DESIGNING WITH TIMBER

Our cities have been comprised of wood buildings for centuries. Plentiful and attractive, wood was a main building material until concrete and steel took over in the twentieth century. Now mass timber is experiencing a renaissance. Contractors, architects, and developers across the country recognize its many financial benefits, aesthetic appeal, and improved environments for occupants. As a material, timber offers structural security and sustainability. As an investment, it provides greater appreciation and return on investment.

LRS Architects has designed with timber since its founding in 1976. Our wood projects vary in size and type, from small offices to 500,000 square foot multi-generational multifamily housing complexes. Through our decades of experience and diversity of work, we’ve gained invaluable knowledge about the intricacies of designing with timber. We are strong advocates for the use of mass timber and are well-suited to provide expertise in utilizing mass timber systems for a variety of project types.

HILLSBORO, OREGON

KIRKLAND, WASHINGTON

PORTLAND, OREGON

PORTLAND, OREGON

PORTLAND, OREGON

BEND, OREGON

HILLSBORO, OREGON

HILLSBORO, OREGON

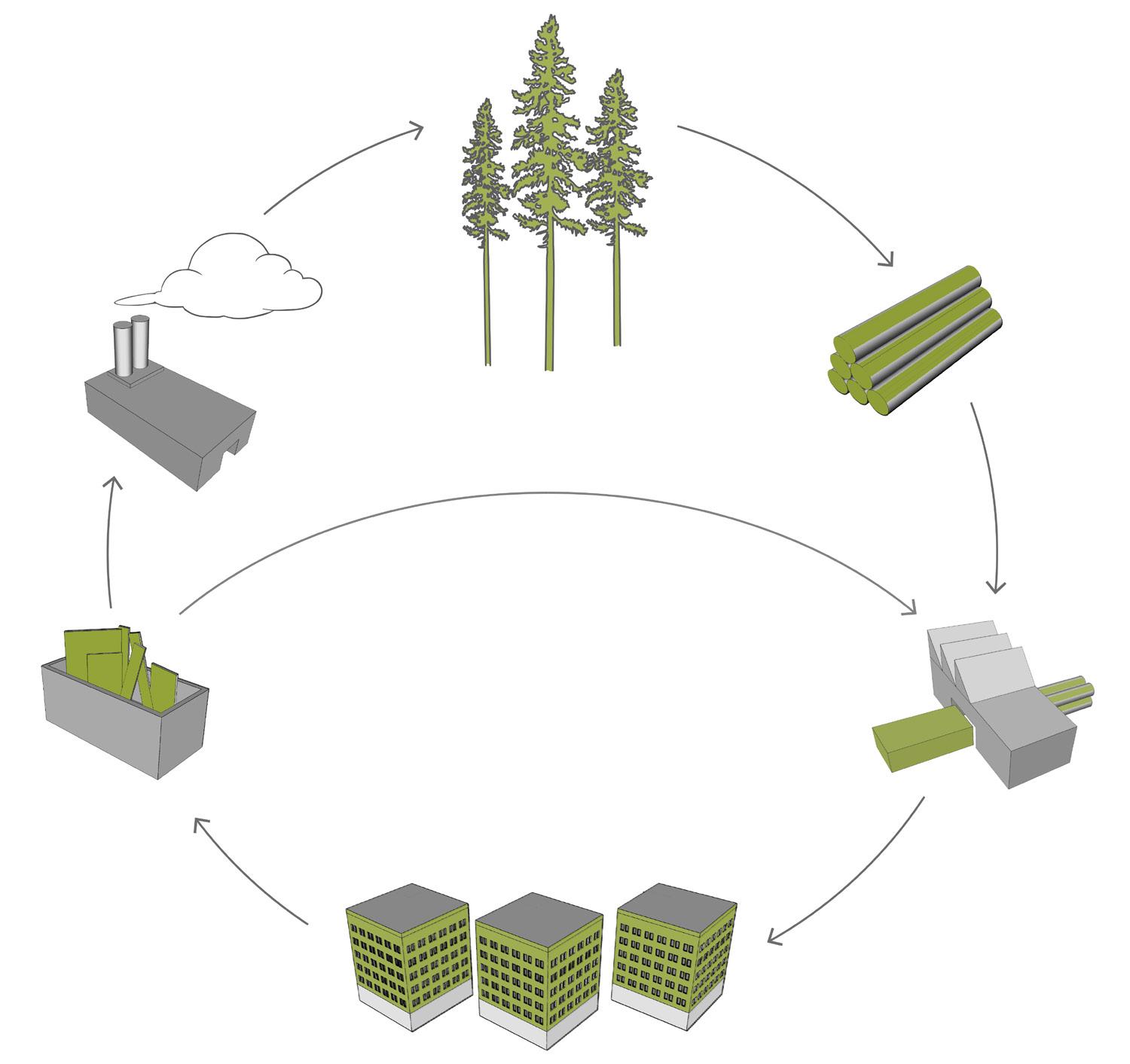

Wood can be burned for clean energy.

Wood products can be reused or recycled to create new products.

Trees are a renewable resource and store carbon.

Manufacturing processes typically use all parts of the log, producing no waste and little pollution.

An integrated approach to design and construction at the outset of the project is a fundamental shift in the industry—one that’s collaborative, optimized, and repeatable, reducing the risk to construction schedules and project budgets. By working closely with manufacturers and leveraging computer-aided production methods design teams can use precise and repeatable components optimized to project-specific conditions, getting mass-production efficiencies without sacrificing customization.

Mass timber buildings have a smaller environmental footprint relative to steel and concrete buildings.

Mass timber chars to prevent massive structural failure in the event of a fire. It outperforms stick framed structures & steel structures in high temperature fires.

Rich and warm, wood materials add texture & visual interest to modern architecture. It also provides a biophillic benefit to building occupants.

Pound for pound, mass timber products are stronger than concrete and steel. It weights less and allows for reduced footings, saving concrete and rebar costs.

Fabricated off-site to precise specifications, mass timber projects come together quickly on-site, reducing months from typical construction timelines.

Manufactured and sent to the site, panels are created with openings for windows, doors, HVAC, etc. Off-site manufacturing can reduce 20% of on-site construction.

Required on-site skilled labor is lower for mass timber, compared to concrete and steel construction. These reduced requirements provide a significant advantage.

CLT panels are made by layering pieces of wood in alternating directions and bonded together. The panel can be as large as 65 feet by 20 feet, and is an alternative to concrete and steel in high-rise buildings.

Glulam is a popular engineered wood commonly used for beams and columns. Its benefit is the stress-rated performance, with the strongest laminations sandwiching the others to better absorb stress. Stronger than steel at comparable weights, glulam is a cost efficient choice for structural spans.

NLT is created from lumber stacked and fastened together with nails into a single structural element. It can be found in many historical buildings. NLT does not require a dedicated manufacturer and it can be fabricated with readily available lumber.

Hybrid Construction combines concrete and steel with a timber system, and recommended for multi-story buildings. These assemblies yield large floor spans, easier sound and fire protection performance, and faster installation.

MPP is an enegineered veneer-based wood product. Its structural attributes are indistinguishable to concrete, steel, and CLT assemblies. Additional benefits include being fire resistant, lighter in weight, less waste from harvest to construction, and ease of installation with a small labor force on-site.

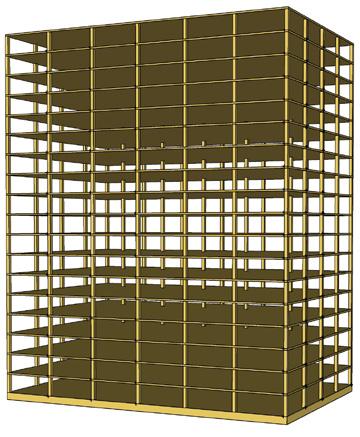

A building’s construction type dictates where and when wood systems can be used. There are five types, Type I through Type V. Types III and V have historically permitted the use of wood frame construction and are used for lowrise mass timber buildings. Recent code changes have introduced several mass timber specific sub-categories within Type IV construction, which significantly increases the allowable height and floor areas creating opportunities to construct mid-rise and high-rise mass timber structures.

TYPE USE

Type IV A

Type IV B

Type IV C

Mass-timber structure fully encapsulated in non-combustible, firerated protective construction, such as gypsum board.

Limited exposure of mass-timber structure. Majority of masstimber structure fully encapsulated in non-combustible, fire-rated protective construction, such as gypsum board.

Exposed mass-timber structure, except for shafts, concealed spaces, and outside face of exterior walls.

TYPE IV A - UP TO 20 STORIES

Building Height 270 FT

Allowance Building Area 972,000 SF

Average Area Per Story 54,000 SF

TYPE IV B - UPTO 12 STORIES

Building Height 180 FT

Allowance Building Area 648,000 SF

Average Area Per Story 54,000 SF

TYPE IV C - UP TO 9 STORIES

Building Height 85 FT

Allowance Building Area 406,000 SF

Average Area Per Story 45,000 SF

SOURCE: Mass Timber Report https://masstimberreport.docsend.com/view/ n6c8qap47cjd99ac

Driven by a passion for good design and supported by endless curiosity, LRS is a forward-thinking architecture and interiors firm offering creative solutions and transformative spaces. Our diverse portfolio of work highlights our commitment to shaping the human experience through the physical environment.

PROJECTS FEATURED IN THE BOOK INCLUDE:

Wingspan Event & Conference Center, Hillsboro, OR

Wood Village Municipal Building, Wood Village, OR

Lifebridge Kirkland, Kirkland, WA.

Towne Storage, Portland, OR

PDX Distillery, Portland, OR

Timberland Retail Center, Portland, OR.

A single principle encompasses all we do: design with integrity. We are your honest project partners. We design sustainably, planning vibrant communities and building structures to stand the test of time. Wellbeing is our top priority, because good design isn’t just about aesthetic, but how we interact within a created space.

Deschutes County Courthouse, Bend, OR.

The Quarry, Hillsboro, OR

Amberglen, Hillsboro, OR

PHOTO CREDIT:

Mass Plywood Panel. Freres Lumber Company and Shanna Hall Photography.

BACK COVER:

Wood Village Municipal Building, Wood Village, OR.