THE PACKAGING ZINE

Editor in Chief

Gabrielle Ho

Art Direction

Samneet Mann

Taylor Tran

Editors

Gabrielle Ho

Taylor Tran

Graphic Designer

Samneet Mann

Writers

Gabrielle Ho

Taylor Tran

Cover Photo

Samneet Mann

Editor in Chief

Gabrielle Ho

Art Direction

Samneet Mann

Taylor Tran

Editors

Gabrielle Ho

Taylor Tran

Graphic Designer

Samneet Mann

Writers

Gabrielle Ho

Taylor Tran

Cover Photo

Samneet Mann

Fall is around the corner, and we’re getting ready for the colder weather!

If it’s your first time reading, welcome! We’re a Canadian-based company that provides custom packaging, branding and sourcing services internationally.

Thank you to our existing customers for trusting us with your business’ brand and vision! We’re truly grateful to be a part of your journey. If you have a question about your order, please contact your Business Development Consultant and they’ll be happy to help!

As a final reminder, please note that our showrooms remain open by appointment only. Scheduling an

appointment not only ensures that one of our consultants will be available to assist you, but also helps them prepare the proper packaging suggestions!

Not comfortable meeting in person or can’t make it to one of our offices? We’ve got you covered. Our consultants are available via phone and video to assist you as well!

Sincerely,

Everyone from LeKAC Sourcing Ltd.Check out pages 20–21 to find Lenny teaching you about packaging terms you’ll find useful the next time you order custom packaging!

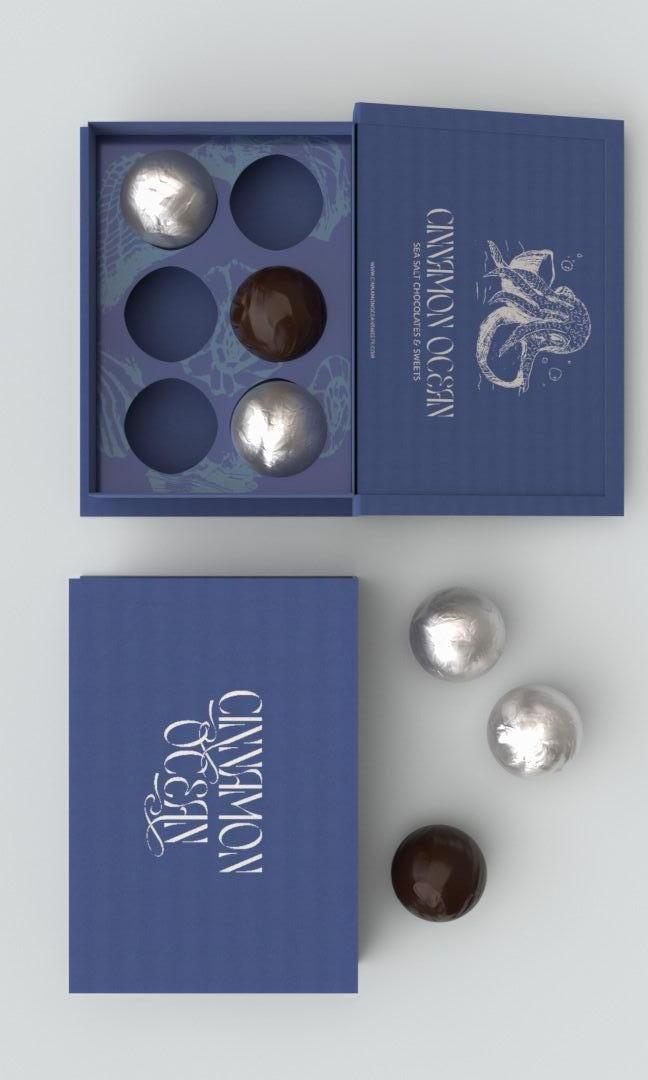

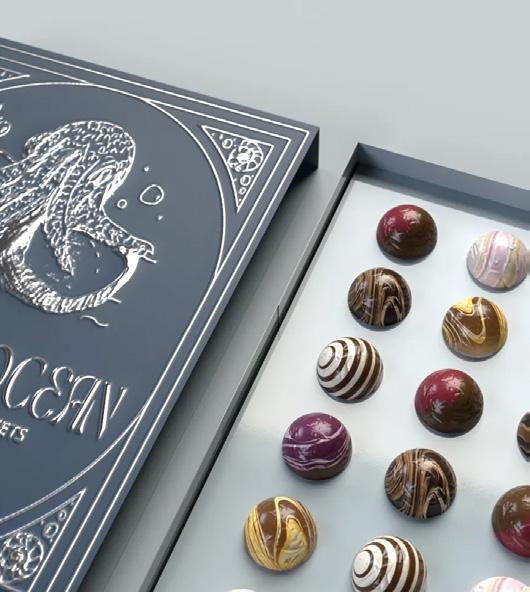

FOR YOUR INNER CHOCO-HOLIC

Make your chocolate even more of a treat with custom packaging!

Our custom rigid boxes are the perfect option to elevate your sweet treats to new levels of deliciousness. These boxes can also include a custom insert perfect for holding all your chocolates in place. PLEASE

It’s a matter of attraction, and our custom magnetic closure rigid boxes can do just that! Starting at $5.00 per unit, these boxes feature magnets that hold the chocolates in until you’re ready to enjoy them.

Slide into some deliciousness with our drawer style rigid boxes! With pricing starting at $4.00 per unit, these boxes are sure to draw-er your customers’ attention to your chocolate.

Classic and timeless, the base and lid rigid box is the perfect vessel for chocolate. From $3.90 per unit, these boxes can be simple or elaborate depending on the look you’re going for!

Looking for a little peekaboo? Check out our cuff rigid boxes! These boxes take our classic base and lid structure to the next level, adding a little pop between the top and bottom layers. These boxes are perfect for adding an extra layer of intrigue to your packaging!

NEED MORE SWEET INSPO?

Not quite satisfied by the boxes above? We’ve got plenty of chocolate packaging to satisfy your sweet tooth.

Check out our Chocolate Industry inspiration page for more packaging ideas!

Avoiding going custom because you think it’s too expensive or just too much effort in general?

At LeKAC, we strive for excellence across all boards. Our consultants work tirelessly to ensure the journey with us is as smooth as possible. We also work to get you the most competitive price on the market.

Customers are more likely to return to your business if they have a reminder of it - and what’s better than a bag they can use everyday? By using custom packaging you’re getting extended publicity, building brand awareness and creating a memorable experience for your customers.

Best of all? You’re getting packaging that’s exactly what you want!

DURABLE | CUSTOMIZABLE | HIGH-END

Looking for luxury packaging? Check out all our rigid box options! From size to printing, we can help design a box that meets your needs. Get in touch with our team to learn more about what we offer.

Rigid boxes are a great option for creating luxury with packaging. These boxes are versatile, highly customizable, and are suitable for a wide array of businesses Read on to learn about the production process behind rigid boxes!

The first step in every packaging production process is making sure that we order the correct materials! Rigid boxes consist of a rigid paper board (also known as greyboard) with paper laid overtop. Paper board is a thicker, more rigid paper material. Unlike corrugation, paper board does not use any corrugation for its rigidity.

One of the features of rigid boxes is that their paper options also include fancy paper! Fancy papers have a variety of unique effects and finishes. This can range from intricate foil designs to imitation fabrics like leather and linen.

Once the paper order is complete, the materials go through the printing process. If the paper is the typical smooth material, then either screen, offset, digital, or relief printing is applicable!

If you’re using fancy paper for your rigid boxes, we use embossing or spot UV! Since these materials usually have a texture or unique finish, ink doesn’t adhere to them in the same way as normal paper.

This phase of the production process is where we include add-ons such as foil, spot UV, and embossing! Add-ons are a great way to add an extra design element to your packaging to compliment your designs

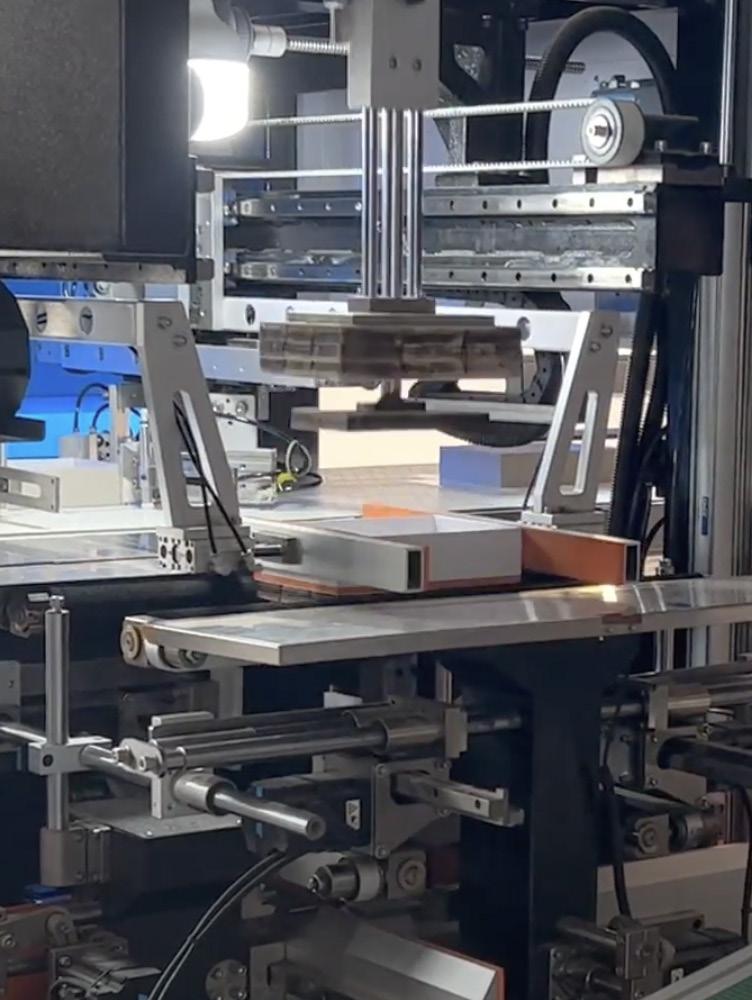

Grooving is a step in the production process that is unique to rigid boxes. Since these boxes are made of a rigid paper board, they don’t bend easily! To solve this problem, a machine takes the uncut paperboard cuts out the flaps as well as making grooves. These grooves go along the fold lines of the box making it easy to fold later!

This step in important as it also removes any excess material that would make the boxes bulky! Taking this extra measure helps ensure a clean finish once forming is complete.

In this phase, we attach the paper and paper board using glue. While the paper board has grooves, the paper itself does not! A worker applies glue using a roller to the paper, which then attaches to the grooved paper board.

The grooves made in the previous step will face inward so the paper on the exterior can provide a more professional, seamless finish. This step is also where any magnets would be added to the box’s structure!

Finally, the flat paper board is ready to become a proper box! This can either be done using a machine or manually. Especially for manual forming, the pre-made grooves from the previous step help make this part of the rigid box production process easier!

Rigid boxes are a great option for a wide variety of businesses! From bakeries, wineries and more, rigid boxes come in a wide variety of structures as well as finishes. The thicker material feels more luxurious than some other box options we have available — plus, they’re great for gifting!

Not sure where to start? From graphic design services to recommendations on what packaging works best for your business, let LeKAC be your one-stop shop for all your packaging needs. Contact us today to find out how we can help!

In August, LeKAC took to the lake on our second annual team retreat. We cooked, played games, had an epic water gun fight and even caught a meteor shower! Overall, this retreat was a great chance for our team to relax and reset. Now, we’re more refreshed and ready than ever to keep helping you make all of your custom packaging dreams come true!

Creating glue-free packaging might sound counter-intuitive. How do you keep your packaging together? Don’t worry, there are lots of different packaging options that use no glue or adhesives!

You might be wondering: why would you want to make packaging without glue? Especially for paper products, some adhesives can stick to paper-making equipment which might impact recycling. Some adhesives are suitable for recycling, but designing packaging with its ability to be recycled in mind is important for the packaging design process. Enter: glue-free packaging!

Many corrugated boxes that we offer are glue-free while still offering the structure and protection that the material is known for. For example, our corrugated mailer boxes are a secure packaging option for sending items through the postal system; and they don’t use any adhesives in their construction!

So… How do they do it? While it might seem like magic, it’s much more simple! By using die cut holes and tabs to hold the sides in place, these boxes stay together. The sides with the tabs fold up and over, and sandwich the two short square flaps to form the short sides of the box.

This creates a double wall of paper material for stability and also creates a place for the tabs on the lid of the box to slide into!

Our pizza boxes have a similar structure to the mailer boxes. But why don’t we use glue for food packaging? Isn’t it more secure?

While food-safe adhesives are available, heat from food could loosen their hold. Enter: the corrugated pizza box!

double-wall method, the paperboard gets more structure, without using any additional materials or adhesives.

While our custom cake boxes are also folding cartons, they are constructed differently! Rather than using the double-wall method, our custom cake boxes use die cut holes to hold everything together.

The main difference between our pizza boxes and the mailer boxes is the die cut vent holes! These holes help release steam so the corrugated paper material doesn’t become soggy as your pizza is in transit.

You can make a number of folding carton styles without using glue! Similar to the way that corrugated boxes fold over to form the walls of the box, folding cartons do the same. Though the concept is the same, some of the construction is a little bit different!

Since the folding carton’s paperboard material isn’t as rigid as the corrugated material is, the small flaps that get tucked in have to be doubled up. How does this work? The flaps come with a perforated line for easy folding, so they can provide more support and structure.

The additional tabs on the shorter ends of the box secure the diagonally folded tabs to create a sturdy folding carton. By using the

Cake boxes arrive flat, with a die cut handle on two sides, and die cut holes on the others. When folding the box, the handles come together and the holes hold them in place. This creates a secure and convenient way for you to transport your baked goods without using any adhesives.

Want to explore glue-free packaging options, but don’t know if it would work for your business? Contact us today to find out how we can help! Our knowledgeable Business Development consultants can help determine the best packaging options for your needs.

Here are a few terms we’ve used these last few months when working with you to create your custom packaging!

The method of transporting containers of goods across seas by ocean transport (cargo ships). Part of the shipping fee includes the cost of pallets used to ship boxes of mass produced goods from the factories to here!

The shipment of goods (your packaging) through an air carrier. Air shipments include the following: air freight, air express and airmail. For rush orders we recommend using air express shipping to get your packaging ASAP!

Ready-made refers to standard sized packaging with little to no room for customization. Some packaging companies often have these already manufactured packaging ready to sell. LeKAC is a 100% custom packaging company and we do not offer readymade packaging at this time – our goal is to prioritize fully customizable packaging solutions for your businesses!

The opposite of embossing. A debossed print is when the logo or design is pressed into the paper to leave an impression. This effect tends to be seen when using hot-foil stamping on packaging, since the act of pressing the hot stamp into the material leaves a depression in the paper.

When a box is assembled by the factory prior to shipping, the box is considered pre-built. Certain types of packaging, such as rigid boxes, are built in the mass-production process and need to shipped fully built. Folding cartons and corugated boxes can also be requested to be pre-built before shipping as a means to conserve time building the boxes yourself!

‘Pre-built’ can also be referred to as ‘pre-assembled’ or ‘pre-constructed’.

Q: Why are shipping rates increasing so much?

A: There are actually a few reasons rates have been increasing lately. Due to the pandemic, global supply chains have been disrupted and there’s a shortage of freight containers! That, coupled with limited staff available to work and increasing fuel prices, lead to delayed shipments. While we’re optimistic that things will go back to normal in the near future, our team is dedicated to keeping costs down for clients.

Unfortunately, there isn’t much we can do since this is a global issue, but if you’re in need of packaging soon, you may want to opt for premium or expedited shipping!

Q: When should I order my packaging?

A: Ideally, ASAP!!! The order process normally takes approximately 4 months, but we recommened ordering it as far in advance as possible.

HAVE MORE QUESTIONS? LEARN MORE ON OUR WEBSITE:

Q: I need help designing my packaging. Does it cost extra?

A: We’ve got you covered! Our in-house graphic designer can help you bring your custom packaging vision to life. This includes the design layout and even 3D mockups! The best part? This service is included in our price!

Q: Are there any hidden fees I need to know about?

A: No! Our pricing includes shipping/handling, customs/duties and plate charges. The only fee that can vary is the local delivery fee which your consultant will let you know about ahead of time. If anything changes, rest assured your consultant will let you know as soon as possible!

Q: I don’t need packaging, but I love your work! Is there another way I can work with LeKAC?

A: Definitely! If you like our design work, but aren’t necessarily looking for packaging, try our custom Branding and Graphic Design services instead. Work with our Marketing team to bring your vision to life! CLICK HERE TO SEE WHAT WE OFFER.