With over 100 years of technical service expertise, LINC Systems application experts provide end-toend packaging service and solutions to help you drive efficiency, minimize downtime and reduce costs in your packaging operations.

We are the industry leader in packaging solutions, supplies and automated equipment designed to lower your total cost of packaging. LINC partners with the most innovative packaging equipment and material manufacturers on the planet with one goal in mind:

your

“Our wrapper installation project went great. Jim and the mechanical foreman work very well together. The old wrapper was out on Saturday and the new wrapper was installed. Sunday they anchored down the equipment and did the safety fencing. The new wrapper was running on Monday morning with no issues. Jim did a great job again for us.”

- Vern Adkins, Bay State Milling“Our LINC tech listens and understands our needs and how we are always in a pinch to make sure equipment continues to operate. He is definitely one of the most approachable and friendly techs that I have encountered. He gets the job done and clearly communicates what we need to do to have our equipment repaired.”

- Tiffany Tate, PAC WWWe are a full service solution in Packaging offering Packaging Materials, Automated Equipment, Marking & Coding, Technical Service, Systems Integration, Safety and Industrial Supply.

We offer the highest-quality brands of industrial packaging equipment, including but not limited to:

For more than 45 years, LINC Systems has partnered with the leader in poly-bagging equipment innovation, Automated Packaging Systems. Together, we offer a wide range of plastic bagging and sealing systems; from simple tabletop models, to semi and fully automatic bag on a roll packaging systems and bagging equipment.

MARKETS SERVED:

Aerospace and Defense

Apparel and Accessory

Automotive

Electronics

Hardware and Fasteners

Healthcare

Hobby and Craft

Household Products

Mail Order & Pharmaceutical Fulfillment

Personal Products

Pet Products

Toys

Fresh & Frozen Snack Foods

Meat Products

Fresh Produce

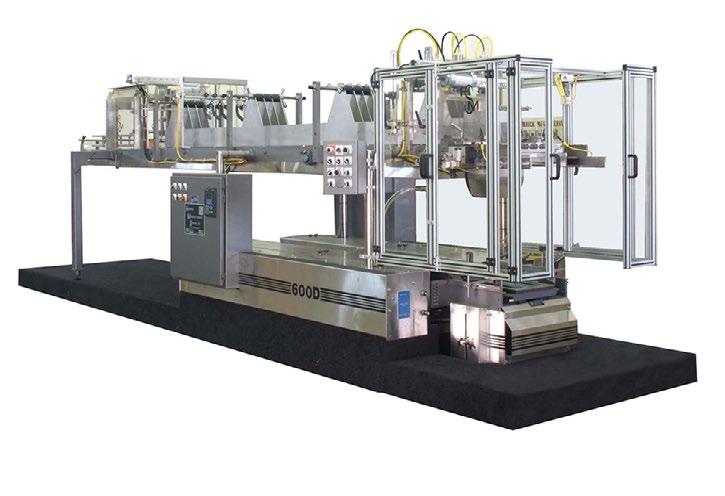

The FAS Sprint Revolution Bagging System brings new levels of speed and versatility to demanding packaging environments that require daily washdown procedures. Operating at speeds up to 900 inches per minute, this state-of-the-art packaging system is designed for the ultimate in bag packaging flexibility, functionality and reliability. This highly flexible design accommodates one or more operators or infeeds and a wide variety of products and bag sizes.

View Online

We offer a wide variety from Automated Packaging Systems of poly film types and special features that improve the quality of your bag packaging, protect your product during shipping, and make your package stand out from the crowd.

View Online

AUTOBAG® brand PS125 tabletop bag sealing machine brings speed and quality to hand load applications. It is ideal for low- to mid-volume packaging operations due to its compact design and plug-and-play configuration. Operating at speeds up to 25 bags per minute, it is simple to operate with a user-friendly display that enables easy access to operating parameters, job set-up, job storage, and on-board system diagnostics.

AUTOBAG® brand 500 bagger is an advanced automatic filling and sealing machine designed for reliability, flexibility, and optimizing packaging throughput. Capable of cycling over 100 bags per minute, this system delivers maximum machine uptime while lowering total cost of ownership. Configurations for left- or right-hand access to the HMI, cycle switch, and bag loading area, improve ergonomics and operator productivity.

View Online

LINC Systems partners with vendors such as Wexxar Bel to provide multiple unique carton sealing machines for your business. Depending on what your needs are, we can serve you with a wide variety of options that deliver high-quality, semi or fully-automatic, top or bottom sealing, and random or uniform sealing.

A variety of Wexxar Bel case and tray-forming and packing options are also available to you that include both semi and fully automatic carton forming machines. These systems “yield the lowest cost of ownership through greater dependability, higher productivity, maximum throughput and a high standard of safety.”

MARKETS SERVED:

Automotive

Hardware

Bakery

Beverage

Confectionary/Snacks

Dairy

Furniture

Household Goods

Electronics

Meat

Seafood

Retail Ready

Personal Care & Cosmedics

Pharmaceutical

Medical

Produce Agriculture

Textiles

Apparel

A compact and ergonomic packaging solution for manual hand pack lines. When combined with a BEL case sealer, it allows one operator to form, pack and seal corrugated cases in a single operation. It’s ease of maintenance and operation is also what makes this the perfect fit when looking for an entry level machine.

View Online

Provides tray forming solutions in many industries including agriculture, baking, food processing and consumer good applications. Through use of our proprietary mandrel and compression configurations, the TF-200 forms a wide range of tray styles and sizes. With multiple footprint configurations, your 200 Series can be configured to meet your current and future tray forming requirements.

A revolutionary, fully automatic tape case sealer featuring Wexxar Bel’s Snap Folder technology. This ultra-safe design allows the machine to be versatile and compact without the need for excessive guarding. This allows the machine to fit in operations with limited floor space and also keeps the machine easy to access and maintain.

DOWNLOAD BROCHURE

View Online

Shurtape’s Tape Head Program may be just right for you. Increase production, decrease downtime, and experience the confidence of using our SP Series Tape Heads with HP Series carton sealing tapes.

DOWNLOAD BROCHURE

Random, and uniform case sealer. It is able to adjust to the width and height of the inserted case and features locking movements for safety in case of sudden air loss. The BEL 180’s ability to lock into position with the push of a button for uniform sealing also makes this machine very convenient and adaptable to fluctuations in product demand.

These Case Erectors deliver quick and trouble free changeovers, consistently square cases, fewer wear parts and less maintenance –for maximum operational efficiencies in your end-of-line packaging operations.

Shurtape Case Erectors offer:

• 40-50% fewer parts than competing machines

• Dependable opposing-cup case opening

• Active case squaring for square cases, every time

• Secure Seals, Every Time.TM

LINC Systems is a distributer of Hamrick case packing equipment. Hamrick case packers are manufactured with three principles in mind; simplicity, versatility, durability. Designed with simple operator controls, the functionality to incorporate different product styles, and engineered to the highest durability standards in our industry. Our case packers have speeds ranging from 15 – 60 cycles per minute and can run most rigid containers (metal, glass, and plastic) in various pack patterns.

MARKETS SERVED:

Food and Beverage

Chemical

Personal Care Products

Detergent

Ecommerce

Pet Food and Treats

Pharmaeutical

Automatic Drop Packer 20 cycles per minute and medium to high production volume.

Automatic Drop Packer 30 cycles per minute and medium to high production volume.

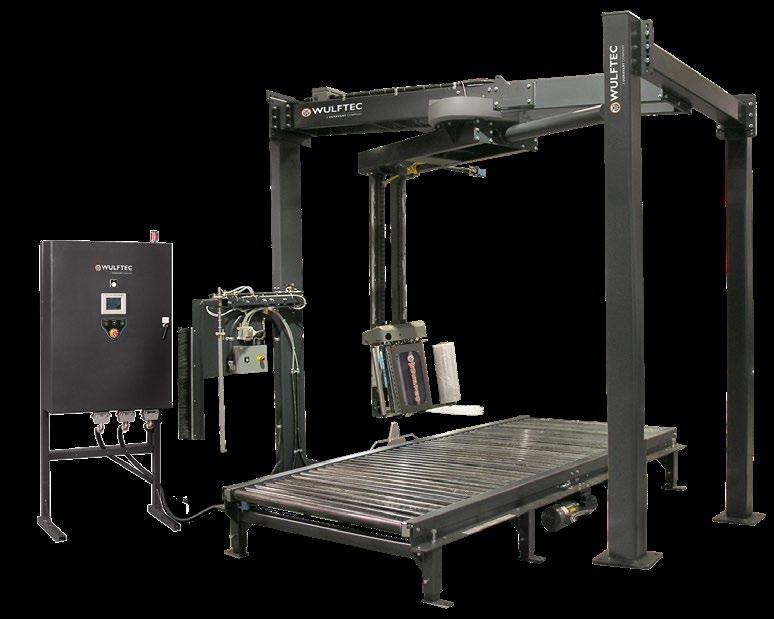

LINC Systems offers stretch wrapping machines for wrapping industrial loads to secure them for transport. We offer full line of end-of-line fully automatic stretch wrappers and semi-automatic stretch wrappers. These include rotary turntable stretch wrappers, rotary tower stretch wrappers, orbital stretch wrappers, and custom engineered automatic stretch wrapping systems to meet the end of line stretch wrapping needs of our customers.

We carry stretch wrapping machines from top-rated brands including, but not limited to, Orion, Robopac and Wulftec. Below are some examples of machines LINC carries.

MARKETS SERVED:

Distribution & Logistics

Food & Beverage

Co-packing

Consumer Goods Door & Window eCommerce

Construction Materials Manufacturing Carpet

Packaging And more!

Reduce Film Usage, Paper Core Waste, Landfill Space, Energy Savings and Carbon Dioxide Emissions with a LINC Systems Film Analysis on your stretch wrapping systems. Call Our Experts Today!

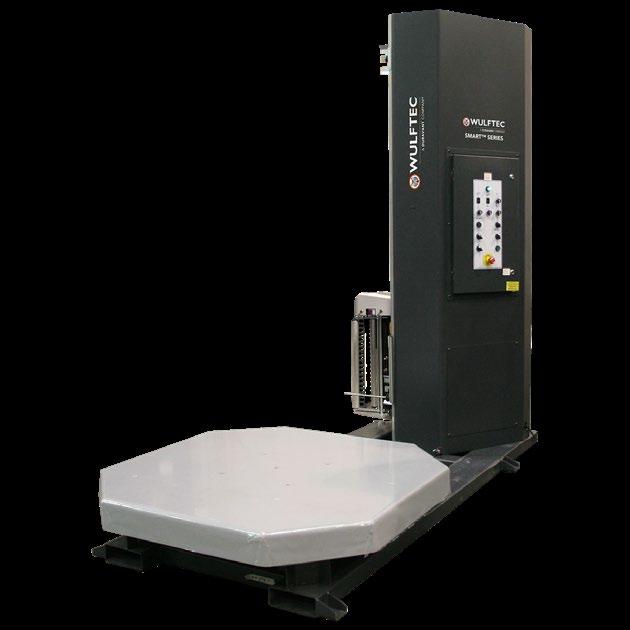

Wulftec Smart Series Semi-Automatic Stretch Wrappers: SML 150, 200, SML-EXT, SML277, SMH150, SMH 200, SMH-SPL, SMH-HVY

Wulftec’s exceptional performance characteristics ensure reliability in the harshest conditions. It is the most robust stretch wrapper in packaging equipment and is backed by a 5-year unlimited cycle warranty, 10-year warranty on the structural frame, 10-year warranty on 25” ring gear bearing (SMH-HVY) and a Lifetime warranty on prestretch rollers’ blue compound.

View Online

An entry level, semi-automatic turntable style stretch wrapping machine for economical and efficient unitization of pallet loads with stretch film. The Sentry LP can dramatically increase efficiency and lower film cost per load, especially compared to manually applying stretch film by hand.

Technoplat 708 CS (clamp, cutting and sealing unit) or CW (cut and weld) semi-automatic turntable stretch wrapper cuts and attaches the film tail to the load at the end of the wrap cycle for superior load containment. The Technoplat 708 CS/CW pallet wrapper saves two minutes of labor per load by keeping the operator on the fork truck. For the average customer, this translates to labor savings of $29,000 over five years and $60,000 over the life of the machine!

The Robot S7 can be up and running in less than 30 minutes when installed by a certified LINC Systems technician. It’s easy to use thanks to the intuitive seven (7)-inch icon-driven color touchscreen. The portability alone can deliver 25% or more in productivity improvement and is a GREAT solution for customers who have extremely large loads, as it can wrap loads of any length and width. DOWNLOAD

View Online

Semi-Automatic

WRT 100, 150, 175, 200

Rotary arm models provide increased flexibility for unique load shapes or weights. They can wrap almost anything. Since the load remains stationary, it is ideal for wrapping very light, very heavy tall or unstable loads. DOWNLOAD BROCHURE

View Online

DOWNLOAD BROCHURE

View Online

Wrappers: SMLCA 277, WCA SMART, SMHPA 200, SMHPA 300, SMLPA 200

Fully Automatic turntable stretch wrappers are ideal for wrapping stable loads of under 8,000 lbs. They are typically less expensive than rotary arm models and have a smaller footprint — a definite asset when space is at a premium.

Wrappers: WCRT 175, WRTA 100, WRTA 150, WRTA 175, WCRT 200, WRTA 200

Maximize throughput and efficiency. They take care of everything; you only change the roll of film. An automatic stretch wrapper will save significant time and money. They can keep up with even the most demanding production rates. They can wrap almost anything. Since the load remains stationary, they are ideal for wrapping very light, very heavy, tall or unstable loads.

DOWNLOAD BROCHURE

View Online

Engineered for long-term reliability in even the harshest industrial environments so you can count on maximum uptime. Additionally, the film delivery system on the FA will help you reduce cost with every load you wrap. With a standard film prestretch rate of 260% you’ll not only reduce cost by using less film, the film on the load will be stronger. DOWNLOAD

The Orbit R horizontal stretch wrapper line provides high-speed and high performance and can be added to existing work cells or integrated lines. The Orbit R is a rotating ring machine for spiral wrapping elongated products. The machine is equipped with electro-welded mesh safety guards to protect the operator during operation. DOWNLOAD

DOWNLOAD BROCHURE View Online

The WRWA-200 carriage features a loading clamp and rapid-lock film roll device that make loading a snap. Everything can be done in the same area, with easy access to the carriage for simplified re-loading. Maintenance free clamping and cutting device. The user-friendly digital panel interface offers multiple mode selection for more flexibility. Just set, load and go!

LINC Systems offers a variety of stretch film products for containing loads in industrial packaging, including hand stretch film, machine stretch film and stretch film dispensers. We carry these products in multiple gauges and sizes to accommodate various applications.

We carry stretch film products from top-rated brands like Berry and Paragon Films.

DOWNLOAD BERRY BROCHURE

DOWNLOAD PARAGON BROCHURE

DOWNLOAD BERRY BROCHURE

DOWNLOAD PARAGON BROCHURE

Film savings and reduction from pre-stretch options. Contact LINC for more info.

LINC Systems offers a variety of checkweighers for weighing your packaged products precisely and accurately. We carry a range of checkweighers to suit the needs of different industries, such as food and beverage, cosmetics, and pharmaceuticals. The right checkweighers can improve your efficiency and reduce costs.

We carry checkweighers from top-rated brands like A&D Weighing.

MARKETS SERVED:

Produce

Special Candies

Bakery Confectionary

Dairy

Bread

Bulk Protein Powder

Meat Trays

Automotive

Hardware

Household Goods

Electronics

Retail Ready

Personal Care

Cosmedics

Pharmaceutical

Medical Agricultural Botlled Paint Samples

If you are looking for a mighty machine with a small form factor, the 600g checkweigher is the right choice. This system can achieve speeds up to 400 pieces per minute and has an overall system length under 3 feet.

View Online

There’s no tradeoff necessary: simplicity and best-in-class precision with the 2,000g Checkweigher. The in-motion checkweigher is versatile with dual range capacity and high repeatability.

Boost productivity and uptime with an automated palletizer from LINC Systems. You’ll see an increase in accuracy and consistency while significantly reducing labor requirements.

Palletizing machines have low maintenance needs and deliver a high rate of speed — up to four cycles per minute for some models.

Save time and money while realizing a quicker return on your investment with a palletizer from LINC Systems.

Food and Beverage

Agricultural

Lawn and Garden

Paint

Building Materials

Animal Food Soils

Salt

Chemicals

Concrete

Ecommerce

Distribution Fulfillment

Agricultural Feed

Automotive

Fully automatic case, tray, bundle or bag palletizer systems. Only a single operator is required to load and unload pallets. The system eliminates labor intensive hand stacking and can deliver up to 50 cases per minute depending on layer patterns.

View

Arpac Brand Robotic Palletizer Model is a pre-engineered robotic palletizing cell that automatically stacks and wraps pallets to exact specifications. End of Arm Tools (grippers) are matched to the application and range from simple suction cups and vacuum plates, to fork and bag style tools. Custom tool designs are also available to accommodate virtually any product. The system can accommodate cases, trays, bundles, bags, etc. Speeds vary by application; however, rates up to 60 pieces per minute are possible.

LINC Systems offers Arpac, Kallfass, Seal-A-Tron, Texwrap and Tekkra shrink wrapping and shrink bundling systems for a wide variety of shrink packaging applications, such as single packs, multi packs, display packaging as well as protective packaging.

We also offer full body, tamper evident, and multi-packing solutions shrink sleeve equipment and installations. Tripack full body sleeve labeling, tamper evident banding and multi-packing equipment is the best in the industry. Our extensive experience, combined with the design and performance of Tripack equipment, makes us the right choice for a wide range of markets and customers.

Regardless of the volume of products to be packaged, there are a variety of shrink systems available to match your particular needs.

Food & Beverage

Apparel & Accessory

Automotive

Electronics

Hardware

Fasteners

Healthcare

Hobby & Craft

Household Products

Mail Order &

Pharmaceutical Fulfillment

Personal Products

Pet Products & Toys

This continuous motion bundler is capable of wrapping up to 45 products per minute, depending on product size. This system will wrap any unitized or tray-packed product, including random pack sizes. The 45TW Model guarantees years of reliable service and is ready to ship in as little as two weeks from the order date.

View Online

The Arpac Brand 708HBD Model is a right-angle, intermittent motion shrink bundler designed specifically for today’s pharmaceutical, health and beauty industries. Ultra-compact in design and economical in price, the 709HB Model is capable of shrink wrapping up to 20 bundles per minute in a single lane configuration. This model uses motorized pulleys rather than separate drives and chain. This allows for clean, safe operation and a slim machine frame.

A hybrid that closes the gap between intermittent-motion and continuous-motion machines of today. The smooth product transport through the machine minimizes slippages of stacked products and problems with slightly unstable collations of products. The UNIVERSA 500 SERVO also incorporates the features of the UNIVERSA 400 that provide an almost effortless product changeover with only a few adjustments.

DOWNLOAD BROCHURE

View Online

This shrink system has a chamber with two of Kallfass’ patented concentric nozzle heating systems which provides an outstanding shrink capacity. Film is shrunk tightly to products, even when they have complex and irregular shapes. This optimized shrink process consistently delivers high-quality display packaging when polyolefin films are used.

The 100 Series is designed to shrink wrap products that, by themselves, are stable enough to transport on a conveyor and transfer into the film section without assistance or tipping over. Ideal products are boxes, loaded trays, or anything that holds itself together well. Available for use in a wide range of industries, this machinery offers a variety of features to wrap products quickly and precisely.

DOWNLOAD BROCHURE

View Online

DOWNLOAD BROCHURE

View Online

The intermittent motion 200 Series is perfect for taking one product that is unsupported (not in a tray or on a pad) and turning it into a multipack. There are a variety of standard and custom collation systems available to achieve the desired multipack configuration. The product is contained and assisted through the entire shrink wrapping process.

DOWNLOAD BROCHURE

View Online

This 3 L-Bar Sealer and Shrink Tunnel can hold up to a 20” W roll of plastic, has Tru-Temp digital seal wire control, and has a proximity sensor switching for impulse seal wires. Additionally, it provides a cool down cycle, digital temperature controls, and surround airflow on all 4 sides.

DOWNLOAD BROCHURE

View Online

Seal-A-Tron S-2330 Sealer & Shrink Bundler

Semi-Automatic L-Bar Sealer is equipped with proximity sensor switching for impulse seal wires, Tru-Temp digital seal wire control, and motorized seal table adjustment. It provides premium machinery at a reasonable price with superior benefits.

DOWNLOAD BROCHURE

View Online

Seal-A-Tron T-2213 Sealer & Shrink Bundler

This Production Shrink Tunnel comes with a surround air flow design, a cool down cycle, and a Kool-Touch exterior surface. With additional options available and premium benefits, this machine will allow for safe productivity and create increased performance.

Automatic L-Bar provides V-grooved conveyor belts which reduces belt ware, variable frequency driven motor controls, and auto reverse for tall packages. The machine also features the new electronic seal stroke.

LINC Systems offers shrink film from Intertaoe Polymer Group (IPG). For the past 25 years, IPG has been shrink wrapping products throughout the world with films produced at their manufacturing sites in the US and Portugal. IPG’s Research and Development teams continue to bring new and improved products to market.

As a long time distributor of Signode and Samuel Strapping Systems, LINC Systems has the strapping product knowledge and technical expertise to provide the cord strapping, polyester strapping, polypropylene strapping, plastic strapping, and steel strapping solutions for the most challenging of strapping applications.

We offer an extensive line of cord, poly, plastic, and steel strapping equipment, ranging from simple strapping hand tools to fully automated strapping machines. We will match them with the correct strapping materials, resulting in an optimal, high-efficiency solution for your business.

Lumber

End-of-Line Packaging

Food & Beverage

Automotive

Electronics

Hardware & Fasteners

Healthcare

Household Products

Industrial Products

Mail Order & Pharmaceutical Fulfillment

Plastic strapping machines offer a fully automated inline solution, a walk-up, a side-seal and a small anvil system. Designed for integration into many industries and applications, the SGP features stainless steel options.

Built with few wearing parts, the TableTyer requires very little maintenance. The TableTyer’s internal strapping dispenser helps to conserve floor space. The TableTyer features a flexible design for varying applications. Strapping guides are adjustable for strap sizes from 1/4” to 1/2” and the height is adjustable for integration into varying production lines.

Trackless Strapping Machine is completely portable and very compact, this tabletop style strapping machine requires only six feet of floor space yet can strap virtually any shape or size of product bundle or package that can be placed on the machine. The P100 will automatically tension, heat seal, cut the strap, and immediately pre-feed for the next application.

World class high speed automatic strapping machine that is known to be the most operator friendly machine in its class. The compact frame of the P702-59 features an inside mount strap dispenser that hinges up for auto strap loading at waist height. They also feature quick release feed guides for immediate access to the strap feed system with the need for tools.

With a wide variety of strapping products, we can provide you with the equipment and necessary materials you need for your business’s exact applications. Our strapping materials from Signode, Samuel, and Carolina Strapping have the capacity to take on your specific jobs.

The Samuel Packaging Systems Group is a long-standing manufacturer of high-quality strapping products and is proud to introduce our STL-SERIES tool line. We believe that we have an obligation to our customers, and the packaging industry, to deliver continuous product, equipment, and tool innovation. The STL-SERIES provides customers with a high-quality, ergonomic, and reliable hand tool line for any application.

Manual Combination Tensioner and Sealer

FEATURES

• Adjustable to fit 1/2 - 3/4”

• SD/HT up to .025

• Rolled Edge at seal

For more information on the full STL-Series contact us at 800.252.5894.

Battery Operated Plastic Strapping

Tool for Polyester and Polypropylene

FEATURES

• Feed Wheel Release

• Soft Mode

• Minimal Baseplate

• High Battery Amps

• Perfect Ergonomic Balance

• Multiple Operator Settings

• Lightest Line Up in the Market

• Low Cost of Ownership

YOUR SUCCESS IS OUR BUSINESS

Through process review and packaging trials, LINC Systems helps determine the correct product to match your void fill and protective packaging needs. Whether you are a smaller user shipping 5 to 10 packages per day or a user with multiple packing & shipping stations, we can provide the ideal void fill and protective packaging solutions for your specific void fill application. LINC Systems will help keep your products safe in transit with some of the most sustainable products in the market from top brands including STOROpack.

“Storopack is the first manufacturer with a fully integrated and patented production of the new raw material rEPS. It consists of 100% recycled EPS or PS and the protective packaging can also be produced with up to 100% content using this raw material.” - Storopack’s Sustainability Report 2020

MARKETS SERVED:

Distribution

eCommerce

End-of-Line Packaging

Food & Beverage

Mail Order

Automotive

Pharmaceutical Fulfillment

Electronics

Hardware & Fasteners

Healthcare Household Products

Shipping goods are optimally protected with the environmentally friendly paper pads of the STOROpack PAPERplus® Track. Depending on the desired cushioning characteristics, the crimp of the paper pad can be tailored to any product in advance. Users also benefit from the blade-free technology of perforated paper and mechanically separated paper pad.

AIRplus® film products are an economical choice for a diverse range of protective packaging applications. With options from square bags, bubble film, cushion film and more, you won’t have to worry about your packages getting damaged.

The FastWrap system produces filled bubbles and tubes used for wrapping, interleaving and block-and-brace applications. FastWrap secures and cushions your products while in transit, reducing returns and increasing customer satisfaction. AirPouch FastWrap cushioning bubbles feature our patented, channel-filled honeycomb design, which allows multi-direction wrapping and improved product protection.

With a comprehensive portfolio of machines and paper, inflatable, and foam options, our void fill fits every application - void fill, cushioning, or blocking and bracing. With your packing team in mind we’ve created the safest, most reliable and easy to use paper, inflatable, and foam systems on the market.

These edge protectors serve a variety of packaging functions including edge protection, pallet guarding, unitization, load stability, beam strength, and stacking strength. Angleboard Anglewrap is made from 100% recycled materials and is 100% recyclable.

Cornerboard edge protection is a high-strength, moisture-resistant corner protector made of recycled paper and plastic making it ideal for products that are exposed to the elements and shipped on flatbed trucks, stored outdoors, or exposed to high humidity. Cornerboard is made from 100% recycled materials and is 100% recyclable.

VBoard stabilizes and contains loads, distributes load weight evenly, and easily combines with other materials to create custom packaging solutions.

NotchBoard is VBoard with precise die-cut notches and scores that permit it to be hand-folded quickly into a 90-degree, one-piece edge guard and corner protector often used for custom packaging applications. NotchBoard is shipped and stored unfolded for freight savings and storage efficiency.

UChannel is engineered to deliver precise three-sided edge protection for windows and doors, including garage doors. Its unique single-piece construction can be formed into a wide variety of widths and leg lengths, offering a cost and time saving custom substitute for expensive wood crates or hard-to-handle corrugate. UChannel is manufactured using laminated paperboard up to 18” wide, and also available in asymmetrical leg width combinations that allow for highly specialized applications. Standard caliper options range from 0.080” to 0.600”. Standard leg lengths extend to 300”, but longer custom lengths are also available.

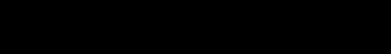

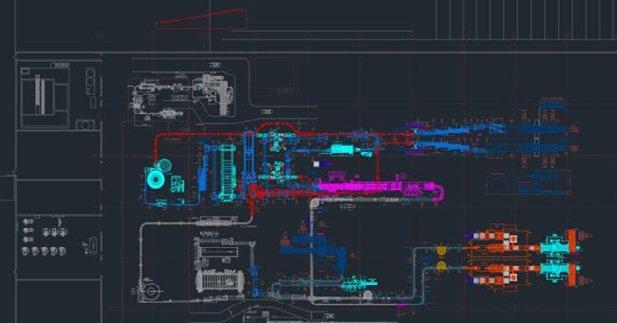

LINC Systems can provide custom packaging solutions or integration for your situation and industry. Many production lines call for such specially designed solutions to accommodate their products, materials, capacities and more. Customizing your packaging system and/or integrating new packaging equipment can lead to greater efficiency, faster production and better results on your production line. Such a solution, designed to fit your exact needs, saves on costs and helps you fulfill your production goals.

Our Technical Service Team offers full line integration services. If you need a line to include a new case packer, palletizer, and stretch wrapper. For example, Linc Systems can provide the equipment, install the equipment, and provide the line integration services to allow this equipment to communicate and to operate as a system. We can provide all the equipment including the necessary conveyor and controls to allow multiple machines to work for you as a finely tuned system.

LINC Systems Service Team can provide line drawings to help you get the best line layout for the equipment you want and the space in which you have available. We can provide conceptual drawing of a line to create solution, or we can add our equipment to your existing production line to show you different options that will help you to provide the most efficient flow for your facility.

We design and build control panels for equipment on the entire production line. We can help you size and spec out the panel as well as supply the components and build the panel. We also offer the capability to program the PLC or PC to your specification. (See also Markem Imaje CoLOS Software in marking & Coding.)

Hytrol Conveyors have been producing conveyors and other material handling solutions since 1947. Our products are known for their high quality, dependability, durability, and timely delivery. Hytrol’s product line offers solutions for a variety of product weight and sizes that include accumulation, sortation, transport, pallet handling, and more.

Promach’s Shuttleworth Slip Torque Conveyor is not only gentle on products, but also integrated machines and operators working within the production line. The inherent low backpressure and low friction protects integrated packaging machinery from over feeding. Our patented surface is safe to the touch. Rollers stop when a hand is placed on the surface while our frame designs allow for better ergonomics for operators.

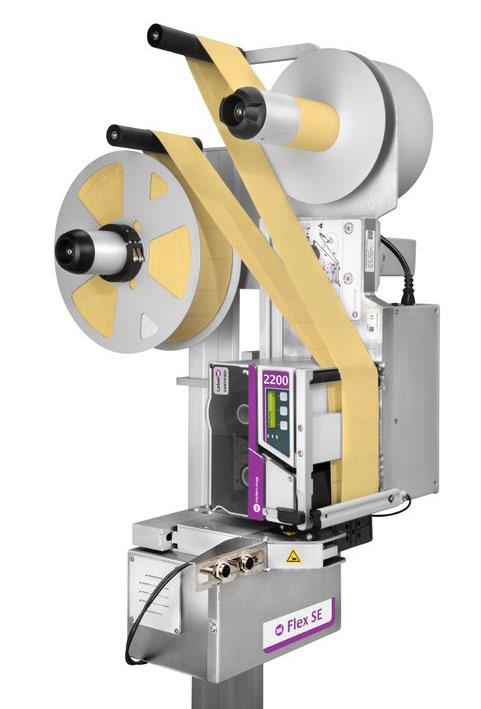

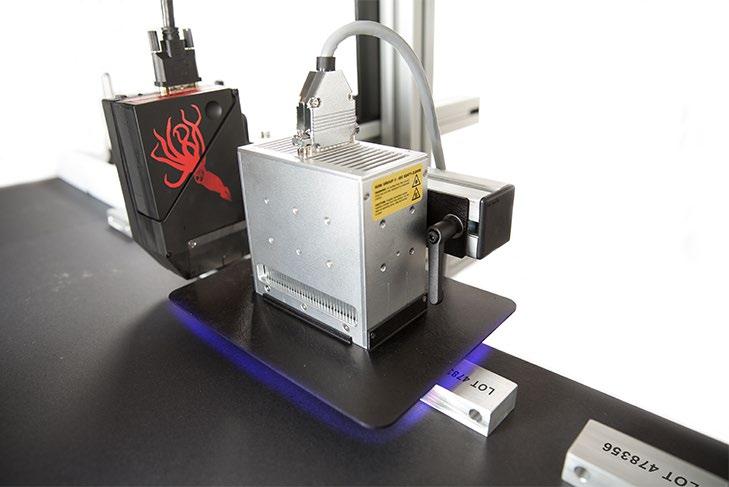

LINC Systems is a global provider of marking and coding, labeling equipment, thermal transfer and print systems. Over the decades we have secured an offering of some of the industry’s most recognized systems to help you find the best solution to nearly any production challenge or application.

LINC Systems is a distributor of marking and coding, labeling equipment, thermal transfer and print systems from Markem Imaje, Foxjet, FlexPackPRO, Zebra and Squid Ink. As a distributor for these companies, LINC Systems is proud to offer the latest technological advances and solutions to our valued business partners.

Food & Beverage

Automotive

Electronics

Hardware Fasteners

Healthcare

Household Products

Pharmaceutical

Personal Products

Pet Products

Corrugated Boxes

Contract Packaging

FoxJet’s Marksman ELITE is a flexible stand-alone industrial controller that is capable of operating two production lines simultaneously and up to four printheads. The Marksman ELITE controls ProSeries Trident based printheads to print industrial compliant barcodes, graphics, and/or alphanumeric characters on porous materials and cases.

DOWNLOAD BROCHURE

View Online

FoxJet’s Marksman Matrix™ is a flexible stand-alone industrial controller that is capable of operating two production lines simultaneously and up to four printheads. The Marksman Matrix™ controls ProSeries Trident based printheads to print industrial compliant barcodes, graphics, and/or alphanumeric characters on porous materials and cases.

DOWNLOAD BROCHURE

View Online

Designed to deliver superior performance when requiring large complex print messages consisting of graphics, logos, alphanumerics and barcodes. FoxJet ProSeries 768e allows manufacturers to completely replace costly labels with print-ondemand messages.

View Online

Enhanced for printing high contrast, high quality barcodes, the ProSeries 384e allows manufacturers to produce scannable and verifiable barcodes at the highest available speeds to achieve maximum throughput. Featuring industry leading ink throw distances, the ProSeries Enhanced printers offer the most forgiving distance tolerances between the printhead and product being marked as well as ensure maximum print quality on irregular surfaces.

View Online

A high-resolution cartridge-based inkjet system based on the extremely reliable Hewlett Packard Technology. It is designed to be a robust asset to manufacturers’ production lines giving them a dependable method for product identification that includes up to five vertical lines of print. FoxJet’s intuitive software also gives an easy method for message creation. The fully featured software includes built-in autocodes, such as date, time, count and expiration.

Markem Imaje has earned a reputation as one of the most reliable inkjet printer suppliers by driving innovations grounded in stringent manufacturing standards. No matter where you are in your technological adoption, the 9750 high resolution continuous inkjet secures your investment by giving you flexibility, performance and security to meet your customers’ needs now and in the future.

A print and apply system prints fixed and variable information onto self-adhesive labels which are then automatically placed onto outer cases, boxes or pallets in secondary and tertiary packaging. Print and apply (P&A) labeling can accommodate the widest range of materials and cases. Labels can be printed and applied to front, top, side, rear or over a corner.

The 5940 G sets the standard of coding quality, compliance, operational efficiency and reduced total cost of ownership (TCO) with a sustainable solution. Greater throughput and compliant barcodes including GS1-128 requirements.

The piezo inkjet drop-on-demand printer offers a faster return on investment by boosting production throughput while enabling manufacturers to improve their supply chain management through traceability and brand protection. That’s printing intelligence beyond the mark.

CoLOS is a scalable modular solution that cuts waste from coding and marking errors, increases line efficiency and protects brand value by ensuring printing compliance.

In addition to providing printer performance reports and overall equipment effectiveness (OEE) data to drive increased packaging line productivity, CoLOS seamlessly liaises with your production and information system infrastructure to further maximize efficiency and support your Industry 4.0 strategy.

View Online

Thermal Transfer Overprinting is a contact coding process which transfers ink from a ribbon to the material, using a thermal printhead. Thermal transfer technology combines a thermal printhead and a polyester ribbon coated with ink on one side. Ink is transferred from a ribbon to the packaging material using a thermal printhead. This is made up of a row of independent tiny heating elements, mounted on a ceramic support. The different heating elements are activated based on the characters to be printed, melting the ink on the ribbon and transferring the selected characters to the packaging film.

The SmartLase® F250 fiber laser coder delivers superb code quality in highspeed applications, even with increasing code complexity of 1D and 2D codes, all in an easy-to-integrate and easy-to operate compact unit. DOWNLOAD

View Online

View Online

Squid Ink’s CoPilot uses proven Xaar piezo technology to print up to .7” of hi-resolution characters, razor-sharp text, scannable bar codes, and great looking logos at 185 dpi and a 4.3” full color touchscreen provides access to the system’s internal messages and print functions. Messages are created and edited on Squid Ink’s easy-to-use Orion™ PC Software and transferred via Ethernet or USB device.

The Squid UV LED Curing System from Squid Ink offers accurate and consistent UV curing across a variety of commercial and industrial applications. Whether you need to cure ink on metal, glass, automotive products, plastics, electronics and more, you’re sure to find the right solution with Squid Ink’s new UV Curing System.

View Online

Marsh Label Technologies is an industry leading custom and stock label manufacturer with a strong focus in the industrial and secondary packaging markets. Our core products include blank and color thermal transfer, direct thermal, laser sheets and inkjet labels with a particular emphasis on specialty material and adhesive applications.

Solutions for all your Packaging Labeling needs!

Products:

Thermal Transfer Labels

Thermal Transfer Ribbon

Direct Thermal Labels

Durable Film Labels

UL Recognized Labels

Removable Labels

Aggressive Adhesive Labels

Cover-Up/Opaque Labels

Variable Data Imprinted Labels

Cold Temperature/ Freezer Labels

Retro-Re ective Labels

Color Industrial Labels

Process Color Labels

GHS Labels

Laser Sheets

Ink Jet Labels

Non P/S Tags

Security Labels

We service all major brands of strapping tools. Signode, Fromm, Samuel, PAC Strapping, Carolina Strapping, and more.

Our repaired tools carry a 30-day parts and labor warranty!

Flat R epair R

Professional, quality service by trained service technicians

We are happy to evaluate other brands of tools, please call for availability.

OUR PEOPLE AND OUR CULTURE ARE CENTERED AROUND PROVIDING SUSTAINABLE CUSTOMER SOLUTIONS

OUR DEPTH OF KNOWLEDGE AND EXPERIENCE ARE INVALUABLE TO OUR CUSTOMERS

WE BRING INCREASED PRODUCTIVITY THROUGH INNOVATIVE PRODUCTS AND APPLICATION EXPERTISE

ON-SITE SERVICE AND REPAIR IS TRACKED AND MONITORED BY MACHINE SERIAL NUMBER

OUR WELL-TRAINED AND EXPERIENCED PROFESSIONAL SERVICE TEAM UNDERSTANDS CUSTOMER NEEDS

SAME-DAY SHIPPING WITH EFFICIENT DC’s, ALLOWING FOR NEXT-DAY DELIVERY OF MANY PRODUCTS

NOTHING IS MORE IMPORTANT THAN THE SAFETY OF OUR CUSTOMERS’ EMPLOYEES AND OUR LINC SYSTEMS EMPLOYEES

WE PROVIDE COMPREHENSIVE SOLUTIONS THAT IMPROVE ERGONOMICS, REDUCING WORKERS COMP CLAIMS

WE OFFER AN EXTENSIVE LIST OF INDUSTRIAL SAFETY PRODUCTS FOR MAINTAINING AN ERGONOMIC AND SAFE WORKPLACE

INDUSTRY-LEADING TECHNOLOGIES NOT ONLY MAKE US MORE EFFICIENT BUT, MORE IMPORTANTLY, THEY IMPROVE THE EFFICIENCY OF OUR CUSTOMERS

WE ARE CONSISTENTLY INVESTING IN OUR TECH TO ENHANCE THE CUSTOMER EXPERIENCE

WE WORK TO PROVIDE THE BEST DIGITAL TOOLS TO MAKE IT EASIER FOR CUSTOMERS TO DO BUSINESS WITH US