TURF TALK

NITROGEN PROGRAMS

for Tall Fescue Sod Development By Erik Ervin, Ph.D., and Mike Goatley, Ph.D., Virginia Tech

T

he faster Mother Nature and sod producers’ skills allow them to harvest a crop, the better the potential profitability. As the nutrient most required by turfgrasses for proper growth and development, nitrogen (N) plays a primary role in the quest for quick harvest of a high-quality sod. Unfortunately, as natural gas and oil prices continue to rise, so do the costs of nitrogen. While soil tests are quite adequate in recommending how much phosphorus (P) and potassium (K) should be added to the soil at establishment to provide sufficiency during sod development, there is no such test for N needs. Given variable soil conditions and fall weather patterns that exert substantial controlling effects on the rate of fescue development, sod growers must base much of their nitrogen scheduling on experience. To provide growers with more detailed information on which to base their nitrogen scheduling decisions, we conducted a study at Brookmeade Sod Farm in Doswell, VA, from September 2005 to June 2006, investigating a number of nitrogen sources, applied at two rates and two timings. Our objective was to determine the most cost-effective nitrogen fertilization program to go from an early September seeding of netted tall fescue to an effective harvest.

Approximately two weeks after seedling emergence (September 30), we applied the following N-fertilizer treatments every 30 or 60 days, through November, for a range of two to three fall applications. Total N applied during grow-in (not including the amount supplied by the starter fertilizer) ranged from 1.5 to 6 lb./1000 ft2. Table 1 outlines the treatments and the estimated total cost of each treatment as of December 2005. Here is a short summary of the nitrogen sources or products tested in this trial. • Urea (46-0-0) is a quick-release, soluble N source. • Ammonium sulfate (AS) is a quick-release, soluble N source. • Sulfur-coated urea (SCU) is a slow-release N source. SCU is made by spraying preheated urea prills with molten sulfur. A sealant such as wax is usually applied to seal pores and imperfections in the sulfur coating, and a diatomaceous earth conditioner is used to decrease stickiness. N content of SCU

Materials and methods The soil test conducted prior to seeding indicated a pH of 6.6, organic matter of 1.3%, with P levels rated as high and K as low. On Sept. 1, 2005, we seeded a test area with 200 lbs./acre of a 90% tall fescue/10% Kentucky bluegrass mix. A starter fertilizer to supply 100 lbs. N/acre, 50 lbs. P2O5/acre and 150 lbs. K2O/acre was applied uniformly over the whole test area, followed by netting.

24

TENNESSEE TURFGRASS OCTOBER/NOVEMBER 2006

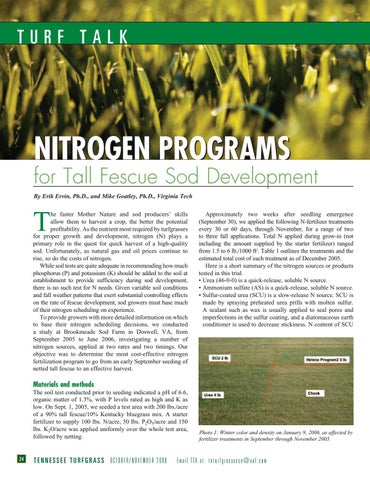

Photo 1: Winter color and density on January 9, 2006, as affected by fertilizer treatments in September through November 2005.

Email TTA at: tnturfgrassassn@aol.com