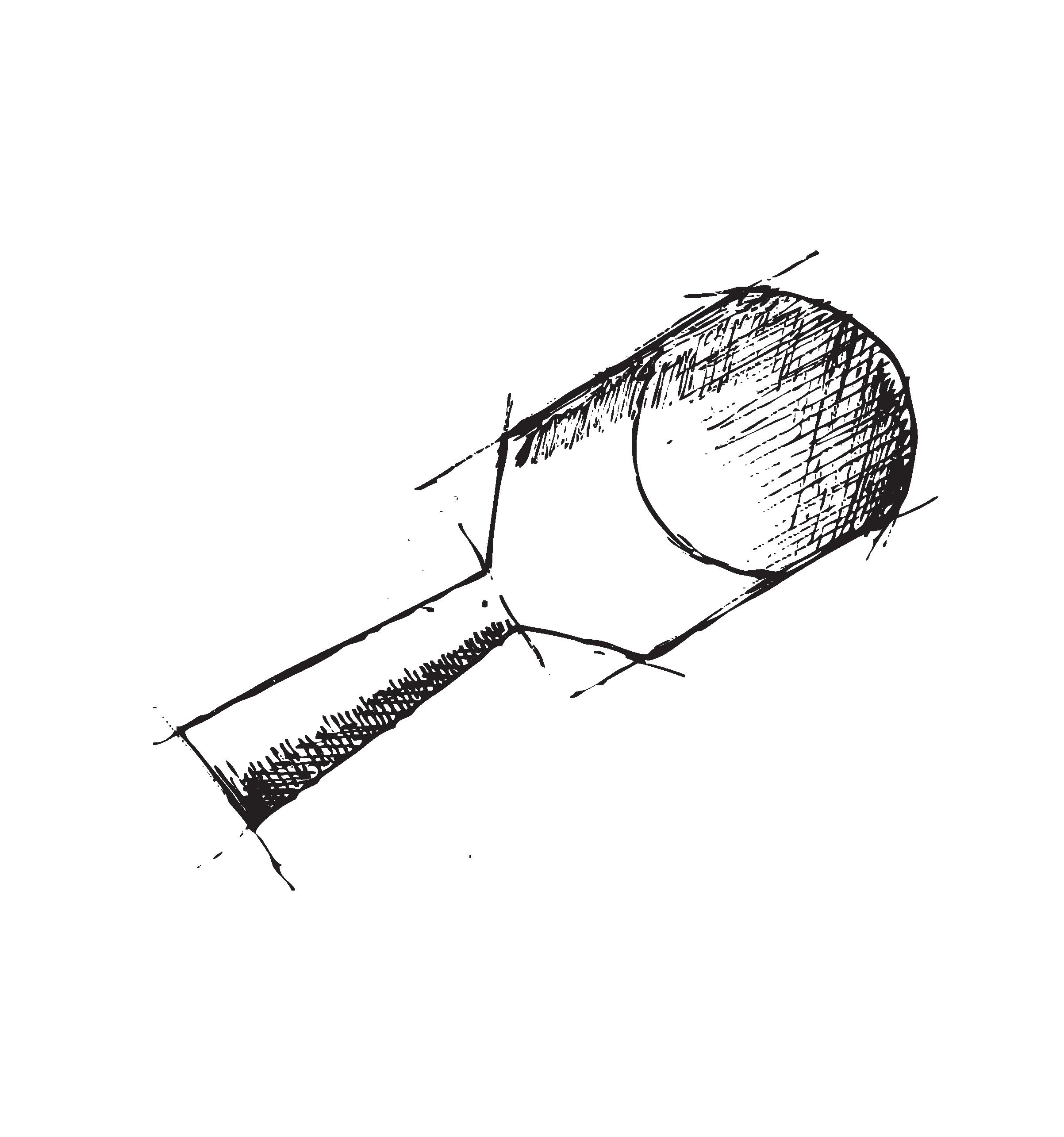

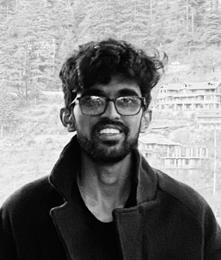

Wooden Paddle

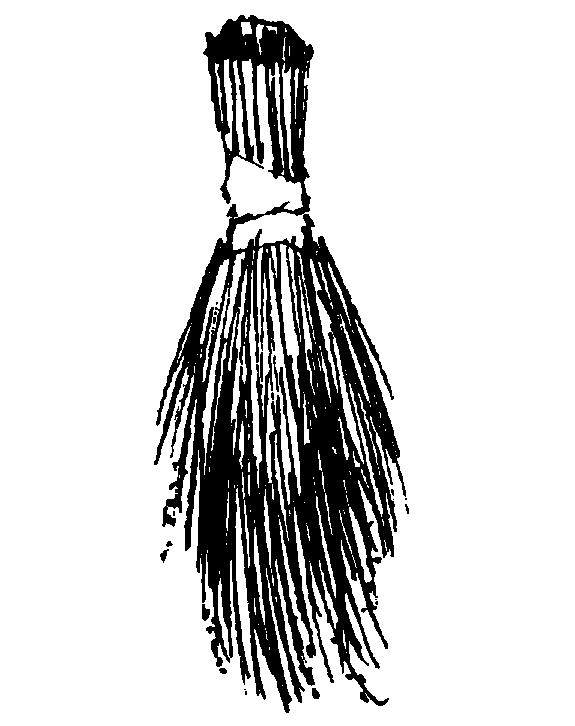

Material Used: Straw

A traditional tool used by potters for thinning and shaping the edges of their ceramics in order to attach other parts of the clay together is a shaping tool, such as a rib. A rib is a thin, flat tool that is used to shape and smooth the edges of the pottery, making it thin and even, allowing it to be attached to other parts of the clay. This tool is often made of wood or metal and the shape, size and material of the rib can vary depending on the intended use.

थाप ड़ु

Bat

चप्पू

0 25 50 75 12.5

17

Material Used: Rikhal Wood

Used for storing water and maintaining a damp work surface is a water container, such as a jar, jug or pitcher. This container is used to hold water, which can be used for various tasks, including keeping the clay moist, cleaning tools and smoothing surfaces. Additionally, a damp cloth or sponge is often kept nearby to help maintain the appropriate level of moisture in the clay while working.

Material Used: Rikhal Wood

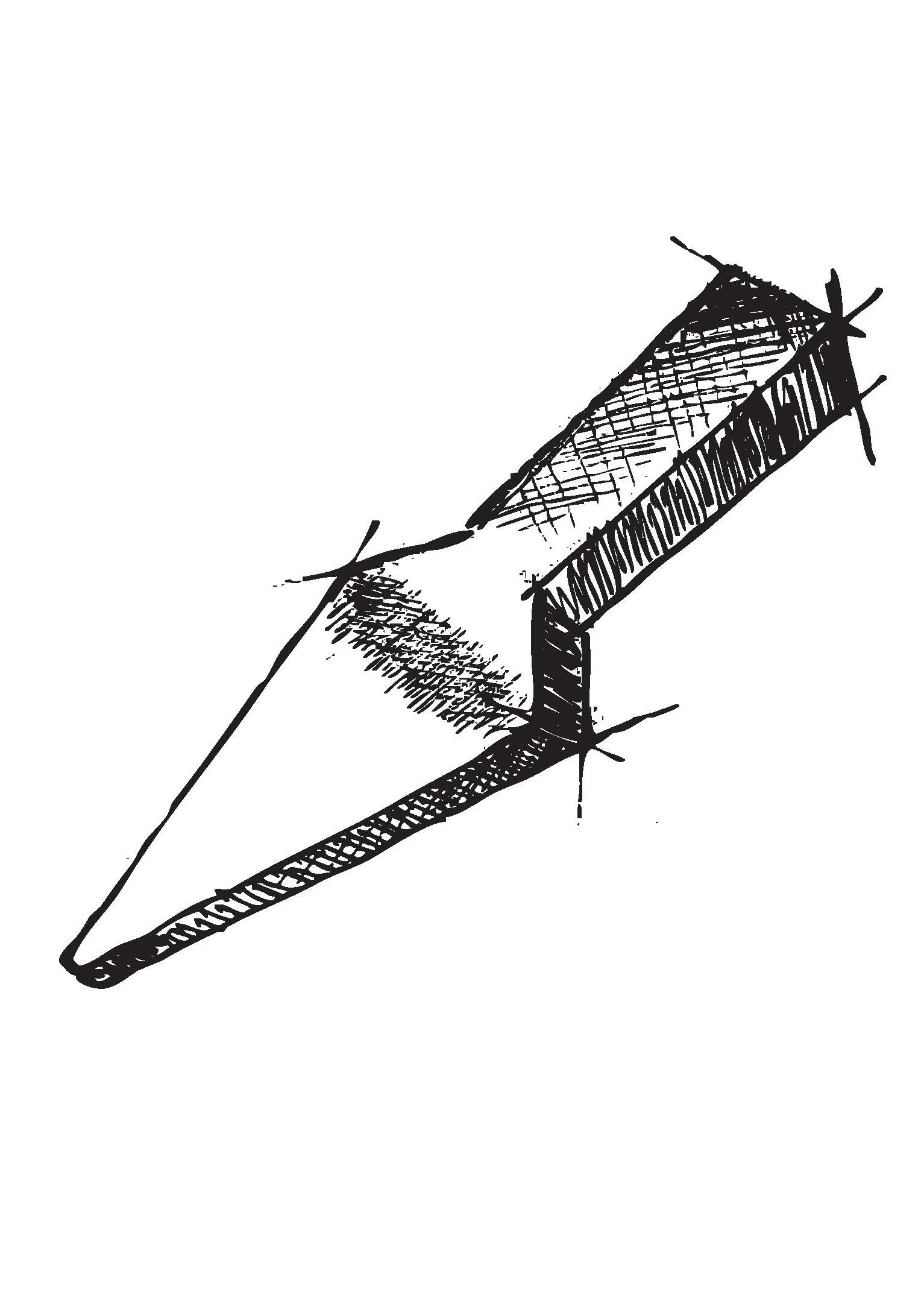

Tool used for carving and shaping the edges of their ceramics is a cutting tool, such as a blade or scraper, which is used in conjunction with another material, such as Tapdi (a type of abrasive material). Together, these tools are used to carve and refine the edges of the pottery. The cutting tool is used to make incisions or cuts in the clay, while the Tapdi is used to smooth and refine the edges.

19

कुण्डधरु Kunddhru

तोशी Bowl 0 12.5 25 50 6.25 0 15 30 45 7

Material Used: Rikhal Wood.

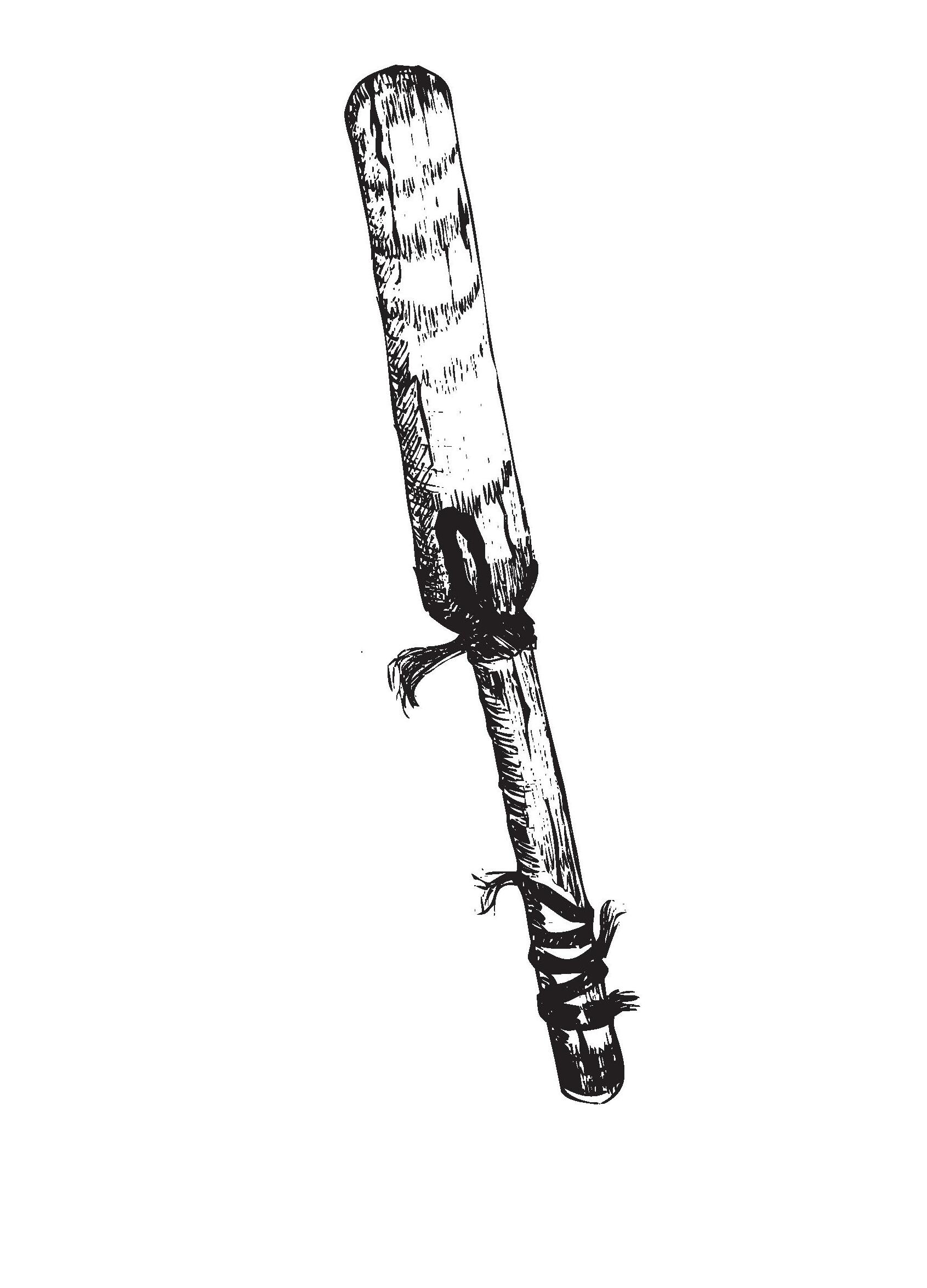

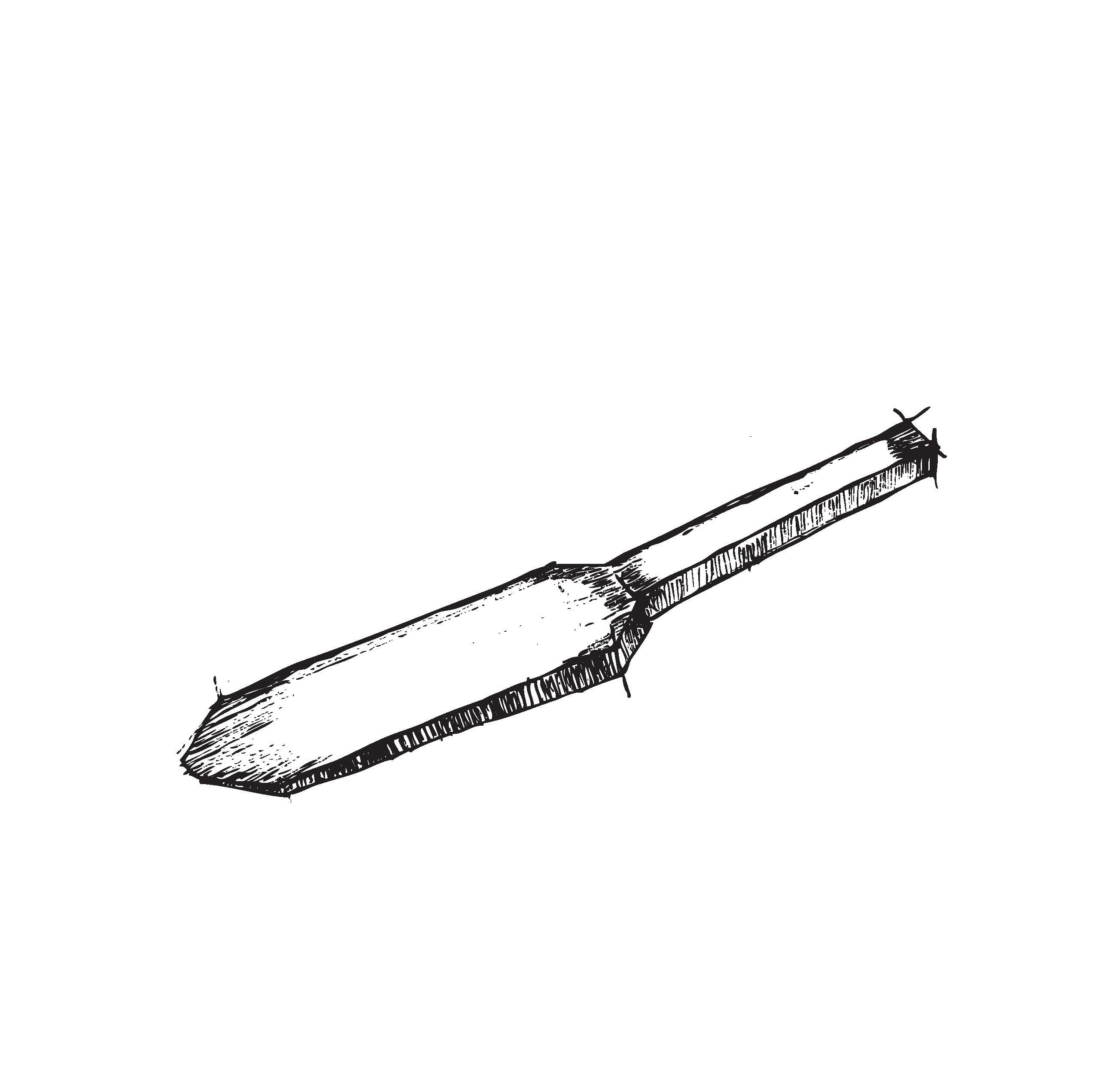

Used by potters to break up lumps and achieve a fine, granulated texture in their clay is a pounding tool, such as a pestle or mallet. This tool is used to manually break down the clay, making it more pliable and easier to work with.

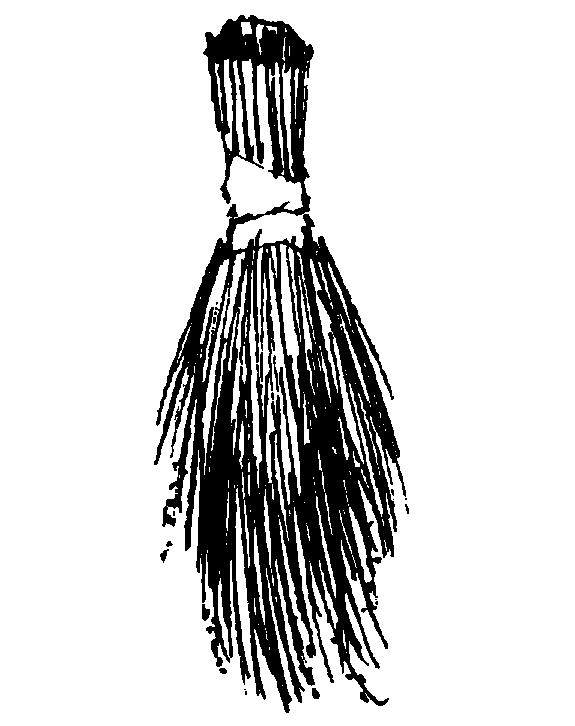

Material Used: Straw

A basic tool used by traditional potters to clean their work space and remove impurities is a broom or brush specifically designed for this purpose. This tool is used to sweep away debris and collect clay particles, ensuring a clean and pure work surface.

मुंगरी Bat

गहरी Broom 0 70 140 210 45 0 50 100 150 25

21

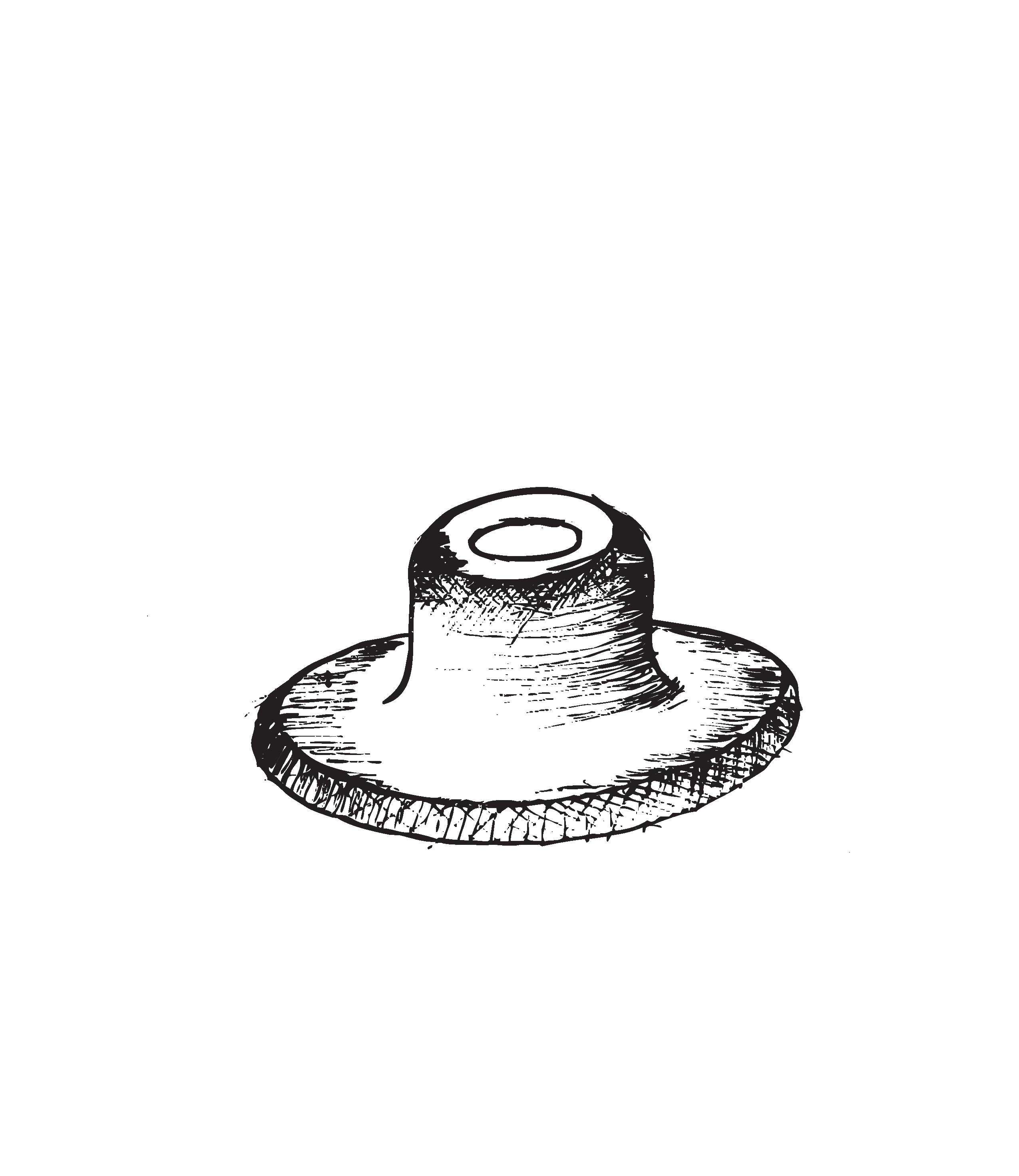

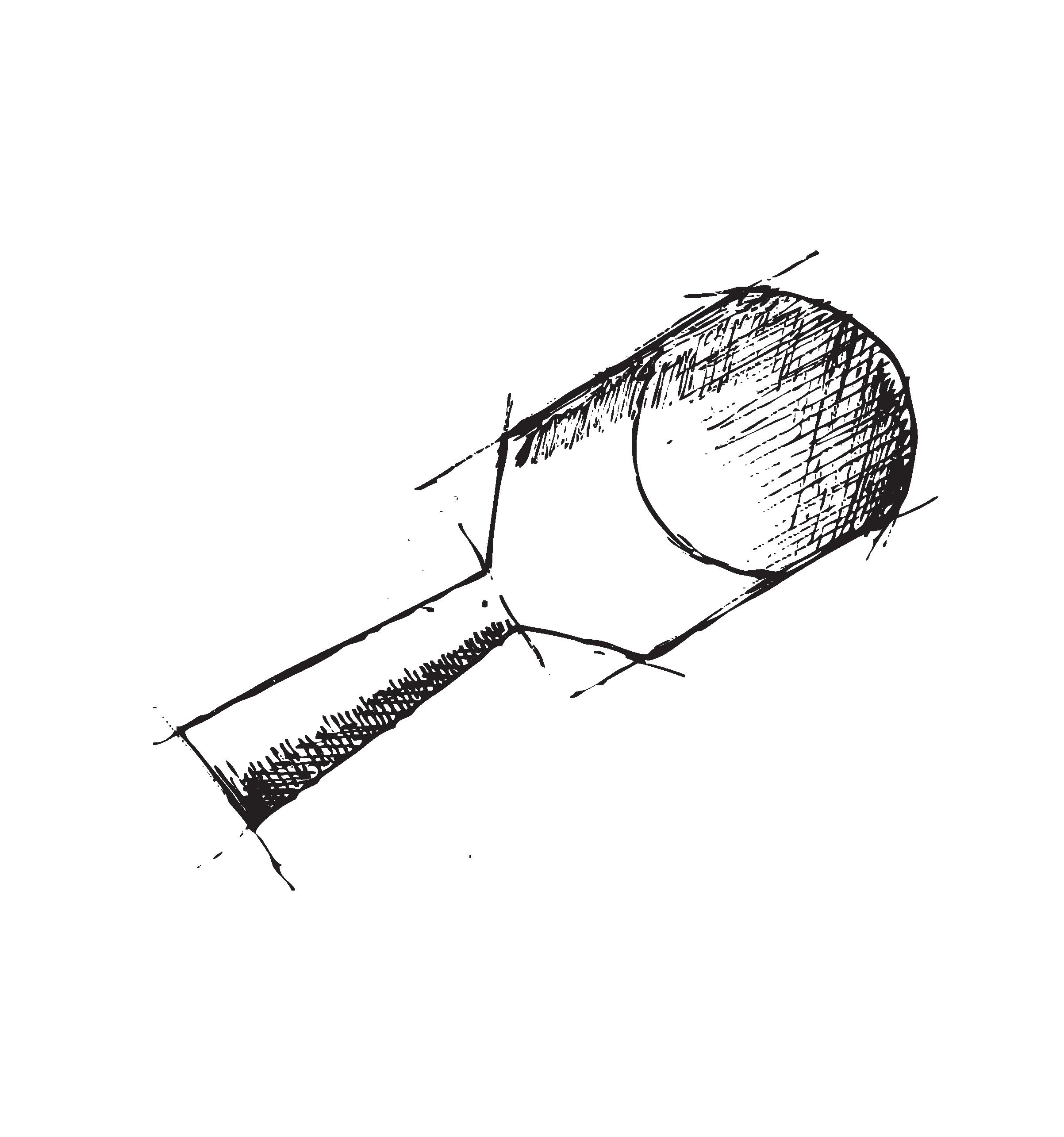

Material Used: Rakhal Wood

A spinning bowl with fabric on top. Used to place the undried pot

Rock

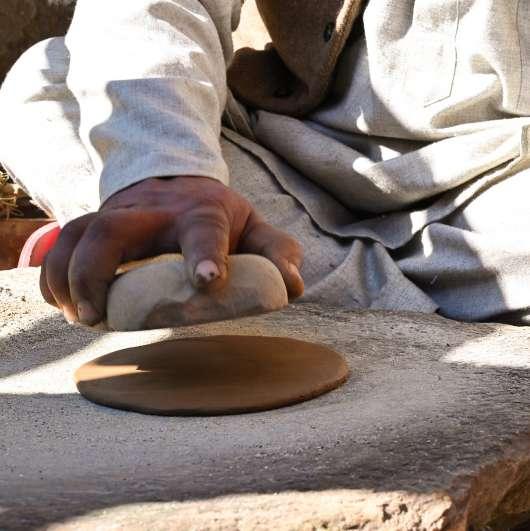

Material Used: Granite

Is ground on the stone base, creating fine particles of stone to reduce the stickiness for the clay.

23

पत्थर

Top View Top View Front View Front View

कोशिया

0 35 0 20 70 40 105 60 17 12

Koshiya

Scraper

Material Used: Straw

The equipment which is used to trim the edge.

Material Used: Stones, Clay

A small Setup to cook the Clay Products, Cooking of clay pots is done under a naturally existing boulder and under it, the fire is setup under it in this covered setup

खुरपी

भट्टी Kiln 0 0.5 0.25 1.0 2.0 meters 0 25 50 75 12.5

25

The Process

Selection and Preperation of Raw Materials

Collected soil is first beaten to fine powder with a tool locallyv known as Mungri. After beating the soil, lumps are cleared out by seaving or filtering them. It starts looking like sand.

The mud is watered, molded and rolled by hand.

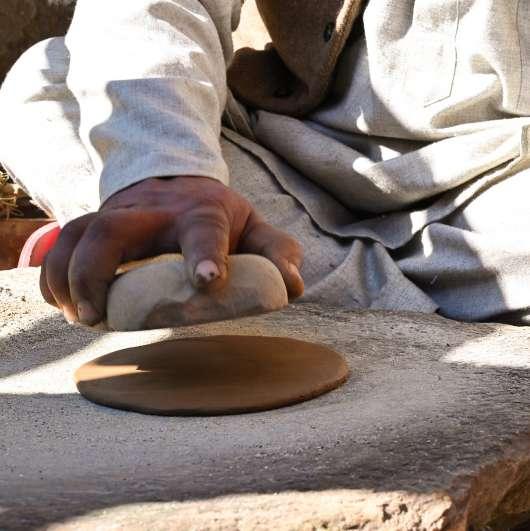

A Piece of this molded clay is placed on a large flat stone. This stone is readied by crushing smaller rocks with another bigger rock onto it and cleaned with a broom made of Gahri.

The molded clay is flattened with a rock. This clay starts to look like a circular disc.

It is then placed on the pots round surface to shape the clay.

27

Kneading the dough and Making Clay

The craftsman then dampens is fingers and patts the clay. He later later uses a wet Bohri to smote the clay.

Using a Tapdi the edges of the clay are cut out and the pot is placed under the sun. This forms the 1st half of the pot.

The same process is followed for the 2nd half except that part isn’t polished or smoothened like the 1st half.

29

Morphing of Clay

The dried upper part is beaten with a damp Tapdi on the outside and Kuhduru on the inside.

He makes a hole at the bottom center of the pot with his finger and uses it as leverage to hold it and place it on top of smaller 2nd half.

With a damp hand both pots are attached and smoothened.

31

Completing and Drying the Clay

The hole on the upper part is smoothened and a 3rd part is attached on top.

This part is handcrafted with damp fingers and placed similarly onto the pot.

The pots are then sundried.

Teetne (Pine tree cones), a layer of grasses, and a layer of wood are all piled on top of one another to cover the entire stack. The baking process is then initiated by lighting the fire.

33

TRANSFER OF KNOWLEDGE

The tradional craft of regional pottery being passed on by Craftsmen at Faryadi village to the students of National Association of Students of Architecture, India. This program opened new doors of self exploration in the field by young architecture proffessionals. Realising the value of diminishing art and craftsmanship in the region we are trying to imbibe the imperical knowledge which plays a key factor in improving the crafting and making it resilient over the course of time.

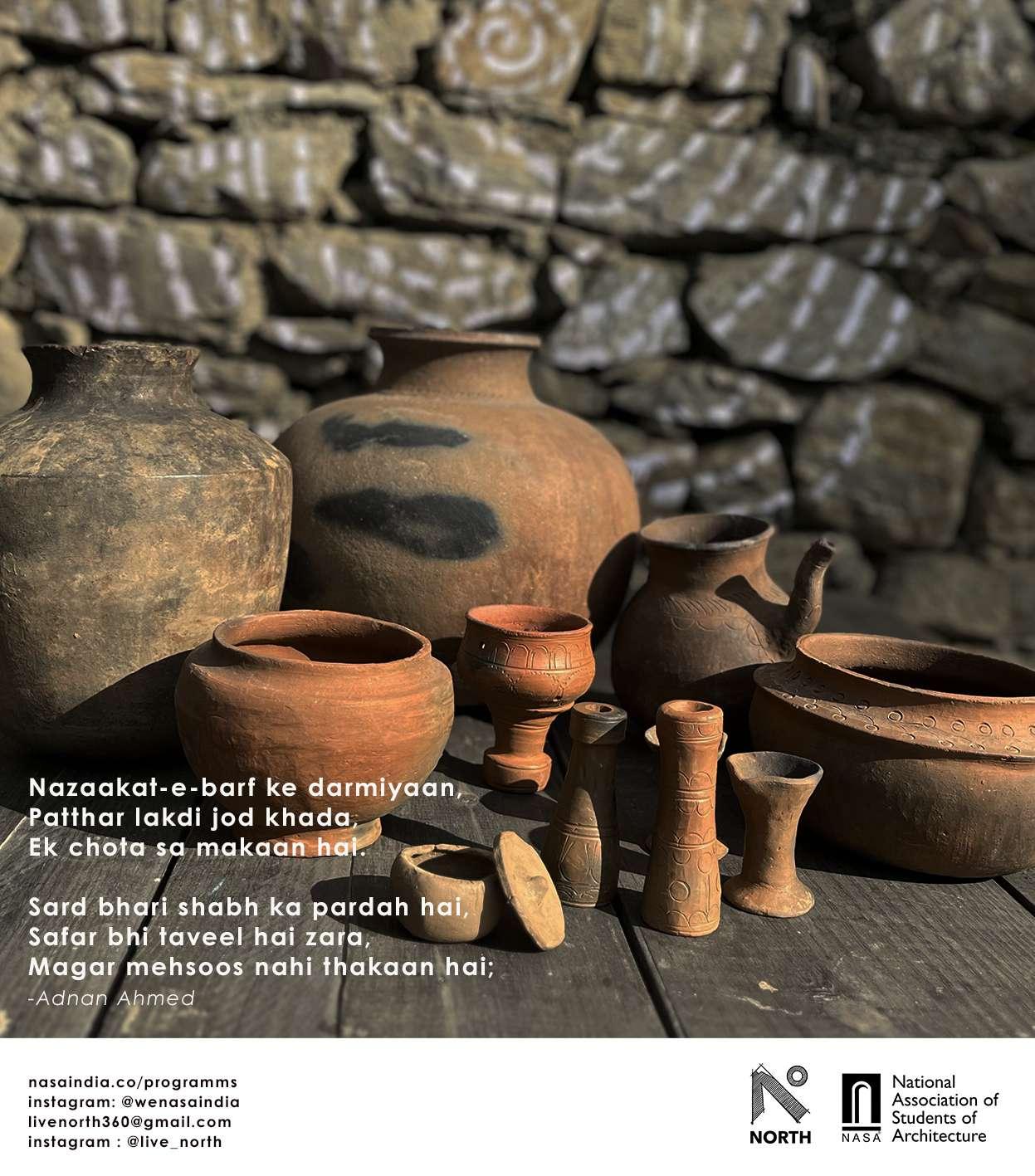

Container made of clay or ceramic, round in shape and used for holding, decorative or functional purposes. It can be glazed or unglazed, in various sizes and shapes.

typically round and made of clay or ceramic, used for cooking, storing or serving food and other items. It can be glazed or unglazed and come in various sizes and shapes.

A kettle in pottery is a handcrafted container, made of clay or ceramic, used for boiling liquids over an open flame.

An urn is a container with a lid, narrow opening, rounded shape and a base, used mainly for decorative or ceremonial purposes. It resembles a vase in shape.

35

PRODUCTS

केतली लोटा

टोकरी

घड़ा Pot Utensil Kettle Urn

CONCLUSION

The research was set to investigate the indigenous pottery culture in the valleys of Tirthan, to understand the practices & cultures of the locals living in Faryadi Village.

The research involved understanding the narrative of the kalakars through their perspective. The study involved attempts to not just understand the artform and its origins, but also the people of the village coexisting in it and making their living in varied fields. It is quite important to understand that the knowledge of this kala has been passed down through generations of the kalakar families.

As time and generations have flown by, the significance of the artform has faded, forcing the craftsmen to find alternative fields of occupation which has led this rare art form to move towards redundancy. The reasons might range from modernisation to corruption to negligence towards the art-form, resulting in the numbers of kalakari population to go down drastically. The research aims to discover the skills that have been fading with time.

This raises the need to answer the 3 questions,

WHAT CAN WE DO?

HOW DO WE ACHIEVE IT?

WHO CAN HELP THEM?

Organizations like NORTH have taken initiative towards connecting students of architecture to the crafts and its people to the core in collaboration with NASA India. Initiatives like these from all other organizations can help bring the craftsmen a step closer to the world which had been blinded by our ignorance all this while. India being a greater part of the World Trade Organization (WTO) has always helped revive such dying art forms. Government initiatives towards the same is one of the most efficient means of protecting the craft.

As the readers of this book; students, employees, homemakers and entrepreneurs should acknowledge the learnings from the craft and the authenticity it carries. Since assimilation of these crafts form an identity to this world which truly makes it ours.

“Crafts are vessels of vernacular identity, where each of these make a whole of us; bits of us left in the past, pushes our identity to be lost”

37

GLOSSARY

The craft: Traditional pottery making techniques and skills passed down through generations in the Faryadi village.

Faryadi: Village known for its traditional pottery.

Sthanivasi: Local residents of the village.

Giri-Sthanivasis: Local residents of the village who are from the mountains.

Kangra Kingdom: A historical kingdom in the region.

Kullu Kingdom: A historical kingdom in the region.

Buzurghs: Elderly ancestors of the village.

Kalakars: Traditional craftsmen of the village.

Koshya: A spinning bowl used by the traditional potters of the village instead of a conventional pottery wheel.

Phatta: A base-plate used in conjunction with a spinning bowl for pottery making in the village.

Pahadi

थाप ड़ : Bat used to join parts of pots.

चप्पू : Paddle

तोशी : Bowl

कुण्डधरु : Kunddhru, a type of traditional Indian pottery tool.

मुंगरी : Bat used to prepare the clay.

गहरी : Broom.

कोशिया : Spinning bowl used instead of a conventional pottery wheel, with a cushion made out of cloth that spins on a marble inserted on a base-plate.

पत्थर : Rock

खुरपी : Scraper

भट्टी : Kiln

Rikhal wood: A type of wood available in the region and used as fuel in baking kilns.

Clay (here): A form of dirt, used as the main ingredient in traditional pottery, gathered from specific regions such as Brelga and Beheda.

Lal-matta: Another term for red clay, commonly used in the village.

Chikni Mitti: Local name for red clay.

Tirthan River: Source of water used for mixing and molding clay into various shapes.

Wood (here): The main fuel used in baking kilns, traditionally sourced from Kail (Pinus wallichiana) and Chil (Pinus roxburghii) forests.

Grass (here): Used as a layer in the kiln when baking pottery.

Teetne: Pine tree cones used as a layer in the kiln when baking pottery.

Craftsmen (here): Traditional pottery makers of Faryadi village who have been documented.

Imperical knowledge: The valuable knowledge and techniques passed down through generations, which is crucial for improving and preserving traditional pottery making.

39

WRITING

K. Anjana Nandan

Adnan Ahmed

Maryam Afeefa Mehkri

Sanjana Cherukupalli

Akshitha Pannala

M. Varun Rao

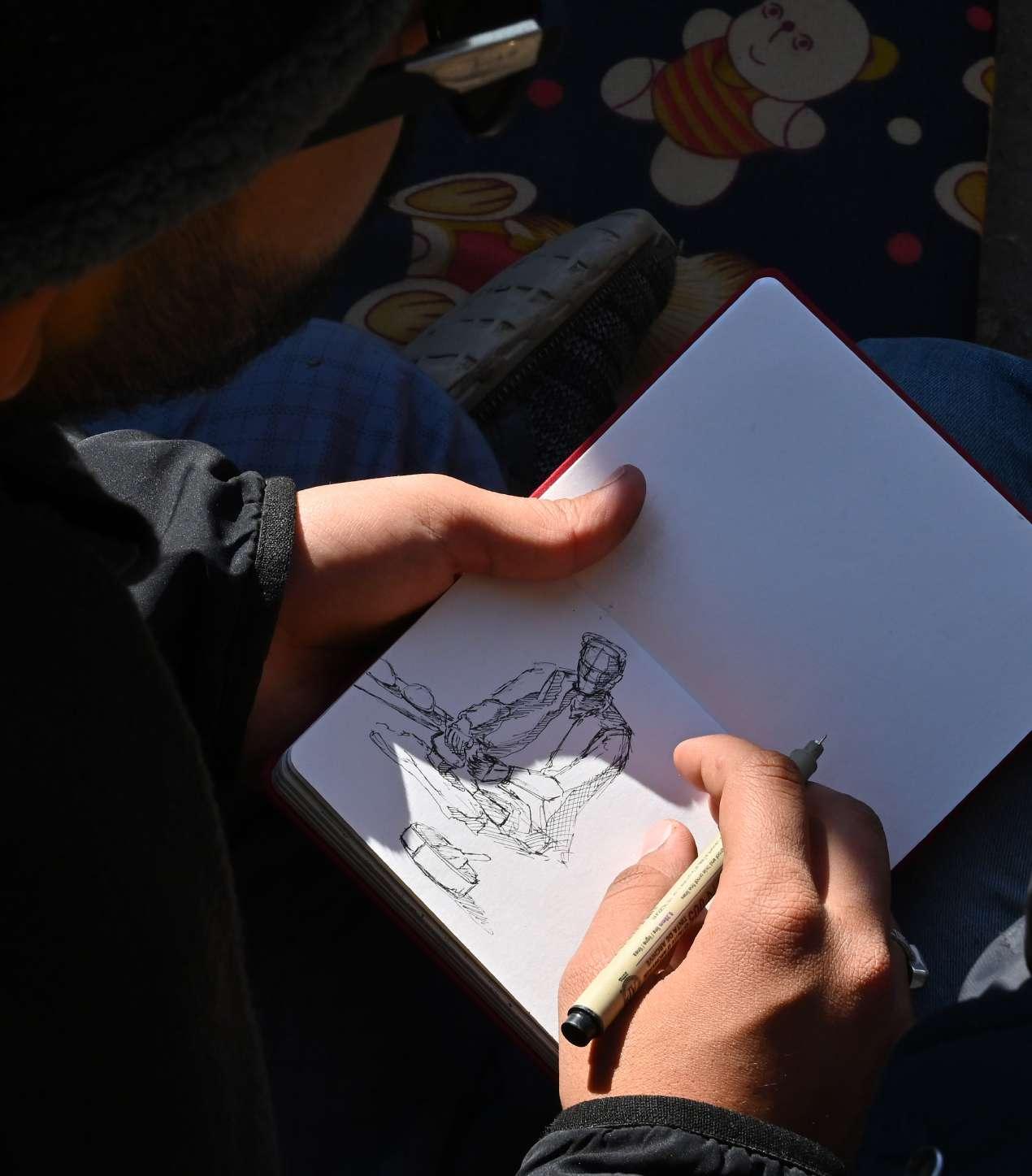

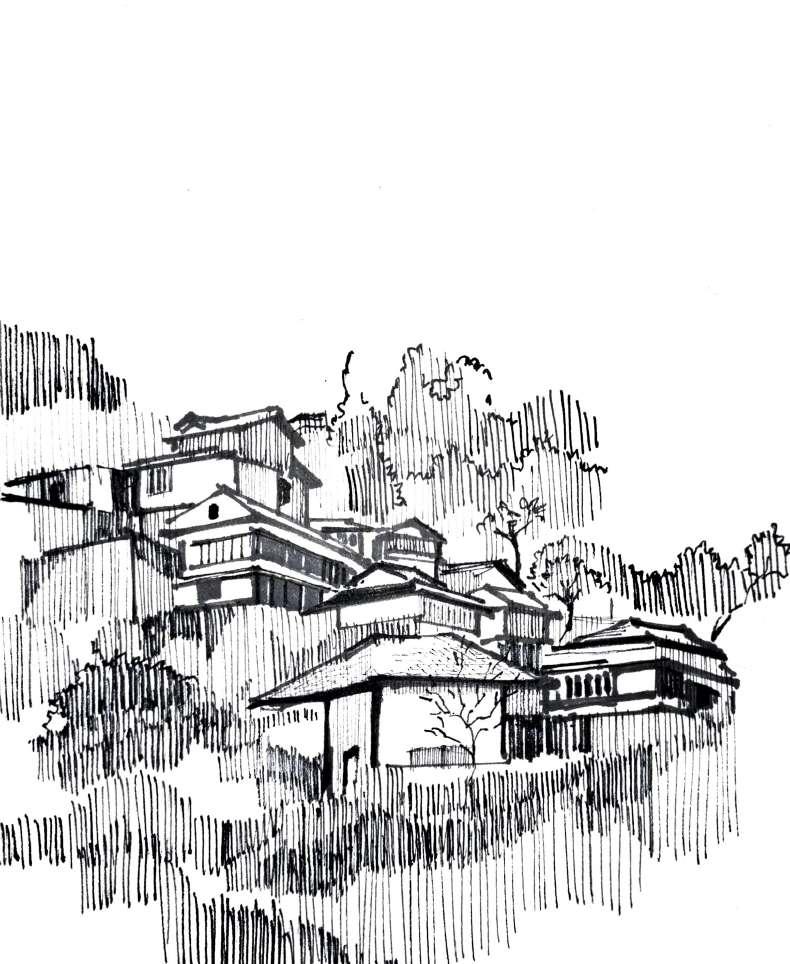

GRAPHICS & SKETCHING

Maheedhar Kotapati

Shravani Narvekar

Ram Pinlodi

E. Indu Manasa

PHOTOGRAPHY

Ruthvik Pulluri

Vedanti Kashid

Sathiyashree Shankar

COMPOSING

Aman Arora

Keerthana S.

Maheedhar Kotapati

Mayank Choudhari

Shaik Umaruddin

RESEARCH & ANALYSIS

Keerthana S.

Sanjana Cherukupalli

41