SELF PERFORM

SELF PERFORM

SECTION 1

SECTION 2

SECTION 3

SECTION 4

SECTION 5

SECTION 6

SECTION 7

SECTION 8

SECTION 9

SECTION 10

SECTION 11

SECTION 12

SECTION 13

SECTION 14

SECTION 15

SECTION 16

SECTION 17

SECTION 18

SECTION 19

SECTION 20

SECTION 21

SECTION 22

SECTION 23

Purpose

Submittals

Concrete Mixes

Pre-Pour Discussions

Concrete Testing

Concrete Cylinders

Concrete Finishing

Elevated Slabs

Slab on Metal Deck Placement

Curing Plan

Hot Weather Concrete

Cold Weather Concrete

Mass Concrete

Vibration/Consolidation

Maturing Meters/Maturity Testing

Exposed Concrete

Concrete to Receive Coatings

Joints in Concrete Slabs

Joints in CIP Walls

Post-Tensioning

Formwork/ Wrecking / Reshores

ACI Login

Contacts

The goal of this document is to provide questions and considerations that can guide project teams in developing a Concrete Self-Perform Site Specific Quality Control Plan. It should help generate discussion, identify responsibilities for execution, and can inform the Preconstruction Conference (example agenda), typically required by the specifications

This document focuses on various components of the work that project teams must address and serves as a template to facilitate effective completion of the Concrete Self-Perform QC Plan.

Commodities submittals are often forgotten but need to be submitted It’s important to confirm whether the superintendent has any concerns with the specified materials, and also who the vendor will be, so we can verify whether they’re able to provide what we submit.

Examples of commodities submittals are vapor barrier, dowels, form oil, construction joint, waterstop, curing compound, Stayform, etc

Determine where we stand on the log and status of all submittals with concrete impact:

Anchor bolt shop drawings/templates

Reinforcing steel shop drawings

Post tensioning shop drawings

Approved mix designs

Thermal Control Plan (for mass concrete)

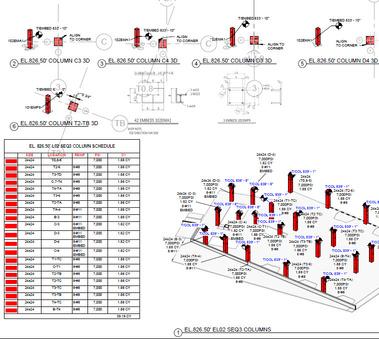

Lift drawings from VDC (see example)

Line drawings from VDC to include pour breaks and edge of slab dimensions

Embed drawings - Consider miscellaneous steel attachments, curtainwall attachment, window washing tiebacks/equipment, loading dock equipment, dovetail slots, operable walls needing overhead support embeds etc.

MEP block outs / embeds / rough-in

Embeds, sleeves, etc. coordinated with PT

Shoring / reshoring / any temp shoring

Stud rails, elevator shops, stair shops, Halfen/ Stay boxes

Concrete Accessories and Reinforcement (Academy64)

Required mil thickness

Detail requirements - How are we treating penetrations, transitions/terminations in slab to foundation wall, and other perimeter detailing considerations?

Pre-placement inspection and documentation

Will finishing operations impact vapor barrier (e.g., grade pins)? Is this allowed?

Stego Industries is a commonly used product with detailed installation instructions on their website

Lapping, direction, tape requirement, etc.

We get one shot at installing a vapor barrier correctly. Moisture sensitive floor coverings will reveal any mistakes made in the process.

It is recommended to utilize a Class A vapor retarder that complies with ASTM E-1745 Be very careful with any value analysis or substitution requests here Cheap insurance in a good product

Placement of barrier should be directly against concrete. Placing below GAB for example creates a space to hold water which will prolong the time to get moisture out of the slab.

Do the drawings or Specs mention VIMS? (Vapor Intrusion Mitigation System) This is typically a more elaborate system than just a vapor barrier. There are two types: (1) Passive: Create a barrier between the soil and building foundation and vent vapor at the roof line (2) Active: Mechanical System (such as a fan) to pull vapor from underneath a structure and expel it above the structure. We see these often in Residential if there's a presence of Radon in the soil or rock.

SECTION 3

Has a schedule of mixes been prepared? Is it clear where each mix is to be utilized?

Do we need to require a laminated card or other document of teams for mix designs and where they are to be used?

Print the mix matrix and put on curing box; ensure third-party has access, too.

Any concern with reinforcing density and compatibility with aggregate size? Should a smaller aggregate be suggested for certain conditions? Self-consolidating.

Don't take for granted the level of sophistication of your ready-mix supplier based on location of your project

Ensure the team is on the same page as to expectations. Visit the plant if possible. What is the distance from the plant/plants serving this project?

How are aggregates stored at the ready-mix plant, and how does this affect your mix?

For example, how does the supplier account for the impact of rain or temperature on aggregate?

Do we need high early mixes? If so, where and what specifically do we need?

Who is quantifying the yardage for the placement?

Who can reject a truck and what is the process?

REMEMBER: Pay attention to air content in mixes. Do not trowel finish mixes in excess of 3 percent air. See ACI 302 Section 8.4.7.

Note that lightweight mixes may require more air than can be trowel finished. What is the plan for this? Will additional floor prep be necessary?

Are we using admixtures? If so, who is making the call on what is needed and when?

This should be a dedicated person. Workability admixtures needed? What about cold/hot weather admixtures?

Have we submitted what we think we might need?

Chloride vs. non-chloride)

If using, consider the following: Sticky finishing as a result of admixture

Excess bleedwater concerns

Extended setting time

Any admixtures that are added once the truck is on site?

Need RM QC guys, if we are using Super P or other onsite adds, as mentioned.

Any specialty admixtures (e.g., Xypex)

Hot water/ice needs?

Have pump mixes been established? Who can adjust the mix?

Is allowable water that can be added listed on the mix delivery ticket?

Concrete Admixtures (Academy64)

Establish maximum allowable slump and water allowed by specifications

Request the maximum allowable water that can be added to maintain w/c ratio be noted on the ticket.

Process to be implemented after water has been added - Number of rotations/RPM after adding

Request for water should be based on each truck. Don't assume because one truck was delivered one way that subsequent truck require adjustment as well.

Batch times/Delivery Times

Temperature requirements / Temperature limits

Who is responsible for maintaining temperature range?

What do our specifications say are minimum and maximum concrete temperatures? Push for 95 degree max Is ready mix providing an onsite QC Manager?

Is there a specified yardage or mix where we would require one?

Who is checking batch tickets? What are they looking for?

Correct mix design Time of batch Admixtures

Did the fiber we ordered make it in the truck?

Color

Did the hot water/cold water/ice make it in the truck?

Ready Mix Concrete Checklist

Control of Batching, Mixing and Delivery of Concrete

To learn more ... Concrete 101 (Academy64)

View an in depth quality control course on Concrete Mix Control.

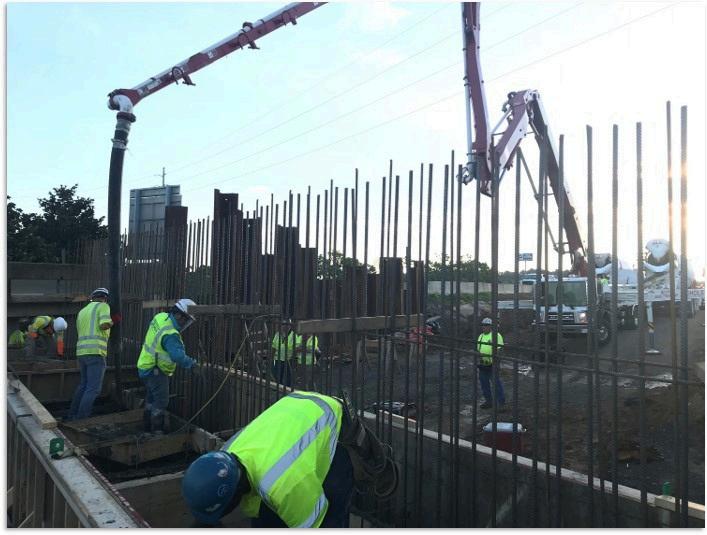

Work hours/noise ordinances understood?

Truck timing defined?

How many trucks can they give us?

Require 100 cy per hour on purchase order

How many trucks can we physically hold on site in a staging pattern compared to what we want to pour an hour?

Delivery route clear including gate to enter?

Make key plan/map

Where are we washing out?

If there is not enough room to washout on site has that been clearly noted in the purchase order? Depending on your site, wash out is likely not an option. Make sure that the project team is on the same page and that the ready-mix supplier is aware and is correctly documented in the purchase order.

Consider traffic control, lighting, proper tools to sweep chutes and turn trucks.

Soil bearing capacity

Reinforcing Steel-cover and compliance

Deck inspections

Engineer of Record required inspections

Determine what the AHJ wants to see on the front end

Pump sizing confirmed?

Who is scheduling the pump?

Who is ordering grout to prime the pump?

What are you pumping the grout into and where? How is that being removed and where is that being dumped?

Have utilities been located and coordinated with pump outriggers? Are any other outrigger load considerations necessary?

Was the outrigger load on shoring walls confirmed?

Rule of thumb: For every 100 lf of hose, you are losing 1" of slump.

Is a placing boom being used or needed? What is the best location for leave outs? Where will the stationary pump go? Blow down process into truck or can? Best practice on some sites is to state on both the ready-mix purchase order and pumping purchase order that we will be blowing back into the trucks. Boxes can be a logistical challenge and are costly. Is a Spyder boom needed? At what level is it needed? Engineering and reshoring needed Does the team have all of the pump truck size cut sheets on file for layout if needed?

Any discussion necessary concerning a backup pump at the yard?

Confirm yards/hour with the pump. Confirm your admixtures with the pump operator

Do we need any additional system/hose on the pump?

Do we need an air compressor?

How Close Can You Get to a Wall?

Coordinate with the engineer of record or Brasfield & Gorrie in house engineering

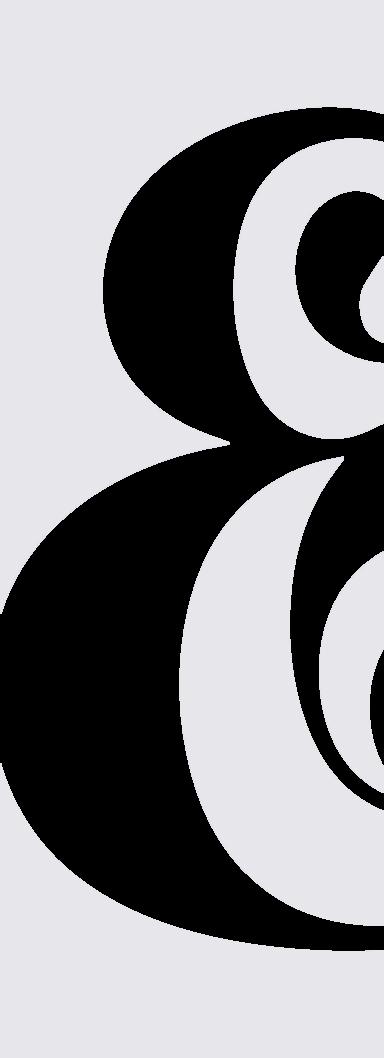

Pour cards shall be used for concrete placement. Consider the use of a group text for communication.

Pre-Pour checklists? Who all is signing off on them?

Who is documenting/taking photos? Action plan established in the event of pump, crane, or other failure

If volumetric trucks are planned to be utilized understand that special quality considerations are necessary We have had several issues as a company with the quality of the concrete produced in this fashion.

Pour Card Checklist

SECTION 5

Who is scheduling the testing agency? What are their notification requirements?

Is the testing agency capable of meeting demands of our pour schedule?

Are in-place concrete sensors being utilized?

SECTION 6

How many cylinders are we taking?

For example: 1-day, 7-day, 28-day, 56day, and 2 spares on elevated slab for a total of 6. All other concrete okay with 5. (This should be on a case-by-case basis.) What size cylinders are to be taken? 6x12 or 4x8?

Is aggregate size compatible with cylinder size? (e g , 6x12 max aggregate is 2" as aggregate cannot exceed 1/3 of cylinder diameter)

NOTE: Number of cylinders required is affected by cylinder size as compressive strength requires an average of two tests for 6x12 cylinders and an average of three tests for 4x8 cylinders

Early breaks needed? Additional cylinders to accommodate early breaks? How are we storing cylinders? We need to use a curing box, as well as dedicated/uninterrupted power source Who is providing this?

What is the timing and process for cylinders to go to the lab?

Any temperature requirements for cylinders? Typically, 60-80 degrees for 48 hours shielded from direct sunlight and limiting moisture loss

Laboratory curing required?

What activities are pending cylinder tests (e g , formwork removal, post tensioning, shoring, etc )?

At what age are cylinders being tested? Age or time (e.g., 5 AM the next morning we need a break).

When is the cylinder being taken?

Rule of thumb is not before 10% or after 90% of discharge from the truck

What tests are being taken? Slump

Air

Density

Temperature

What is the point of sampling? Point of discharge or point of placement? Preference is to be taken at point of placement (at the truck).

Would side on taking cylinders at the hopper of the pump truck vs on deck. Point of placement sample may be too late For example, if you have a 63-meter pump and the concrete in the line to point of placement doesn't meet specifications, you have a lot of noncompliant concrete filling a line. Point of placement does or does not accurately reflect any impact the pump has on the mix

(What to look out for) Process for Taking a Cylinder

1.Test for slump, temperature, and air first.

2 Concrete placed in test cylinder should include any field adjustments that have been made.

3.Cylinder mold should be placed on a level, rigid surface that is free of vibrations. The fender of a truck or pump is not a good place to take a cylinder

4 Cylinder is filled in three equal lifts

5 Rodding of each lift is required-25 times per lift.

6.Sides of cylinder are tapped with a mallet to remove air bubbles.

7.Top of cylinder is cleanly struck off.

8 Cylinder is marked

What is our plan for tracking discrepancies and resolution? Is the testing agency keeping a log (for discrepancies and resolution process)? Establish a communication plan with the design team and owner to get out ahead of any discrepancies Are we flagging low breaks at 7 days for monitoring and not labeling it as a low break?

Who do testing reports need to go to on the Brasfield & Gorrie team? Who is responsible for reading reports? Multiple Brasfield & Gorrie team members are getting copied on these reports Need to ensure that someone is reading and reacting/responding to these as needed. We shouldn't have open items on a deficiency log except pending breaks we are awaiting to come up to strength All deficiencies in the structure phase should be dealt with in real time. This should be a talking point with our project teams and the testing agency to avoid something getting covered up that is not in compliance.

Low Breaks

Additional options

Swiss Hammer or Rebound Hammer

Core samples

Windsor Probe

Ultrasonic pulse velocity

If Structural Steel will be erected on anchor bolts or embeds placed into concrete foundations / slabs it is an OSHA requirement that we provide a letter to the Steel Erector certifying that the concrete has reached an acceptable strength See example below

If you encounter low breaks, consult with the engineer and ready mix supplier for testing options that can determine if the in-place concrete is actually deficient Sometimes cylinders do not accurately reflect the strength of the in-place concrete. If the in-place concrete is found to be compliant, ensure that the proper care and storage is being done with the cylinders moving forward.

Template Strength Letter for Steel Erection Commencement

SECTION 7

Air Entrained Concrete

Do not trowel finish concrete with entrained air in excess of 3 percent.

Lightweight concrete may require an air content that cannot be trowel finished

Coordinate this with your ready-mix supplier and design team. May require a light finishing technique followed by subsequent floor prep. Reduction of air content in lightweight concrete will increase the weight / sf There are numerous items that require early coordination related to concrete finishing

Some examples include:

Hard Trowel finish

Broom Finish

Direction of broom?

Texture?

Creation of a concrete finish exhibit, including stair treads, and submit to the design team for approval.

Air content in Lightweight Concrete is often specified for Fire Rating.

Float Finish

Polished Concrete If you have a polished concrete project See polished concrete best practice notes.

Stained concrete

Consult with your RQM or self-perform group for stained concrete best practices

Any hardener or sealer requirements? How does this affect our finishing plan?

Make sure all structural/architectural grouts for patching have been reviewed/approved by EOR

What is our slab protection plan for exposed concrete areas?

Best practice to make a concrete finishing key plan.

Ff / Fl Requirements

Floor flatness: Measures how bumpy or wavy a slab is

Floor levelness: Measures the pitch of a slab Floor levelness measures elevation change along a line. Typically, over a 10' run.

The higher the F number the more stringent the requirement. Numbers are linear so an Ff of 20 is half as flat as an FF 40. An Fl of 50 is twice as level as an Fl of 25.

Excess of Ff 100 is considered “superflat ”

Can we accomplish the required Ff/Fl levels with standard trowel equipment or do we need to consider specialty equipment such as a laser screed.

Can the Brasfield & Gorrie finishers accomplish the required Ff/Fl levels or is specialty equipment and placement procedures necessary? Have this conversation early.

Slab on grade vs elevated Ff/Fl requirements

When is testing to be performed? Floor is flattest right after finishing and before any curing compound is installed Take this measurement ASAP ACI indicates it must be taken within 72 hours of installation as later tests could be affected by shrinkage, curling or deflection. The sooner you test the better the results.

Specifications for Tolerances - FF & FL

The 40 Most Asked Questions about F-Numbers - Dipstick com

If the concrete placement runs late what is the plan for the testing agency to test Ff/Fl? If they leave, will we have curing or cold weather blankets in place that might affect their testing?

Floor levelness isn't applicable to elevated slabs due to deflection Floor flatness testing of elevated slabs should be performed before shoring is removed. Has the designer accounted for deflection of steel structure for flatness testing? If not, the testing is invalid

Post Tension Slabs should also not be subject to Fl number since they will deflect after cables are stressed.

Older specifications may reference straightedge testing for floor flatness which has flaws. Dipstick profiler should be the method used The flooring industry uses a straightedge method and typically performs this long after concrete was initially placed. Note if you have polished concrete the minimum recommended Ff is 35 with recommended being 50.

NOTE: VDC provides a service to teams to scan the slab as it is being placed for compliance with Ff/Fl requirements

Stayform can be used at beams to prevent puddling concrete from running; get approved by a structural engineer.

Is Puddling required? If so, what options are available to potentially avoid this? Increasing the floor mix PSI to match (or be closer) to the column PSI may alleviate this requirement Typically, we see the decks are allowed to be 2Kless than the columns However, it may not be worth moving away from a proven mix (such as a 5000 HE) just in order to avoid puddling.

Perform a final visual inspection of formwork prior to placement Who is involved in this inspection? Be mindful of any elevated slab mix PSI that might change on a level. Be careful of copy/paste on pour cards missing out on a change in PSI requirements. Who is coming in during the pours who is competent and knowledgeable about the formwork?

Minimum slab thickness to maintain for fireproofing Method for verification: Dipstick method to ensure minimum thickness.

Should get the maximum thickness to account for camber.

If a "Level" slab is expected, how is camber affecting placement?

Do not use a laser or level to place concrete on metal deck.

Sloping elevated slabs for drainage

Typically, we do not sawcut composite metal deck slabs.

If the drawings call for this, please confirm with the structural engineer and understand the depth of the cut in order not to cut the reinforcing mesh.

Wet curing or curing compound?

Make sure this has been submitted to design team. Are dissipating curing compounds compatible with flooring?

What do the specs require?

Ensure we consult and coordinate any curing compounds with flooring. Has schedule accounted for curing method? What are we curing beyond slabs? Top of walls, foundations, stairs, sidewalks, etc.

Note wet curing mass concrete is not recommended. See mass concrete notes. How does cold and hot weather affect our curing plan?

Are dissipating curing compounds compatible with flooring?

Review floor covering finish specifications, submittals, and installation instructions to ensure you are complying with substrate requirements.

SECTION 11

Does the project have a hot weather concrete plan?

Do we need one?

How do the specifications define hot weather concrete?

Is sprinkling of forms and reinforcement with water necessary?

Mix adjustments needed? Higher fly ash needed or use of a retarder necessary?

Hot weather concrete will require a higher level of communication / coordination with the ready-mix supplier to ensure batch/ delivery times are maintained within specifications or are meeting a stricter criteria

Is the ready-mix supplier spraying the aggregate to cool it? If so, is this being accounted for in the water/cement ratio?

Hot weather will contribute to early slump loss. Are mix adjustments or admixtures needed?

Concrete temperature changes by about 1 degree with each of the following:

A change of 1 5 degrees in aggregate temperature

A change of 4 degrees in water temperature

A change of 10 degrees in cement temperature

* Credit: Concrete Constructor Handbook, 2nd Edition

Plastic shrinkage cracking, crazing, curling, and a wavy surface can occur during hot weather concrete conditions Be mindful of the impact of hot weather concrete on final appearance and any Ff/Fl requirements.

Does the project have a cold weather concrete plan? Do we need one?

How do the specifications define cold weather concrete?

If fresh concrete cools below 32 degrees, the expansion of the freezing water will permanently damage the concrete Concrete must reach roughly 500 psi before it is unaffected by freezing temperatures Colder temperatures delay strength development. Will cold weather delay our cycle?

Confirm cold weather labor dollars are included to account for setting up heaters, plastic, blankets

Often use (1) 150k-180k heater per 1000sqft. Be mindful of shrinkage cracking in cold weather concrete as well. As the outside cools faster than the inside resulting in shrinkage Making the mix hotter than it needs to be exacerbates this issue

Do we need to plan on heating reinforcing or formwork?

Hot and Cold Weather Concrete Guidelines

Design team should specifically define what criteria is to be utilized for mass concrete in accordance with ACI207 and ACI301 (Section 8)

Fundamentally we are trying to control the temperature during the process of hydration.

Stresses/cracking can occur when the internal temperature and external temperatures of the concrete differ The temperature difference between the interior and exterior surface of the concrete shall not exceed 35 degrees "unless otherwise justified and permitted." The thermal control plan is intended to control the heat of hydration to maintain a balance of these temperatures over time. ACI 301 indicates the maximum temperature within a mass concrete placement shall not exceed 160 degrees unless "otherwise justified and permitted " Higher levels of fly ash or slag in the mix may allow an increase up to 185 degrees. The designer of the thermal control plan and EOR would be the ones to provide this permission if we justify the need.

If components of your project are defined as mass concrete a thermal control plan will need to be developed.

Thermal control plan-Who is obtaining this? Who is performing it?

Schedule impacts of thermal control plan?

For example, is insulation required around the perimeter of a mass footing that will prevent backfill from being performed? Are blankets required that will prevent subsequent levels of formwork being placed?

Is temperature monitoring required? If so, which product are we using, who is monitoring etc ?

How long will the thermal control measures need to remain in place? ACI 301 indicates thermal control can cease when the hottest portion of the placement cools from its maximum temperature to be within the temperature difference limit (35 degrees) of the average air temperature

Communicating with the ready-mix supplier about weather conditions and the effect it will have on initial concrete temperatures is key. Your thermal control plan should include a table to aid in determining this based on your specific mix design so informed decisions can be made regarding any precooling measures needed.

Wet curing is not recommended for mass concrete as it will cool the surface too quickly while not lowering the internal temperature of the concrete. Ensure thermal control plan matches preferred methods of construction If it does not challenge the plan.

Mass Concrete Checklist

Mass Concrete Planning Guidelines

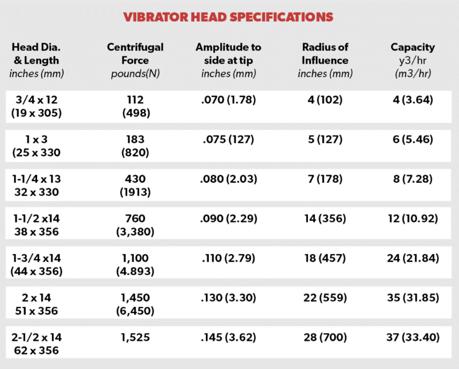

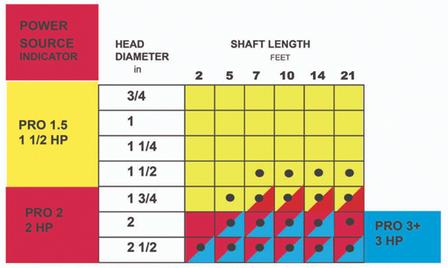

Do the specifications require the use of a Tremie tube (elephant trunk)? Will it work with our reinforcement? Any self-consolidating concrete? If so, how does that affect our vibration approach? Is our vibrator up to the task of our specific job conditions? Note that head size impacts the "radius of influence" the vibrator will have The horsepower of the vibrator motor need be compatible with the head size and length of the shaft as well.

Selecting NORTHROCK Electric Motor

1.Determine diameter of head based on radius of influence needed as shown on vibrator specifications chart

2 Determine length of shaft needed to reach bottom of form

3 Using selections from steps 1 and 2, determine the appropriate motor

SECTION 15

Would the project benefit from utilizing maturity testing even if it hasn't been specified?

Commonly Used Manufactured

Make sure the testing agent and structural engineer are familiar with the ones we choose.

Command Center Concrete

Smart Rock - Giatec Science InSite

SECTION 16

Any surface finish requirements for vertical or horizontal?

What "Class" expectations are required by the specifications? Any mockups needed?

What class finish did we clarify?

SECTION 17

Form oil or release agent removal necessary prior to coating?

Basement walls that require waterproofing

Curing requirement prior to waterproofing?

Buyout “green” concrete glue with waterproofing sub (allows waterproofing to be applied while concrete is still “green”)

Waterproofing tolerances for fins, etc.

Patching requirements?

Keyway/Waterstop

Form oil or release agent removal necessary prior to coating? This may require mechanical removal / bead blasting!

Coordinate Surface profile requirements to receive coatings. (Does surface need to be sanded or roughed for coating to adhere?)

Slabs on Grad Control Joi

(Submit to Constructio to design t Do the eng detail work the detail f

Ensure that we have detail from the structural engineer for construction and control joints. It’s important to understand the reinforcing requirements at these locations.

Control joints: Ensure that both the design team and our construction team are clear on what the spacing requirements are for each and the coordination of these locations with any other architectural elements?

Aesthetic joints: Is the expected profile clear?

Layout defined? Mockup reflecting this accurately?

Stressing equipment calibration

Always make sure we have a backup stressing machine and that it also stays calibrated.

Elongations-marking and measuring Elongation documentation

Elongation approval and subsequent cut letter

Pocket grouting

Process for broken cable defined

Importance of consolidated concrete around PT anchors

Review timeliness and process for testing agent to sign off on strength of concrete to all cables to be stressed so we can cycle our formwork

Post tensioning is a delegated design. Make sure the vendor PO requires professional liability insurance, and shop drawings are stamped/sealed.

What criteria is to be met prior to wrecking? How many levels of reshores are required? What is reshoring criteria to be satisfied? Does our schedule accurately reflect this criteria?

Confirm shoring requirements at pour breaks and leavouts

We don’t want to have to leave reshores in all the way to grade in these areas if we can avoid it.

Brasfield & Gorrie has an ACI login. Please contact your regional quality manager for ACI access and resources. Each region in the company now has a hard copy of the ACI Field Reference Manual, if you need a copy

For questions regarding this document, please contact your Self-Perform representative or QC Group Representative.

DIRECTOR OF SELF-PERFORM

Drew Kelley

DKelley@BrasfieldGorrie com 678 581 6344

Atlanta

REGIONAL QUALITY MANAGER

Brian Smith

BrSmith@BrasfieldGorrie.com 770.423.3686

Atlanta

SENIOR PRECON MANAGER

Eric Lynn

ELynn@BrasfieldGorrie com 770 423 3722

Nashville

SENIOR FIELD MANAGER

Jason Tuten

JTuten@BrasfieldGorrie com 615 806 8127

Birmingham

REGIONAL QUALITY MANAGER

David Reed

DaReed@BrasfieldGorrie.com 678.581.6564

Atlanta