Corporate and Social Responsibility Report 2023

ollowing our management buy out 12 months ago. onmental impact of greetings cards and in the past year our investment in new technology bility of our production process primarily by reducing both our electricity consumption and use of plastic packaging, along with a switch to processless plates.

As a long established Sheffield business we have strengthened our link with the local community by engaging with local schools and colleges to provide work experience and apprenticeship opportunities to young students.

Looking forward we will continue to develop our eco-friendly product offering with a focus on adapting our existing equipment to deliver new eco solutions.

Finally, I am proud to hear that for the fourth year in a row 100% of our litho customers would recommend us to others - this is great feedback to receive! My sincere thanks to all of our staff, suppliers and customers for their continued support.

Tony Lorriman - Managing Director

Tony Lorriman - Managing Director

Our Vision

"To be the low cost manufacturing and fulfilment partner of choice for the UK greeting card market"

Our customer satisfaction survey

Apprenticeships and work experience

Donations to Talbot school

Our environmental performace

Managing our electricity usage

Investing in paper banding

Eco friendly products

Moving to processless plates

Pallet recycling

Certifications: FSC and Zero foil to landfill

4 5 6 7 8 10 11 12 13 14

Contents

Customer Satisfaction Survey 2023

, distributed to our active customers, of the business. The survey allows us of our production services and nsight.

Always friendly with professional services, competitive prices and quality products

We’re extremely proud to hear for the fourth year in a row that 100% of our lithographic customers would recommend us to others and rated their overall experience working with us as either good or excellent. Within digital print over 85% of respondents agreed or strongly agreed that our printed products were of a high quality and were interested in further development of digital print products.

Great service -

As a result of the survey results alongside our 2023 business plan, we will continue to assess ways to improve and add value to our customers experience.

I know that things will get done when I'm told it will get done

Customer feedback on their experience working with Loxleys

Apprenticeships and Work Experience

As an established business with over 160 years at our Sheffield site we are passionate about providing opportunities in our local community and promoting jobs in the print industry to future generations.

As part of our engagement in the community members of the Loxleys team recently attended the 'Be-Inspired' Sheffield City Council careers fair, sharing our fantastic apprenticeship opportunities with students and engaging with future prospects. Our apprentice programme offers full support in skills development across a variety of production processes, with the opportunity to learn in a flexible, creative and innovative environment. Our programme is well suited to individuals looking for practical, hands on roles.

We have also formed links with local schools to offer work experience placements across different areas of the business and moving forward this is an initiative we will be looking to expand further.

“It’s been an eye-opener, we’ve met businesses that you wouldn’t imagine. When you scroll a website, businesses all look the same, It helps to be able to talk to them in-person. I like the sound of Loxleys greeting cards’ apprenticeship.”

Donations to Talbot School

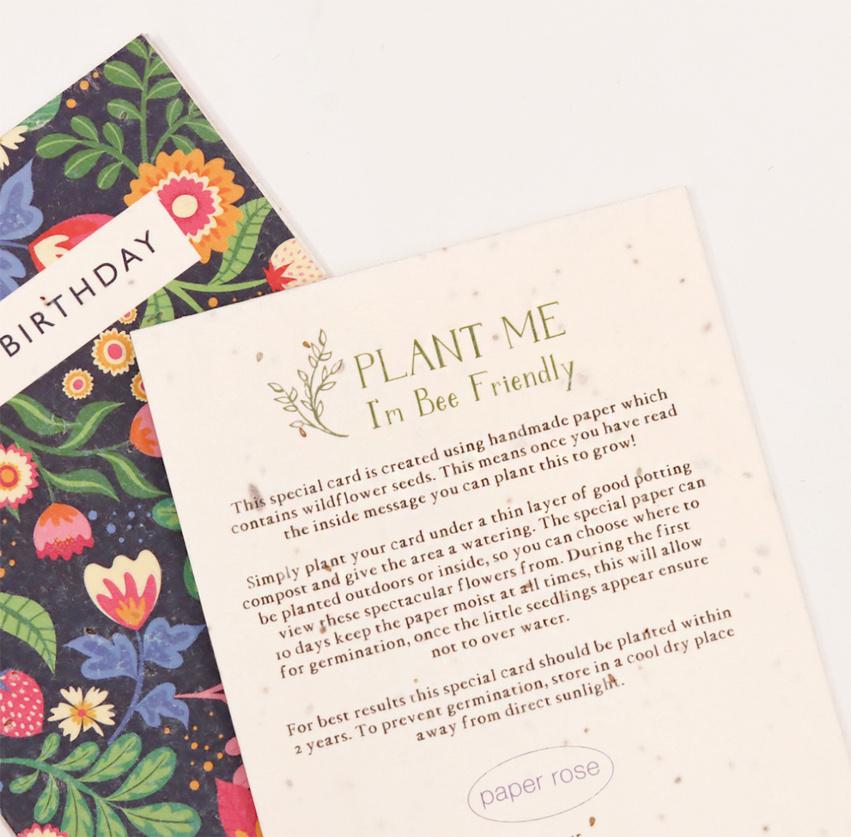

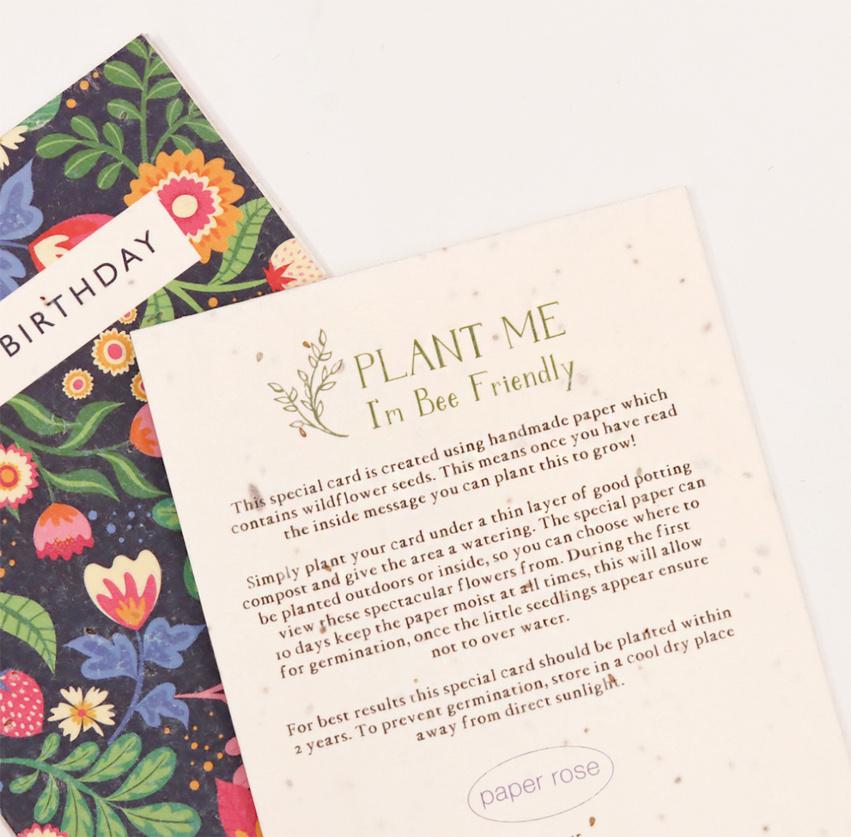

but particularly when they allow us to 023 we ' ve partnered with Talbot alist educational support for pupils aged ers to use within craft projects.

We have been lucky enough to receive a colourful array of greeting card designs from the students themselves, made with the board donated by Loxleys, with messages of thanks!

Alice Woodland, Loxleys Marketing Manager explained, “Seeing the creativity of the student’s designs was one of the most rewarding aspects of this project, not only were we able to help support our local community, but we got to see first hand the imagination and talent of what I’m sure will be some of the next generation of greeting card designers! It’s fantastic to be able to make a difference to such deserving causes.”

Our Envrionmental Performance

As shown in the results table above, we have seen improvements in all aspects of our environmental performance in 2022.

Our consumption has reduced across electricity, gas and water, our use of solvents in the printing process has reduced and our use of packaging has reduced.

Most noticeably our use of plastic has reduced by 53% as a result of our plastic free eco packaging solutions.

Looking forward we will see further improvements in both electricity consumption and plastic usage given our recent investments in voltage optimisation, LED lighting and paper banding technologies.

2022 2021 2020 2019 Solvents used (Kg) 3900 4530 2560 5200 Electricity used (Kg) 1,038,967 1,051,545 1,036,322 1,293,393 Gas (kWh) 422,144 519,829 446,103 460,181 Water (m3) 597 1006 956 1101 Packaging used (Kg) 100, 078 103,916 95,528 115,499 Plastic used (Kg) 17,347 36,382 36,103 48,285

orefront of our n numerous initiatives to help us work towards cleaner and greener energy sources to fuel our factory input and output.

Managing our Electricity Usage

Our first project involved the complete installation of LED lighting throughout all areas of the business, reducing our energy usage on lighting by over 50% reducing our total carbon output by 9,316 KgCO2e.

Voltage Optimisation

Our second project for 2023 included the installation of a Voltage Optimisation unit, with the aim of stabilising and reducing incoming voltage, mitigating the energy intensive production processes consumed on-site.

The unit installation reduces our incoming voltage consumption by 7%, again further cutting our total carbon emissions. Driven by the ongoing target to reduce our environmental footprint and continuous assessment of our supply chain processes, we’re proud to see the initial tangible benefits from these projects.

Investing in Paper Banding

s their responsibility to continuously ing their customers to reduce the

n a new fully automated paper banding line, diverting an estimated 6.2 tonnes of plastic per year from landfill. The eco-band is a sustainable solution to transit packing, collating greeting cards and envelopes in multiples, replacing the need to transit wrap with traditional OPP plastic film.

The investment will be beneficial to both Loxleys as a producer and our customers as publishers, by offering a more sustainable option to grouping and shipping greetings cards. Looking forward, the machine has the potential to be adapted to offer further methods of plastic free production and packaging for greeting cards.

6.2 Tonnes of plastic diverted from landfill a year

Investing in Paper Banding

fill, equivalent to the weight of an African elephant!

1 African Elephant

6.2

3 Adult Hippos

2 Ford F-250 Trucks

T

Loxleys have been focusing on a full range of environmental solutions across our greeting card production with the aim of becoming more sustainable. Below are just a few of the eco-friendly alternatives we currently offer:

Eco Friendly Products

Production - Recycled and recyclable boards including a 100% compostable seeded board. Environmentally friendly and food safe print in our digital department.

Finishing - Eco friendly finishes to elevate your greeting card design without costing the planet, including plastic free glitter, gem alternatives and faux sequins.

Packaging - A choice of biodegradable and compostable bags aswell as paper based solutions to collating and packing, secure-seal, intergrated euro hooks and paper banding.

nts spill over into all aspects of our supply ment. After successful trails, this year we (or process free) plates within our precessed plates to process free plates has ed chemical waste.

Replacing traditional chemically processed plates, the new plate system has a special coating which allows the non-image area to be washed out on the press and waste coating to be transferred to the first waste sheets.

Processless Plates

By removing the processer, we have been able to reduce our overall energy consumption within this stage, eliminate chemical and water usage during this process, as well as reducing our environmental waste, allowing the complete process to become greener in practice.

ontinue to partner with recycling

wooden pallets into multiple recycling

Pallet Recyling

s a source of bio-mass fuel, a carbon neutral alternative to burning fossil fuels to generate electricity. Enva also use the pallet wood to create award winning pet bedding for poultry and cattle and finally to create panel boards suitable for furniture production. By working with Enva an estimated 28 tonnes of wood from damaged pallets passing through Loxleys are fed back into the reycling loop.

Zero foil-2-landfill FSC certification

Loxleys have been a member of the Zero-Foil-2-Landfill scheme since October 2019, repurposing around 52 tonnes of foil per year which would otherwise be destined for landfill. The excess foil collected from Loxleys site is processed into an alternative fuel directly substituted for coal and supplied to cement kilns all over the UK.

Following our 2022 year’s audit, we are proud to have successfully retained and achieved the re-certification of our FSC accreditation for the next five years. This further highlights our wider ongoing commitment to the sourcing of sustainable components throughout all stages of our supply chain and enables us to continue to offer responsibly sourced boards to the market.

Our Certification

If you'd like to hear more about any of the projects in this report please email enquiries@loxleys.co.uk

Kiln Street, Sheffield S8 0YS 0114 2501150 www.loxleys.co.uk

Tony Lorriman - Managing Director

Tony Lorriman - Managing Director