End-of-year message from Dan Leaney, Sales

Issue 9 Winter 2024

Director

As 2024 comes to an end, it’s a good time to look back on a year of great progress for Xwatch. Reaching the milestone of 5000 systems—and now nearing 5500—has been a major achievement, reflecting the strong relationships we’ve built with our partners and customers.

Since becoming part of Hexagon, we’ve had new opportunities to grow globally, bringing our safety solutions to more markets and projects than ever before.

This year, we’ve made big strides internationally with the launch of Xwatch Americas and Xwatch France. Our calendar is packed with major events, including Bauma, Conexpo, and Hexagon Live, as well as local shows like Rail Live and the long-awaited PlantWorx 2025.

We’ve continued to work closely with leading tier-one contractors and joint ventures, delivering solutions that make a difference. As a team, we’ve set high standards and are proud of what we’ve achieved.

Our R&D team has been busy developing new products, including one that could change the game for the industry. We’re always pushing to improve, ensuring our systems not only meet but exceed safety standards.

It’s also been a strong year for partnerships. By working with Explore, Lynch, Flannery, Molson Hitachi, and many other OEMs, we’ve been able to bring our technology to more machines and job sites, helping to improve safety in high-risk environments.

Looking ahead, 2025 is shaping up to be another exciting year. With new products on the way and the ongoing support of our customers and partners, we’re ready to keep raising the bar for site safety.

Thank you for being part of our journey. Together, we’ll keep making worksites safer and smarter.

We hope you enjoy this newsletter, and if you’d like to feature in the next one, please get in touch.

Transforming safety and efficiency - A real-time telematics platform for the construction industry

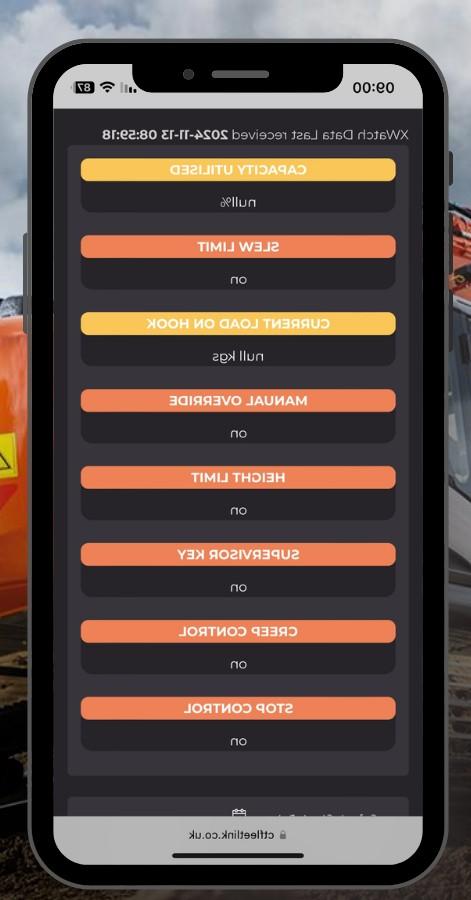

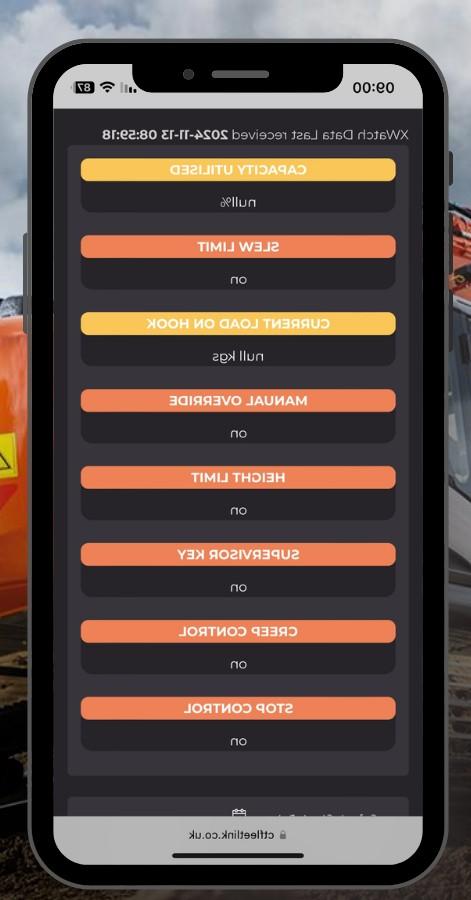

Managing machine hours, tracking fuel usage, and monitoring load capacities no longer rely on manual processes or on-site checks. PVS Data (Plant and Vehicle Services Ltd) has transformed fleet management for plant and construction companies worldwide, encompassing brands from all OEMs. With the installation of the new D2 unit, businesses can access over 300 real-time data parameters, including live engine reports, precise machine locations through the w3w (What 3 Words) app integration, and safety metrics, including height, slew, and RCI (Rated Capacity Indicator) data from Xwatch Safety Solutions.

Xwatch Safety Solutions, part of the Hexagon Group, is redefining on-site and in-cab safety standards. Operators can now set precise height, slew, and RCI limitations directly from their excavator’s cab, providing a new level of control and assurance. Safety has always been a cornerstone of the construction industry, and Xwatch builds on this legacy with advanced in-app telematics across its product range. This innovation enables live, global visibility of key safety data, ensuring the highest levels of protection for operators, machines, and ground personnel.

Dan Leaney, Xwatch Safety Solutions, Sales Director, commented on the new technology, saying "The telematics system for the D2 units from PVS, branded as XW-Insite by Xwatch, represents our most advanced safety and telematics solution to date. Currently being trialled with a leading plant hire firm, a tier-one contractor, and through PVS’s own trials, this system integrates Xwatch’s precise height, slew, and RCI data with PVS Data’s cloud-based platform. It delivers seamless telematics access across fleets, covering all major equipment brands. Operators can configure and monitor critical safety parameters directly from the cab, while managers gain real-time visibility into machine performance and safety metrics, whether on-site or working remotely.

This innovation is designed to prevent accidents, reduce downtime, and enable smarter, data-driven decisions. At Xwatch, we are proud to collaborate with PVS to lead the industry in making construction sites safer and more efficient, and we look forward to seeing comparable data emerge from these trials in the coming months."

This collaboration between PVS Data and Xwatch Safety Solutions brings powerful functionality to fleet management. PVS Data’s cloud-based computing and live reporting provide seamless access to telematics across an entire fleet, covering all major brands, including JCB, Sany, Hitachi and Takeuchi to name a few. Site managers gain a clear visual overview of their machinery equipped with Xwatch Safety Solutions. They can monitor height and slew settings, view the exact weight on the hook, confirm whether stop and creep controls are active, and analyse overall capacity utilisation—all in real-time.

Page 2

Combine this safety information with real-time data such as fuel usage, engine performance, fault reporting, idle and productive hours, and carbon dioxide emissions. The result is a construction site that operates more efficiently, ensures greater safety for ground personnel, meets zero-emissions goals, reduces costs and downtime, extends machinery life, and encourages smarter machine operation.

Scott McCabe, Owner and Director of PVS Data, commented on the partnership: “Heightened safety on site has been at the heart of the industry for decades. Our partnerships with innovators like Xwatch make the platform the logical all-in-one solution for fleet health and safety. We’re excited to see where our current trials take us, advancing the platform to show a greater number of meaningful data parameters, and growing our partnership with the Xwatch team”.

Hitachi Construction Machinery UK has been at the forefront of this partnership by delivering connected technology to their customers when purchasing new machines. Their custom-branded platform, created by PVS Data, is CTFleet Link®, and it’s changed the way their customers all over the country see their fleets of mixed-brand machinery.

Stephen Creaser, Director of Product Support for HCMUK, shared his thoughts on the intuitive platform and its capabilities:

“At Hitachi UK, we’ve always been proud to take the first step to a more connected industry, a safer industry for operators and ground personnel, and a wider network of opportunities by innovative organisations. PVS, the D2 units and their platform showcasing Xwatch’s safety solutions are the logical solution for fleets worldwide, connecting OEMs in a single sign-on solution. Giving users on and off-site the ability to check on machine status and driver controls for designated safety equipment is logical and works. We’ve seen no end of evidence that the more eyes on what’s going on in the operator’s cab, the safer the construction site becomes”.

A safer site has more eyes on the machines and the controls their operators are using. A more efficient site is well-connected, with pools of analysed data readily available to support decisions about an organisation’s economic growth and future investments. Construction sites can unlock significant potential by embracing the expertise, knowledge, and safety improvements offered by Xwatch Safety Solutions and PVS Data.

Page 3

Safety in size - ensuring even the smallest machines are secure with Sunbelt Rentals and Xwatch Safety Solutions

In 2021, Sunbelt Rentals formed a partnership with Xwatch Safety Solutions to deliver the best in highperformance safety solutions. This collaboration highlights Sunbelt Rentals' commitment to safety, an important priority for the firm. The integration of Xwatch Solutions strengthens the company's efforts to supply the safest and most innovative equipment to customer sites throughout the UK.

Xwatch systems, designed to improve site safety, are installed on all types of equipment from excavators to dumpers and access equipment to piling machines. These systems aim to reduce damage to machinery and structures while prioritising the safety of the life of the operator and surrounding personnel, which is the most crucial factor of all. They are known for their reliability and simplicity, enabling customers to monitor plant machines on-site effectively. These systems can limit height, slew, and load, and the software can send alerts to the driver, particularly if there's a risk of the machine rolling when navigating inclines.

The potential risks associated with small excavators, despite their compact size, cannot be overlooked. These powerful machines can cause considerable damage, especially in congested and busy workspaces. Therefore, it's crucial to install slew limitation devices on these machines to strengthen safety protocols.

The recent installation work by Xwatch engineers

Billy Hughes and Ryan Tudor for Sunbelt Rentals involved four JCB 8026 CTS (2867kgs) mini excavators. This highlights the continuous efforts to maintain high safety standards even on smaller excavators.

Dan Leaney, Xwatch Sales and Operations Director, said, "Every piece of equipment, regardless of its size, must meet the highest safety standards. Over my years in the industry, I've witnessed firsthand that even the most compact machines can lead to significant issues if they lack proper safety features. This reality drives home the critical need for us to equip every machine with the appropriate safety solutions.

It's not just about compliance or ticking boxes; it's about real-world impacts. Ensuring the safety of all machines is crucial to protect workers, bystanders, and the surroundings from potential harm. At the end of the day, our goal is to create a workplace where everyone returns home safely, and that starts with making sure every piece of machinery, no matter how small, is as safe as it can be."

Dan added, “This commitment to safety is why Sunbelt Rentals has been the ideal partner for us. They share our vision of ensuring every machine is as safe as possible, making our partnership a perfect match in working towards and ensuring a safer workplace.”

Warwick Ward Machinery selects Xwatch Safety Solutions for key drainage projects

Warwick Ward (Machinery) Ltd has recently fitted Xwatch Safety Solutions part of Hexagon XW1 height restriction systems on two Case CX130E machines, both heading to work on drainage projects. Xwatch engineer Billy Hughes completed the installations. Robert Hughes, Senior Sales Manager (North West and Midlands) at Warwick Ward (Machinery) Ltd, placed the order. When asked why he chose Xwatch, Robert said:

“We chose Xwatch for their customer-first approach, which aligns with our commitment to being customerdriven. The support we receive is outstanding, and the Xwatch system quality is second to none. Xwatch offers a cost-efficient solution that doesn’t compromise performance. Our customers appreciate the intuitive and simple interface, making the system incredibly user-friendly—crucial in ensuring operators can work efficiently and safely. Xwatch is the obvious choice regarding height control, particularly in complex environments like drainage projects, where a machine may be working under powerlines and trees, where precision and reliability are key. We’ve specified products from the Xwatch suite of safety systems, including height, slew and RCI, many times, and the systems have consistently delivered exactly what we need for projects like these.”

The XW1 system can be configured to work on various articulated hydraulic plants. Height limitation is controlled using proportional soft-stop hydraulic valves, ensuring precise and repeatable performance without detriment to the machine. This makes it ideal for tasks that require careful height management, such as working under powerlines or around trees. The system is fail-safe and fully automatic, with function selection never more than two key presses away, giving operators the confidence to focus on the job without worrying about operational complexity. To find out more about the XW1 visit XW1 Series Protect your working Height Excavators & more.

“We’re grateful to Warwick Ward for their continued trust in Xwatch Safety Solutions. It’s always a pleasure working with a company that shares our commitment to quality and customer satisfaction. We look forward to supporting their projects with the reliability and innovation that Xwatch is known for,” said Jemma Dycer Hopkins, Sales and Operations Manager at Xwatch.

Page 6

Keeping HS2 (High Speed Two) Ltd tunnelling operations safe

Gareth James from GJ Plant & Vehicle Solutions recently spent a few days at the HS2 Old Oak Common site in West London, working on behalf of Fitzgerald Rail & Construction Equipment to fit two Hitachi Construction Machinery ZX350 excavators with advanced safety systems.

The excavators are part of an interesting operation, processing London clay from tunnelling works by RFS Works Ltd.

The clay travels along a 1.7-mile conveyor to the Euroterminal site, and to protect the conveyor structure, an Xwatch Safety Solutions part of Hexagon XW5 system and Leica Geosystems part of Hexagon GPS, have been integrated to create a 3D collision avoidance zone.

This isn’t your usual day on the job—it’s great to see Xwatch being installed on an out of the ordinary project and see technology making a real difference in a project as significant as HS2. Thanks Gareth James for sharing your pictures - brilliant as always.

MDig leads the charge: Another 30 Xwatch XW5 systems installed on Komatsu Machines for tier-one contractor

The Xwatch team has been exceptionally busy behind the scenes, and we're aware that our valued followers have been missing our updates (and we've missed you too). So, we're excited to share a little snippet of what we've been up to. As we speak, 30 of our Xwatch XW5 'Full Monty' kits are currently being installed. Our partners, MDiG, are hard at work fitting these systems onto Komatsu Construction machines for a premier tierone contractor. We promise to share some "kit pics" once the installations are complete.

The XW5 system is becoming increasingly popular among tier-one contractors, and it's easy to see why. It creates a total safe working envelope around both the machinery and the operator, managing the machine's height, slew, and rated capacity indication. This ensures a comprehensive safety solution, covering every possible scenario for both machine and operator security, thereby offering complete peace of mind. A standout feature of the XW5 is its Rated Capacity Indicator (RCI). The RCI is crucial for the safe operation of lifting equipment within the machine's working envelope. It continually measures height, radius, and load, allowing operators to maximise lifting capacity while staying within the machine's Safe Working Load (SWL).

Seamless control and safety with 3D avoidance zones: Xwatch XW5 and Leica integration

XW5 Rated Capacity Indicator & Integration with Leica Machine Control 3D Avoidance

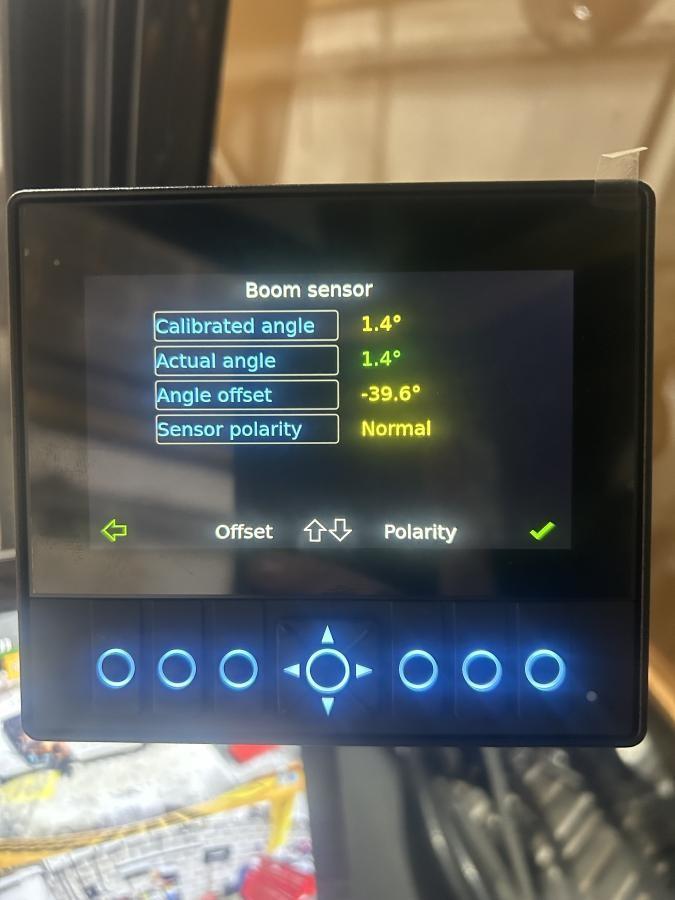

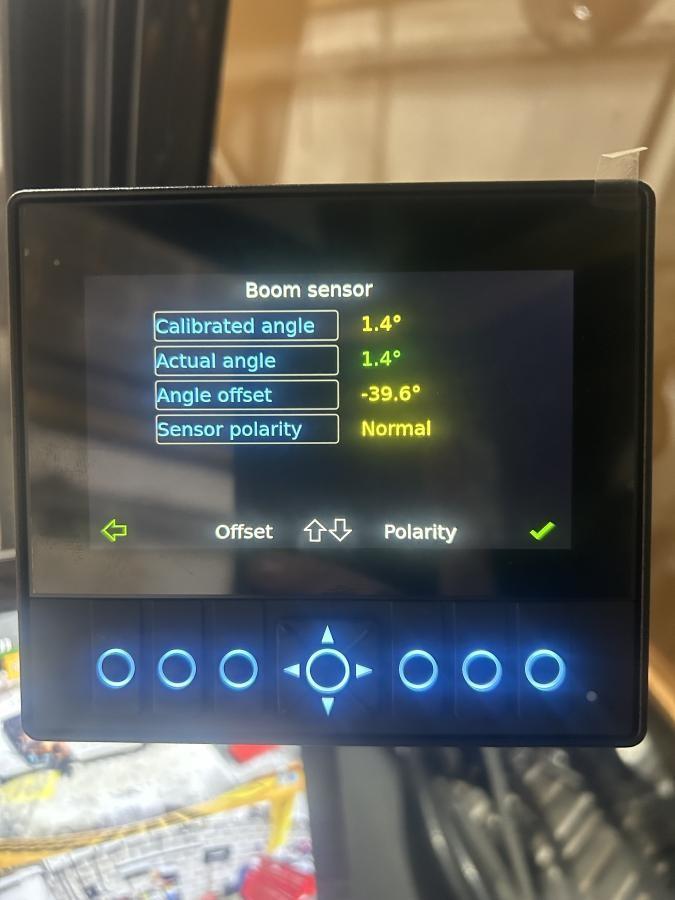

The Xwatch XW5 delivers overload (RCI), height, and slew/swing limitation, all controlled via proportional softstop hydraulic valves, ensuring precise and repeatable performance without compromising the machine’s capabilities.

Motion control extends to managing machine movement, including track drive, swing/offset boom, and blade down movement (if applicable), when integrated with Leica’s MC1 machine control.

The Leica MC1 machine control software, paired with the 3D avoidance zone system, allows users to create or import avoidance zones both above and below ground. As the machine approaches an avoidance zone, the system takes control of its height, depth, and slew, automatically triggering the hydraulic functions to slow and eventually stop the machine before breaching the zone.

The proportional hydraulic control ensures a gradual slowdown, preventing sudden halts. Additionally, the excavator’s track motion can be disabled to prevent breaching environmental areas, designated no-go zones, or obstacles like overhead power cables or gantries. Once the machine is stopped, the Leica MC1 software triggers a visual warning that must be acknowledged before continuing any other operation.

This integrated system reduces downtime, unexpected costs, and enhances safety for both operators and workers in the vicinity, providing a repeatable, easy-to-use 3D avoidance solution.

In collaboration with PVS (Plant & Vehicle Services), the Xwatch XW5 and Leica MC1 integration offers enhanced telematics capabilities. P&V Solutions’ advanced telematics systems provide real-time insights into equipment performance, location tracking, and preventative maintenance. This partnership delivers a comprehensive safety and operational solution, combining 3D avoidance technology with intelligent data monitoring to optimise fleet management, reduce downtime, and improve on-site safety.

To find out more visit XW5 Series 3D Avoidance

Xwatch fleet upgrade for Flannery Plant Hire

Flannery Plant Hire has consistently demonstrated its commitment to innovation and safety by continuing to upgrade its fleet with cutting-edge technology. A recent example is the upgrade of a Caterpillar Inc. 308E excavator in Manchester, where Xwatch engineers Ryan Tudor and Ryan Andres installed the Xwatch Safety Solutions part of Hexagon XW5 safety system, preparing the machine for integration with Leica Geosystems part of Hexagon's MC1 machine control software.

The Xwatch XW5 system offers advanced safety features, including real-time monitoring and control of machine movements, which significantly reduce the risk of accidents on construction sites. This system is designed to integrate seamlessly with Leica's MC1 platform, a comprehensive solution that consolidates all machine applications to guide and automate heavy construction equipment. The MC1 software enhances operational efficiency through features like Modify Models and surface logging, supporting the digitisation of the heavy construction industry.

The machine also benefits from the Xwatch EOHC (Electric Over Hydraulic Control) box which integrates four motion controls into one streamlined unit, simplifying operations for operators and technicians. While some excavators offer limited control options, EOHC’s versatility and efficiency are expected to make it a new industry standard. The system modernises excavator controls by replacing traditional hydraulic components with a compact electric unit. This shift makes installations faster and more efficient, setting a new benchmark in equipment upgrades. Unlike basic systems, Xwatch’s EOHC offers precise proportional control, which significantly improves the operator’s experience by providing smoother and more responsive handling.

Once integrated with Leica's MC1 machine control software, this setup becomes an even more powerful tool. The MC1 platform consolidates all machine applications into a single interface, providing functionalities like Modify Models and surface logging to guide and automate heavy construction equipment. This cohesive approach enables operators to handle complex site tasks with confidence, accuracy, and enhanced safety.

With engineering expertise from Ryan and Ryan, Flannery Plant Hire ensures that every machine upgrade reflects the highest standards of technology and safety, meeting the demands of modern construction projects head-on.

Page 9