LEYBOLD – INNOVATIVE TRAINING SYSTEMS FOR

THEORY AND PRACTICE

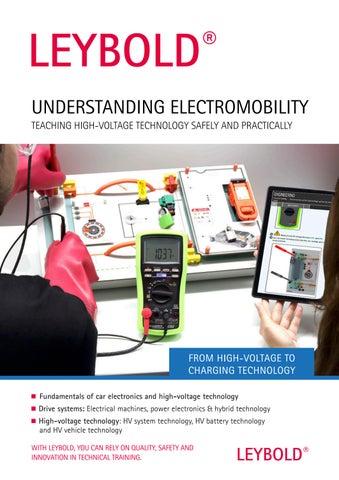

From tried-and-tested plug-in systems to versatile teaching from panel systems to practical compact trainers - LEYBOLD offers solutions that perfectly combine theory and practice. Our systems rely on safe low voltage or offer safe measures for higher voltages - without any risk.

Thanks to practical exercises, including safe cutting with real high voltages, trainees experience realistic workshop scenarios. Original measuring devices and components ensure authentic tests, while integrated fault switches enable targeted diagnostics.

From battery technologies and high-voltage components to charging infrastructure - our training systems provide comprehensive expertise and optimally prepare students for electromobility.

With LEYBOLD you can experience electromobility at first hand - future-proof, practical and inspiring!

TRAINING SETS FOR ELECTROMOBILITY

Our advantages for your training success:

Safe learning - Safe low voltages and safe high-voltage exercises for maximum protection.

Practical scenarios - Realistic workshop environments with original measuring devices and real vehicle components.

Targeted diagnostics - integrated fault switches for precise fault analyses.

Comprehensive expertise - From battery technology to charging infrastructure: Everything for electromobility in one system.

Future-proof and innovative - prepare your trainees optimally for the challenges of modern vehicle technology.

With LEYBOLD, you can rely on quality, safety and innovation in technical training.

Fundamentals of electrics/electronics

Fundamentals of electrics & high-voltage technology

FOCUS ON DRIVE SYSTEMS

Electrical machines in hybrid and electric cars

Workstation vehicle hybrid drives

FOCUS ON HIGH-VOLTAGE TECHNOLOGY

High-voltage system technology

High-voltage battery technology

High-voltage vehicle technology

Workstation high-voltage vehicle technology

Start now - The perfect basis for electromobility training! FUNDAMENTALS

OF ELECTRICS/ELECTRONICS (A1.1.1.1)

Modern vehicles are based on complex electronic systems. Our plug-in system teaches the basics of electrics and electronics in a practical way - from sensors and actuators to lighting and data transmission. Through realistic experiments, students gain a sound understanding of vehicle technology and are well prepared for the future of electromobility.

The intuitive plug-in system as an introduction to automotive technology

Transparent components for maximum clarity

Typical automotive components

Robust construction

Circuit diagram-compliant superstructures on a grid plug-in board

ISO-compliant symbolism

Understanding vehicle electrics holistically

With equipment set A1.1.1.1, trainees learn the basics of automotive electronics:

Electrical circuits, resistors, capacitors and coils, Transformers, relays, diodes and LEDs, transistors and thyristors.

Highlight: Your students will build circuits such as electronic rev counters, voltage regulators or transistor control units and experience technology at first hand!

Electromobility is not neglected either. Learn about forward-looking topics such as high-voltage technology, DC/DC converters, high-voltage battery management (HV-BMS) and protective measures in IT networks of intrinsically safe electric vehicles.

PRODUCT HIGHLIGHTS

Basic system for automotive electrics and electronics

basic exercises and

project tasks

Safety at the highest level: high-voltage systems in intrinsically safe vehicles FUNDAMENTALS OF ELECTRICS & HIGH-VOLTAGE TECHNOLOGY (A1.1.1.5)

An intrinsically safe vehicle offers maximum protection against contact and arcing hazards from the highvoltage system.

Important features include permanent insulation monitoring and low-resistance potential equalisation. These systems can be safely tested with LEYBOLD‘s plug-in elements - thanks to 24 V low voltage, practical and safe.

With LEYBOLD plug-in systems, you can experience this technology safely and tangibly:

Low voltage (24 V) for risk-free training

Direct measurement of voltages and potential equalisation resistance with Sensor-CASSY 2

Determining the insulation resistance with a special measuring device

The basis of electromobility: electrical machines & power electronics

ELECTRICAL MACHINES IN HYBRID AND ELECTRIC CARS

Hybrid and electric vehicles are based on electric machines and power electronics. With the modular „ELM“ electric training machine system from LEYBOLD, trainees learn how DC, AC and rotary field machines and inverters for controlling traction and recuperation work in a practical way. All experiments are carried out using safe 24 V technology - ideal for training.

Key topics:

Design and operation of different types of machines: Direct current, alternating current, rotary field and servo machines

Power electronics: Controlled by a modern inverter

Independent assembly of complete systems

Enable in-depth understanding:

Electromagnetism, induction and voltage generation

DC/DC and DC/AC converters

Motor and generator functions

Power flow and energy direction

All machines are designed to be transparent and safe: In addition, the inverter operates at less than 24 volts - ideal for trainees.

PRODUCT

Experience hybrid technology - compact and practical WORKSTATION VEHICLE HYBRID DRIVES (A2.7.2.3)

With the innovative workstation from LEYBOLD, trainees can investigate all the key aspects of hybrid drives in a minimum of space.

The trainees explore the complex hybrid technology independently and choose flexibly between different systems using 3 support masks. The PC connection enables additional analyses, such as the display of the energy flow.

The workstation for trainees include:

PMSM electric motor

Inverter

Dual-voltage electrical system with engine CAN bus networking

Operating modes to experience:

Start

Electric driving

Boosting

Regenerative braking Operation with non-hazardous voltage

Digital, interactive courses for independent learning (COM4LAB) Ready for use without additional devices

Mastering high-voltage technology safely HIGH-VOLTAGE SYSTEM TECHNOLOGY (A2.7.2.5)

The high-voltage system technology training system offers safe and practical training in handling highvoltage components. It simulates realistic fault patterns and allows safe measurements on high-voltage components.

Brand-independent training

Diagnosis, testing & repair of all hybrid and high-voltage systems

Measurements under voltage

Insulation, potential equalisation & voltage drop measurement

Integrated fault switches

Realistic diagnostic exercises and analysis of measured values & signals

Safe cutting

Practise cutting the high-voltage cables safely

Understanding charging processes

PRODUCT HIGHLIGHTS

Charging station with original charging controller to simulate all charging states

High-voltage training system with charging station

Understanding and safely mastering high-voltage batteries

HIGH-VOLTAGE BATTERY TECHNOLOGY (A2.7.2.6)

The high-voltage battery technology training system is specially designed for the training of automotive highvoltage technicians. The focus of the trainer is on the safe handling of high-voltage batteries, whose voltages can reach up to 800 V - a potential danger that should not be underestimated. For safe learning, the trainer transforms the high-voltage into a safe voltage of up to 32 V. With interchangeable cell blocks, a variety of cell chemistries can be analysed, which enables an indepth under-standing of the different battery types.

The training system includes functions such as battery management units, main contactor with switching logic, monitoring by a safety line, service disconnect, battery data acquisition, cell temperature simulation and fault switches.

The system offers modern training:

Replaceable cell blocks & battery management

Main contactor with switching logic & service disconnect

Battery data logging & cell temperature measurement simulation

Fault diagnosis for defective cells

On-board charging infrastructure & optional insulation monitoring

In addition, an inverter unit in combination with the „ELM“ electric training machine system makes it possible to set up a complete traction drive - from the motor with recuperation to the activation of the vehicle.

PRODUCT HIGHLIGHTS

Intrinsic safety on a 24 volt basis

Operation with different cell chemistry structures

Use of LiLo or LiFe cells in the same system and future battery cell chemistries

Integrated fault switch box

Safe and effective troubleshooting HIGH-VOLTAGE VEHICLE TECHNOLOGY (A2.7.2.7)

With the high-voltage vehicle technology training system, you can simulate specific insulation faults and practise systematic troubleshooting - without risc! Thanks to easily accessible high-voltage components and low current carrying capacity, training remains practical and safe at all times.

The high-voltage system trainer offers:

All high-voltage components from original vehicles, easily accessible

Realistic training such as unlocking, under simplified conditions

Manageable design that reduces the complexity of the high-voltage technology

Application and feel like in a real vehicle

Teaching high-voltage technology safely WORKSTATION HIGH-VOLTAGE VEHICLE TECHNOLOGY (A2.7.2.8)

With the workstation high-voltage vehicle technology, your trainees learn how to handle high-voltage safely on original components and use standard workshop measuring devices to test high-voltage components and diagnose faults.

The compact tabletop device enables small groups to work independently and practically on realistic scenarios.

Advantages at a glance

Designing lessons simply and safely

Active & independent learning in the classroom safe environment

Coverage of DGUV training courses level 1-3

Working under voltage

Integrated fault switches and lockable access protection

Original components

Versatile use thanks to support masks

PRODUCT HIGHLIGHTS

Illustrative fault diagnosis –realistically practise critical scenarios

Modular learning masks –Flexible visualisation & verificable

Understanding intrinsic safety –Pilot line visualises high-voltage protection principle

2

REALISTIC CUTTING

Training systems utilise real highvoltages of >60 V for realistic vehicle workshop scenarios

Safe training on real voltages (the safety of the trainees is guaranteed at all times)