04 |

09 | Grease for cotton pickers

14 | Multipurpose industrial lubricant: when to use it?

20 | The right way to lubricate steel cables

24 | Launch: ULTRAFORM

EVC 20 - Stamping fluid

28 | How heat waves affect your machinery

34 | Food Grade Lubricants:

3 German brands you need to know

3

Editorial

INDEX

EDITORIAL

“In the past, it was important to change. Now it’s no longer enough to just change. We need to transform.”

Daniel Burrus

Digital transformation is a crucial aspect of the significant changes that brands such as Klüber, Fuchs, Tunap and Rocol are applying. Digital transformation directly impacts the way these brands rela-

te to the global market, requiring the incorporation of innovative technologies into their processes and operations.

For example, digitalization can influence the way these brands manage their supply chain, interact with customers, develop products and carry out their marketing operations. By understanding and adopting these transforma-

tions, brands can improve their efficiency, reach new markets and offer products and services that are more aligned with the demands of international customers.

Therefore, digital transformation is an essential element to be considered when analyzing the process of internationalization and development of the Klüber, Fuchs and Tunap brands in the lubricants scenario.

Lubvap Special Lubricants is ready for international standards and prepared to meet international requirements, especially considering the importance of digital transformation for global brands.

By adopting innovative technologies in its processes and operations, Lubvap improves its efficiency, expands its global market presence and offers hi-

gh-quality products that meet customer demands.

I am sure that this approach will contribute significantly to Lubvap’s success on the international lubricant scene, that’s what you will see in this magazine.

Good reading!

Luiz Carlos Maldonado CEO Lubvap

EXPEDIENTE

Vol. 12 | February 2024

Publisher: LubVap

Contributors: Inova G

Design & Layout: Inova G

Frequency: Quarterly

Contact us: contato@lubvap.com.br

(12) 3204-7567 | 3933-6851

WhatsApp (11) 94393-0393

www.lubvap.com.br

www.oreidasgraxas.com.br

www.oleolubrificanteonline. com.br

5

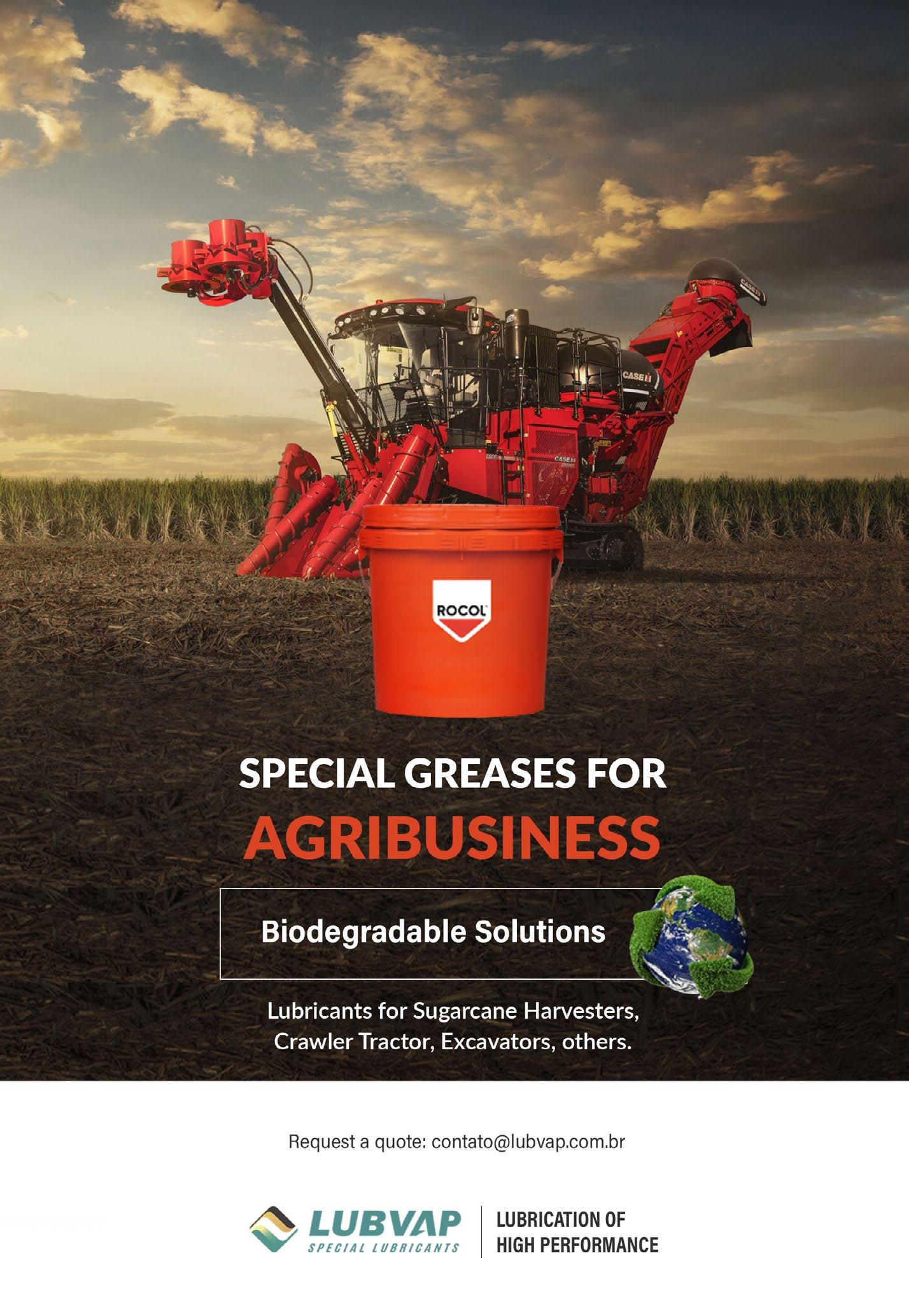

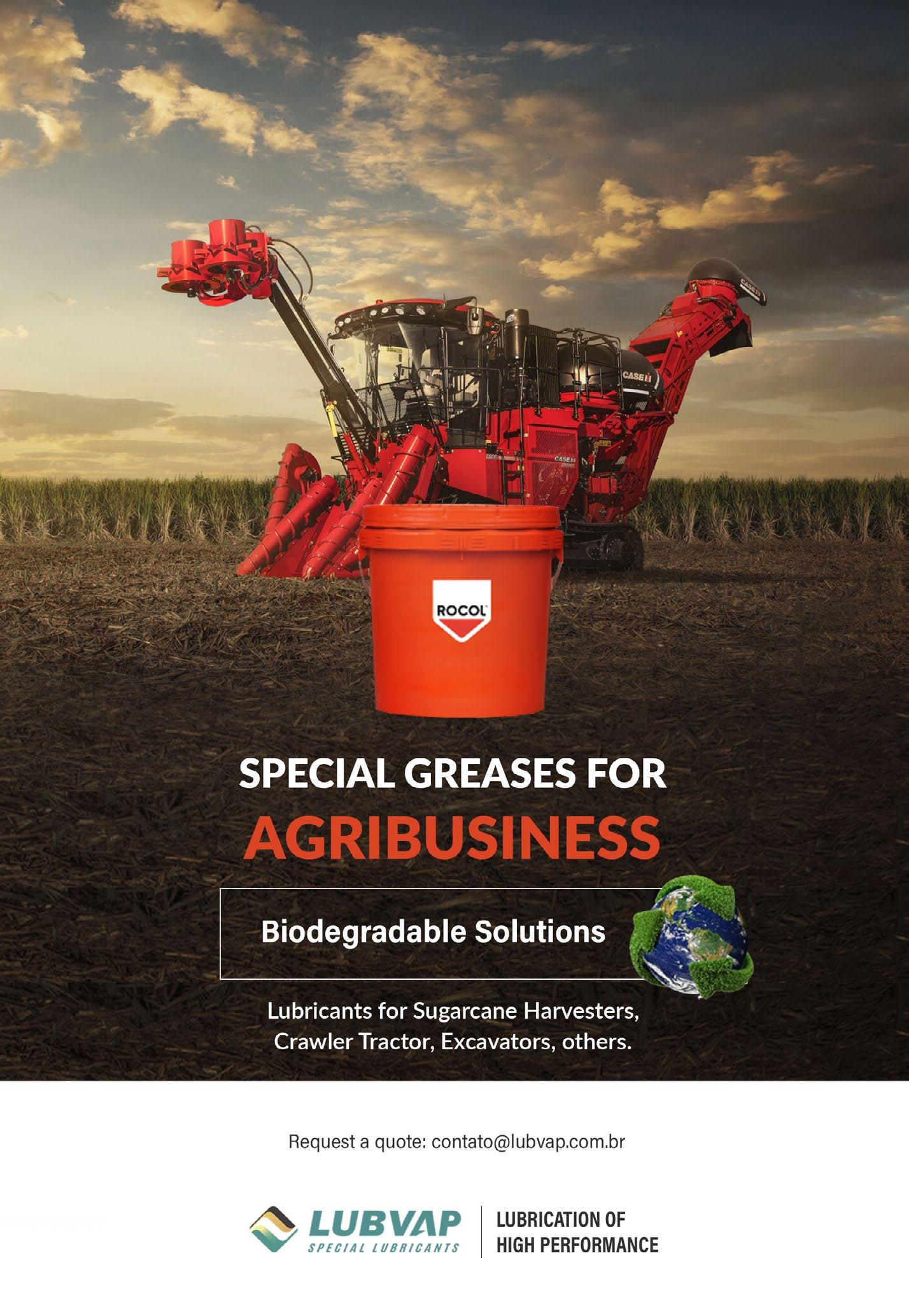

Grease for Cotton Harvesters

Brazil will surpass the United States in cotton production in the 2023/24 harvest. The forecast was made by the United States Department of Agriculture - USDA, which projects a reduction in the American harvest and growth in the Brazilian one, leaving Brazil as the third largest cotton producer in the world, behind China and India.

According to ABRAPA –Brazilian Association of Cotton Producers, the 2023/24

harvest should reach 1.81 million hectares and production of 3.29 million tons in a conservative projection due to climate unpredictability.

But for this growth to be truly beneficial, costs cannot increase, which means it is extremely important to reduce downtime to increase harvest yield.

One of the tasks that most impacts downtime is harvester lubrication.

LUBRICATION OF COTTON PICKERS

In a cotton harvester are lubricated:

• Spindles that rotate at speeds of up to 4,000 rpm;

• The gears;

• And the bearings.

During operation, grease is lost at a considerable rate, so it is industry practice to refill every number of hours.

John Deere recommends for its combines:

Every 6 hours

• Lubricate the row unit selector bars, sun gears, upper gear train and cam rails using the integrated lubrication system.

Every 12 hours

• Check the grease tank level;

• Lubricate the unit’s lifting oscillating shaft bearings;

• Lubricate the unit’s drive shaft covers;

• Lubricate the guide shaft king pins.

Every 50 hours

• Lubricate the RMB oscillating shaft pivots;

• Lubricate the line unit exchanger column bearings;

• Lubricate the unit’s articulation pins and lifting cylinders;

• Lubricate the couplers and bearings of the final drive shaft;

• Lubricate the guide shaft joint and the ends of the guide shaft rod;

• Lubricate row unit drive shafts, universal joints and frame rollers.

It is important to consider whether the grease you are using meets your operation and quality needs. You don’t want to waste time and labor using a lubricant that doesn’t meet the necessary requirements.

GREASE FOR COTTON PICKERS

Downtime is of critical importance during the harvest

10

period, therefore, and the appropriate choice of grease reduces the chances of unscheduled stops that put crop productivity at risk.

Lubvap Super has in its line of special high-performance lubricants LUBVAP SUPER COTONE-00, Nlg1

00 grease specially formulated for cotton harvesters, with special additives that meet the most demanding operating conditions.

Request more information about LUBVAP SUPER COTONE-00 by email: contato@lubvap.com.br ■

Industrial lubricant

multipurpose : when to use it?

Wouldn’t lubrication be much easier if you could use the same product on all machines and components?

In many cases you can. With a reliable multipurpose industrial lubricant, you protect your equipment and simplify the process. But before opting for a special multipurpose lubricant, you need to know in which situations it can be used.

WHEN TO USE MULTIPURPOSE LUBRICANT

Multipurpose greases are products applicable in several situations, but not all.

Some types of operations have characteristics that require specific lubricants, such as the mining industry, which requires high-temperature lubricants; and other

industries operating in hostile environments.

Although it is tempting to use the same grease for all equipment, caution must be taken to avoid excessive standardization, which can lead to suboptimal lubrication in some equipment. It’s like a piece of clothing classified as one size fits all, it will fit the average man and the average woman, but it won’t fit the two extremes that fall outside the “average”.

Discover the typical applications that allow the use of a multipurpose lubricant:

• Bearings,

• Gearboxes (open),

• Chains,

• Fans,

• Axes,

• And others.

14

ADVANTAGES OF USING A MULTIPURPOSE GREASE

Multipurpose grease, oil or spray are versatile and efficient.

This maintenance wild card is the ideal solution for a wide range of applications and keeps everything running smoothly.

In addition to fulfilling all the expected functions of reducing friction, wear and corrosion, the high-performance multipurpose lubricant also:

• Simplifies stock management and reduces the

amount of specific-use lubricants stored;

• Reduces waste, as lubricants with very specific uses can easily expire or undergo changes when stored for a long time;

• Mitigates the risks of using the wrong lubricant and simplifies application.

CHOOSING THE IDEAL LUBRICANT

When choosing a multipurpose lubricant for your machines and components, keep in mind that only a high-quality product guarantees the best protection, longer lubrication intervals,

lower grease consumption, longer service life and more productivity.

The “multipurpose” classification does not have a formalized definition, therefore, each grease, oil or spray has a different indication and properties, even if they are all designated as multipurpose.

This difference is due to the thickener, base oil and additives used in each formulation, which provide very varied properties. Therefore, when choosing a lubricant, do not just rely on the term “multipurpose”, at the risk of making a disastrous choice for the health of your machines.

As an example, we selected three multipurpose products for you to discover:

LPS 1

Premium multipurpose spray lubricant, with fast penetrating action. Forms a thin dry and lubricating

film. Resists oil, dust, does not accumulate dirt and repels moisture.

Indications for use: cables, circuit breakers, electrical motors and connectors, generators, hinges, ignition systems, padlocks, micrometers, molds, nuts and bolts, precision gears, power tools, relays, sliding mechanisms and electrical switches.

16

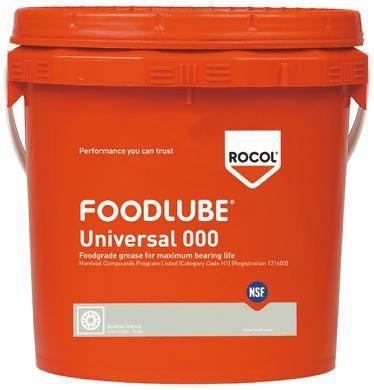

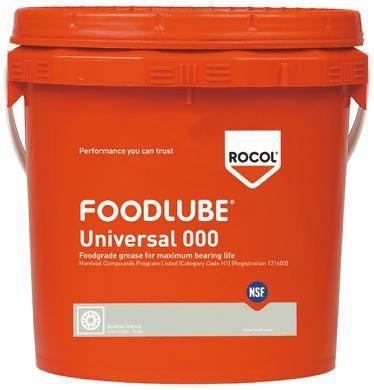

ROCOL FOODLUBE

UNIVERSAL 0

Synthetic white grease, food grade (NSF H1), multipurpose, with PTFE additives. Use temperature -50ºC to +160ºC. Highly resistant to water washing.

Indications for use: all types of bearings, housings, reducers and centralized systems for the food, beverage, pharmaceutical, paper and cellulose, packaging, plastics, hospital equipment, household appliances and chemical industries.

CENTOPLEX 2 & 3

Multipurpose greases based on oxidation-resistant mineral oils; and lithium soap. Due to the good resistance to work under normal temperatures and under loads, these greases can be used for long-term lubrication.

Indications for use: bearings, journals, guides, threaded shafts, gears subject to high loads and other components.

To learn about other multipurpose greases or find out the best option for your needs, talk to our lubrication experts, they will be happy to help you. ■

17

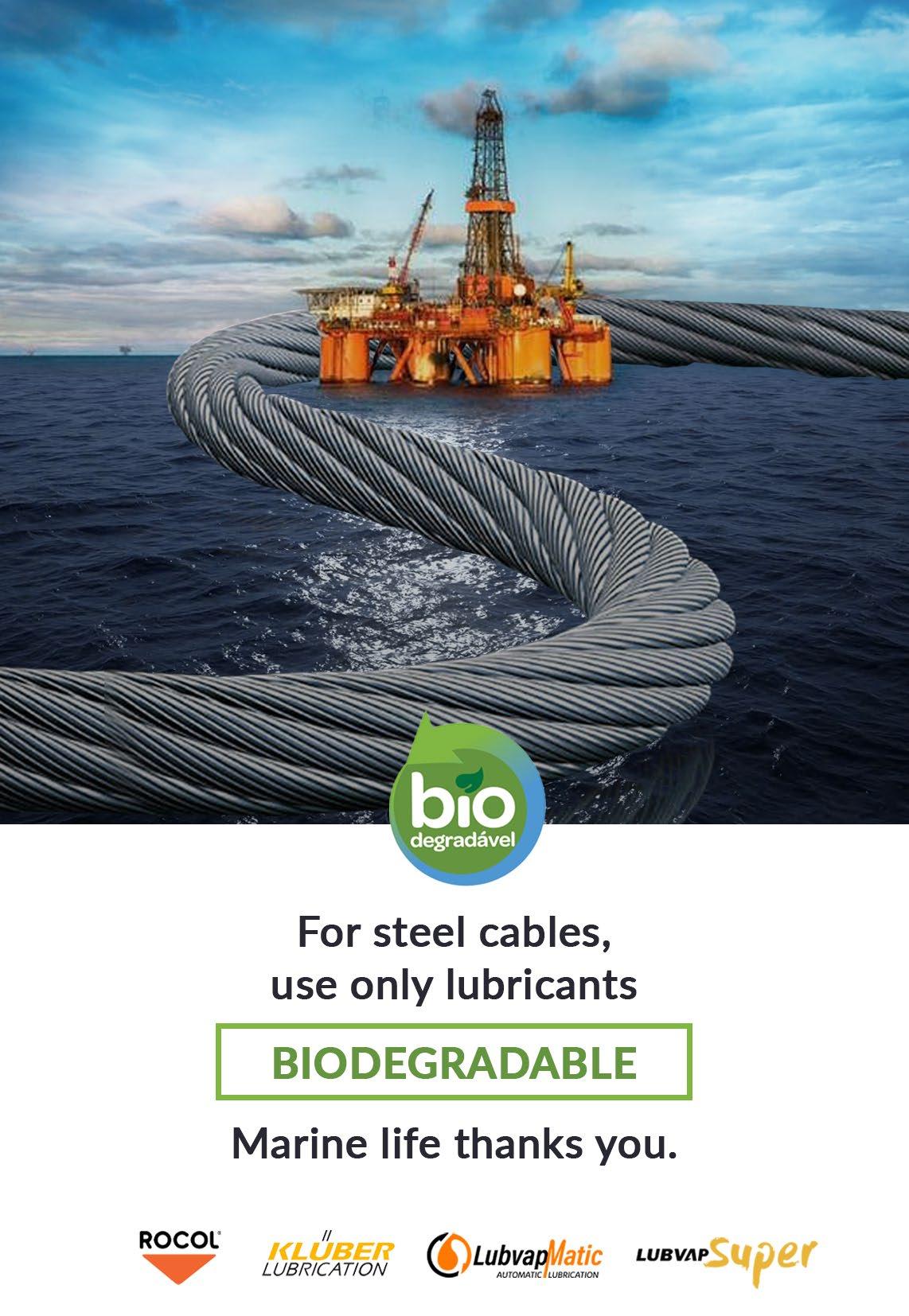

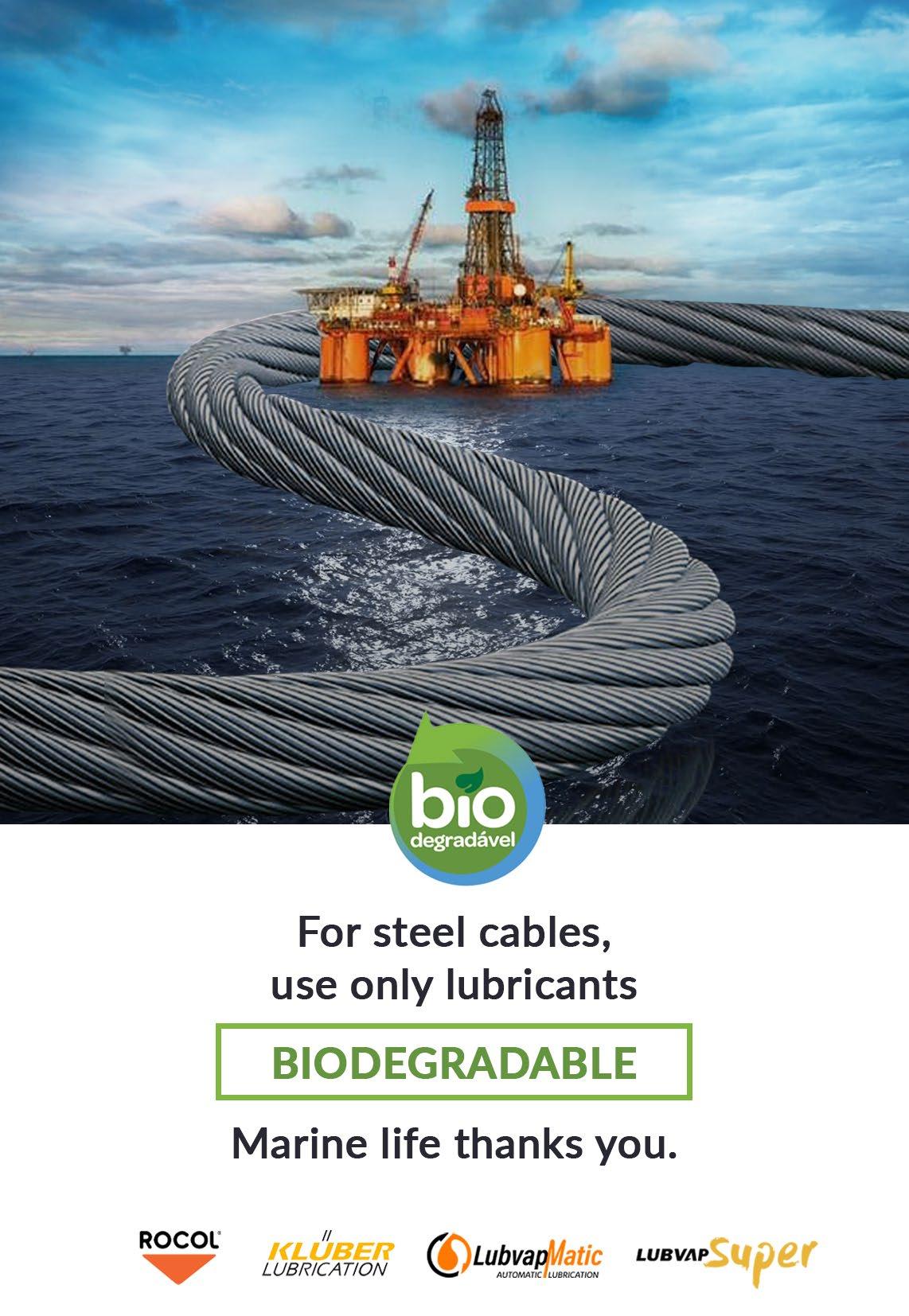

The right way to lubricate steel cables

How do you lubricate your wire ropes? With the wrong method, lubrication can require a lot of work and still be inefficient. Using an automatic lubricator saves work and keeps the cable at peak performance.

In this article we will explain the problems of manual lubrication using a brush, tow or spray, and how you can reduce the work and labor required for lubrication to a minimum using an automatic lubricator.

LUBRICATION METHODS

Manually lubricating wire ropes is not an easy task, but it is essential to reduce friction as the wires move over each other and protect against corrosion on the core and outer surface.

However, when manually lubricating with brushes,

brushes, brushes or sprays, the lubrication is less than ideal, because there is no precision in the amount of grease applied, which can result in either lack or excess.

Additionally, parts of the cable can go unnoticed and run out of lubricant.

The problems generated by inefficient lubrication are:

• Wear of the internal part, core failure and internal breakage of the thread;

• Oxidation, corrosion and increase in tension;

• Accumulation of dirt and contaminants on the surface of the cable, causing abrasive wear that corrodes external wires and cords;

• Reduced cable life.

20

As if the problems were not few, manual lubrication demands a lot of work and risks for operators, as the cables are generally located in dangerous or difficult to access locations.

But these problems are optional, as you can easily choose not to have them by adopting automatic lubrication.

AUTOMATIC LUBRIFIER

The automatic lubricator operates without having to stop the equipment to carry out lubrication. It can be mounted on any part of the cable, preferably close to the winding drum and performs its work without you having to do any work.

Pumping the lubricant to the lubricator can be done using a pneumatic pump or automated single-point system. The automatic single point lubricator can be installed remotely (up to 5 meters)

and is safe for use in Hazardous Zones 1 and 0, making it ideal for underground and offshore mining operations

When the cable enters the lubricator, cleaning and removal of dried grease is automatically carried out using a scraper bush installed at the cable entry, in front of the lubricator.

HAVE A GOOD SUPPLIER

Having a reliable supplier is essential to obtain good lubricants within the time frame you need. A good supplier needs to have efficient quotations, fair prices and short delivery times, as well as market experience and good customer reviews.■

21

Launch: ULTRAFORM EVC 20 Stamping Fluid

MaxVap Bio Clean, a brand with products already consolidated on the market, such as MaxVap Truck – biodegradable degreaser, for cleaning any type of surface -, and MaxVap Hand Clean – hand cleaning gel with polyethylene microparticles, which does not dry out the skin - , now has another launch: ULTRAFORM EVC 20 – Fluid for stamping.

ULTRAFORM EVC 20 is a low viscosity fluid, formulated with highly refined hydrocarbons and lubricity additives that guarantee the best performance in your operation with the great advantage of leaving the part clean at the end of the process.

After stamping, the lubricating film evaporates, leaving a residue-free part

and, in most cases, without the need for degreasing before subsequent operations.

FEATURES AND ADVANTAGES

• Non-flammable product, meeting NR 20 requirements;

• Safe for the operator, free from heavy metals, chlorinated and aromatic solvents;

• Odorless product;

• Eliminates the need for degreasing;

• Allows higher stamping speeds.

24

APPLICATIONS

Recommended for bending or drawing operations, of light or moderate severity, of ferrous and non-ferrous metals, including yellow metals, such as brass, stainless steel and nickel-based alloys, aluminum, graphite, carbon alloys, bronze and copper.

ULTRAFORM EVC 20 is particularly recommended for stamping processes at high speeds for small parts.

USE

ULTRAFORM EVC 20 must be applied pure, directly under the sheet to be stamped. It can be applied automatically by spray or roller or manually with a brush. In general, there is no need to degrease after the process due to the complete evaporation of the product from the surface of the part.

HOW TO PURCHASE

Don’t put the useful life of your stamping dies and the quality of your products at risk with second-line fluids.

ULTRAFORM EVC 20 from MaxVap was specially developed to provide the best lubrication for metal forming and preserve the surface finish of products.

The MaxVap line products are exclusively distributed by Lubvap Special Lubricants, which has been bringing high-performance lubricants and cleaning solutions to all industry segments for 19 years. Request our catalog via email or WhatsApp.■

ULTRAFORM EVC 20 FOR

YOUR FACTORY

25

Like hot flashes affect your machinery

In 2023, Brazil was impacted by heat waves, a result of the climate crisis and El Niño – which increases the temperature of the oceans – and intensified by the lack of green cover in large urban and industrial centers, which form heat islands.

With temperatures above average, we, the animals, the environment and its machinery suffer. Yes, your industrial equipment is also impacted by extreme heat and you need to be aware of this if you want to main-

tain its performance.

EQUIPMENT

INDUSTRIAL AND EXTREME HEAT

Heat waves have raised the temperature of some cities to more than 40°, with a thermal sensation of more than 50°.

In industry, heat affects worker productivity, not only those who work outdoors, such as in agribusiness and construction, but also those who work inside

industries.

Just as our bodies are affected by high temperatures, equipment is too.

In 2022, heat waves in Europe collapsed Google’s data centers and affected Oracle’s refrigeration units, which were overloaded by operating above the limits for which they were designed.

The result was that, as the refrigerators were unable to contain the heat, the computing equipment shut itself down as a form of protection.

In industry, high temperatures increase stress on machines, causing failures, requiring more frequent maintenance, degrading materials at a faster rate or making them unusable.

To contain these effects, the only solution is to invest in more powerful refrigeration systems and higher quality materials that are more resistant to heat, such

as lubricants.

LUBRICANTS THAT HANDLE THE HEAT WAVES

Without lubrication there is no movement.

The lubricant is essential for the equipment to move smoothly, at an acceptable temperature and level of friction, reducing failures and allowing more consistent operation, with greater equipment reliability.

When temperatures are higher than usual, the lubricant starts to operate at a temperature for which it may not be suitable and compromise equipment performance as well as reducing the useful life of components due to accelerated wear.

Exposed to high temperatures, the lubricant considerably loses its lifespan and efficiency, causing a reduction in the relubrication cycle and the inefficiency of the lubricant.

29

In addition to the problems already mentioned, extreme heat changes the viscosity of the lubricant, causing it to flow or evaporate and leaving the equipment unprotected.

Considering that heat waves were not a one-time event and will most likely happen again, it is important that the industry prepares by adopting lubricants with greater thermal stability at high temperatures.

SPECIAL LUBRICANTS WITH THERMAL STABILITY

If you want to keep your equipment – and therefore your profit – immune to heat waves, you need to switch from common lubricants to thermally stable lubricants suitable for a wide temperature range.

An example of a lubricant is Klübersynth UH1 6-100, which exhibits excellent viscosity-temperature beha-

30

vior, supporting the formation of a sufficient lubricant film over a wide service temperature range, even at elevated and high temperatures. Therefore, a single viscosity class can cover both low and high temperatures in many applications.

As climate change advances, heat waves will beco-

me a persistent problem for industries, which will need to adopt permanent heat mitigation measures, such as replacing common lubricants.

It is up to each business leader not to wait for the next heat wave to arrive, solving problems before they have them.■

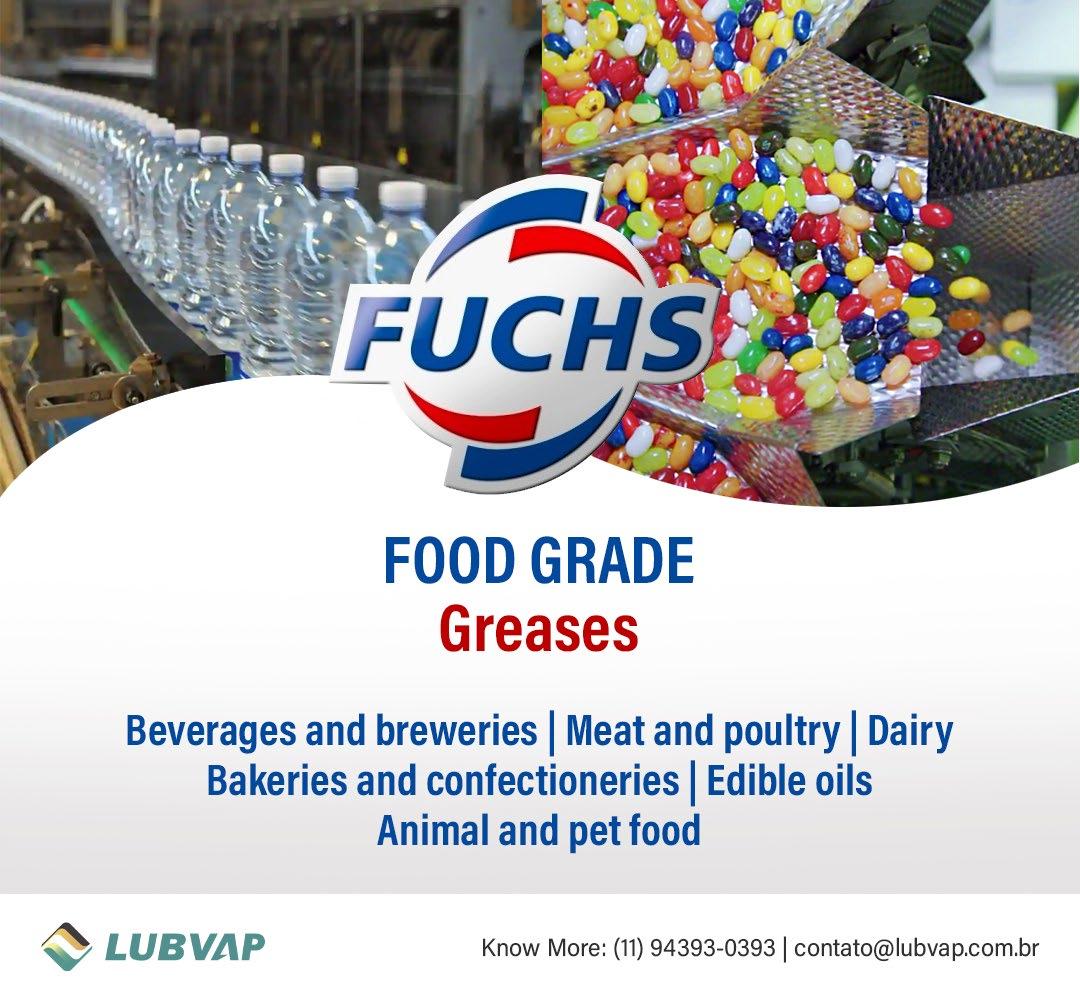

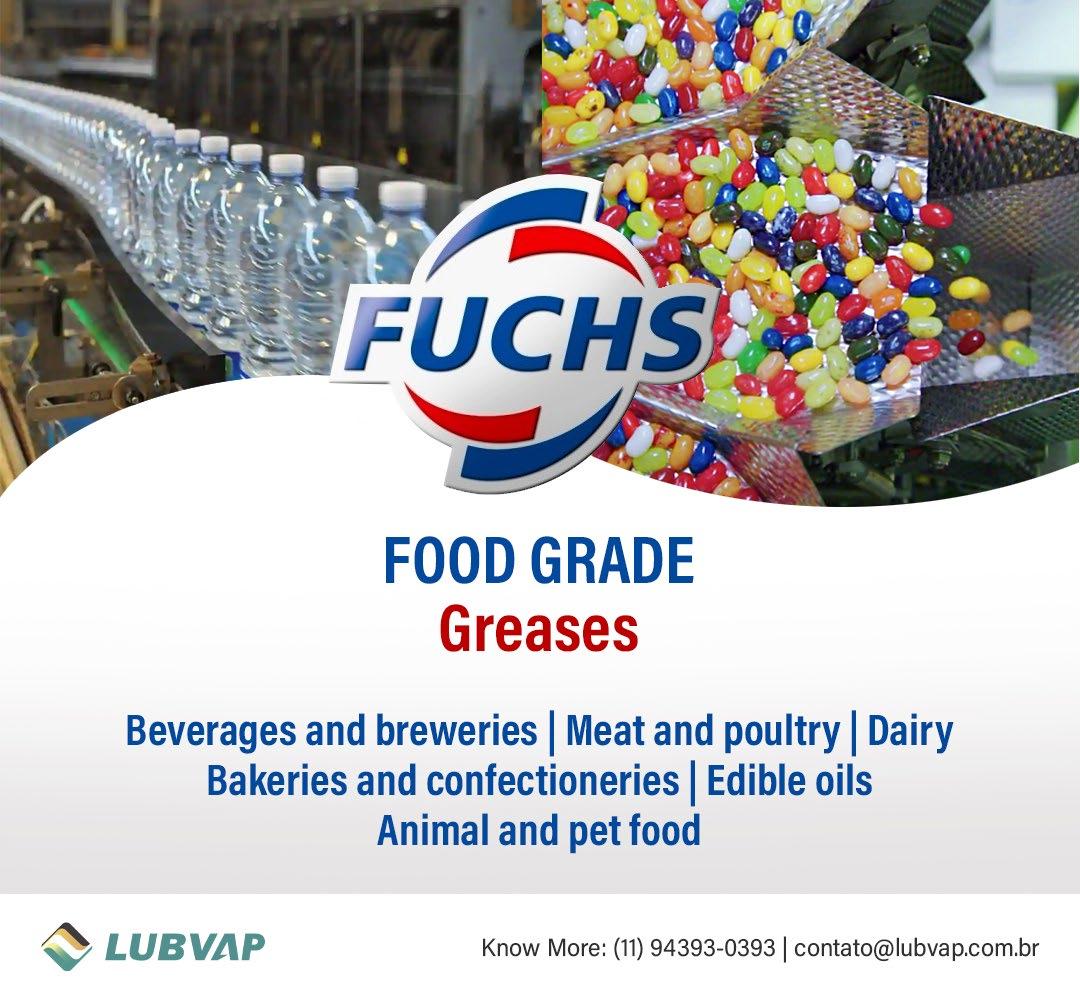

Food Grade Lubricants:

3 German brands you need to know

In food, beverage and pharmaceutical industries, lubricating oil and grease play a significant role in operational reliability and food safety.

Greases and oils, in addition to having improved performance, must be food grade, NSF H1 registered, for incidental contact with

food and Kosher and Halal certified.

If reliability is what you expect from food grade lubricants, you need to look for reliable and already established brands, which is the case with these three German brands that we are going to present to you.

FUCHS LUBRITECH

CASSIDA special lubricants from FUCHS LUBRITECH are distinguished by high performance and sustainability, safety and reliability, efficiency and cost savings. They represent a promise: technology with a guaranteed return.

The Food Grade CASSIDA line was developed to meet with excellence various applications in the food, beverage, packaging, pharmaceutical, cosmetics and animal feed industries. Its products meet the highest hygiene, safety and traceability requirements of their process.

TUNAP

TUNAP is a German company that has been developing high-performance, food-grade solutions for the food and beverage industry for 50 years: separating agents, lubricants, cleaning products and surface protection products.

• Lubricating oils;

• High temperature greases;

• Pastes for high temperatures, assembly and separation pastes, metal-free and lubricating pastes.

• Assembly, safety and NSF H1 and K1 registered cleaners.

TUNAP products are manufactured with the highest technical hygiene and product safety requirements, meeting NSF, Kosher and Halal certification standards.

KLÜBER LUBRICATION

Klüber Lubrication has 60 years of experience in the food industry and 280 NSF H1 certified products in its portfolio. They have 6 ISO 21,469 certified manufacturing units and 1,655 OEM (Original Equipment Manufacturer) approvals.

For the food segment,

it has the Klübersynth, Klüberfood, Klüber Summit, Klüberoil 4 UH1 and Klüberpaste Lines.

Lubvap can help you with your Food Grade Lubricants and Greases needs. Get in touch and count on specialized advice or request a virtual visit. Fast delivery throughout Brazil and South America.■