LAUMASoffersawiderangeofloadcellsofthemost commontypesinthemainindustrialsectorsprovidingfor eachofthemthequality,availabilityandassistance.

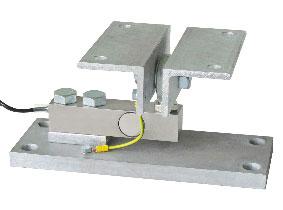

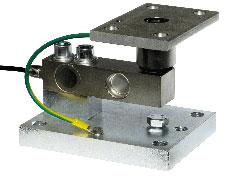

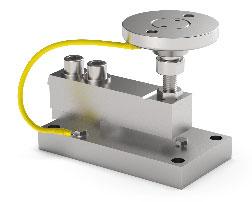

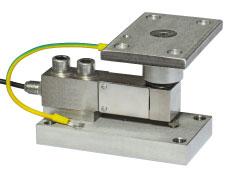

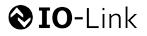

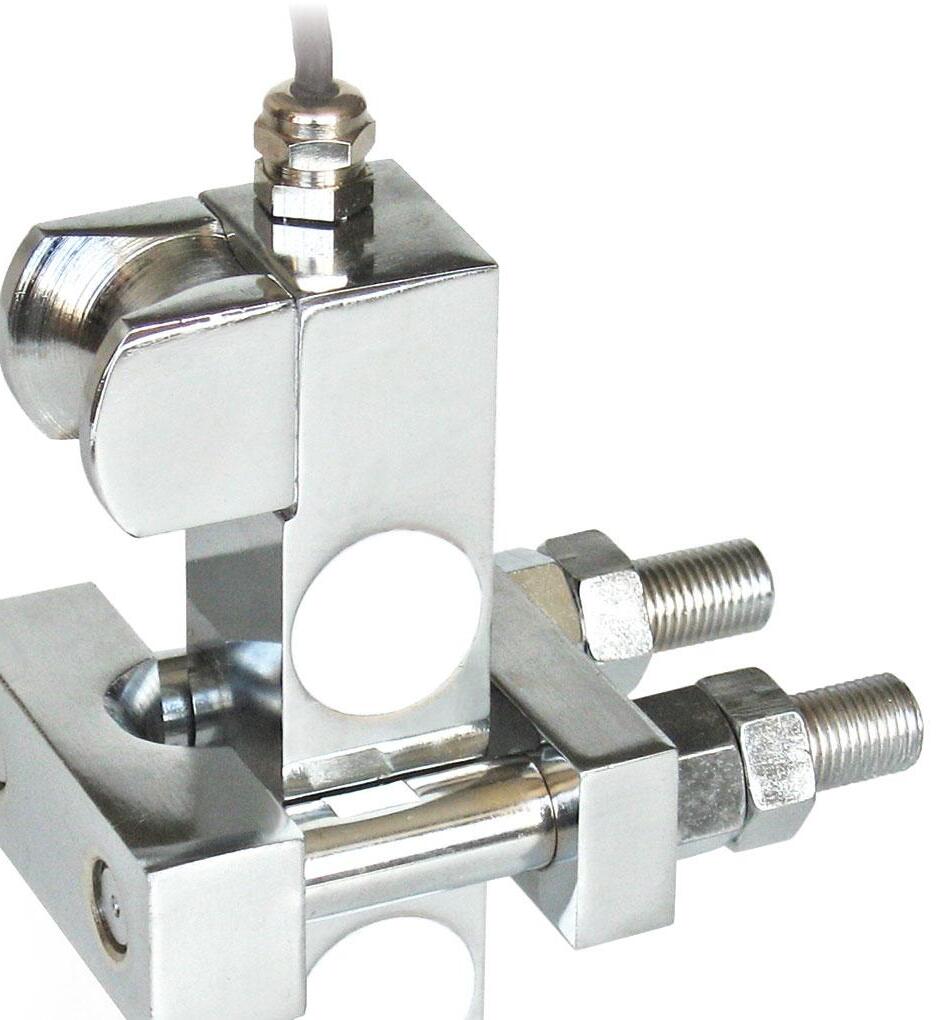

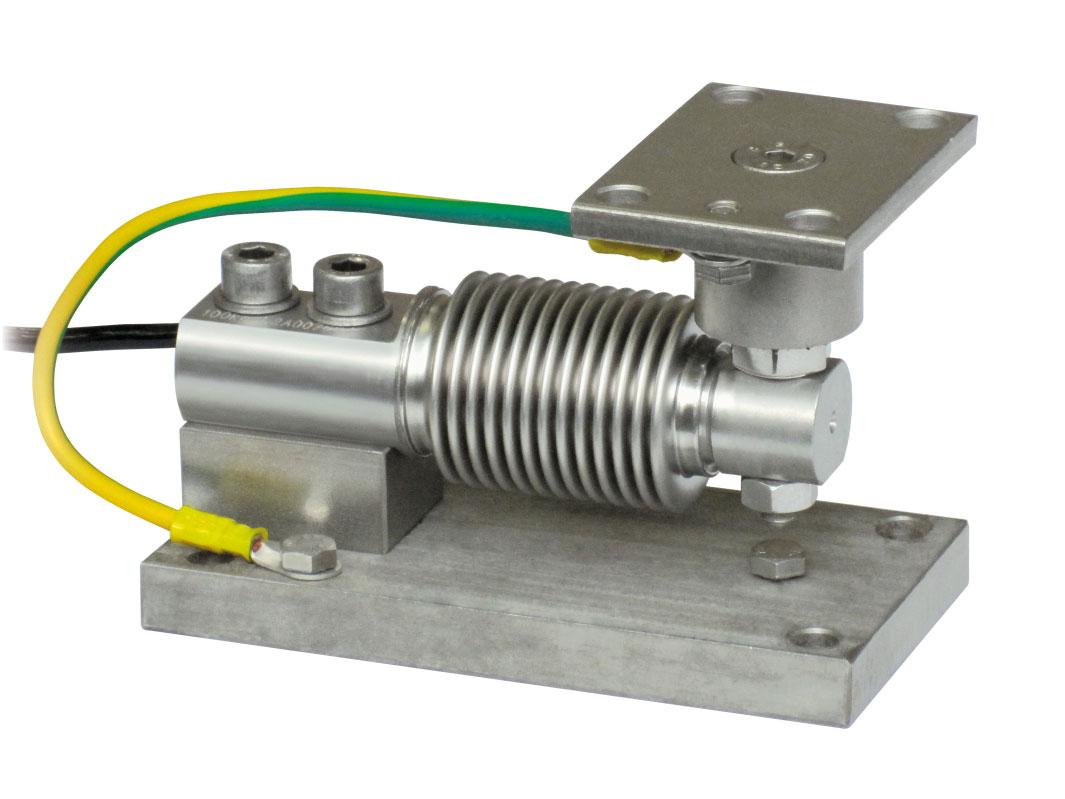

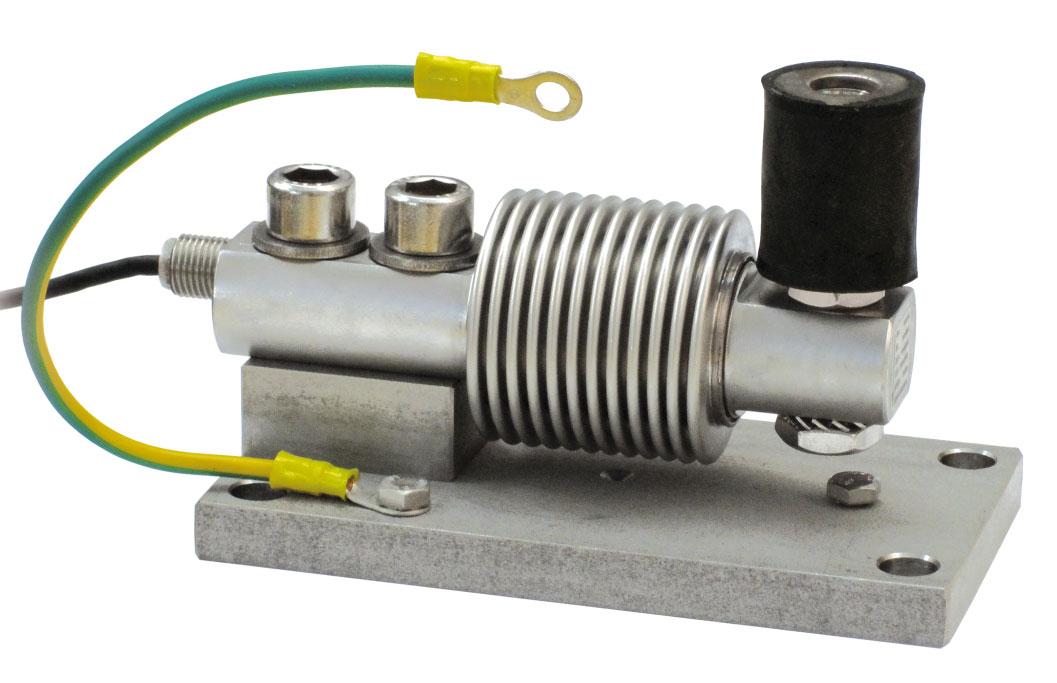

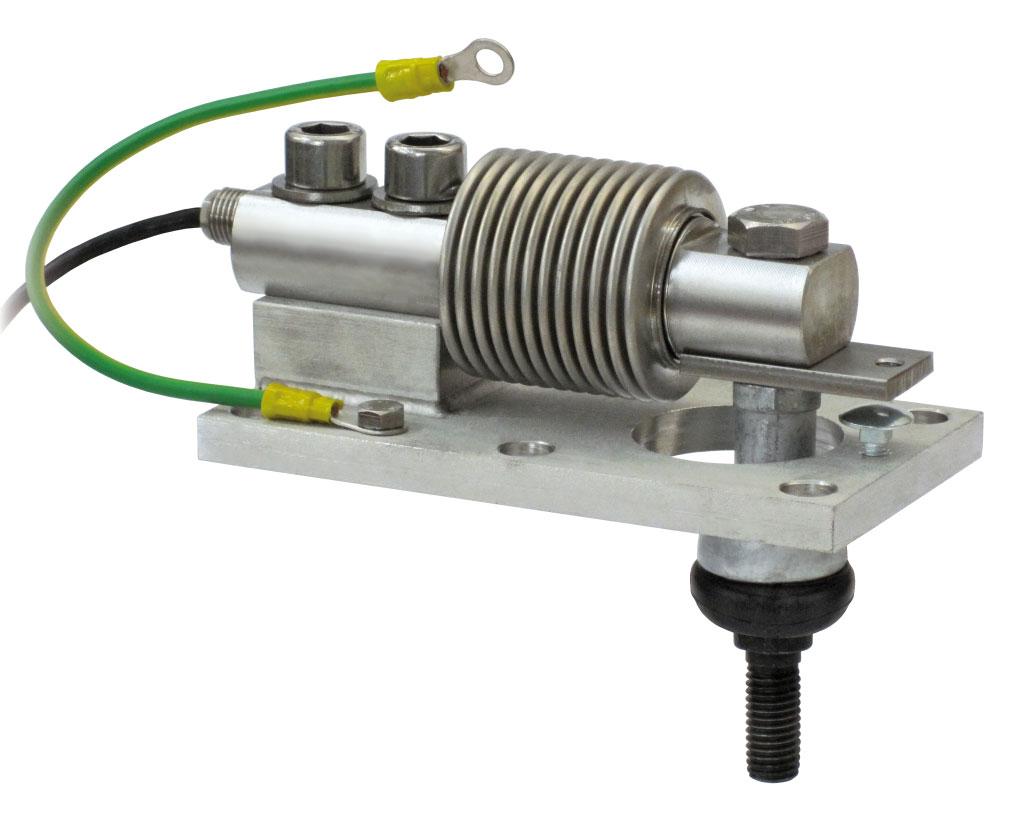

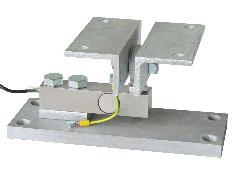

Forallloadcells,LAUMASisabletoprovidesuitable mountingkits,withtheaimofobtainingthecorrect applicationofthecellandmaximumreliabilityandaccuracy, andcompatiblywiththemechanical,electricaland pneumaticconnectionspresentontheweighingstructure.

European Conformity Mark (CE)UKCA CERTIFICATION (UK Conformity Assessed) for the United Kingdom

EAC CERTIFICATION

OIML APPROVALEU TYPE EXAMINATION CERTIFICATE FOR UK Non-Automatic Weighing Instruments (NAWI)

3-A SANITARY STANDARDS

NTEP CERTIFICATIONATEX CERTIFICATION

EAC Ex CERTIFICATION

CPA CERTIFICATION (Chinese Pattern Approval)

Ex NEPSI CERTIFICATION

FM HazLoc (Hazardous Locations) CERTIFICATION

IECEx CERTIFICATION

PAC CERTIFICATION (Pattern Approval Certificate)

EN1090DECLARATION OF CONFORMITY

IP69K MARKING PROTECTION RATING

Testing, calibration, quality control

Calibration services accredited by Accredia for load cells and load cells + instrument, performed in our laboratory LAT No. 02141 for force values between 2 and 100 kN, according to UNI EN ISO 376 and ASTM E74 standards. Accredia is the Sole National accreditation body (European Regulation 765/2008) and guarantees compliance with standards and the reliability of conformity certificates issued on the market. The Accredia calibration certificate is an official document recognized worldwide because it is covered by the EA, IAF, and ILAC Mutual Recognition Agreements. In our laboratory, we also perform calibration reports for force values between 0.5 and 5000 kN (compression) and between 0.5 and 600 kN (tension).

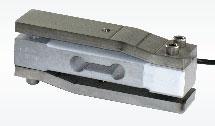

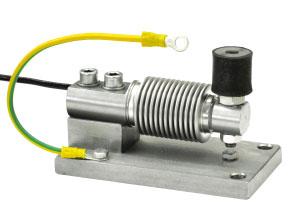

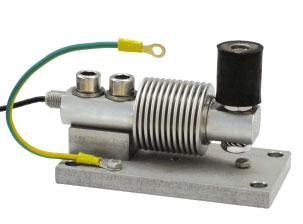

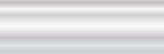

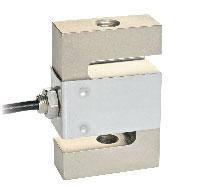

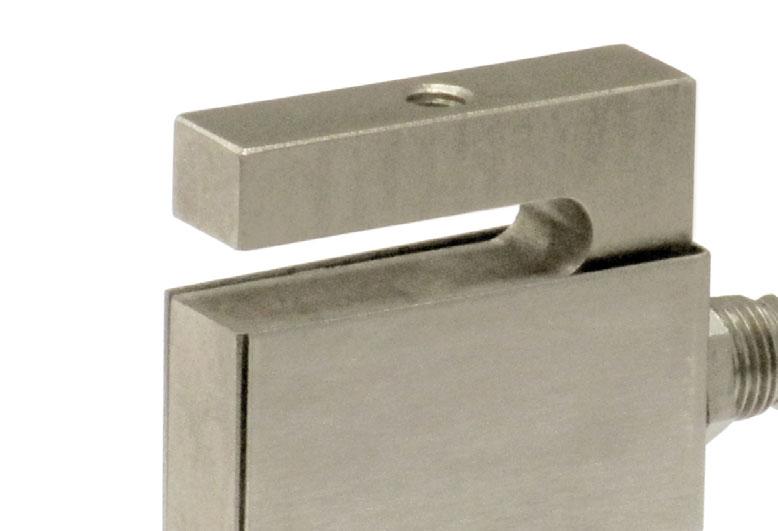

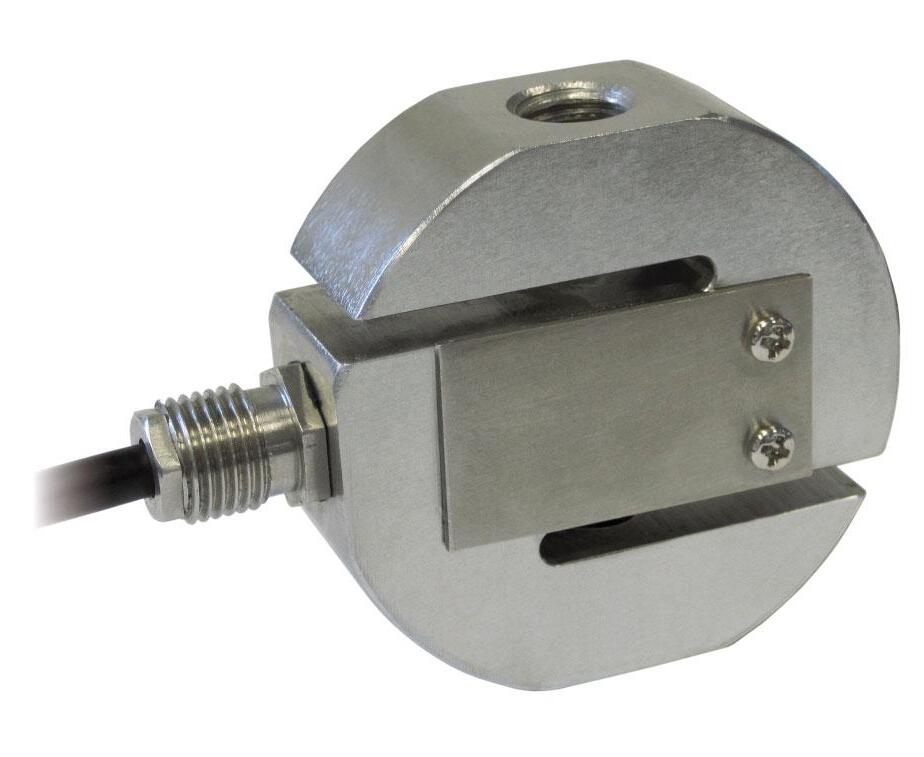

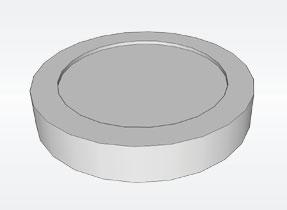

ManufacturedaccordingtoOIMLR60standards

Capacity from 5 kg to 50 kg

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

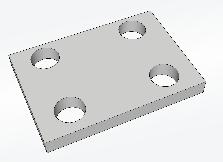

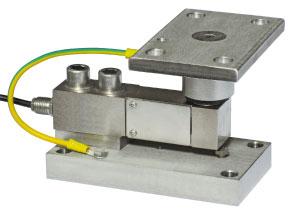

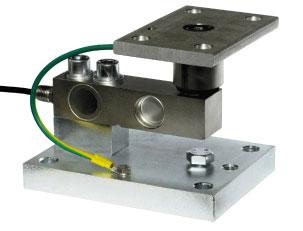

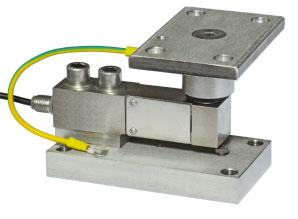

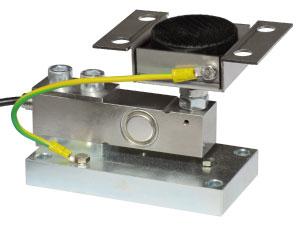

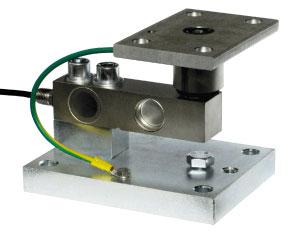

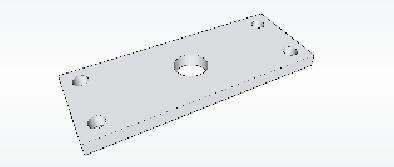

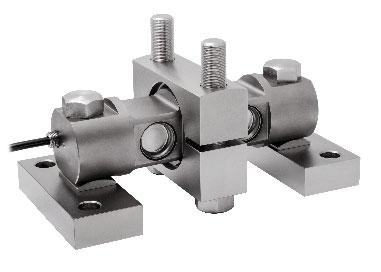

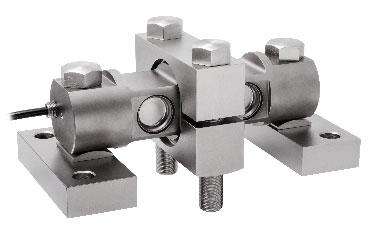

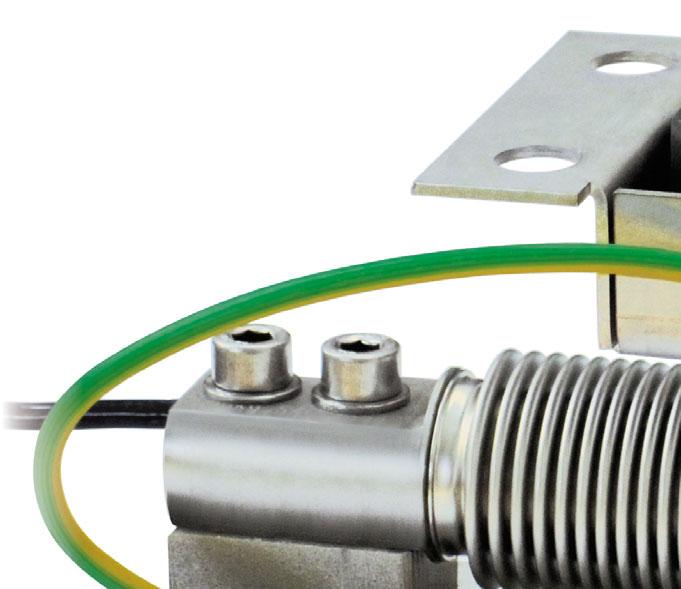

MOUNTING SURFACE MOUNTING SURFACE

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass Tighteningtorque

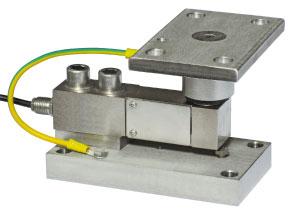

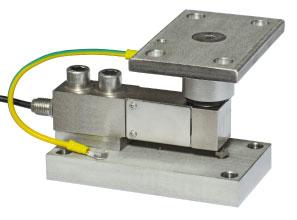

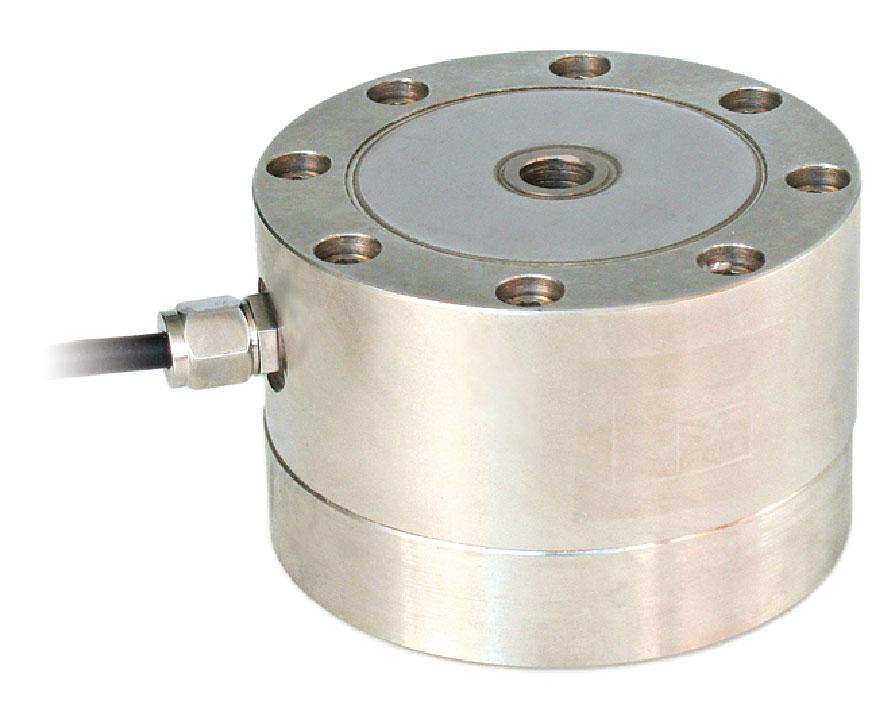

TECHNICAL FEATURES

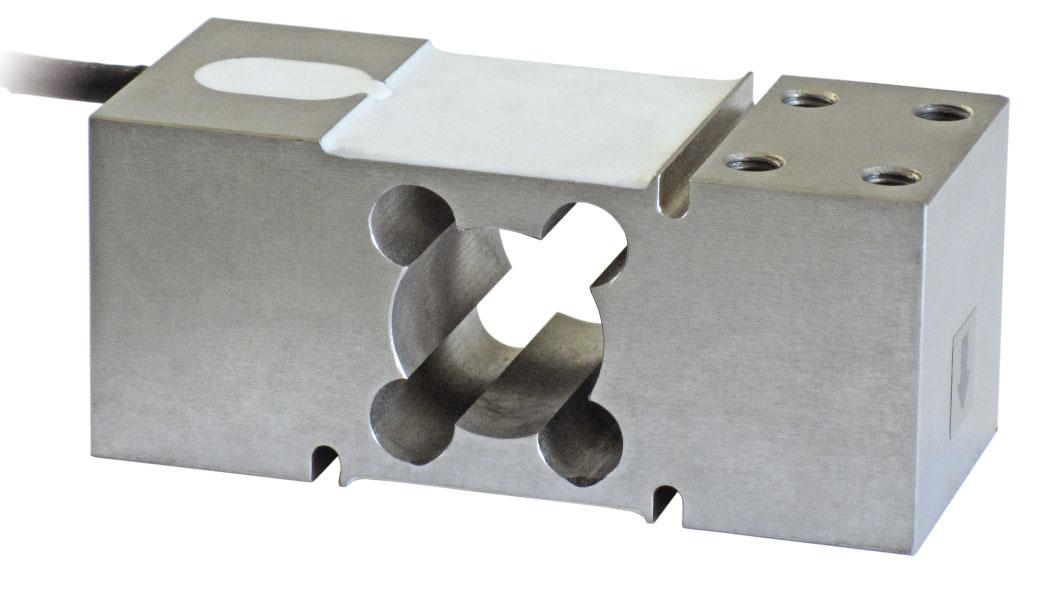

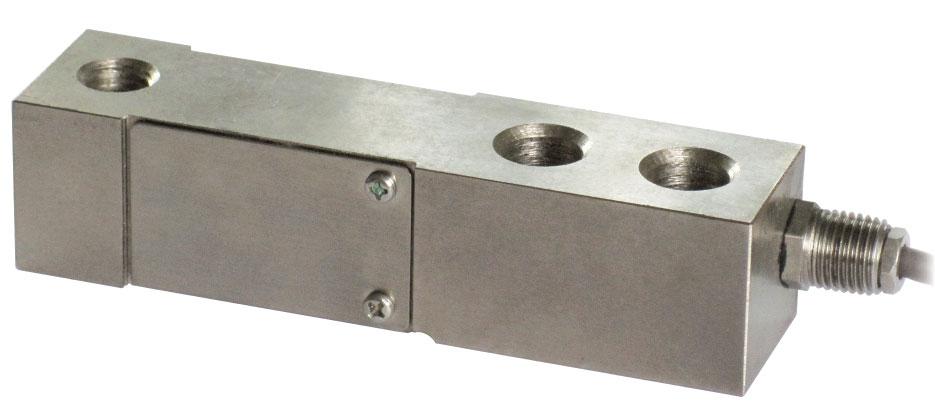

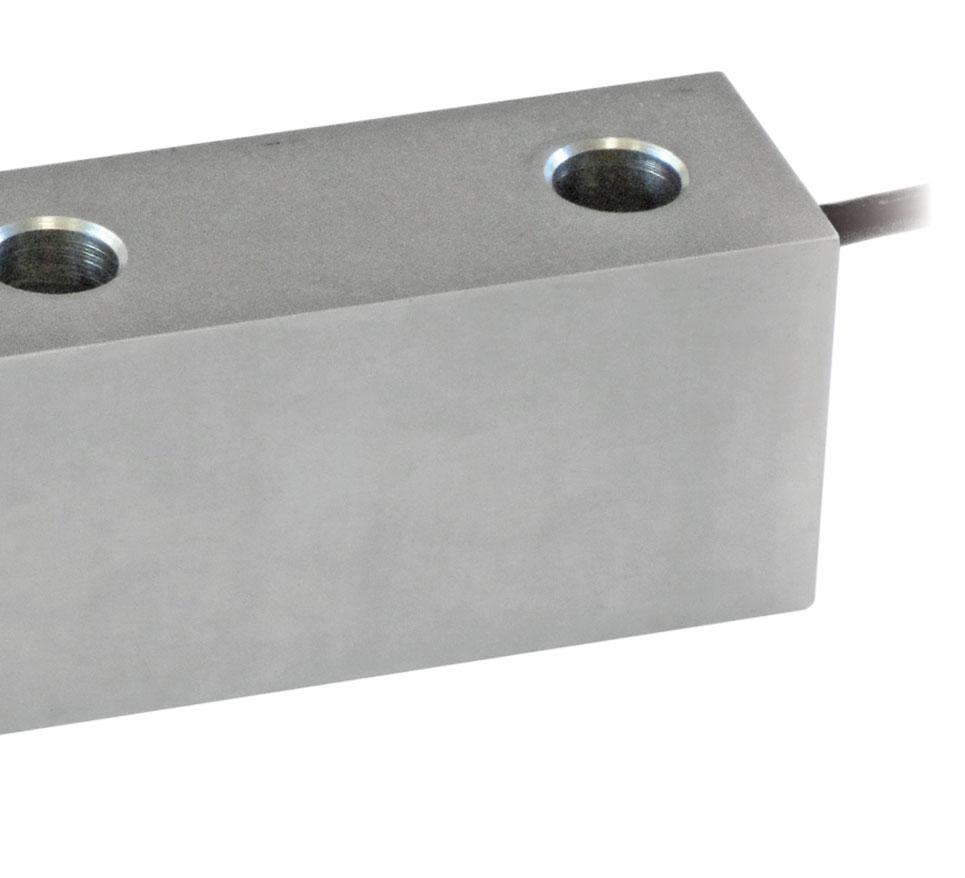

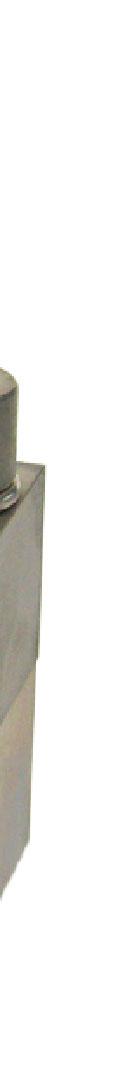

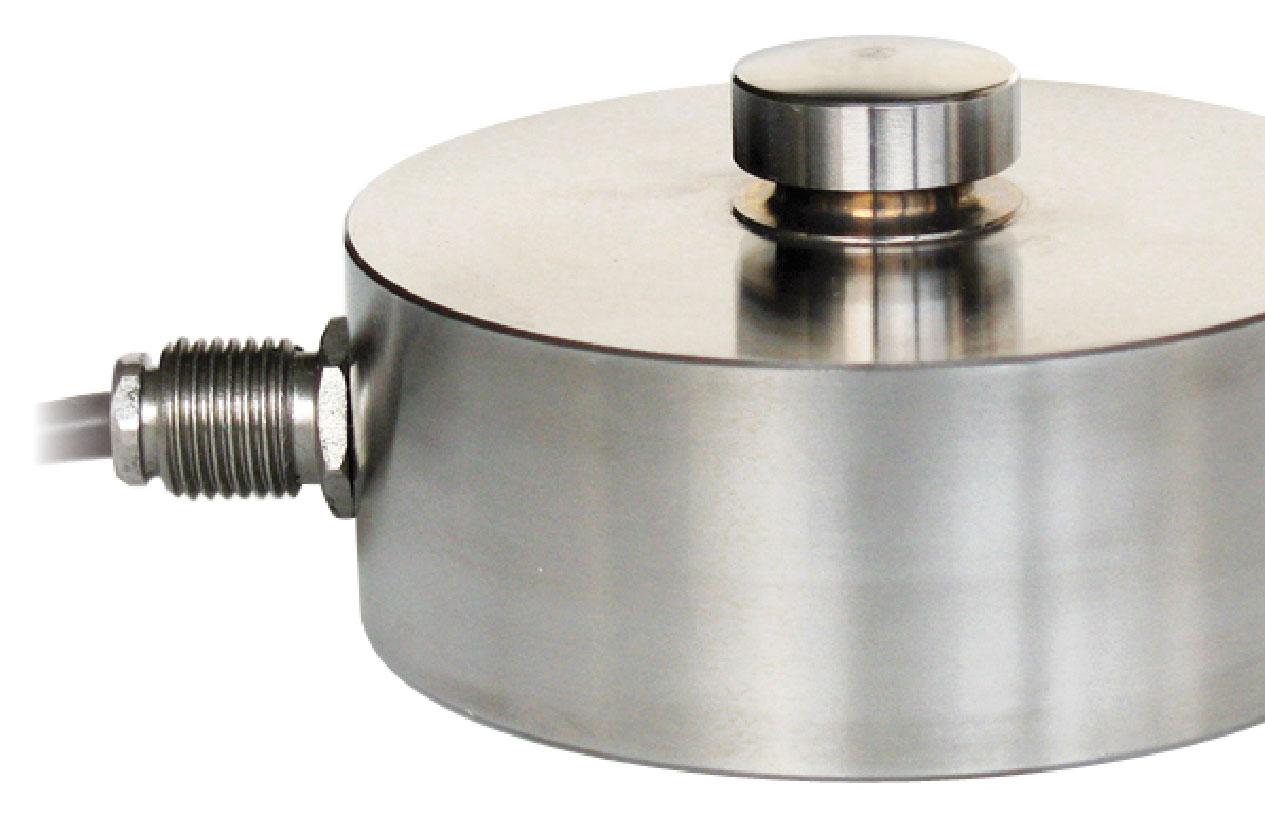

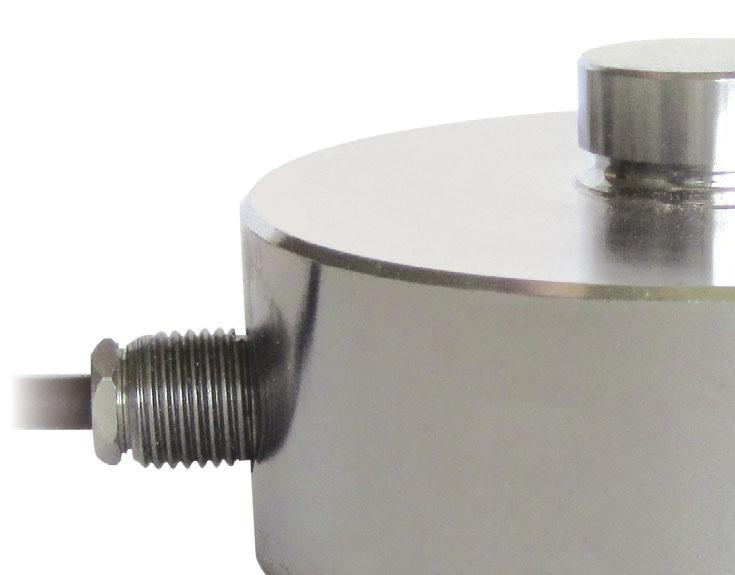

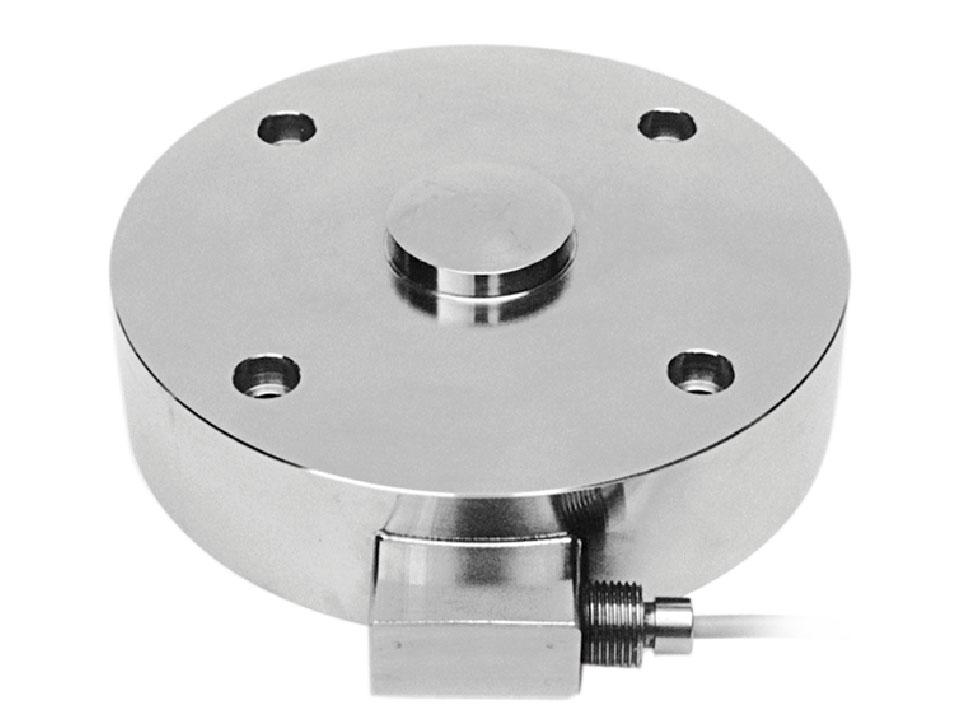

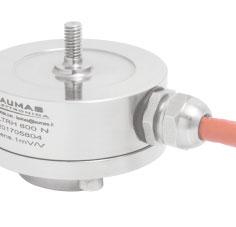

MaterialAISI420stainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

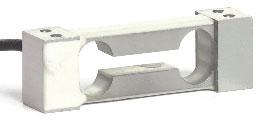

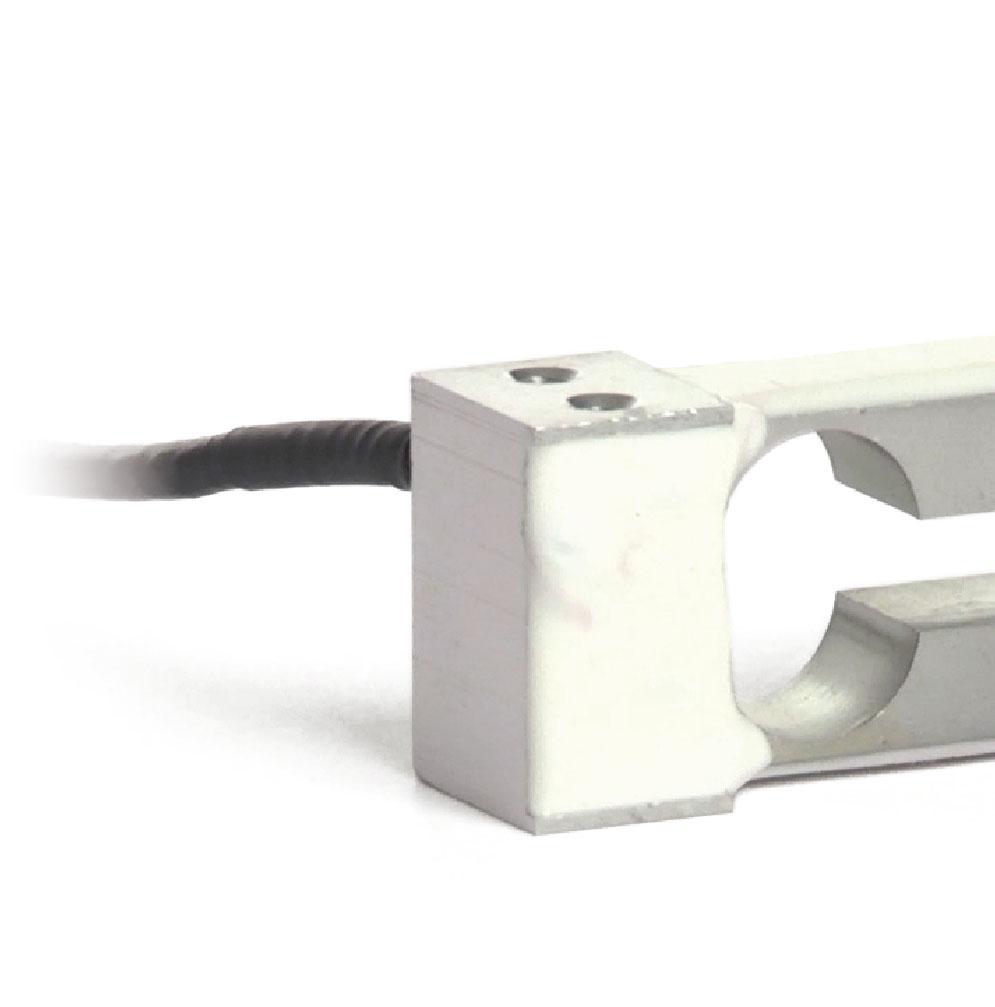

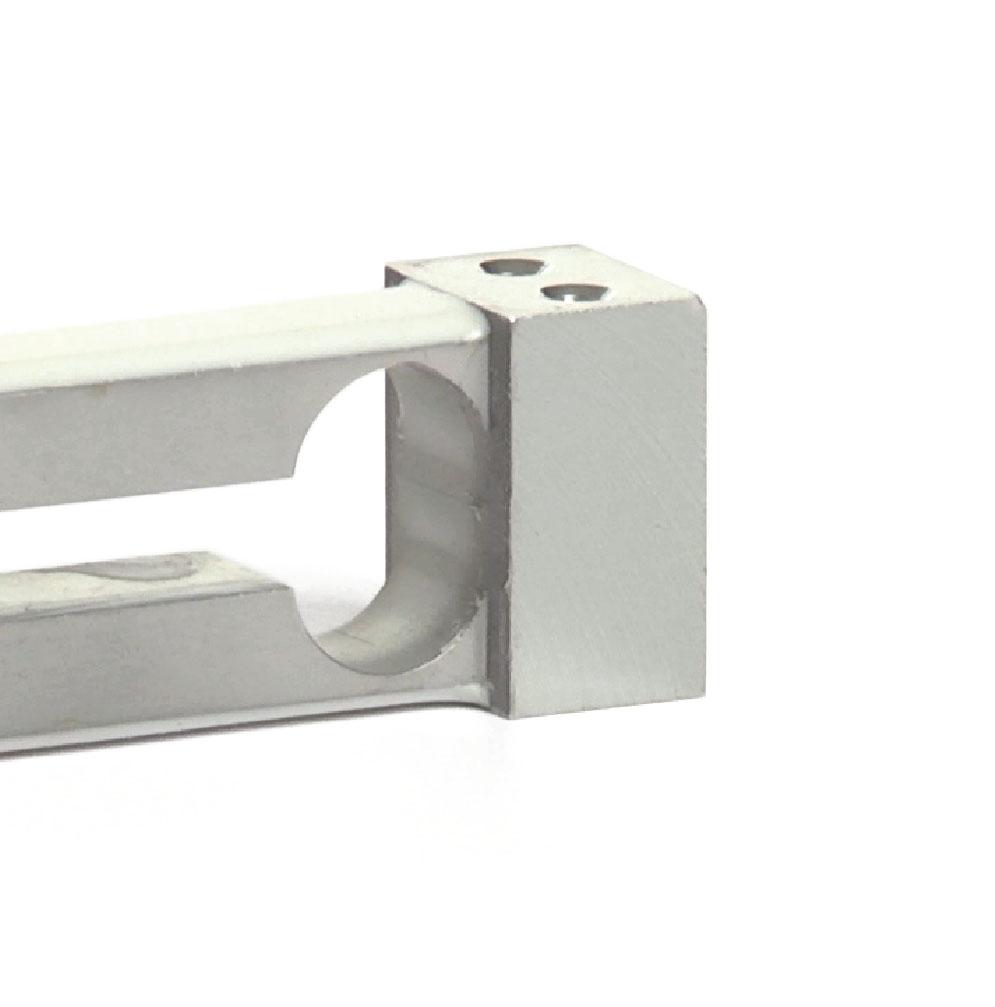

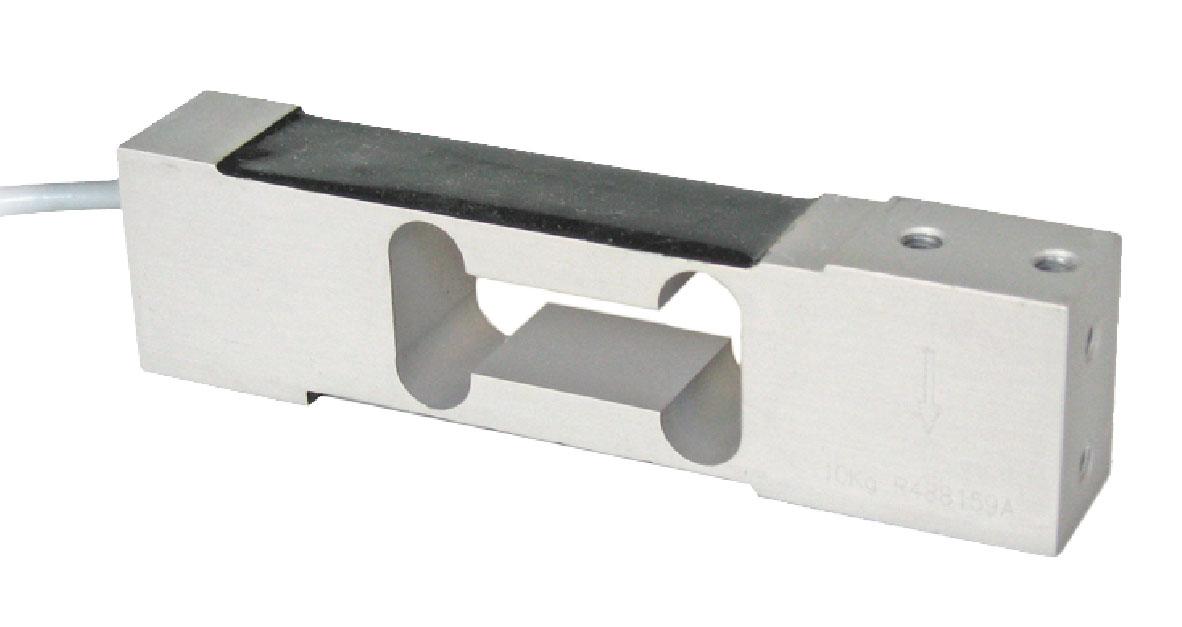

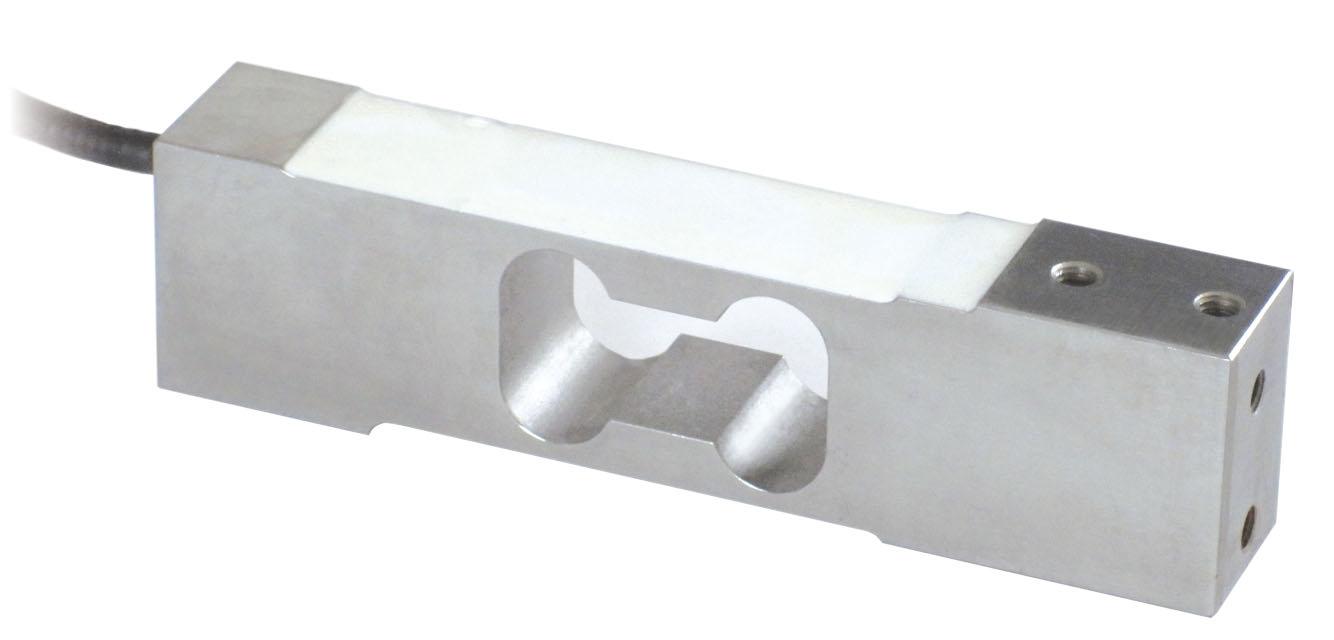

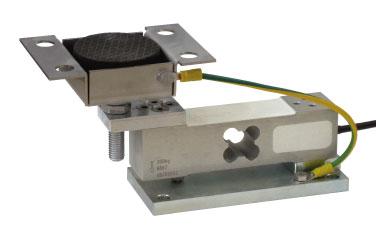

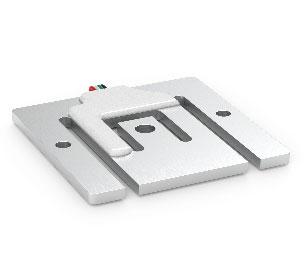

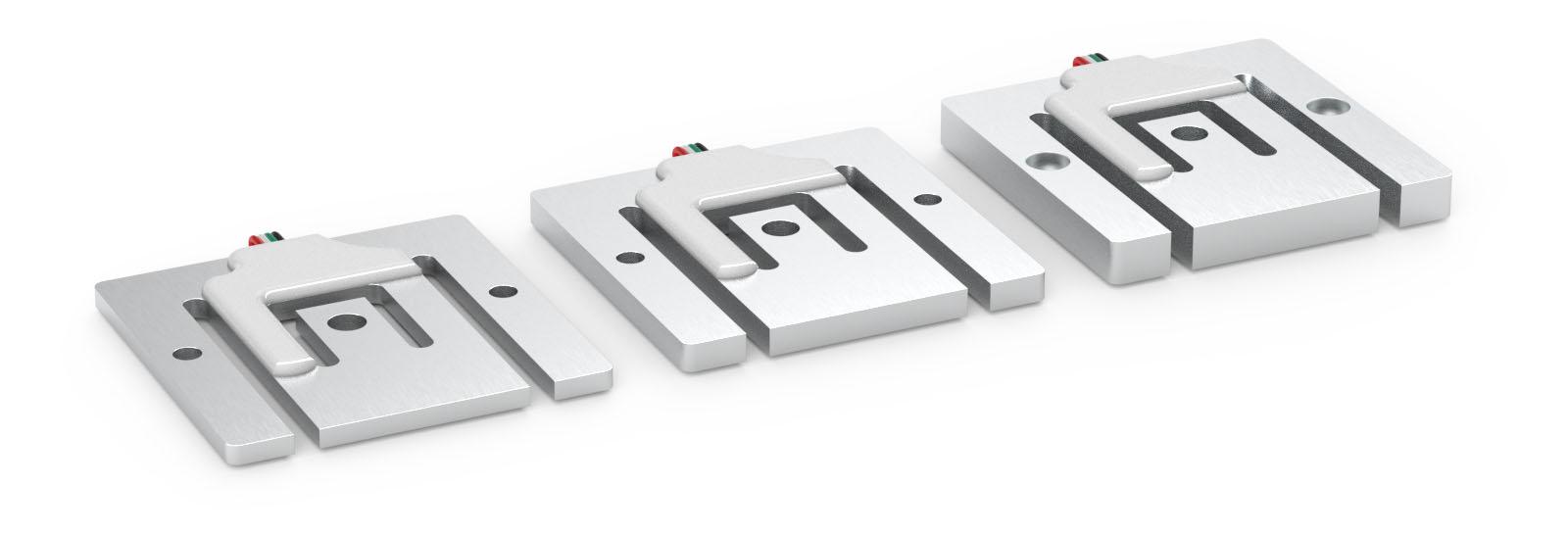

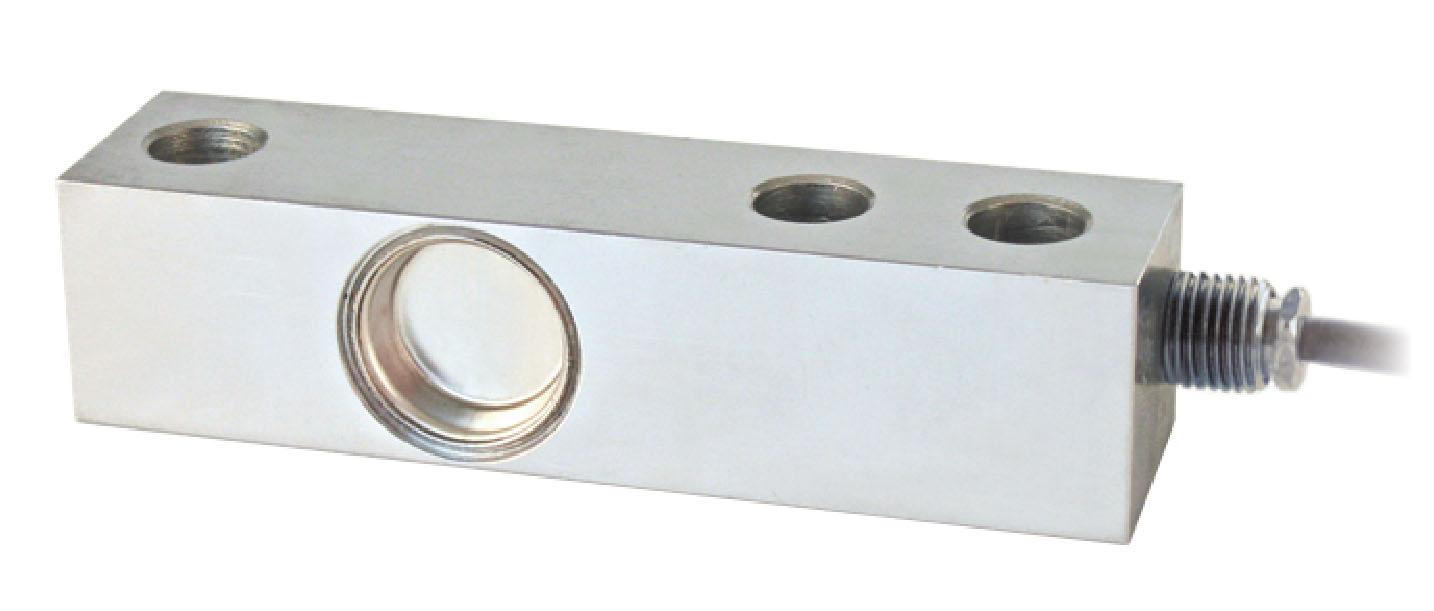

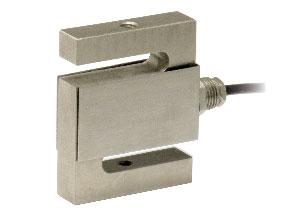

ManufacturedaccordingtoOIMLR60standards

Capacity from 0.25 kg to 1 kg

ALUMINUMALLOY COMBINEDERROR±0.03% IP65PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass

Tighteningtorque

TECHNICAL FEATURES

MaterialAluminumalloy

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS CablelengthSHIELD

OIMLR60C3

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

OIMLR60C4/C5

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

NTEP-ComplieswithUnitedStatesregulationsforlegalfortradeuse

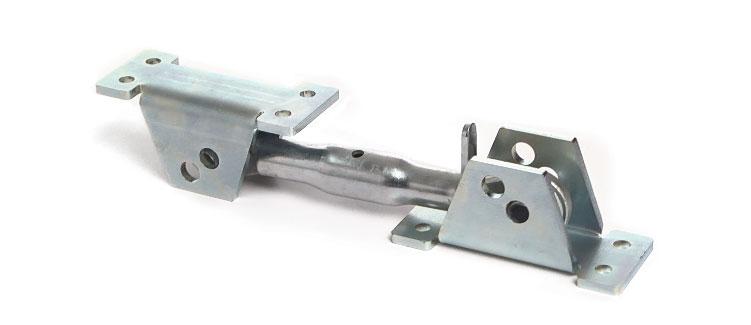

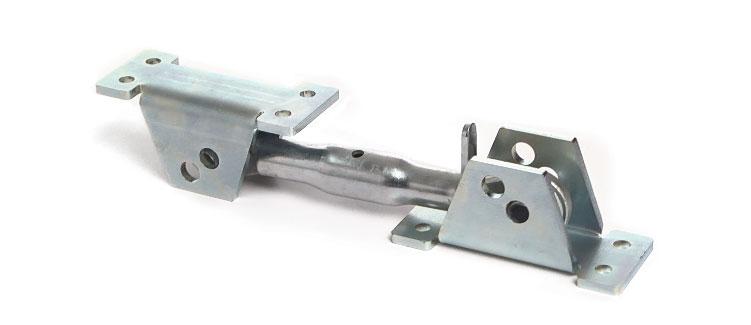

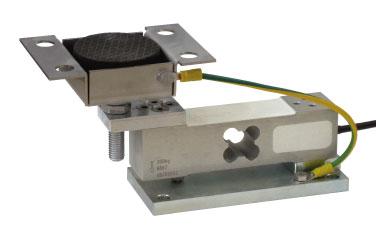

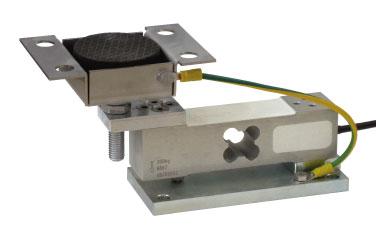

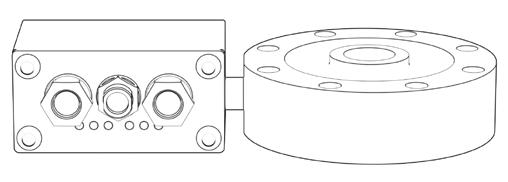

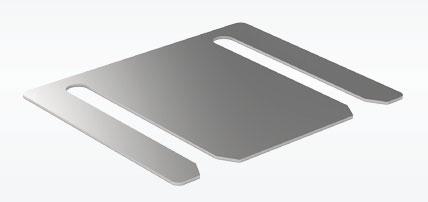

COMPLEMENTARY ACCESSORIES

DESCRIPTION

Pairofstainlesssteeltensionbrackets. Maximumstaticload:50kg.

TECHNICAL FEATURES

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable Screw

Screwclass Tighteningtorque

C3•3000C4•4000C5•5000 3-5-10-15-20-30-50kg

Emax/10000Emax/15000Emax/20000 ±0.02%±0.017%±0.014% IP65

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

2mV/V±10%409±6 0.001%°C350±3 0.001%°C±2% -10°C/+40°C5000M -35°C/+65°C150%

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

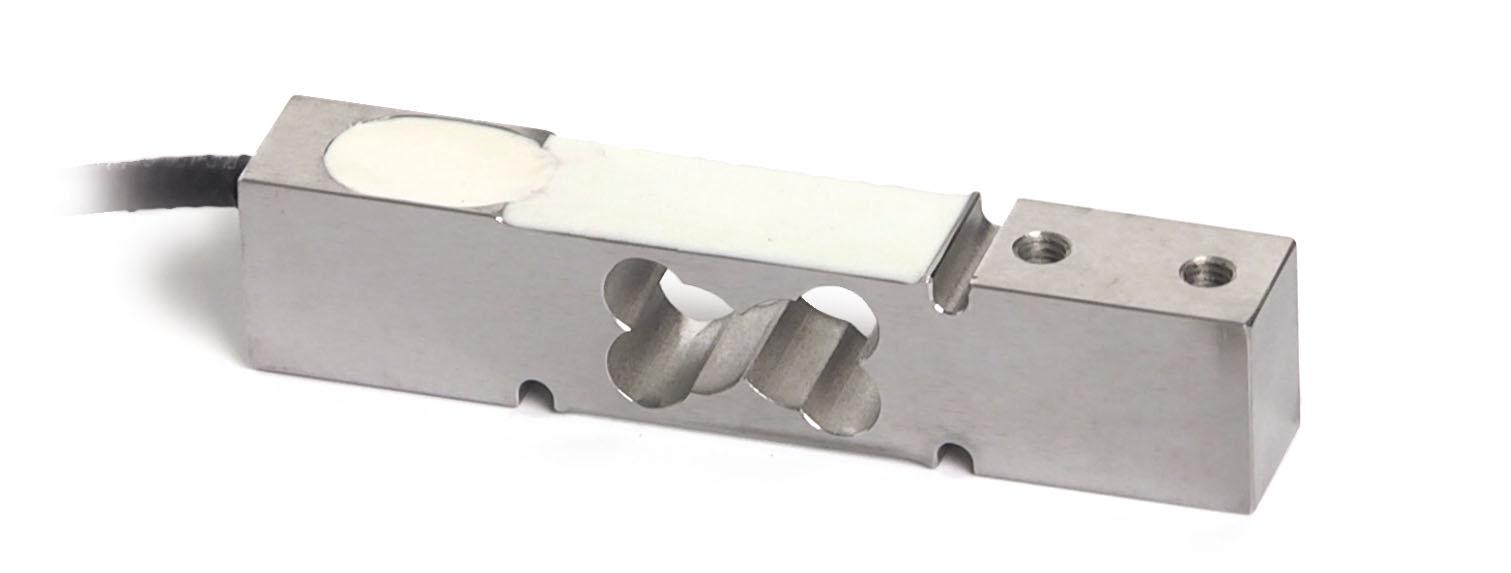

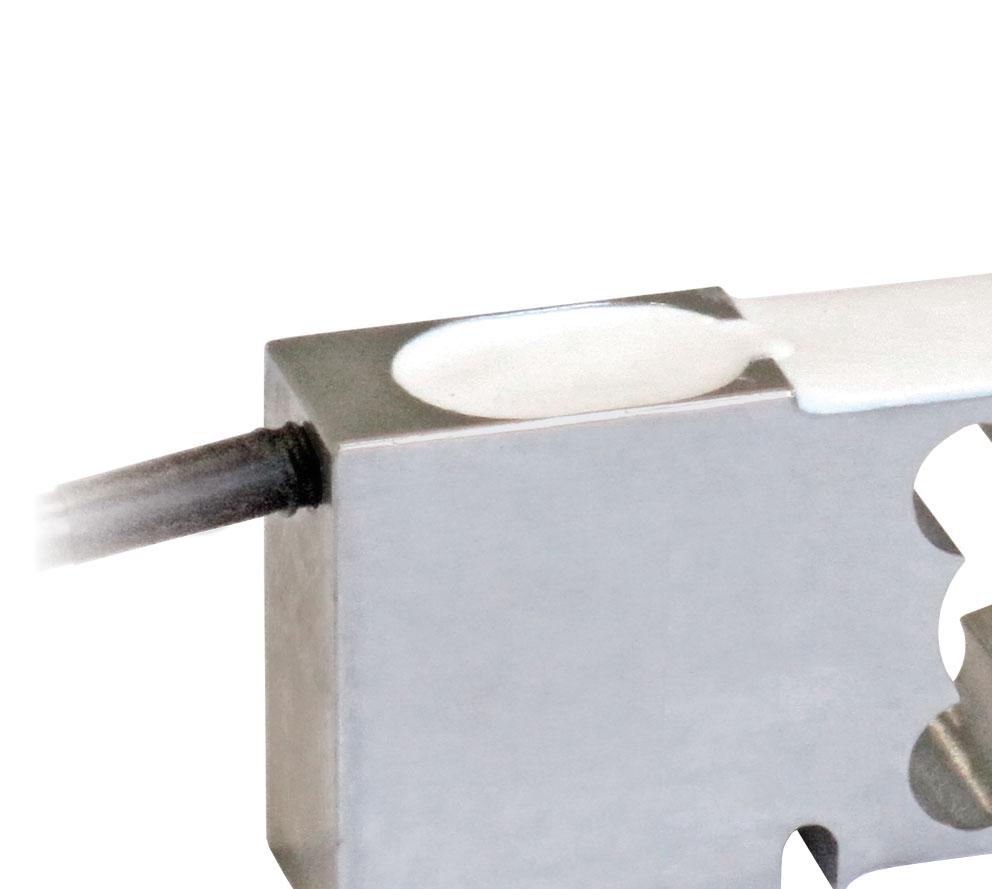

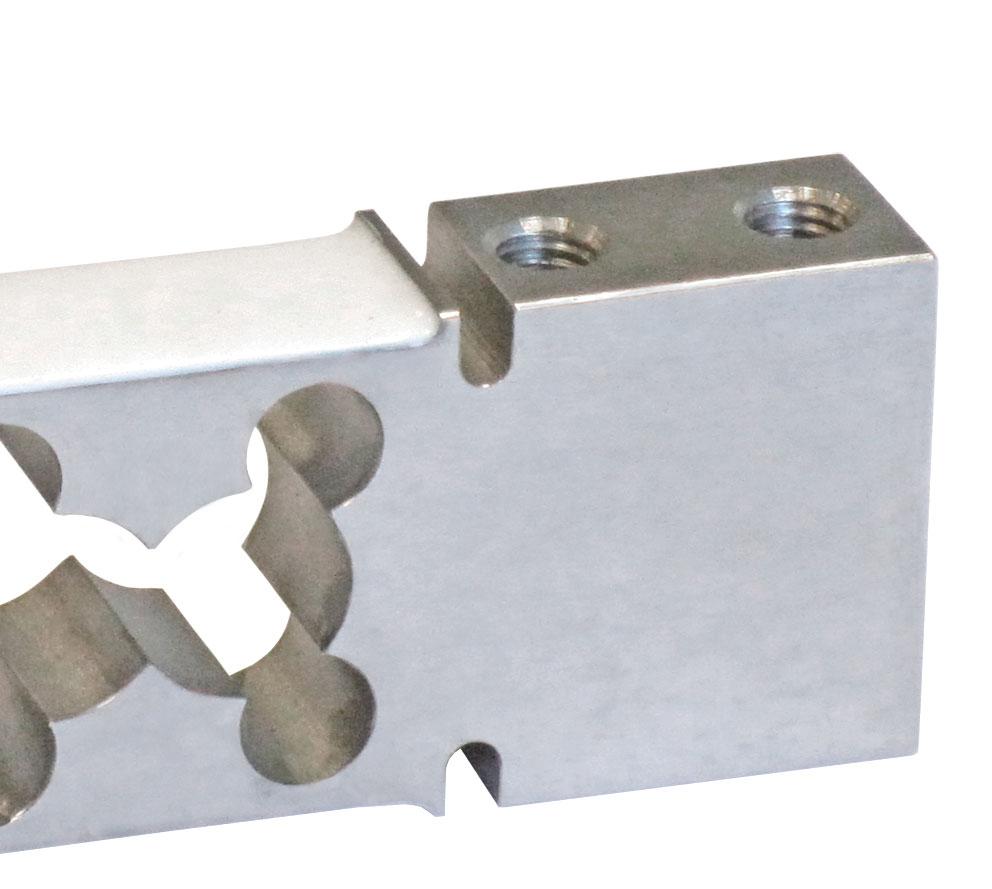

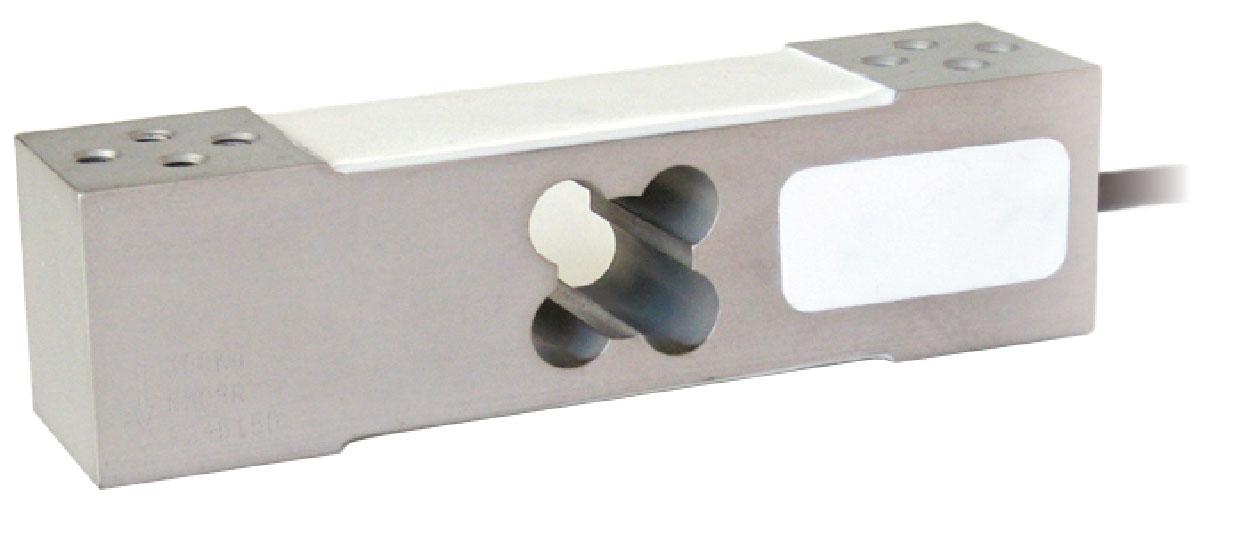

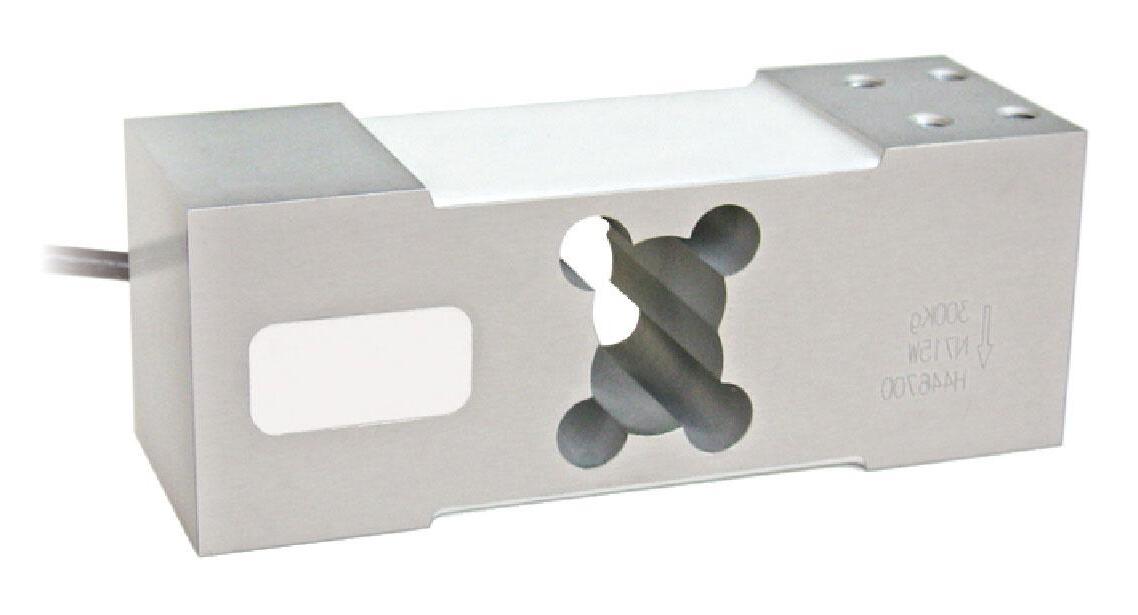

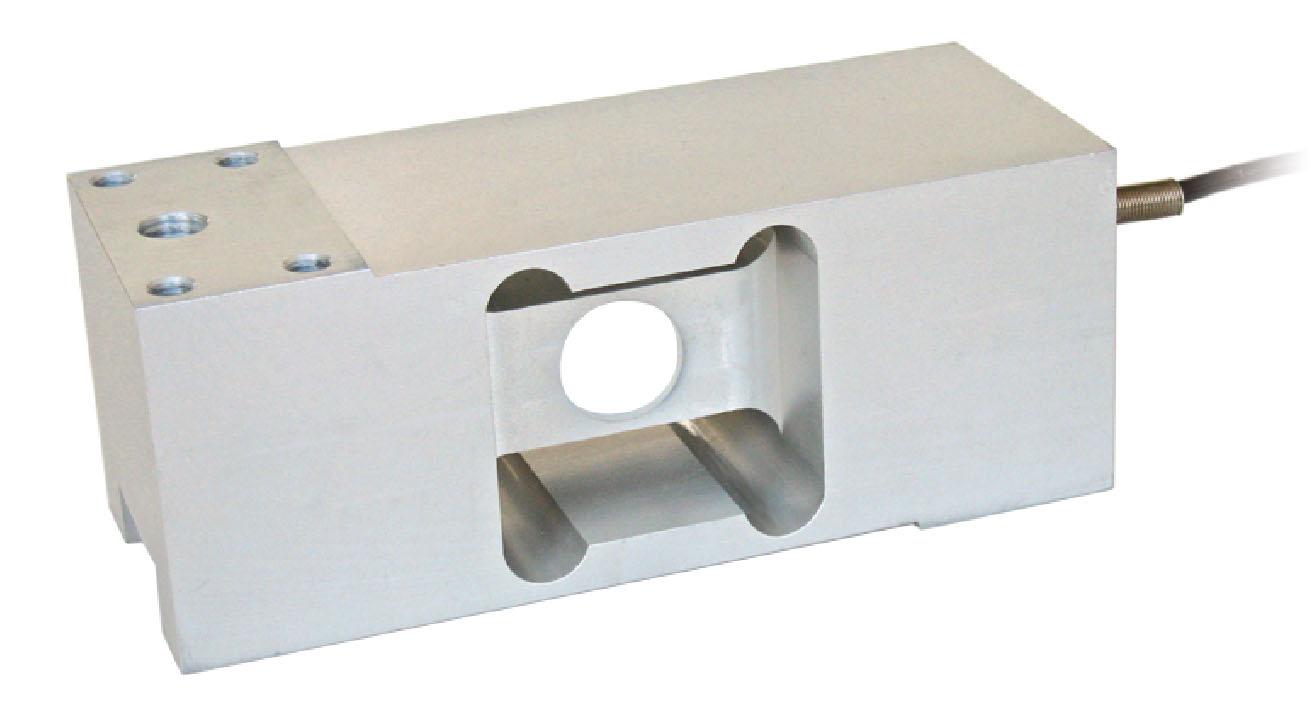

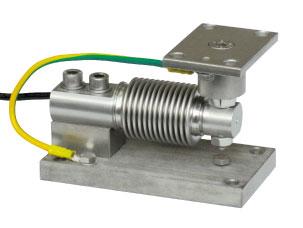

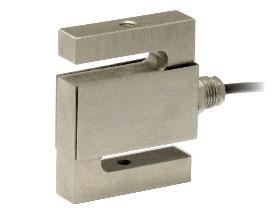

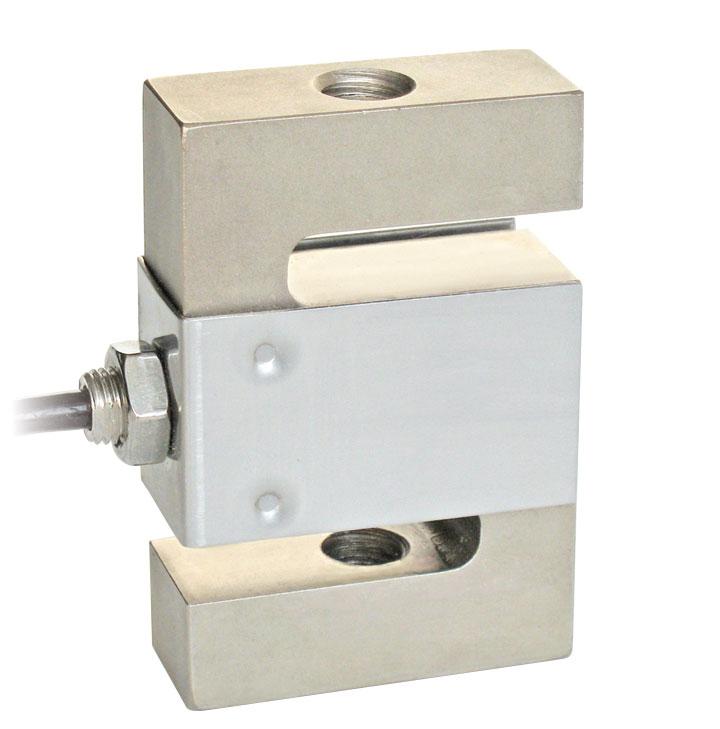

ManufacturedaccordingtoOIMLR60standards

Capacity from 6 kg to 50 kg

AISI420STAINLESSSTEEL COMBINEDERROR±0.02% IP67PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

COMPLEMENTARY ACCESSORIES

DESCRIPTIONCODE Stainlesssteeldrawnblock.

Fortheloadcellfixingscrews,providethetightening

torqueindicatedinthetable

Screw

Screwclass

Tighteningtorque

TECHNICAL FEATURES

MaterialAISI420stainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

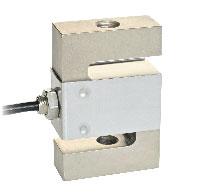

ManufacturedaccordingtoOIMLR60standards

ALUMINUMALLOY COMBINEDERROR±0.02% IP65PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

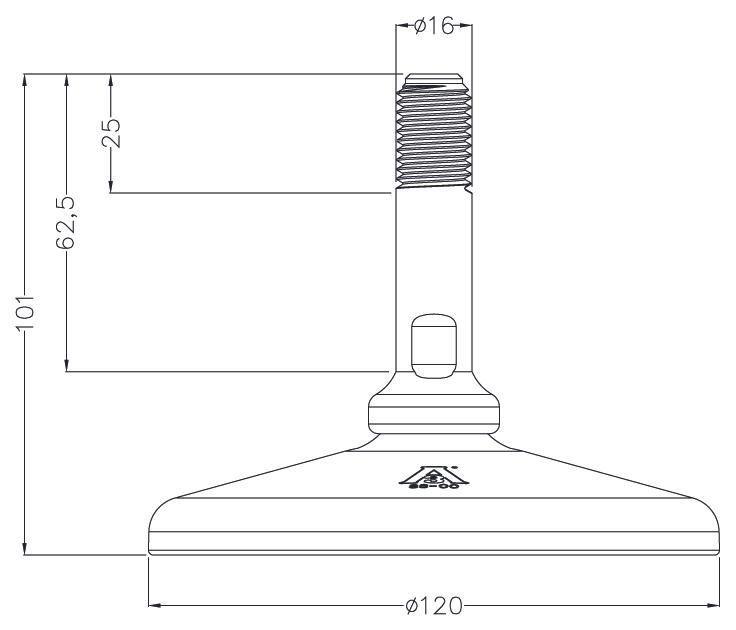

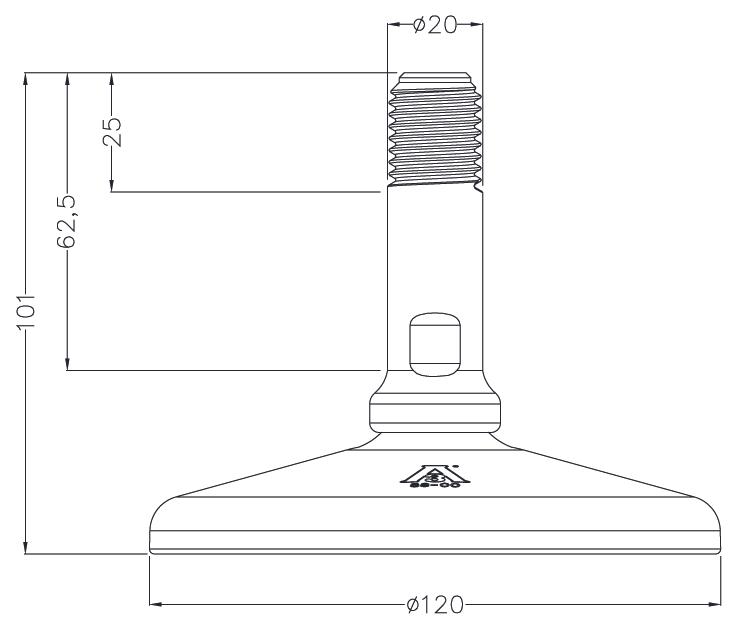

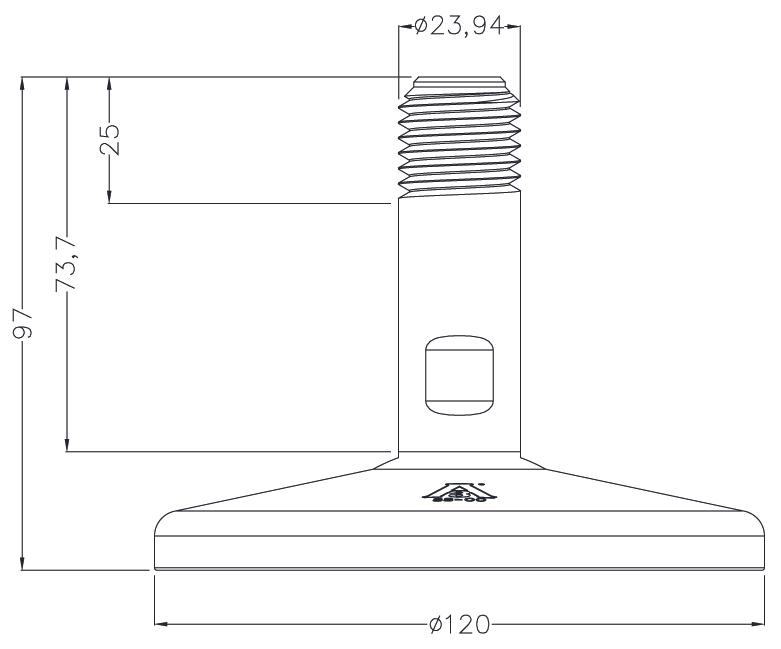

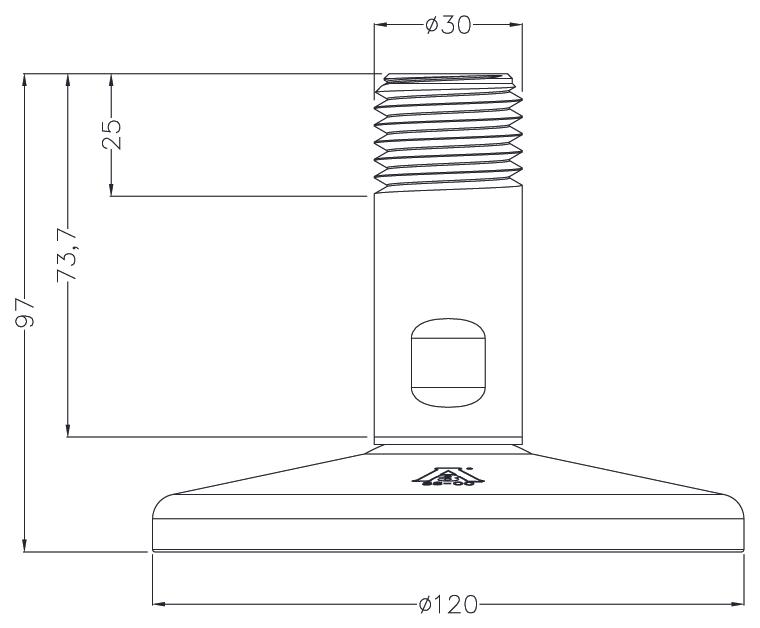

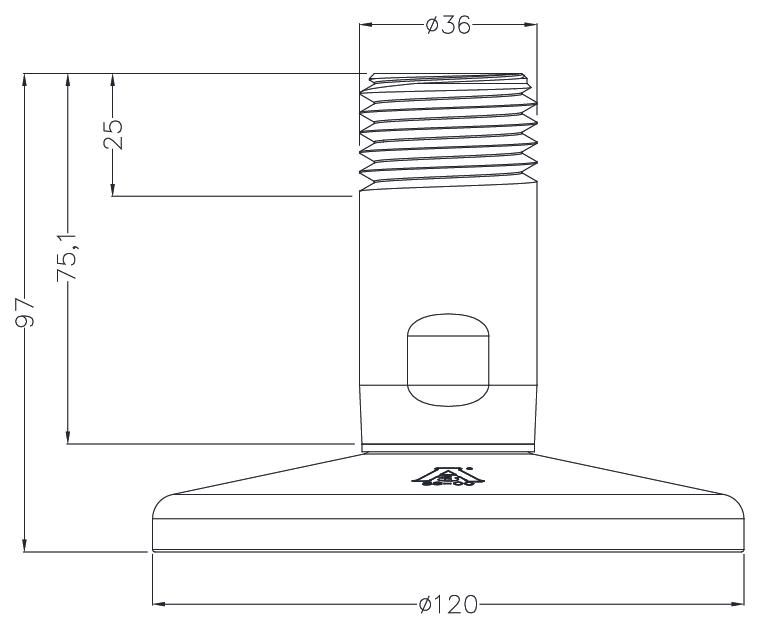

DIMENSIONS (mm)

Fortheloadcellfixingscrews,providethetighteningtorqueindicatedinthetable

Screw

Screwclass Tighteningtorque

TECHNICAL FEATURES

MaterialAluminumalloy

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

Capacity from 10 kg to 100 kg

ALUMINUMALLOY COMBINEDERROR±0.02%(0.017%C4) IP65PROTECTIONRATING

CERTIFICATIONS

OIMLR60C3

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

Canbeusedforsystemswithatleast 3supports

IECEx (zone 0-1-2-20-21-22)

OIMLR60C4

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

NTEP-ComplieswithUnitedStatesregulationsforlegalfortradeuse

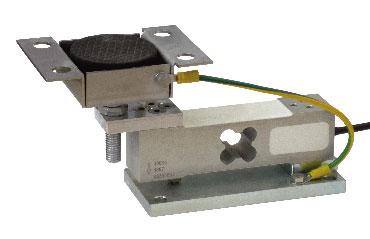

COMPLEMENTARY ACCESSORIES

DESCRIPTIONCODE Stainlesssteeldrawnblock.

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw Screwclass Tighteningtorque

TECHNICAL FEATURES

MaterialAluminumalloy

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

C3•3000C4•4000 10-15-20-30-50-100kg15-20-30-50kg Emax/12000Emax/20000 ±0.02%±0.017%

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

CablelengthSHIELD

Cablediameter+SIGNALGREEN Cores+EXCITATION +REF./SENSE RED BLUE -SIGNALWHITE -EXCITATION -REF./SENSE BLACK BROWN

Canbeusedforsystemswithatleast 3supports

ON REQUEST

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Declarationofconformity+IP69Kmarkingprotectionrating

Water protection in case of high-pressure or steam jet cleaning (test: pressurized water is sprayed from a distance of max 150 mm)

Water pressure: 100 bar; temperature: 80 °C; test duration: 250 seconds (reference standard: DIN 40050-9)

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

FMHazLoc-ComplieswiththeUnitedStatesandCanadaregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

NTEP-ComplieswithUnitedStatesregulationsforlegalfortradeuse

DIMENSIONS (mm)

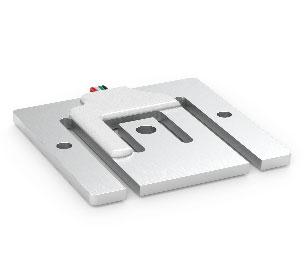

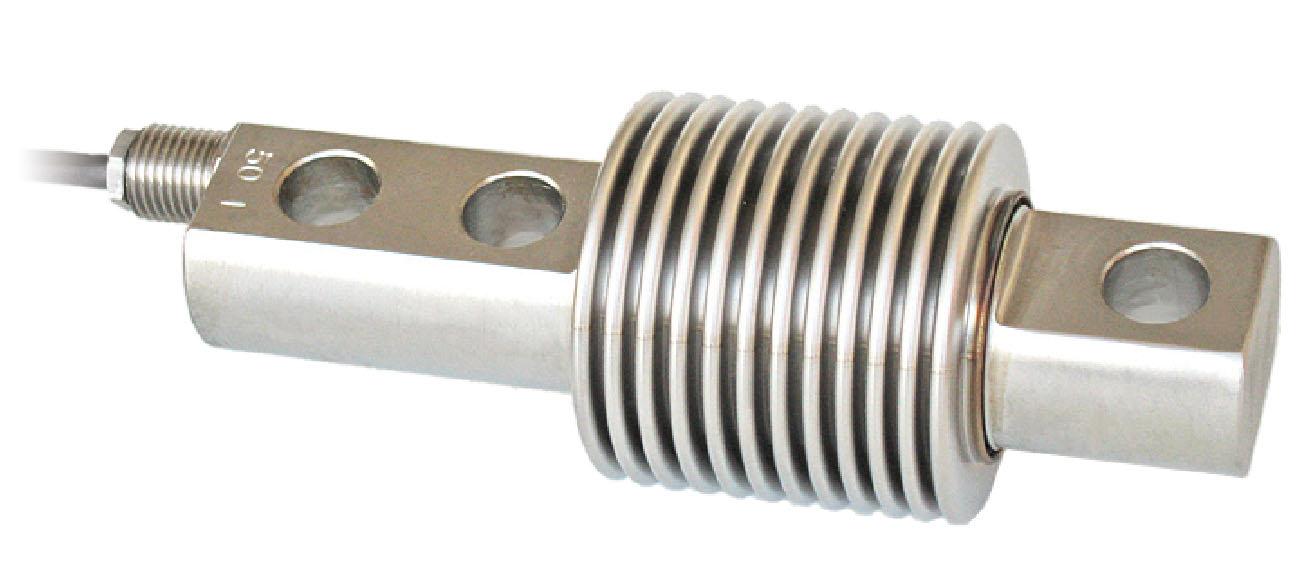

PLATFORM

Fortheloadcellfixingscrews,providethetighteningtorqueindicatedinthetable

Screw

Screwclass Tighteningtorque

TECHNICAL FEATURES

Material17-4PHStainlesssteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror Protectionrating

C3•3000C4•4000 10-20-50-100-200-300-500kg10-20-50kg Emax/10000Emax/40000 ±0.02%±0.017%

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN Cores+EXCITATION +REF./SENSE RED BLUE -SIGNALWHITE -EXCITATION -REF./SENSE BLACK YELLOW whereprovided

COMPLEMENTARY ACCESSORIES

DESCRIPTIONCODE

Stainlesssteeldrawnblock forcapacitiesupto50kg.

Stainlesssteeldrawnblock forcapacitiesfrom100to500kg.

ManufacturedaccordingtoOIMLR60standards

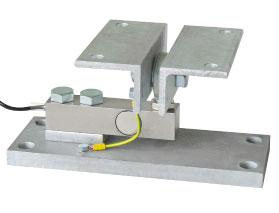

Capacity from 10 kg to 200 kg

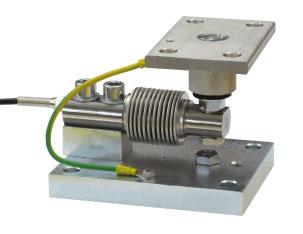

MOUNTINGKIT CAPACITY

Canbeusedforsystemswithatleast 3supports

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

COMPLEMENTARY ACCESSORIES

DESCRIPTIONCODE

Stainlesssteeldrawnblock.

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass Tighteningtorque

TECHNICAL FEATURES

MaterialAISI420stainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

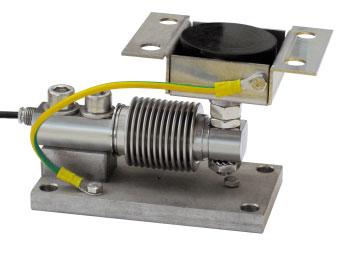

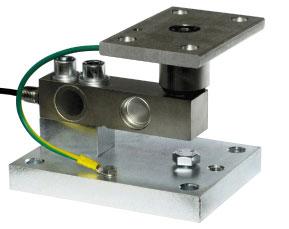

ManufacturedaccordingtoOIMLR60standards

Capacity from 30 kg to 150 kg

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass Tighteningtorque

TECHNICAL FEATURES

MaterialAISI420stainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

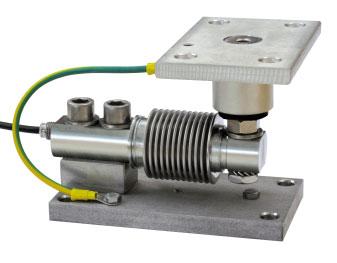

MOUNTINGKIT

Canbeusedforsystemswithatleast 3supports

ON REQUEST

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

NTEP-ComplieswithUnitedStatesregulationsforlegalfortradeuse

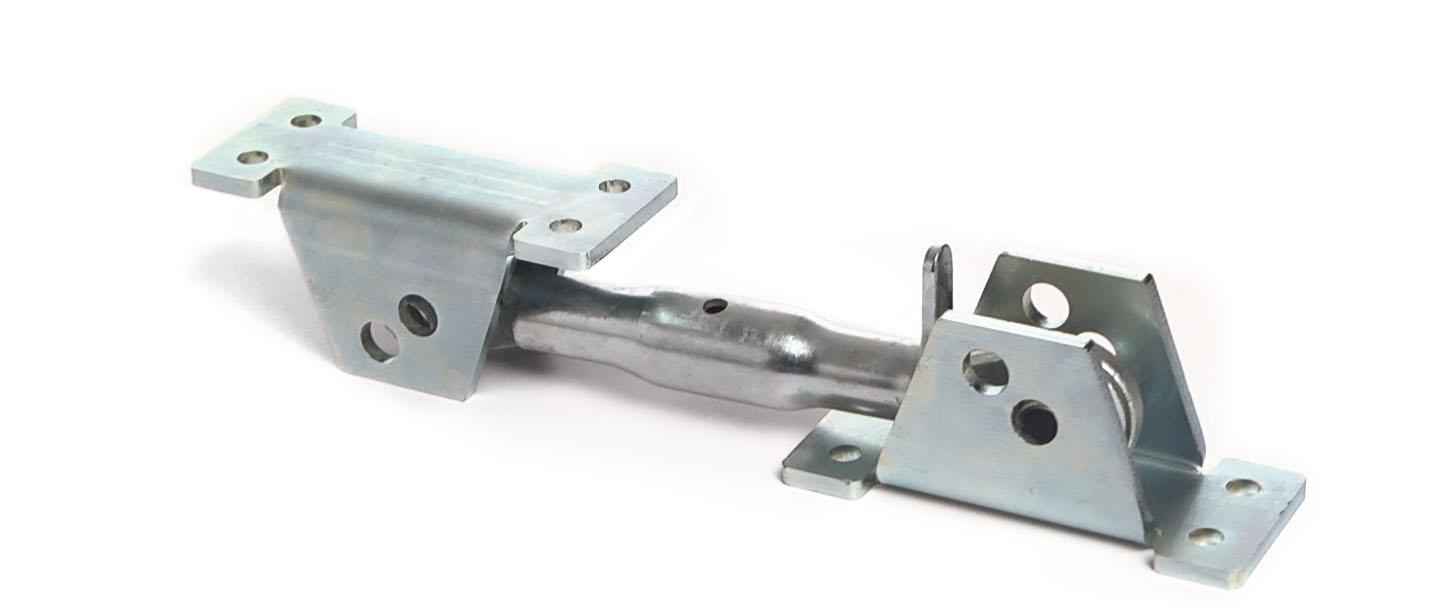

COMPLEMENTARY ACCESSORIES

DESCRIPTIONCODE

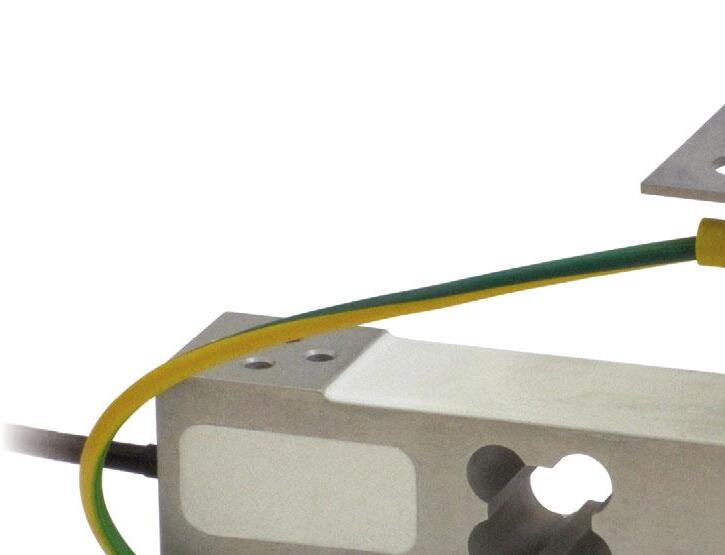

Stainlesssteelandrubberwaterproofkit.

Galvanizedsteeldrawnblock.

DIMENSIONS (mm)

TECHNICAL FEATURES ELECTRICAL CONNECTIONS

OIMLR60Accuracyclass•Verificationintervals Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass

Tighteningtorque

C3•3000C4•4000C5•5000 60-100-150-200-300kg300kg

Emax/10000Emax/15000Emax/20000 ±0.02%±0.017%±0.014%

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

2mV/V±10%406±6 0.003%°C350±3 0.002%°C±2% -10°C/+40°C5000M -35°C/+65°C150% 0.025%300% 18V0.5mm

ALUMINUMALLOY

COMBINEDERROR±0.02%(0.017%C4) IP65PROTECTIONRATING

CERTIFICATIONS

OIMLR60C3

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

OIMLR60C4

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

COMPLEMENTARY ACCESSORIES

DESCRIPTIONCODE

Stainlesssteelandrubberwaterproofkit (Ø107x245mmcableglandincluded)

Stainlesssteeldrawnblock. ON REQUEST

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass

Tighteningtorque

TECHNICAL FEATURES

MaterialAluminumalloy

OIMLR60Accuracyclass•Verificationintervals Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

RatedoutputInputresistance

C3•3000C4•4000 50-100-150-200-300-500kg150-200-300-500kg Emax/12000Emax/15000 ±0.02%±0.017% IP65 2mV/V±10%409±6

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale) Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ManufacturedaccordingtoOIMLR60standards

Capacity from 75 kg to 500 kg

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

COMPLEMENTARY ACCESSORIES

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass

Tighteningtorque

TECHNICAL FEATURES

MaterialAISI420stainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ManufacturedaccordingtoOIMLR60standards

Capacity from 500 kg to 1000 kg

COMBINEDERROR±0.05% IP65PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass Tighteningtorque

TECHNICAL FEATURES

MaterialAluminumalloy

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

Capacity from 1000 kg to 2000 kg

ALUMINUMALLOY COMBINEDERROR±0.02% IP65PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

PLATFORM (mm)

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass

Tighteningtorque

TECHNICAL FEATURES

MaterialAluminumalloy

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

ManufacturedaccordingtoOIMLR60standards

Capacity from 22 kg to 110 kg

ANODIZEDALUMINUMALLOY COMBINEDERROR±0.023% IP65PROTECTIONRATING

CERTIFICATIONS

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

DIMENSIONS (mm)

TECHNICAL FEATURES

MaterialAnodizedaluminumalloy

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

ManufacturedaccordingtoOIMLR60standards

Capacity from 5 kg to 10 kg

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.02% IP68PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

MOUNTINGKITS

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

COMPLEMENTARY ACCESSORIES

DESCRIPTIONCODE

Pairoftensionstainlesssteelbrackets. Maximumstaticload:100kg

DIMENSIONS (mm)

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw Screwclass Tighteningtorque

TECHNICAL FEATURES

Material17-4PHstainlesssteel

Nominalload(Emax)

Combinederror Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS CablelengthSHIELD Cablediameter+SIGNALGREEN Cores+EXCITATIONRED

Capacity from 20 kg to 500 kg

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.02%(0.017%C4)

IP68PROTECTIONRATING

CERTIFICATIONS

OIMLR60C3

ON REQUEST

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

OIMLR60C4

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

FMHazLoc-ComplieswiththeUnitedStatesandCanadaregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

NTEP-ComplieswithUnitedStatesregulationsforlegalfortradeuse

DESCRIPTIONCODE

Pairoftensionstainlesssteelbrackets. Maximumstaticload:100kg

DIMENSIONS (mm) TENSIONSTAINLESSSTEEL BRACKETS

MOUNTING SURFACE

Fortheloadcellfixingscrews,providethetighteningtorqueindicatedinthetable

Screw

Screwclass Tighteningtorque

TECHNICAL FEATURES

Material17-4PHstainlesssteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

C3•3000C4•4000 20-50-100-200-350-500kg Emax/10000Emax/15000 ±0.02%±0.017%

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

Calibratedcurrentoutput

ELECTRICAL CONNECTIONS

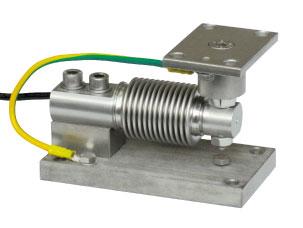

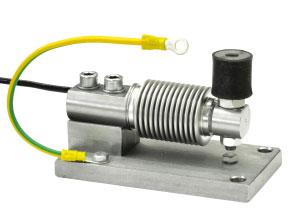

ManufacturedaccordingtoOIMLR60standards

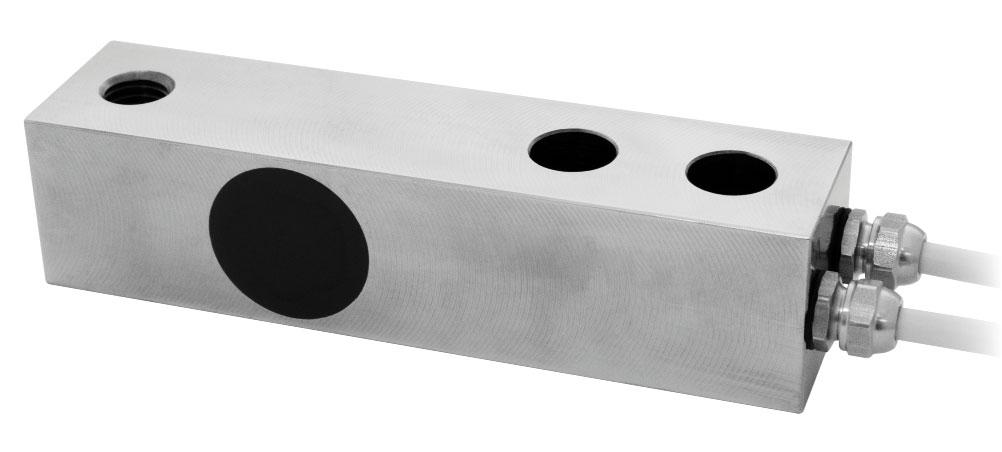

BENDING BEAM: capacity from 30 kg to 500 kg

SHEAR BEAM: capacity from 750 kg to 1500 kg

AISI420STAINLESSSTEEL COMBINEDERROR±0.02% IP68PROTECTIONRATING

MOUNTINGKITS

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

COMPLEMENTARY ACCESSORIES DESCRIPTIONCODE

DIMENSIONS (mm)

Pairoftensionstainlesssteelbrackets. Maximumstaticload:300kg

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass Tighteningtorque

TECHNICAL FEATURES

MaterialAISI420stainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload ELECTRICAL CONNECTIONS

Capacity from 50 kg to 300 kg

AISI420STAINLESSSTEEL COMBINEDERROR±0.017% IP68PROTECTIONRATING

MOUNTINGKITS

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

COMPLEMENTARY ACCESSORIES

DESCRIPTIONCODE

Pairoftensionstainlesssteelbrackets. Maximumstaticload:300kg

DIMENSIONS (mm)

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass

Tighteningtorque

TECHNICAL FEATURES

MaterialAISI420stainlesssteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

C3•3000

50-75-150-300kg

Emax/10000 ±0.017%

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN Cores+EXCITATIONRED -SIGNALWHITE -EXCITATIONBLACK

BENDING BEAM: capacity from 75 kg to 300 kg

SHEAR BEAM: capacity from 500 kg to 10000 kg

AISI420STAINLESSSTEEL COMBINEDERROR±0.02% IP67-IP68PROTECTIONRATING

CERTIFICATIONS

OIMLR60C3

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Declarationofconformity+IP69Kmarkingprotectionrating

Water protection in case of high-pressure or steam jet cleaning (test: pressurized water is sprayed from a distance of max 150 mm)

Water pressure: 100 bar; temperature: 80 °C; test duration: 250 seconds (reference standard: DIN 40050-9)

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforlegalfortradeuse

DIMENSIONS (mm)

Fortheloadcellfixingscrews,providethetighteningtorqueindicatedinthetable Screw

Screwclass Tighteningtorque

MaterialAISI420stainlesssteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

Inputresistance

Outputresistance

C3•300075-150-300-500-750 1000-1500-2000kg3000-5000-10000kg Emax/15000-

±0.02%

IP67(75-300kg),IP68(500-10000kg)

385±10400±15

350±3350±5

RatedoutputMaxsupplyvoltagewithoutdamage

TemperatureeffectonzeroZerobalance

TemperatureeffectonspanInsulationresistance

CompensatedtemperaturerangeSafeoverload(%offullscale)

OperatingtemperaturerangeUltimateoverload(%offullscale)

Creepatnominalloadin30minutesDeflectionatnominalload

2mV/V±0.4%15V 0.002%°C±2% 0.0012%°C5000M -10°C/+40°C150% -20°C/+70°C200% 0.03%0.4mm

ELECTRICAL CONNECTIONS

CablelengthSHIELD

5m(75-5000kg);10m(10000kg) 5mm 6x0.25mm2

Cablediameter+SIGNALGREEN Cores+EXCITATION +REF./SENSE RED BLUE -SIGNALWHITE -EXCITATION -REF./SENSE BLACK YELLOW

BENDING BEAM: capacity from 75 kg to 300 kgSHEAR BEAM: capacity from 500 kg to 5000 kg

AISI4340NICKELPLATEDSTEEL COMBINEDERROR±0.02% IP67-IP68PROTECTIONRATING

TF500/2000series

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

DIMENSIONS (mm)

Fortheloadcellfixingscrews,providethetighteningtorqueindicatedinthetable Screw

Screwclass Tighteningtorque

TECHNICAL FEATURES

MaterialAISI4340nickelplatedsteel

OIMLR60Accuracyclass•Verificationintervals Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

75-150-300-500kg1000-2000-3000-5000kg -Emax/12000 ±0.02%

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

IP67(75-300kg),IP68(500-5000kg) 2mV/V±0.1%400±10 0.002%°C352±2 0.0012%°C±2% -10°C/+40°C5000M -20°C/+70°C150% 0.03%250%

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

CablelengthSHIELD Cablediameter+SIGNALGREEN Cores+EXCITATION +REF./SENSE RED BLUE -SIGNALWHITE -EXCITATION -REF./SENSE BLACK YELLOW/BROWN

DESCRIPTIONCODE

Specialsteelblock forcapacitiesupto2000kg.

Capacity from 300 kg to 2000 kg

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.02% IP68PROTECTIONRATING

MOUNTINGKITS CAPACITY

CLASS

CERTIFICATIONS

OIMLR60C3

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Declarationofconformity+IP69Kmarkingprotectionrating

Water protection in case of high-pressure or steam jet cleaning (test: pressurized water is sprayed from a distance of max 150 mm)

TFPS2000series

TF500/2000series

IP69K

Water pressure: 100 bar; temperature: 80 °C; test duration: 250 seconds (reference standard: DIN 40050-9)

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

DIMENSIONS (mm)

Fortheloadcellfixingscrews,providethetightening torqueindicatedinthetable

Screw

Screwclass

Tighteningtorque

TECHNICAL FEATURES

Material17-4PHstainlesssteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN

Cores+EXCITATION +REF./SENSE RED BLUE -SIGNALWHITE -EXCITATION -REF./SENSE BLACK YELLOW

Capacity from 500 kg to 5000 kg

AISI4340NICKELPLATEDSTEEL

COMBINEDERROR±0.02%(0.017%C4;0.014%C5)

IP67PROTECTIONRATING

MOUNTINGKITS

CERTIFICATIONS

OIMLR60C3

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

OIMLR60C4/C5

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

FMHazLoc-ComplieswiththeUnitedStatesandCanadaregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

NTEP-ComplieswithUnitedStatesregulationsforlegalfortradeuse

DESCRIPTION

DIMENSIONS (mm)

TECHNICAL FEATURES

Specialsteelblock forcapacitiesupto2000kg. CODE

M12M18 6.88.86.88.8 50Nm79Nm205Nm280Nm

Fortheloadcellfixingscrews,providethetighteningtorqueindicatedinthetable Screw Screwclass Tighteningtorque

MaterialAISI4340nickelplatedsteel

OIMLR60Accuracyclass•Verificationintervals Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

RatedoutputInputresistance

C3•3000C4•4000C5•5000 500-1000-1500kg 2000-3000-5000kg 500-1000kg 1500-2000kg3000-5000kg Emax/10000Emax/15000Emax/20000Emax/18000 ±0.02%±0.017%±0.014% IP67 3mV/V±0.1%350±3.5

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload ELECTRICAL CONNECTIONS

4m(500-2000kg);6m(3000-5000kg) 5mm 4x0.22mm2

CablelengthSHIELD

Cablediameter+SIGNALGREEN Cores+EXCITATIONRED -SIGNALWHITE -EXCITATIONBLACK

Capacity from 500 kg to 5000 kg

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.02% IP67PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

MOUNTINGKITS

TFPS2000series

TF500/2000series

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

FMHazLoc-ComplieswiththeUnitedStatesandCanadaregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

DIMENSIONS (mm)

Fortheloadcellfixingscrews,providethetighteningtorqueindicatedinthetable

Screw

Screwclass

Tighteningtorque

TECHNICAL FEATURES

Material17-4PHstainlesssteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

C3•3000 500-1000-2000kg5000kg Emax/7500Emax/9000

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN

Cores+EXCITATIONRED -SIGNALWHITE -EXCITATIONBLACK

Capacity from 500 kg to 10000 kg

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.02%(0.017%C4) IP68PROTECTIONRATING CAPACITY

CERTIFICATIONS

OIMLR60C3

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

OIMLR60C4

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

DIMENSIONS (mm)

Fortheloadcellfixingscrews,providethetighteningtorqueindicatedinthetable

Screw Screwclass Tighteningtorque

TECHNICAL FEATURES

Material17-4PHstainlesssteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

Calibratedcurrentoutput

ELECTRICAL CONNECTIONS

5m(500-7500kg);10m(10000kg) 5mm 4x0.20mm2 M12M20M24 6.88.86.88.86.88.8 50Nm795Nm290Nm400Nm500Nm690Nm

C3•3000C4•4000 500-1000-2000 5000-7500-10000kg500-1000-2000kg Emax/10000Emax/15000 ±0.02%±0.017% IP68 2mV/V±0.2%350±3.5 0.0018%°C350±3.5 0.0014%°C<±1% -10°C/+40°C5000M -35°C/+65°C150% 0.02%300% 18V0.4mm

ManufacturedaccordingtoOIMLR60standards

Capacity from 5000 kg to 10000 kg

SPECIALSTEEL COMBINEDERROR±0.1% IP68PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

DIMENSIONS (mm)

TECHNICAL FEATURES

MaterialSpecialsteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.03% IP67-IP68PROTECTIONRATING TWOOUTPUTCABLESFORDUALSAFETYSYSTEMS

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg ATEXII3GD (zone 2-22) (-) capacity

DIMENSIONS (mm)

TECHNICAL FEATURES

Material17-4PHstainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

1000-6000kg ±0.03% IP67(1000kg)-IP68(6000kg) 2mV/V±0.1%370±10 0.005%°C355±5 0.005%°C±2% -10°C/+50°C>5000M -20°C/+70°C150% 0.02%300% 15V0.25mm

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN

Cores+EXCITATION +REF./SENSE

The

AISI4340NICKELPLATEDSTEEL COMBINEDERROR±0.02% IP68PROTECTIONRATING MOUNTINGKIT

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

FMHazLoc-ComplieswiththeUnitedStatesandCanadaregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

COMPLEMENTARY ACCESSORIES

DESCRIPTIONCODE Galvanizedsteelplate.

DIMENSIONS (mm)

TECHNICAL FEATURES

MaterialAISI4340nickelplatedsteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale) MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

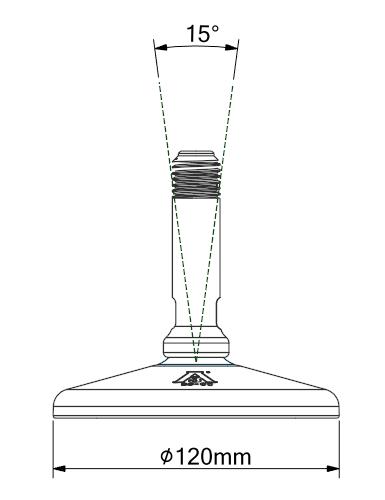

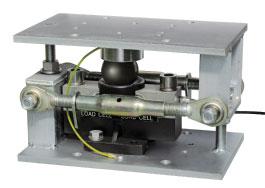

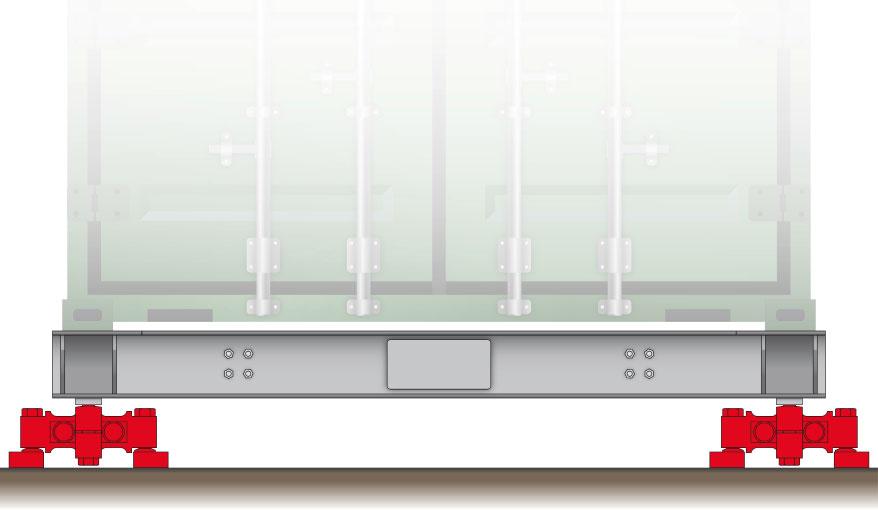

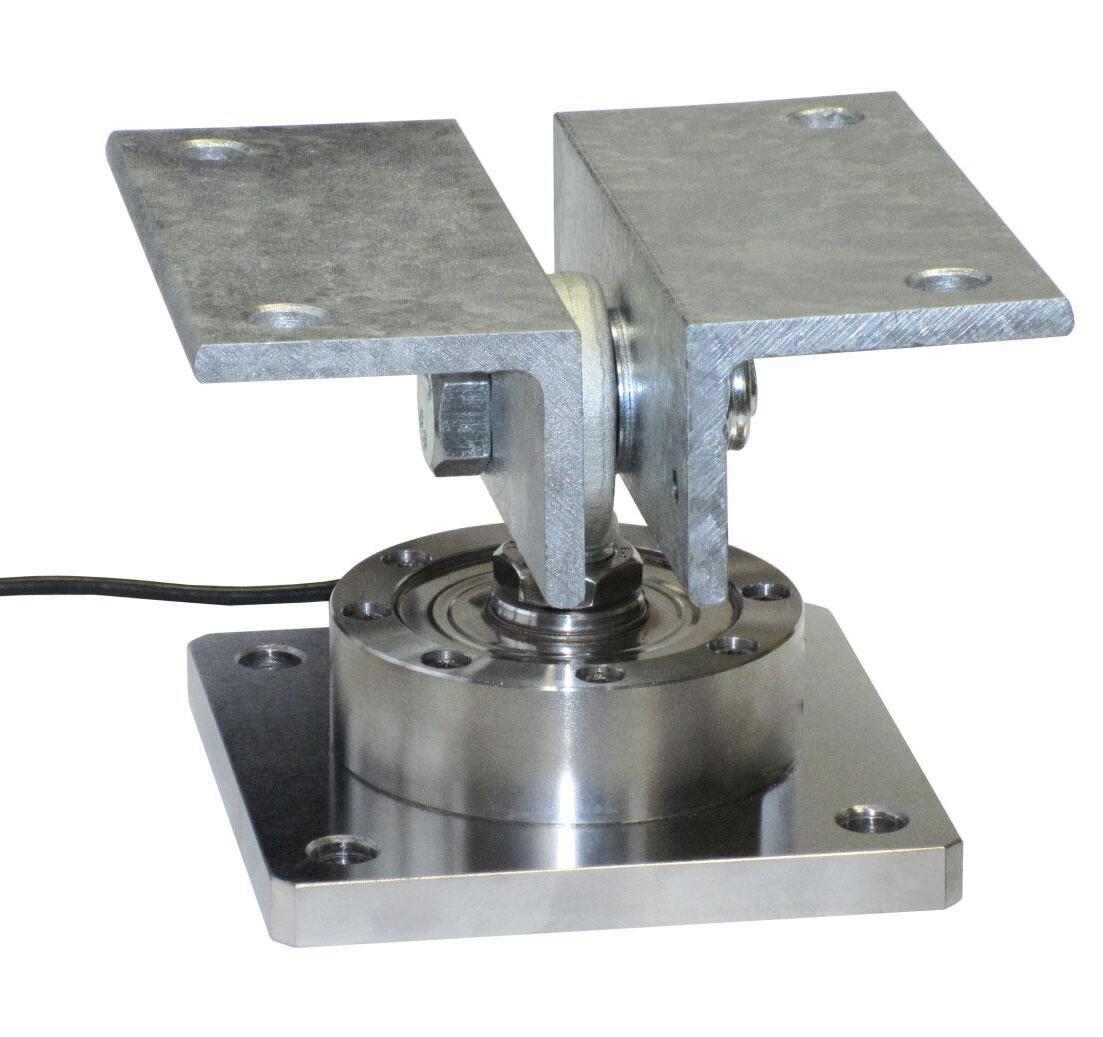

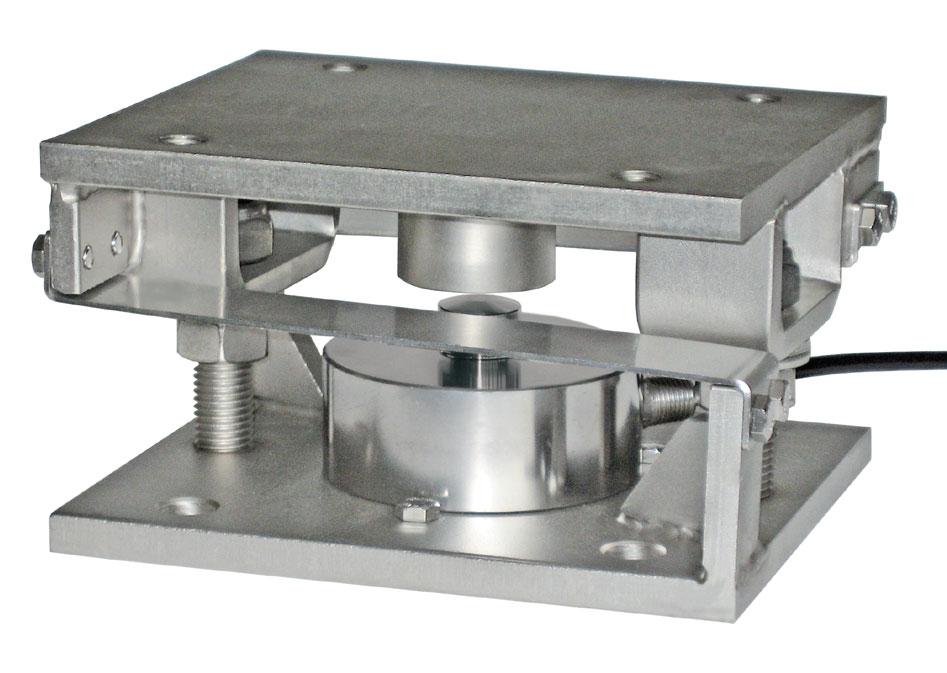

LEVELMEASUREMENTS

“Pointsupporthinge”canbeusedincombinationwiththeload cellsformeasuringthelevelofliquidorweighingpowderproducts thatdonotrequireahighdegreeofprecision.Itisabsolutely necessarythatthestructuretoweighthasauniformshapeandis geometricallydivisible.

Itmustbeperfectlylevelandthetypeofproducttobeweighed mustenablehorizontalpositioning,asifitwerealiquid(otherwise itloadingsystemswhichdistributetheproduct/loaduniformlyare required).Theelectronicweightdisplaywillshowtheeffective weightmultiplyingthesignalbytwoorthree,dependingonthe application.

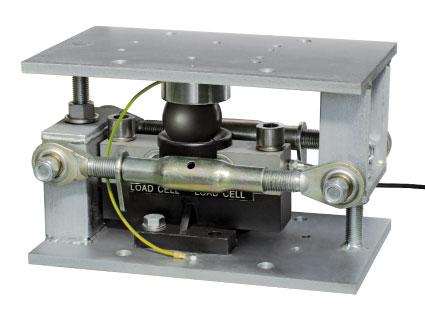

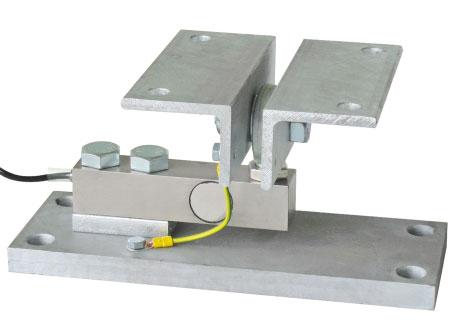

3SUPPORTSSTRUCTURES

1loadcell(A)+2hinges(B)

4SUPPORTSSTRUCTURES

2loadcelss(A)+2hinges(B) Hinges support

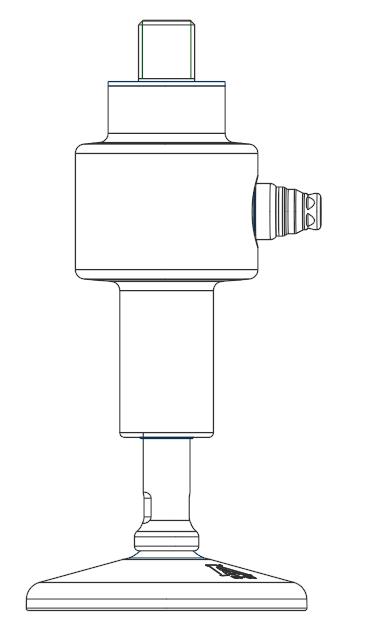

WEIGHINGSTRUCTURESNOTSUBJECTTOKNOCKSOR WINDEFFECT

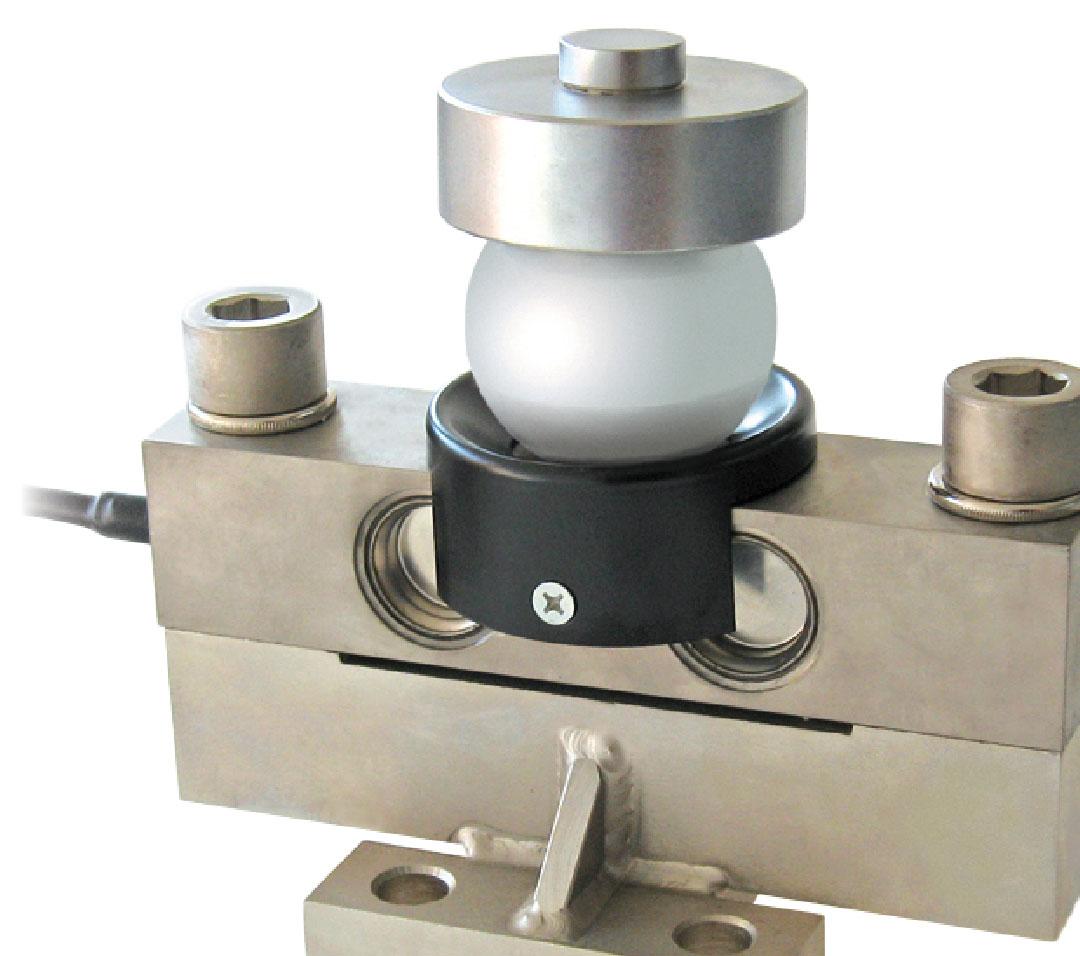

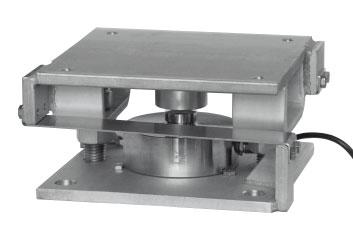

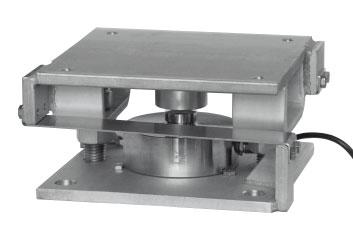

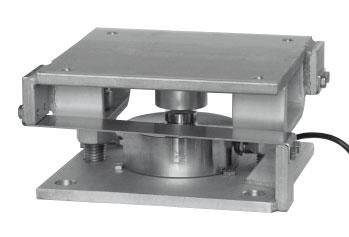

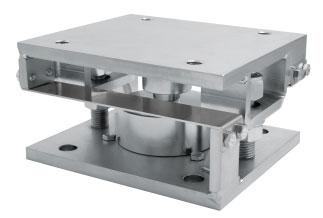

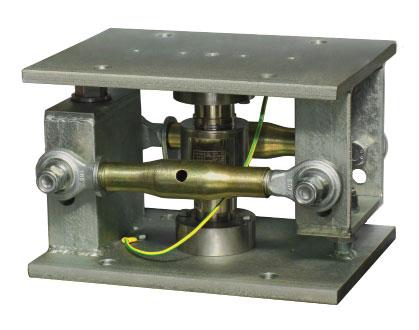

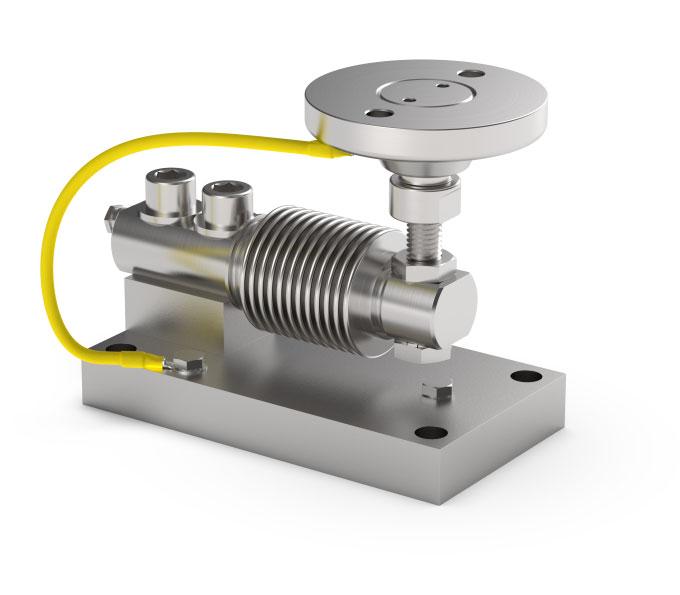

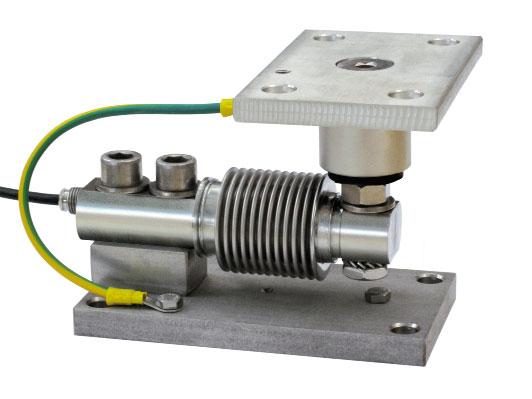

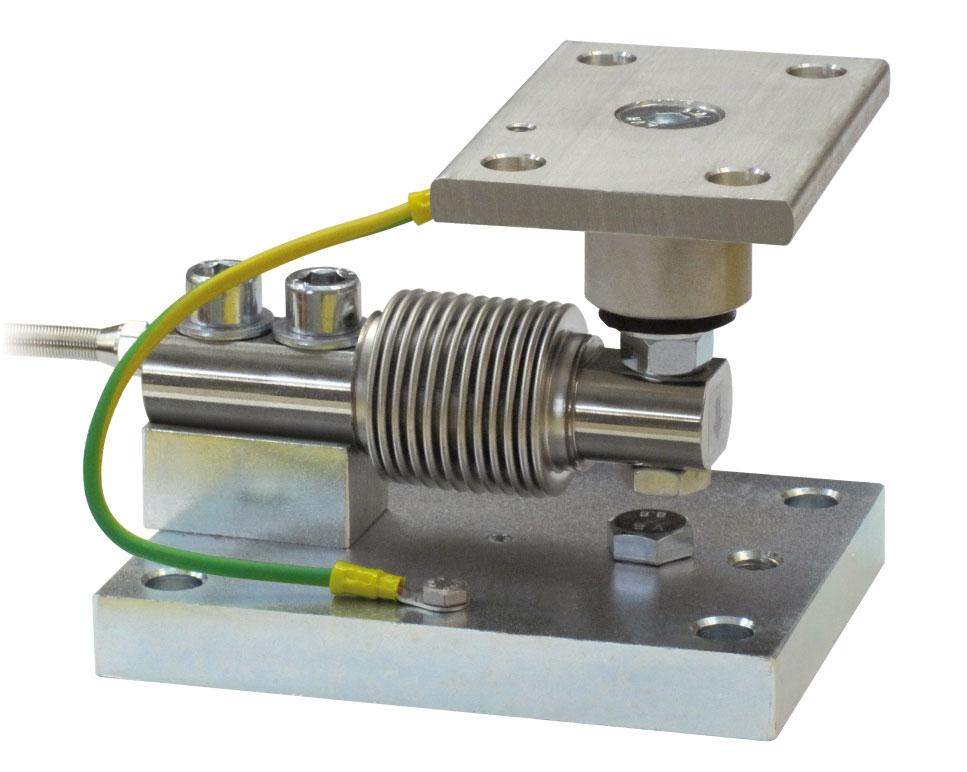

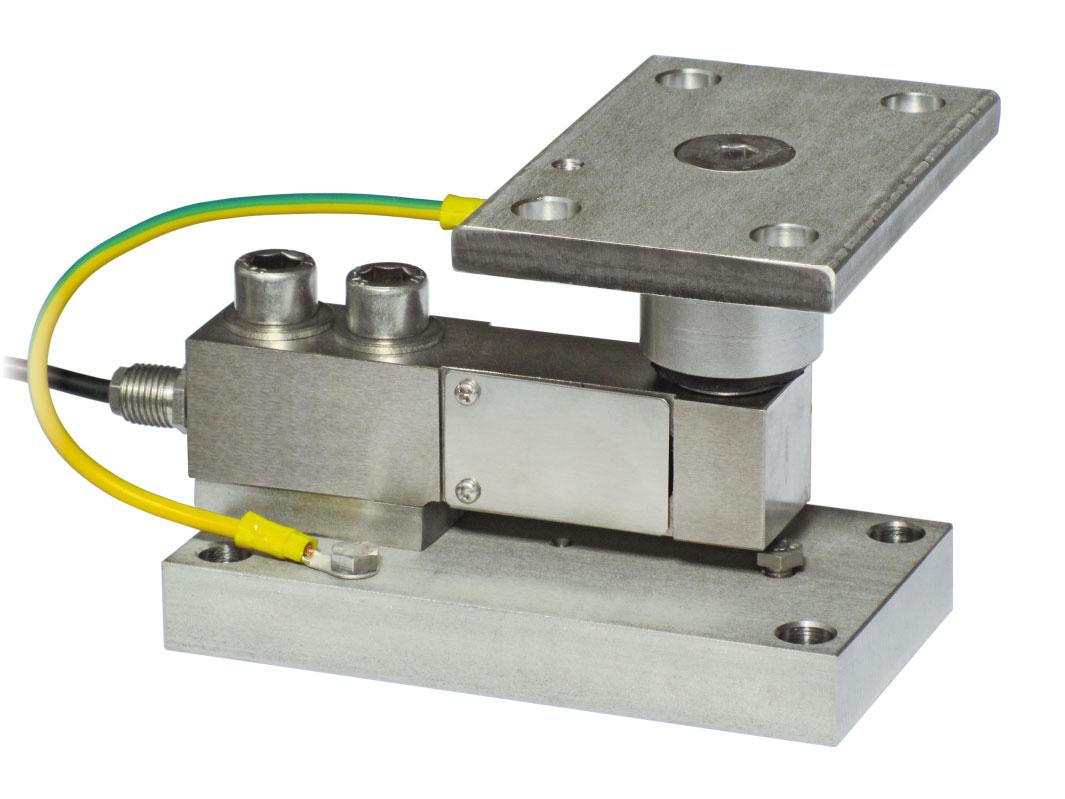

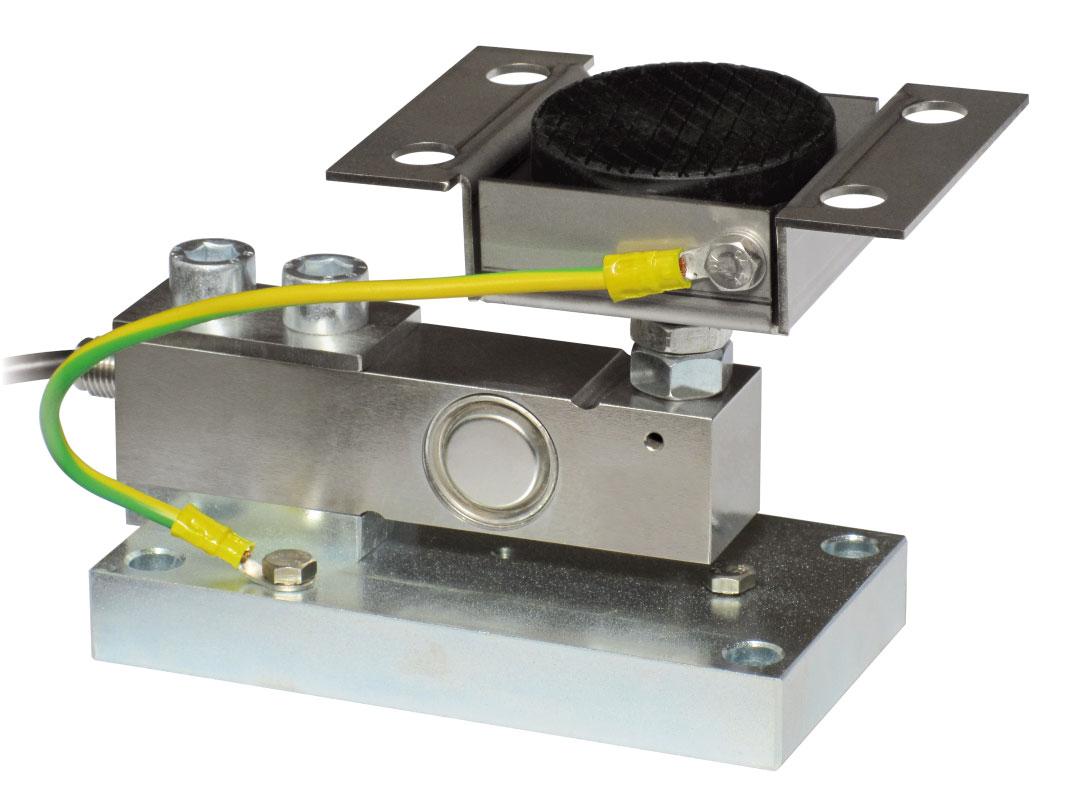

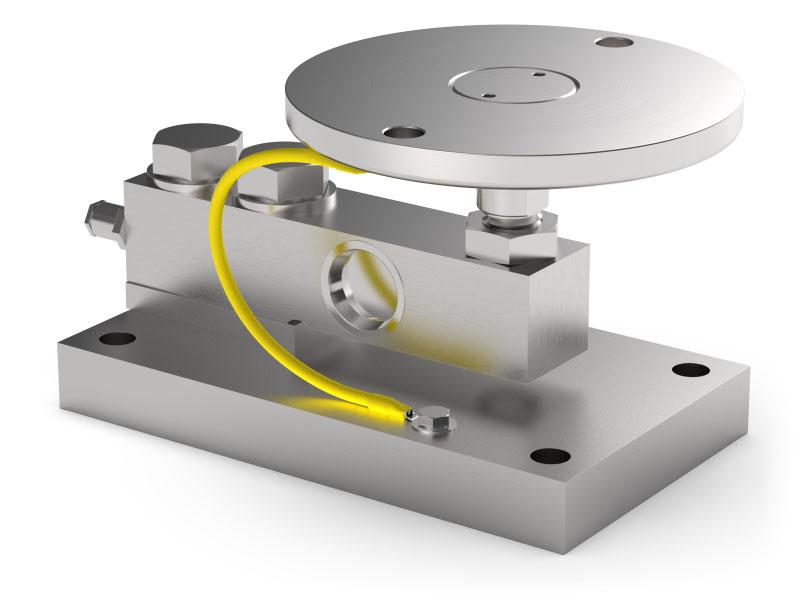

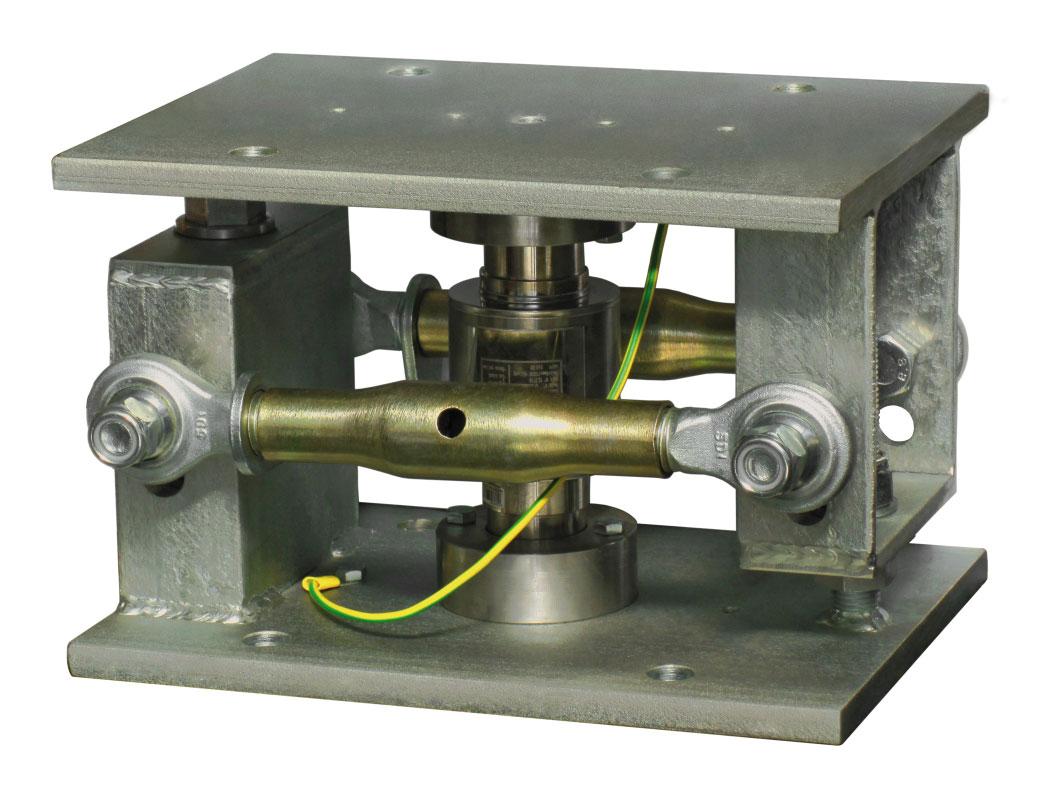

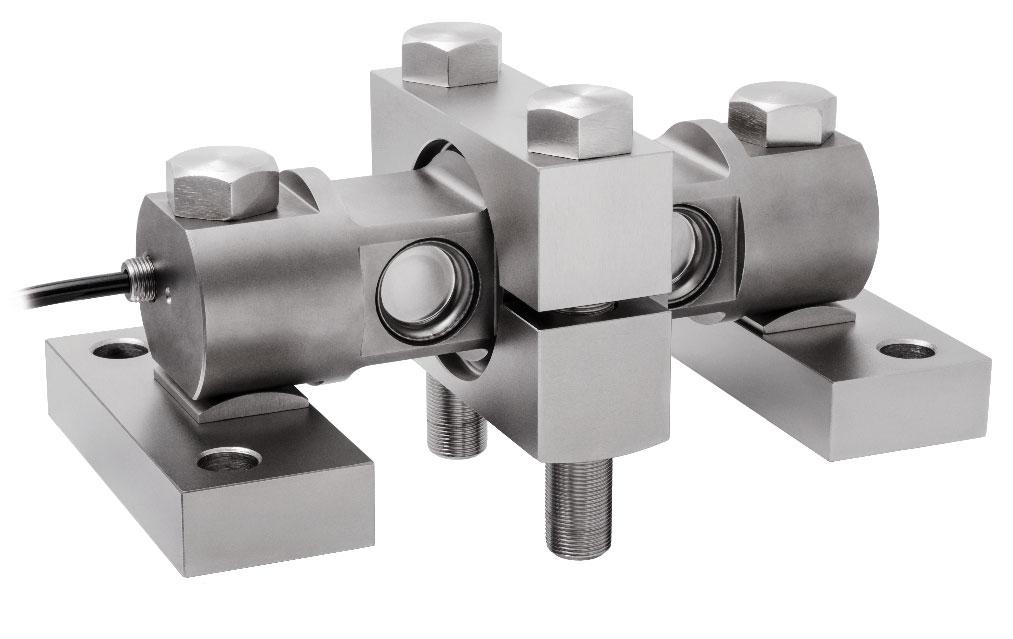

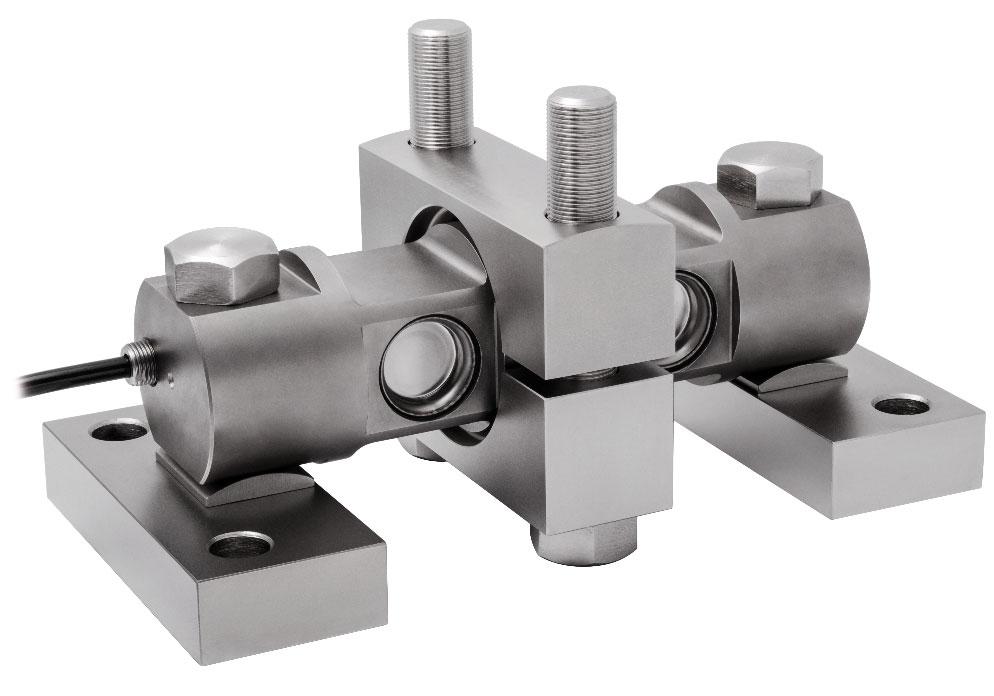

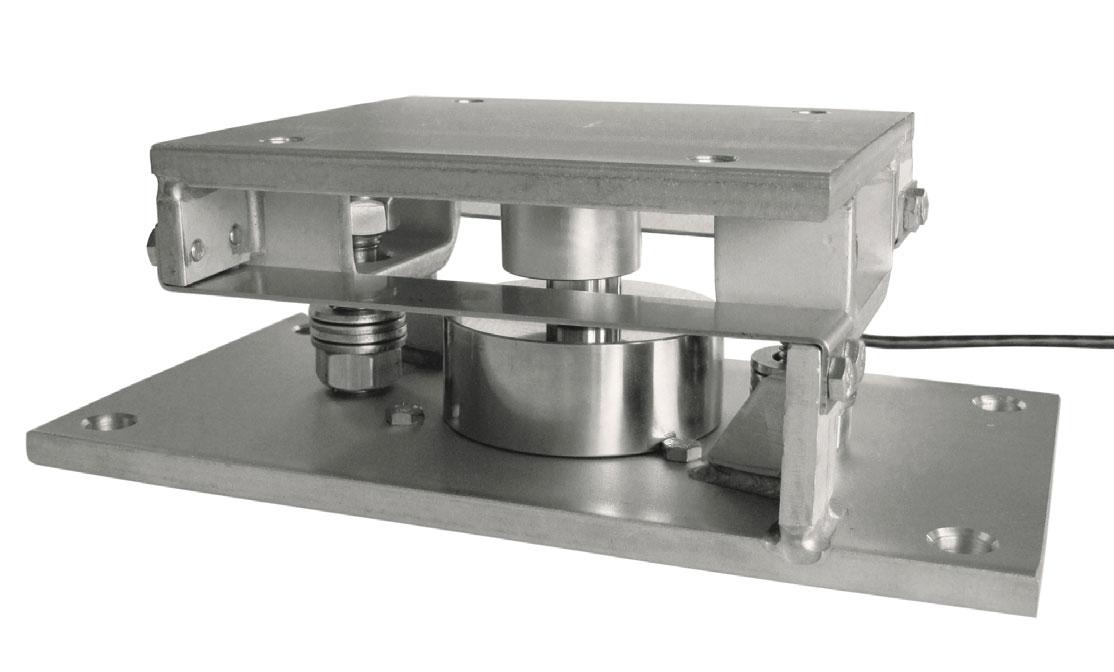

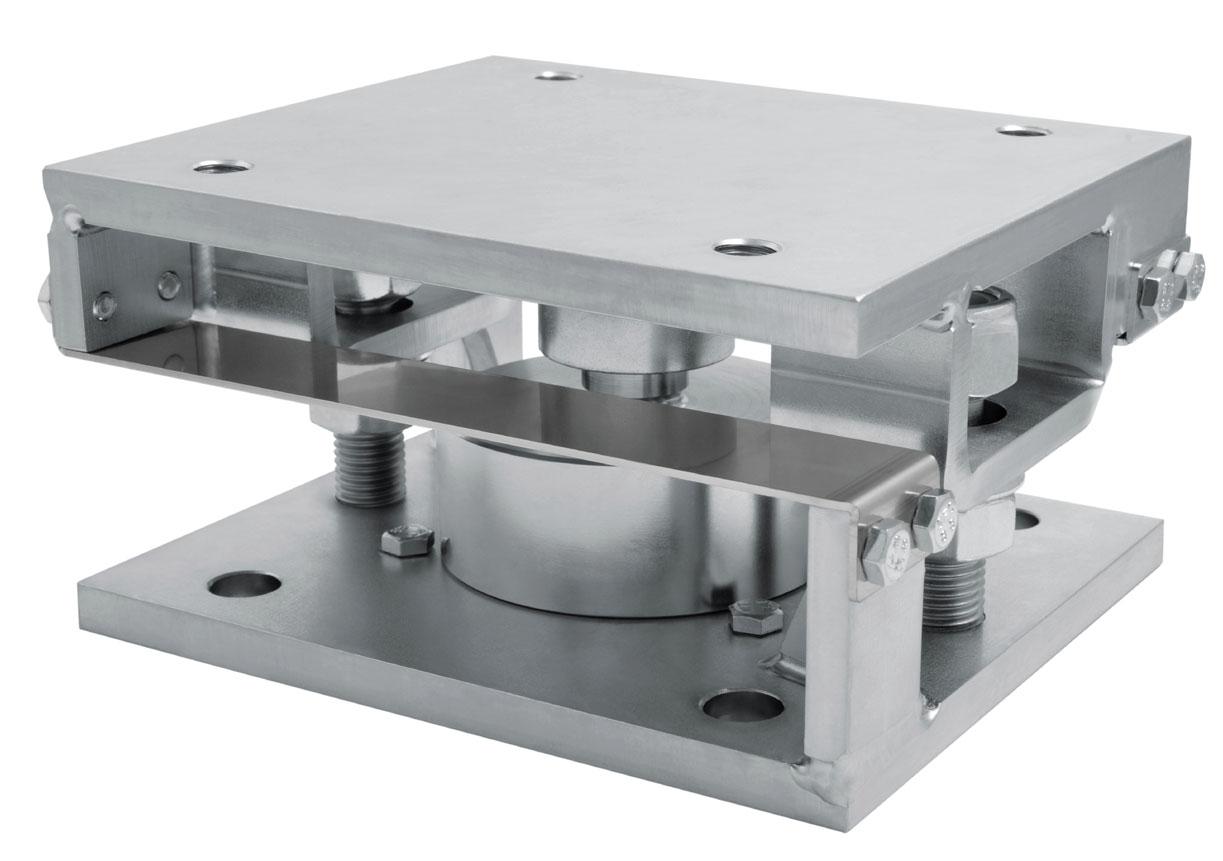

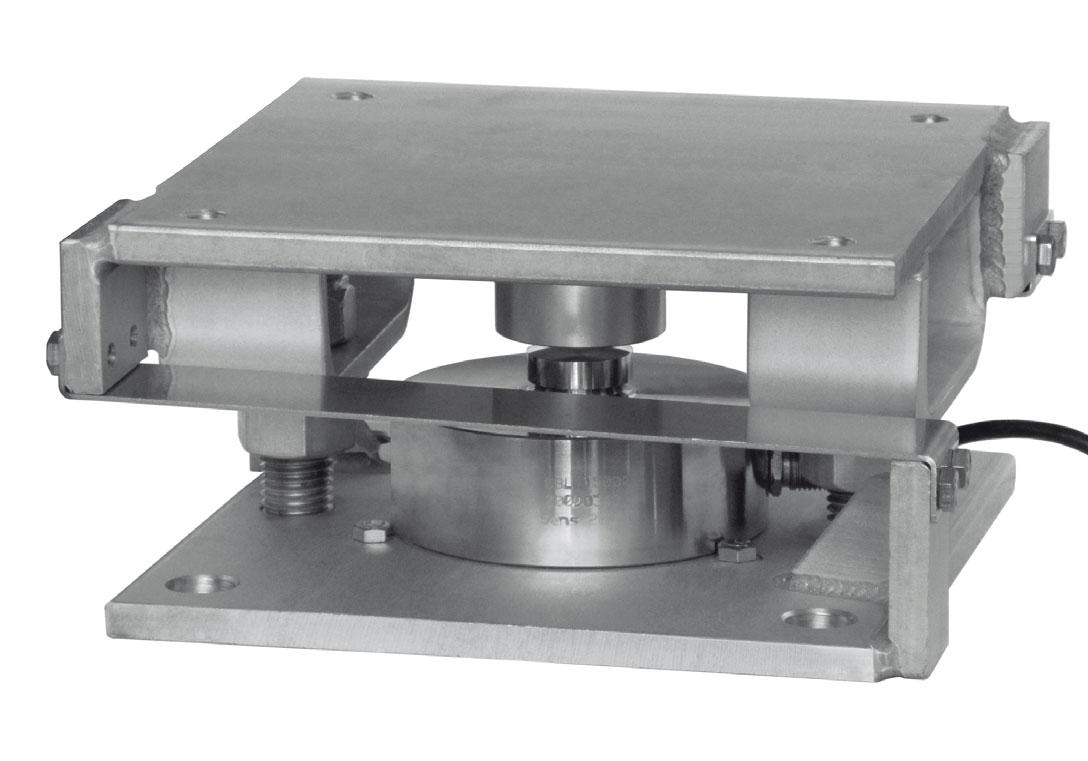

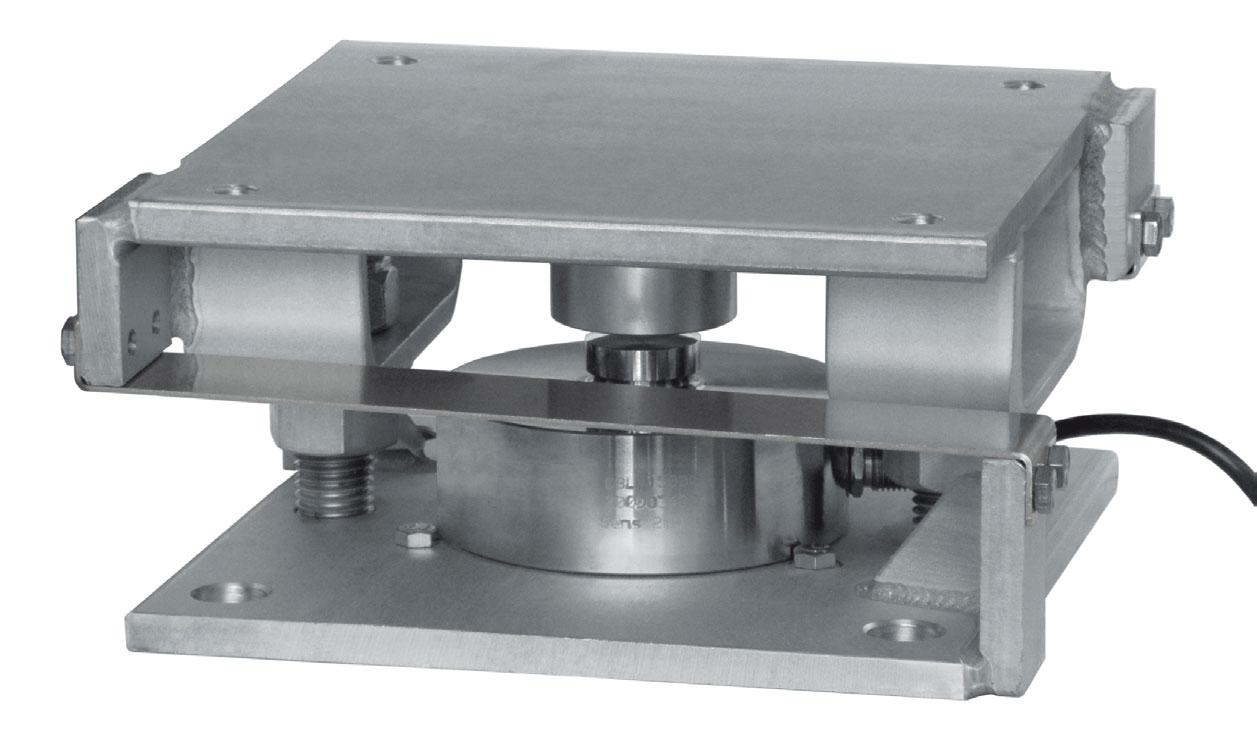

Theloadcell,equippedwithbasesplusball,isdesignedfor weighingstructuresnotsubjecttoknocksorwindeffect.

PIATTODTLisdesignedforfacilitatetheloadcellinstallationand removal;itwillbeenoughtolift1mmthestructure.Thedifferent bendingradiusbetweentheballandthebaseswhichcontainit, makesthatanysideshiftsleadtoonincreaseofthestructure.

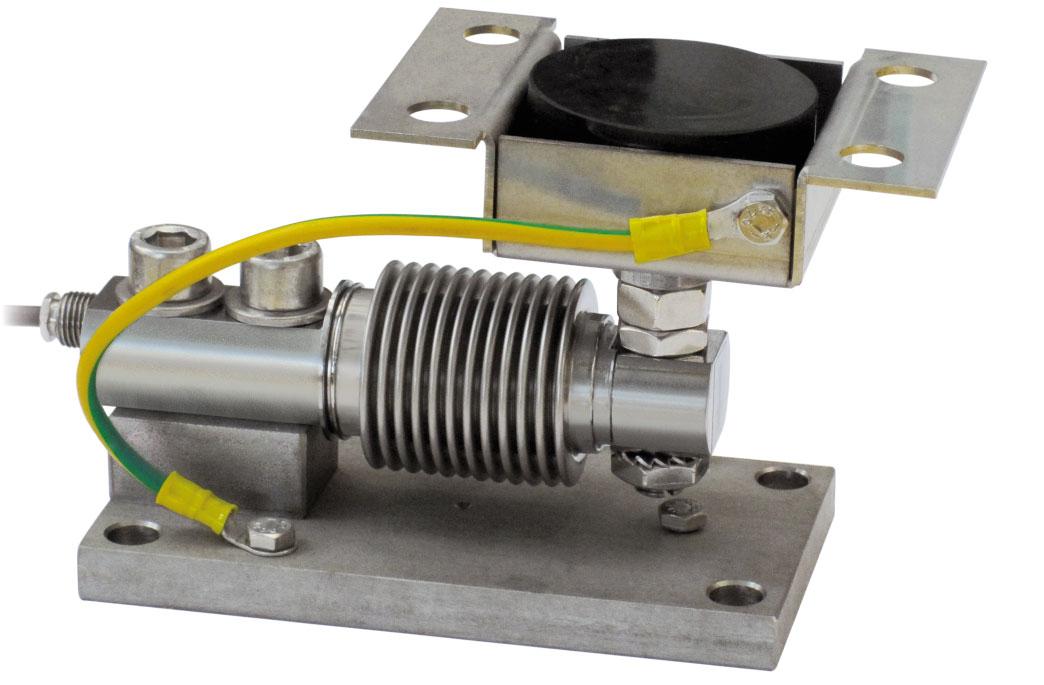

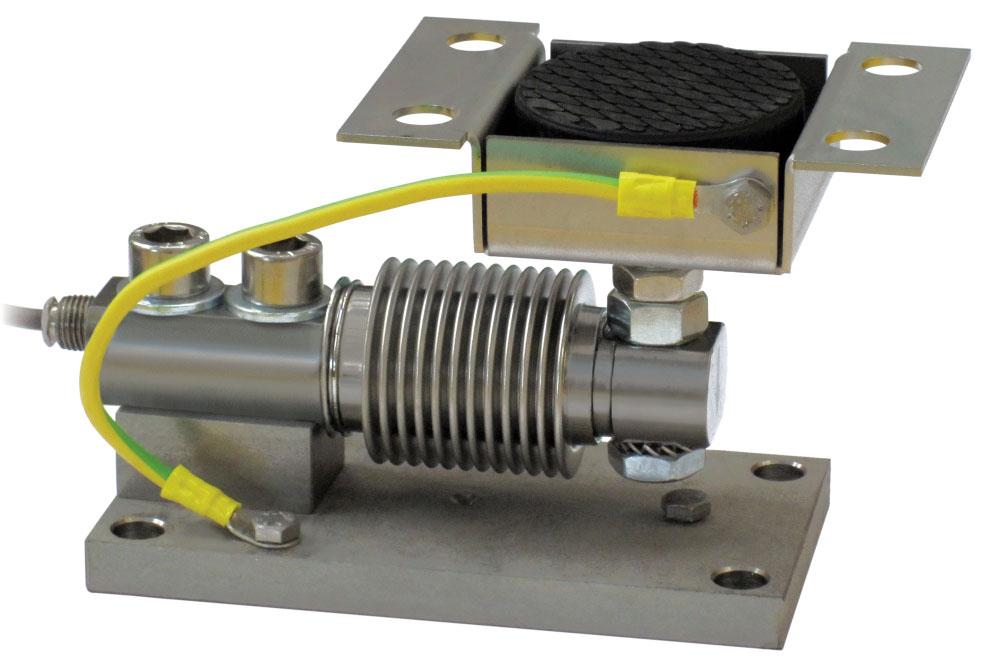

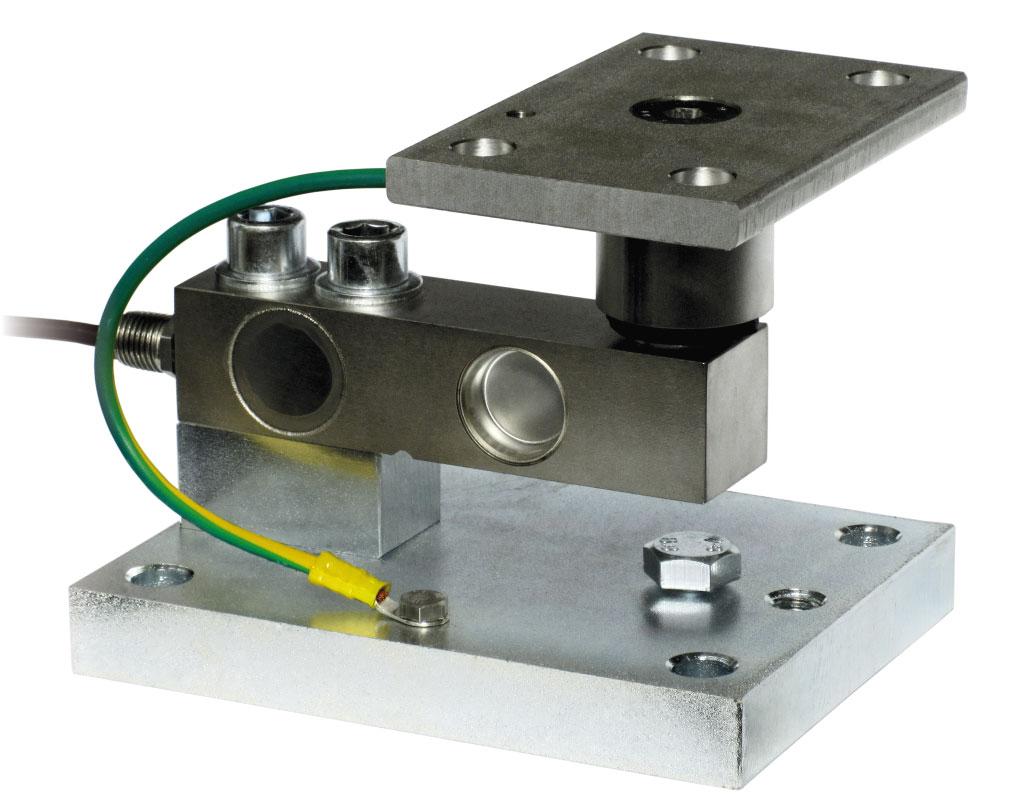

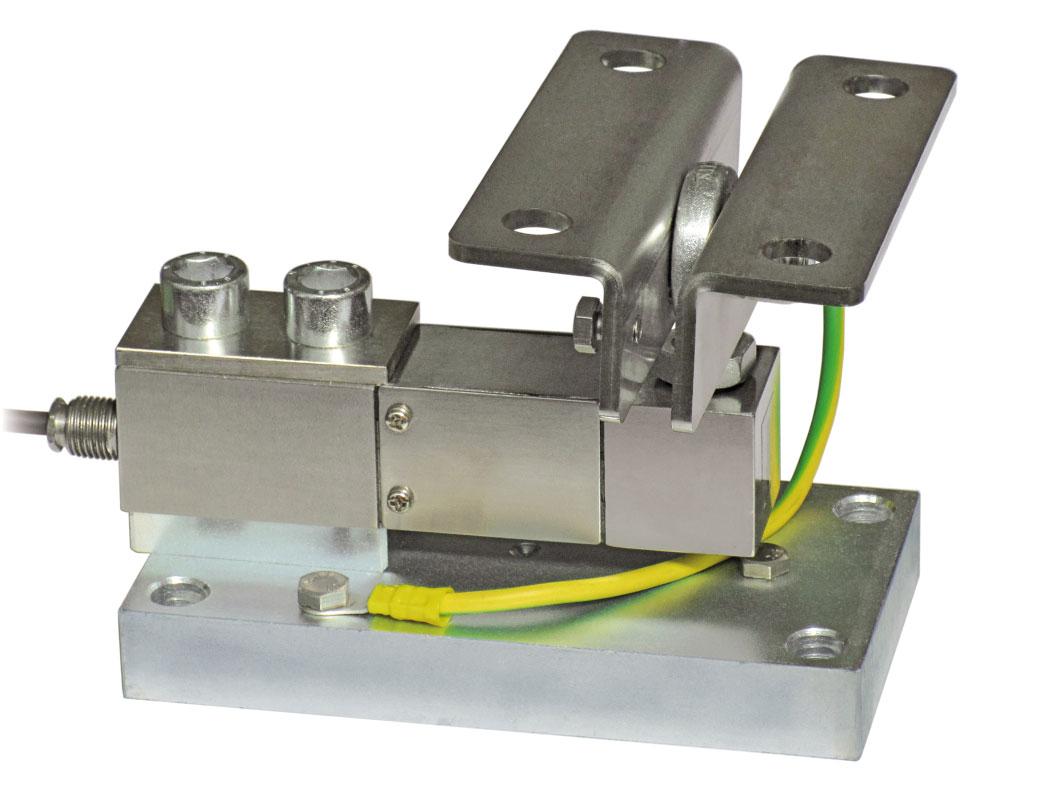

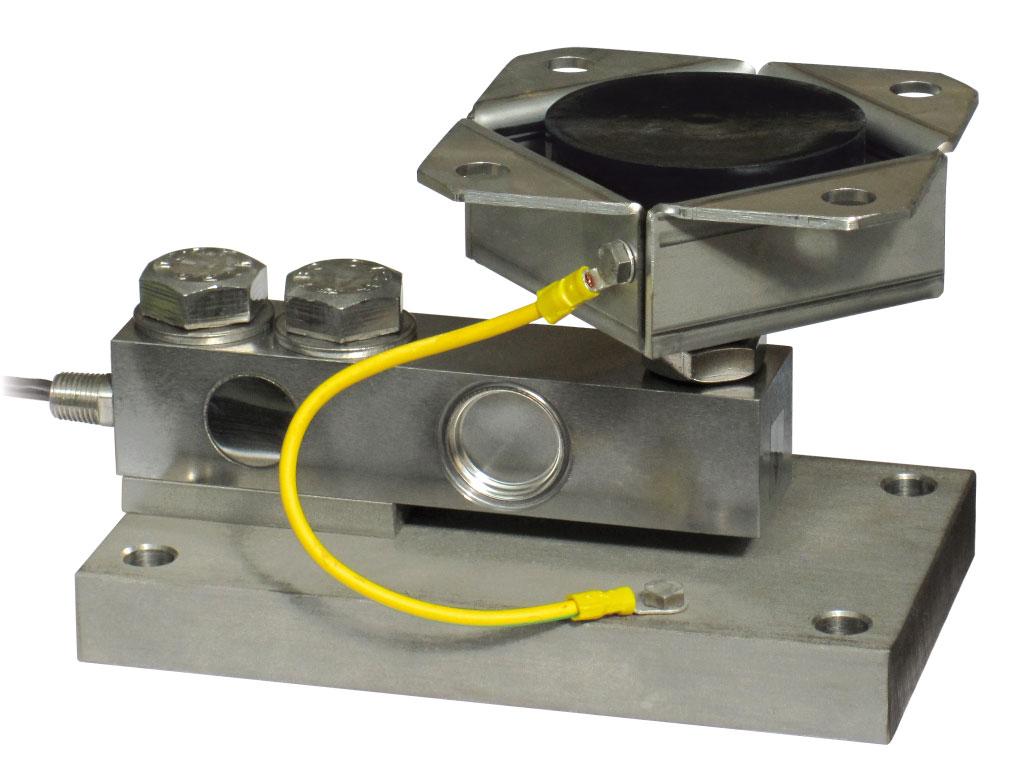

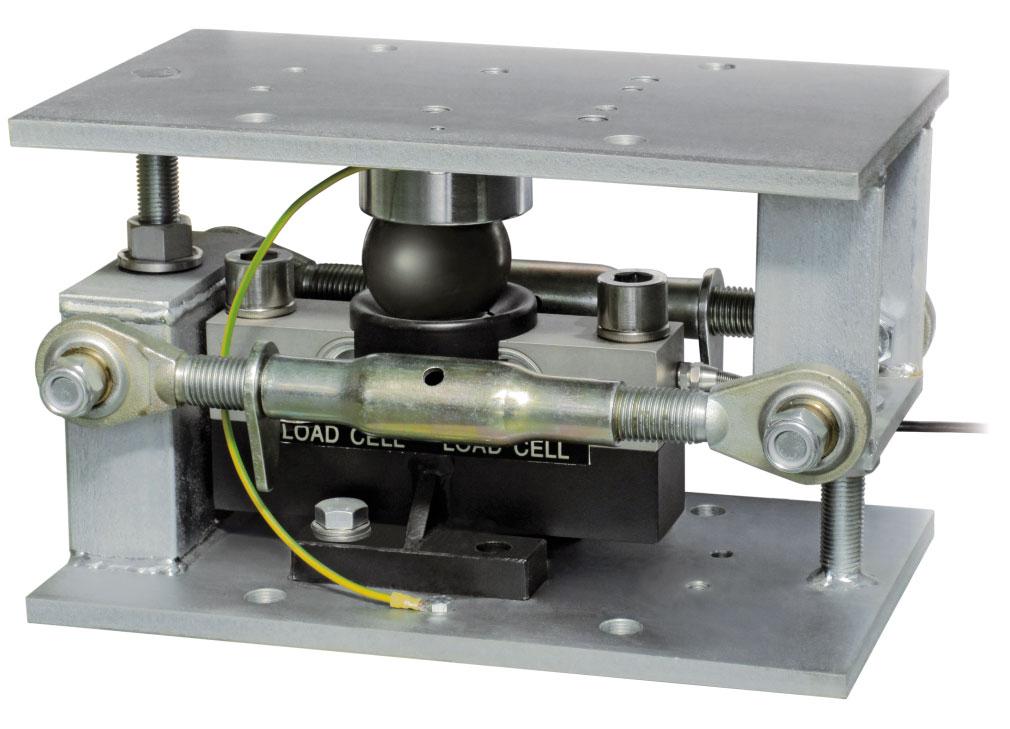

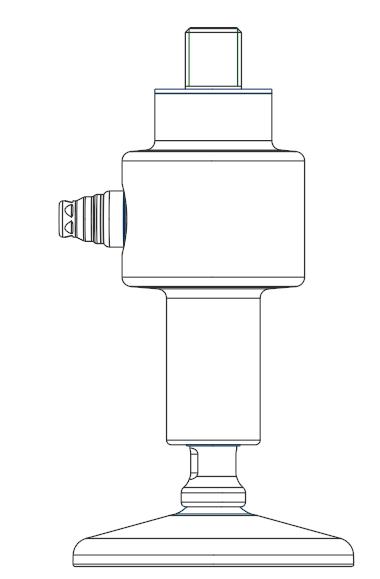

WEIGHINGSTRUCTURESSUBJECTTOKNOCKSORWIND EFFECT

TheVCOKDTLmountingkitisequippedwithtwostayrods againstlateralforceswithanultimatetensilestrengthof10000kg each,andtwothreadedrods(22mmdiameter)withnutstouse asajackfortheinsertionandextractionofthecellsandwith twoself-lockingnutsforanti-tiltfunction.Toensurethestability ofthestructure,thedesignermustconsiderfurthercontrivances accordingtothefollowingconditions:knocksandvibrations; windeffect;seismicconditions;hardnessofsupportstructure.

3SUPPORTSSTRUCTURES4SUPPORTSSTRUCTURES

Capacity from 20 klb to 60 klb

AISI4340NICKELPLATEDSTEEL COMBINEDERROR±0.02% IP68PROTECTIONRATING

MOUNTINGKIT

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

FMHazLoc-ComplieswiththeUnitedStatesandCanadaregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

DIMENSIONS (mm)

TECHNICAL FEATURES

MaterialAISI4340nickelplatedsteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

C3•3000 20,30,40,50,60klb Emax/10000-Emax/15000 ±0.023%

IP68

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN Cores+EXCITATIONRED -SIGNALWHITE -EXCITATIONBLACK

2

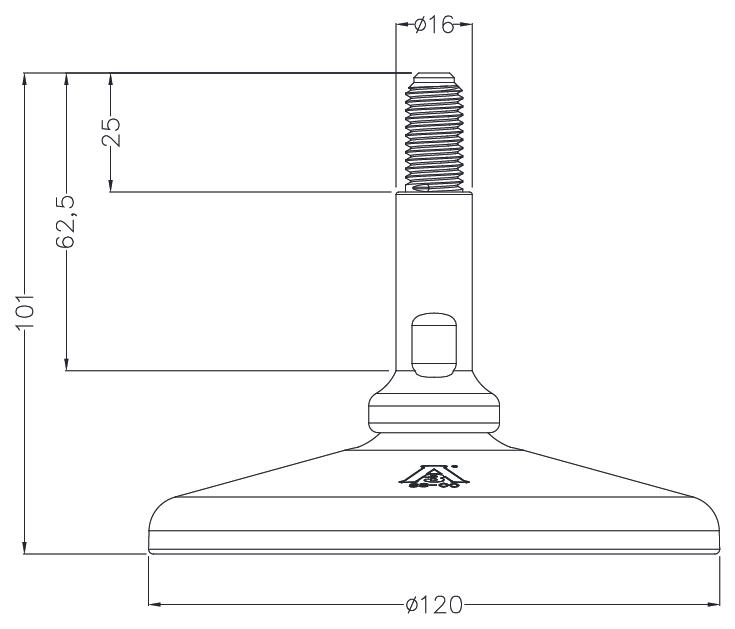

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.07% IP67PROTECTIONRATING ADJUSTABLEHEIGHT CAPACITY

CERTIFICATIONS

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST Calibrationreport

ATEXII3GD (zone 2-22) (-)

COMPLEMENTARY ACCESSORIES

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

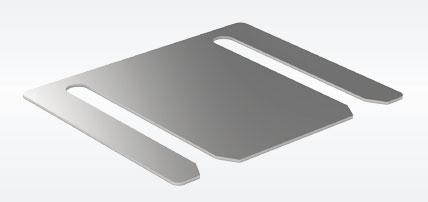

DESCRIPTIONCODE

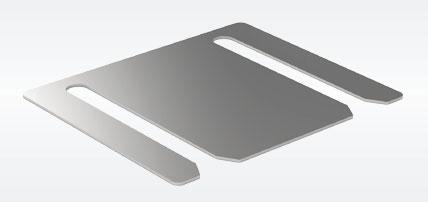

AISI304stainlesssteelplateforconstraintsagainstlateral forcesandanti-tilt. OnlyforSB2seriesfeet.

DIMENSIONS AND TECHNICAL SPECIFICATIONS

CAPACITY

75kgM12x1.75

150kgM12x1.75

300kgM12x1.75

500kgM12x1.75

1000kgM12x1.75

2000kgM12x1.75

5000kgM20x2.5

Installationnotes: screwthefootallthewayin; slightlyunscrewthefoottoadjust(maximumexcursion:10mm); tightenthefixingnut.

190÷200mm182÷192mm

10000kgM24x3-

ForfurtherinformationseetheSTRandSB2datasheets

TECHNICAL FEATURES

Material17-4PHstainlesssteel Nominalload

Combinederror Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN

Cores+EXCITATION +REF./SENSE RED BLUE -SIGNALWHITE -EXCITATION -REF./SENSE BLACK YELLOW

The Company reserves the right to make changes to the technical data, drawings and images without notice.

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.1% IP69KPROTECTIONRATING CABLESUITABLEFORCONTACTWITHFOOD ADJUSTABLEHEIGHT HYGIENICDEVICERPSCQCAUTHORIZEDBY3-ASSI. CAPACITY

Foot not included.

CERTIFICATIONS

EquivalentoftheCEmarkingfortheUnitedKingdom

Americanstandardthatregulatesthedesign,productionanduseofhygienicequipment

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII3GD (zone 2-22) (-)

EXAMPLEOFINSTALLATIONON HYGIENICFOOT

DIMENSIONS AND TECHNICAL SPECIFICATIONS

CAPACITY

XL(mm)M(mm)H(FLC+HD)

1000kgM12x1.752440

2000kgM12x1.752440

5000kgM16x23040

5000kgM20x2.53540

10000kgM24x35040

10000kgM30x3.55050

20000kgM36x45050

TECHNICAL FEATURES

ANGULARADJUSTMENT

Installationnotes: screwthefootallthewayin; slightlyunscrewthefoottoadjust(maximumexcursion:10mm).

ForfurtherinformationseetheHDdatasheets Onrequest:hygienicfootwithdowelfastening

For other types of hygienic, non-hygienic feet or customizations feet customizations contact https://martinlevelling.it

Material17-4PHstainlesssteel Nominalload Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

ManufacturedaccordingtoOIMLR60standards

Capacity from 200 kg to 2500 kg

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.5% IP67PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

TECHNICAL FEATURES

Material17-4PHstainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

ManufacturedaccordingtoOIMLR60standards

Capacity from 1000 kg to 5000 kg

MOUNTINGKITS

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

DIMENSIONS (mm)

TECHNICAL FEATURES

MaterialAISI420stainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

MOUNTINGKITS

V15000/V100000-EN1090series

Z15000/100000series

OIMLR60C2

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Declarationofconformity+IP69Kmarkingprotectionrating

Water protection in case of high-pressure or steam jet cleaning (test: pressurized water is sprayed from a distance of max 150 mm)

Water pressure: 100 bar; temperature: 80 °C; test duration: 250 seconds (reference standard: DIN 40050-9)

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

OIMLR60C3

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswiththeregulationsoftheRussianFederationforlegalfortradeuse

ComplieswithChinesemarketregulationsforlegalfortradeuse

TECHNICAL FEATURES

Material17-4PHstainlesssteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

-C2•2000C3•3000

250-500-1000-15000kg 30000-50000-100000kg 2500-5000kg 7500-10000kg

2500-5000-7500kg 10000-12500kg

-Emax/15000Emax/15000 ±0.03%±0.03%±0.02% IP68

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

TemperaturerangeOIMLR60Insulationresistance

CompensatedtemperaturerangeSafeoverload(%offullscale)

OperatingtemperaturerangeUltimateoverload(%offullscale)

Creepatnominalloadin30minutesDeflectionatnominalload Maxsupplyvoltagewithoutdamage

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN

5m*(250-10000kg);10m(12500-100000kg) 5mm

6x0.14mm2

Cores+EXCITATION +REF./SENSE RED BLUE

*) On request: 10 m long cable version -SIGNALWHITE

TheOIMLR60C3approvedloadcellsareequippedwith10mlongcable-EXCITATION -REF./SENSE BLACK YELLOW

OPTIONS ON REQUEST

DESCRIPTION

10mlongcableversionfor250-10000kgcapacities

AISI420stainlesssteelloadcellversion(notOIMLapproved)

TworedundantstraingaugesWheatstonebridges(350)withtwooutputcables; fordualsafetysystems

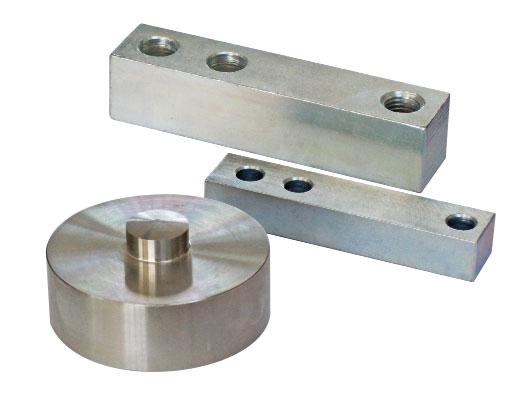

COMPLEMENTARY ACCESSORIES

DESCRIPTION

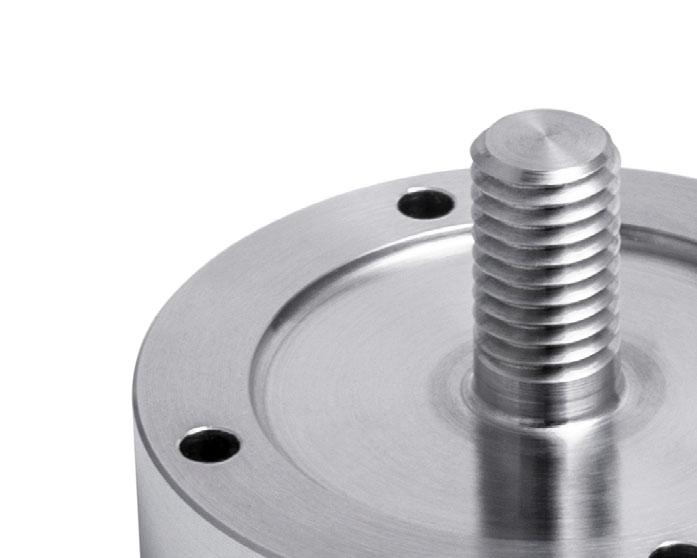

AISI304stainlesssteelthreadedupper baseforcompressionloadcells.

CODE

M12x1.75mmBASESUPFIL

AISI304stainlesssteelturnedlowerbase forcompressionloadcells.

Ø110x22mm Ø140x23mm Ø180x23mm

LowerplateandturnedupperbaseinAISI304stainlesssteel. Loadcellcapacity:upto12500kg.

BINF100 BINF126 BINF165

BASESUP P10000

TurnedupperandlowerbasesinAISI304stainlesssteel. Loadcellcapacity:upto12500kg.

BASESUP BASEINF

LowerplateandturnedlowerbaseinAISI304stainlesssteel. Loadcellcapacity:upto12500kg.

BASEINF PIASTRA200

BOLTSTOFIX

Capacity from 1000 kg to 30000 kg

AISI420STAINLESSSTEEL COMBINEDERROR±0.05%

IP68PROTECTIONRATING

MOUNTINGKITS

V10000V15000-V30000-V100000Z10000Z15000/100000 -V10275

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Declarationofconformity+IP69Kmarkingprotectionrating

Water protection in case of high-pressure or steam jet cleaning (test: pressurized water is sprayed from a distance of max 150 mm)

Water pressure: 100 bar; temperature: 80 °C; test duration: 250 seconds (reference standard: DIN 40050-9)

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

TECHNICAL FEATURES

MaterialAISI420stainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

COMPLEMENTARY ACCESSORIES

DESCRIPTION

AISI304stainlesssteelthreadedupper baseforcompressionloadcells.

AISI304stainlesssteelturnedlowerbase forcompressionloadcells.

LowerplateandturnedupperbaseinAISI304stainlesssteel. Loadcellcapacity:upto15000kg.

CODE

-SIGNALWHITE -EXCITATION -REF./SENSE BLACK YELLOW

TurnedupperandlowerbasesinAISI304stainlesssteel. Loadcellcapacity:upto15000kg.

LowerplateandturnedlowerbaseinAISI304stainlesssteel. Loadcellcapacity:upto15000kg.

BOLTSTOFIX THELOADCELL

ManufacturedaccordingtoOIMLR60standards

Capacity from 15000 kg to 50000 kg

MOUNTINGKITS

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

OPTIONS ON REQUEST

DESCRIPTION

TworedundantstraingaugesWheatstonebridges(350) withtwooutputcables;fordualsafetysystems

V10000/V10275-EN1090series

V15000/V100000-EN1090series

Z15000/100000series

TECHNICAL FEATURES

Material17-4PHstainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN Cores+EXCITATION +REF./SENSE RED BLUE -SIGNALWHITE -EXCITATION -REF./SENSE BLACK YELLOW

COMPLEMENTARY ACCESSORIES

DESCRIPTION

AISI304stainlesssteelthreadedupper baseforcompressionloadcells.

AISI304stainlesssteelturnedlowerbase forcompressionloadcells.

CODE

M12x1.75mmBASESUPFIL

Ø110x22mm Ø140x23mm BINF100 BINF126

LowerplateandturnedupperbaseinAISI304stainlesssteel. Loadcellcapacity:upto15000kg.

TurnedupperandlowerbasesinAISI304stainlesssteel. Loadcellcapacity:upto15000kg.

LowerplateandturnedlowerbaseinAISI304stainlesssteel. Loadcellcapacity:upto15000kg.

AISI304stainlesssteeladapterformountingkit: forØ82mmloadcells forØ100mmloadcells forØ126mmloadcells

BASESUP P10000

BASESUP BASEINF

BASEINF PIASTRA200

BOLTSTOFIX THELOADCELL

ManufacturedaccordingtoOIMLR60standards

Capacity from 200000 kg to 750000 kg

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.10% IP68PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

OPTIONS ON REQUEST

DESCRIPTION

TworedundantstraingaugesWheatstonebridges(350) withtwooutputcables;fordualsafetysystems

COMPLEMENTARY ACCESSORIES DESCRIPTION

Upperloading base.

Dimensions:Maximumstaticload:

DIMENSIONS (mm)

Material17-4PHstainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

Capacity from 15000 kg to 50000 kg

AISI4340NICKELPLATEDSTEEL COMBINEDERROR±0.02% IP68PROTECTIONRATING KITCOKMOUNTINGACCESSORYINCLUDED MOUNTINGKIT

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswiththeregulationsoftheRussianFederationforlegalfortradeuse

DESCRIPTIONCODE

DIMENSIONS

AISI5140nickelplatedsteelaccessorycomposedbyantirotationsystem,protectiverubberseal,2bases(upperand lower)and3self-centeringcylindricalplates.

TECHNICAL FEATURES

MaterialAISI4340nickelplatedsteel

OIMLR60Accuracyclass•Verificationintervals Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

C3•3000 15000-25000-50000kg

Emax/10000 ±0.02% IP68

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

CablelengthSHIELD Cablediameter+SIGNALGREEN Cores+EXCITATION +REF./SENSE

DESCRIPTION

AISI4340nickel-platedsteelbodyandAISI304stainlesssteelshell

Combinederror±0.014%

IP69Kprotectionrating

Two-connectordigitaloutput

CompatiblewithWINOXBGEandWTABBGE

Loadcellbaseswithanti-rotationmechanism

Earthingcable

Pipeclamps

Lightningandelectricalshockprotection

OIMLR60C5 IP69K

EquivalentoftheCEmarkingfortheUnitedKingdom

Declarationofconformity+IP69Kmarkingprotectionrating

Water protection in case of high-pressure or steam jet cleaning (test: pressurized water is sprayed from a distance of max 150 mm)

Water pressure: 100 bar; temperature: 80 °C; test duration: 250 seconds (reference standard: DIN 40050-9)

CERTIFICATIONS ON REQUEST

Calibrationreport

ComplieswithChinesemarketregulationsforlegalfortradeuse

OPTIONS ON REQUEST

DESCRIPTION

Anti-ratcableforconnectingtoindicator,length:20m, equippedwithconnectorononeendonly.

Anti-ratcable,length:10m, equippedwithconnectoronbothends.

Anti-ratcable,length:5m, equippedwithconnectoronbothends.

DIMENSIONS (mm)

MaterialAISI4340nickel-platedsteelbodyandAISI304stainlesssteelshell

OIML R60 Accuracy class • Verification intervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

TemperatureeffectonzeroRecommendedpowersupplyvoltage

TemperatureeffectonspanSafeoverload(%offullscale)

CompensatedtemperaturerangeUltimateoverload(%offullscale)

OperatingtemperaturerangeRS485serialinterface

Creepatnominalloadin30minutesMaximumtransmissiondistance

Maxsupplyvoltagewithoutdamage

EXAMPLE OF APPLICATION

Capacity 25000 kg

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.017% IP68PROTECTIONRATING LIGHTNINGPROTECTION

CERTIFICATIONS

OIMLR60C4

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

FMHazLoc-ComplieswiththeUnitedStatesandCanadaregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswiththeregulationsoftheRussianFederationforlegalfortradeuse

COMPLEMENTARY ACCESSORIES

DESCRIPTIONCODE

Stainlesssteelaccessorycomposedbyanti-rotationsystemwith O-ringand2bases(upperandlower).

Kitcomposedby2AISI5140nickelplatedsteelplates(upper andlower)forKITCObases.

(mm)

TECHNICAL FEATURES

Material17-4PHstainlesssteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

C4•4000 25000kg Emax/15000 ±0.017% IP68

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN

Cores+EXCITATIONRED -SIGNALWHITE -EXCITATIONBLACK

Capacity 30000 kg

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.017% IP68PROTECTIONRATING

CERTIFICATIONS

OIMLR60C4

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswiththeregulationsoftheRussianFederationforlegalfortradeuse

COMPLEMENTARY ACCESSORIES

DESCRIPTIONCODE

HardenedAISI420stainlesssteelaccessorycomposedby anti-rotationsystem,protectiverubberseal,2bases(upperand lower)and3self-centeringcylindricalplates.

DIMENSIONS (mm)

TECHNICAL FEATURES

Material17-4PHstainlesssteel

OIMLR60Accuracyclass•Verificationintervals Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

RatedoutputInputresistance

C4•4000 30000kg Emax/10000 ±0.017% IP68 2mV/V±0.1%800±30

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

Calibratedcurrentoutput

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN

Cores+EXCITATION +REF./SENSE

ManufacturedaccordingtoOIMLR60standards

Capacity from 50 kg to 500 kg

50-100kg:ALUMINUMALLOY(AVIONAL)

500kg:17-4PHSTAINLESSSTEEL COMBINEDERROR±0.05% IP65PROTECTIONRATING

COMPLEMENTARY ACCESSORIES

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII3GD (zone 2-22) (-)

DIMENSIONS (mm)

TECHNICAL FEATURES

MaterialAluminumalloy(Avional)17-4PHstainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin20minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

CablelengthSHIELD

Cablediameter+SIGNALGREEN

Cores+EXCITATION

ManufacturedaccordingtoOIMLR60standards

Capacity from 500 kg to 200000 kg

17-4PHSTAINLESSSTEEL BIDIRECTIONALTENSIONANDCOMPRESSION COMBINEDERROR±0.05%

PROTECTIONRATING:IP68(500-60000kg)-IP67(100000-200000kg)

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

OPTIONS ON REQUEST

DESCRIPTION

TworedundantstraingaugesWheatstonebridges(350)withtwooutputcables; fordualsafetysystems.

DIMENSIONS

Fortheloadcellfixingscrews(•),providethetighteningtorqueindicatedinthetable Screw Screwclass Tighteningtorque forcapacitiesof10000,30000,60000,150000,200000kgusescrewsofclass8.8orhigher

M8M16M24

6.8A2-708.8A2-806.8A2-708.8A2-806.8A2-708.8A2-80 15Nm20Nm120Nm160Nm400Nm550Nm

TECHNICAL FEATURES

Material17-4PHstainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

500-1000-2000-5000-10000-20000-30000-60000-100000-150000-200000kg

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

±0.05% IP68(500-60000kg),IP67(100000-200000kg) 2mV/V±0.3%700±20 0.005%°C700±5 0.005%°C±1% -20°C/+70°C>5000M

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

ManufacturedaccordingtoOIMLR60standards

Capacity from 10000 kg to 20000 kg

SPECIALSTEEL BIDIRECTIONALTENSIONANDCOMPRESSION COMBINEDERROR±0.1% IP67PROTECTIONRATING

CAPACITY

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

TECHNICAL FEATURES

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

ELECTRICAL CONNECTIONS

Capacity from 15 kg to 60 kg

AISI4140NICKELPLATEDSTEEL COMBINEDERROR±0.02% IP65PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

COMPLEMENTARY ACCESSORIES

DESCRIPTION

galvanizedC40 steelball-andsocketjointwithnut

Dimensions:Loadcellcapacity:

DIMENSIONS (mm)

MaterialAISI4140nickelplatedsteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

CablelengthSHIELD Cablediameter+SIGNALGREEN Cores+EXCITATIONRED -SIGNALWHITE -EXCITATIONBLACK

Capacity from 25 kg to 2500 kg

AISI4340NICKELPLATEDSTEEL COMBINEDERROR±0.02%(0.017%C4)

IP67PROTECTIONRATING

CERTIFICATIONS

OIMLR60C3

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

OIMLR60C4

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

FMHazLoc-ComplieswiththeUnitedStatesandCanadaregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

NTEP-ComplieswithUnitedStatesregulationsforlegalfortradeuse

COMPLEMENTARY ACCESSORIES

DIMENSIONS (mm)

DESCRIPTIONDIMENSIONSLOAD CELL CAPACITYCODE Ball-and-socketjointwithnut: stainlesssteel galvanizedC40steel

M12x1.75

M20x1.5 200-1000kg 2500kg EM-INOX

M8x1.25

M10x1.5

M12x1.75

M20x1.5 25kg 100kg 200-1000kg 2500kg EM

TECHNICAL FEATURES

MaterialAISI4340nickelplatedsteel

OIMLR60Accuracyclass•Verificationintervals

Nominalload(Emax)

Minimumverificationinterval(Vmin)

Combinederror

Protectionrating

-C3•3000C4•4000 25kg100-200-300kg 500-1000-2500kg 100-200-300kg 500-1000-2500kgEmax/10000 Emax/15000Emax/20000

±0.02%±0.02%±0.017%

IP67

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

2mV/V±0.2%350±3.5 0.0015%°C350±3.5 0.0017%°C±1% -10°C/+40°C>5000M -35°C/+65°C150% 0.03%300% 18V0.4mm

ELECTRICAL CONNECTIONS

CablelengthSHIELD

5m(25-300kg);10m(500-2500kg) 5mm 4x0.24mm2

Cablediameter+SIGNALGREEN Cores+EXCITATIONRED -SIGNALWHITE -EXCITATIONBLACK

ManufacturedaccordingtoOIMLR60standards

Capacity from 50 kg to 300 kg

AISI420STAINLESSSTEEL COMBINEDERROR±0.03% IP67PROTECTIONRATING

CERTIFICATIONS

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

CERTIFICATIONS ON REQUEST

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres

COMPLEMENTARY ACCESSORIES

DESCRIPTIONDIMENSIONSLOAD CELL CAPACITYCODE Ball-and-socketjointwithnut:

DIMENSIONS (mm)

stainlesssteel

galvanizedC40steel

M12x1.75

M16x2

M20x1.5

M24x2

M12x1.75

M16x2

M20x1.5

M24x2

50-500kg 1000kg 2500kg 5000kg EM-INOX

50-500kg 1000kg 2500kg 5000kg EM

MaterialAISI420stainlesssteel

Nominalload(Emax)

Combinederror

Protectionrating

RatedoutputInputresistance

TemperatureeffectonzeroOutputresistance

TemperatureeffectonspanZerobalance

CompensatedtemperaturerangeInsulationresistance

OperatingtemperaturerangeSafeoverload(%offullscale)

Creepatnominalloadin30minutesUltimateoverload(%offullscale)

MaxsupplyvoltagewithoutdamageDeflectionatnominalload

Capacity from 100 kg to 12500 kg

17-4PHSTAINLESSSTEEL COMBINEDERROR±0.02% IP68PROTECTIONRATING

CERTIFICATIONS

OIMLR60C3

ComplieswiththeEurasianCustomsUnionregulations

EquivalentoftheCEmarkingfortheUnitedKingdom

ComplieswithUnitedKingdomregulationsforlegalfortradeuse

CERTIFICATIONS ON REQUEST

Declarationofconformity+IP69Kmarkingprotectionrating

Water protection in case of high-pressure or steam jet cleaning (test: pressurized water is sprayed from a distance of max 150 mm)

Water pressure: 100 bar; temperature: 80 °C; test duration: 250 seconds (reference standard: DIN 40050-9)

Calibrationreport

LATAccrediacalibrationcertificateISO376orASTME74forcapacitiesfrom1000kgto10000kg

ATEXII1G2D (zone 0-1-2-21-22) (-)

IECEx (zone 0-1-2-20-21-22)

ComplieswiththeEurasianCustomsUnionregulationsforuseinpotentiallyexplosiveatmospheres

ComplieswithChinesemarketregulationsforuseinpotentiallyexplosiveatmospheres