In recent years, the number of $100M projects has grown significantly spreading across all market sectors with the most frequent being housed in Commercial, Healthcare, and Mission Critical

With increased overall project values, the value of subcontracts has grown substantially, with the largest exceeding $200M. Historically, the largest subcontract packages were mechanical scopes in the Healthcare market sector The largest subcontract packages have now shifted to electrical scopes in the Mission Critical market sector. Mega subcontract trades are typically electrical and mechanical scopes, but sitework, concrete, and steel have also reached the $50M mega subcontract level. Additionally, we have seen mega subcontracts that include sub-tier contract values up to $15M with their trade partners

Mega subcontracts bring additional risk that we must manage. While we have been successful in partnering with subcontractors that have the experience to support being awarded $50M+ subcontracts, the pool of these companies is limited The reality is that we have, and will continue to, partner with subcontractors on mega subcontracts who are stepping up beyond their typical job size. We must ensure we have a plan to manage these subcontractors in a way that mitigates risk and supports their success on the project

While any subcontractor default can impact project success, the failure of a mega subcontractor can exponentially increase the risk of financial and reputational losses. The average SDI multiplier across the industry when a subcontractor defaults is 1 66, meaning the cost to complete the contract averages 1.66 times the original contract value.

Brasfield & Gorrie recently experienced a bonded default that confirmed the accuracy of this multiplier. See a cost breakdown of the major items contributing to this multiplier A bonded subcontract’s maximum recovery is the penal sum of the bond (subcontract value plus change orders). An SDI-enrolled subcontract’s recovery is up to the maximum limit of Brasfield & Gorrie’s SDP policy limitations.

The MEGA Subcontract Playbook is intended to provide our teams with recommendations to mitigate risks throughout the entire lifecycle of the subcontracting process starting with considerations for packaging the scope of work, through the RFP and selection process, planning, start-up, execution, and quality control

This playbook is designed as a menu of management best practices that follow the lifecycle of a project. It is not intended as a mandate but as a resource of best-practice options that teams can tailor to fit a project-specific approach to successfully managing the inherent risks associated with a mega subcontract.

This play book is recommended to be utilized for the following subcontract conditions:

Subcontracts > $50M

High risk subcontracts that meet any or a combination of the following characteristics

Sole source subcontracts

Owner-directed subcontractors

Subcontracts with high-risk profiles/highly technical requirements

Subcontractors with no great plan B

Subcontractors new to us or to a market

All Subcontracts 50M+ are required to have a risk mitigation plan.

All subcontracts $50M or greater are to include the additional requirements below and are to be included in the Schedule A of the Subcontract Procore has a template for $50M+ Subcontracts that includes these items in the subcontract.

In addition to all other terms contained in the Subcontract and the attached Schedules, the following terms shall apply to all Subcontracts with a Subcontract Price over $50 million:

If Subcontractor is expected to have between 50 and 99 workers on site at any given time, including workers for lower-tier subcontractors, Subcontractor shall have at least one full-time, on-site safety manager If Subcontractor is expected to have 100 or more workers on site at any given time, including workers for lower-tier subcontractors, Subcontractor shall have at least two full-time, on-site safety managers.

In preparing the schedule required by Article 6.2(a) prior to mobilization, Subcontractor shall load all planned activities with expected manpower requirements and shall submit a separate manhour plan for each week of the expected duration of its Work.

In the event of any supplementation under Article 27 3 or default and termination under Articles 27 3 and 27 4, Subcontractor understands that the costs of supplementation or default and termination will likely exceed the costs that would have been incurred by Subcontractor for the same work performed and agrees that all such costs caused by Subcontractor’s failure to perform, shall be deemed reasonable and necessary to timely complete the Work.

If the Subcontract Price, inclusive of Change Orders, is $50 million or more, the Minimum Limits required in Schedule D, Section 4.1 shall be $30,000,000 each Occurrence and Aggregate Limit of Liability. If the Subcontract Price, inclusive of Change Orders, is $100 million or more, Contractor reserves the right to require higher limits

If selected in Schedule D, Section 5.0 or the Work is within the description in Schedule D, Section 5.2, the Minimum Limits for Professional Liability coverage required in Schedule D, Section 5 1 shall be increased to $5,000,000 each Loss and Annual Aggregate.

In the event Subcontractor plans to utilize any temporary storage facilities, it will notify Contractor prior to storing materials collectively valued at $5,000,000 or more If Subcontractor fails to do so, it assumes all risk of loss to the extent such materials are not covered by the Project’s builders risk insurance.

Subcontractor shall notify Contractor in writing within five days of: (a) any supplementation(s), default(s), or termination(s) declared on other projects; (b) any insurance claims filed valued at $1,000,000 or more; or (c) any litigation initiated in which Subcontractor is a defendant in which the amount in controversy is $1,000,000 or more

Subcontracts over $50M – Schedule A Supplement (cont’d)

With respect to the information Subcontractor agrees to provide under Article 11 1, Subcontractor shall specifically provide Contractor with the following:

(a) no less than quarterly, Subcontractor’s financial statements and work-in-progress report

(b) annually, Subcontractor’s CPA-prepared financial statements

Subcontractor agrees to provide the above information in addition to any other information that Contractor may reasonably request under Article 11.1.

In accordance with Article 3 2, Subcontractor shall obtain interim conditional and final unconditional lien releases from its lower-tier subcontractors and vendors, and Subcontractor agrees to do so as part of each payment application

This list is only intended to outline the minimum requirements of the Work included in this Subcontract Exclusion from this list shall not relieve the Subcontractor of their responsibility to perform all work included within their scope in accordance with the Contract Documents.

Scope Strategy Session Risk / SDP Review

Teams should start their risk mitigation planning efforts prior to sending out Formal RFPs to the subcontractor market. Following are topics that should be considered.

Subcontractor Solicitation and Prequalification

Subcontractor Solicitation

Consider meeting with key trades to determine interest and ability to execute project.

Determine if formal prequalification process is needed.

Full SDP analyst review prior to issuing RFPs to market

For Prime subs

For Major sub-tiers as well Bonding

Project Specific Bonding Approval documentation from subs surety

Example: Project Specific Surety Letter

Sub-tier bonding if the first tier financial review warrants the requirement

Scope Packages

Based on above, do we split up the scope to mitigate risk?

Example: Separate Plumbing and HVAC Packages

Multiple Subcontractors for a Specific Trade

Example: One sub to be awarded the podium and a 2nd subcontractor to be awarded the tower.

Contract Direct with typical major subtiers (e.g., fire alarm, mechanical controls, utilities)

Easier to enroll in SDI or bond

Larger labor pool (sometimes)

Keeps subs from getting spread too thin across larger projects

Competitive environment for their performance

Potential supplementation option on site with subcontractor that is familiar with the project

Not all scopes are easily split

Not all subs are willing to chase a partial scope

Union vs Non-Union Labor

More subs to manage, QC, etc.

Sub resources spread to other jobs instead?

Subcontract Type

Lump Sum or Cost Plus

Typically, many of these mega subcontracts are being awarded early in the design phase of the project and the scope These projects will involve higher degree of uncertainty regarding its scope, materials, or unforeseen challenges that might arise during the project lifecycle, and a Cost Plus subcontract should be considered

Is a third-party review required?

Require Risk Mitigation Plan?

Provide Plan for Contract Administration of each discipline.

Submit PL Insurance in the amount of $5M

B&G cannot be an additional insured for professional liability insurance.

Subcontractors need to provide a sample certificate of insurance compliant with Schedule D.

Define Scope or Services the designers will have on the project during contract administration.

If cost plus decision is made, the RFP should be structure to define the subcontract type and address the following items:

Cost of Work Matrix defining

General Conditions

General Requirements

General Contractor (B&G)

Responsibility

Permits

Nonbillable items

Items that are to be included in Fee General Conditions Will the GCs be Lump Sum or Capped?

Pay Applications — Options that must be considered.

% Billing and reconciled at the end of the project

Sub to submit back-up quarterly to ensure they are not excessively cash positive

Fully backed up monthly

Transparency and accountability

Open book (ability to audit)

Fosters collaboration

Increased Owner oversight and administrative burden

Added PM time to review monthly pay application back-up

Quality Control - Recommended Requirements for all Mega Subcontracts

Project specific Quality Control Program inclusive of the following:

Project Specific QC Plan for each System

Dedicated Quality Control Manager from Prime

Dedicate Quality Control Manager for each sub-tier over $5M

Provide resumes for quality control positions.

If subcontractor cannot staff these positions with qualified personnel, include 3rd party quality control staff

Owner Contract Risk Mitigation with Subcontractor Bid Packages

Consult with Legal & Risk Departments based on the scope and complexity of the project What owner contract provisions do we need to specifically transfer to subcontractors?

Insurance

Determine if increased insurance requirements should be priced out 100M+ Subcontractors

Specialized Insurance based on Owner Contract Requirements

Excess Liability, Professional Liability, OCIP or CCIP

Alternate Strategy Brainstorms (If there is a financial concern)

PO for materials, joint checks

Cost plus billings (backed up) during project, but allow lump sum billing at project close

Consider requiring a full RFP response from the bidders similar to a process B&G goes through when we compete to win work. You can use the RFP Template below to tailor fit an RFP specific to your project.

Example RFPs

CHOA MEP RFP sample

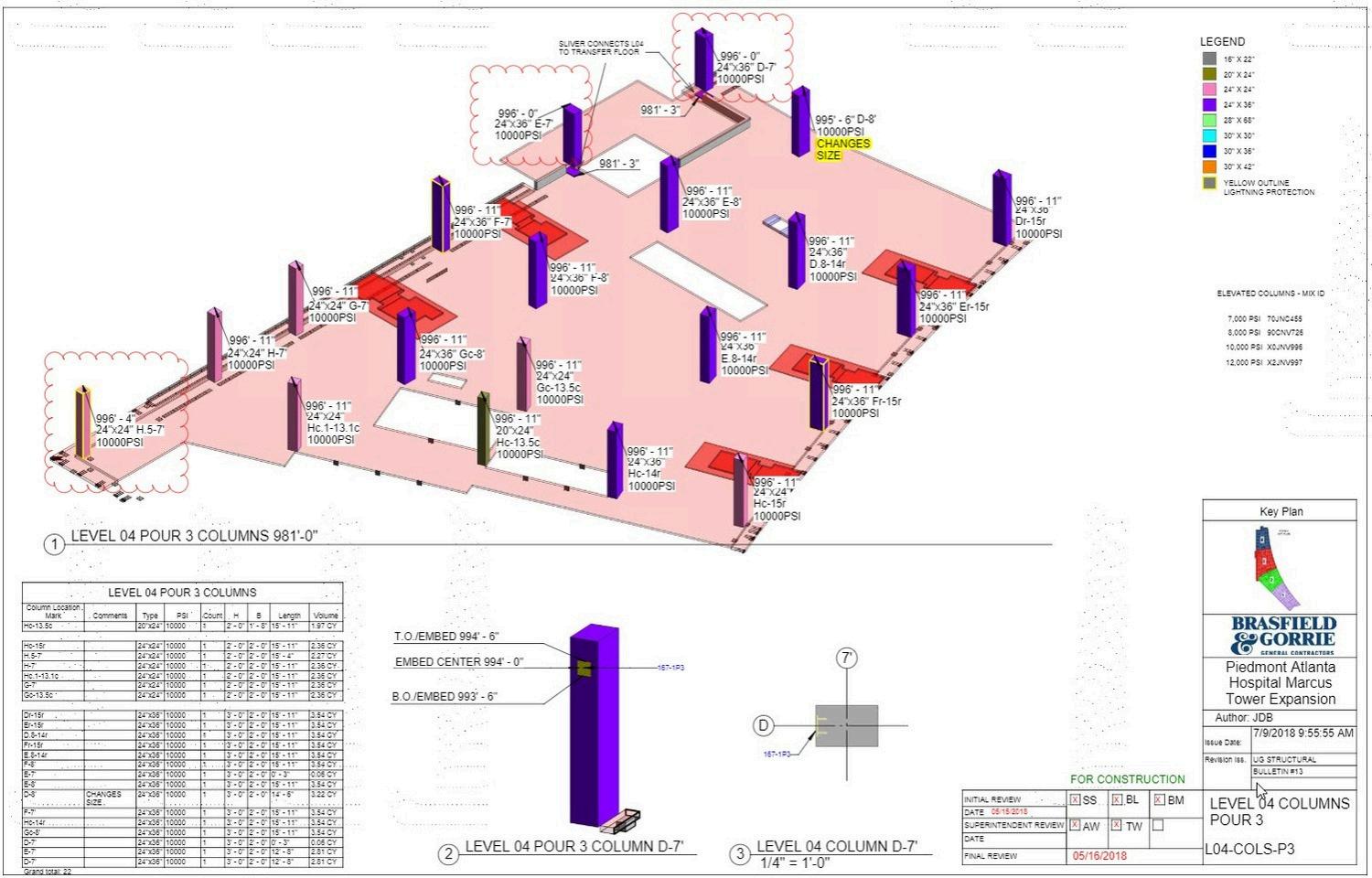

Piedmont MEP RFP sample

Example Sub Responses

CHOA - Mechanical RFP Response - BKI

HOA - Electrical RFP Response - ISCE

Establish schedule / defined scope of work during preconstruction phase to ensure buy-in from bidders and properly allocated resources between RFP award and final CD pricing. It is important to establish the contract type at RFP (i.e., cost plus/lump sum and provide specifics cost of work / general conditions / fee matrix so that bids can be adequately leveled, and terms can be incorporated into the subcontract

Even if not fully established, a high level project schedule should be established.

Interviews

Consider requiring interviews similar to process B&G goes through when we compete for a project

See sample agenda for a formal interview process.

Sample Agenda for MEP Sub Interview

Consider how you are you are going to rate, score, and eventually award the package.

Contractor Scorecard

Final Scope Review Meetings

Either a formal interview and scope review meeting is highly recommended

Subcontractor Required Attendees:

Preconstruction representatives

Proposed Lead Project Manager

Proposed Lead Supt

Proposed Lead Quality Control Manager

Key executives

Person signing the subcontract

Project Executive

Key Sub-tiers

B&G team:

Preconstruction

Division Manager

Project executive - OM, PD, SPM

Lead B&G Supt

General Superintendent

MEP Department Rep - if applicable

Self-Perform Group Rep - if applicable

Deliverables required from Subcontractor

Project organizational chart, and amount of time dedicated to project

Chart to include all sub-tiers and who from the prime will be responsible to manage each sub-tier

Resumes of key personnel

Prime

Major Sub-tiers

List of overlapping significant projects including monthly manpower schedules

Monthly Labor / Capacity Plan

Schedule Plan

Buyout Log

Planned lower tier subcontractors

Vendors

Sub-Tier Tracking Log

Vendor Tracking Log

Sub Tiers Subcontractors

Award approval requirements for lower tier subs

We may be awarding the prime subcontractor early, but sub-tiers later (example - mechanical insulation).

Establish how much input we want to have on sub-tier awards over 5 M Financial review/prequalification, #bidders, contract terms (CP v LS), reconciliation to budget, etc.

Procurement Plan

Communicate expectations for sub’s mgt (periodic site visits by upper mgt)

Virtual Design & Coordination Plan

Quality Control

Company Quality Control Manual

Sample Project Specific QC Plan

Subcontract Legal Review Comments

Sample Insurance Certificate for the project Letter from Surety (project specific) if intent is to bond the subcontract

subcontract:

Project Manager

Superintendent

Relationship holder with key executive of Subcontractor

Who is allowed to sign the subcontract?

Formalize Risk Mitigation Plan (RMP) and schedule appropriate check points

Who is involved in the meetings to review the RMP and/or with sub execs?

Senior PM and OM required, DM if available

See Example RMP Plan

Contact George Talley in Risk Department to help establish the RMP Plan

Prime Subcontractor Business Plan (Metrics)

Prime to establish a business plan (similar to B&G Metrics) that serves as the base line for the prime to report to B&G the status of their scope on a monthly basis. The plan and monthly updates to be focused on:

Schedule Milestone

Procurement

Financials

Labor

Safety

Quality

Submit Resumes of key Sub-tiers

Major Vendors

Note who from the prime is managing major vendors (PM and superintendent))

Provide Project Directory to B&G including contact info for all prime, sub-tier, and vendors team members.

Labor Planning

Provide manpower plan for Prime and all Subtiers.

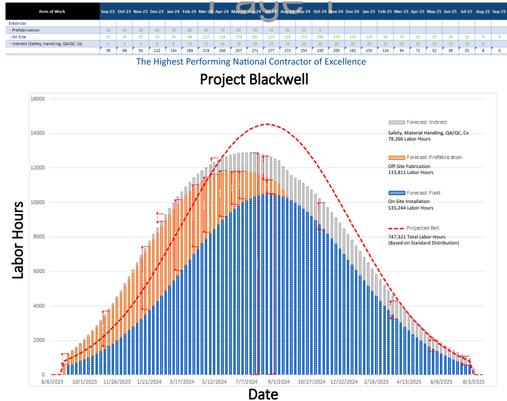

Gaylor Blackwell Manpower Curve

Keep updated throughout project.

Agree upon the cadence to update forecast VS actual comparison

Track Labor Curve and production against plan

Discuss how subcontractor forecasts labor to complete

Is it crew based?

Is it production quantity based?

Understand how they plan for contingency and peaks/valleys.

Set up a meeting rotation to revisit the labor curve, site staffing, and schedule versus plan

Ensure Sub is meeting defined goals and make appropriate adjustments if necessary.

Understand the ratio of supervision to production workers is established and tracked. Submit wage rate worksheets (road map to billable rates) and update as union rates change

Request a break down of fringe rates and what is included (e.g., travel, truck, living allowances, technology charges, etc.) This avoids double billing for these items.

Buyout log to be submitted to B&G weekly until complete, $ can be hidden

Obtain Submittal Schedule from Subtiers and Vendors

Send B&G overall submittal schedule for subtiers and prime

Permit Log - submit updates to B&G monthly

Licenses - provide B&G all licenses of subtiers

Provide insurance certificates for all subtiers

Certificate of insurance compliant with Schedule D

Change Order template + standard indirects (i.e. small tools, incidentals, equipment rental, labor inefficiency, warranty, etc.)

Discuss how labor will be charged for changes during construction - regular time vs. OT rates, how many hours (industry standard or subgenerated)

Internal Contingency Management - establish and review amount and how it is to be tracked / used

SOV Breakdowns - Prime Subcontractor

It is extremely important to have an accurate SOV Breakdown, considerations below:

General Conditions

Area/Phase

Material

Labor

Sub-tier breakout Values

This will help tremendously if there is ever a need for a claim or supplementation.

Counterpoint:

For large cost-plus contracts

an overly-detailed SOV does not provide value equivalent to the effort required to accurately produce, allocate, and track cost throughout the course of the project. A simpler SOV (e.g., material, labor, equipment, and subcontracts) can provide similar insight into GMP progress throughout the billing process without bogging it down

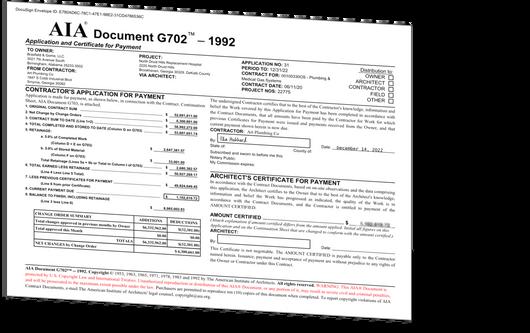

Sample Subcontractor Pay Applications and SOVs

EXAMPLE PAY APP

SOV Breakdowns - Sub Tiers

We also need detailed SOV's for tiered subcontractors as applicable not just line item invoices.

Discuss special requests around early payment

Stored Material paperwork requirements

Projected labor allowance (from actual due date until end of month)

Deposits on large equipment/materials

Thorough Pay App Reviews

Critical to not let the sub get ahead on their billings.

Include field in pay app review process.

Stored Materials

Trust but verify!

Ensure we have proper paperwork in place:

Site/shop visits or pictures

Insurance certificate for stored material

Bill of sale transferring ownership of material

Establish relationships with key sub-tiers and vendors so you can contact them directly when needed.

Each vendor and sub-tier to submit submittal and procurement logs bi-weekly to Prime Prime to submit submittal and procurement logs to Brasfield & Gorrie biweekly.

Schedule factory/shop visits as needed to verify critical procurement.

Schedule

Schedule and Production

Don't overly detail out the schedule until the right people and partners are onboard Include prime and subtier subs and vendors in final detailing of the schedule process. (You will need buy-in from their operations, field staff, and subtier partners to be successful.)

Establish Key Milestones for the project

VDC Plan

Budget and track VDC cost by design phase. The sub's productivity will depend on the productivity of the design team. Resist the urge to engage them too early, they will waste time and money unnecessarily

Subtier Subcontractor Management Plan

Understand what contractual flowdown is being established with prime sub's agreements with sub-tiers (e.g., schedule delays, damages, etc.)

Set expectations around management and supervision responsibilities, meeting attendance, billing, procurement, schedule, QAQC, etc

Invite Brasfield & Gorrie to attend the meetings, if necessary.

Define which Prime Sub team members are managing each Subtier (office and field).

Vendor Management Plan

Understand what contractual flowdown is being established with prime sub’s PO/ agreements to sub-tiers (e g , schedule delays, damages, etc ) Include extended warranties, multiple factory startups, etc. if necessary.

Define which Prime Sub team members are managing each sub-tier (Office and field).

MOP Planning - Shut Down and Tie In

Request draft log of all MOPs that will be required on the project

Determine process flow for all MOPs.

Determine where the log will be housed and managed.

MOP Log Template

Critical Facility Impact Procedure Plan

Sample MOP Plan

Temp Provisions Planning

Request detailed plans for any temp provisions (temp generators, temp HVAC, etc )

Coordinate/Verify any MEP and/or Structural needs for temp provisions.

Potential systems that would be delegated design

Seismic

Structural Components

Fire Protection

Fire Alarm Systems

Low Voltage Systems

Follow guidelines per your project specifications

Consult with the Brasfield & Gorrie Design and Engineering group

SDP Subcontractor Periodic Reviews

SDP to perform checks ins with the subcontractor as required by the RMP Financials

Status with other active B&G projects

Backlog/WIP

Discuss project pursuits with other GCs

Safety Planning

Advanced safety program and leadership expected from a mega subcontractor.

Dedicated safety manager for prime, consider need from major subtiers.

Prime to partner with B&G onsite safety manager, help lead overall project safety, be an advocate for overall project safety

Submit Site Specific Safety Plan for each System/Subtier.

LOTO compliance and execution

MOP compliance and execution

Conduct bi-weekly safety and focus walks for their trade and subtiers

Help lead and conduct Committed from the top periodic meetings with Ownership and Subcontractors.

Committed from the Top - Sample Agenda

Labor Tracking

Keep Labor Tracking Log/Curves updated throughout project.

Agree upon the cadence to update forecast VS actual comparison.

Track Labor Curve and production against Plan.

Discuss how subcontractor forecasts labor to complete

Is it crew based?

Is it production quantity based?

Understand how they plan for contingency and peaks/valleys

Set up a meeting rotation to revisit the labor curve, site staffing, and schedule versus plan

Ensure Sub is meeting defined goals and make appropriate adjustments if necessary.

Understand the ratio of supervision to production workers is established and tracked.

Prime to submit submittal and procurement logs to Brasfield & Gorrie biweekly. Schedule factory/shop visits as needed to verify critical procurement.

Encourage sub to keep their own schedule with defining all subtier work

In more detail than the B&G schedule

Establish baselines and milestones to track against.

Prime to conduct periodic schedule meetings with subtiers and vendors.

Invite B&G to the schedule meetings.

Subtiers to walk job prior to meeting and provide update forms to prime Daily Huddles and Weekly Work Plans

Prime and major subtiers to attend B&G huddles and meetings.

Encourage Prime to conduct similar huddles and meetings with their Subtiers in advance of the B&G Huddles/Meetings

Establish a Project Metrics (or monthly report) type of reporting that the Prime is to submit to Brasfield & Gorrie to provides a status report of their scope.

Schedule Milestone

Procurement

Financials

Payment status to Subtiers and % complete

Labor Safety

Quality

Leadership

with B&G, Prime, and Major Subtiers

Senior Leadership from B&G, Prime, and Subtiers must attend

Agenda

Procurement

Schedule Manpower

Financials

Subtiers

Overall Performance Status

(Procurement, Labor, Schedule, QC)

Payment Status

Team Health: Challenges and successes

Open Discussion

Site walk if needed

Consider including Prime in OAC Meetings as they are integral team members to these projects.

Provide resume for dedicated QC Manager for Prime

Quality Control Plan for EACH system; define who is responsible

Pre-Fab Plan

Each subtier to have their own QC plan; define who is responsible from subtier

Prime to conduct monthly QC meetings with Subtiers and vendors

Meeting to be separate from Schedule meeting

Meeting to include a jobsite walk per system

Initial Inspections: Prime to establish a program for initial inspections for all work performed with their own and subtier field forces.

Identify areas that need support from B&G MEP group or third party consultants

Daily QC Process: Subcontractor to define process and how it will integrate into B&G Procore

Establish the lead responsibility for daily QC the Prime.

Establish process for checks and balances to ensure QC is being perform by running weekly analytics from Procore

Total open items

Items added this week and month

Items completed this week and month

Performance based specs planning to ensure compliance at start-up

Start-up plan for each system

Extended warranties for early equipment start-up

Management and maintenance of CEP/CUP/plant systems prior to substantial completion.

Owner Furnished Equipment Responsibilities

Receiving/handling/storage responsibilities

Peer Reviews

Consider conducting periodic collaboration meetings with other B&G projects of similar size within the market sector See sample agendas below.

Data Center Peer Group Meeting Agenda

Data Center Peer Group Meeting Notes

Create a Risk Mitigation Plan with the lead PM, OM, and SDP group

Include Quarterly Leadership meetings in this plan

Request a planned billing schedule. Reserve the right to visit their offsite storage and prefabrication facilities.

Create a log of all their vendors and subcontractors (a more extensive version of their typical Pay Application Vendor Certification)

An example of what I used is attached. Since some of their sub-tiers are larger than a typical B&G subcontract, check SubDB to ensure there are no red flags for their planned sub-tiers.

Require interim and final lien waivers for all vendors and subcontractors over $(some value) even if they don’t file a Notice to Contractor.

Consider removing some sub-tier work from their scope and manage them directly (e.g., EPMS, Fire Alarm, ERRC, NETA, TAB) The extra coordination requires more B&G personnel but doing so can reduce risk.

Especially for Phased projects, consider having line items for lump sum payouts that will only be paid when Punch and CxAlloy issues are 100% resolved for a given phase. That can help prevent small items from lingering for too long when it means releasing $1M An alternative is basing retainage release off progress milestones.

Temporary Power: Engage electrician early for temporary power planning, most major contractors will have sophisticated plans already developed that need to be fine-tuned for site specific planning Work with electrical contractor to help establish power allowances

RE: Temporary power, engage county power provider early for renting and setting of any temporary/permanent equipment (xfmrs). Work to "temp" in major distribution switchboards, permanently feed all panels from main electrical rooms

Consider including Sub Org Chart

Requirements in the "Buyout" section. Refer to notes in "construction" header.

Include in Schedule A design assist scope responsibility.

Share scope of work with EORs, outline expectation clearly

MEP Equipment Interview and Buyout Process Decide early with MEP subs and EOR if this is possible, include owner in this decision if required.

Ensure MEP group has capacity to lead this effort

Try to minimize sleeves within pod footprint, take advantage of any wall chases adjacent.

Need strong pod sleeving plan / QC Headwalls

Consider mockups for pods and headwalls where walls are shared - can create a lot of access concerns

Electrical Rooms / Panels / Gutters and Terminal Blocks

Underground and OH Racks

Ensure B&G team buys in to internal BIM schedule and it supports fabrication and install, ensure BIM schedule is updated in same intervals as the OPS and shows BIM schedule variances

Electrical

Triple check all equipment and correct clearances are in model (common items missed such as Bus ducts, FCUs)

Good practice to always install sprinkler branch above door.

Understand drain pan requirements and coordinate to minimize work

Try to stack TDR and Electric rooms whenever possible, ensure plumbing penetrations not in rooms; If so 2HR separation required.

B&G

Include 6" clearance off rated walls

AHJ dependent - In FL, AHCA is strict on this clearance to allow inspectors to see head of wall firestopping.

Work with B&G team to print RCP plans for all systems; will save a lot of headache and field coordination for the "low hanging fruit" such as smoke detectors installed within 3' of mech grille

Specialty Rooms (ORs, Caths, etc.) - Include vendor access requirements, B&G take lead on modeling unistrut (get cad from sub) and vendor boom access requirements, coordinate sub responsibility for access panel procurement

MRIs

Ensure shielding included in model, with correct ceiling elevation Provide shielding contractor with mechanical waveguide, MEPFP penetration locations.

Coordinate with design team to attend BIM meetings once a week; dedicate first of last 15-30 min of call for design questions and feedback. Set expectations early - Ensure all parties are aligned and that clash detection is resolved in the model and not left to be resolved in the field

Scrub general notes in structural set and review with design team early Look for general notes that all major system mains to be supported from structural beam or joist.

Blubeam Studio is a great tool for drawing scrubs and mark ups. Set up sessions with subcontractors and design team to provide mark ups / ask questions

Overlay MEP Equipment with Electrical drawings to ensure power to all equipment. Electric Door Hardware - Overlay security drawings with electrical drawings to ensure power to all devices. Coordinate the furnishing of power transformer devices with Door Hardware schedule

Ensure Hardware sets also match T sheets if you have security plans.

FA coordination with mag locks and door hold opens. Consider coordination call with DFH / Elec / FA, create responsibility matrix.

Coordinate all shafts to ensure that MEP systems can be properly installed and firestopped. This may require reconfiguration or resizing of structural openings or drop down shaftwall framing (bathtubs)

In-Wall Scrubs

Coordinate all shafts to ensure that MEP systems can be properly installed and firestopped This may require reconfiguration or resizing of structural openings or drop down shaftwall framing (bathtubs).

RCP Scrubs

Scrub design documents to coordinate ceiling layout in all critical spaces (Example - clinical spaces in hospital). Overlay (with assistance from VDC) reflected ceiling plans, electrical lighting plan, life safety exit lighting plan, HVAC diffuser plan, low voltage systems design and/or shop drawings (nurse call, fire alarm, CCTV, structured cabling/WAP's, DAS, etc )

Drawing Scrubbing Examples

Futureproofing

Consider future expansion areas. Provide provisions for future tie-ins to reduce shutdowns. Example - valves, pull boxes, raceways. Locate outside of critical areas. Consider access below to shell space or future vertical expansion. Consider future capacity / sizing for source equipment and conveyance

Future Proofing Checklists

Fire Alarm Matrix vs Life Safety Plans vs Mechanical Systems - review fire alarm system and LS smoke compartments to ensure mechanical design aligns, if FA design is a "defend in place" strategy ILO general alarm and only the compartment a smoke or heat is detected shuts down, try to influence design to ensure AHUs follow these compartment walls

Applicable Building Codes

A lot of jurisdictions are starting to adopt 2021 IBC - major change mechanically in this code is clarification around what is a fully ducted system allowing for the elimination of fire dampers in duct penetrations of 1 hour fire barriers, even with the presence of flex duct.

This is a major VE item / owner maintenance / access coordination

Consider engaging your AHJ with proposal to adopt code if not already done so - refer to attached code clarification request submitted and accepted by B&G and design team previously

Signage Shop Drawings to be coordinated with the Fire Alarm & Controls subs. For Major Shop Drawings and submittals consider hosting onsite submittal party with subs / manufacturer reps / EORs

Generators

Paralleling Gear

COORDINATION MEETINGS TO CONDUCT

Cx Kick-off

Equipment Start-up

Power Start-up

Include electrical rooms beyond main electric room. Sometimes attention is focused on major gear, distribution boards, establish scheduled activities and plan to not lose sight of feeders to branch electrical rooms.

Conditioned Air Planning

Flushing plan

Controls start up

Safeties on AHU

Damper Logs (Link): When possible, engage QC group to help setup Procore templates Ensure mech sub buy in and Mech sub responsible for FD labeling and shop drawings with labels.

Damper Log Processes

Permit Tracking Logs

Permit Sign-off Tracking Log

Hospital IT Coordination and TDR Buildout (need link)

Know the sub's level of experience with the product type and the scale of project Use the reviews from other projects on build and bring the sub in for a buyout meeting to discuss their proposed management and field team.

Request a job-specific Organization Chart, even if some names start as “TBD”. Org chart should list both office and field leadership Also, it is recommended to request the percentage of time each person will be dedicated to the project.

Subcontractor shall include sufficient office staff for change orders, scheduling needs, procurement, safety, BIM coordination etc. Often times, 2-3 PMs aren't enough. It’s recommended that a part-time scheduler be included.

Have subcontractors submit a labor management chart including a manpower chart that ties into a P6 schedule This chart should include field labor as well as supervision (Foreman, General Foreman, Superintendents, Safety, QA/QC) to ensure enough coverage at the top for such a large scope of work.

Request their plan for labor sourcing and the expected ratio of contract labor.

Set up way to track their manpower beyond daily reports (e.g., turnstyle).

Require monthly on-site presence from a designated 1 or 2 executives that were involved in precon/buyout.

Damper Log Processes

Receive and review their ‘risk mitigation log’ monthly. Compare actual manpower with planned manpower curve and inquire about any significant deviations. Beyond reviewing lien waivers, call major subtiers/vendors occasionally to ensure there are no red flags (financial, lead time, lack of information) on their end.

Visit prefabrication shop and major stored material facilities occasionally

Consider hiring a third-party QC company (or a separate trusted sub) to spot check early progress and help identify systemic issues early into installation.

For repetitive scope, add ‘First of kind’ (FOK) durations and inspections into the P6 schedule early on Document FOK conditions formally Document work at least weekly with a 360 camera, such as OpenSpace When there were 700+ electricians on site, that becomes an incredibly valuable tool for tracking everything from general progress to ticket disputes. Mandate that there is an individual dedicated to backchecking inventory to ensure they have enough material to complete the job. Build as much detail in the schedule as is beneficial. Get to know the details of how the MEPs are installed. Include procurement activities for as much as is necessary

Understand how the sub is breaking up their field staff? Make the job small by breaking it up into areas (share key plans with subs early) and have leaders for each area that report to one foreman. Getting a firm understanding of how the sub crews are set up can inform our schedule so that we help subs know which areas are critical and when to increase manpower.

It’s good practice to share B&G org chart early, setting the expectation that their field structure should be of similar scale to B&G (i e , However B&G has divided dedicated AFM, assistant superintendent, and superintendent should match sub lead structure).

Having separate QC guys who at were dedicated to CxAlloy, startup, and Cx support can be very beneficial as it allows the foreman to not pull away from the install.

Get a QC plan up front from the sub and identify the key areas. Make sure you are focusing on each "first of kind" install.

For cost management make sure you get a CO log from the sub each month so they don't have cost that you aren't aware of. A monthly check in helpful depending on how many changes your project has.

It’s recommended to have a monthly financial meeting with the subcontractor to review outstanding change orders, upcoming spends, risks, and challenges to the project.

Temporary Rainwater Management - On greenfield projects, anticipate structure top out ahead of civil utility tie ins at building, and establish some sort of rainwater mitigation plan

Temporary Systems to Plan For Temp jobsite water and riser (assume need a booster pump)

Temp Power

Temp FDC and Riser

Temp Water Flow Monitoring - Engage controls contractor to establish plan for temp control valves and monitoring of systems, alarm for flows outside of normal construction hours

Domestic water

Hydronic Water Fire protection

Conditioned air and flushing coordination planning

Challenge Mechanical/Plumbing subs (depending on mech room layout) to fab and install CHW risers and loop as early as possible, utilizing open footprint and cranes onsite to drop risers in place.

Bi-Weekly MEP Meeting - onsite meeting (HVAC, Elec, FA, TAB, FP, Plumb)

Schedule Constraints

Procurement

QC

Field Coordination

Consider setting up an internal MEP check in (recommend weekly) meeting onsite with project leadership (e g , Senior PMs / Senior Supers) There are a ton of complex items you will be responsible for managing and coordinating, having a 30 minute touch point to keep your leadership up to speed ensures B&G is marching to the same beat.

Examples

Risk Mitigation Plan for Electrician

Risk Mitigation Log

Manpower Curve from Electrician

Quality Control "School"

Subcontractor Staffing Plan

In-Wall Scrub Example

RCP Scrub Example

Future Proofing Checklist

For questions regarding this document, please reach out to any of the following contacts.

CHRISTIAN PITTS

CPitts@BrasfieldGorrie.com

615.313.2906

Nashville

KYLE GASTON

Kgaston@BrasfieldGorrie.com

334.332.2207

Birmingham

DAVE HAJJAR

DHajjar@BrasfieldGorrie com

678.581.6320

Atlanta

DAVID HAJJAR

DHajjar@BrasfieldGorrie.com

678.581.6320

Atlanta

GEORGE TALLEY

Gtalley@BrasfieldGorrie.com 205.572.8924

Birmingham

DREW KELLEY

Dkelley@BrasfieldGorrie com 770 833 2906

Atlanta

JEFF LYNN

Jlynn@BrasfieldGorrie com 205 381 0777

Birmingham

ERIC LYNN

Elynn@BrasfieldGorrie com 334 614 2587

Nashville