PORTFOLIO

LINA BEDDA

SELECTED WORKS 2024

SELECTED WORKS 2024

WORKSHOPS & COURSES

TECHNICAL SKILLS

lhbedda@gmail.com

Phone

+201503663660

Address Email

Cairo, Egypt

Experimental product designer specializing in the fabrication and prototyping of consumer home products and furniture.

Adept at translating conceptual designs into functional prototypes using rapid prototyping techniques and various materials. Proven ability to drive the design process from initial sketches to final production, ensuring high-quality outcomes and efficient use of resources.

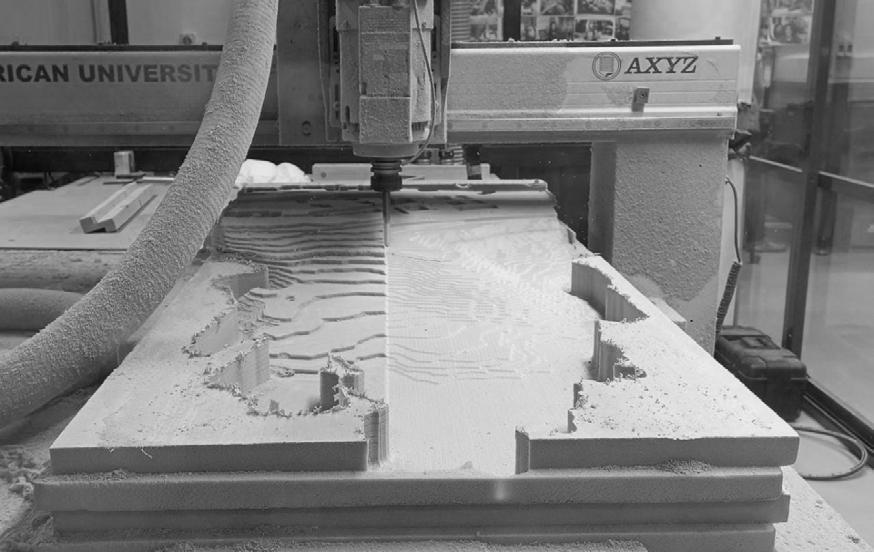

Skilled in blending traditional handcraft techniques with advanced digital design and fabrication tools such Rhino+Grasshopper, 3-axis CNC machining, laser cutting, and 3D printing. Passionate about creating user-centered designs that balance aesthetics, functionality, and manufacturability.

Bachelor of Architecture | American University of Beirut

Product Developer and CAD/CAM Programmer | DAMJ

Dec 22 - Dec 23

DAMJ is a design & fabrication firm designing residential, commercial & high-end architecture, interior elements and products.

• Researching, developing, and prototyping home products’ user experience, manufacturing details, and internal mechanisms

• Managing projects given schematic design through to execution while coordinating between feedback from supervisor and workshop employees

• Programming and printing files for FDM & SLA Resin 3d printing

• Programming CNC operations to ensure safety and reduced time and cost

• Setting up wood stock on the CNC machine in collaboration with the CNC

Computational & Algorithmic Design Instructor | Freelance

July 22 - Jan 23

Having a keen interest in applications of mathematical, physical and biological principles for architectural and product design purposes, I have put together a course covering theoretical and technical skills of computational and algorithmic thinking. These skills are taught through exercises on Grasshopper 3D using practical applications as examples.

Intern Architect | D4C

Jun 19 - Sep 19

D4C adopts an action-oriented research approach within an interdisciplinary framework to engage in community-based projects.

• Mapped site natural and cultural opportunities and constraints

• Surveyed needs of local population and natural elements of site

• Designed strategies for integrating community recreational programs

• Prototyped structures for 1:1 installation

Fab Lab Assistant | ArD TechLab | AUB

Sep 17 - Sep 19

The ArD TechLab is a collaborative educational space providing a platform for advanced digital design and digital fabrication where designers experiment, tinker and iterate informing their designs through the process of digital fabrication.

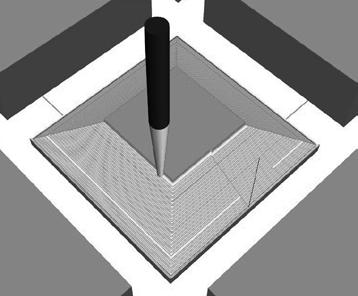

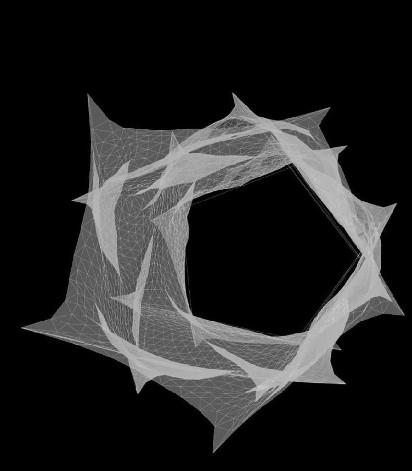

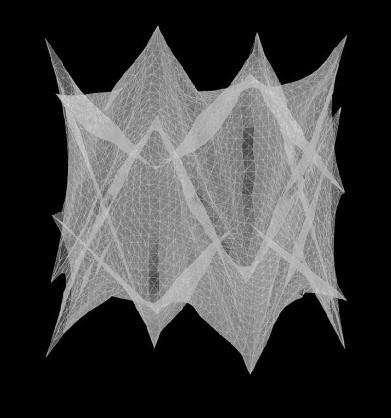

Unconventional Toolpaths | Co-de-it | Andrea Graziano

Apr 19

Exploring the interplay of digital fabrication and parametric design processes by generating CNC milling machine g-code through Rhino / Grasshopper

Studying Cities: Social Science Methods for Urban Research | Coursera

Jan 22

Learning research cycle steps, data collection types and techniques, and data analysis.

Desert Oasis X Siwa Workshop | Salma Damluji

Feb 20

Building using vernacular construction techniques using salt stones and mud amongst other materials in the Siwa Oasis

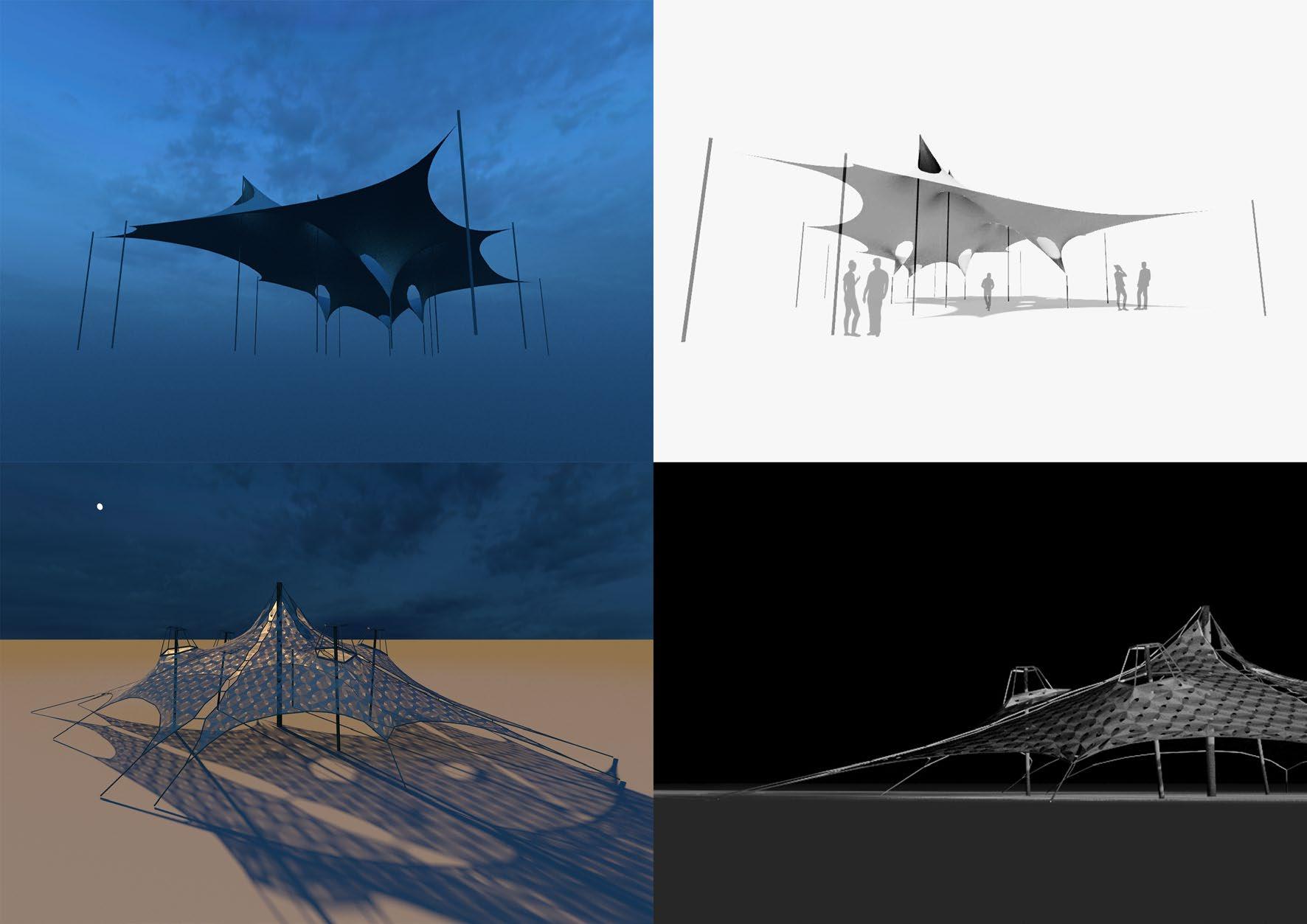

Things that are fascinatingly boring | AA Visting School Beirut

Jun 19

Breaking the city's conventional invisible boundaries by investigating ready made objects beyond their function and form.

Digital Fabrication

WEBSITES

linkedin.com/in/lina-bedda-536070249

• Guided designers and engineers through their design and fabrication iterations

• Prepared G-codes for laser cutters, CNC routers and 3D Printers

• Assisted in managing Fab Lab and its workshops

• Operated digital fabrication machines

• Operated wood and metal workshop machines

May 19

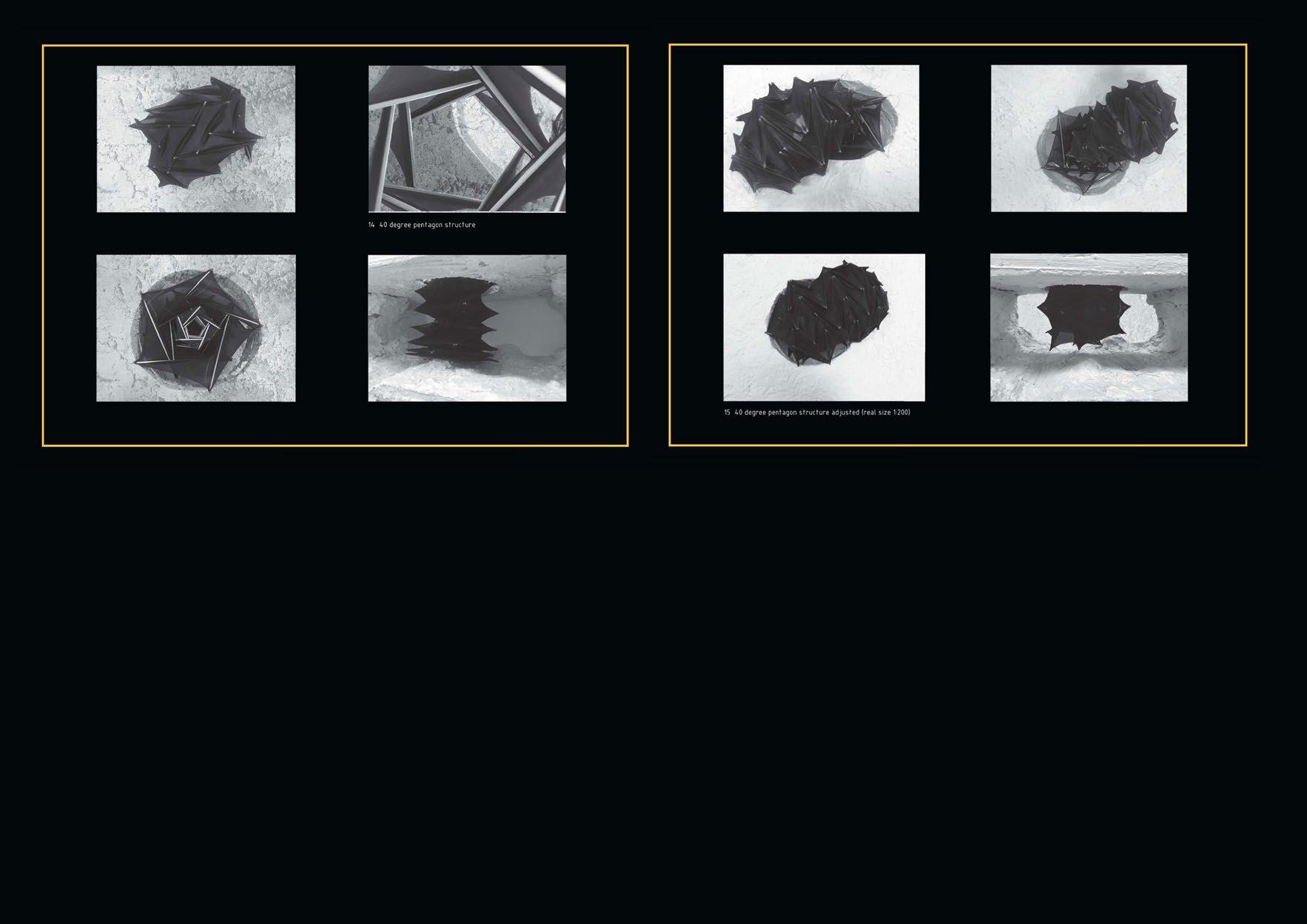

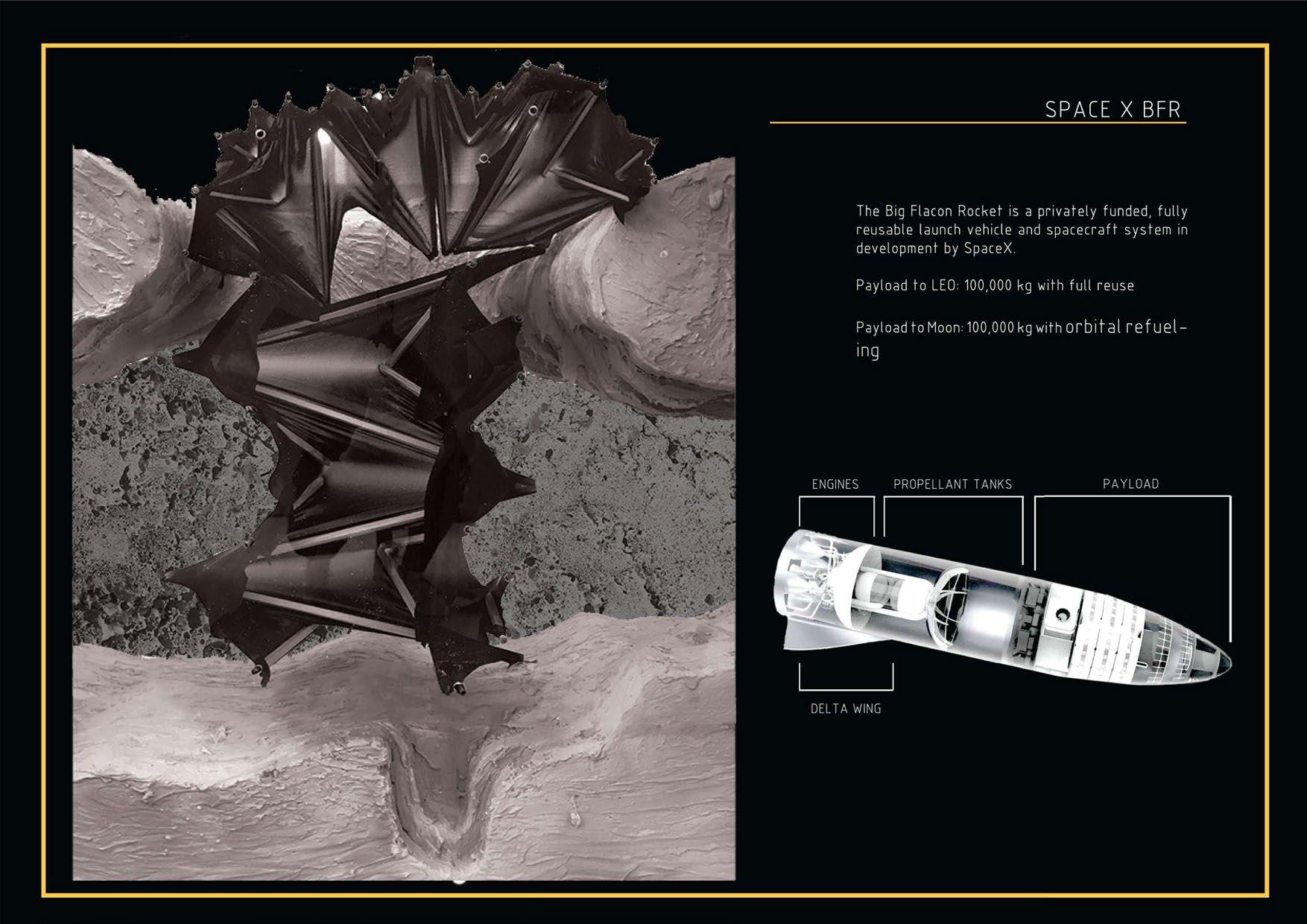

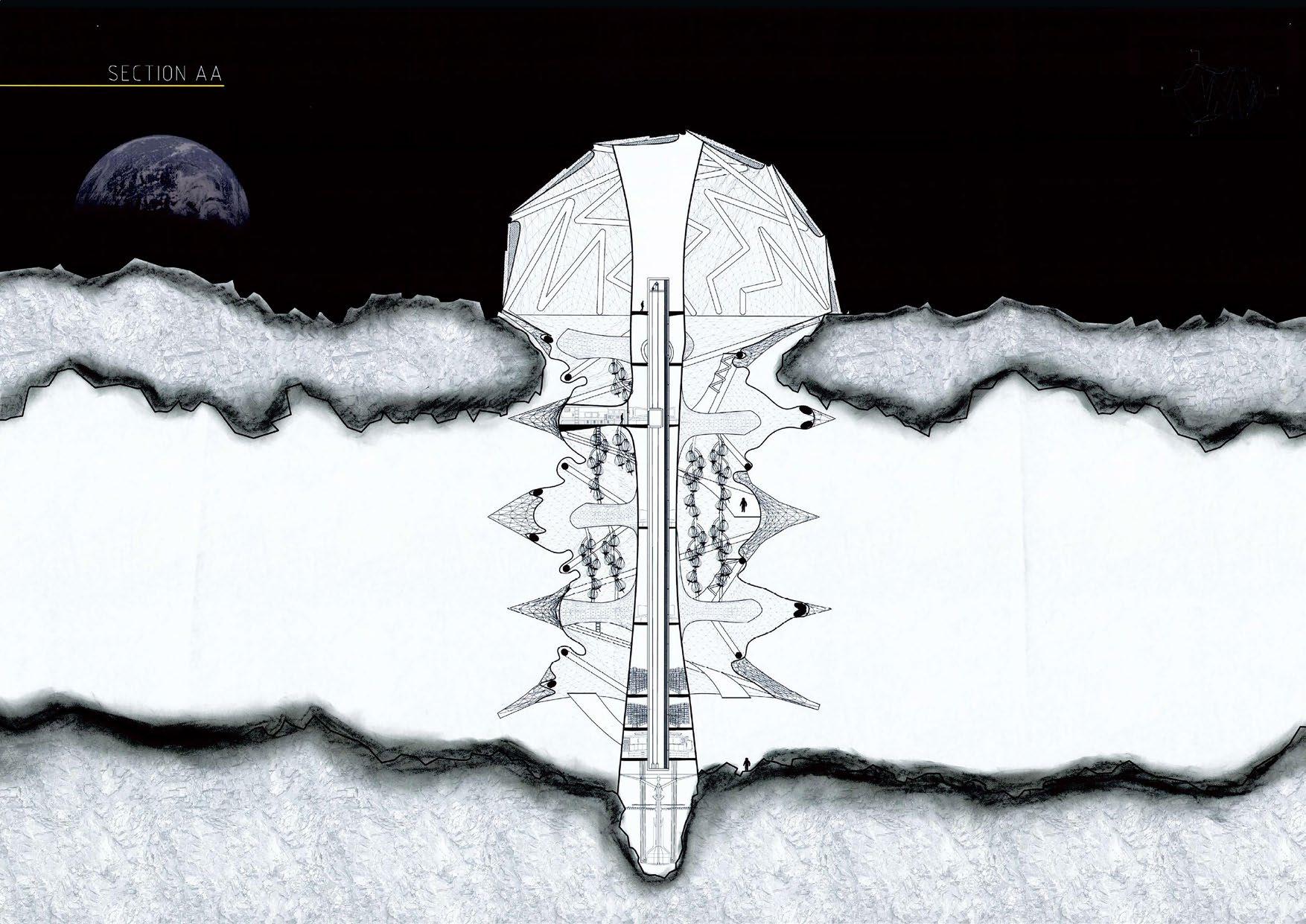

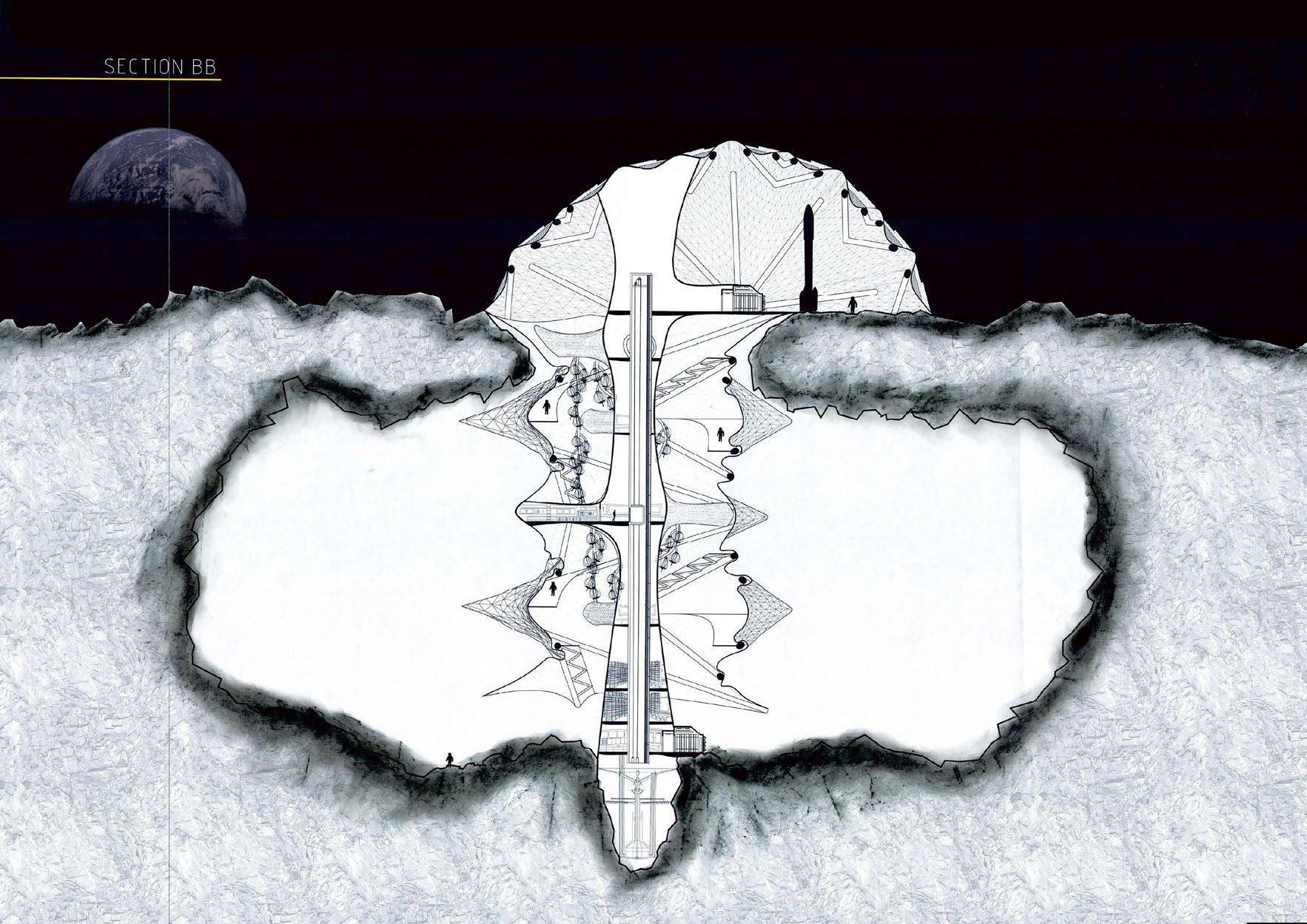

Learning about the physics informing space architecture. Lunatopia Astrophysics Workshop | Barbara Imhof

Chitubox

Programming Python 3

AutoCAD Rhino + V-Ray Grasshopper Revit QGIS 2D | 3D | BIM | GIS

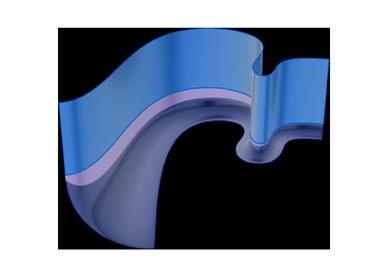

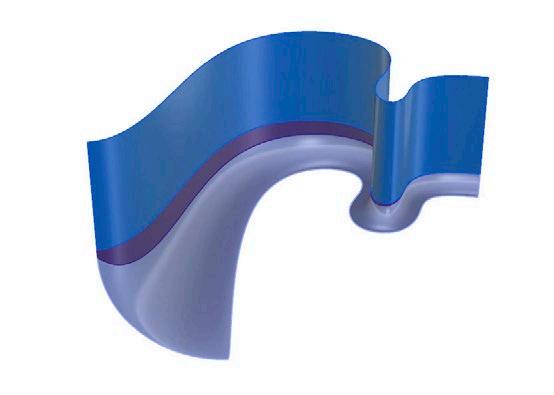

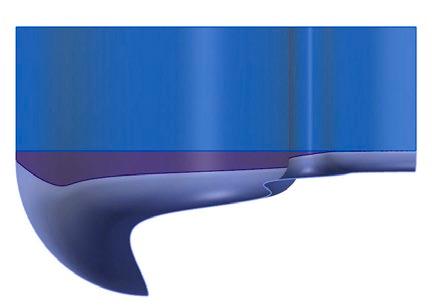

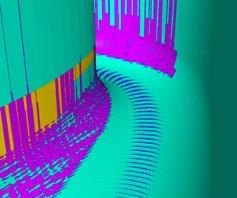

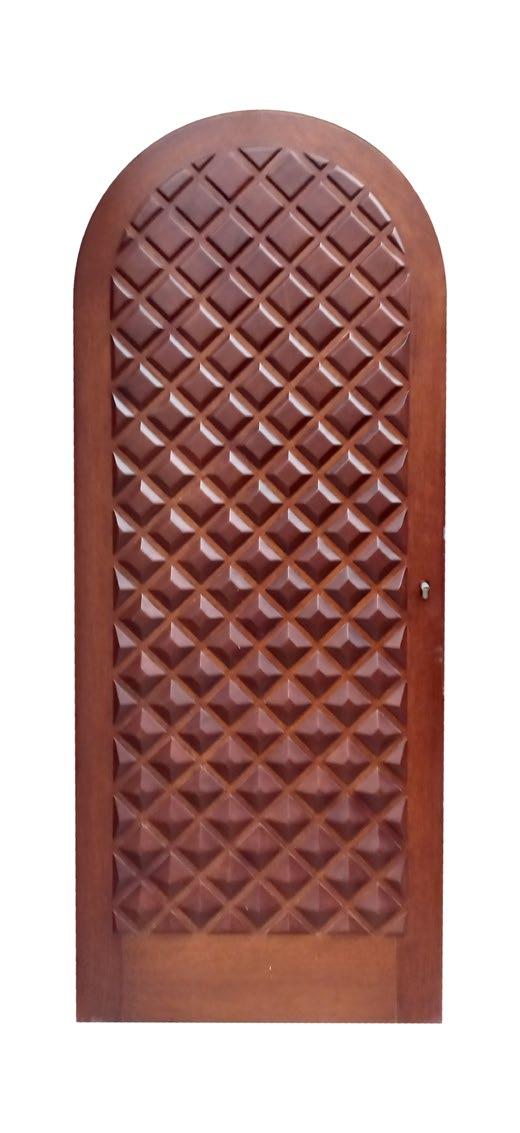

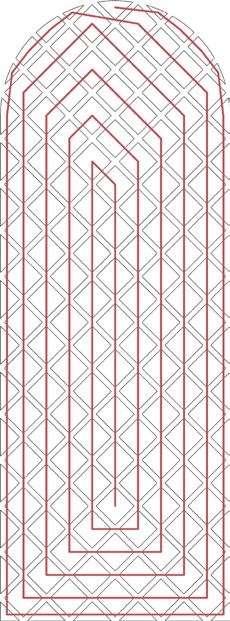

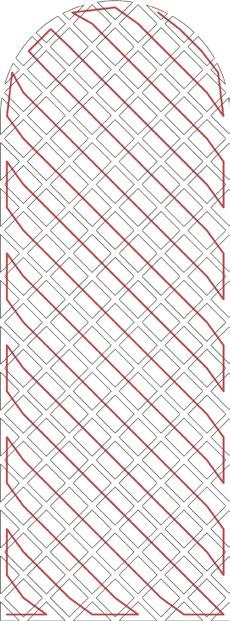

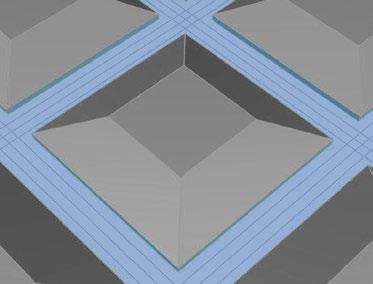

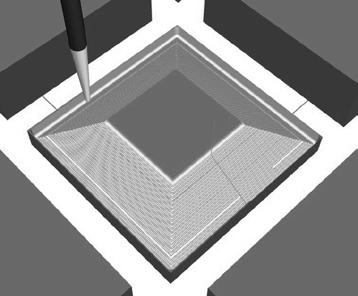

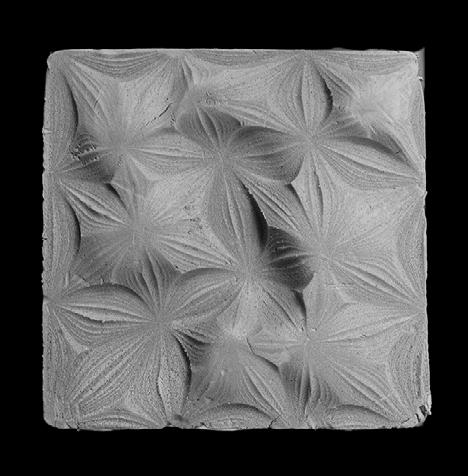

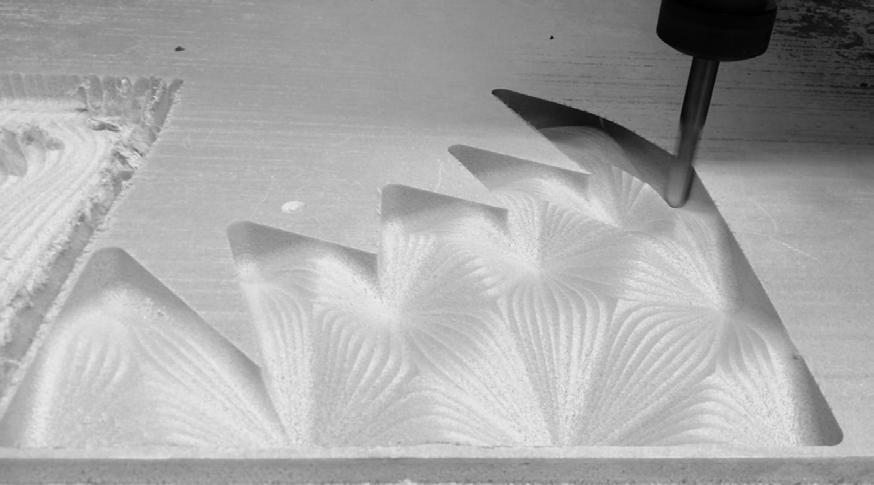

Challenge:

Horizontal finishing leaves a rough finish on flat area. Parallel finishing burns surface of inner vertical walls.

Approach:

Subdivide into surfaces of different characteristics

[A] Veritcal surface ending at one depth

[B] Vertical surface at varying depth

[C] Curved surface

To ensure a smooth and clean finish....

Surface [a] was finished using a profiling operation

Projection pocketing leaves a smooth surface under on surfaces [b] & [c]

Comparing alternatives: Curved Surfaces [B] & [C]

Stock Comparsion Toolpaths

Horizontal Finishing leaves burn marks on vertical surfaces

Parallel Finishing requires much more time than alternatives

Projection Pocketing: results in smoother finish and a 50% reduction in total finishing operations’ duration

Gear 1 Top Lamp Shade Rotation

Driver Gear

Gear 2 Axis Guide

Gear 1 Axis Guide

Structural Wall

Driver Gear Axis Guide

Supporting Ribs

Vibration Plate

5 RPM Motor

Motor Axis

Tightly-Fitted Locking Pin (Gear 2)

Screws

Axis Frame's Cap

Gear 2: Beveled Gear

Gear 1 Bottom: Idler Gear

Gear 3: Driven Beveled Gear (Rotates Drum)

Drum

Drum's Stainless Steel Axis

Axis Frame

Sound Chamber

Motor-Gear Adapter

Shell-Base Placement Hints

Connection to Wire

Screw Hole [Downward]

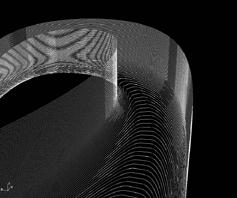

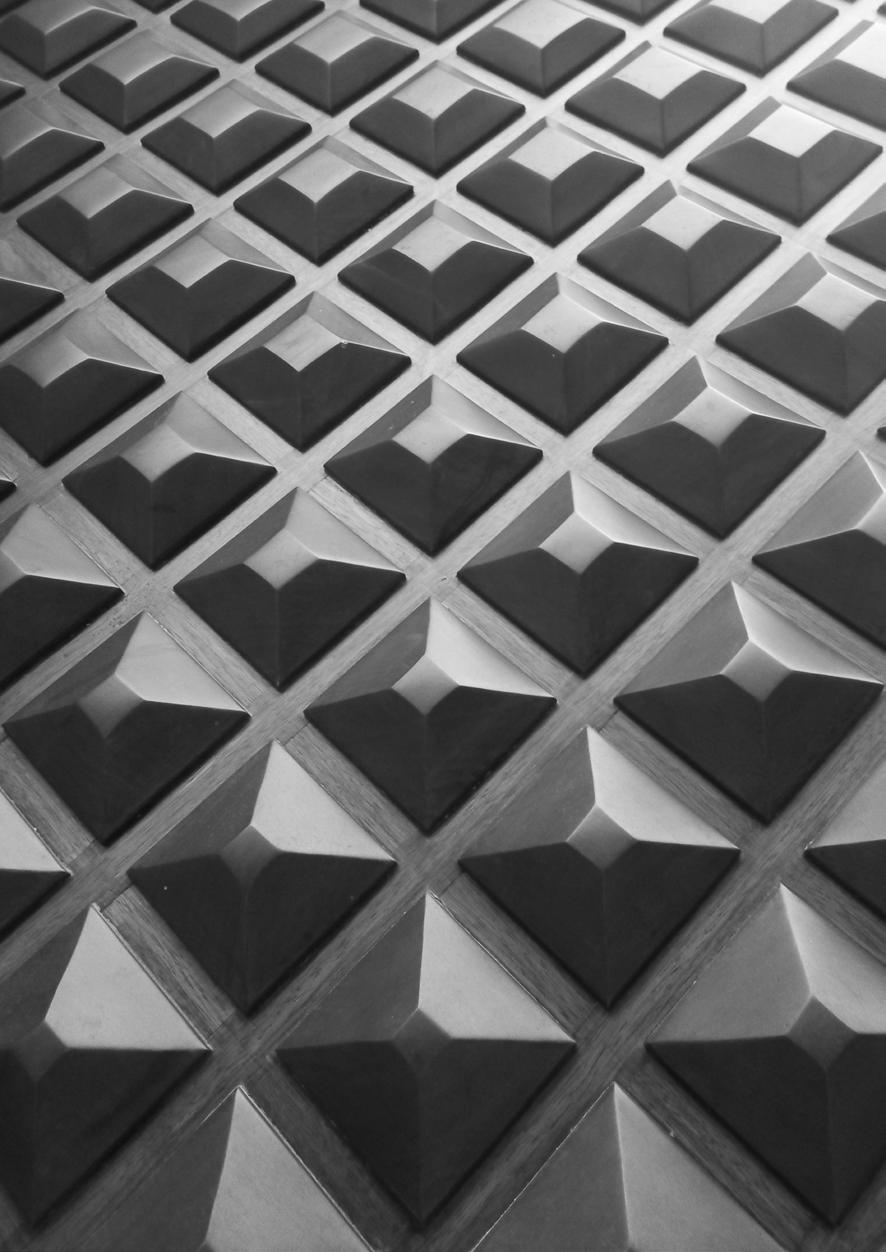

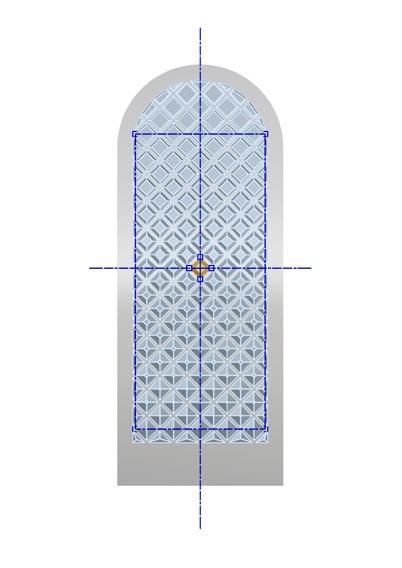

The tesselated door has 150 pieces to be roughed. The pieces have to be sorted efficiently to reduce operation time since the horizontal roughing operation does not have a sorting option. Without sorting , the operation would take around 20 hours.

Sorting using grasshopper and baking the curves gives us sorted GUIDs.

Offset Sort : 15 h 5 m Zigzag sort : 14 h 30 m

Sorting saved 6 h 30 m of machine time.

To avoid the possibility of the milling bit cutting through the surface of the door’s base, the surfaces to be carved are lifted a few millimeters off the frame.

When running the finishing operation, the last cut will break the wood away as it becomes thinner.

The vertical and horizontal lines’ intersection serves as the point of origin. rectangle’s are used double-check along scattered points.

Reversing the toolpaths guarantees a clean cut.

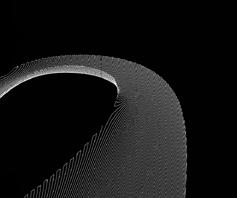

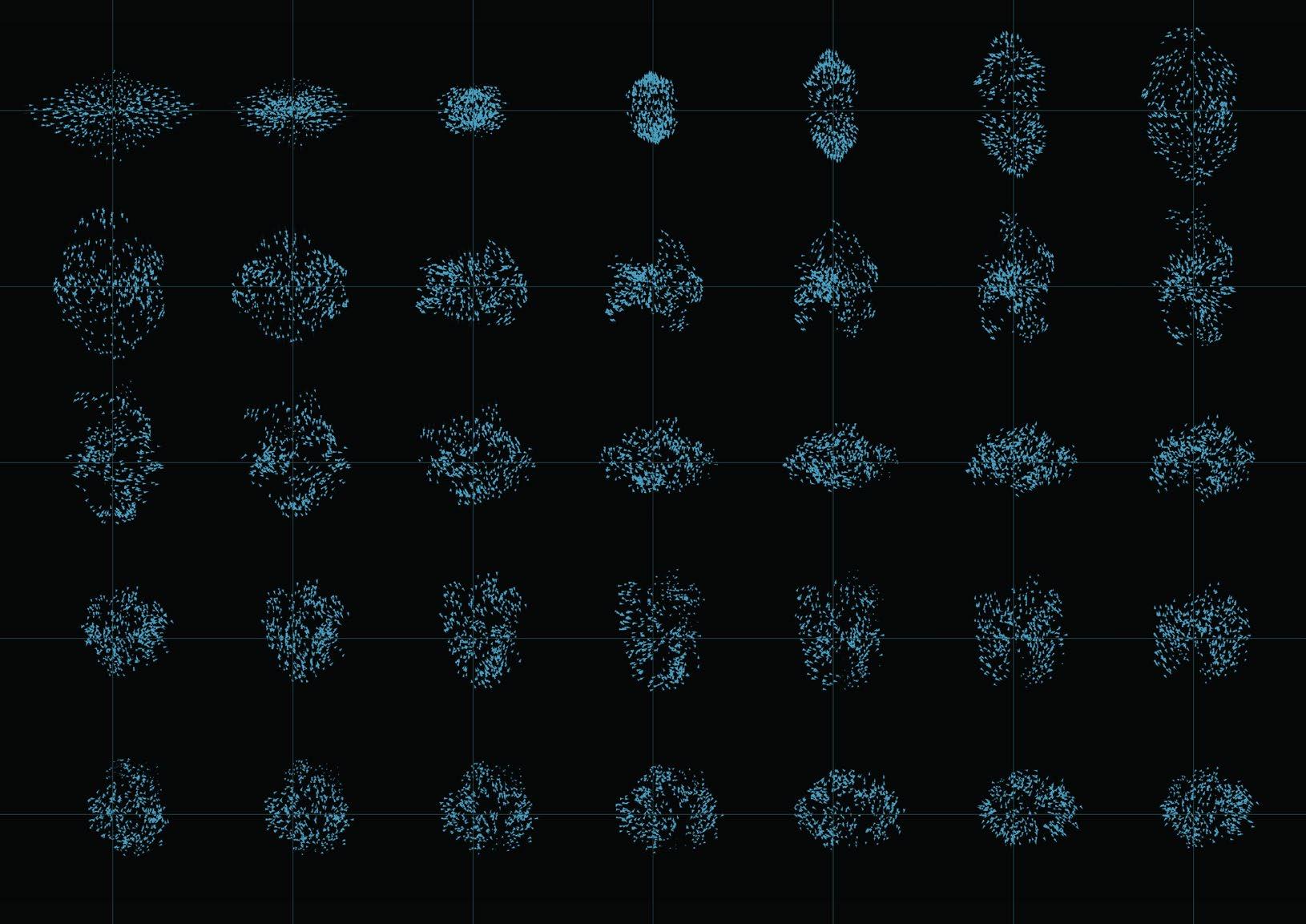

Motion frames of a simulation of fish boids (swarms)

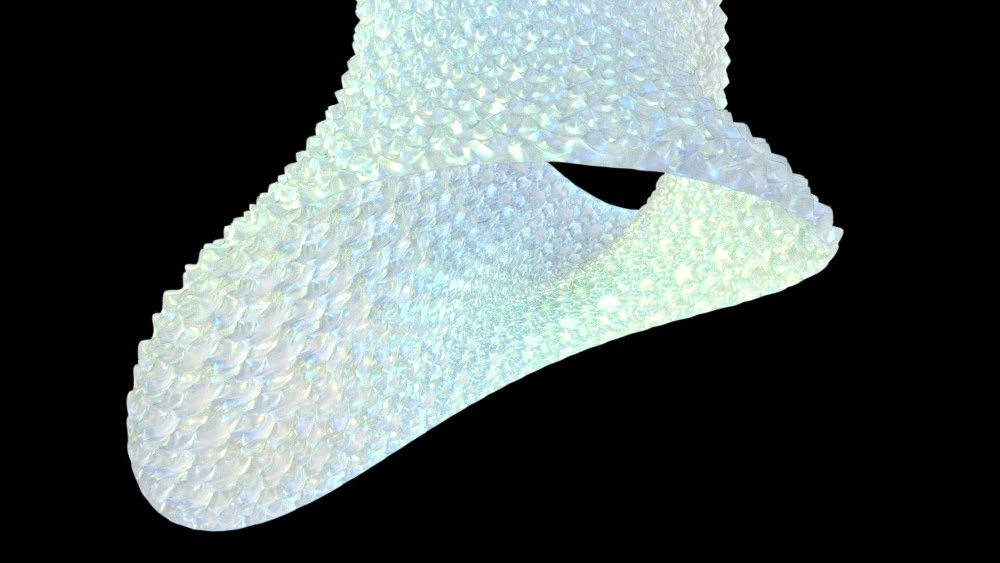

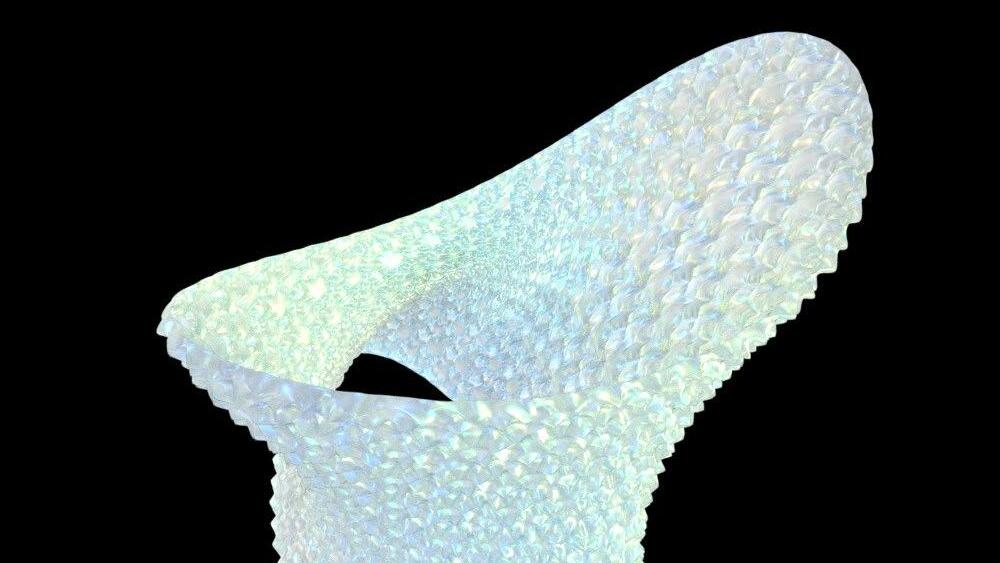

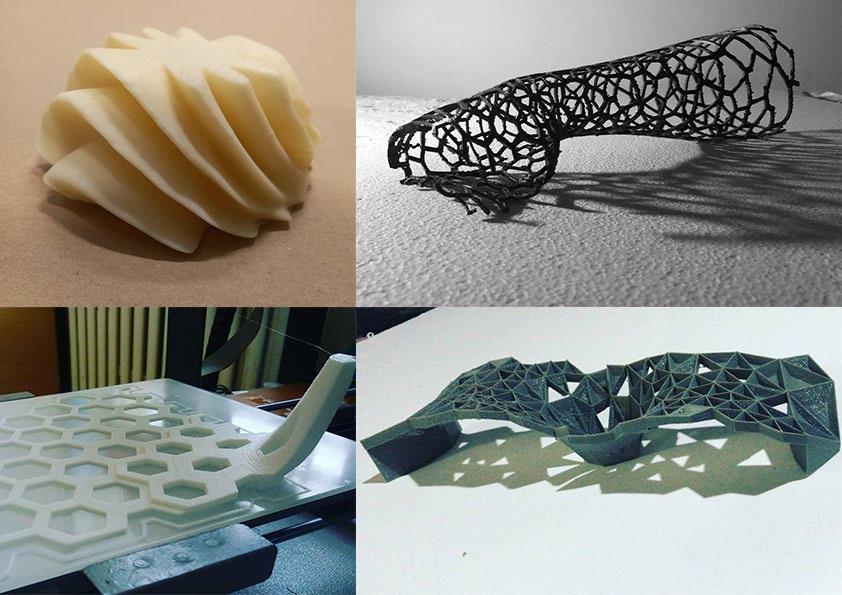

Disclamer:

I did not create these projects, I 3d printed them.

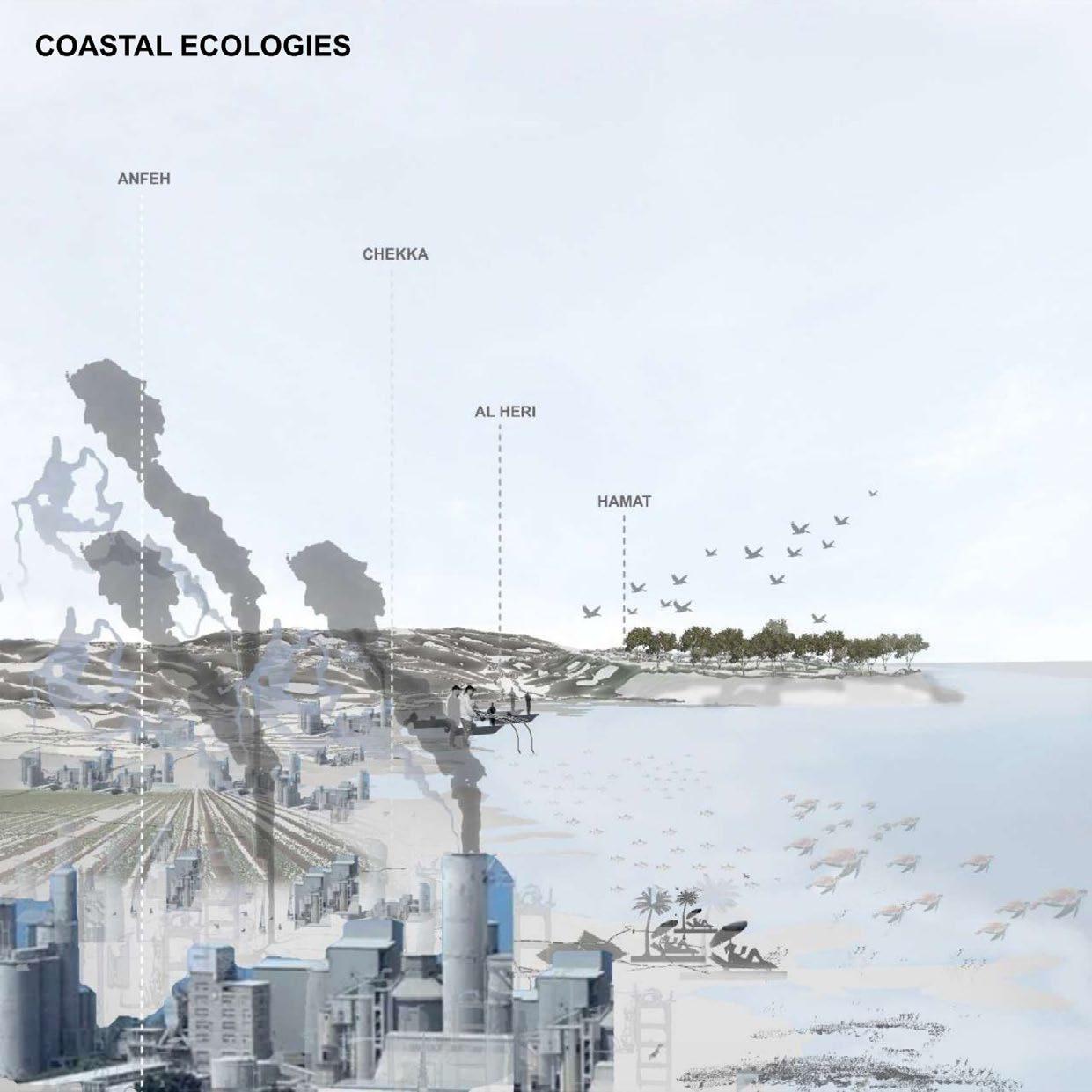

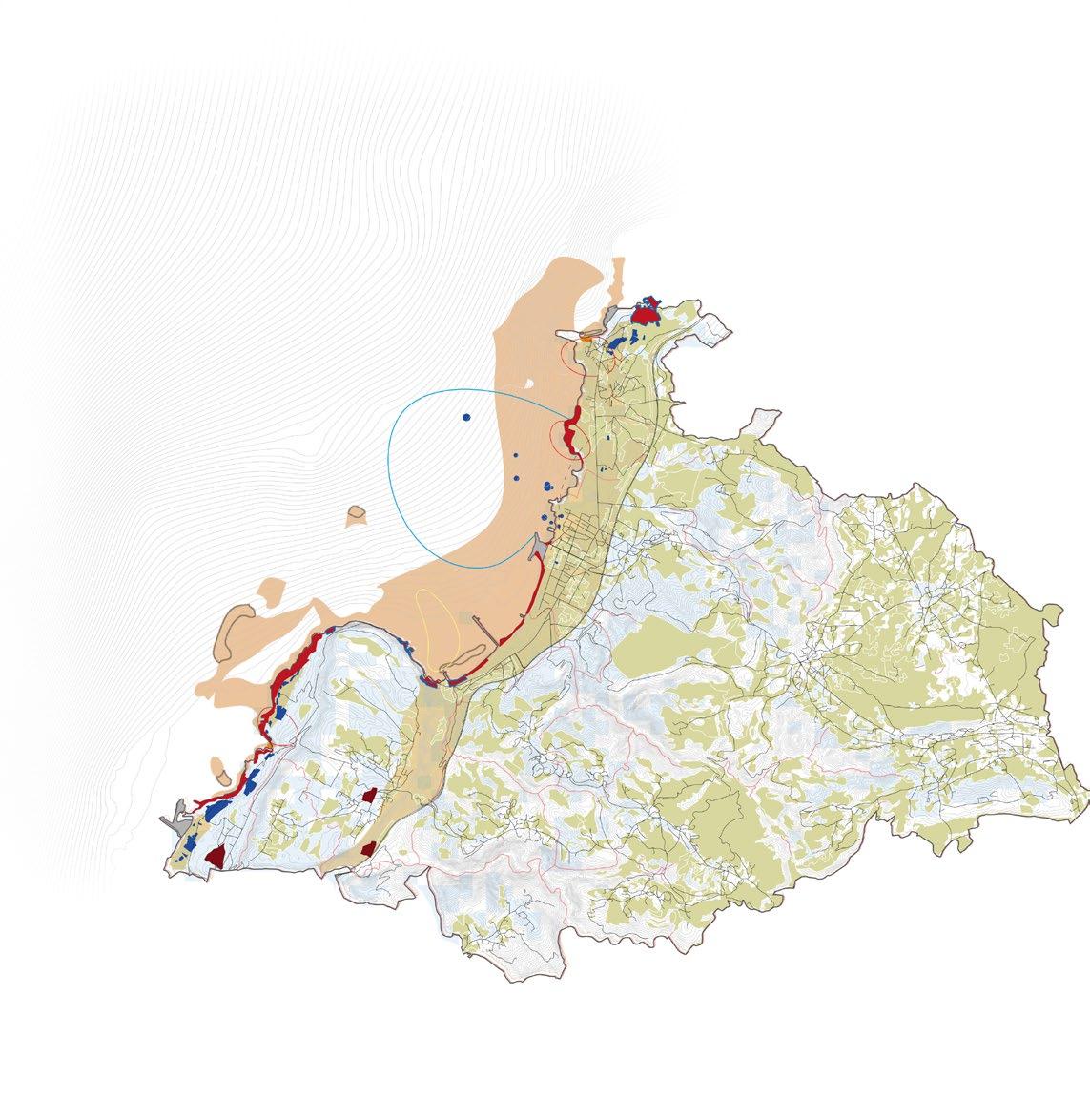

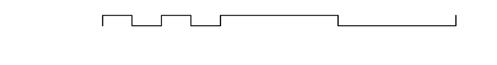

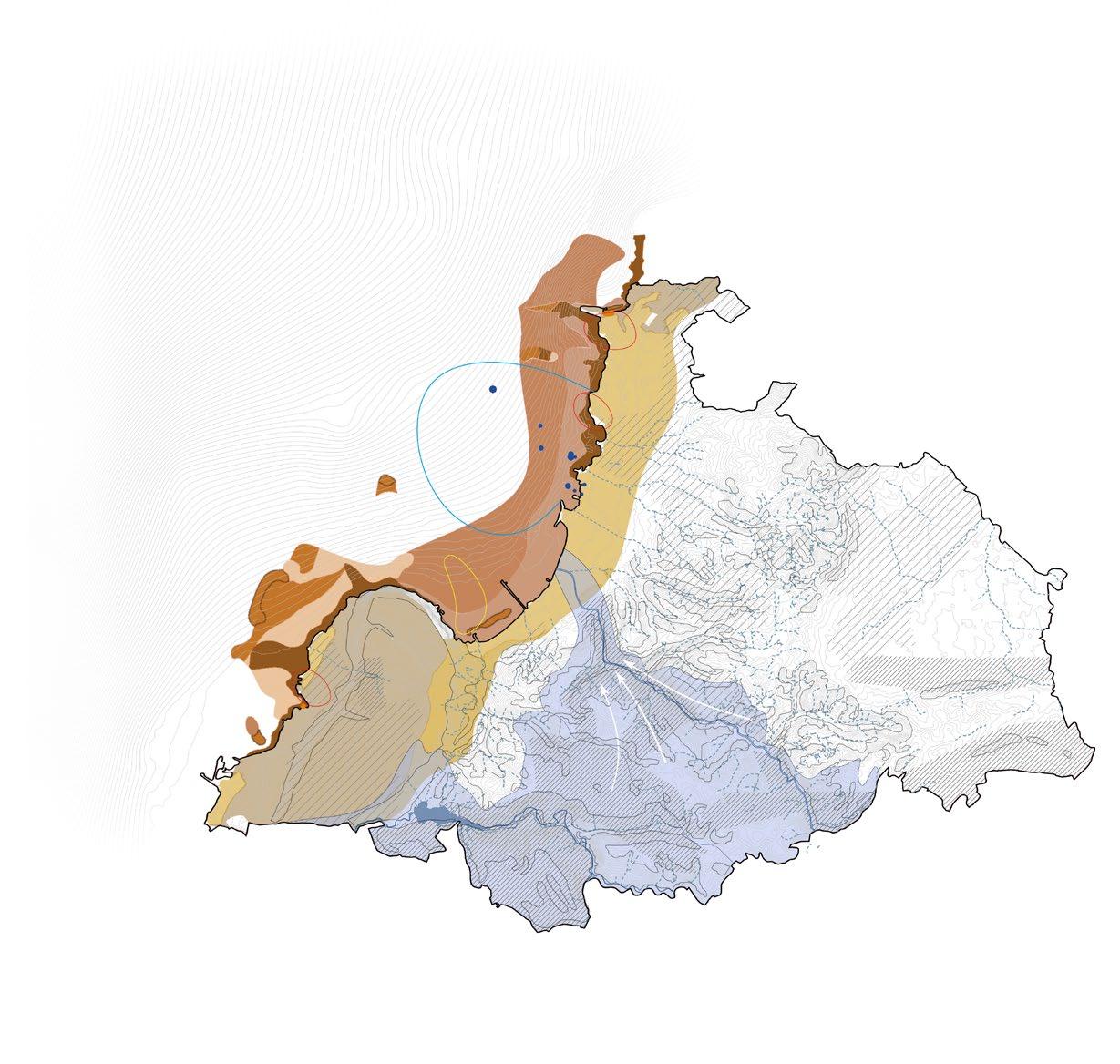

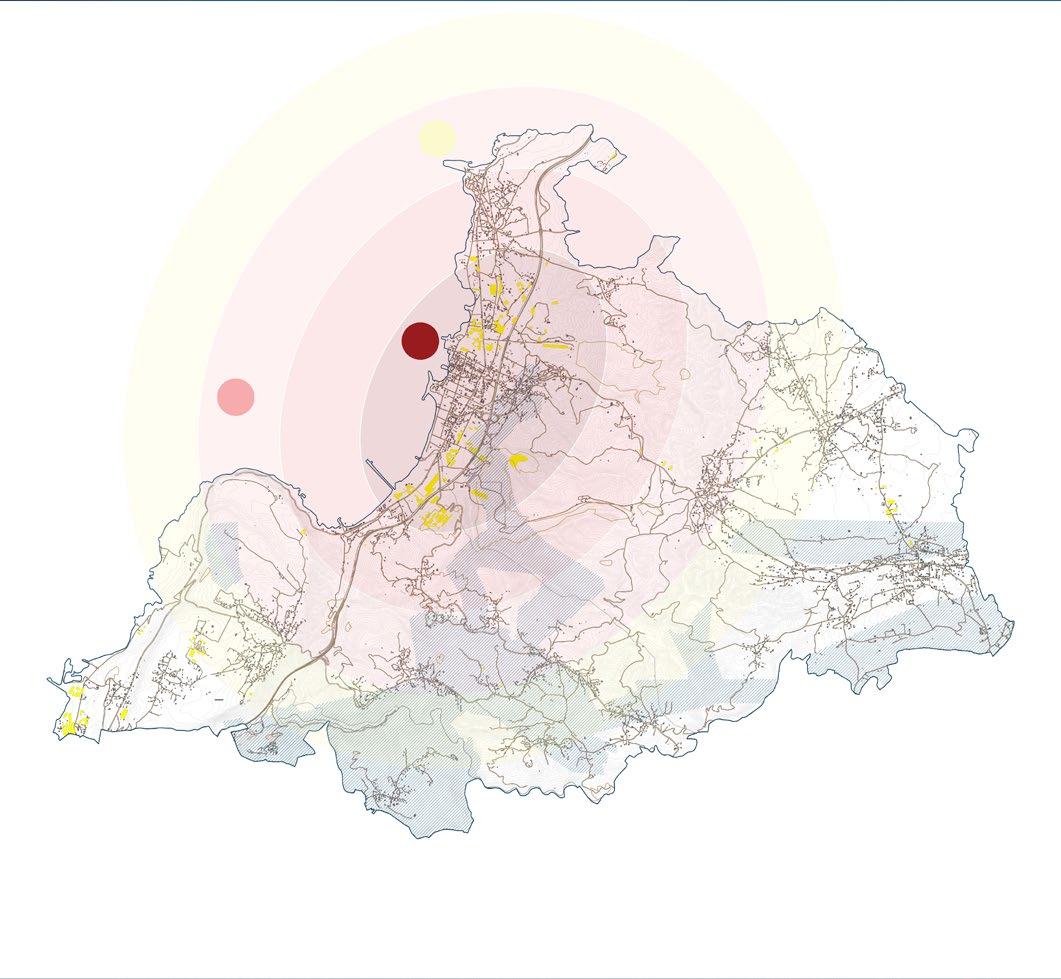

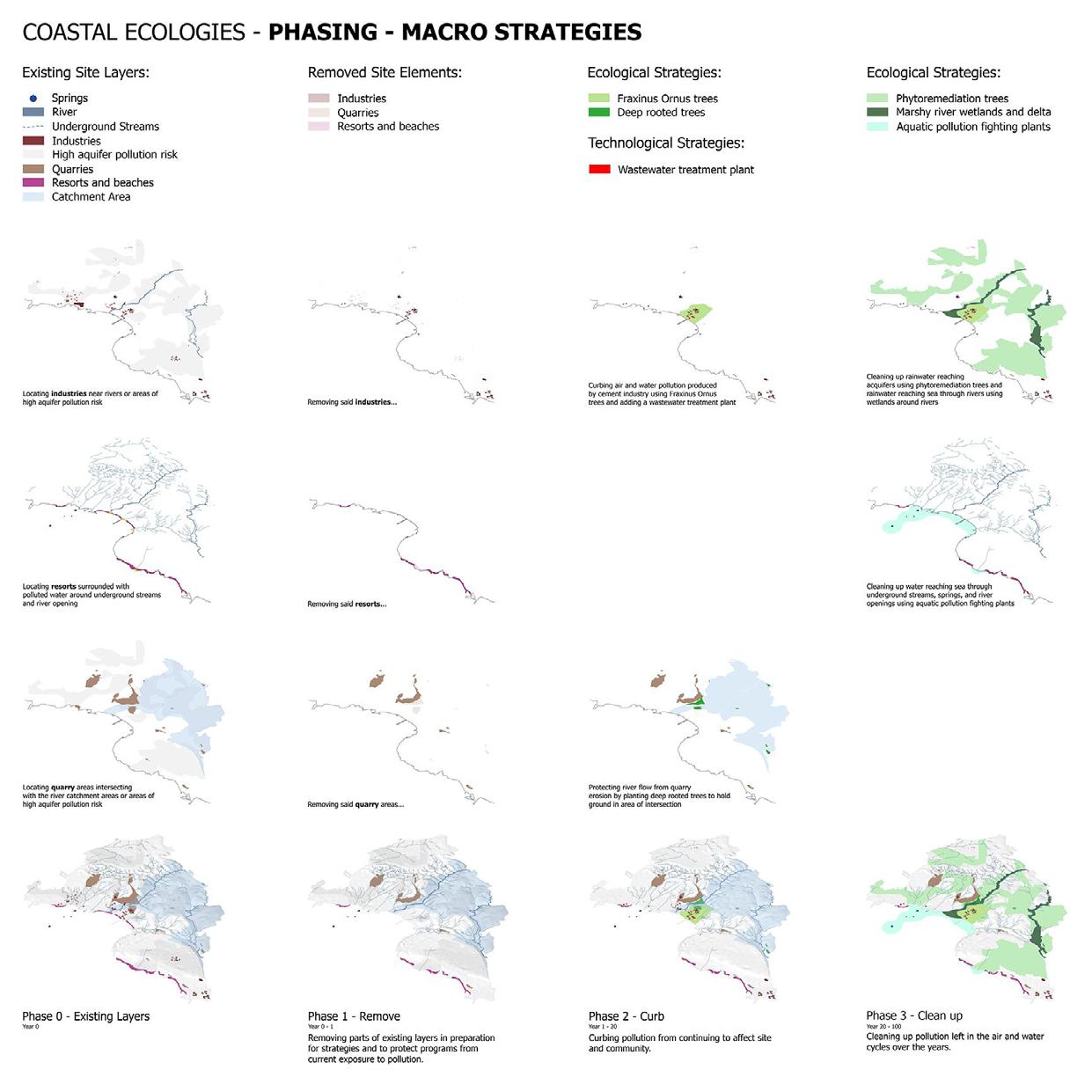

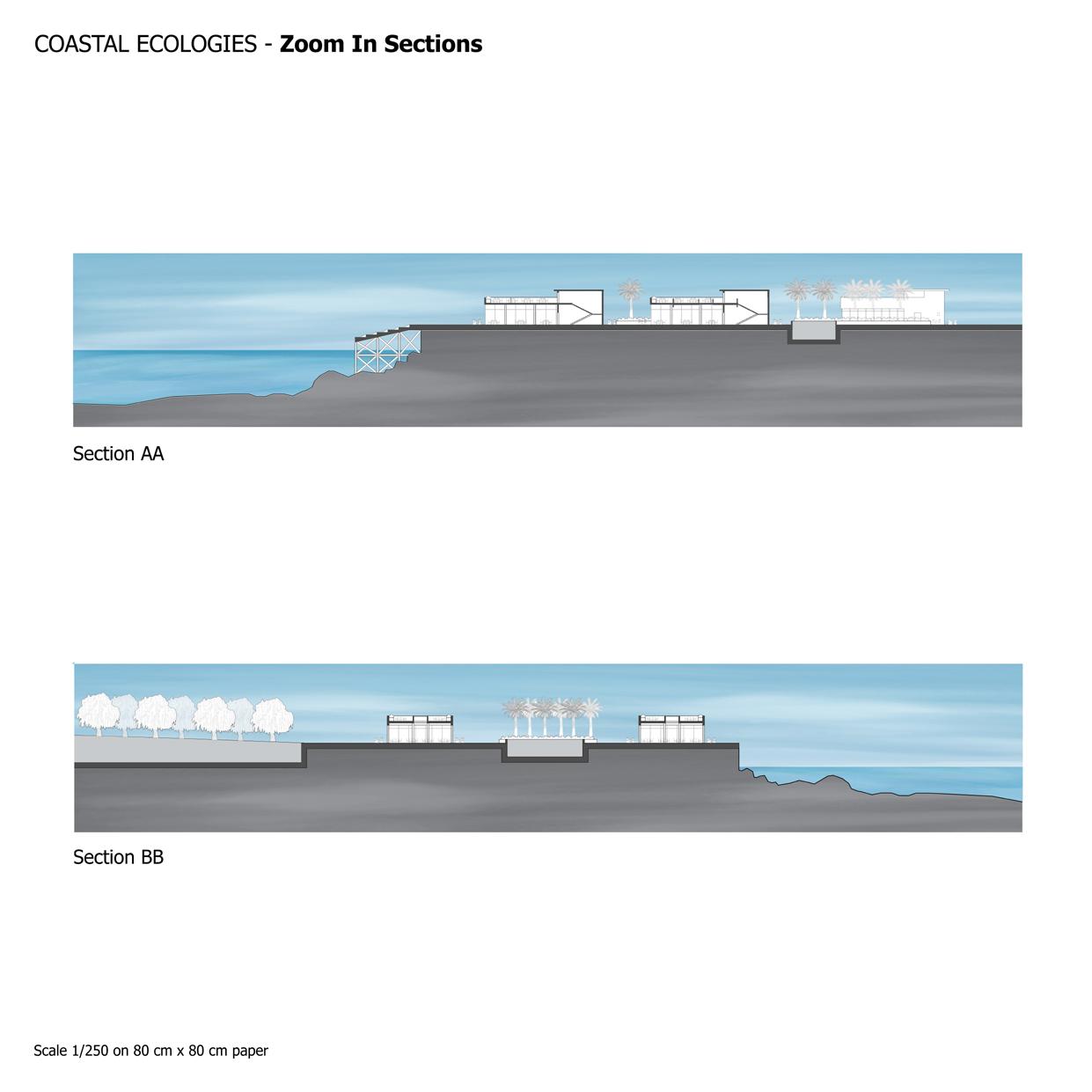

Natural Opportunities:

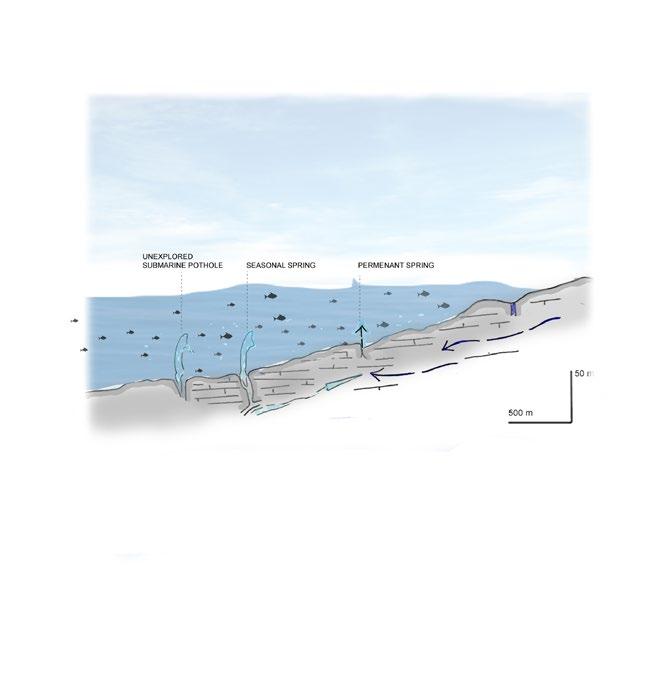

Seabed Materials

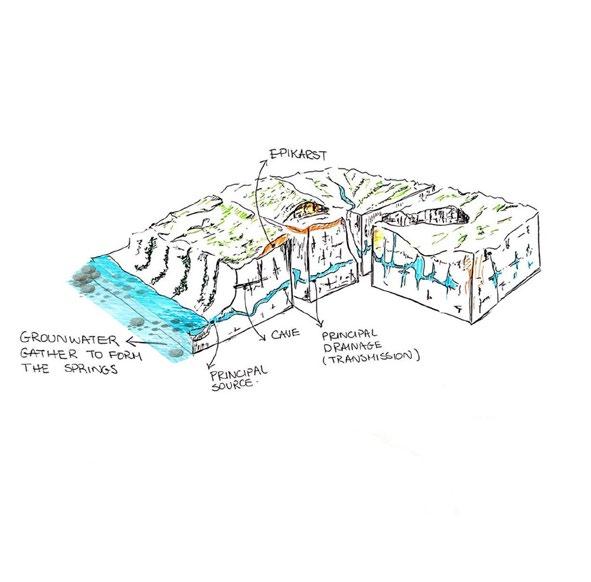

Caves

Submarine Springs

Marine Species Enriching Biodiversity

Turtles

Strombe Snails

Sea Sponges and Endangered Fish

Maerl and coral meadows

Soils on the Coastal Area

Agriculturally Productive Sites

Social and Cultural Opportunities:

Practices with Potential of Being Revived:

Salt Marshes

Agriculture Practices

Fishing Ports

Historical/Cultural/Religious Landmarks enhancing tourism View to the Sea

Technological Opportunities:

Villages

Roads crossing the villages, allowing access to the coast

providing job opportunities

Highway

The overlaying of the opportunities has allowed us to realize the potential this opportunities it has potential of providing, to the tourism aspect it also provides.

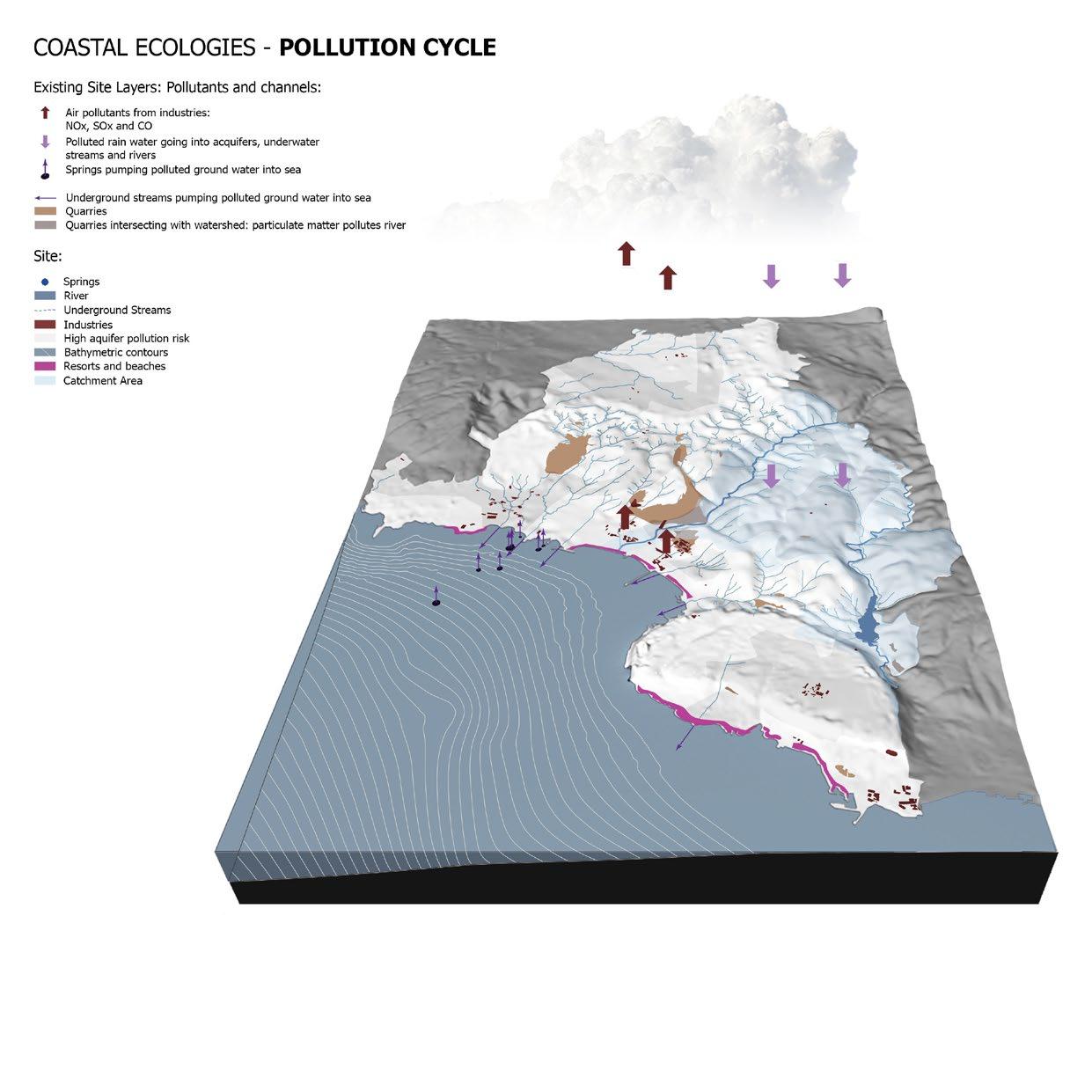

River

River Catchment Area

Underground Water Streams

Submarine Springs pumping polluted water into sea

High Erosion Risk that might contribute

High Urban Density

their complementary quarries. They are types (Air pollution, watershed pollution, visual pollution, and soil pollution...

with portential Viewpoints towards the Factories

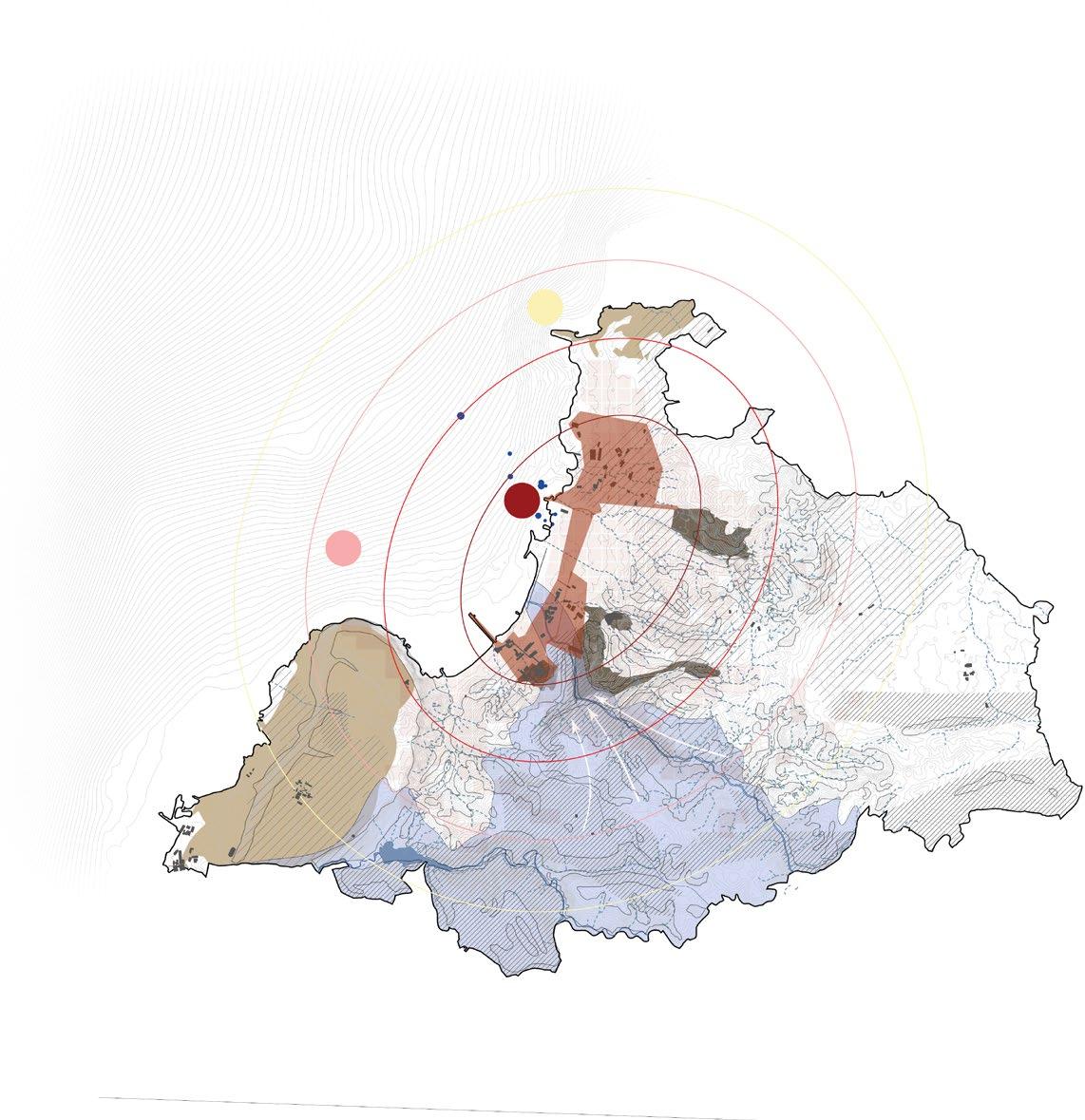

Air Pollutant Levels

SO2=1 PPM

SO2=0.8 PPM

SO2=0.6 PPM

SO2=0.4 PPM

Marine Pollution Levels

Norm: 100 Bacteria/100ml

High

40000 Bact./100 ml

150 Bact./100 ml

100 Bact./100 ml

Visual/Physical Disconnection

Oil and Gaz Station

Quarries

Residential Buildings-View to the Sea

Zones of High risk Aquifers Pollution

Quarries that cause soil erosion and degradation

SO2=1 PPM

SO2=0.8 PPM

SO2=0.6 PPM

SO2=0.4 PPM High

High Urban Density

The Soil is dominantly suitable for agriculture

The Beaches enhance tourism and create social life

enrich the sea with nutrients

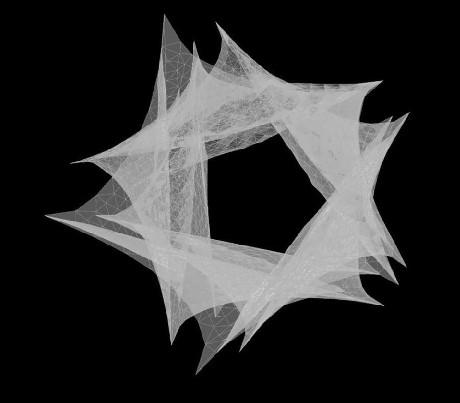

M O O N A R C H I V E S