Portfolio

Product design engineer

Spatial designer painter

In 2017, Arie Hooimeijer started a project in a team with 6 other companies. This project is called Fiber2Fiber. The aim of the project is to develop products with waste streams such as dredging and slip. The project is divided into two types:

- Soil improvement

- Tackling soil contamination

A product for soil improvement has been developed within a project of one team partner. This product consisted of compressed dredged material, compost, fungi and soil life. They call this product Brickz. Fiber2Fiber has been asked to solve asbestos soil contamination using Brickz.

Within the agricultural sector, a lot of asbestos was used as roofing material without gutters being used. Weather conditions and aging of the asbestos corrugated sheets cause contamination along the barns. This is called the drip zone.

Within the team it has been proven on a laboratory basis that Brickz ensures that asbestos can be rendered harmless with specific components. They call this product VezelBrickz.

The asbestos is decomposed in the soil through the cooperation between the roots of the Miscanthus grass species and a fungus. This collaboration is called Mycorrhiza. The fungus grows into a dense network of threads between the roots. These create an extra absorption of nutrients. The fungus uses the minerals of the asbestos as a nutrient, which causes the asbestos to decompose. Miscanthus feeds the fungi with sugar so that the fungus grows larger.

By laying this VezelBrickz ‘on’ the drip zone, asbestos soil remediation is carried out in a circular biological manner. As a result, asbestos is theoretically no longer harmful and the soil can be declared clean.

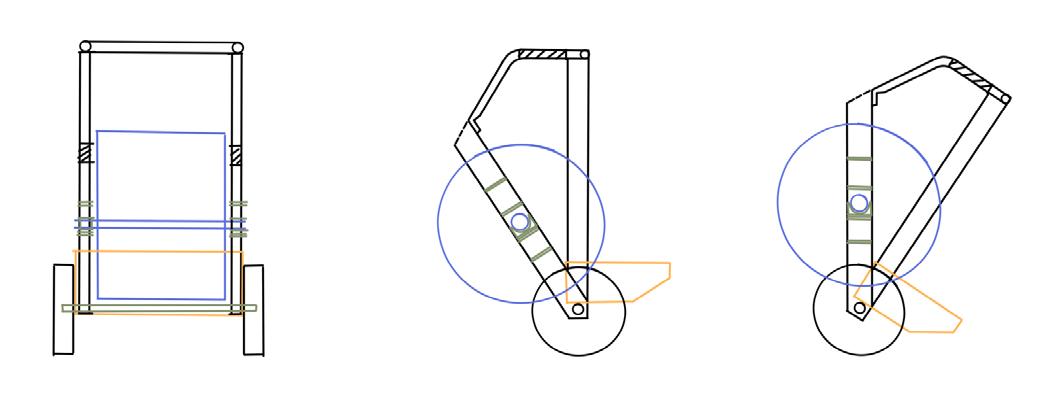

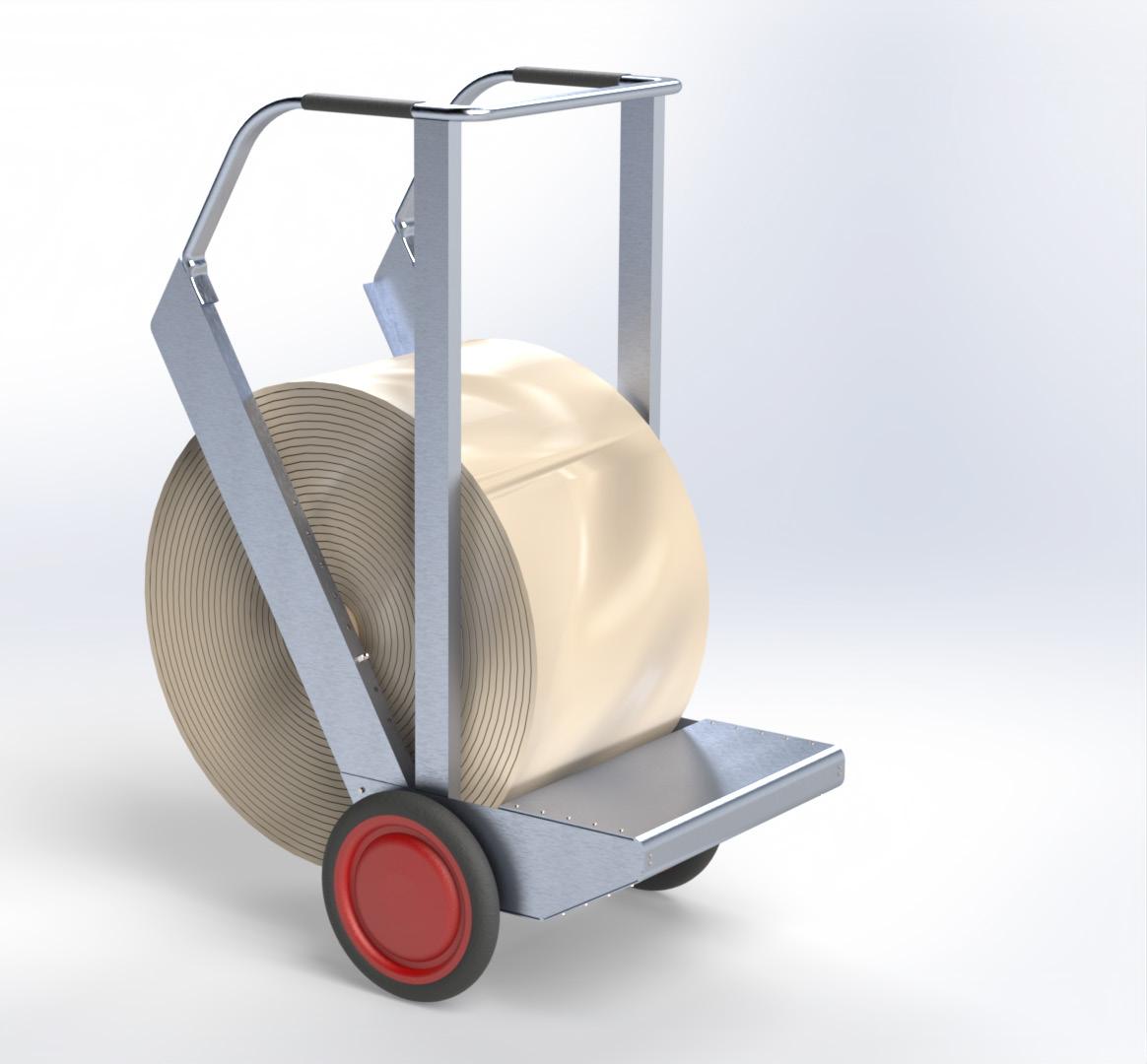

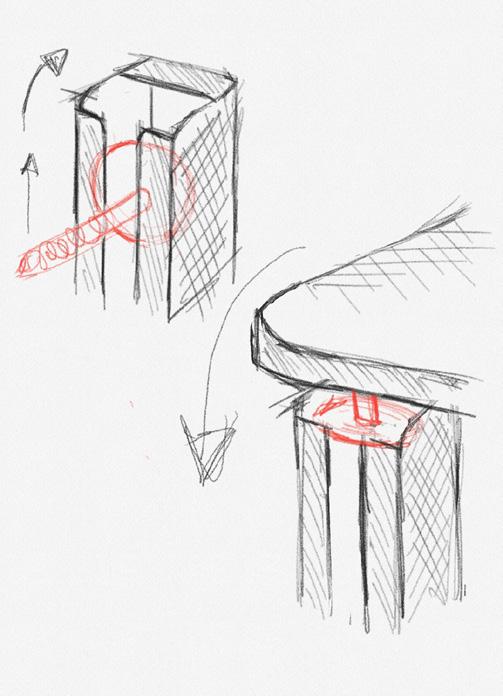

The VezelBrickz were tested on a small scale and had to be made suitable for scaling up. The current production method was not developed for this. This method consists only of a concrete mixer and a small press machine. The placement of the VezelBrickz had not yet been considered. This graduation project concerns these logistical sub-problems in which the focus was placed on the installation of the VezelBrickz, but also its production is included in the design of the solutions.

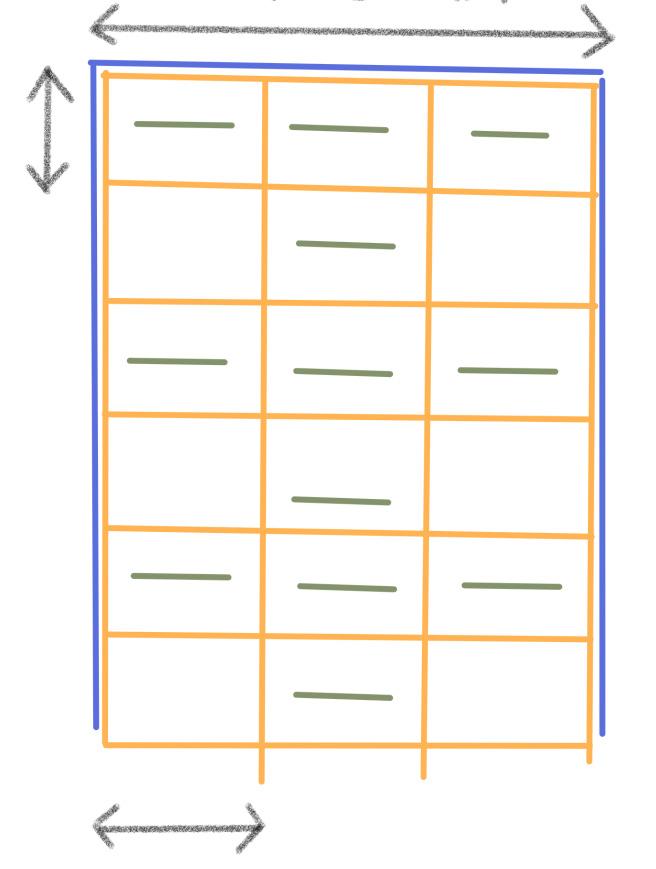

The challenge of the project was to reduce the costs and to make the logistics of the remediation process effective for all parties. The logistics were given an extra challenge because they had not thought about the different yard conditions (figure X) during the project and had to be taken into account. Because the planting has a strong influence on the project.

Several dilemmas arose during the project. For example, because of all the different opinions and information from partners and stakeholders, with the conclusion that the VezelBrickz design would not be feasible in practice and the field trial that failed.

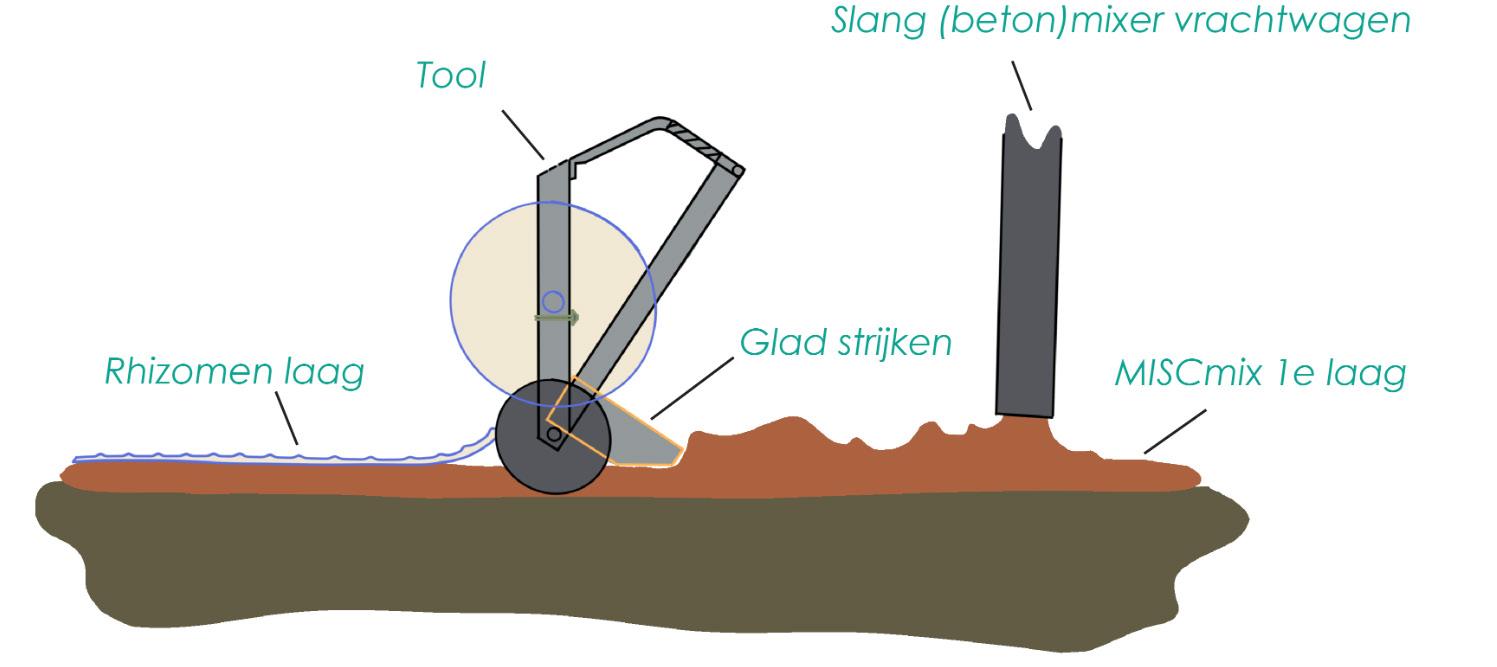

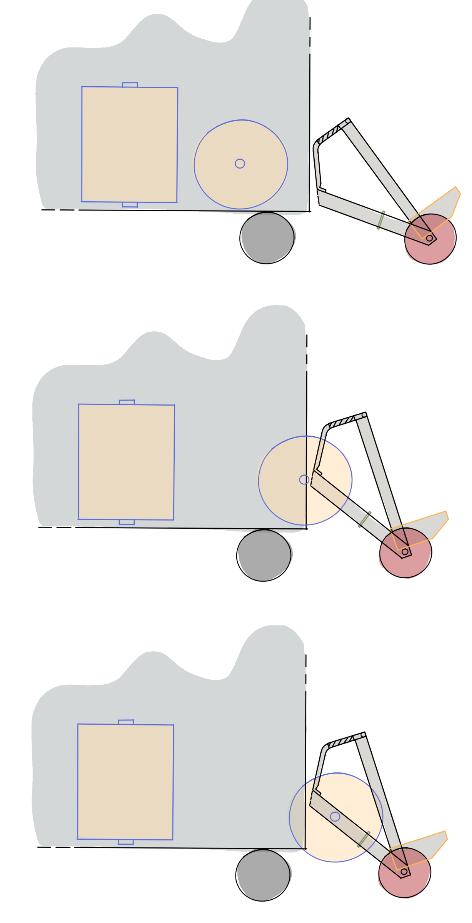

My solution is to adjust the base of the production in such a way that really only a Brickz-Mix material needs to be produced in a concrete mixer truck. After that, only a tool has to drive over the sprayed mix for the rhizome planting and to ensure a good remediation amount.

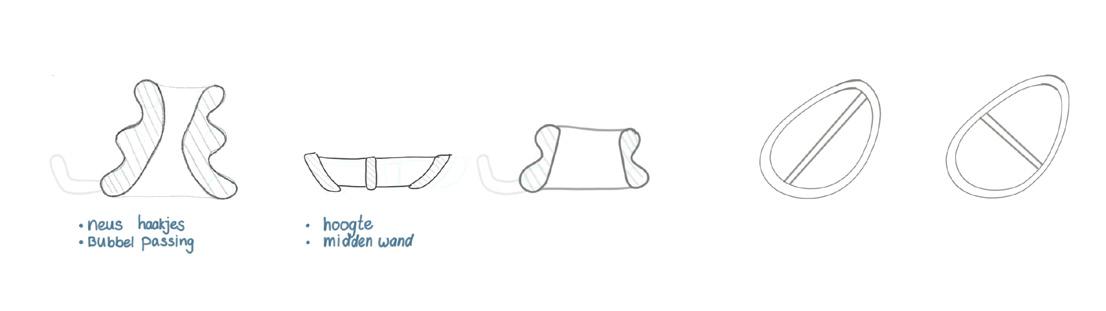

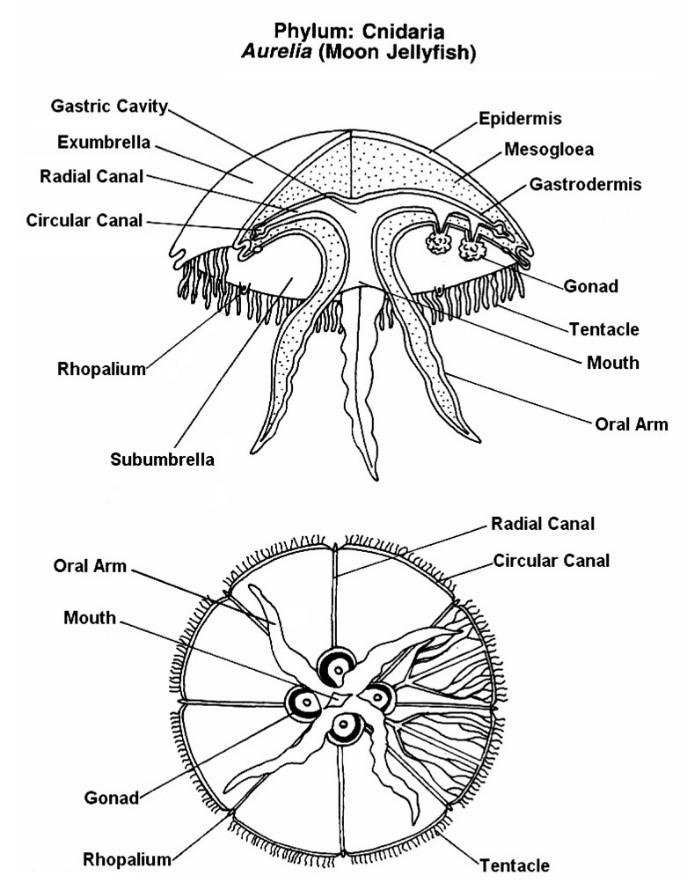

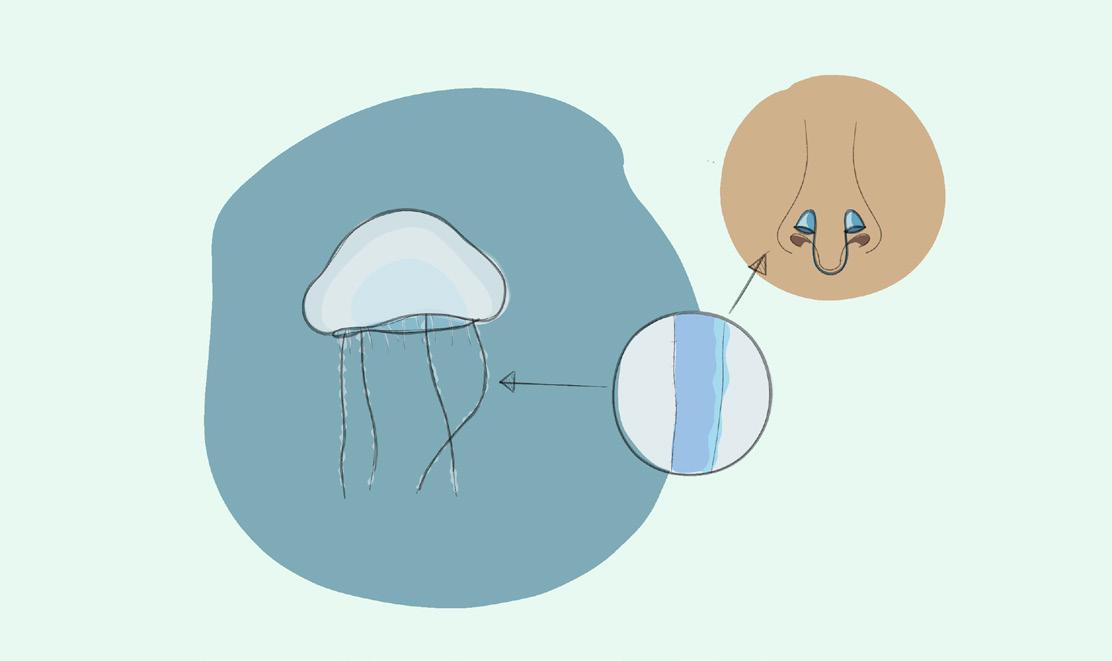

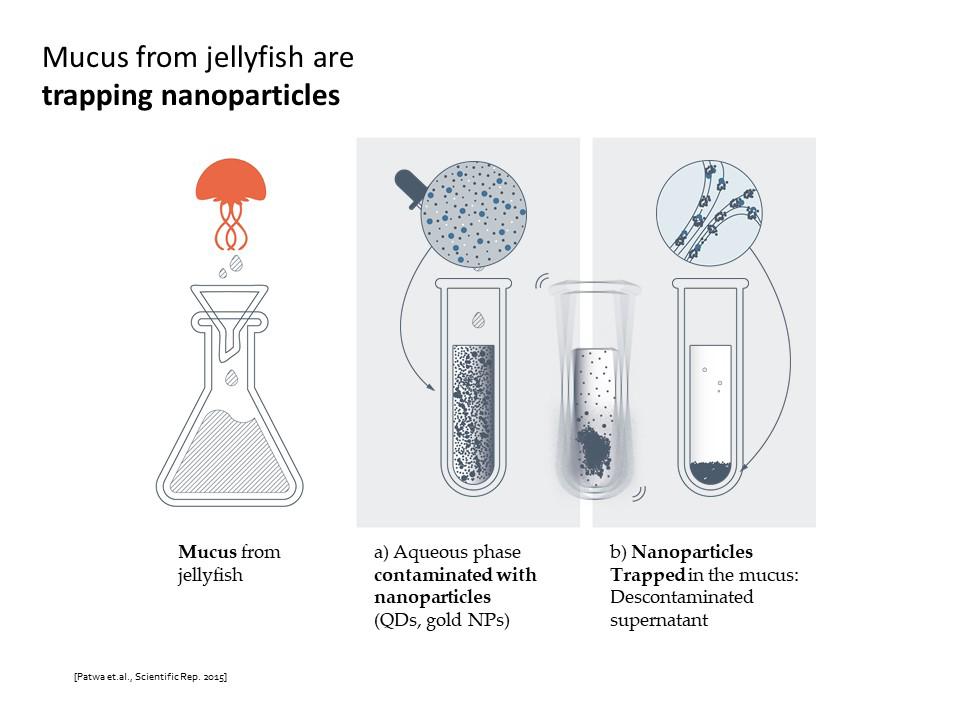

Together with Rijk Herremans, Tayer van Oetelaar and Pieter Beenhakkers I developed a product for our IPO study by means of jellyfish biomimicry. We started with a thorough analsysis, unraveling all the mysteries. We were busy with what properties of the jellyfish we could use to make a sustainable product solution for a daily problem. We found out that they have a special filter quality of mucus they secrete. This is how the product “Noppe Doppe” was born. The Noppe Doppe is a product that can filter pollen from the air because it has the mucus in the cap. The mucus contains micro fine group of packed needles that large and small particles by letting them clump together. We did a lot of testing with different cap shapes for ergonomics and breathing. It’s a concept that still needs a lot of time to develop, but maybe it’s in the future really achievable.

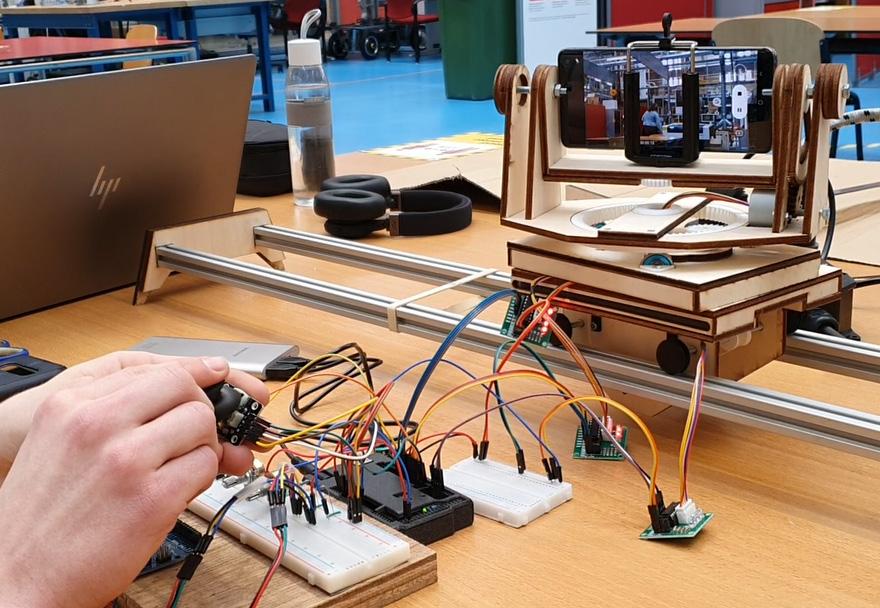

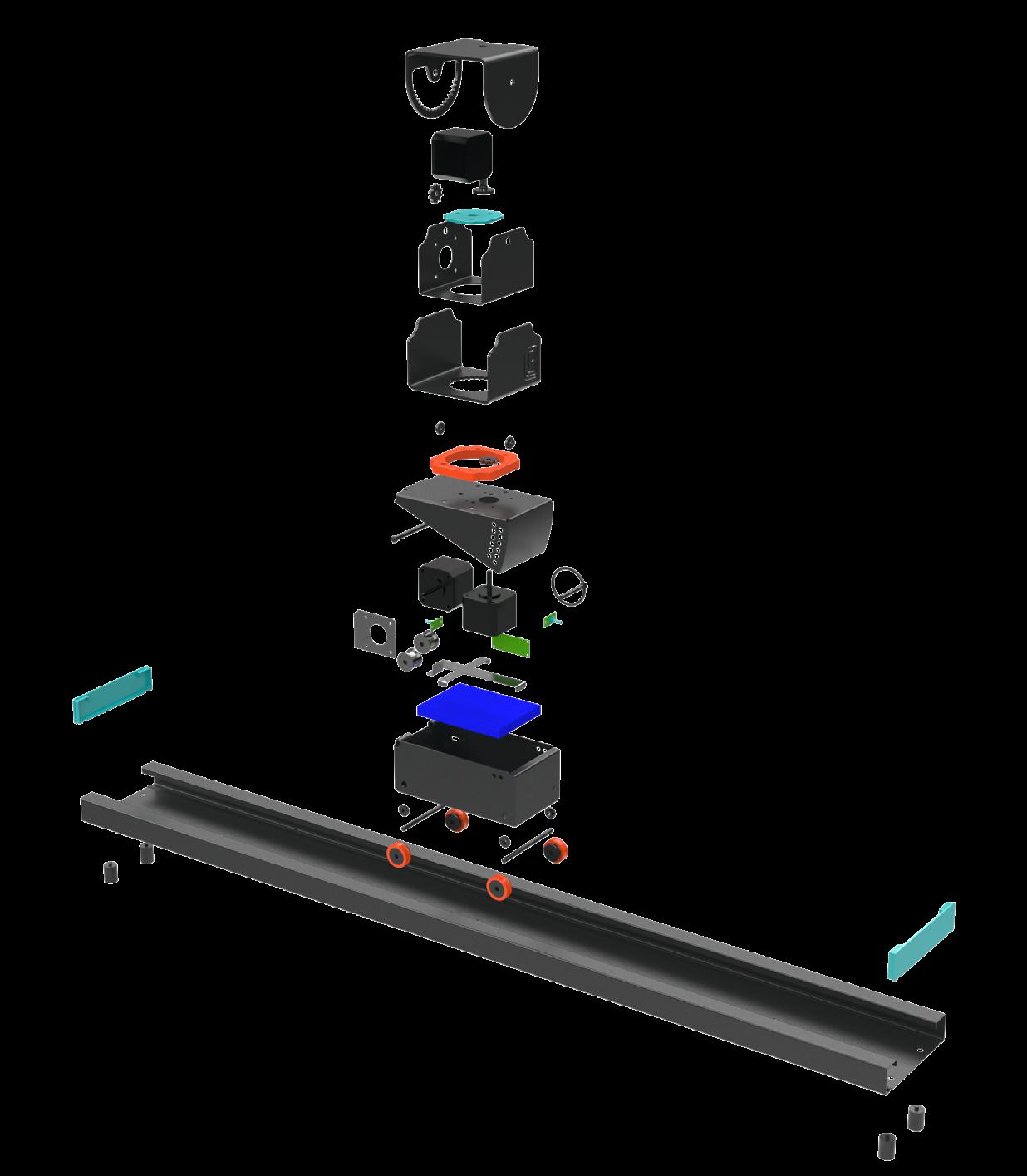

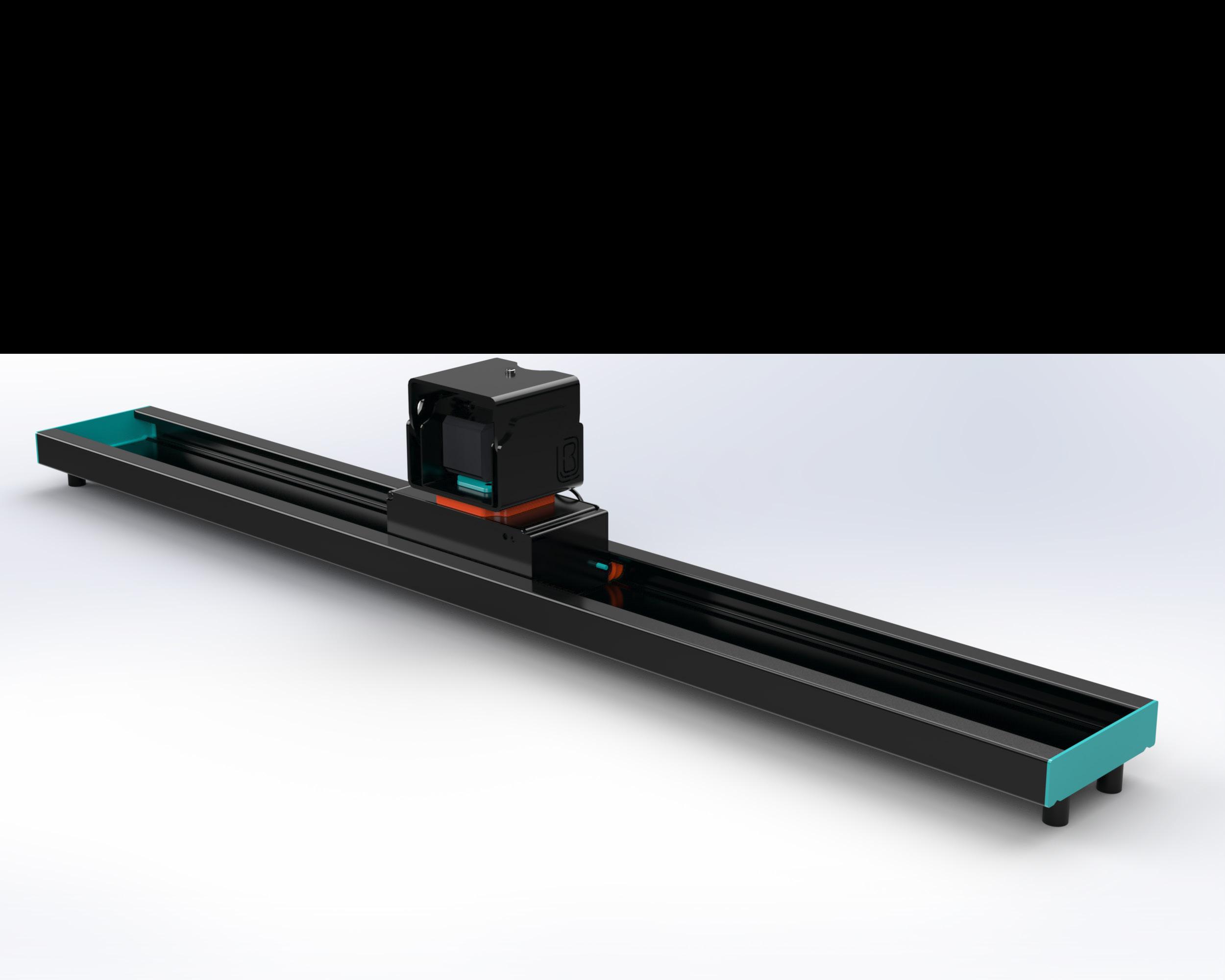

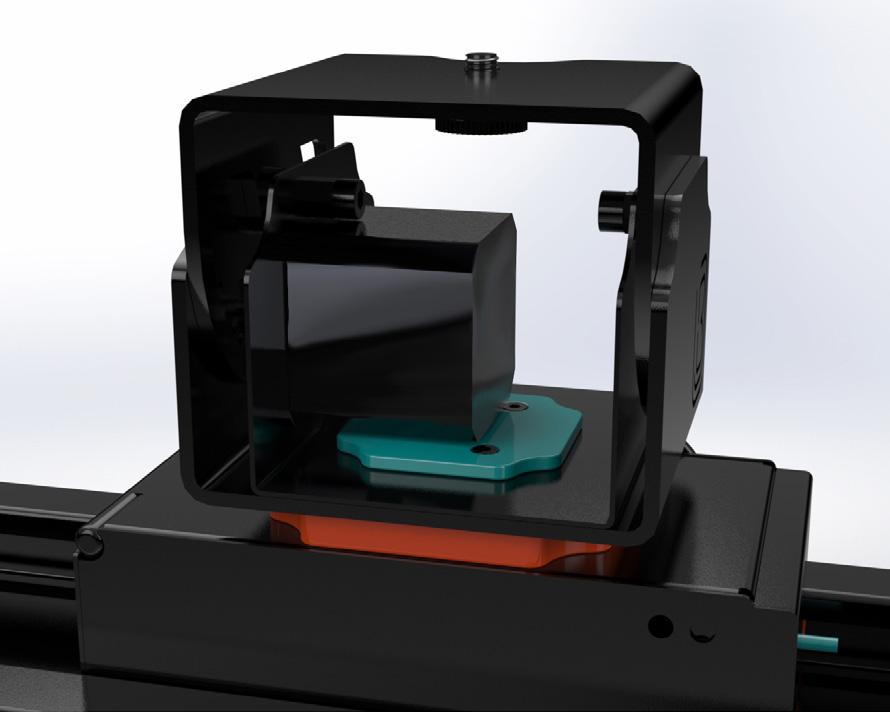

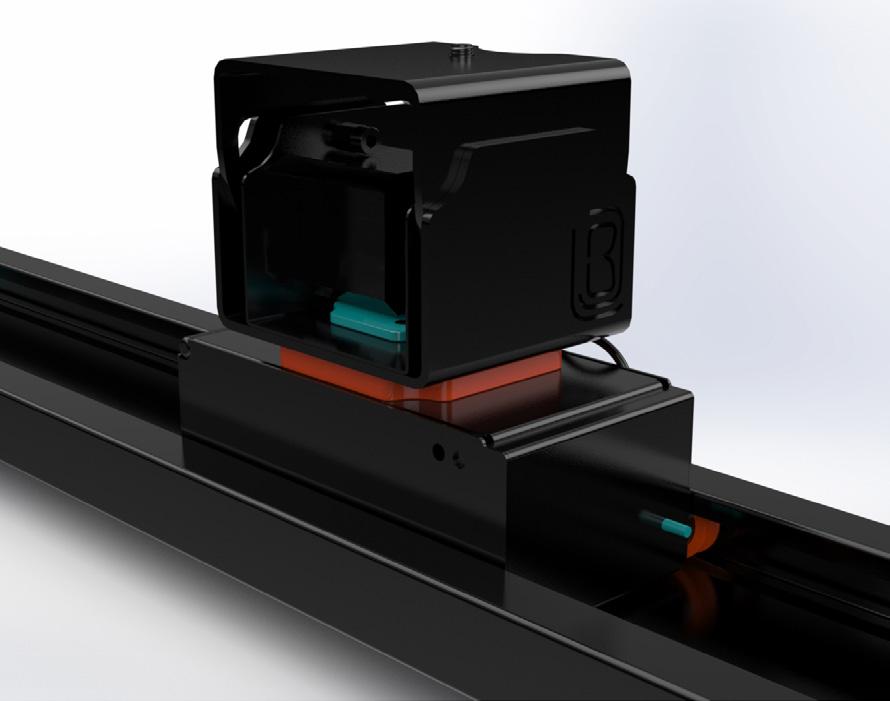

Together with Janna Spoon and Bas van Hassel I was able to work on a super fun project for our Industrial Product Design course. Together we have chosen to design a product for the slightly experienced filmmaker. We have designed a ‘Camera Slider’ where each of the axis can be controlled mechatronically through an app. So you can make a nice timelapse or a shot of your product what you want to sell, for example. It was a very nice collaboration and I think we can be proud of what we have delivered in such a short amount of time!

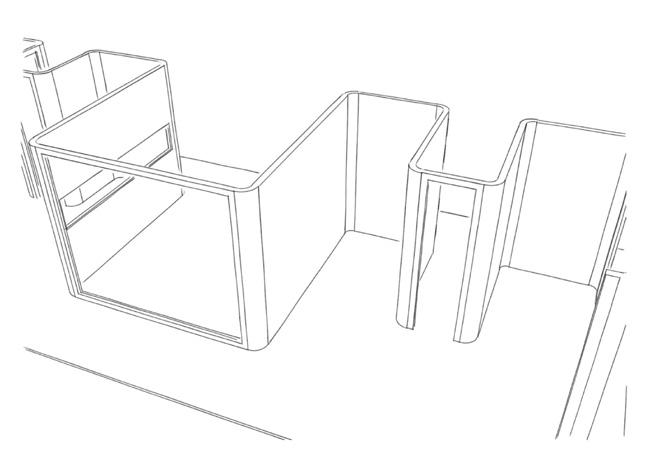

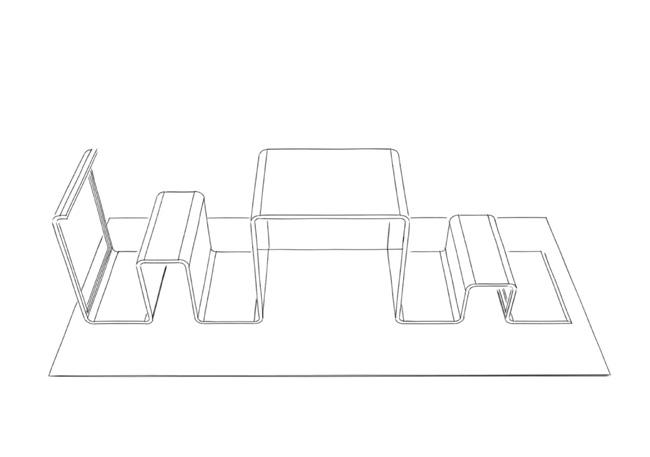

A table filled with people who make you forget the moment in the hospital for a while.

This table is intended for the Intensive care room. so that children can eat with their family and friends. But you can also do other activities at bed, like playing games together.

The intention is that you can fold it in and out so that the table can be moved quickly in the event of an emergency, for example.

You can put the chairs in the frame and it is a package that you can move every time.

Eettafel_tafelblad_gel eider.versteviging

Due to the lack of space with a bed due to all the machines, people can’t sit on all sides. So I chose this setup as shown above.

The table has a standing table height so that it can go well over the bed with enough clearance.

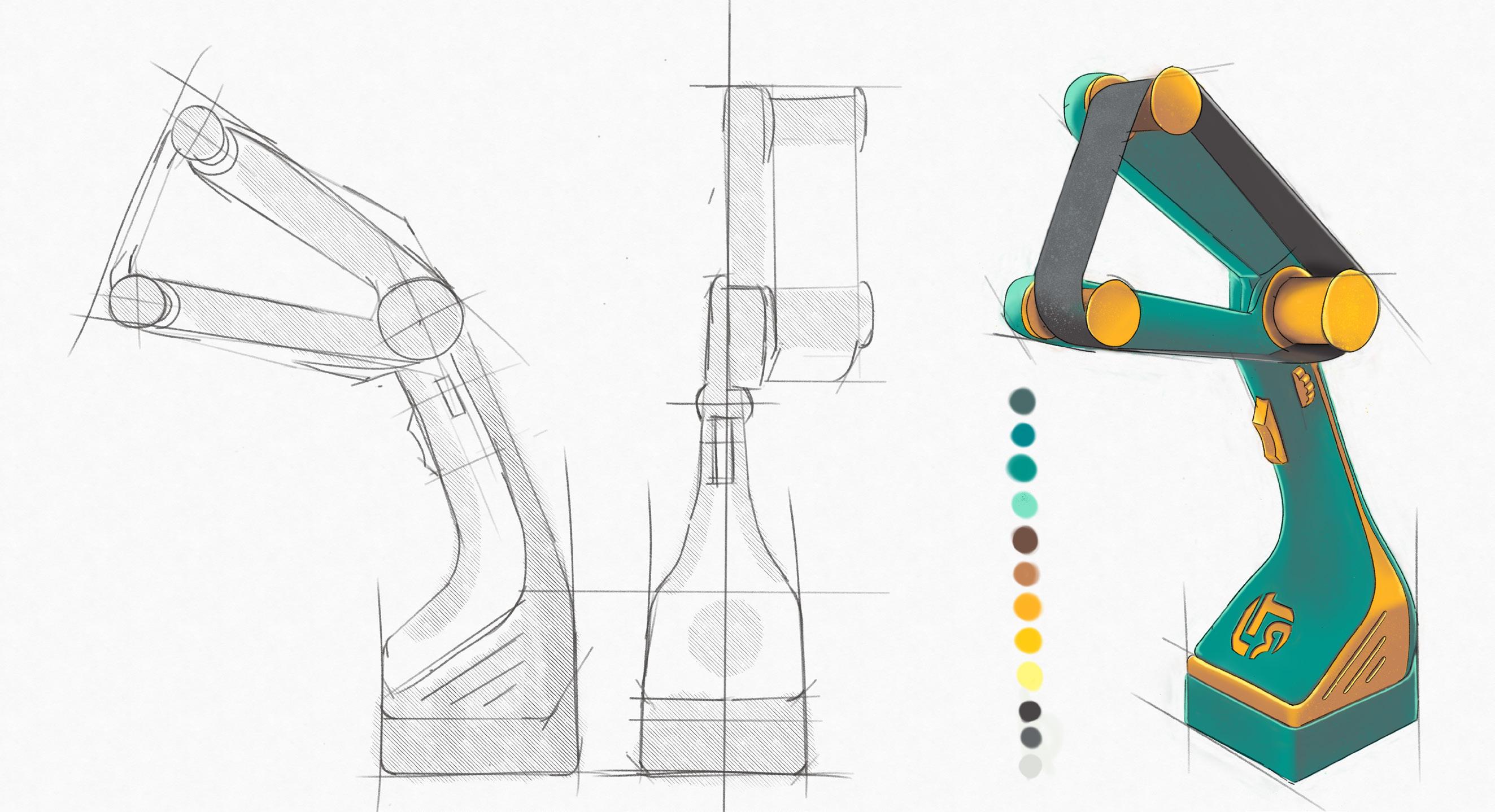

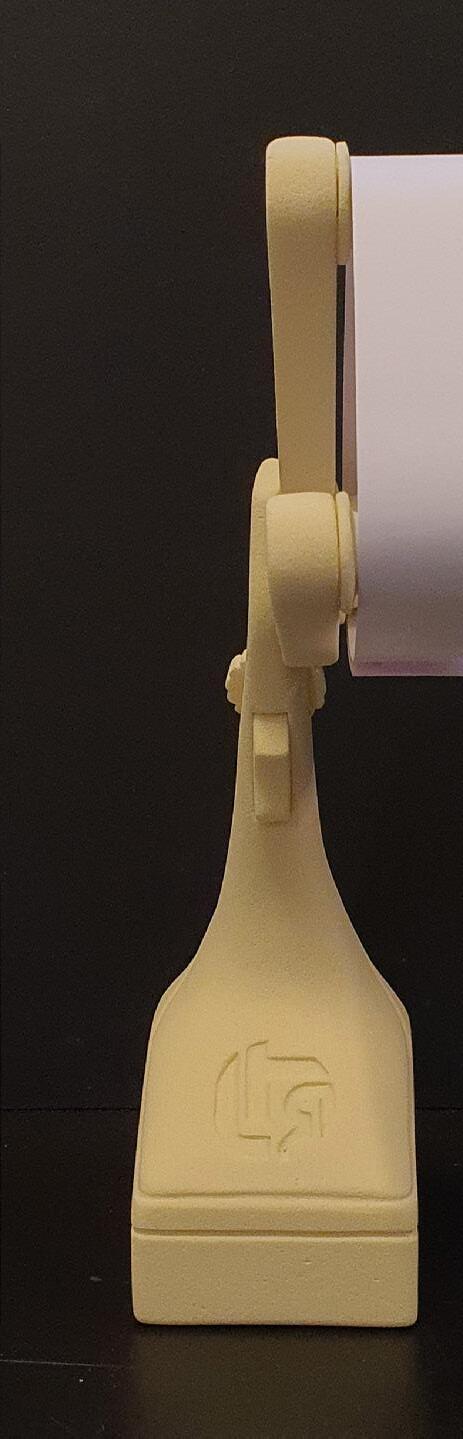

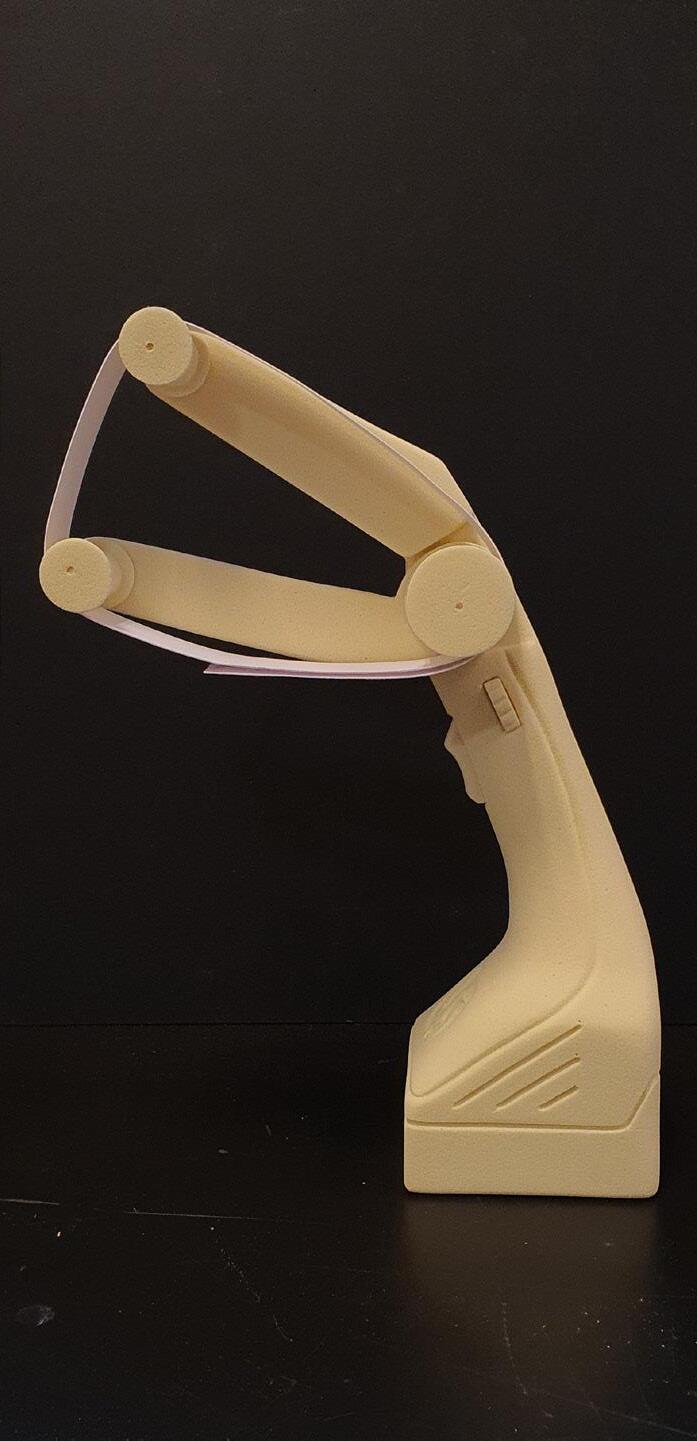

For KVA we were commissioned to design a sanding machine in a new jacket. You could also give it new requirements.

My sander is intended for sanding round (metal) pipes, incl. battery.

My target group: the upcyclers, those are people who specifically have all kinds of different pipes around the yard, in the back of the shed, or in the attic, for example, and they would like to reuse them. The age is very varied. They can then sand off leftover paint just like rust spots.

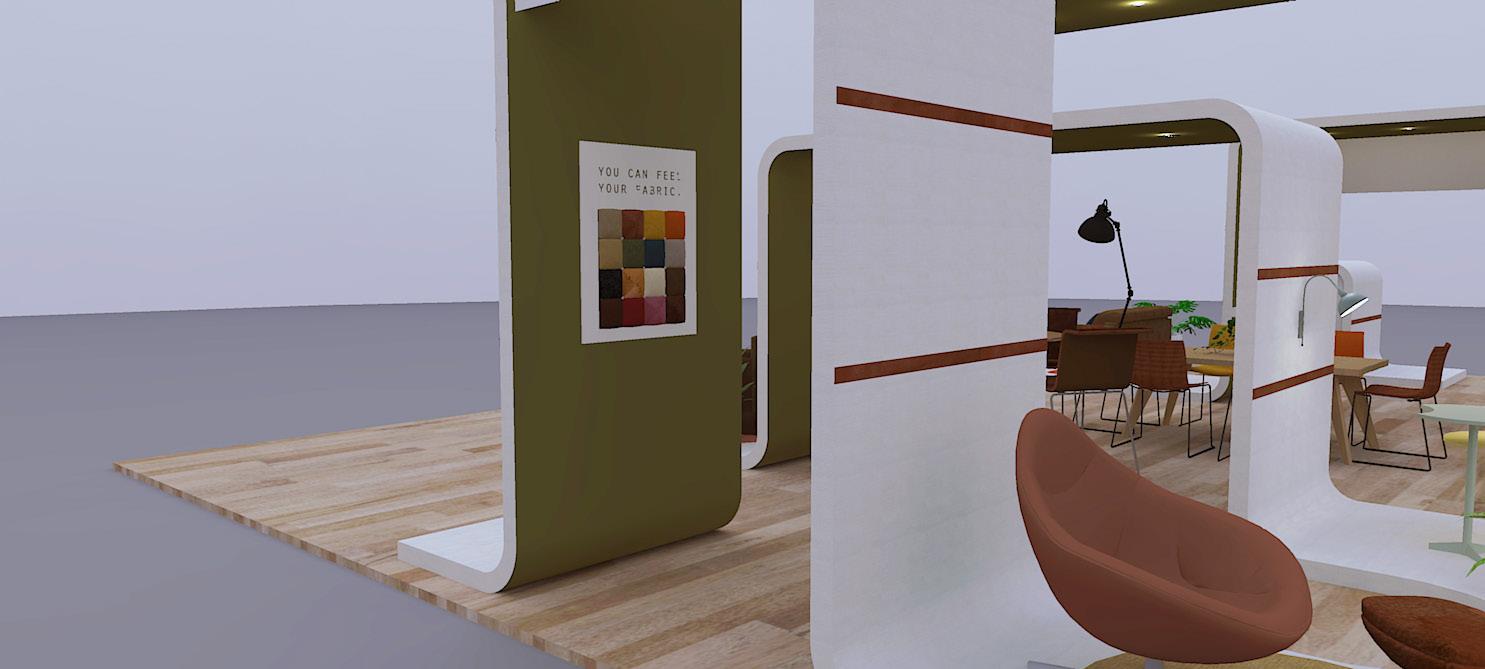

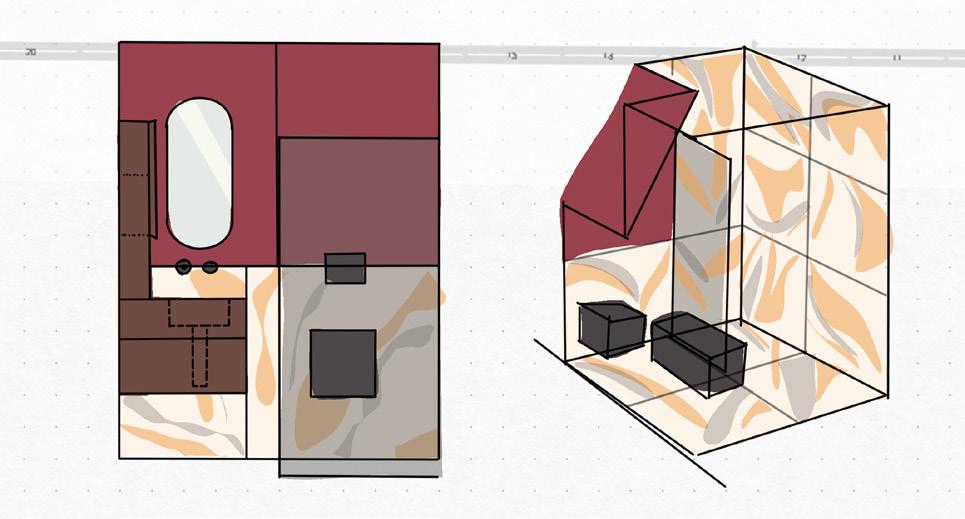

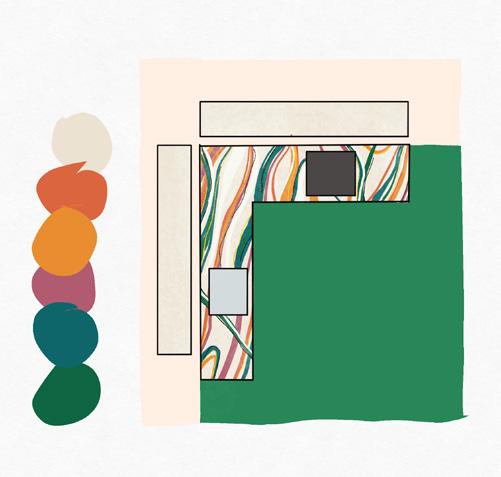

This was my final exam assignment from the Cibap. For the Spatial Design course.

Label de client is a company that mainly produces fabric and leather furniture.

My concept behind the stand was that fabric never has straight shapes, but is very organic and I wanted to portray this by folding the fabric you see. Fabric is organic.

My Jenga project.

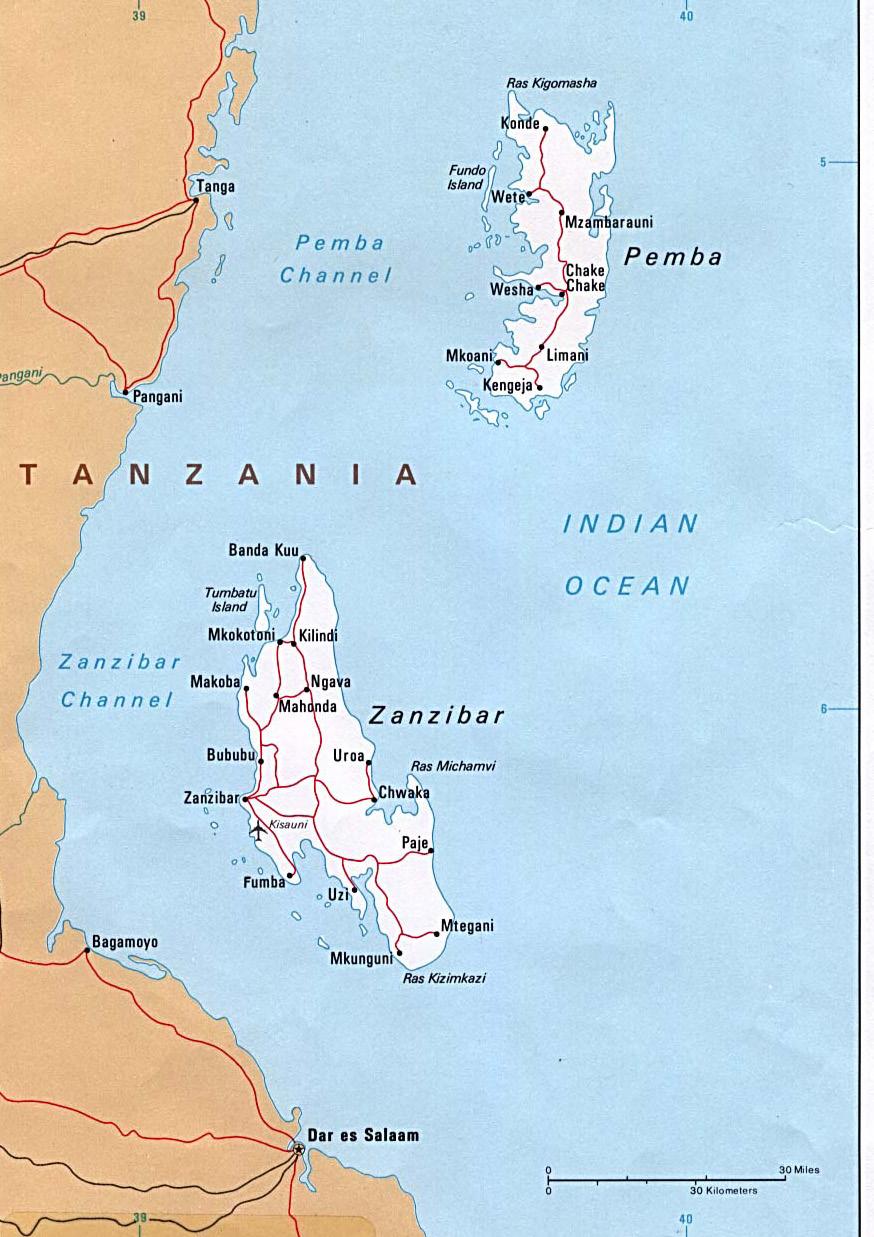

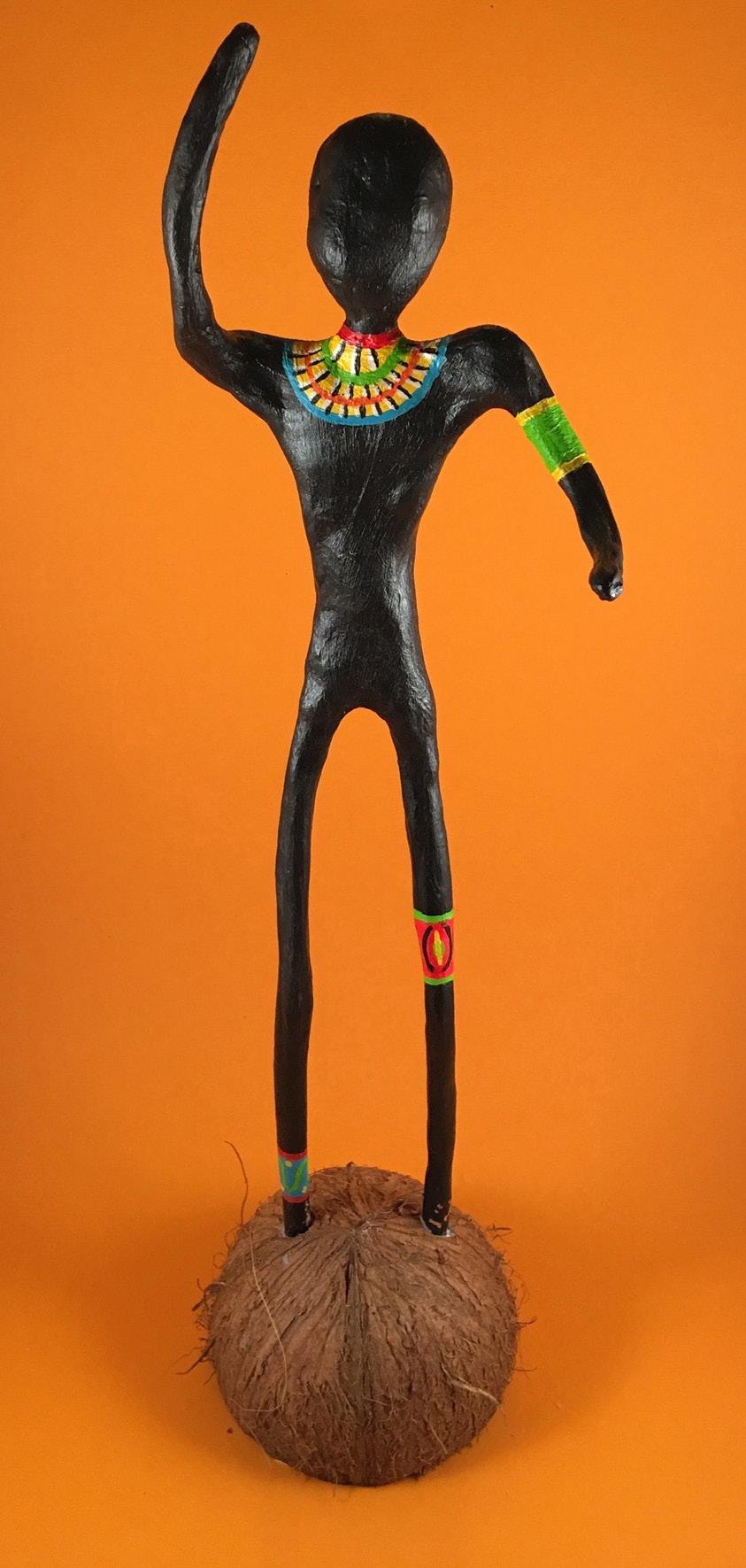

I went to Zanzibar with a group of 6 students to get to know the island, the people, their materials, culture and qualities.

Our goal was to make new souvenirs with their techniques and materials so that they can make and sell them themselves. Because everything they make now has been the same for about 20 years.

My design has become a Masai figurine with bottle packaging. Made of clay that they can make themselves.

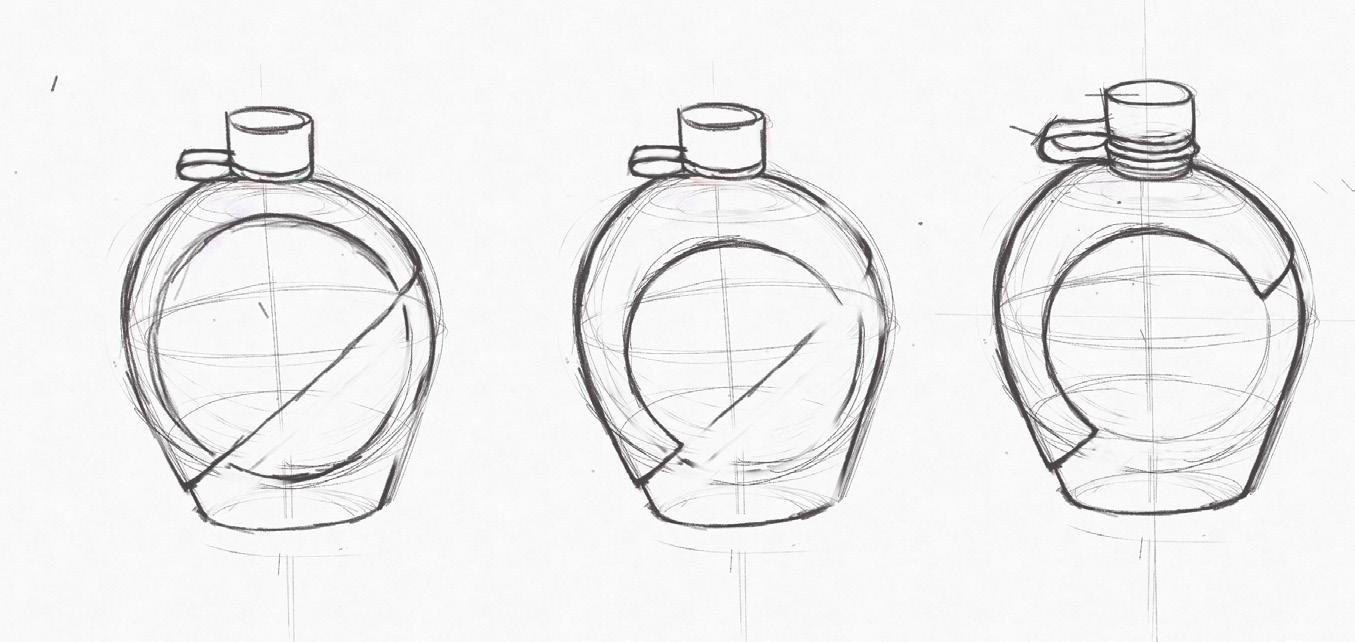

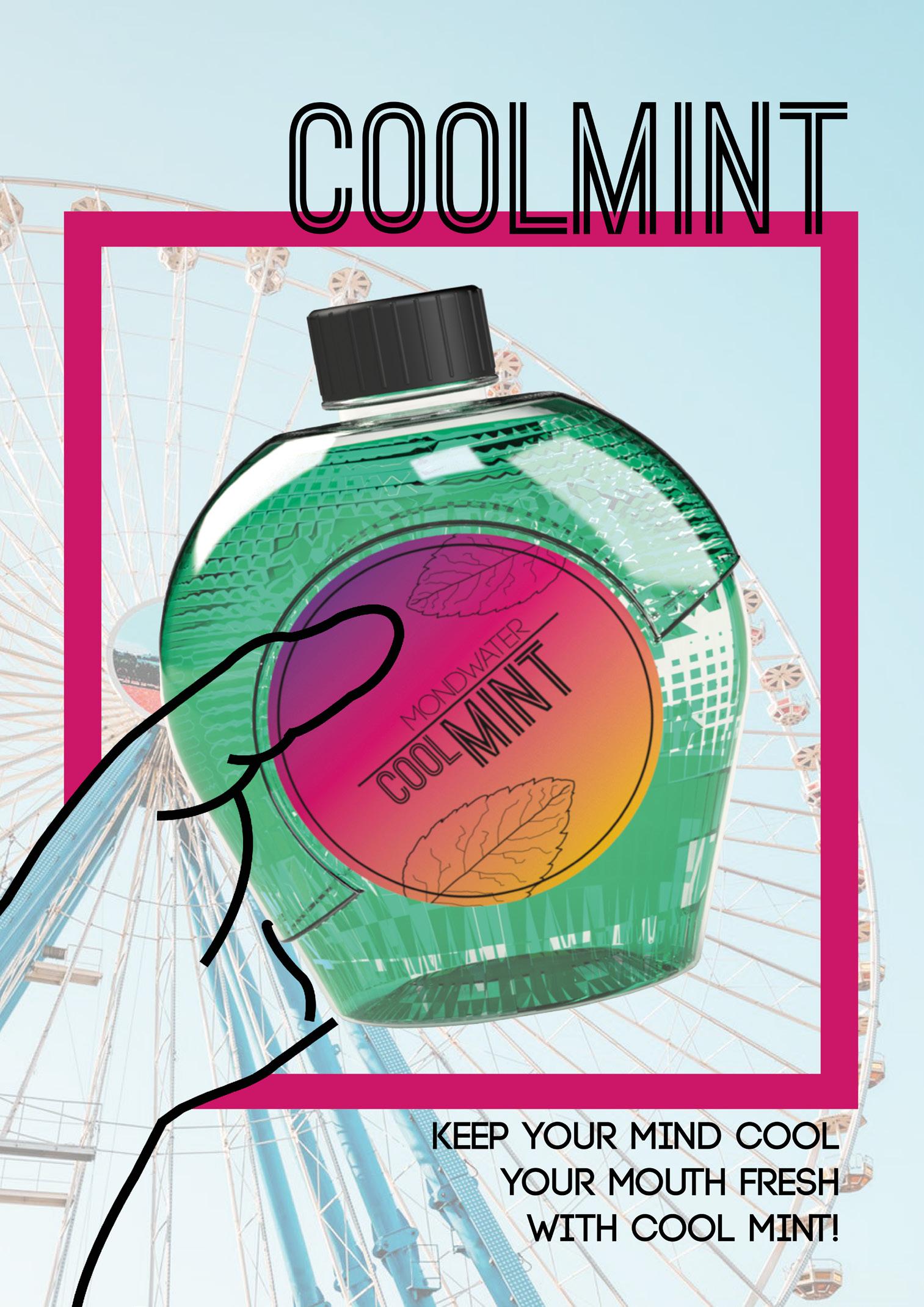

A KVA assignment was to design a bottle with a label for a random target group and random content.

My target audience were Festival enthusiasts 25-30 years old with mouthwash as content.

My inspiration was mainly cheerful colors, Ferris wheel and a canteen.

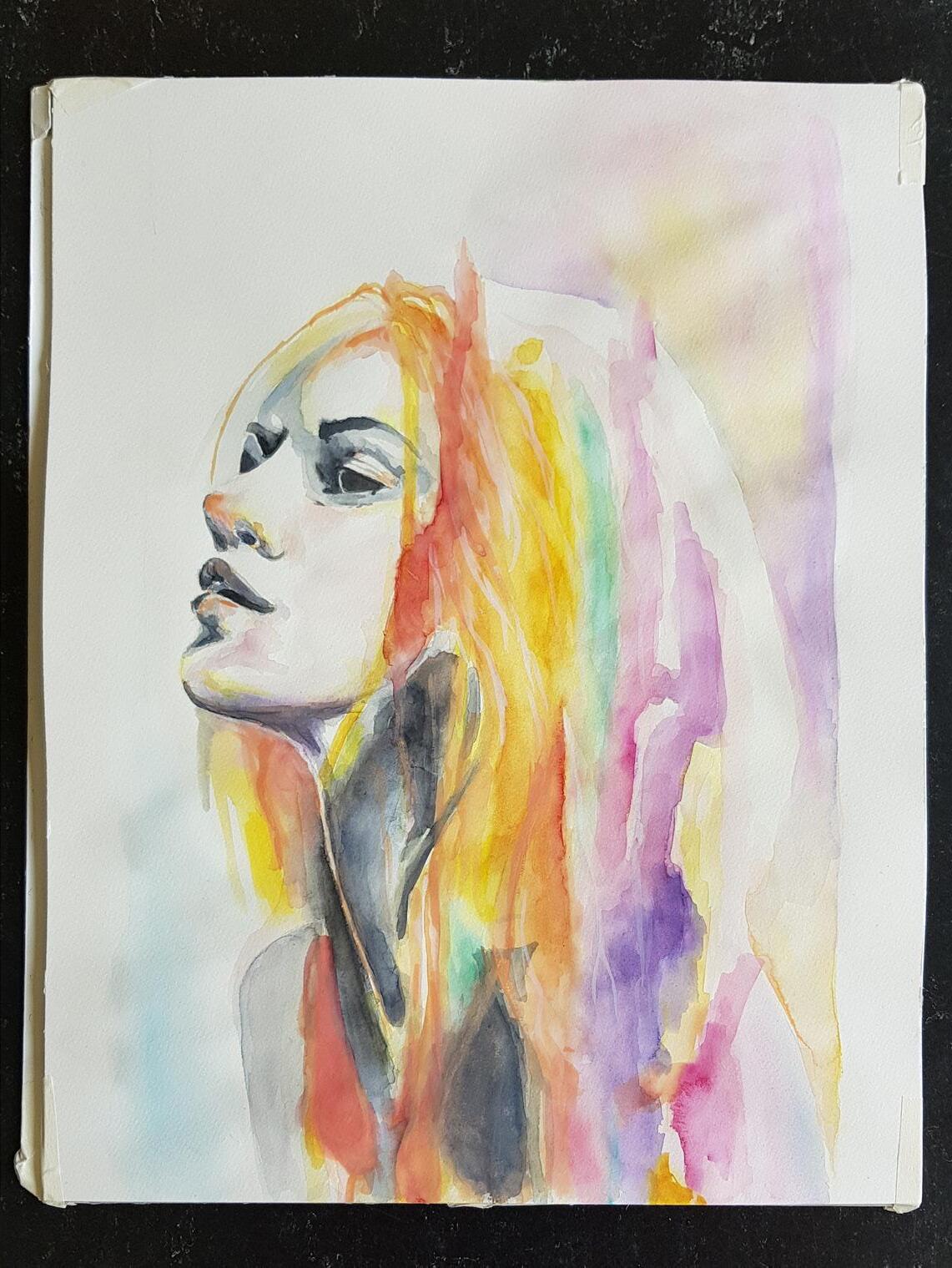

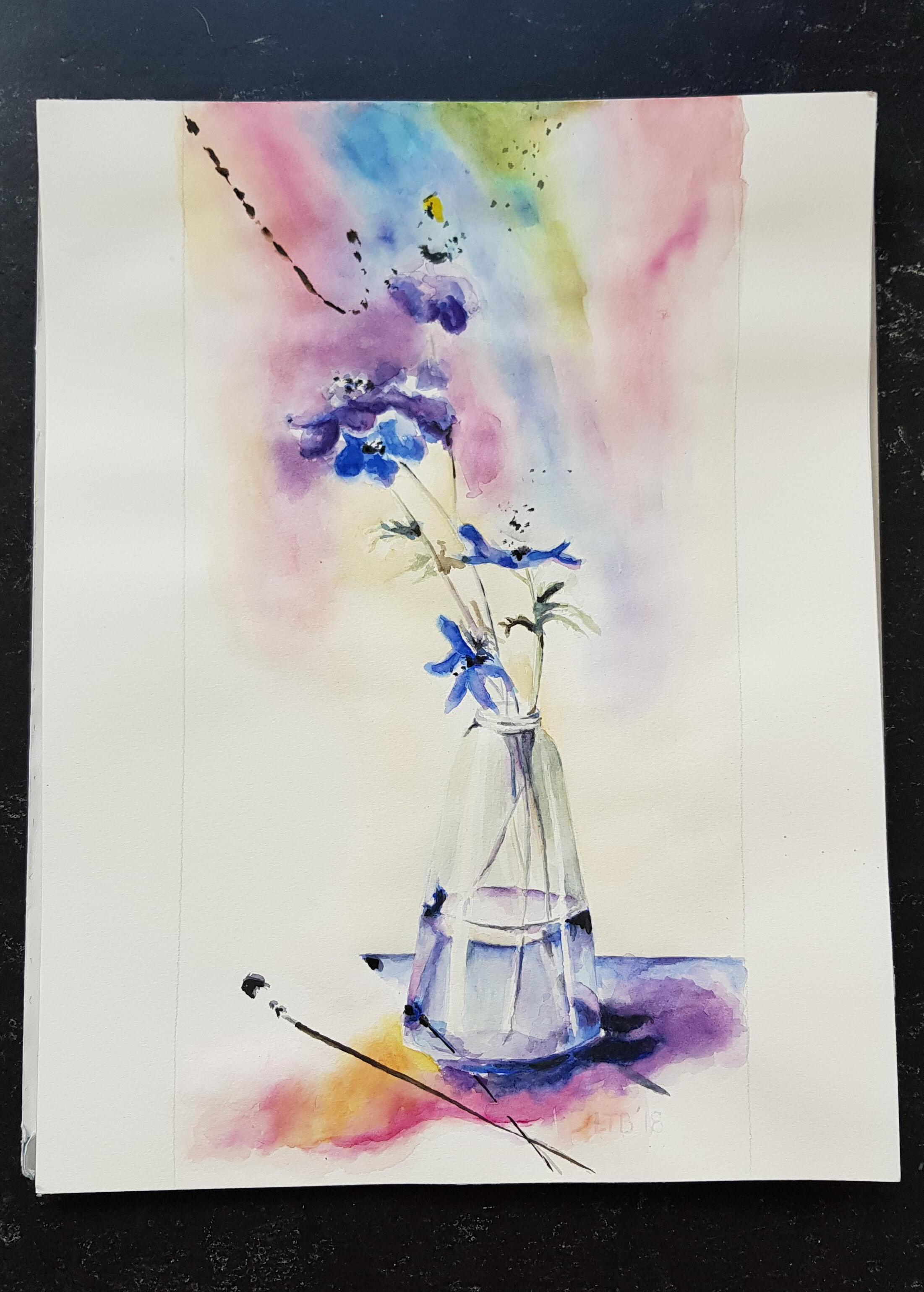

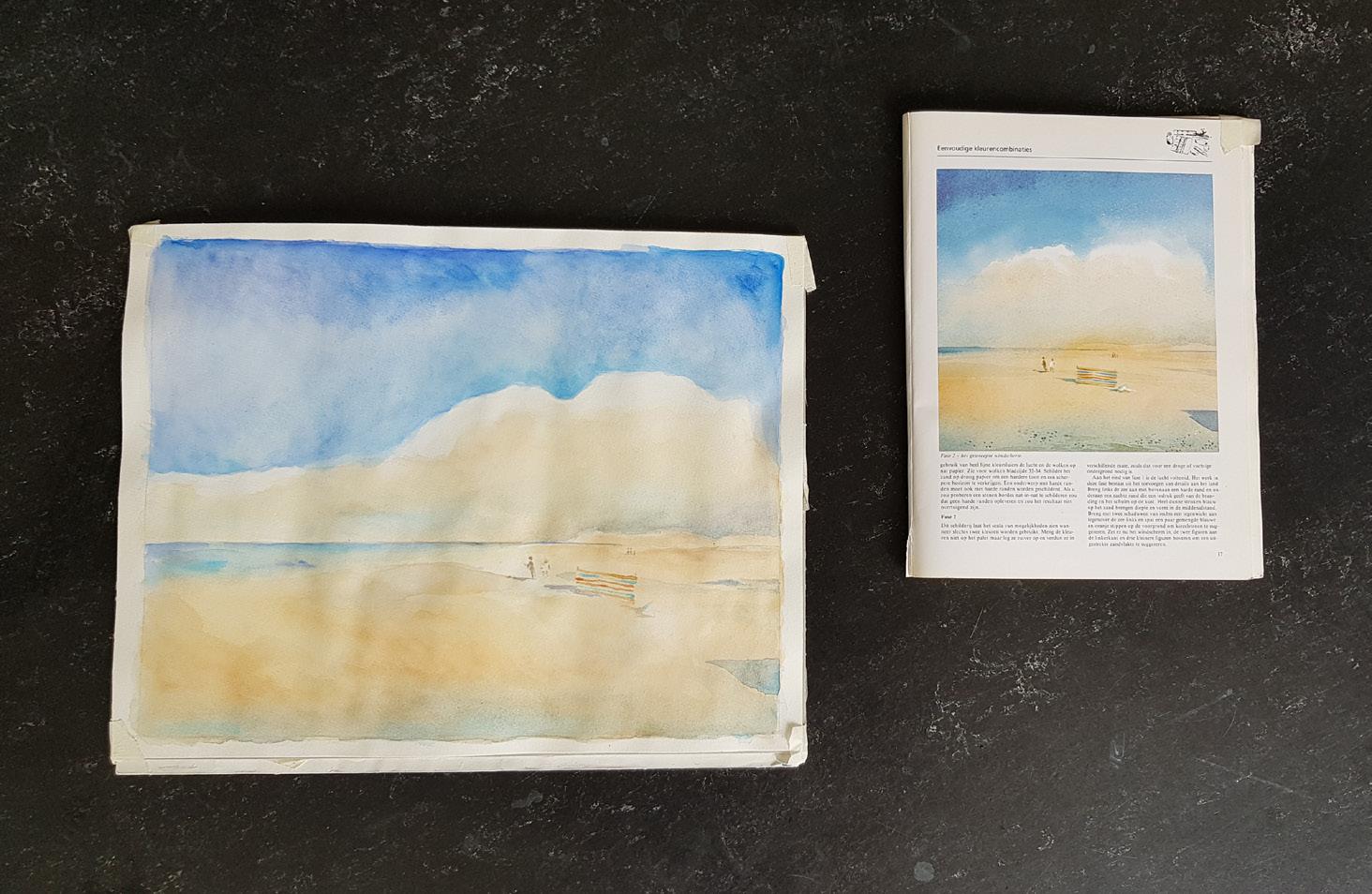

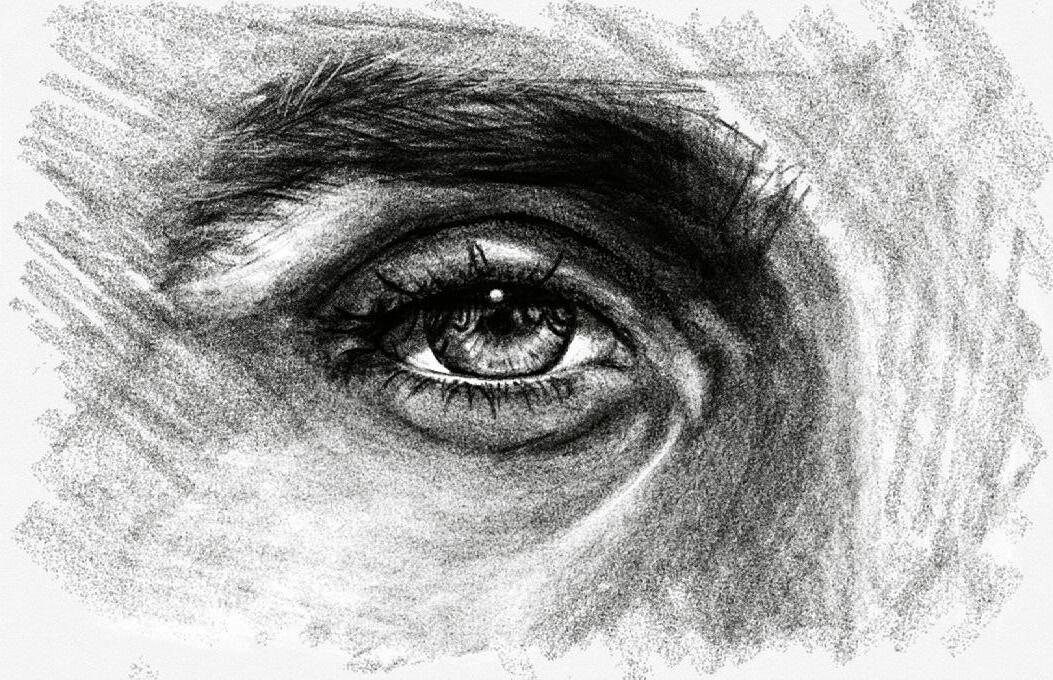

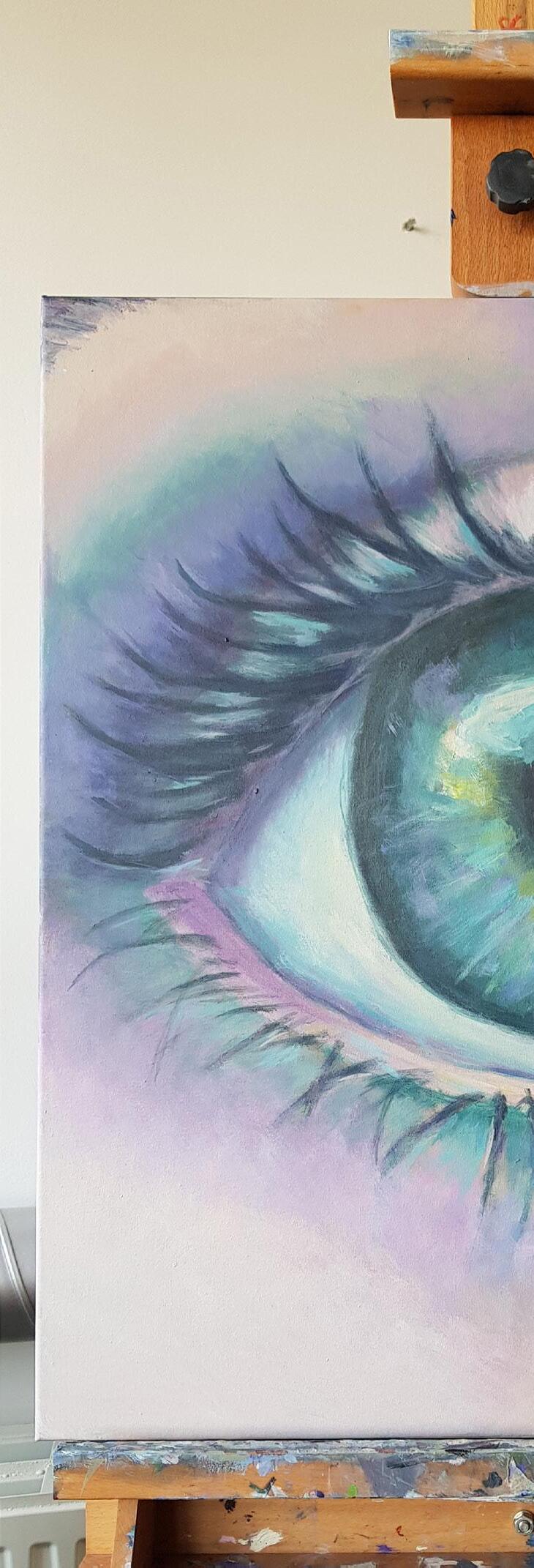

In my spare time I like to paint and draw. Here are a few examples. I especially like to work with watercolor, acrylic and pencil.

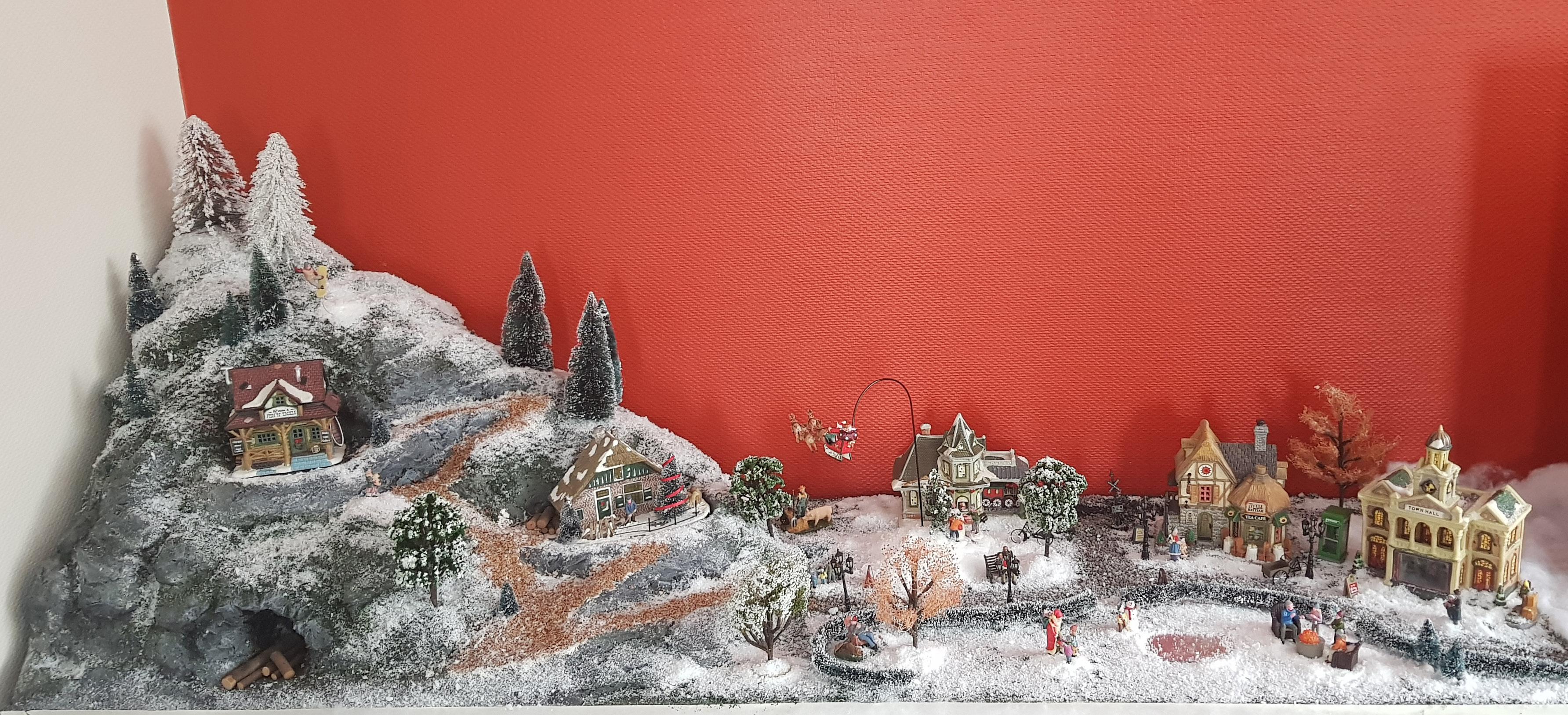

Other things I do in my spare time are tinkering and working in the workshop. Here you can see that I made a mountain for the Christmas village for my parents. Here I used chicken wire, pur and a mix of wood glue and paint.

I also like to help build a decorated car for a parade during Gramsbergen party week during the summer holidays. Summer of 2019 I made and painted this big globe. The theme was “time”. We wanted to show and make clear whether we have all the time in the world. Clocks with the time of world cities hung around the car and these are pinned in red on the globe. The sphere was 2m in diameter.

Upcycling furniture.

Family members have asked me to pimp their tables so that they have a new one have a protective layer and give it a new atmosphere in the room. This was so much fun to do that I have now applied it to multiple table top projects. I try out different styles with the paint.

For my latest table project I also have my own design welded legs underneath. I will be putting this together with my father. (He spent years of working in a metal factory)

It’s fun to give old furniture a new look and breathe new life into it.

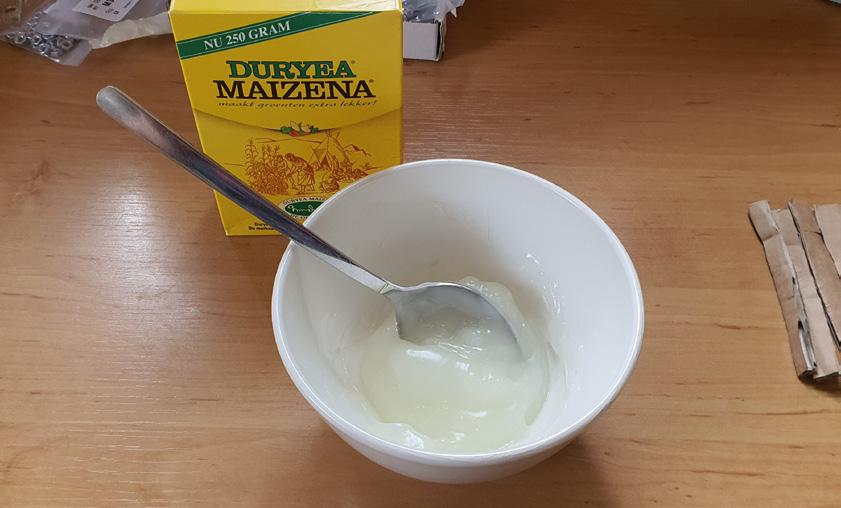

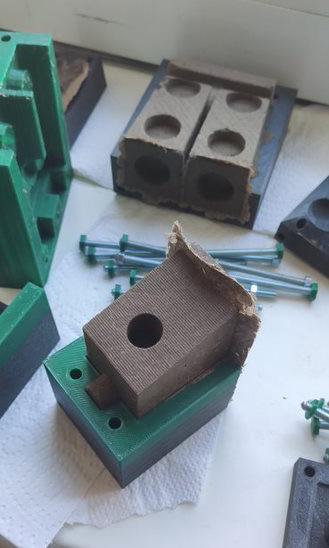

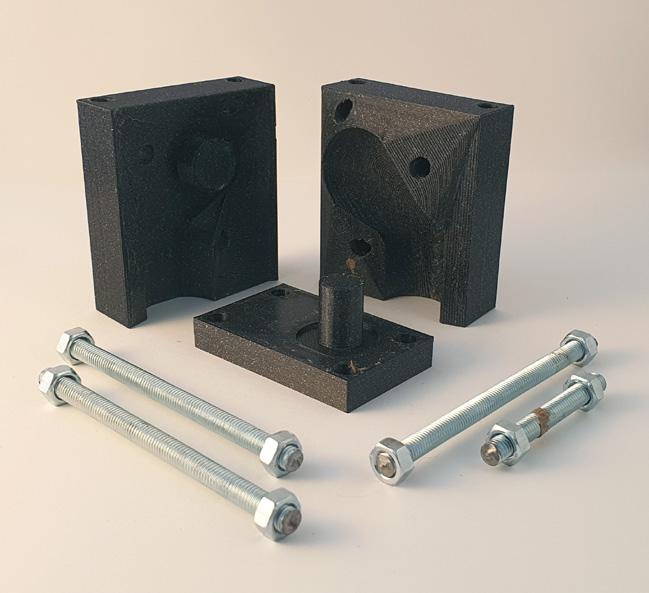

I started this project together with Bart Houtman. We wanted to see if we could turn our first year of KVA lego case into a new project. Our plan was to make a mold of each part in SolidWorks and to press and mold a sustainable recyclable material into the Lego doll. Because it involves a lot of testing, we always wanted to be able to reuse the material, so we opted for a homemade bio glue. For this we have tested many varieties and tried to press them in our test mould. This showed that 2 could stick well for our doll. In the end we opted for Maizena. This glue is very quick and easy to make and to clean up. We immediately started making a lot of paper pulp with the glue and also tested whether it was reusable when it dried and is made wet again and this was so. So we were able to fill our large molds and test them several times. We’ll take this even further in our future.

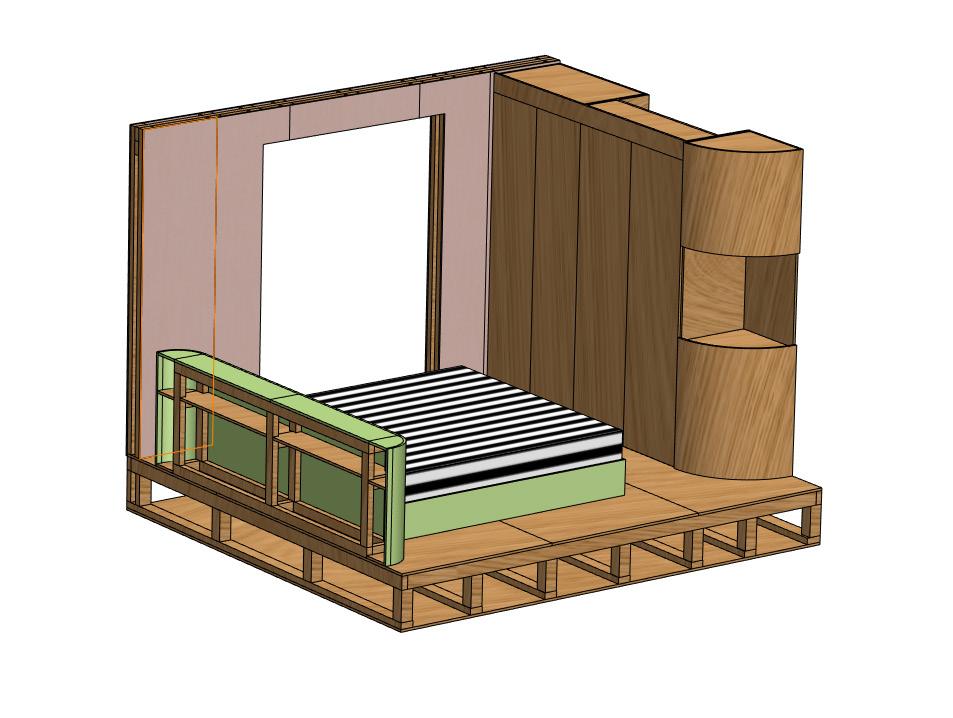

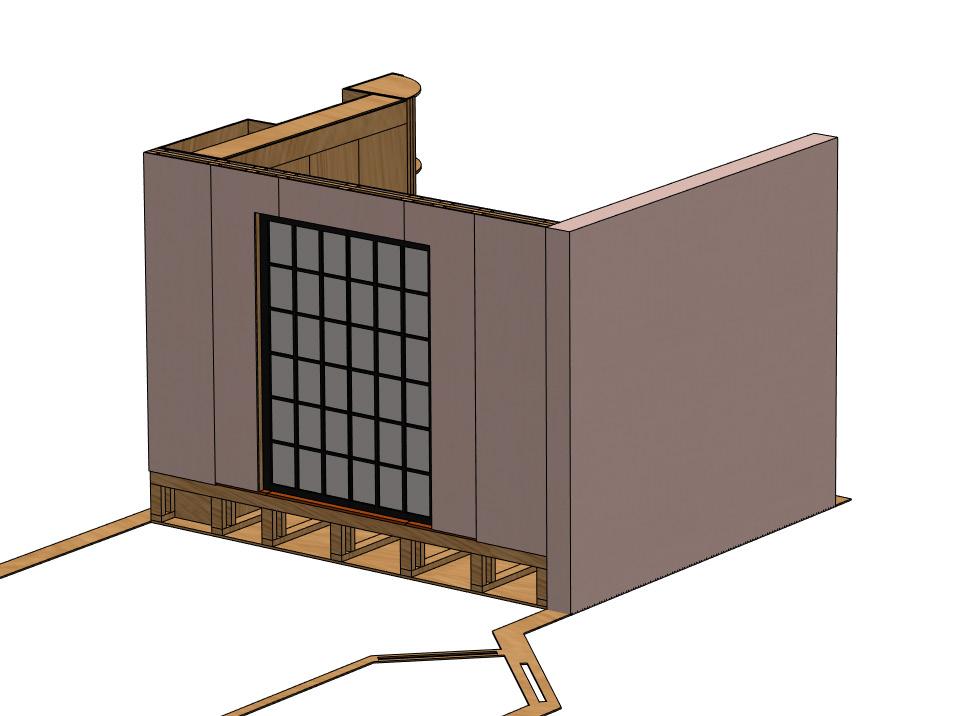

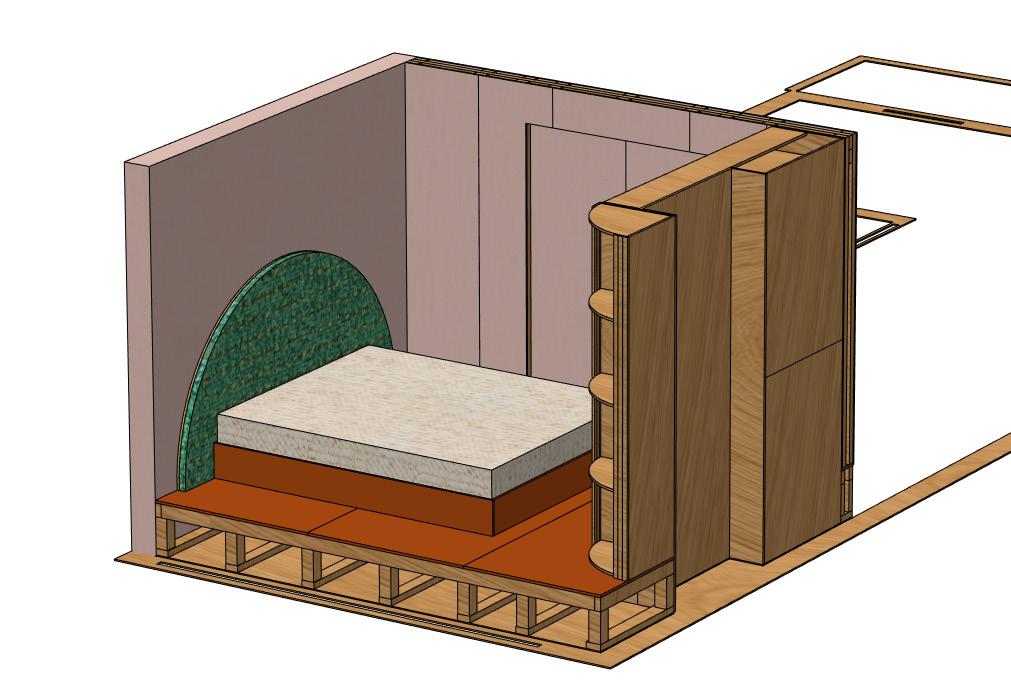

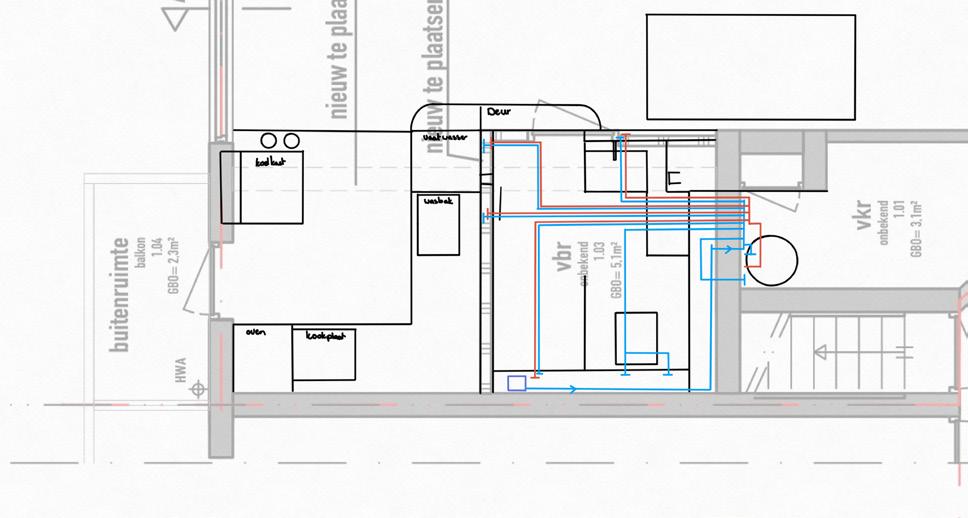

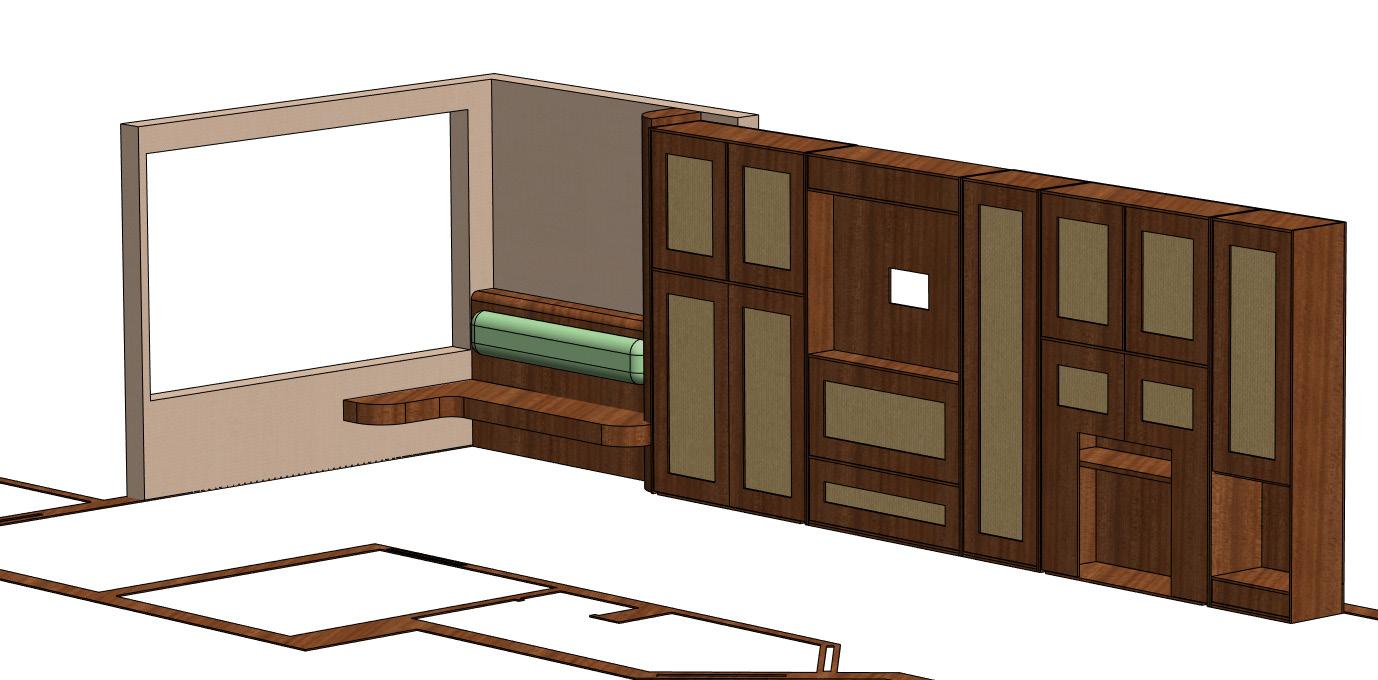

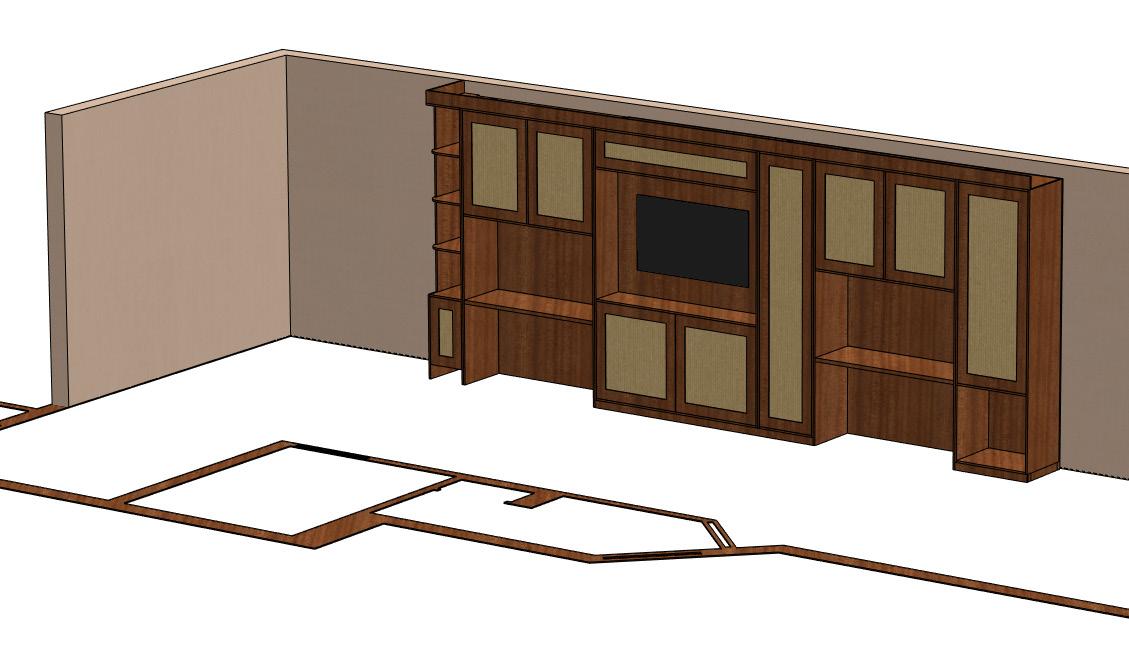

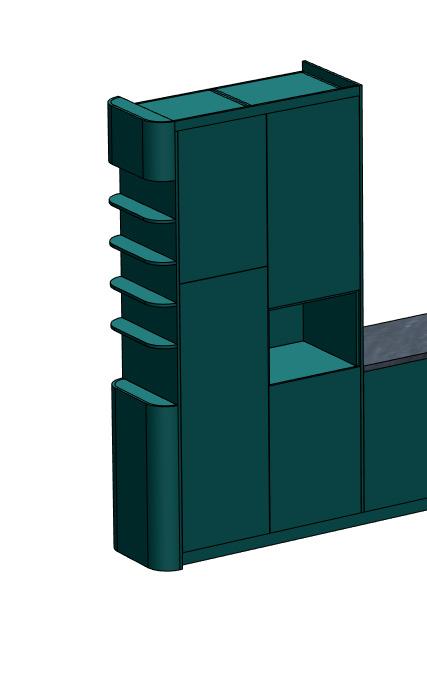

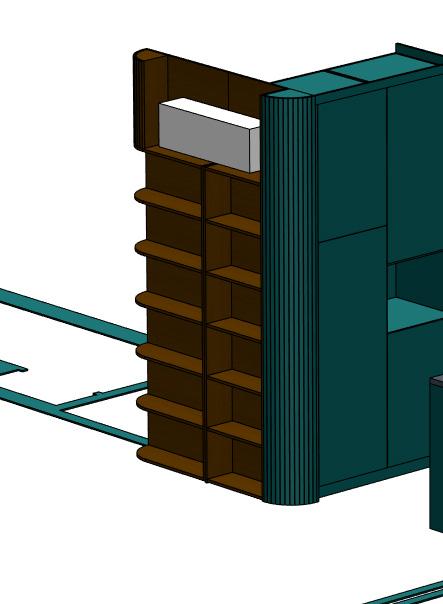

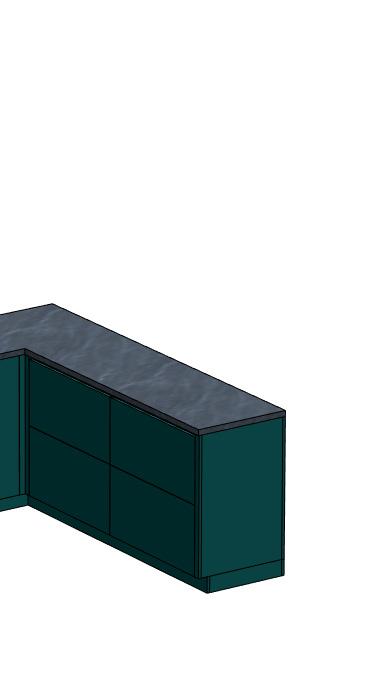

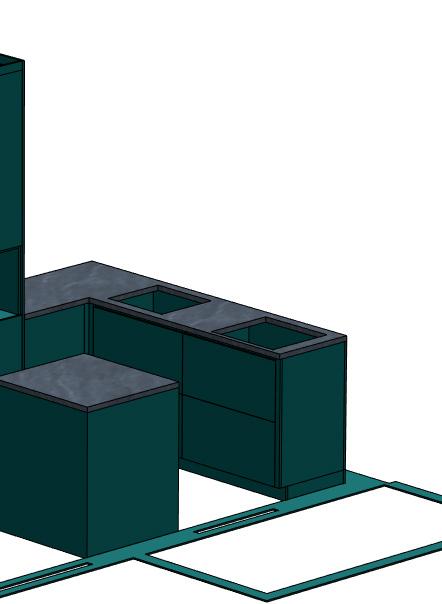

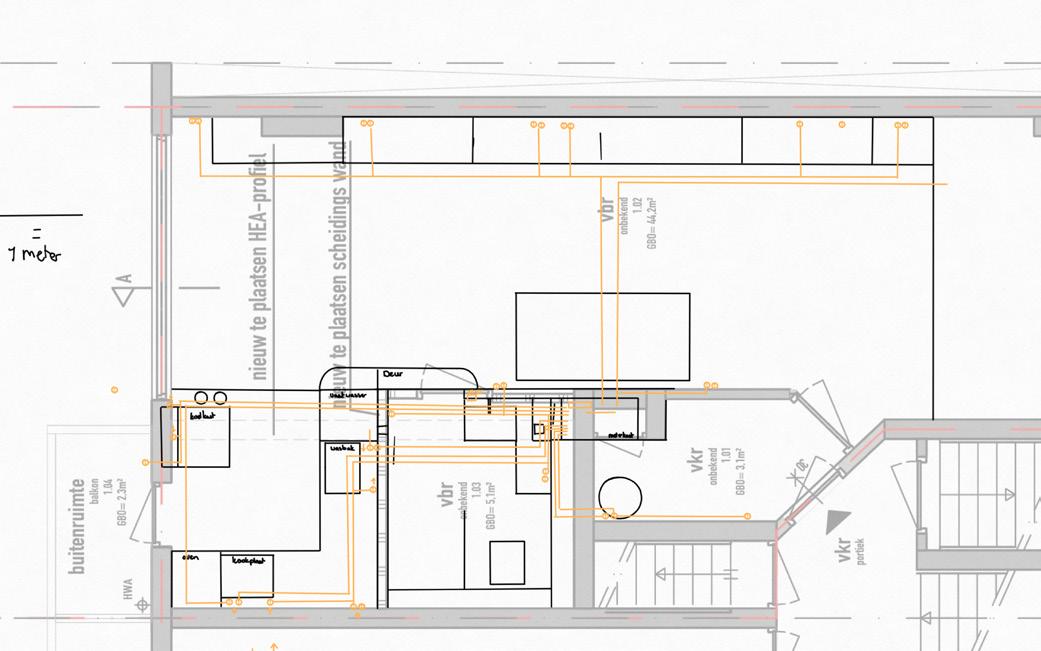

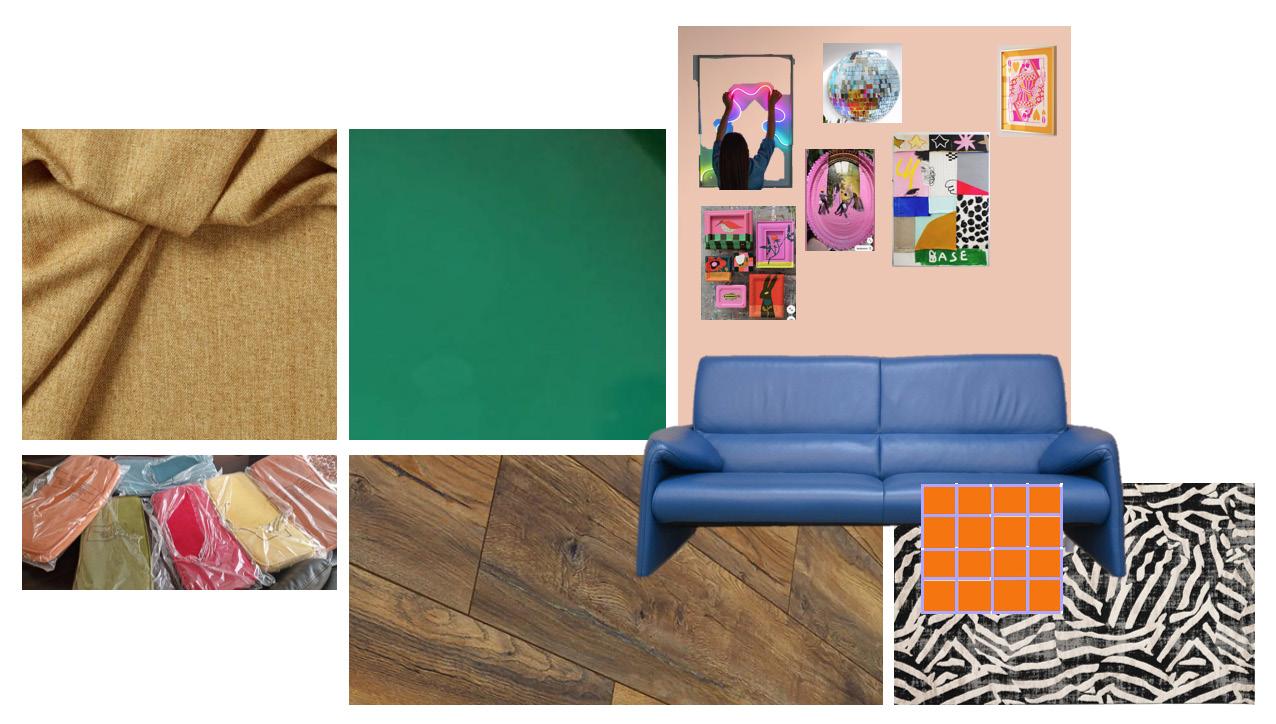

Together with Bart I bought an apartment in Rotterdam South in 2023. We wanted a renovation house where we could put all our own ideas into it. Bart gave me quite a bit of freedom in the rather idiotic ideas and colours. When I saw this house I immediately had an idea of the interior. I actually wanted to try to get the idea of a tiny house in this space. Because it is only 54 m2, it was decided to create extra storage in various places, which is why the bedroom was raised by 400 mm so that drawers can eventually be placed underneath it over the entire length.

We literally did everything ourselves (except for the shared main drain, air conditioning and removing a supporting wall). From designing and installing all the electrical systems, to plastering and painting everything, but also tiling the entire bathroom and connecting water with a new boiler, to finally designing, sawing, assembling and casting a resin worktop for the entire kitchen and the same for the bedroom.

We are not finished yet unfortunately, so our weekends still mainly consist of renovating. But I secretly look more and more at real furnishing and decoration to give it a more image of how it can hopefully look this year. To be continued…