Leading the transition to net zero leisure facilities

Leading the transition to net zero leisure facilities

The Net Zero Pod is the leading solution for transitioning to net zero facilities.

• An innovative and pioneering application of heat pump and green technology.

• An acoustic Packaged Plant Room for better quality control and ease of installation / commissioning. Designed and built off-site at the Leisure Energy Technology Centre.

• Natural Refrigerant (CO2) with a Global Warming Potential (GWP) of 1.

• Capable of delivering sCOP’s of 4+.

• Range of Heat Pump sizes available (for example: 2x250kw / 2x 150kw) suitable for leisure and other buildings.

• Significantly more efficient with lower running costs – compelling ROI and better value for money.

• 50°C and 75°C (up to 90°C) flow and return circuits as standard.

• Chilled circuit upgrade available – for “free” cooling Studios, Gym, Soft play etc.

• Making decarbonisation affordable and uniquely suited to Swimming Pools in particular.

• Smart building management – accessing off-peak utility tariffs.

• Funded solutions available linked to maintenance / service package underpinned by a Performance Warranty – breaking the link and reliance on grant funding.

2.0 Data Sheet

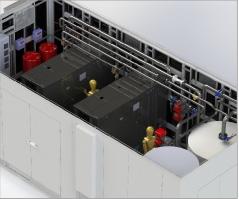

This data sheet is for a Net Zero Pod 250kw Twin Pack as shown in the above picture.

4.0

CO₂

Buffer Vessel (nominal) 1,500 litres

Grundfos Primary circulating Pump with VSD 0.33 kW

CO₂

Fluid

Buffer Vessel (Nominal) 2,500 litres

Grundfos Primary circulating Pump with VSD 2.2 kW

Location Remote – near / flexible

Orientation V BANK

Fans 7 x 2

Refrigerant R744

Circulation method DX

Maximum Allowable Pressure 80 Bar Air Flow rate 53.5 M³/s

Fin Material Aluminium

Inlet Connection Size 4 x 41.3mm

Outlet Connection Size 4 x 33.7mm

Fan Type EC

kW Full Load Current (per fan) 1.85 Amps

Defrost type Hot Gas

Sound Pressure @ 10mtr 45dBA

Preliminary Dimensions L 9.3m x W 2.3m x H 2.60m Net Weight preliminary 3,500 Kg

8.0 Net Zero Pod Performance

Address: Units 6-8, Site 8, Gemini Business Park,

Note actual SCoP is dependant on DHW : Heating ratio. Assumed 15%

Communication Modbus TCP 1 off

IP Link, Cradlepoint modem connection 1 off

Change Over Valve, boil Protection HE10 Yes

Liquid Level transmitter in receiver Yes

H48 filter drier 320 liquid line Yes

VSD on lead compressor Yes

External Start/Stop Yes

Anti vibration mount of MT compressors Yes

Low lift by-pass valve HP Pressure Switch 130Bar Yes

Hot Gas defrost system Yes

defrost kit

Meter

off

Address:

Pipework Insulation Yes

CO₂ Leak Detection Yes

Preliminary Dimensions L 8.2m x W 3.6m x H 3.0m Net Wet Weight preliminary

Exterior Colour

Note: Other colours are available

10.0