LTex frontlit

Textile Backlit 1100 - 190

2 bar woven 100% polyester fabric with a dense structure offers easy handling (wrinkle-free) nice softness and bright whiteness. Excellent light diffusion properties as well as colors reproduction.

End-use:

Furnish:

Finish:

Inkcompatibility:

Light-box, display and other indoor decoration.

100% 2 bar woven polyester.

Matt. DyeSub Direct, DyeSub Transfer.

Technical Target Values

Coating method

Grammage

Yarn dtex

Light transmittance

Shrinkage

Cutting method

Recommended

Certifications

1-2min.

Compatibleinks Ink

Printingside

Outside

Inside

Available sizes

Rollwidths (mm)

Not printable.

DyeSub Direct, DyeSub Transfer.

(m) Core (in)

Pallet packaging information

Finishing and handling information

Make sure the printed textile is completely dry and the ink is fully cured before proceeding to the finishing stage. When folding (preparing for transportation) middle layer of paper is recommended. Cold cutting technique is not recommended. When sewing the Textile Backlit 1100 - 190, it's advisable to use polyester thread with a weight of 50-60. The thicker thread might create bulky seams or visible stitching lines. In general, washing the textile before application isn't necessary. However, if the textile becomes contaminated over time, it can be washed using the delicate cycle of a washing machine without any detergent.

Ironing with low temperature.

Tips & Tricks

When folding the fabric, do so carefully to avoid creating creases or wrinkles. Fold the fabric along the grain line, which is the direction of the weave, to prevent stretching or distortion. Avoid folding along the same line repeatedly. Do not fold the fabric too tightly, as this can cause unnecessary stress on the fibers and may create creases or wrinkles. Instead, fold the fabric loosely and avoid pressing down on the folds. Avoid stacking heavy objects on top of the folded fabric, as this can create pressure points and potentially damage the fibers.

General storage information

Storage of the media is recommended in original packaging. In cool (10°C-25°C) and dry environment (30%-60% of relative humidity). Avoid storing media in areas that are subject to extreme temperature fluctuations, such as near windows or doors. High humidity (more than 60% of relative humidity) can cause the media to absorb moisture, which can affect its print quality.

If you plan to not print on the media for an extended period of time, it is always recommended to unload it from the printer. Storing unused media in the printer can cause it to absorb moisture, which can affect its print quality. By unloading the media and storing it in a proper environment, you can help to ensure that it maintains its quality and is ready for use when needed.

Printing information

It is important to maintain appropriate temperatures and humidity levels in your printing environment to ensure optimal print quality. Temperature range of 18-24°C and a humidity range of 40-60% are considered ideal for large format printing. Temperature range of 15-30°C and a humidity range of 30-70% are considered critical and may possibly impact the printing quality.

Always use the right settings for the media. The best printing results are achieved when a special profile is created for the specific media being used. If you require assistance or have any questions, please do not hesitate to contact us.

Verify that the media is compatible with the printer and ink type intended to be used. Select the appropriate media profile. Using the correct media profile is essential for achieving optimal print quality. Please contact GM Media representative to help you out if needed.

General handling information

Unpacking

Carefully remove the media from its original packaging, taking care not to damage the edges or corners. Hold the media by the edges or wear gloves to prevent skin oils from transferring to the surface.

Inspection

Inspect the media for any signs of damage or defects. This includes checking the edges, corners, and surface of the media for any cracks, tears, or scratches. If any damage or defects are found, do not load the media into the printer. Instead, set it aside and notify the appropriate personnel.

Transporting/carrying

When transporting the media to the printer, handle it with care to prevent any damage or deformations. This includes avoiding dropping or bumping the media against any surfaces. Hold the media by the edges or corners to prevent any smudging or scratching of the surface. If the media is too large to be carried by hand, use a trolley or other appropriate equipment to transport it safely. Keep the media in a protective sleeve or packaging during transportation to prevent any dust or dirt from settling on the surface.

Test Report Report No.: AJFS2404003449FF Date: APR.23, 2024 Page 1 of 7

UAB "GM MEDIA"

GELEŽINIO VILKO G. 18A LT-08104 VILNIUS LITHUANIA

Sample Description: TEXTILE BACKLIT 1100 - 190

SGS Ref No.: CZHL2404002387HI

Style No.: TLW110190

The above sample(s) was / were submitted and identified on behalf of the client. SGS is not responsible for the authenticity, integrity and results of the data and information and / or the validity of the conclusion arising therefrom. Results apply to the sample as received.

Test Requested:

EN 13501-1:2018 Fire classification of construction products and building elements Part 1: Classification using data from reaction to fire tests.

Test Results: -- See attached sheet –

Test Period:

Sample Receiving Date : APR.07, 2024

Test Performing Date : APR.07, 2024 TO APR.22, 2024

Signed for and on behalf of SGS-CSTC Standards Technical Services Co., Ltd. Anji Branch

Echo Li

Approved Signatory

Test Report Report No.: AJFS2404003449FF Date: APR.23, 2024 Page 2 of 7

I. Test conducted

This test is conducted as per EN 13501-1:2018 Fire classification of construction products and building elements-Part 1: Classification using data from reaction to fire tests. And the test methods as following:

1. EN 13823:2020+A1:2022 Reaction to fire tests for building products - Building products excluding floorings exposed to the thermal attack by a single burning item.

2. EN ISO 11925-2:2020 Reaction to fire tests — Ignitability of products subjected to direct impingement of flame — Part 2: Single-flame source test.

II. Details of classified product

a) Nature and end use application

The product “Textile Backlit 1100 -190 (provided by client)” is defined as a decorative sheet. Its classification is valid for the following end use application: backlit fabric.

b) Description

Description Textile Backlit 1100 -190 (provided by client)

Color White

Sample size

EN 13823: 1500mm×1000mm & 1500mm×495mm

EN ISO 11925-2: 250mm×90mm

Mass per unit area 184 g/m2

Exposed surface Marking surface (see the appendix photo)

Mounting and fixing:

Calcium silicate board with a density of approximate 900kg/m3 and a thickness of approximate 9mm, was used as the substrate. The test specimens were fixed mechanically to the substrate. No joint in the long wing of the specimens.

III. Test results

ISO 11925-2 Exposure = 30 s

Whether lateral flame spread (LFS) to the edge of specimen (Yes/No)

Whether vertical flame spread (Fs) in excess of 150 mm within 60s (Yes/No)

Ignition of the filter paper (Yes/No)

IV. Classification and field of application

a) Reference of classification

This classification has been carried out in accordance with EN 13501-1:2018.

b) Classification

The product, Textile Backlit 1100 -190 (provided by client), in relation to its reaction to fire behaviour is classified:

Remark: The classes with their corresponding fire performance are given in annex A.

Test

c) Field of application

This classification is valid for the following end use applications:

--- With all substrates classified as A1 or A2

--- With mechanically fixing

--- No joint

This classification is valid for the following product parameters: --- Characteristics as described in section II b) of this test reports.

Statement:

This declaration of conformity is only based on the result of this laboratory activity, the impact of the uncertainty of the results was not included.

The test results relate to the behaviour of the test specimens of a product under the particular conditions of the test; they are not intended to be the sole criterion for assessing the potential fire hazard of the product in use.

Warning:

This classification report does not represent type approval or certification of the product. The test laboratory has, therefore, play no part in sampling the product for the test, although it holds appropriate references to the manufacturer’s factory production control that is aimed to be relevant to the samples tested and that will provide for their traceability.

Annex A

Classes of reaction to fire performance for construction products excluding floorings and linear pipe thermal insulation products

Class Test method(s)

A1

Classification criteria Additional classification

EN ISO 1182 a and △T≤30, and ℃

△m≤50%, and tf=0(i.e. no sustained flaming) -

A2

EN ISO 1716

PCS≤2.0MJ/kg a and PCS≤2.0MJ/kg b c and PCS≤1.4MJ/m2 d and PCS≤2.0MJ/kg e -

EN ISO 1182 a or and △T≤50, and ℃

EN ISO 1716

EN 13823

EN 13823 and

B

△m≤50%, and tf≤20 s -

PCS≤3.0MJ/kg a and PCS≤4.0MJ/m2 b and PCS≤4.0MJ/m2 d and PCS≤3.0MJ/kg e -

FIGRA≤120W/s and LFS<edge of specimen and THR600s≤7.5MJ

FIGRA≤120W/s and LFS<edge of specimen and THR600s≤7.5MJ

EN ISO 11925-2 i Exposure =30s within 60s Fs≤150mm

EN 13823 and

C

D

E

FIGRA≤250W/s and LFS<edge of specimen and THR600s≤15MJ

EN ISO 11925-2 i Exposure=30s Fs≤150mm within 60 s

EN 13823 and FIGRA≤750W/s

EN ISO 11925-2 i Exposure=30s Fs≤150mm within 60 s

Smoke production f and Flaming droplets/particles g

Smoke production f and Flaming droplets/particles g

Smoke production f and Flaming droplets/particles g

Smoke production f and Flaming droplets/particles g

EN ISO 11925-2 i Exposure =15s Fs≤150mm within 20 s flaming droplets/particles h

F EN ISO 11925-2i Exposure = 15 s Fs>150mm within 20 s

a For homogeneous products and substantial components of non-homogeneous products.

b For any external non-substantial component of non-homogeneous products.

c Alternatively, any external non-substantial component having a PCS ≤ 2,0 MJ/m2 , provided that the product satisfies the following criteria of EN 13823: FIGRA ≤ 20 W/s, and LFS < edge of specimen, and THR600s ≤ 4,0 MJ, and s1, and d0.

d For any internal non-substantial component of non-homogeneous products.

e For the product as a whole.

f s1 = SMOGRA ≤ 30m2/s2 and TSP600s ≤ 50m2 ; s2 = SMOGRA ≤ 180m2/s2 and TSP600s ≤ 200m2; s3 = not s1 or s2

g d0 = No flaming droplets/ particles in EN 13823 within 600 s; d1 = no flaming droplets/ particles persisting longer than 10 s in EN 13823 within 600 s; d2 = not d0 or d1.

Ignition of the paper in EN ISO 11925-2 results in a d2 classification.

h Pass = no ignition of the paper (no classification); Fail = ignition of the paper (d2 classification).

i Under conditions of surface flame attack and, if appropriate to the end–use application of the product, edge flame attack.

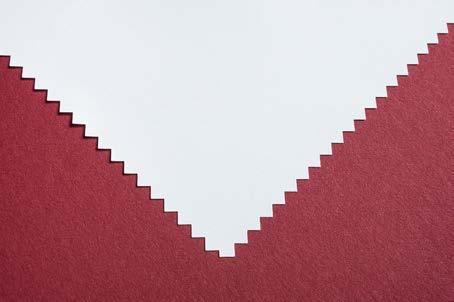

Photo Appendix:

Before test

Before test

After test

After test

SGS authenticate the photo on original report only ***End of Report***