DESIGNING DRAWINGS RENDERING

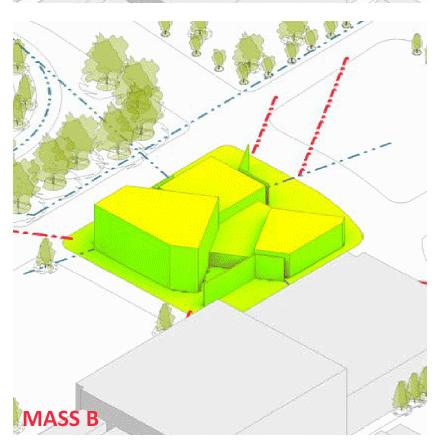

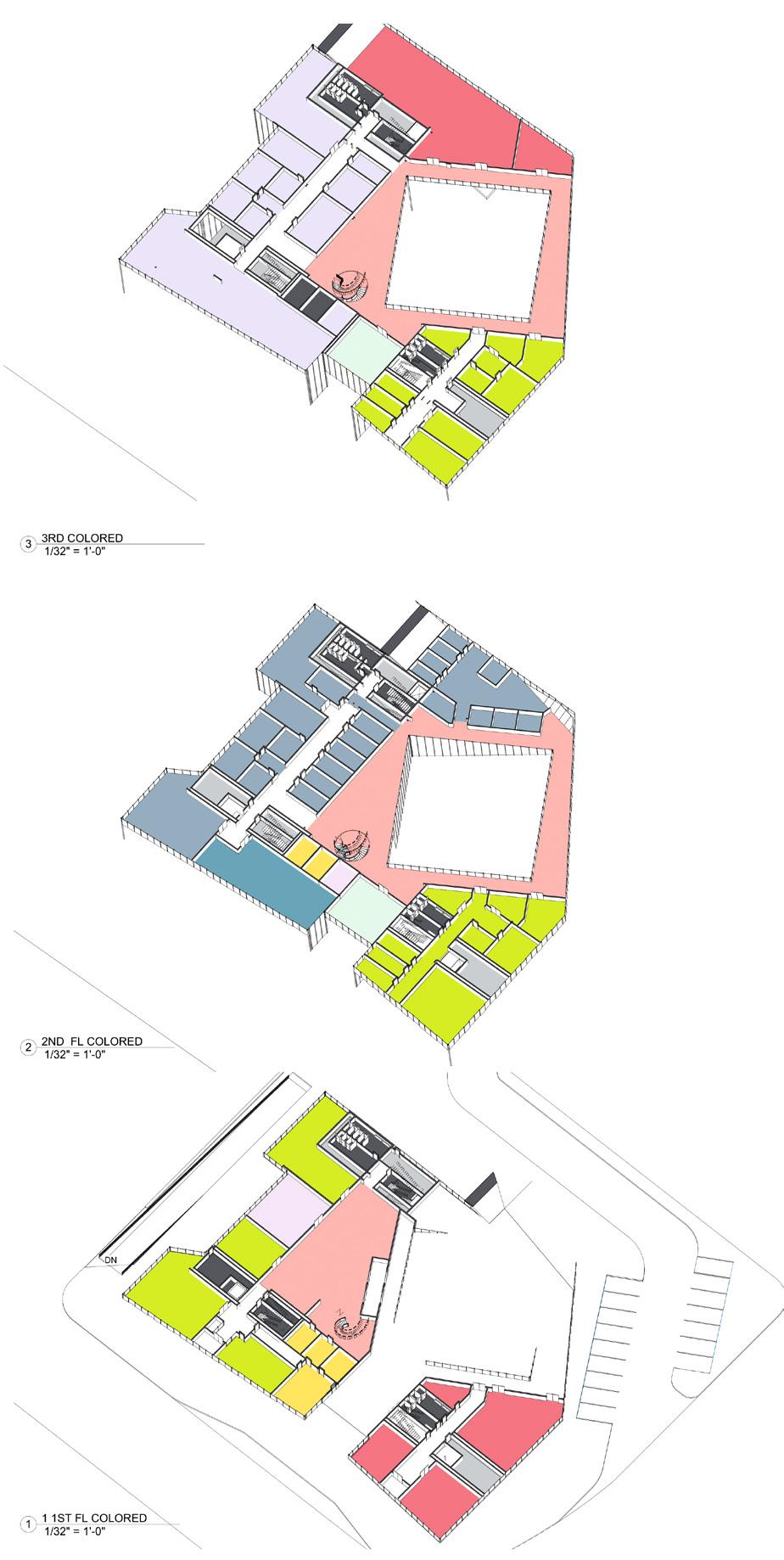

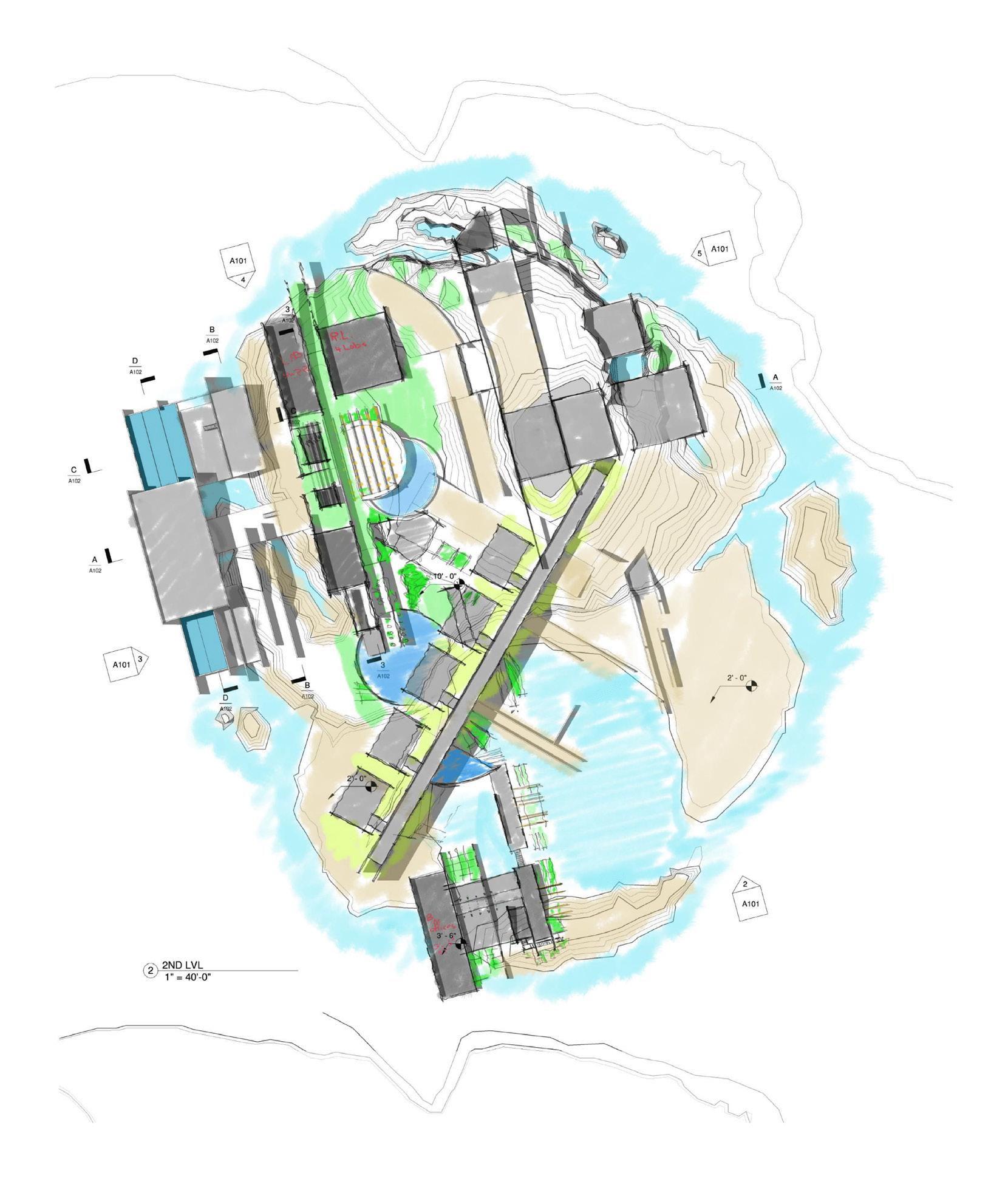

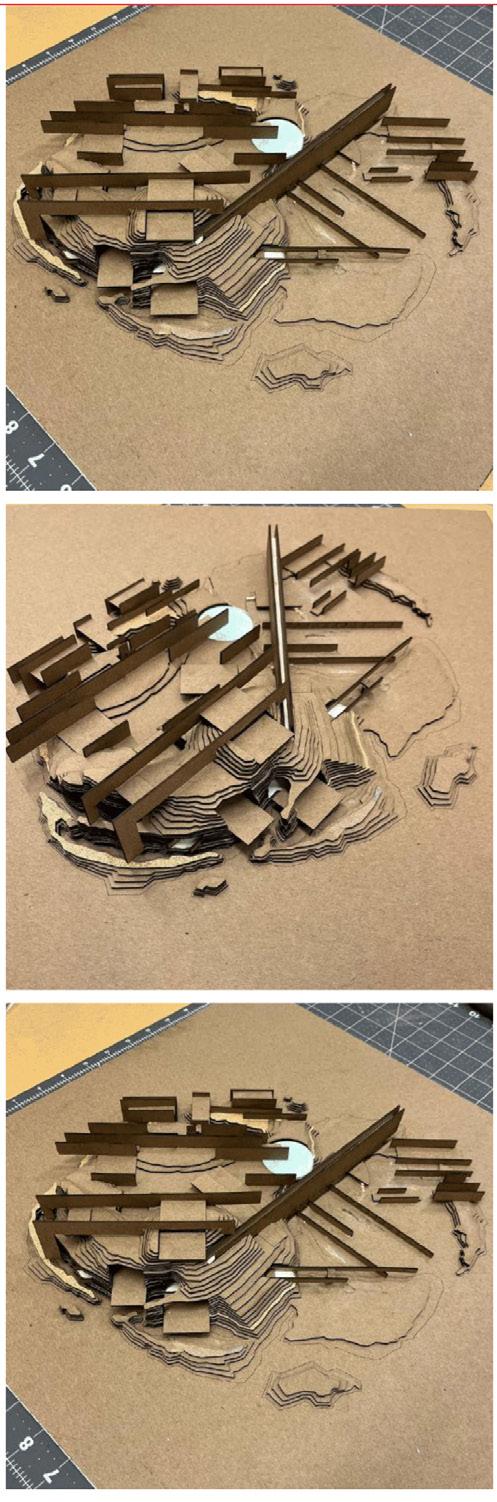

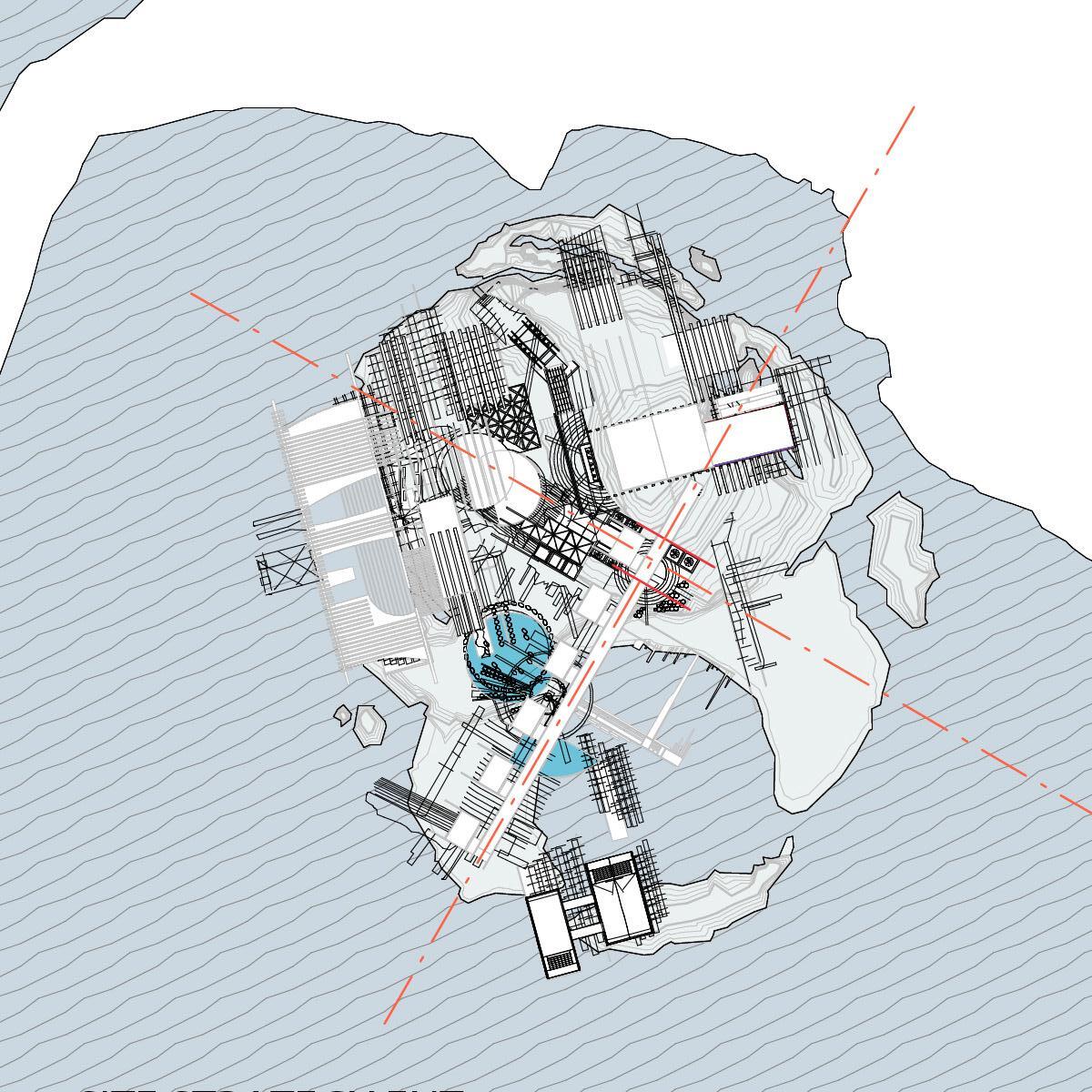

Resolving topographical challenges , in site, while maintaining accessibility and connectivity between the buildings was critical. The design had to meet sustainable development goals by integrating energy-efficient solutions, environmentally conscious infrastructure, and innovative urban strategies.

Achieving these goals involves:

• Meeting all space and performance requirements.

• Addressing functional circulation.

• Maintaining design consistency across the site.

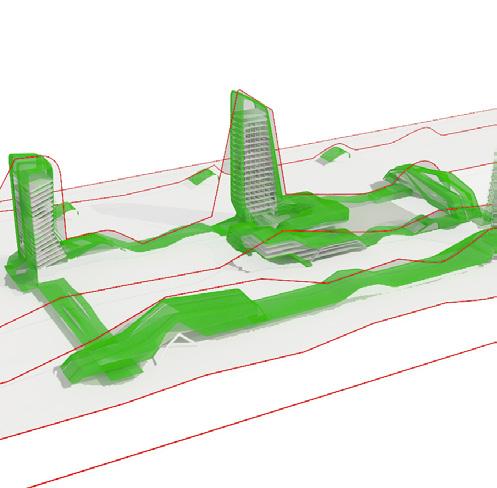

The "green line" concept connected the buildings both physically and visually, shaping pathways, defining entrances, and unifying the project’s overall flow. Collaboration with engineers and sustainability experts ensured the integration of energy-efficient systems, shaded walkways, and strategic topographical adjustments.

The design emphasized continuity by linking all buildings while enhancing functionality and accessibility across the site.

The "green line" served as the central element, addressing sustainability goals and creating a cohesive urban environment that balanced innovation with practical design solutions.

The "green line" concept linked all five buildings physically and visually, creating a cohesive flow across the entire site. This feature shaped pathways, defined entrances, and unified the overall design while addressing the need for continuity.

Engineers and sustainability experts collaborated to incorporate green infrastructure, energy-efficient systems, and shaded walkways, ensuring the project adhered to environmental goals. Topographical challenges were resolved through strategic adjustments, allowing the buildings to harmonize with the natural landscape.

The "green line" became the central design element, fostering accessibility and enhancing the functional and

aesthetic quality of the space. This approach balanced innovation with practicality, creating an interconnected urban environment that prioritized sustainable practices while delivering a visually appealing and user-friendly experience. The design also emphasized seamless movement between buildings, ensuring logical circulation patterns and clear spatial organization. By integrating the "green line," the project established connections that extended beyond function, creating a shared identity across the entire development. Green spaces were carefully positioned along pathways to enhance the user experience and provide visual continuity.

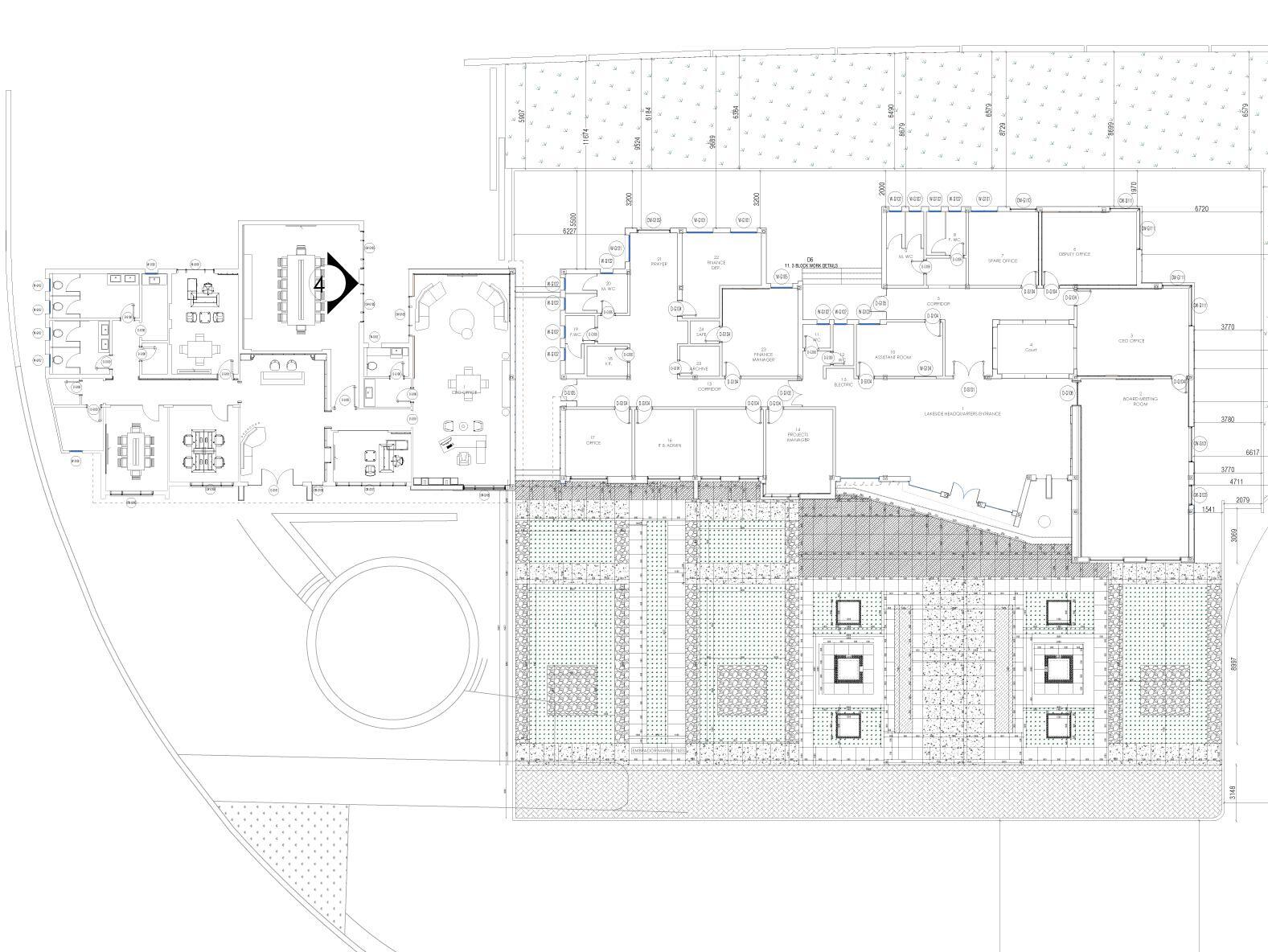

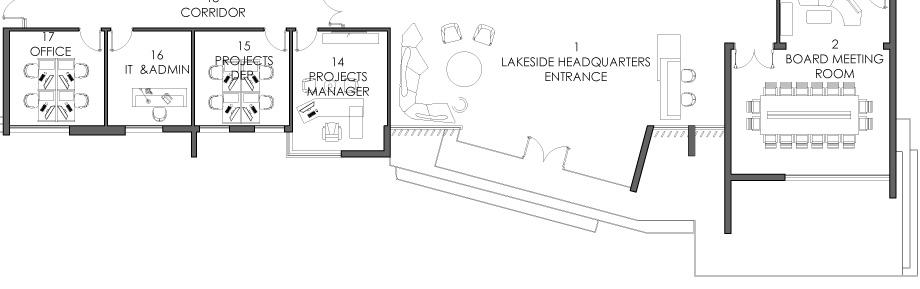

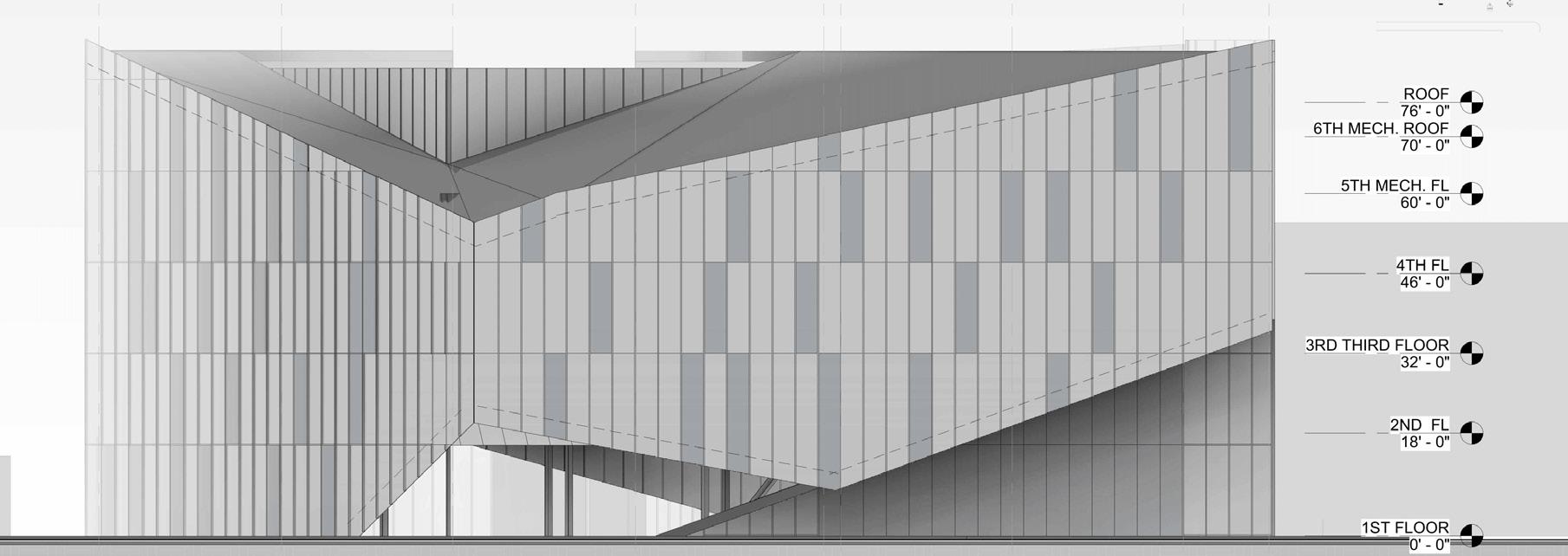

The Lakeside Headquarters project was a temporary administrative building forming part of a massive commercial development, the One-ninety, in New Cairo, Egypt. It was commissioned by Lakeside Company under the strict oversight of the consultant Hill Construction. The building had a planned lifespan of only five years and required a high-quality outcome on a very limited budget and under significant time constraints. Despite its temporary nature, the headquarters needed to integrate seamlessly into the broader commercial context and serve as a high-standard facility to attract visitors to the overall development.

LAKE-SIDE HEADQUARTER

ADMINISTRATIVE MANAGEMENT

COORDINATION INTERIOR FINISHES

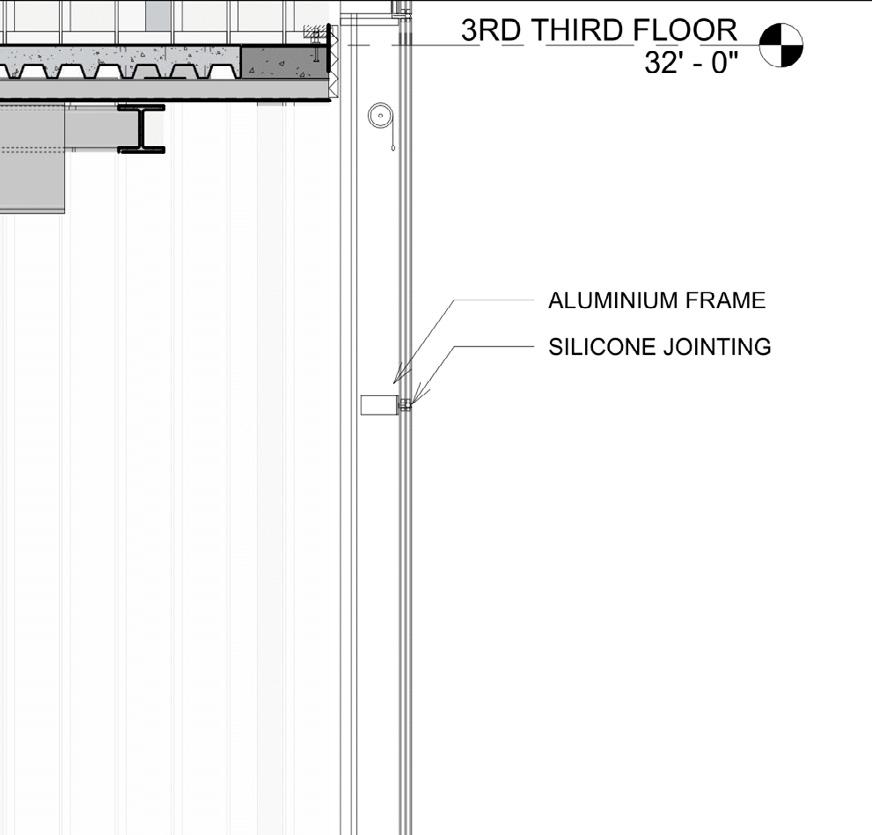

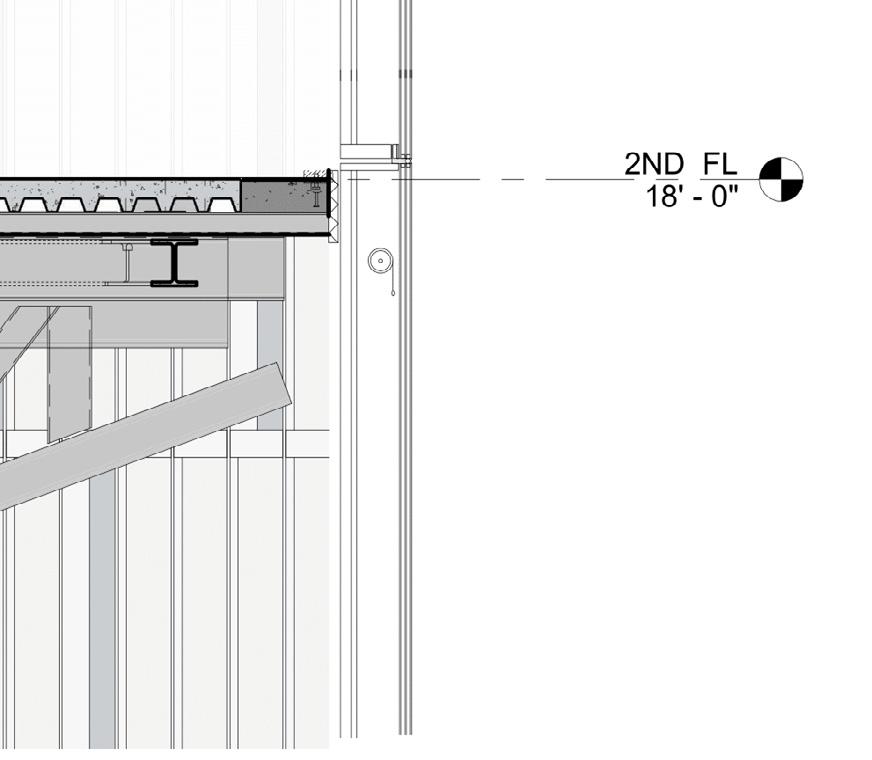

serve as a high-standard facility to attract visitors to the overall development. The goal was to design and construct a building that balanced exceptional quality with cost-efficiency and a fast turnaround. Tasks included grading the site, designing the facade and landscaping, and delivering interior spaces with premium finishes. The project demanded adherence to sustainability principles, insulation efficiency, and integration with the larger site plan. Achieving these objectives required innovative solutions and meticulous planning to ensure the building met both functional and environmental standards within the tight constraints.

Strategic Planning and Value Engineering in The Temporary Construction Project

All work required precise sequencing to gain consultant approvals at every stage. Coordinating subcontractors, meeting client expectations, and maintaining strict adherence to budgetary and temporal constraints presented major challenges. Delivering such a high-quality structure, despite its planned demolition in five years, called for strategic planning and innovative solutions.

The project implemented value engineering to balance cost and quality effectively, ensuring that high standards were maintained within budget constraints. This process involved a detailed analysis of materials, construction methods, and design elements to identify opportunities for cost-saving without compromising functionality or aesthetic appeal. Construction teams adopted a proactive approach by holding frequent meetings—often multiple times a week—to coordinate workflows and address challenges in real-time.

Tasks were overlapped strategically to expedite progress while maintaining precision. The facade was designed with high-end materials that offered durability and visual appeal, while efficient insulation systems separated the interior environment from the external elements. Landscaping and grading efforts harmonized the building with its surroundings, ensuring functional and aesthetic integration.

STONE SLAB

STONE LINER

Weekly reviews addressed any emerging challenges, ensuring all aspects of the project met the consultant’s strict standards and gained approvals promptly. These efforts allowed for streamlined execution, maintaining quality at every phase of construction.

LIQUID-APPLIED AIRWEATHER REATARDER

CMU BACKUP WALL

STAINLESS STEEL J-SHAPED BENT-PLATE SHELF ANGLE CLIP ANCHORED TO BACKUP WALL

SHIMS AS NEEDED 1/2 IN. MAXIMUM (FULL HEIGHT OF ANGLE LED)

The Lakeside Headquarters was completed in just eight months, meeting all deadlines and budgetary constraints while exceeding expectations for quality. The facade’s premium materials and the interior’s high-quality finishes impressed stakeholders, reinforcing the building’s role as an essential part of the larger One-ninety.

Visitors praised the design for its aesthetic appeal and comfort, ensuring the headquarters fulfilled its purpose as an administrative and welcoming space. By overcoming significant challenges through value engineering and efficient coordination, the project highlighted the capacity to deliver exceptional results under pressure.

INTERIOR DESIGN COORDINATIONS SHOP DROWINGS

The task involved selecting, coordinating, and detailing materials for the building's interiors and elevations, ensuring they met the owner’s aesthetic and functional expectations. This process required working closely with manufacturers to identify appropriate materials, obtaining consultant approvals, and maintaining quality control.

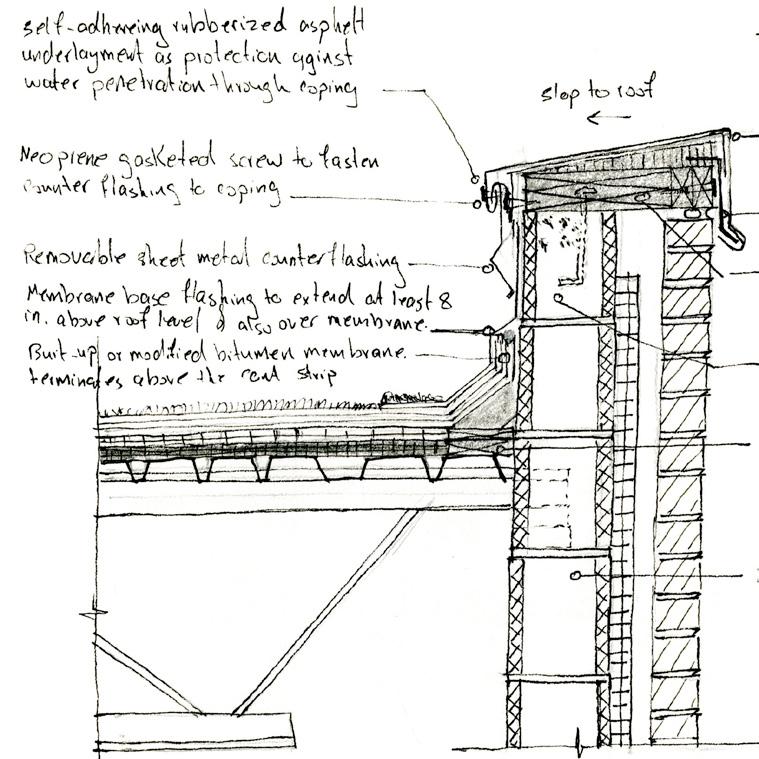

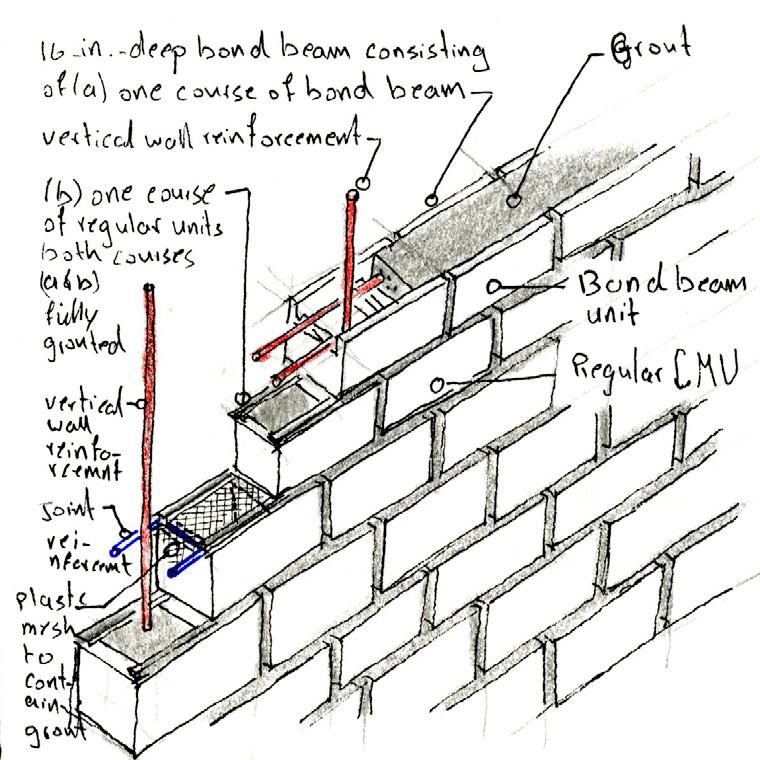

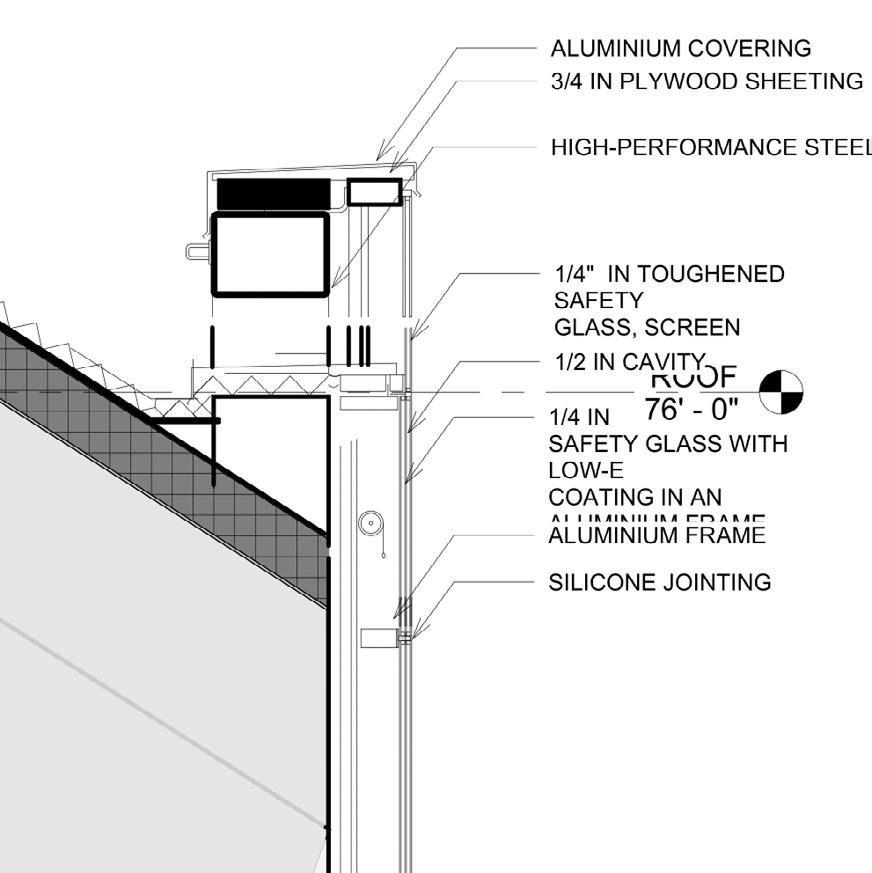

The goal was to achieve a cohesive and luxurious interior with precise detailing and optimal integration of all components. Key objectives included preparing workshop drawings for materials, ensuring proper insulation, and addressing critical detailing at intersections like marble-to-anchor connections

Material Selection and Precision Detailing in Architectural Design:

Starting the process by identifying material options aligned with the owner’s vision and functional requirements. Extensive coordination took place with manufacturers to select high-quality materials, including marble, wood veneers, and glass. Samples were submitted for approval by both the owner and the consultant, ensuring alignment on aesthetics and performance.

After material approval, detailed workshop drawings were developed for each interior and exterior element. These drawings documented the precise placement, connections, and installation details. For instance, where marble met the anchoring system, drawings showcased the integration with the backup wall, ensuring proper insulation and air barriers were incorporated. Other elements, such as the wood panels and glass, were detailed to provide seamless transitions, ensuring no gaps in the design’s overall quality.

Special attention was given to ceiling systems, using stretched ceilings and other modern techniques to harmonize with the walls and floors. The marble was bookmatched to create visually stunning patterns, and wood accents were strategically placed to warm the interior aesthetic. Insulation was incorporated into the backup walls to optimize energy efficiency and meet weatherproofing standards. Regular coordination meetings with consultants ensured that all detailing adhered to quality expectations while addressing site-specific challenges.

The completed Lakeside Headquarters achieved the intended luxurious appearance while adhering to budgetary and functional constraints. The carefully selected materials, paired with detailed workshop drawings, allowed for precise execution on-site.

The marble finishes, with their open bookmatched patterns, created an elegant and striking visual effect. Wood paneling and glass elements added warmth and sophistication, while the coordinated ceiling designs tied the entire space together. By addressing critical details such as insulation and connection points, the project delivered high-quality finishes that were not only visually stunning but also practical and durable. The collaborative approach among the team, consultants, and manufacturers ensured that all requirements were met, resulting in a functional and aesthetically spaces.

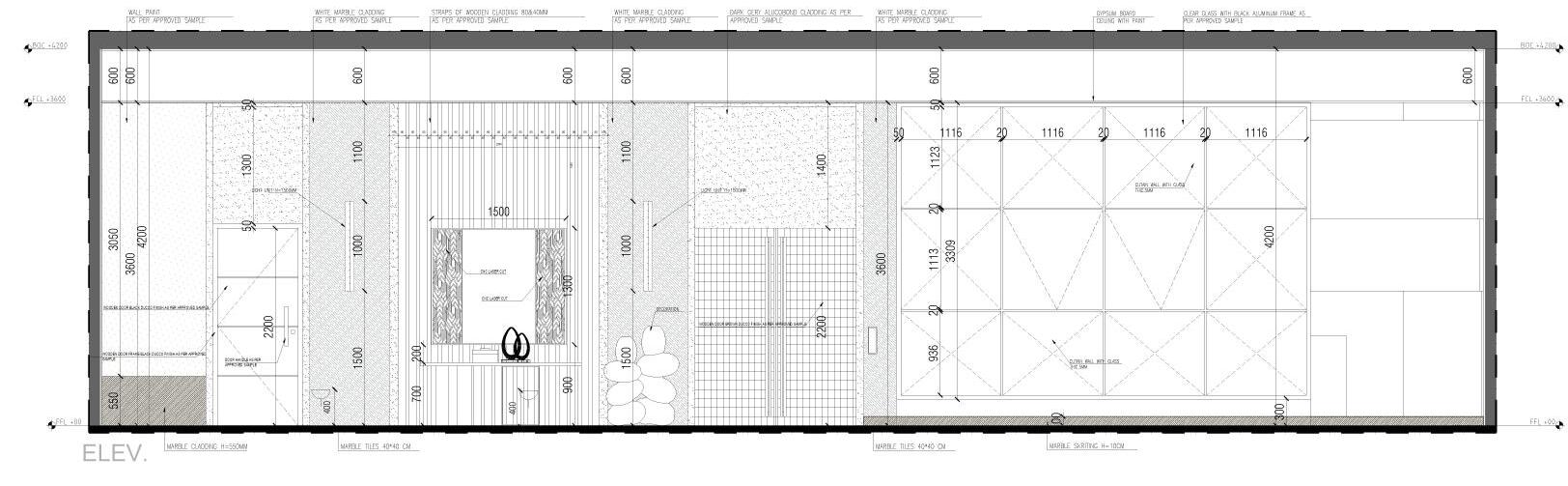

SOLAR ANALYSIS MASS |ENERGY PERFORMANCE STRUCTURE

Urban Integration and Sustainability in Healthcare Design

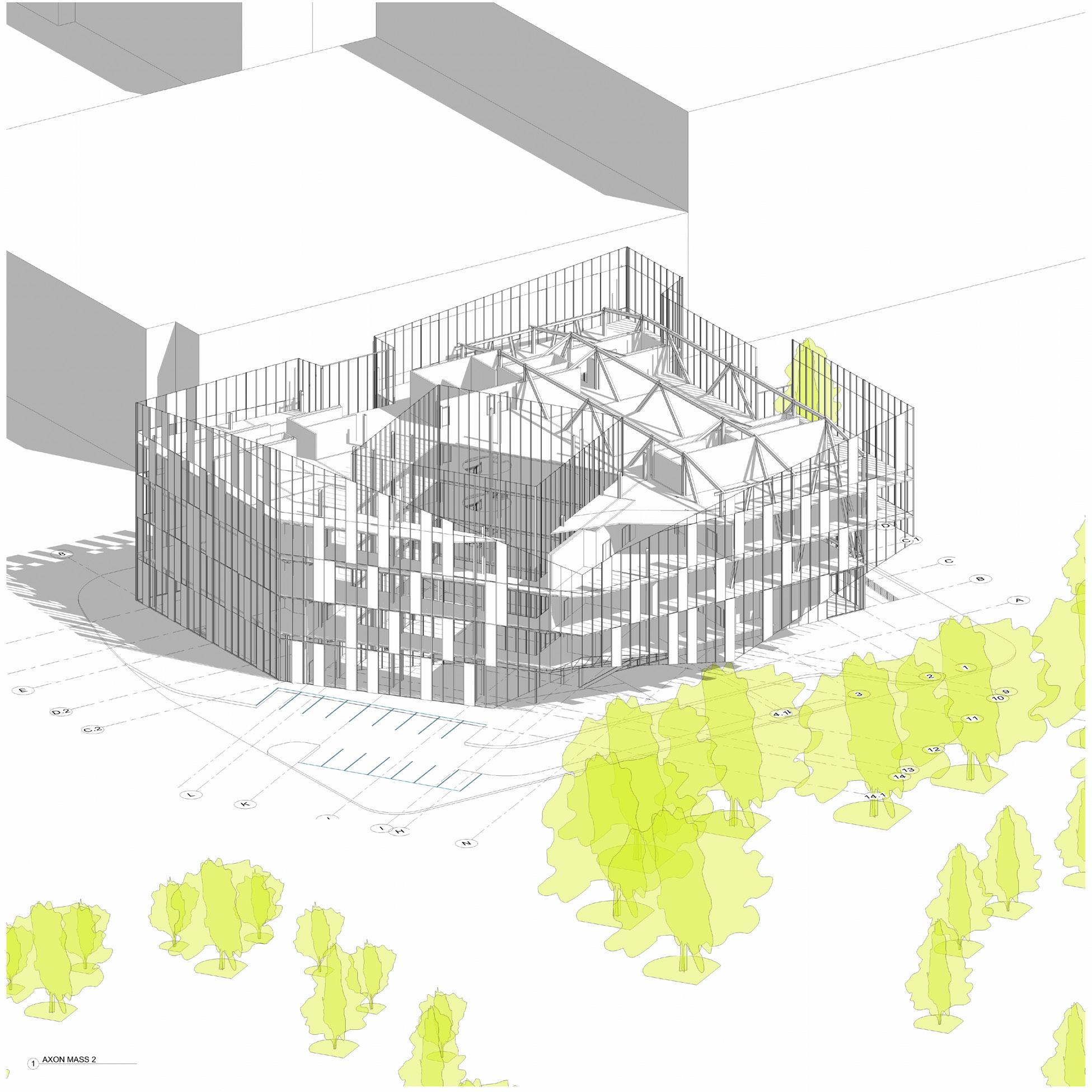

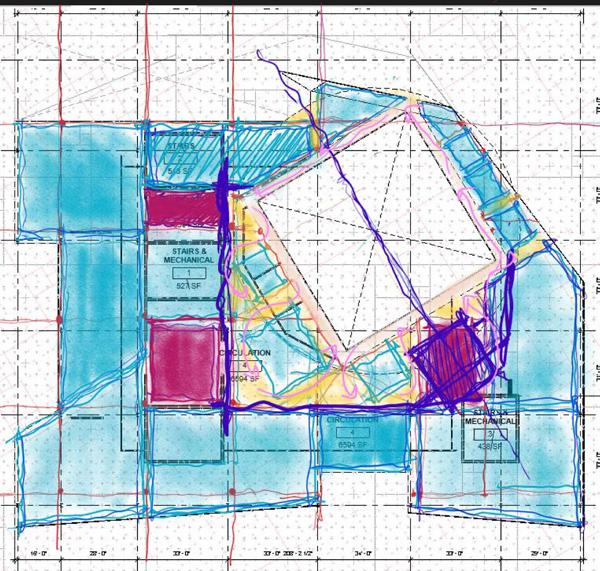

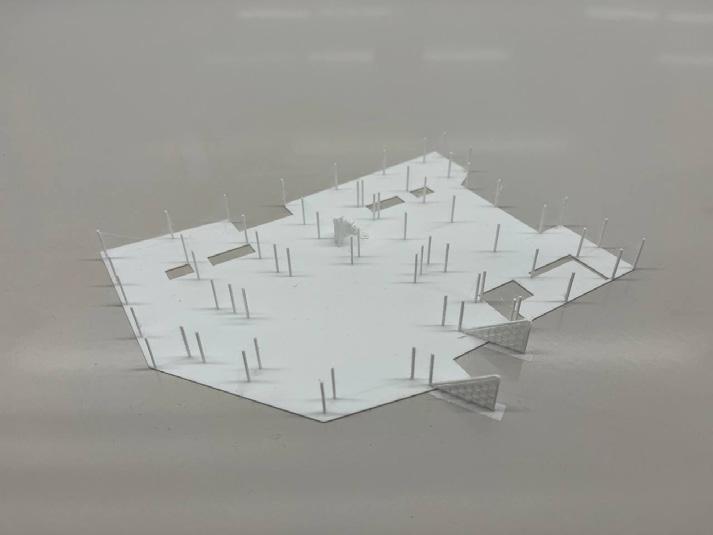

The primary objective was to design and deliver a healthcare facility that integrated seamlessly with the urban landscape while addressing the needs of wellness and sustainability. The project’s scope included innovative architectural strategies, advanced environmental systems, and comprehensive site integration. Key challenges emerged during the planning stages. The first was addressing the site’s unique urban fabric, characterized by intersecting grids and dynamic pedestrian patterns. The building needed to blend harmoniously with the existing context while enhancing urban connectivity and respecting historical influences.

A robust site analysis was crucial to achieve this integration, requiring detailed studies of pedestrian movement, environmental conditions, and urban dynamics. Another critical task was designing a building that balanced functionality and aesthetics. The facility required spaces for laboratory operations, administrative work, recreational activities, and circulation. These spaces had to be optimized for environmental performance, ensuring energy efficiency and user comfort. The integration of advanced technologies and sustainable design principles was essential to meet these requirements. Sustainability played a pivotal role in the project.

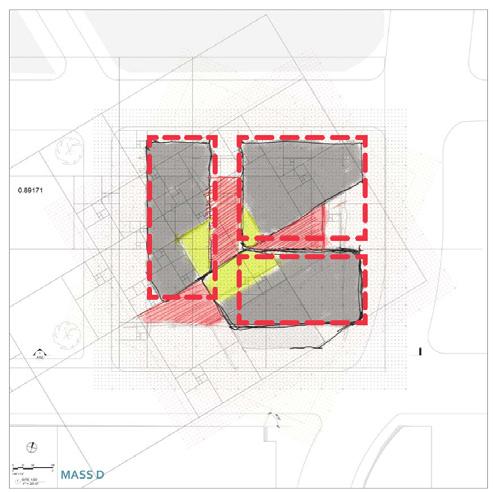

The design process began with a comprehensive analysis of the site and its surrounding urban context, taking into account both the physical and social dimensions of the area. The grid system of Downtown Dallas, a hallmark

the building could enhance public spaces, support urban activity, and contribute to the vibrancy of the area. At the conclusion of the site and surrounding analysis stage,

of the city’s historical and urban planning, served as the foundation for developing a design language that integrated seamlessly into the city’s fabric. This grid system provided a blueprint for aligning the building with exist-

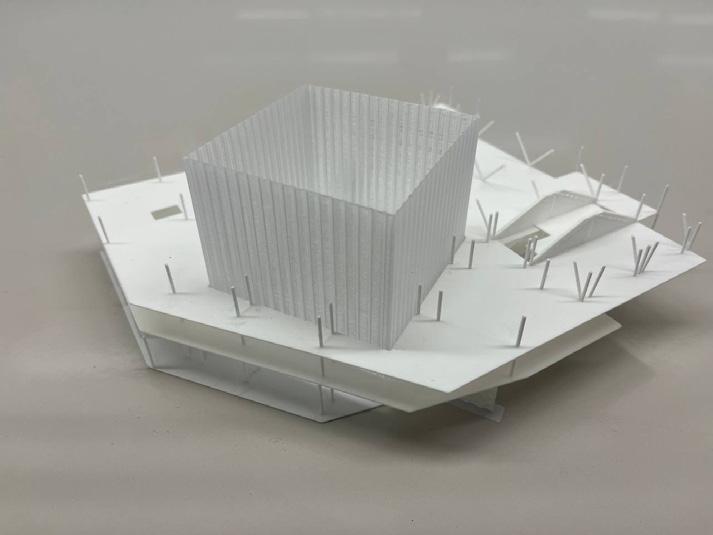

the final massing strategy was selected based on its ability to achieve the highest level of sustainability and align seamlessly with urban dynamics. This approach prior-

ing streets, ensuring a cohesive visual and functional connection with the surrounding environment. The site analysis examined a variety of factors, including pedestrian movement patterns, historical influences, traffic flow, and

itized minimizing the environmental impact while maximizing efficiency, aesthetic appeal, and integration with the urban context. The chosen design demonstrated

environmental conditions such as sun orientation and prevailing wind directions. These insights were instrumental in shaping key design decisions, including massing, orientation, and connectivity. Special attention was given to how

the best balance of sustainable features, functionality, and architectural harmony, ensuring the project aligned with both environmental goals and urban connectivity.

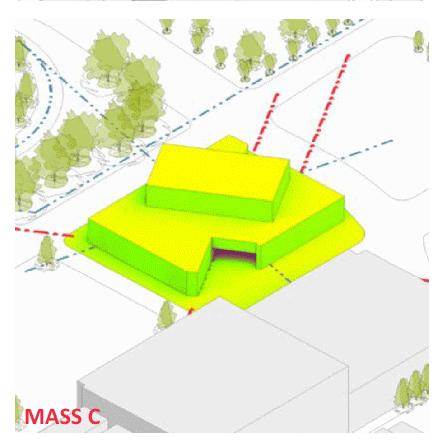

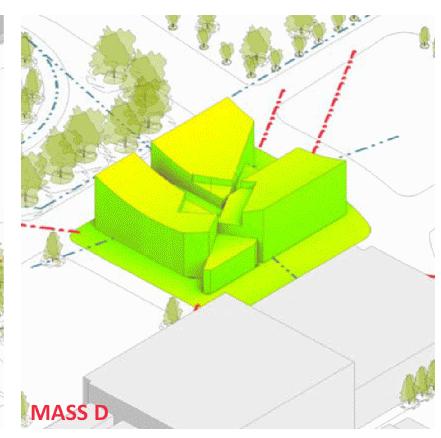

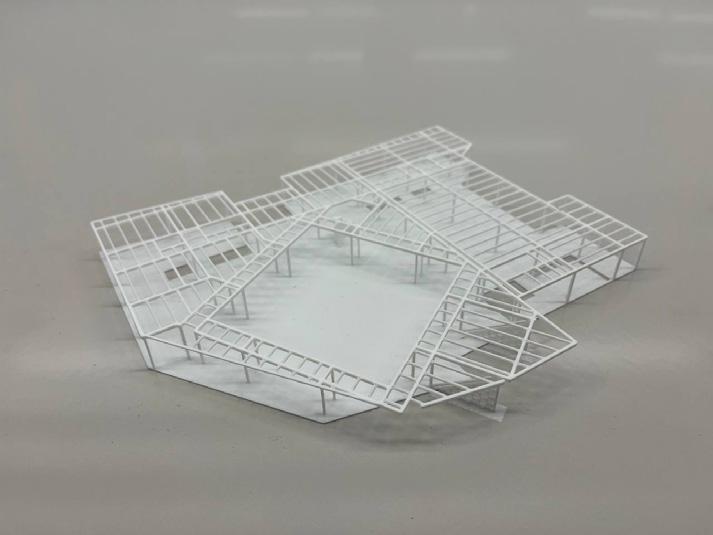

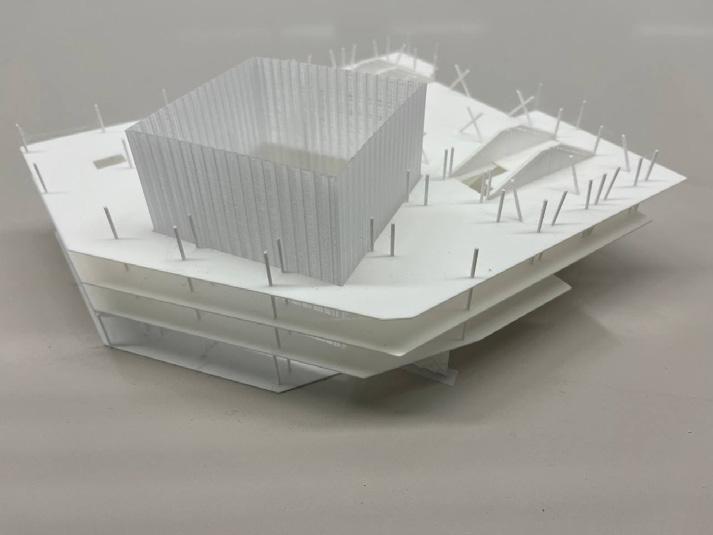

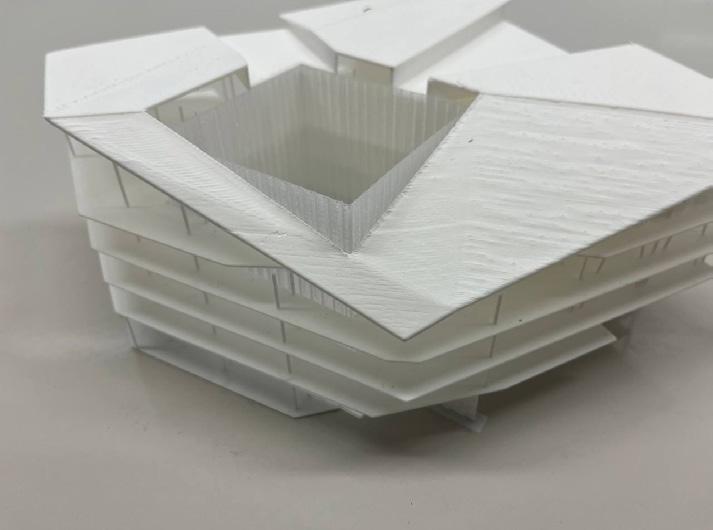

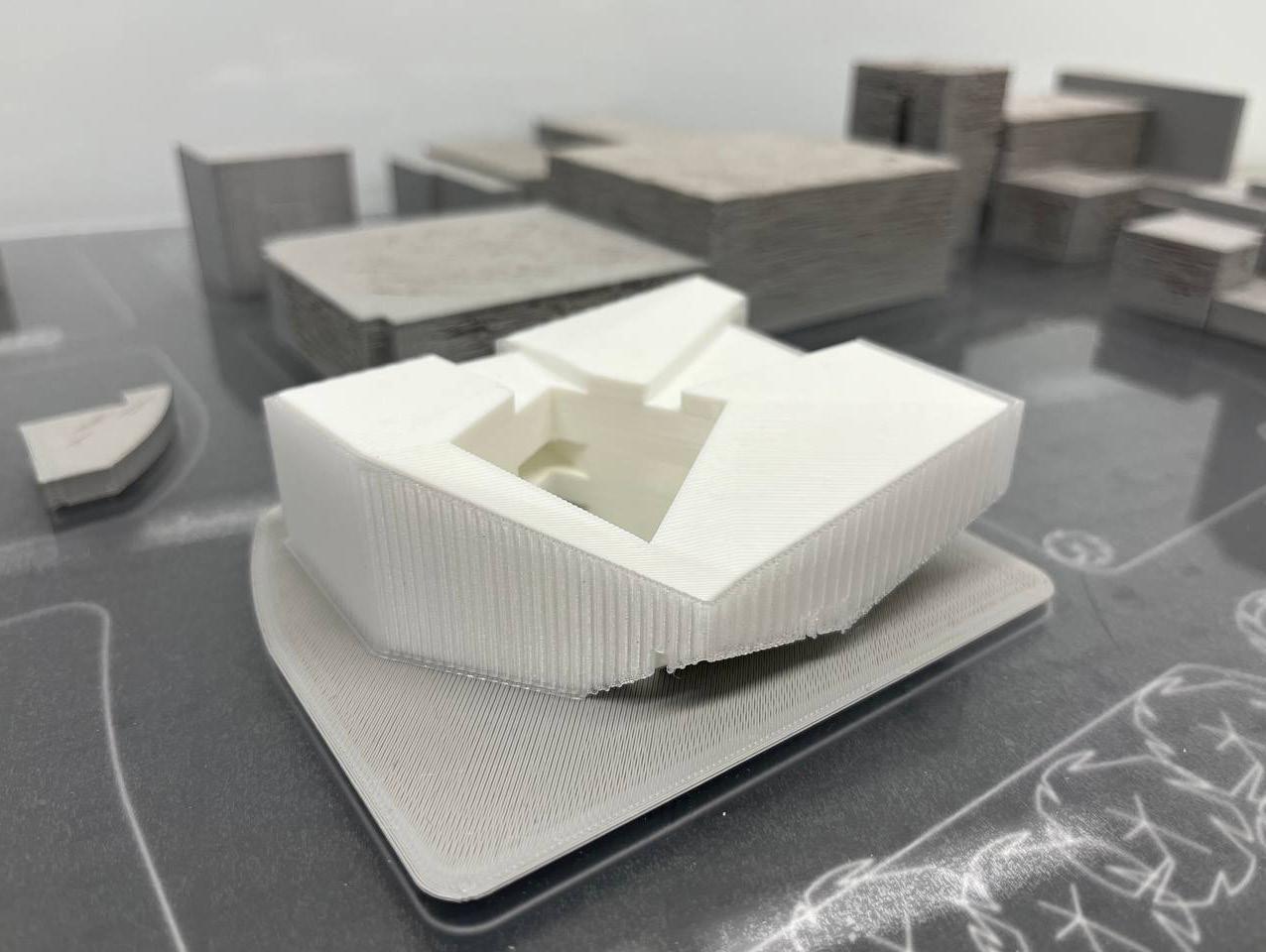

The initial design phase adopted a modular approach, starting with a basic box form. This form underwent rigorous analysis and iterations to identify optimal configurations. Each iteration explored ways to harness natural light, optimize ventilation, and enhance environmental performance. These studies led to the selection of a preferred massing strategy, characterized by three interconnected masses. This configuration balanced functionality, aesthetics, and environmental responsiveness.

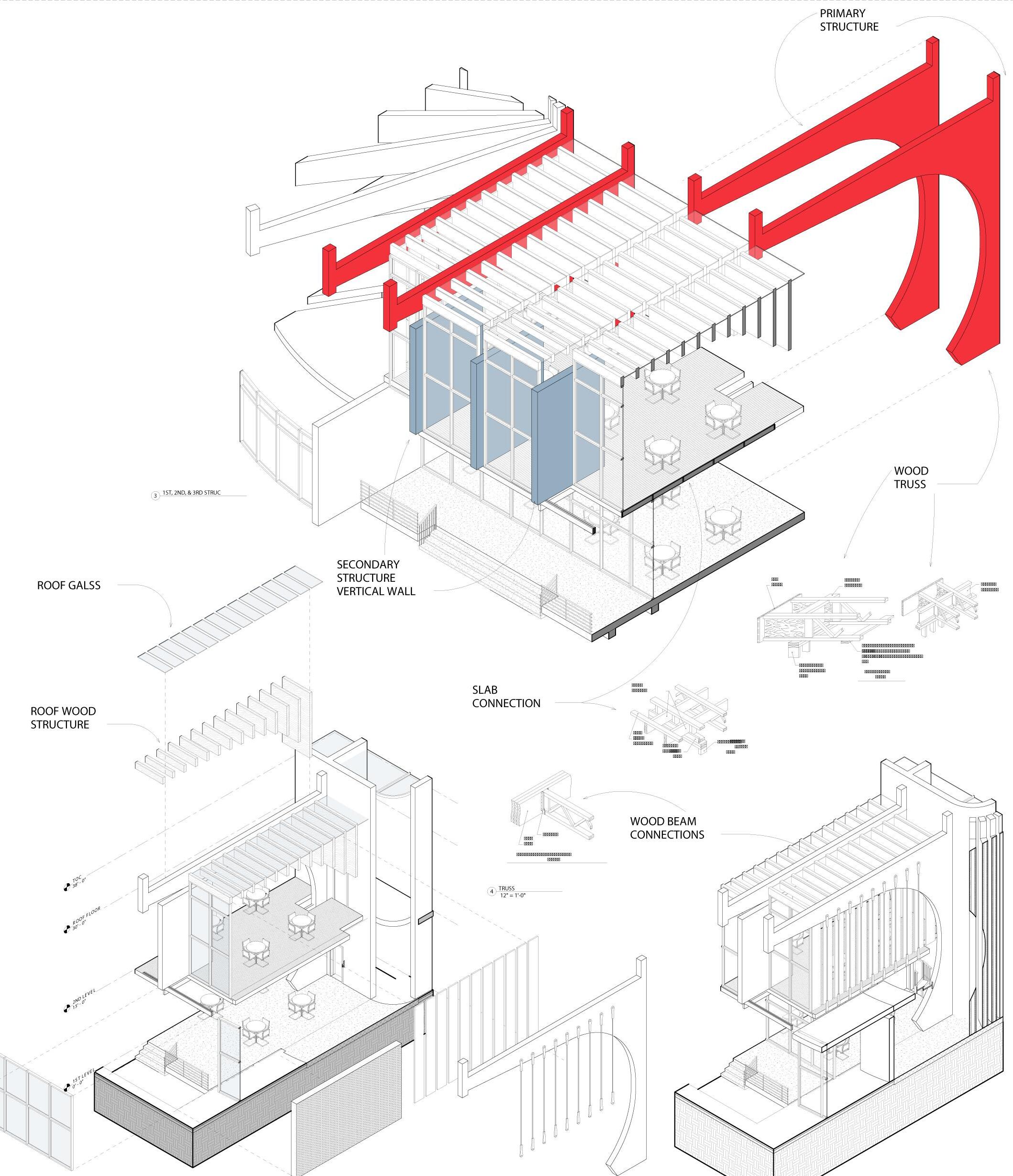

A key architectural strategy involved dividing the building into two primary wings. The left wing housed laboratory spaces supported by a robust truss system, ensuring structural stability and flexibility. The right wing contained administrative functions, recreational areas, and circulation spaces. At the heart of the design was a central courtyard, designed as a communal hub that enhanced natural light penetration and fostered social interaction. Sustainability was a guiding principle throughout the project.

Advanced environmental systems were integrated into the design, including operable facade elements for adaptive environmental control. These elements allowed for precise management of energy consumption, optimizing thermal comfort and user well-being. Renewable energy sources, water conservation systems, and sustainable materials were prioritized to minimize the building’s environmental footprint. To promote wellness, the design

incorporated elements that encouraged physical activity and social engagement. The central courtyard provided a space for relaxation and interaction, while the building’s layout encouraged movement and connectivity. Landscaping and site grading were carefully planned to ensure a seamless connection between the building and its surroundings. Advanced control systems were implemented to manage environmental efficiently.

The building plan closely followed the development of the site, which featured two intersecting grids derived from the site's urban fabric. These grids informed the layout, ensuring alignment with the surrounding

context. This planning approach led to the creation of a central courtyard, a key element highlighted in initial sketches, which fosters natural light and connectivity within the building. For the structural design, a steel system incorporating large trusses was utilized. This innovative approach allowed for expansive, open spaces in the laboratory areas, ensuring functionality and adaptability for various uses.

The courtyard was strategically incorporated to bring natural light into the entire building, enhancing its overall ambiance. It also served as a central circulation hub, creating not just an efficient flow within the health center but also an engaging space where people could interact and connect. This design fosters a sense of community, transforming the health center into more than just a functional space—it's a vibrant environment that promotes social interaction and well-being.

The Nexus Health Center in Downtown Dallas integrates wellness, sustainability, and innovative design. Its mass configuration aligns with the city’s grid, enhancing connectivity and creating a dynamic urban presence. The building’s layout, informed by pedestrian patterns and urban dynamics, complements its surroundings while offering accessible spaces. The advanced environmental systems and operable facades optimize energy use and comfort, reducing its environmental footprint. A central courtyard fosters natural light, social interaction, and community engagement, promoting physical and mental well-being. The design combines functionality and environmental efficiency, creating a vibrant, welcoming space that demonstrates the potential of thoughtful urban architecture.

FABRICATION DETAILING DESGINING CRAFTSMANSHIP

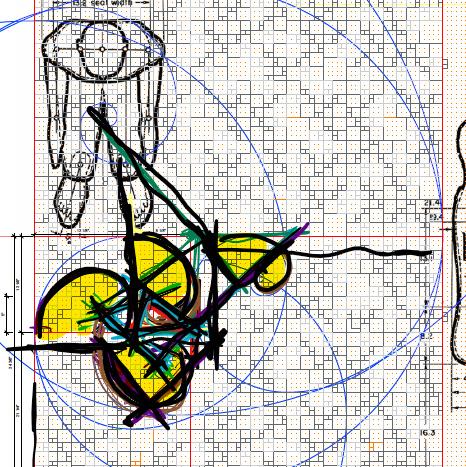

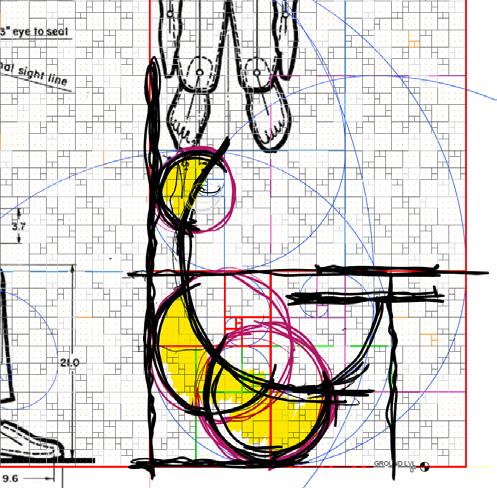

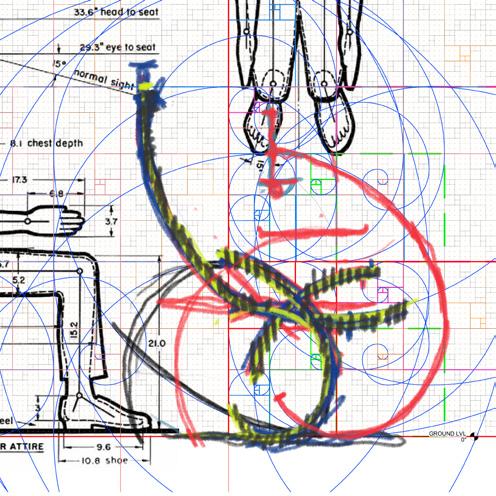

As part of the "Golden Harmony Collection" by AUREA ERGONOMICS, the project involved creating a chair that harmonized aesthetics, comfort, and functionality, guided by the golden ratio and ergonomic principles. The challenge lay in translating a theoretical design into a tangible product that balanced these principles while ensuring practical usability and durability. This required precise execution, innovative problem-solving, and a strong understanding of materials, tools, and construction techniques to achieve both structural integrity and visual harmony. Maintaining adherence to the golden ratio throughout the process added complexity, emphasizing the importance of attention to detail in every phase.

The goal was to fabricate a chair adhering to the golden ratio grid while aligning with the natural contours of the human body. The design demanded precise proportions to achieve visual and physical balance, optimal ergonomic support, and seamless integration of materials, including Baltic Birch plywood and steel components. Achieving these goals required harmonizing theoretical design principles with real-world fabrication challenges. The final product needed to embody the collection's philosophy of blending timeless design concepts with contemporary functionality, creating a piece that was both artistically compelling and highly practical.

Fabrication began with material preparation. Using a table saw and plasma cutter, plywood and steel components were cut to approximate sizes, leaving room for adjustments. A laser cutting machine was

Flexibility played a crucial role. When challenges arose—such as achieving seamless joints between materials— adjustments were made to dimensions or components without compromising the integrity of the design.

employed to shape the wooden elements, ensuring that curves and angles adhered to the golden ratio. Steel components were shaped with a metal cold saw and welded into a supportive frame using a metal welding machine.

ing the chair’s contours with ergonomic needs required iterative measurements and adjustments, utilizing tools such as a level and tape measure to ensure balance and precision.

The completed chair successfully combined aesthetics and comfort. Its ergonomic design provided excellent support in various sitting positions, while the golden ratio proportions created a Precision was prioritized, with all pieces meticulously sanded to refine edges and achieve a smooth finish. During assembly, clamps and wood glue secured the wooden parts, reinforced by connector bolts and nuts for stability. Alignvisually harmonious appearance. This project highlighted the importance of bridging design theory with practical execution, emphasizing the need for precision, adaptability, and problem-solving

throughout the process. A deeper understanding of materials and construction techniques emerged, showcasing how each step in fabrication brings a concept closer to reality.