P-bianco / PES 310 g/m2 / Fire classi cation / 300 cm print width / Sublimation frontlit

P-bianco / PES 310 g/m2 / Fire classi cation / 300 cm print width / Sublimation frontlit

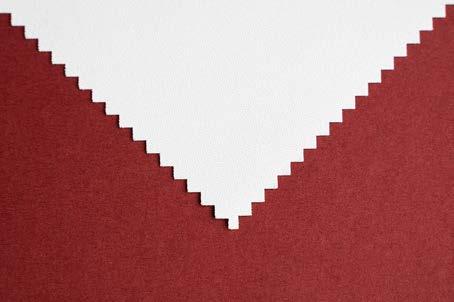

2 bar warp-knitted textile made of 100% polyester, featuring a wrinkle-free and flat construction, a middle layer block-out for enhanced opacity. Both sides white and printable.

End-use:

Furnish:

Finish:

Inkcompatibility:

Backdrop, pop-up display, frame systems and other indoor applications.

100% 2 bar warp-knitted polyester.

Matt.

DyeSub Direct / Transfer, UV.

Coating method

Grammage

Yarn dtex

Shielding rate

Shrinkage

Cutting method

Recommended calender settings

1-2min.

Outside

Available sizes

DyeSub Direct, DyeSub Transfer.

Make sure the printed textile is completely dry and the ink is fully cured before proceeding to the finishing stage.

We recommend using the hot cutting technique to prevent fraying, as cold cutting can cause issues. If using cold cutting technique, pay attention to the cutting tools and sharpness of the blades. The fabric may come with some odors and smoke when cutting by hot cut.

When sewing the Textile Block-Out Whiteback 1100, it's advisable to use polyester thread with a weight of 100-120 to increase longevity and maintain the banner/display softness. Washing is not recommended. Cleanable with damp cloth if necessary. Ironing with low temperatures.

When folding the fabric, consider those general key points: - fold the fabric along the grain line (in direction of weave); - avoid folding along the same line repeatedly; - fold the fabric loosely and avoid pressing down on the folds; - avoid stacking heavy objects on top of the folded fabric.

When using "in-line heater" (not a calender), use of lower temperature for ink fixation is recommended. Contact the printer manufacturer for recommendation.

Storage of the media is recommended in original packaging. In cool (10°C-25°C) and dry environment (30%-60% of relative humidity). Avoid storing media in areas that are subject to extreme temperature fluctuations, such as near windows or doors. High humidity (more than 60% of relative humidity) can cause the media to absorb moisture, which can affect its print quality

If you plan to not print on the media for an extended period of time, it is always recommended to unload it from the printer. Storing unused media in the printer can cause it to absorb moisture, which can affect its print quality. By unloading the media and storing it in a proper environment, you can help to ensure that it maintains its quality and is ready for use when needed.

Important! Un-tubbed textile media must be kept in original "TIDY"/pyramid packaging or on flat and even surface to avoid media rolls from bending and forming wrinkles.

It is important to maintain appropriate temperatures and humidity levels in your printing environment to ensure optimal print quality. Temperature range of 18-24°C and a humidity range of 40-60% are considered ideal for large format printing. Temperature range of 15-30°C and a humidity range of 30-70% are considered critical and may possibly impact the printing quality.

Always use the right settings for the media. The best printing results are achieved when a special profile is created for the specific media being used. If you require assistance or have any questions, please do not hesitate to contact us.

Verify that the media is compatible with the printer and ink type intended to be used. Select the appropriate media profile. Using the correct media profile is essential for achieving optimal print quality. Please contact GM Media representative to help you out if needed.

Unpacking

Carefully remove the media from its original packaging, taking care not to damage the edges or corners. Hold the media by the edges or wear gloves to prevent skin oils from transferring to the surface.

Inspection

Inspect the media for any signs of damage or defects. This includes checking the edges, corners, and surface of the media for any cracks, tears, or scratches. If any damage or defects are found, do not load the media into the printer. Instead, set it aside and notify the appropriate personnel.

Transporting/carrying

When transporting the media to the printer, handle it with care to prevent any damage or deformations. This includes avoiding dropping or bumping the media against any surfaces. Hold the media by the edges or corners to prevent any smudging or scratching of the surface. If the media is too large to be carried by hand, use a trolley or other appropriate equipment to transport it safely. Keep the media in a protective sleeve or packaging during transportation to prevent any dust or dirt from settling on the surface.

浙江亦阳新材料有限公司

浙江省海宁市尖山新区金牛路 36 号 No36 JinniuRoad,jianshandistrict,Hainingcity,ZhejiangPR,China

Date:2024-1-12

Sample Description:WHITEBACK SOFT FABRIC

Style No.:ST-206

Test Requested:

To determine the flammability (building materials class B1) in accordance with DIN 4102-1(May 1998) Fire behavior ofbuilding materials and elements Part 1:Classification ofbuilding materials,

Requirements and testing

Test Results: See attached sheet

Classification: The tested sample meets class B1 building materials requirements ofDIN 4102-1(May 1998)

Ⅰ.Testconducted

This test was conducted as per DIN 4102-15:1990 &DIN4102-16:2015 and DIN 4102-1:1998

Clause 6.2,and Classification in according to DIN 4102-1(May 1998)Clause 6.1-Class B1 materials.

Ⅱ. Sample details

Color Whiteback

Area Density

Size of sample

Conditioning

260g/㎡

190mm×1000mm & 190mm×90mm

Prior to testing,the sample was condition at least 14 days to constant mass at a temperature of 23±2℃,and a relative humidity of 50±5%.

Ⅲ. Test results

1)“Brandschacht”Test according to DIN 4102-15 & 16

Exposed surface:The Black face

Results of“Brandschacht”Test (part 3)

*Reduction in number oftest (DIN 4102 Part 16,clause 5.2)

Class B1 materials:

Ifthe residual length measured after the first test is 45cm or greater,futher tests are not required.

2) Normal Flammability Test according to DIN 4102-1 Clause 6.2

Edge ignition

Fire application time:15s

Parameter

Whether or not flaming extinguished before reach the gauge mark (Yes/No)

Whether or not flaming reach the measuring mark within 20 seconds (Yes/No)

Time for the flame tip to reach the gauge mark (s)

time (s)

flame height (cm)

Molten dripping (Yes/No) No No No No No

Smoke developments (visual impression) Slight

Sample No.

Whether or not flaming extinguished before reach the gauge mark (Yes/No)

Whether or not flaming reach the measuring mark within 20 seconds (Yes/No)

Time for the flame tip to reach the gauge mark (s)

Afterflame time (s)

No No No No No

Max. flame height (cm) 6

Molten dripping (Yes/No) No No No No No

Smoke developments (visual impression) Slight

Note: L-Lengthwise C-Crosswise NA-Not applicable

Ⅳ. DIN 4102-1:1998 Criteria for classification

1)Allmaterials,exceptflooring,may be classed as B1 materials if they meet the following requirements a) and b):

a) The test using the ‘Brandschacht’ apparatus described in DIN 4102-15(cf. subclause 6.1.3.1) shall be deemed passed if

-The mean value for the residual length (portion of specimen that has not burned or charred;cf.

subclause 9.1 of DIN 4102-16) of each specimen is at least 15 cm and no individual values are lower than 0 cm,

-The requirement for the residual length of each specimen is met even where there is afterflame, afterglow, or smouldering.

b) Pass DIN 4102-1:1998 sub-clause 6.2.3 lgnitability Test if

For each specimen, flaming doesn’t reach the gage mark within 20s after flame application.

2)Materials may be classed as B2 materials if they ignitibility test specified in DIN 4102-1:1998 subclause 6.2.5.

For each specimen, flaming does’t reach the gage mark(150mm marks) within 20s after flame application.

3) Combustible materials which cannot be classed as B1 or B2 materials shall be classed as B3 materials.

STATEMENTS:

This declaration of conformity is only based on the result ofthis laboratory activity, the impact of the uncertainty ofthe results was not included.

This test report does not replace any mandatory certification ofthe product that maybe required The test results relate to the behavior of the test specimens of a product under the particular conditions ofthe test; they are not intended to be the sole criterion for assessing the potential fire and smoke hazard ofthe product in use.

SOYANG R&D