PEAK Performance

Your Panel

Panel Upgrades

Move up to LED with our Back-Lit Panels. With a range of available options, including integrated SmartLoop wireless lighting control and Power and Color Select technology, they allow you to customize your environment and save energy.

Standard

EVEN LIGHT DISTRIBUTION

Frosted lens makes hot spots a non-issue

Emergency Solutions

Integrated Emergency Back-Lit Panel

WIRELESS CONTROL

Available with integrated SmartLoop controls

KEYSTONE DRIVER

100% end-of-line tested, rugged, and reliable

Contractor

Prime

KEYSTONE DRIVER

100% end-of-line tested, rugged, and reliable

EASY J-BOX ADD-ON

Included larger J-box for more room to make switched leg or daisy chain connections

LAMPS | FIXTURES | POWER SUPPLIES | CONTROLS

Panel Fixture Solution

Easy Retrofits

RUGGED CONSTRUCTION

Stamped steel body in an aluminum frame

Upgrade to energy-e icient LED without replacing the entire fixture. Our innovative Future Fit Tro er Kits include everything needed for a seamless retrofit to LED flat panels without modifying the existing fixture mounting— or even needing to remove it from the ceiling.

Retrofit Kit

EMERGENCY BACKUP

Integrated 8W battery capable of 90 minutes of illumination

WIRELESS CONTROL

Available with integrated SmartLoop controls

CONTRIBUTOR

Editor and Publisher

Randy Reid

Assistant Editor

Parker Allen

VP, Associate Publisher, Advertising Cliff Smith 917.705.3439

SHIRLEY COYLE

Shirley Coyle has worked in the North American commercial lighting industry for several decades, holding various leadership roles. A Past President of the Illuminating Engineering Society (IES), Shirley is very active in the lighting community, including participation on lighting standards development.

Art Direction Seraphine Morris

Lighting Management & Maintenance (LM&M) publishes information for the benefit of its members and readers. The sponsor (NALMCO), publisher and editor of LM&M cannot be held liable for changes, revision or inaccuracies contained in the material published. For detailed information on the products, programs, services or policies covered, it is recommended readers contact the appropriate person, company agency of industry group.

LM&M is published by EdisonReport (ISSN 2835-821X). Statements and opinions expressed in articles and editorials in LM&M are the expressions of contributors and do not necessarily represent the policies or opinions of the EdisonReport. Advertisements appearing in the publication are the sole responsibility of the advertiser.

On The Cover

Mt. Hood Meadows

BOARD OF DIRECTORS

What They Don’t Know About Their LEDs Could Hurt Their Bottom Line

Your customers may think their LED systems are still performing like day one—but you know better. Let’s turn that insight into opportunity:

Systems running for 5–8 years likely have:

■ 30% light loss

■ Drivers nearing failure

■ Negative employee/customer experience due to reduced visual impact and in productivity

With Acuity, you can:

■ Re-engage past clients with meaningful solutions

■ Improve performance and safety with strategic upgrades

■ Deliver energy savings and smarter controls

■ Extend system life and enhance value

When you win, we win. We’re not just a manufacturer—we’re your growth partner.

Don’t leave opportunity on the table.

Contact George McIntyre at Acuity and start your next retrofit win—with a partner who’s all in on your success.

CONTACT

LEDVANCE Hazardous Location LED light fixtures are built to perform at their best in the worst environments, under the most extreme conditions. They’re explosion-proof, supremely rugged, and they meet or exceed all industry safety standards for hazardous areas.

No

President's MESSAGE

ERIK J. ENNEN CLMC, CLA, CLCP, CSLC, CLEP, C-GUVMP President, NALMCO Board of Directors

Dear

members and industry colleagues,

As we wrap up another successful year at NALMCO, I want to extend my sincere appreciation to everyone who has contributed to our continued growth and success. Together, we are well-positioned to lead, adapt, and elevate the standards of our profession in the year ahead.

A special thank you goes out to all who supported our organization this year—from first-time attendees to our dedicated NALMCO committees and the NALMCO Board of Directors. Your energy, expertise, and forward-thinking ideas have strengthened our community and positioned us exceptionally well for what’s ahead.

We are entering 2026 with tremendous momentum, driven by expanded member involvement, impactful initiatives launched this year, and a shared vision for elevating lighting management across the industry.

I’m confident that, together, we will continue to advance NALMCO’s mission and create even greater impact in the year to come.

As the holiday season approaches, I hope you find time to relax, recharge, and enjoy meaningful moments with family and friends. Thank you once again for all you do. I look forward to the opportunities that await us in 2026.

Wishing you a safe, joyful, and restorative holiday season.

Warm regards,

Local Inventory + Lighting Design Support from One Partner

More than a supplier

Our local lighting design and controls specialists are here to make your job easy. We’ll support you with:

• Professional on-site audits

• Design layouts

• Specifying products

• Identifying rebates

• Controls commissioning

Sonepar brands across the US have extensive lighting inventory – and a single point of contact for your projects nationwide.

Look to your local Sonepar distributor for your lighting needs.

FROM THE EDITOR

As 2025 winds down, I keep thinking about a line from Stephen’s keynote in Des Moines: Even when you lose control of the circumstances, you still get to choose your response. Most of us will (thankfully) never face anything as extreme as his years in captivity, but his story of mindset, gratitude, and stubborn hope is one that we can all learn from.

That theme of response, of what we do next, runs through this issue of LM&M. Our 2025 Annual Convention & Trade Show Wrap Up captures the energy in those general sessions, hallway conversations, and late-night shop talk. If you were with us in Des Moines, it’s a chance to relive the week; if you couldn’t make it, consider this your highlight reel.

At the Convention, Taresh Grover pushed us to look past the AI buzz and focus on the real friction in our businesses. We unpack his message that the next wave of innovation isn’t a shiny new fixture; it’s smarter processes that help crews, coordinators, and customers work together with less waste, less guesswork, and maybe even less paperwork.

You’ll see the same spirit in “Making the Case for Luminaire Level Lighting Controls,” where we tackle lingering myths that keep LLLC on the sidelines, and in our Mt. Hood Meadows case study, where Pacific Energy Concepts proves that EV charging can thrive in snow, ice, and everything a mountain can throw at it. Both stories are about taking technologies that once felt risky and turning them into everyday tools.

We also zoom in on the people behind the projects. Our profile of Kyle Landig traces his story of navigating recessions, a pandemic, and rapid growth while keeping his family company grounded in service.

As you read this issue, I hope that you’ll come away a little more encouraged about what’s possible in 2026, and a little more confident in your own response.

As always, I’d love to hear what’s on your radar for the year ahead. Reach out to me anytime to share your thoughts or ideas. ■

FROM THE EDITOR

Certified Apprentice GUV Technician (CA-GUVT)

• Introduction to germicidal GUV technology

• Principles and mechanisms of germicidal GUV disinfection

• Safety considerations and protocols

Exam Fee: $350

Certified Lighting Management Consultant® (CLMC®)

• Characteristics and proper usage of lamps, ballasts, fixtures, and controls

• Lighting layout designs and applications

• Energy conservation related to lighting and controls and sustainable lighting practices

Exam Fee: $500 (Member Rate)

Prerequisites: 3

Contact

Certified Lighting Controls Professional™ (CLCP™)

• Introduction to lighting, switching, dimming, personal lighting, wireless lighting, and intelligent lighting control

• Daylight harvesting, energy codes, LEDs, etc.

Exam Fee: $200 (Member Rate)

Certified Lighting Auditor (CLA)

• Perform accurate, energy-efficient lighting audits

• Assures clients of precise, comprehensive audit recommendations

• Ideal for lighting professionals, energy auditors, and facility managers

Exam Fee: $225 (Member Rate)

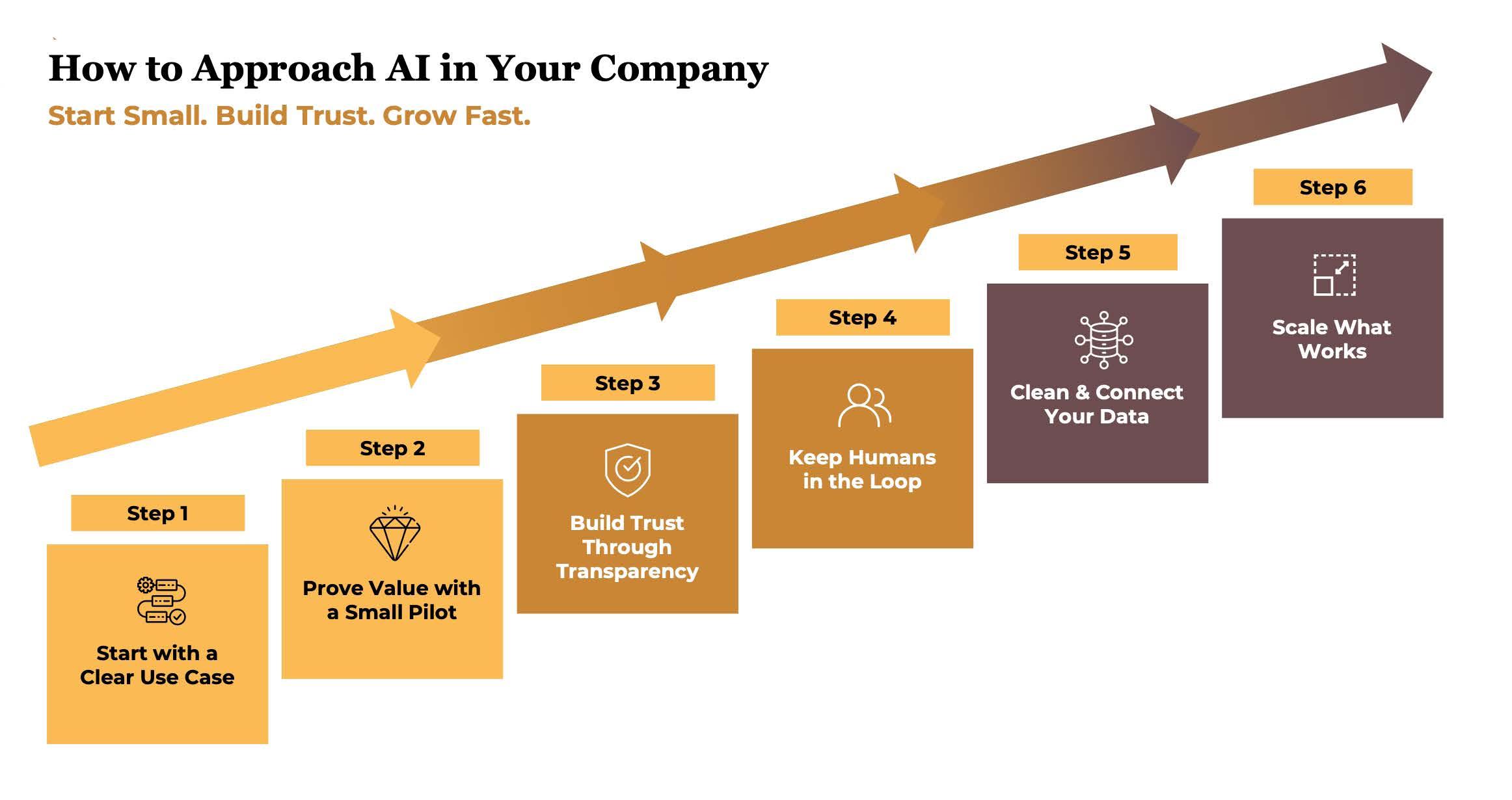

AI MOVES FROM BUZZWORD TO JOBSITE

By Randy Reid

What Taresh Grover Told NALMCO About the Future of Maintenance Contracting

A step-by-step roadmap for contractors to adopt AI—start small, build trust, then scale what works.

Editor’s note: An abbreviated version of this article first appeared on EdisonReport immediately after the conference.

When Taresh Grover, CEO and Co-Founder, Pull Logic stepped onto the stage at NALMCO’s 72nd Annual Convention, he didn’t begin with algorithms, jargon, or the typical AI hype.

He began with his roots. Taresh has spent roughly fifteen years in the trenches of the lighting industry, moving from early software development at ecoInsight to large-scale national rollouts with mySupplier, and now to his current role as co-founder of Pull Logic. That broad perspective— planning, procurement, field execution, and data-driven operations—shaped a talk that resonated deeply with a room full of contractors who live with the friction of everyday field reality.

His message was simple: The next “innovation cycle” for lighting isn’t a new fixture. It’s every process that surrounds the fixture.

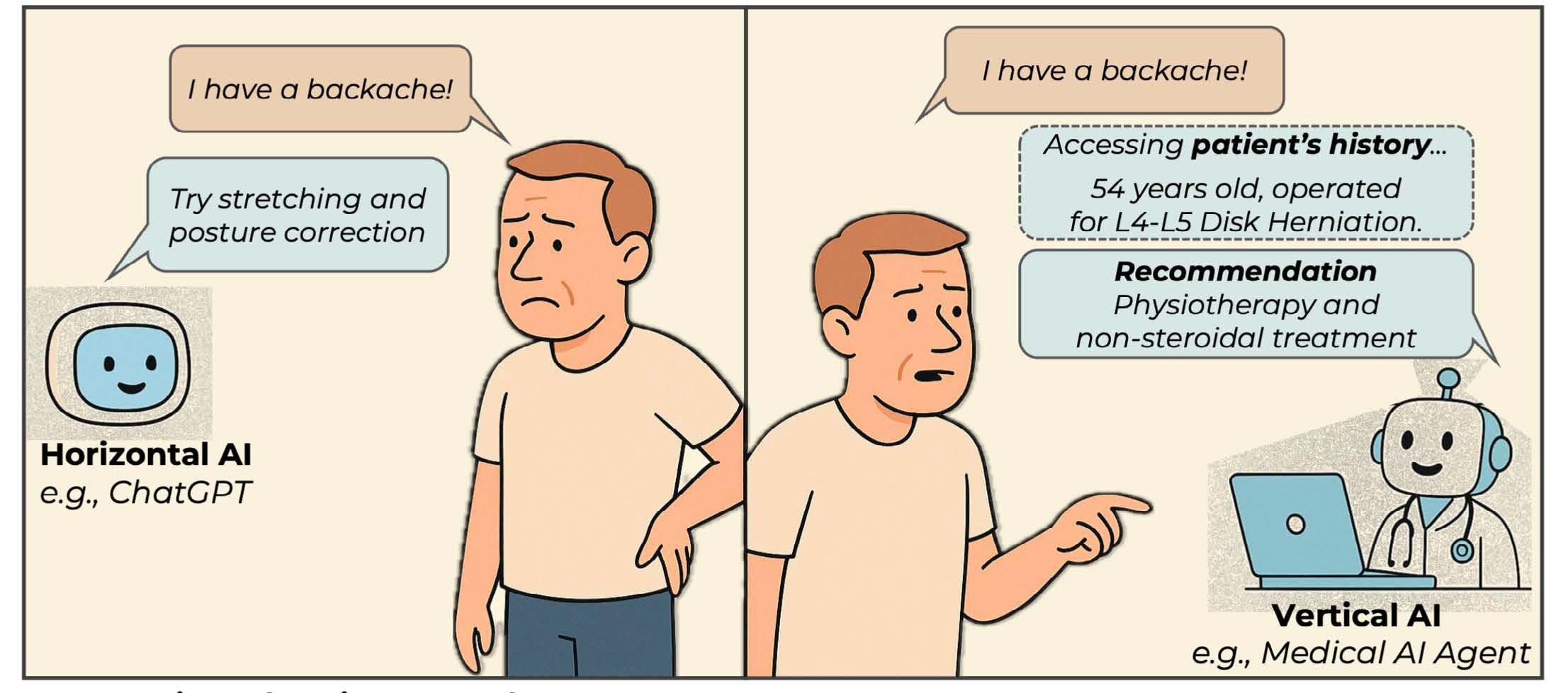

The presentation guided the audience away from the misconception that AI is a single tool or magic replacement for human expertise. Instead, Taresh drew a distinction between the generic AI many already use, such as ChatGPT, Gamma, or simple image utilities, and the vertical, context-aware AI that understands the lighting maintenance world well enough to make decisions rooted in real-world constraints.

Horizontal AI answers questions. Vertical AI helps contractors actually run their business.

The session centered on one idea: The maintenance and retrofit industry is filled with operational bottlenecks that no amount of fixture efficacy can solve. Audits still take too long. Proposals take too long. BOM crossovers eat hours from technicians and distributors. Predicting fixture availability is guesswork. Coordinating crews around delayed deliveries is a daily scramble. And forecasting which customers are due for service depends on memory, spreadsheets, or luck.

Taresh argued that AI is finally at a point where it can take these invisible inefficiencies, the parts of the work that no one bills for, and turn them into measurable productivity.

One example came from his ecoInsight days. Years ago, audits lived inside spreadsheets and camera rolls. ecoInsight digitized that process for the first time, but Taresh now sees even that as the beginning. He described an upcoming world in which a technician snaps a photo of a fixture and the AI instantly identifies the type, wattage, lumen package, efficacy, and the best match from the contractor’s preferred catalog.

From that single image, the system can generate a takeoff, develop a replacement recommendation, and produce an

ROI calculation before the contractor has returned to the truck.

That kind of audit acceleration is no longer science fiction. The models exist, and the last missing piece is connecting them to the contractor’s data.

The most compelling part of the talk for LM&M readers was Taresh’s discussion of proactive maintenance. LEDs have always been sold as a “no-maintenance” solution, yet contractors know the calls haven’t disappeared. They’ve simply changed. Fixtures fail early. Drivers age. Hours-ofuse assumptions vary wildly. And the decline of lamp-andballast cycles has shifted revenue models.

Instead of waiting for the phone to ring, Taresh described what he calls an install-base opportunity agent: a tool that monitors every past project, every product installed, its rated life, expected burn hours, and real usage patterns. The AI flags which customers are likely due for service, which are entering risk windows, and which are nearing end-of-life.

A contractor could open the tool each morning and see a ranked list of customers who should be contacted that day. The same tool can generate a proposal, attach lineitem calculations, and even draft the outbound email. It is proactive maintenance on autopilot.

He then shifted into the world of field execution. Every contractor knows the pain of delayed fixtures. A job is scheduled, crews are assigned, lifts are rented … and then a shipment slips by forty-eight hours. Today, the response is frantic texting, spreadsheet edits, and shuffling crews like a shell game.

Taresh showed how an AI project-execution agent monitors tracking numbers, lead times, and committed schedules. When a delay appears, the agent can automatically reshuffle crews, compress or expand tasks, and present an updated plan that keeps everyone billable and the project on track.

For maintenance contractors working across dozens or hundreds of sites at once, this kind of dynamic scheduling is a breakthrough.

The talk moved next to crossovers, a reality no one in the chain enjoys but everyone depends on. According to Taresh, manufacturers admit that up to 90 percent of the crossovers they generate never convert to an order, yet teams still spend hours producing them.

He demonstrated a vertical AI tool that ingests a BOM, analyzes each line item at a specification level, and offers replacements from the manufacturer’s catalog with availability data built in. It can process dozens of products in seconds. For contractors and distributors, it removes the slowest, most repetitive part of the quoting cycle.

Taresh then addressed the question many in the room wondered about: Will customers and channel partners actually trust the data sharing required for these tools to work? His answer was that adoption must begin with small pilots.

Clean data, clear guardrails, and transparent decisionmaking build trust. And trust, not technology, determines whether AI takes root inside a company. He stressed that AI must never operate as a black box. The agent should

always be able to explain why it recommended a fixture, why it assigned a crew to a task, or why it believes a project is at risk.

When people understand the reasoning, they adopt the tool. When they don’t, they abandon it.

Taresh closed with a reminder that no contractor needs to “implement AI” as a single sweeping initiative. Instead, pick one pain point, be it crossovers, audits, forecasting, or scheduling, and solve it with a targeted agent. Once that capability proves itself, layer in the next. That incremental approach, he argued, is what will define the next decade of lighting maintenance.

AI will not replace contractors. But the contractors who learn how to use AI will replace those who don’t. The lighting maintenance industry has reached a point where efficiency gains no longer come from the hardware; they come from the systems wrapped around it. And as Taresh demonstrated, those systems are finally ready.

If LM&M readers left the room with one lingering thought, it was this: The future of lighting maintenance may not be built on LEDs, drivers, sensors, or controls. It will be built on data—and the contractors who learn to use it best. ■

Horizontal AI gives generic answers; vertical AI uses your data to make context-aware decisions.

at Mt. Hood Meadows PEAK PERFORMANCE

Pacific Energy Concepts Delivers EV

Charging

By Parker Allen

When guests pull into Mt. Hood Meadows for a day on the slopes, the first thing many EV drivers see is a bank of Level 2 charging stations quietly humming away while skiers and riders head for the lifts. It’s a small visual cue that the resort’s long-standing commitment to sustainability now extends all the way out to the parking lot.

For Pacific Energy Concepts (PEC), a NALMCO member with deep roots in lighting and energy projects, the installation was more than another EV job. It was a chance to prove that welldesigned charging infrastructure can thrive in one of the harshest operating environments a site host can throw at it.

Located about an hour east of Portland, Mt. Hood Meadows operates on a special use permit in the Mt. Hood National Forest. Its terrain sprawls across the “sunny side” of Mt. Hood and offers terrain that “welcomes and challenges all levels of skiers and snowboarders,” as the resort describes on its website.1

The resort has long framed sustainability as core to its operation, from how it builds trails to how it powers facilities. Adding EV charging on-site was a natural next step in that journey.

FROM SEASON PASS HOLDER TO PROJECT CHAMPION

Tanner Carew, EVSE Sales Manager at PEC, didn’t come to the project as a stranger. He’d been a Meadows season pass holder for a while, and his first instinct when PEC launched its EV division about four years ago was to look uphill.

On one opening day, he walked from his car to the first lift and counted 30 Teslas in the lot. Just Teslas, not even counting other EV brands. The customer demand was literally parked in front of him.

Carew began prospecting and eventually connected with the resort’s Environmental Sustainability Manager, Heidi Logosz. The first reply he received from her wasn’t encouraging. Meadows was “all set” and moving forward with another vendor. A vendor who had proposed a charging solution that, in PEC’s view, wouldn’t stand up to the mountain’s brutal winters.

So, Carew kept at it; over the course of the next two years, he kept calling and emailing, staying on Logosz’s radar. The breakthrough came when a particularly attractive stack of incentives opened up. It was an opportunity Carew and PEC’s internal incentives team knew Meadows couldn’t ignore.

STACKING INCENTIVES TO MAKE THE NUMBERS WORK

EV projects at resorts, multifamily complexes, or commercial sites often live or die on the strength of available incentives. In the resort’s case, three separate programs “stacked” together into what Carew described as a “perfect storm” of funding:

• $4,500 per port from the Oregon Department of Transportation (ODOT)

• $1,000 per port from Portland General Electric (PGE)

• $6,000 per port in infrastructure funding from PGE

PEC ultimately designed the project around six Level 2 charging ports, aligning the scope with program caps and maximizing the available funds. In total, the incentives added up to $67,500 for the six ports.

Behind the scenes was PEC’s dedicated incentives team focused on researching, securing, and executing incentives for customers across markets. The timing, however, was tight. ODOT’s funding was first-come, first-served, and program dashboards showed dollars evaporating quickly.

PEC hustled to get a site walk scheduled—literally shoveling snow off the ground to locate existing conduit routes—then

turned around a proposal in about a day and a half so the resort could authorize the application.

Even with that sprint, Meadows initially appeared to miss out; the funding pool was marked as fully reserved. For several weeks, the project hung in limbo. Then came a miracle email—other projects had dropped out, funds had been freed, and the Meadows application was approved after all.

DESIGNING FOR A MOUNTAIN ENVIRONMENT

Once the numbers worked, PEC’s next priority was finding hardware that would survive and perform in the extreme mountain conditions.

PEC is vendor-agnostic and regularly works with multiple charger manufacturers, pairing hardware with third-party network software when needed. For this project, though, the team zeroed in on Flo, a Canadian manufacturer whose chargers are tested to operate in temperatures as low as -40°F and are designed as fully sealed, networked systems.

Carew explained, “Flo had the capabilities of all the other manufacturers as far as network and load sharing, stall fees—all of that. But the decision to go with this manufacturer was 100% weather-based because it’s proven in Canada.”

Several additional design details also mattered in a resort setting:

• Mounting height was chosen so snowplows could maneuver around the equipment without damaging it.

• Cable management relied on counterbalanced weights instead of bungees, which can snap when they freeze and thaw repeatedly.

• Network features such as load sharing and “stall fees”

(billing drivers who leave vehicles in spaces after charging is complete) gave Meadows operational tools to manage high-demand days when lift lines—and charge bays—are full.

MAKING USE OF EXISTING POWER AND PROTECTING CRITICAL ACCESS

Ski resorts tend to have far more available power than a typical commercial building—lifts, snowmaking, kitchens, and lighting all add up to substantial infrastructure. At Meadows, power capacity was not the limiting factor.

What made the design particularly efficient was a recent renovation to the main lodge. The project had added fresh electrical panels on the second floor near the new restaurant kitchen. PEC was able to pull from those panels and complete a relatively short saw cut to reach the charger locations.

To minimize disruption, PEC placed the chargers on three new concrete bases in a landscaped “softscape” area. That approach preserved existing asphalt where guests park and kept construction impacts focused and manageable.

At the same time, Carew and the design team had to respect operational constraints unique to a ski resort, including a dedicated ambulance space near the lodge that had to remain clear at all times.

Altogether, the final layout delivers:

• Premier parking for EV drivers right at the front of the lodge

• Short conduit runs and minimal trenching for cost control

• Protected emergency access and clear pedestrian circulation

TURNKEY DELIVERY, ON TIME AND ON BUDGET

From Meadows’ perspective, one of PEC’s key values was its ability to manage the project end-to-end. The company subcontracted the physical labor but handled everything else: site evaluation, design, equipment selection, coordination with contractors, utility engagement, incentive applications, and overall project management.

Once the funding was secured and contracts were in place—around August—the clock was ticking. Snow can arrive early on Mt. Hood, and Meadows needed the chargers energized before the winter season. PEC pushed the project through design, procurement, and construction in time to have the system live for skiers before the weather fully closed in.

WHAT ABOUT MAINTENANCE?!

The long-term care of EV infrastructure is a natural concern. In Carew’s experience, true “maintenance” on Level 2 equipment is relatively light when projects are well-designed and properly installed.

Most site calls PEC sees are not about wear-and-tear on the electronics but about accidental damage: a delivery truck or snowplow clipping a pedestal, or connectivity challenges in

areas with weak cell coverage. PEC screens for those issues during the sales and design process, specifying cellular boosters or Wi-Fi-based solutions when needed.

At Meadows, there have been no maintenance callbacks reported since the chargers went live. PEC continues to support the site with warranty facilitation and troubleshooting if needed, but day-to-day operations have been smooth—especially impressive given the mountain environment.

TAKEAWAYS FOR LIGHTING AND MAINTENANCE CONTRACTORS

Mt. Hood Meadows’ EV project highlights several lessons for those who are expanding from lighting into EV infrastructure:

• Follow the load—and the lifestyle. Carew’s initial insight came from simply walking the lot and counting EVs. For many facility service providers, the opportunity is already in their customers’ parking lots.

• Let incentives drive timing and scope. By understanding stackable programs and aligning port counts with caps, PEC turned a “nice to have” into a financially compelling project.

• Design for environment first. In harsh climates, weather-driven hardware choices and small design details (like cable management and mounting height) can make or break long-term performance.

• Respect site operations. Keeping ambulance access clear, minimizing civil work, and locating chargers where they serve both drivers and operations is just as important as the electrical design.

• Treat EV as an extension of existing expertise. For PEC, EV charging grew naturally out of its work in lighting and energy efficiency. The same project management, incentive navigation, and long-term customer relationships that define lighting maintenance can underpin a successful EV practice.

For Mt. Hood Meadows, the payoff is clear: Guests can now plug in, head for the lifts, and come back at the end of the day to both a charged vehicle and the satisfaction of knowing their mountain home is investing in a lower-carbon future.

This project stands as a model for what’s possible when you bring together persistence, incentives expertise, and thoughtful design—at 6,000 feet and beyond. ■

WHAT'S NEW

SEKTOR AREA LIGHT

Sektor Area Light delivers efficient, highperformance outdoor illumination with lumen and wattage selectability, field-changeable optics, and IP65-rated durability. Featuring an integrated 3-pin photocell and Zhaga Z10 receptacle for Bluetooth or PIR controls, it offers modern flexibility for parking lots, campuses, and commercial exteriors in bronze or white housings.

PHUZION PHV™ LED LINEAR HIGH BAY

The new Phuzion PHV™ LED high bay was created to solve even the most challenging industrial applications. This fixture’s unique tilting capability allows for customized light distribution in any space. By delivering true industrial ratings and listings, the Phuzion PHV™ is designed to the highest performance and quality standards.

GLAREX SFL

IKIO’s GlareX SFL delivers broadcast-quality, lowglare illumination using advanced multi-layer optical technology, ideal for Class I & II sports venues. Available in 800W–1200W models, it provides uniform coverage with tight beam control. FlexiDriver™ Technology moves the driver to ground level for safer, faster maintenance, while DMX and SimplySNAP wireless controls enable dynamic lighting scenes for competitive and entertainment events.

SLIM DOWNLIGHTS

MaxLite’s Slim Downlights install directly into the ceiling with no recessed can needed, offering fast retrofit flexibility. A switch on the remote driver/ junction box allows field selection of 2700K–5000K color temperatures, while the low-profile design supports IC-rated and airtight installations. Available in 4", 6", and 8" sizes, the fixture provide 120V Triac dimming and optional emergency battery backup for added versatility.

GRID FRAME LIGHT

BALLAST BYPASS TYPE B

EarthTronics’ new 4' T8 LED Linear Lamp delivers 1700 lumens while using just 10.5 watts, providing an easy, ballast-free direct-wire Type B retrofit solution. Available in 4000K and 5000K with an 82 CRI, the lamp offers a wide beam angle and even illumination. Rated for 50,000 hours and suitable for troffers, strip fixtures, and task lighting, it is DLC, UL, FCC, and RoHS listed.

The EiKO Grid Frame Light (GFL) combines architectural perimeter illumination with easy installation. The single-piece design eliminates field assembly and drops directly into standard T-grid ceilings, delivering continuous light distribution without cutoffs. With field-selectable power (PowerSET) and color temperature (ColorSET) and 120-347V operation, the GFL offers versatile performance for commercial and premium residential applications.

MAKING THE CASE FOR LUMINAIRE LEVEL Lighting Controls

When luminaire level lighting controls (LLLC) first hit the market, even seasoned efficiency pros were skeptical. John Wilson was one of them. The founding director of Fernhill Shopworks and longtime utility/energy-efficiency consultant freely admits he “went from being deeply skeptical” to a full convert after working with the technology for years.

During a recent BetterBricks webinar entitled “Mythbusters: Debunking LLLC myths around cost, complexity, aesthetics, and demand,” Wilson and co-presenter Nikki De Luna of RAB Lighting walked through some of the most persistent misconceptions holding projects back. They showed how today’s LLLC systems look very different from early generations.

They organized the conversation around the life of a project. Across each phase, a clear theme emerged. Most issues with LLLC were true at one time, but the technology and market have evolved.

Myth #1: LLLC only makes sense for new construction.

Early on, that was often the case. Few manufacturers offered retrofit-friendly LLLC options, and the cost premium over standard LED fixtures could be steep, especially once networking hardware was added. That history helped cement the idea that LLLC is a “nice-to-have” for pristine new buildings, not renovations.

Today, that’s outdated thinking. De Luna noted that there are now dozens of qualified LLLC systems on the market, with manufacturers offering:

• Integrated LLLC luminaires

• Retrofit kits for fluorescent-to-LED upgrades

• Options to add controls to existing LED fixtures

Because each fixture effectively has its own “brains,” contractors can do simple one-for-one retrofits while still delivering sophisticated zoning, tuning, and scene control. Wilson pointed out that this allows projects to preserve existing layouts while still achieving the kind of tailored performance that used to require a full redesign.

In other words, LLLC is often more powerful in existing buildings, where flexibility and future-proofing are at a premium.

Myth #2: You must have a gateway to meet

scheduling and code requirements.

By Parker Allen

Early systems did need a dedicated gateway, and adding a gateway meant more hardware, wiring, commissioning time, and cost.

Modern LLLC systems have shifted that logic. As De Luna explained, many manufacturers now embed programmable schedules and timekeeping directly into each device. The fixtures communicate wirelessly (via Bluetooth mesh, cellular, etc.), and the system can store schedules locally, recover after power outages without losing programming, and be configured via a mobile app or laptop.

Gateways still have a role for advanced capabilities such as remote access, BACnet integration, enterprise dashboards, and multi-building coordination. But, they’re no longer a prerequisite for basic scheduling and code compliance.

That’s a big cost and complexity win for smaller and mid-sized projects.

Myth #3: Wireless communication is unreliable and hard to troubleshoot.

This myth blends two older realities. Early wireless controls did have reliability issues and clunky commissioning workflows. And, people often conflate “wireless” with “battery-powered” and assume an endless stream of battery replacements.

Wilson and De Luna stressed that both points miss where the market is now. Improvements in mesh networking mean that modern LLLC systems use self-healing mesh topologies, where each device can send and receive messages, boosting resilience. Contractors can commission groups of fixtures at once, not one-by-one. And, through app-based diagnostics, if something goes wrong, the system flags where and why, often without requiring a site visit from a specialist.

Importantly, Wilson emphasized that wireless LLLC deployments have been accepted in high-security applications because of their secure protocols and certifications. Cyber risk hasn’t been a practical barrier when systems are specified and installed properly.

Myth #4: A sensor in every fixture means every luminaire acts autonomously and setup is a nightmare.

Here, the myth stems from confusing two very different things. With Standalone embedded controls, fixtures have

their own non-networked sensors, programmed one at a time, acting on their own. True LLLC, on the other hand, are inherently networked, with group/zone logic across fixtures.

Standalone embedded controls can be useful, but they do force per-fixture setup and can’t respond as a coordinated system. That experience has soured many people on the idea of “a sensor in every luminaire.”

By contrast, LLLC systems are designed to treat those individual sensors as networked inputs. De Luna explained that in many modern systems, fixtures default into logical groups and can quickly be re-zoned or divided into subgroups. Furthermore, many manufacturers now ship fixtures with integrated sensors as standard, because the sensor can simply be disabled or ignored in software where not needed.

Designers and contractors gain flexibility instead of complexity. They can “over-provision” sensors and sort out the exact control logic later, in software, rather than trying to guess the perfect sensor layout on day one.

Myth #5: More devices on the network means more gateways and more complexity.

In early networked lighting controls, systems often had hard limits on the number of devices. When those thresholds were reached, the project needed more hardware.

Mesh-based LLLC architectures have largely broken that model. Because every luminaire is a node and messages can hop across the mesh, the system can cover large areas and multi-story zones without adding extra networking hardware simply for reach. Hundreds or even thousands of devices can be supported in a single logical system, depending on the manufacturer and topology.

Myth #6: The best way to keep tenants happy is to give everyone maximum individual control.

On paper, it’s tempting: LLLC and networked controls make it easy to give every occupant their own app, slider, or wall station. In practice, Wilson and De Luna agreed this can devolve into “too many cooks in the kitchen.”

The presenters advocated for well-thought-out sequences of operation (SOOs) instead. Engage stakeholders up front to understand real use patterns, and then design scenes, levels, and timeouts that support those patterns. Reserve the finegrained control for facilities staff or designated power users.

Myth #7:

Lighting networks are tied directly into the corporate network (and that’s a security nightmare).

With cyberattacks and ransomware on the rise, it’s understandable that IT teams react strongly to talk of networked lighting. But as Wilson and De Luna stressed, LLLC networks are typically isolated systems by design.

Modern offerings often use:

• Bluetooth mesh, which doesn’t require Wi-Fi access at all,

• Cellular backhaul, completely bypassing the corporate LAN,

• Or segmented network architectures that meet cyber policies when integration is desired

Many manufacturers pursue formal cyber certifications, like UL 2900-1. The DLC’s Networked Lighting Controls Qualified Products List requires disclosure of cyber practices and certifications as part of listing.

Myth #8: Lighting networks always require dedicated gateways.

This myth persists partly because gateways remain important for advanced use cases like remote access, BACnet, enterprise dashboards, or cloud analytics. But for many breadand-butter projects, they’re simply not required anymore.

In mesh-based LLLC systems, each luminaire and control device participates in the network. A contractor’s phone or tablet essentially acts as a temporary gateway when they’re logged in on-site, pushing configurations and firmware updates over Bluetooth or another protocol.

Furthermore, code-minimum features such as occupancy sensing, daylight harvesting, scheduling, and high-end trim can all be delivered without installing a permanent gateway appliance.

That reduces cost and risk for budget- or IT-sensitive projects, while leaving room to add a gateway later if the owner wants additional capabilities.

Myth #9: Customers only care about the cheapest solution.

Value engineering has been a stubborn reality in construction. Lighting and controls often get cut late in the process to offset overruns elsewhere. Because early LLLC products carried a noticeable fixture-level premium, they were easy targets.

But as Wilson pointed out, this mindset tends to backfire. De Luna framed the conversation around what customers actually say they want: lower operating costs, flexibility, ease of use, and minimal maintenance.

LLLC systems directly support those goals by offering:

• Built-in energy savings from layered controls (scheduling, occupancy, daylighting, high-end trim).

• Software-defined flexibility, so layouts and uses can change without ripping out hardware.

• Firmware updates that add new features over time, extending product life and value.

• Reduced need for bucket trucks and ladders, as many adjustments can be made from the ground.

When projects are framed around total cost of ownership and long-term value, rather than initial cost, LLLC frequently becomes the cost-effective choice, not the luxury one.

Busting the Final Myth

Most lingering objections to LLLC are based on an older generation of technology and market conditions.

For specifiers, contractors, utilities, and owners still operating on outdated assumptions, the webinar was a call to revisit LLLC with fresh eyes and to see it not as a niche option, but as a practical path to better, smarter, more adaptable lighting. ■

2025 Annual Convention and Trade Show

QUICK HIGHLIGHTS

215 registered attendees 19 sponsors 40 exhibitors

PROCEEDINGS

General Sessions

The AI Surge: Reinventing the Lighting & Electrical Industry with Taresh Grover, CEO & Co-Founder, Pull Logic

■ For an in-depth discussion of this general session, please see AI Moves from Buzzword to Jobsite.

Freedom Is an Attitude with Stephen McGown, author of Six Years with Al Qaeda

■ For a recap of Stephen’s powerful message, please see Kidnapped by Al Qaeda.

Lumina Award

McGown captivated the audience with the story of his capture, imprisonment, and release, sharing what he learned about human resilience when pushed to the limits of survival.

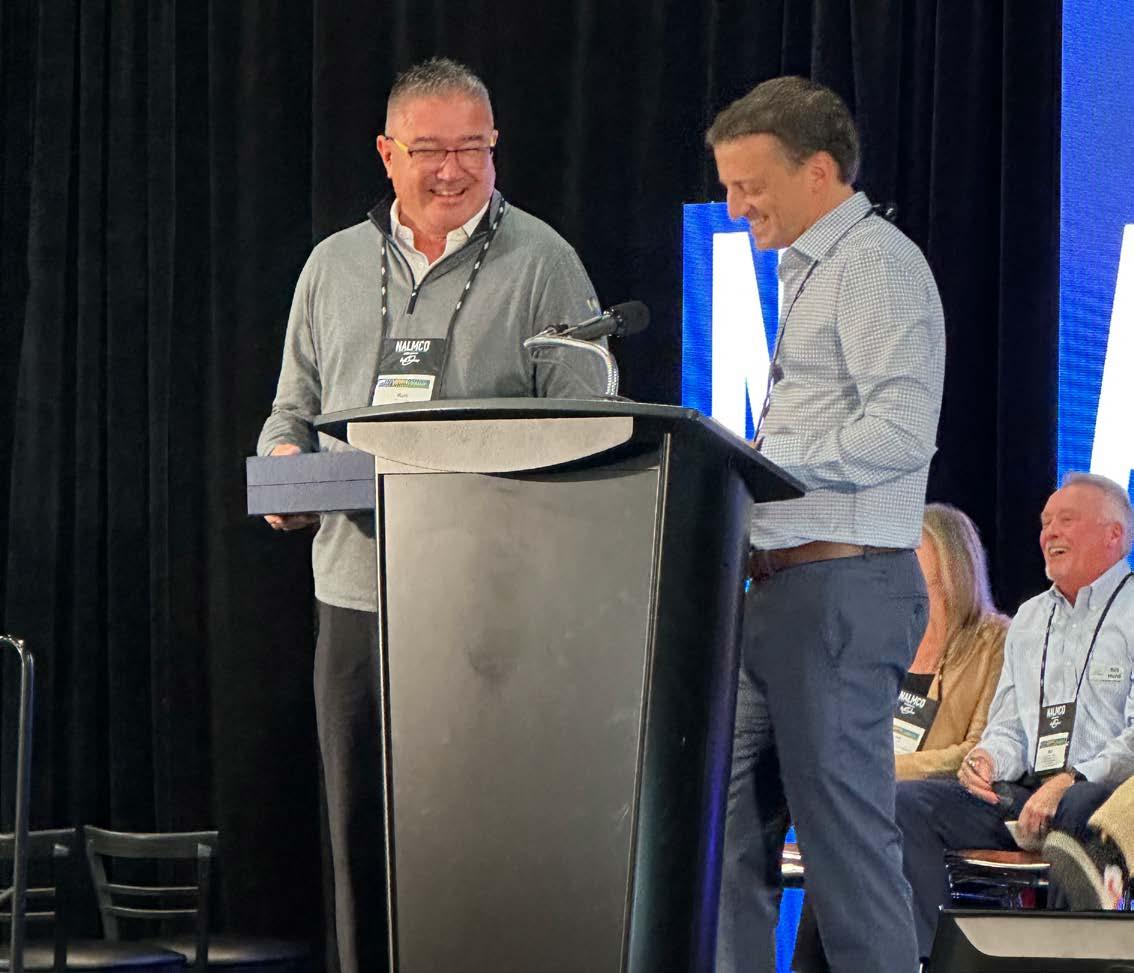

Ron Hughes, longtime NALMCO member and Ex Officio Adviser on the Board of Directors, was honored this year with the Lumina Award. This award is presented for commitment, loyalty and dedication to the leadership of NALMCO.

CONVENTION HIGHLIGHTS

INTERVIEWS

Bill Hurd, NALMCO’s Membership Chair, discusses recordsetting growth in 2025 and the launch of Association’s first mentorship program.

Program Chair Kevin Heid reflects on how NALMCO’s signature networking and timely education on topics like AI will continue to shape future programming and help members stay ahead in a rapidly evolving landscape.

Treasurer and President-Elect Monica Kristo shares what the future holds for NALMCO and how the Association’s leadership is positioning NALMCO—and its “big family” of members—for continued growth and impact in the lighting maintenance industry.

SPECIAL RECOGNITION

NALMCO extends heartfelt gratitude to the sponsors that made this event possible.

PLATINUM

■ Acuity Brands Lighting

■ Keystone Technologies

■ LEDVANCE

GOLD

■ LSI Industries, Inc.

SILVER

■ Energy Solutions International, Inc.

■ MaxLite

■ Peace Services, LLC

■ Satco Products Inc. BRONZE

■ Avi-on Labs, Inc.

■ BWI Light

■ ESCO, Retrofitters Direct

■ ESPEN Technology

■ Graybar Electric

■ Jarvis Lighting

■ Lighting Resources, LLC

■ Linmore LED

■ SENSORWORX

■ SnapCount

■ Utility Management Solutions

And a special thank you to all those on the Program Committee who made the whole event possible.

Kevin Heid, CLMC

Joan Blacker

Andria Parker

Dan Magee, LC, CLMC

Erik J. Ennen, CLMC, CLA, CLCP, CLEP, C-GUVMP

George McIntyre

John Alba

Jonathan Cupples, CLMC

Katina McMillian

Laura Sanchez

Lauren Wilson, CALT

Manuel Andrews, CALT, CLMC

Mike Roy

Monica Kristo, CALT, CLA, CA-GUVT, CLMC, CLEP

Pattie Cagle, CLMC

Ron Hughes

Scott Mendelsohn

Stephen E. Reeves

Wayne Callham, CLMC,CLEP, LC, CLCP

Rogers Electric Northwest Edison

Peace Services, LLC

LEDVANCE (SYLVANIA)

Center for Energy and Environment

Acuity Brands Lighting

Retro Spec Lighting Corp

Delta Wye Group

AGI

ESCO, Retrofitters Direct

Stones River Electric

Brighter Solutions, L.L.C.

Mantis Innovation

Rea Lighting Inc.

Rogers Electric

Lighting Resources, LLC

Imperial Lighting Maintenance Company LEDVANCE (SYLVANIA)

Linmore LED

NEW CERTIFICATIONS

CERTIFIED APPRENTICE

LIGHTING TECHNICIAN™

Brighter Solutions, LLC

Giovann Vega, CALT

Colorado Lighting, Inc.

Mikalai Budzko, CALT

CSL Technology Solutions

Roger Lewis, CALT

Energy Management

Collaborative

Jeff Johnson, CALT

Reed Morgan, CALT

Facilities Solution Group

Geonta Cotton, CALT

Sai Vaughn Mitchell, CALT

Lighting Technologies Inc.

John Rakestraw, CALT

Lumatech Inc.

Matt Dillon, CALT

Pacific Energy Concepts

Brandon Arias, CALT

Willdan

Kerry Wiggins, CALT

Mamadou Sow, CALT

Marlon Aberdeen, CALT

Unaffiliated

Caleb Bourne, CALT

CERTIFIED SENIOR

LIGHTING TECHNICIAN™

Candela Systems Corporation

Joseph Marji, CSLT

SitelogiQ

David Lawley, CSLT

CERTIFIED LIGHTING CONTROLS PROFESSIONAL™

Acuity Inc.

Mahan Royanipour, CLCP

Blackwell Contracting Corp

Harshdeep Singh, CLCP

Enterprise Electrical

Layton Kubish, CLCP

IoT Deployment Services

Sydney Jagneaux, CLCP

Keystone Technologies

Peter Braunston, CLCP

TowerPinkster

Joshua Rinehart, CLCP

CERTIFIED LIGHTING MANAGEMENT

CONSULTANT™

Facility Solutions Group

Frank Agraz, CLMC, LC, IES

Imperial Lighting Maintenance Company

Lisa Orloff, CLMC

LED Solutions

Jacob Glenn, CLMC

NEW MEMBERS

Zeus Lighting LLC

Join Date: 10/7/2025

Lumic Electric

Join Date: 10/14/2025

APS Lighting and Electrical, LLC

Join Date: 10/15/2025

Summit West Signs

Join Date: 11/13/2025

Kidnapped by Al-Qaeda

When Steve McGown stepped onto his motorcycle in 2011, he believed he was starting a defining chapter of his life. After years in banking in South Africa and the UK, he and his wife Catherine were preparing to move home, start a family, and settle into a new season together.

Before doing that, he wanted to fulfill a lifelong dream. He would ride a motorcycle from London to Johannesburg, taking the long way down the west coast of Africa. It would be adventure, reflection, and a final breath of freedom before returning home to build the next stage of his life.

Instead, that dream unraveled into something unimaginable. Steve was kidnapped by Al-Qaeda in northern Mali and held captive for five years and eight months, making him for a time the longest-held Al-Qaeda hostage in the world.

His journey became an extreme test of survival and self-mastery, a stretch of

life that challenged every assumption he had about control, resilience, and what it means to stay human when the world collapses around you.

This past October at the NALMCO Convention, Steve stood before the industry and shared the heart of that experience. His message was simple but powerful. Freedom is an attitude Even when you lose everything, you still choose how you respond.

This is the story behind that message.

A Detour Into the Unthinkable

The trip began the way these journeys often do, with the excitement of open roads and unknown places. Steve traveled with other overlanders he met along the way, including a Dutch couple and a Swedish traveler named Johan. Together, they reached Timbuktu on November 24, 2011, planning only a short stop before moving deeper into West Africa.

They never got the chance.

The next afternoon, as they rested at a small bed and breakfast, three armed men walked into the courtyard. One carried a pistol. Two carried AK-47s. In seconds, the calm day snapped apart.

Steve and the others were ordered to the ground. They were dragged out one by one and handcuffed. When another traveler, a German national named Maertin, resisted, the militants shot him in the street.

Within minutes, Steve and the others were thrown onto the back of a waiting pickup. They were driven into the Sahara through the night, deeper and deeper into the desert until the world Steve knew disappeared entirely.

A Life Reduced to the Bare Minimum

In the early months, every day was chaos. The desert was brutally simple: sand, heat, cold, and endless uncertainty. Camps were little more than scrapes in

The Mindset That Saved Steve McGown’s Life

By Randy Reid

the earth with a tree or a scrap of shade. Food was rice, spaghetti, goat, camel, whatever could be found or cooked. Water came from old fuel drums rinsed out at wells—clean enough to drink, but always with the shimmer of diesel on top.

There were no doctors. No medicine beyond paracetamol. No protection from the elements. No comfort at all. As Steve said, “It was literally medieval.”

The Al-Qaeda fighters around them ranged from teenagers to elderly men. Some were friendly. Others were erratic, hardened, or mentally fractured. At night, Steve was handcuffed. During the day he stayed inside a small, designated area, an attempt to keep him hidden from overhead surveillance.

The physical conditions alone could have broken him. But the hardest battle was mental.

Isolation, fear, and boredom wore at him. Time meant nothing. The days blended. Survival required discipline, focus, and a fierce commitment to not mentally collapse.

Building Routine in a Place Designed to Break You

One of Steve’s earliest realizations was that even the smallest routine could help restore a sense of control. So he built one.

He woke at the same time. He helped with firewood. He created makeshift tools from scraps of packaging. He exercised by walking in figure-eight patterns, jogging in small circles, even inventing boot-camp style drills in the dirt. Anything that produced endorphins was gold.

At night he lay under a blanket on the sand, staring at the stars and thinking of his family. The desert was silent except for the wind and the animals that wandered through camp. Hyenas. Jackals. The occasional snake. Once, a tortoise walked right into his hut and parked itself in the shade beside him.

The routines didn’t just fill time. They protected his mind.

“Simplicity became a strength,” he told the audience. When the world around you is stripped to nothing, keeping even a tiny piece of structure keeps you standing.

The Battle to Stay Human

Perhaps the most remarkable part of Steve’s story is not how he stayed alive, but how he stayed himself.

The three prisoners didn’t always get along. Stress creates friction. Personalities clash under pressure. Steve realized early that if he wanted to survive mentally, he needed to avoid becoming hardened or bitter. So he practiced the small habits that kept him human.

He wrote reminders to himself on scraps of cardboard pulled from the trash pit: Be positive. Be enthusiastic. Don’t be selfish. Smile. These reminders became his lifeline. He read them when he felt himself slipping.

He also watched people closely. Some fighters were angry and withdrawn. Others were calmer, more social. Steve noticed that attitude created its own reality, even in a desert prison. So he chose optimism—not blindly, but deliberately.

He made conversation. He learned to read and write Arabic. He helped with small chores. He stayed curious.

He refused to let the desert shrink him.

“Take life, take what you want from me,” he said, “but don’t take me from me.”

A Decision That Changed Everything

Steve’s captors regarded him as the most valuable hostage because he held dual British and South African citizenship. That put a target on his back. He feared execution constantly. In one moment, a guard pointed a gun at him and told him he had one minute to fall asleep. Steve

Take what you want from me, but don’t take me from me.

lay there counting down, unsure if he would hear a gunshot or nothing at all.

Under that pressure, he made a decision many people struggle to understand. He converted to Islam.

This was not about belief. It was about survival. Conversion changed how he was treated. It allowed him to join daily prayers, learn the language, participate in teaching circles, and be seen as a person rather than an enemy.

It gave him more mental stimulation and more movement. It broke the isolation. It brought balance to a place where balance didn’t exist.

beyond our comfort zones and act.

Holding on to the Future

By Parker Allen

Images courtesy of Morlights

And most importantly, it opened a new channel of connection with the people who controlled his fate.

Some might judge the choice. Steve is clear: When a gun is pressed to your head, and you believe the next heartbeat might be your last, you do what you need to survive.

Violence, Improvisation, and the Constant Search for Solutions

Survival required continuous problemsolving. Steve had to clean wounds without proper medical supplies, protect his skin from the brutal sun, and figure out how to prevent infections in a place where hygiene was almost impossible.

At one point, he developed a painful, constantly bleeding growth on his back that he feared was cancer. With no doctor available, he convinced his fellow hostage Johan to remove it using a boiled razor blade. After cutting it out, Steve cauterized the wound with a heated metal skewer he fashioned from scrap.

It was excruciating. But it worked. Moments like this reinforced something he repeated during his talk: We are far stronger than we think. We only learn that strength when we are forced to step

While Steve worked to stay physically and mentally intact, his family back home fought their own battle. Catherine, his wife, had to live with years of silence, uncertainty, and fear. His parents did, too. Every missed call brought dread. Every rumor brought hope or heartbreak. Steve often thought about them while lying under the desert sky. He was determined not just to survive, but to survive as someone they would still recognize when he came home. That intention shaped every choice he made.

Freedom, When It Finally Came

When Steve was finally released in 2017, he stepped back into a world that had moved forward without him. Technology had shifted. Children he knew were now teenagers. Friends had changed jobs, moved houses, and started new phases of life.

He had to rebuild everything. But he rebuilt it with a new understanding of what freedom really means.

Freedom is not safety. It’s not comfort. It’s not predictability.

Freedom is the ability to choose your attitude.

It’s the ability to control your reactions when you cannot control your circumstances. It’s the power to stay rooted in who you are when everything else has been stripped away.

That is the message Steve brought to NALMCO.

Not that hardship is good. Not that suffering makes you noble. But that even at the bottom—maybe especially at the bottom—you can choose how you respond.

That choice is where resilience begins. ■

MEMBER SPOTLIGHT WITH

LOUVERS INTERNATIONAL

Made-in-USA Problem Solvers with a Maintenance Mindset

By Parker Allen

When Devin and Derek Wall talk about Louvers International, they don’t start with SKUs or spec sheets. They start with contractors, distributors, and maintenance teams in the field.

That focus has shaped the company since their parents founded Louvers International in 1986, and it continues to guide the second generation today.

Headquartered in Elmhurst, Illinois, Louvers International has grown from a small plastics and louvers shop into a nationwide and international manufacturer of LED fixtures, retrofit solutions, and custom optics, supported by multiple U.S. manufacturing plants and third-party distribution partners.

A 60,000-square-foot facility in Spokane, Washington, helps them serve Western customers more efficiently, with additional inventory positioned closer to markets like California where freight can be challenging.

Along the way, their mission has stayed remarkably consistent: Design and build lighting products that are easy to install, easy to maintain, and genuinely solve problems.

FROM LOUVERS TO FULL FIXTURES

The company’s roots are in the legacy side of the business— lenses, louvers, and plastics for existing fixtures. That work continues today in the form of custom lens fabrication and component upgrades.

A good example is their work at Chicago’s O’Hare International Airport, where the city was considering a full fixture replacement that would have required significant labor and a high-end product package. Instead, Louvers International collaborated with the contractor and distributor to design a custom frosted lens solution tailored to dozens of unique run lengths across the terminal.

The solution provided a refreshed, cohesive look and substantial savings while still delivering a premium aesthetic.

That kind of approach has helped Louvers carve out a niche with maintenance-focused customers who need realistic solutions for existing spaces.

LISTENING TO THE FIELD, AND DESIGNING AROUND IT

Devin and Derek didn’t originally plan to join the family business. Nearly two decades ago, they were running their own companies when a staffing change at Louvers prompted the need for help. The two jumped in, quickly immersed themselves in the lighting world, and began building products based on what they were hearing on job sites.

One of their early successes was the Advantage Vaportight, born directly from contractor and distributor feedback. Instead of dropping a strip into a fiberglass body, they leveraged their injection-molding experience to create a purpose-built housing and gear tray that was easier to service and more installer-friendly in the field.

That approach has carried forward into the LED era. Louvers International partners closely with Philips for LED engines, drivers, and components, and designs many of their fixtures to be modular and tube-ready. They also routinely “job pack” and kit products—pre-sorting tubs, gear trays, and lenses—so contractors don’t waste time unboxing and reassembling fixtures on site.

As Devin emphasized, there’s “no red tape” at Louvers International. If a customer brings in a challenging application, anything from elevator cab indicators to decorative post tops, Devin and Derek can walk out to the shop, work with their team, and decide quickly whether they can design and build a solution at a price that works for everyone.

SUSTAINABILITY AS MAINTAINABILITY

Ask Louvers International what “sustainability” means, and you won’t just hear about efficacy charts. For them, sustainability starts with how easy it is to maintain, repair, and upgrade a lighting system over its life.

They’ve been outspoken about the challenges that have come with dedicated, non-serviceable LED fixtures and lumen-per-watt mandates. Louvers International works to keep replacement parts available for the fixtures they sell and embraces retrofit-friendly designs, including tube-ready housings and modular boards, where appropriate.

That philosophy aligns naturally with NALMCO’s membership, where long-term maintainability, owner value, and service revenue all intersect.

WHY NALMCO?

The company has been active in industry organizations for years, including NAILD, where Devin has served on the board and worked alongside other manufacturers on issues like dark-sky practices and education. Those experiences made it clear just how powerful a tight-knit, education-driven community can be for both distributors and manufacturers.

Their first direct exposure to NALMCO came when Devin attended a convention as a NAILD ambassador rather than as a manufacturer. Between the keynote, the education, and structured speed-dating, he saw meaningful connections forming between maintenance contractors and vendors, with real opportunities to talk shop.

Relationships also played a role. Louvers International is friendly with several long-time NALMCO supporters, including board leadership and LCA members who encouraged them to get involved. As Devin noted, NALMCO members tend to listen to and trust fellow NALMCO members. Joining the association was the most direct way to get in front of the lighting management community they already cared about serving.

A first-year manufacturer membership incentive helped make the timing right, but the decision was ultimately about alignment. Louvers International sees itself as “Made-in-USA problem solvers” for the same customers NALMCO serves.

As they look ahead, Louvers International plans to deepen its engagement with NALMCO through conventions, education, and collaboration on projects that showcase what’s possible when you combine field-driven design with a commitment to repairability and made-in-USA manufacturing.

If you’ve got a challenging retrofit, a legacy system you’d rather not rip out, or a maintenance-heavy site that needs smarter solutions, there’s a good chance Devin, Derek, and the Louvers International team have seen something similar— and would be happy to help you bake a better cake and make sure everyone gets a slice. ■

PRESSURE POINTS BENEATH A CALMER SURFACE

By Parker Allen

As 2025 winds down, the global supply chain looks calmer on the surface than it has in years, but there are plenty of pressure points just below the waterline. The story this season is less about dramatic disruption and more about slow-burn changes in rates, regulations, and capacity.

On the ocean side, capacity into North America is generally available and service reliability is better than it was a year ago. C.H. Robinson reports that global schedule reliability has improved to roughly two-thirds of sailings arriving on time, though late ships are still running nearly five days behind schedule on average.1

Global shipping giant Maersk echoes that picture, explaining in their most recent North American Market Update that space is open from Europe and Asia into U.S. ports, but shippers should still expect tightening as we approach Chinese New Year at the end of January and plan bookings accordingly.2

For those relying on imported fixtures, drivers, and components, that translates into a more predictable ocean market where early booking remains cheap insurance.

The bigger story is inland. Truckload spot rates, which sat at cyclical lows earlier in the year, are now climbing, and C.H. Robinson has raised its cost-per-mile outlook for both 2025 and 2026. At the same time, new enforcement around CDLs and English language proficiency is expected to chip away at driver supply as we move into next year.1

Maersk notes that U.S. carrier revocations are running 5,000–6,000 per month. It is one of the most significant structural contractions since deregulation. Drayage networks on the West Coast and key Canadian gateways are already feeling the strain.2

For lighting shipments moving from ports to regional

DCs, that means the risk of tighter truck capacity and higher last-mile costs is growing, even if headline freight rates still look stable.

North of the border, Canadian inland flows are another thing to keep an eye on. Railcar shortages and heavy volumes on the West Coast mean some containers are waiting one to two weeks to get onto trains, and low water levels on the St. Lawrence River are limiting drafts and adding variability to schedules in Eastern Canada.2

If your supply chain runs through Vancouver, Prince Rupert, or Montreal, it’s worth building extra lead time into project schedules and stocking critical SKUs closer to job sites.

Trade policy remains a wild card. Maersk warns of stepped-up enforcement on steel and aluminum origin rules and new duties on selected goods from India, Vietnam, and Turkey, with extra tariffs in the 10–35% range depending on the product.2

For our industry, that could touch everything from sheetmetal housings and hardware to electronics and wiring accessories.

Finally, warehousing is quietly being reshaped. Maersk notes that U.S. warehouse vacancy has climbed to an 11-year high of 7.1%, with third-party logistics providers now accounting for nearly 40% of industrial leasing.2

Rather than locking into long, inflexible leases, many brands are opting for shared or outsourced facilities that let them scale space up and down.

The bottom-line takeaways? Ocean freight is no longer the primary headache. Instead, pay close attention to inland bottlenecks and tariff fine print. Lock in trucking capacity on core lanes where you can, diversify ports and routings for critical imports, and lean on flexible warehousing to keep buffer stock closer to customers. ■

1 C.H. Robinson (6 November 2025). Freight Market Update: November 2025. https://www.chrobinson.com/en-us/resources/insights-and-advisories/north-americafreight-insights/nov-2025-freight-market-update/

2 Serra, F. (3 December 2025). “Maersk North America Market Update – December 2025.” Maersk. https://www.maersk.com/news/articles/2025/12/03/northamerica-market-update-december

AD INDEX

UP CLOSE WITH KYLE LANDIG

During that inevitable grade school class, when students are asked to draw a picture of what they want to be when they grow up, Kyle Landig’s choice was a little atypical. He didn’t draw a teacher, doctor, or fireman. Instead, he drew “a picture of myself holding a briefcase, knowing someday I’m going to take over my dad’s business.”

The business, Sunset Lighting, based in Irvine, California, was founded in 1990, offers services in lighting, electrical and signage repair with a focus on clients operating a national network of facilities.

Kyle graduated from UC Santa Barbara in 2008, having already interned at Sunset Lighting for a couple of summers. He joined the company full time at what quickly became a “brutal” time in the Great Recession.

He noted, “There were layoffs within the first eight months of my career. I took a pay cut my first year. It was rough ... My dad originally wanted me to go into sales, but I wanted to do operations. I am a natural problem solver and saw opportunity to create standard operating procedures, create an operations manual, and overall become more efficient. The changes led to a lot of growth, seriously improving our service. Now, we are fundamentally a customer service company that happens to provide lighting and electrical services. That commitment to service has led us to become seven times bigger than when I joined the company.”

The 2020 pandemic was Kyle’s biggest challenge. He called it “a more formative experience than the 2008 recession,” explaining, “I was much more mature in my career in 2020. I was a Vice President, and my dad was President. He was not keen to embrace a remote work environment at that stage in his career. With my mom battling terminal cancer, he retired in 2020.”

Stepping up to run the business as President, Kyle was already responsible for sales, operations and marketing, and now added accounting and finance. “Our sales were down 50% for the year 2020. It was a crucible for 18 months ... I was able to avoid layoffs and retain the staff. It built my confidence as a business owner as we crawled out of that hole, and then having

year-over-year growth going on six years. I feel like I’m in the right job.”

He continued, “We’re a service first organization. That’s expressed in a lot of ways: our company mission and values, our KPIs that we track for our client services team—things like frequency of proactive outbound communication, the number of days that any work order remains in a single status, and overall days to completion for a work order.”

“We are so incredibly grateful to have so many long-term clients: our biggest, as well as our third- or fourth-biggest customers have both been with us for just over 20 years!”

As part of the facilities maintenance industry, Kyle stresses the importance of specializing in lighting—and having excellent training. “Tapping into NALMCO’s offering of certification and formal technical training sets us apart in the facility management world. We are often competing with companies where lighting and electrical repair and maintenance is not their bread and butter. They are jacksof-all-trades, and masters of none ... we stay on top of the latest in technology. Our commitment to service breaks the mold of a traditional contractor.”

Sunset Lighting requires that new hires earn their NALMO CALT™ certification within ninety days of hire.

Asked about his success, Kyle offered, “Growing a sound leadership team has been a major key. I tell our leaders that their job is very simple—two responsibilities: retain clients and retain talent.”

Respecting and retaining team members includes things like alternative work schedules for hourly staff that gets them a three-day weekend every other week. “We’re flexible when life happens.”

Kyle offered advice to those coming into this industry, saying, “Get into the field. We feel very strongly about new team members, especially those in a project management path. Their job is highly administrative—they’re not electricians. Getting into the field makes the abstract concepts that they’re managing in a work order more real.”

By Shirley Coyle, LC

“This takes the form of ride-alongs with our electricians, site visits to see the light fixtures and the client space, hearing from clients about frustrations when the lights aren’t operating correctly. I’ve observed there’s a greater sense of ownership when they return to their desk to project coordination, particularly when they meet a client!”

When he’s not building his business, Kyle is out building other communities. He has founded and led two different fitness clubs over the past seven years—a running club and a cycling club. “It’s been a great outlet for me, creatively. It’s fun to plan the events we’re doing as a community here in Orange County. We have about sixty people who are showing up to our runs and rides.” Not to mention the five marathons Kyle ran last year, including an ultra-marathon as well as the New York Marathon and the Chicago Marathon.

A builder in both his business and

Coming In February 2026 Coming In February 2026

Theme: Lighting Controls and Connected Systems Theme: Lighting Controls and Connected Systems

Practical strategies for maintaining and tuning lighting control systems

Practical strategies for maintaining and tuning lighting control systems

Connecting lighting controls with other building systems (HVAC, BAS, security)

Connecting lighting controls with other building systems (HVAC, BAS, security)

Common controls problems in existing facilities and how to avoid them

Common controls problems in existing facilities and how to avoid them

To advertise, contact Cliff Smith, Associate Publisher, Advertising at advertising@nalmco.org or 917.805.3439