This sustainability report was automatically translated from the German version.

If you have any questions about specific facts or data, please feel free to email us at sustainability@lasiesta.com

Table of contents

Not-For-ProfitInitiative SOCiLA

> page 34 Forest

> page

> page 14

04 Preface by the management 05 A product full of quality of life 09 Our strategy: a life in balance 12 Our aspiration: economic success through increased sustainability 13 Social corporate behavior 15 Ecological corporate behavior 16 Promoting sustainable consumer behavior 17 Healthy growth through value-based, fair business practices 18 Fair partnerships, transparent supply chains, and certifications 21 LA SIESTA on the path to sustainability 26 The year 2022 in numbers 27 Interview with Marcelo Zegarra, sustainability officer at LA SIESTA 28 At home in the world Value creation and global supply chains 29 1. Raw materials and pre-products 31 1.1 Textile materials 38 1.2 Non-textile materials 40 2. Processing and production 41 Production of Colombian hammocks in Medellín, Colombia 45 Production of Brazilian hammocks in Fortaleza, Brazil 46 Production of travel hammocks and children‘s products in India 47 Wood processing 47 Metal processing 48 Hanging systems 49 3. Transportation routes 51 4. Administration, marketing, sales, and shipping 53 Climate neutrality at LA SIESTA 55 Interview with Leon Krieger, Climate neutrality - how does it work, actually? 57 5. Product use and end-of-life phase 58 Interview with Jean-Christophe Meillan, creative director at LA SIESTA

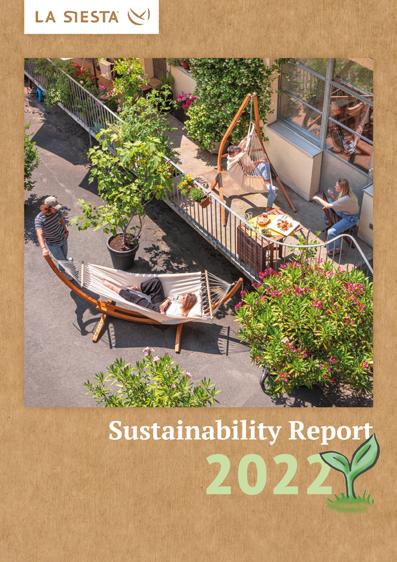

The CENTRO LA SIESTA in Fortaleza, Brazil

Conservation Project

Mataven, Colombia

in

54 3

Why are we writing this sustainability report?

We are aware that the future of our society as a whole, and specifically our company LA SIESTA, depends on our behavior towards people and the environment. We understand that a positive economic development can only be achieved in harmony with sustainability. This realization has driven us since the founding of the company and motivates us to constantly take new steps in the right direction. With this report, we establish a foundation for our ongoing sustainable development.

Our customer base plays a central role in this, as they are part of an enlightened and responsible society. Not least, their demands for quality, utility, environmental protection, and social responsibility motivate us to continually improve our products and question our entrepreneurial actions. This report provides transparency to the reader about the sustainability factors involved in the production and use of our products, as well as the questions and challenges that arise for us. As a company with a global value chain, we strive to contribute to positive development and serve as a role model.

To achieve this, we rely on the innovative power of our team and our partner companies, constantly working towards new insights. We understand sustainability as both a mindset and a continuous process that leads to ongoing improvement.

As we work on this report, many places in the world are facing profound crises: Russia‘s war against Ukraine has exacerbated the global energy problem, and drought and water scarcity prevail in numerous regions. All of this reinforces our commitment to placing sustainability even more at the center of our corporate culture. We aim to act faster and more consistently, and this report will also help us in that endeavor.

Preface by the management Sustainability is our path to the future.

4

Promotion of restful sleep

Space for shared experiences

Back preservation

Reduction of stress

A product full of quality of life

In a LA SIESTA hammock, sustainability is reflected in numerous facets. A hammock represents relaxation, well-being, and quality of life like no other product. It is a symbol of the balance between humans and nature, movement and relaxation.

The gentle sway in a hammock or hammock chair promotes healthy sitting, restful sleep, and provides active relaxation for both children and adults. It is no coincidence that LA SIESTA products are widely used in environments that prioritize the healthy development of children, such as kindergartens, schools, or occupational therapy.

5

Hammocks provide the perfect space to not only fleetingly experience the world but to pause and perceive oneself and nature with all the senses. They encompass many aspects of a sustainable lifestyle: health, open-mindedness, connection to nature, mindfulness, simplicity, and community. What started as restful idleness in a hammock has now become a philosophy of relaxation known as „hammocking.“ This philosophy is constantly present in our everyday work, and we are committed to actively contributing to its dissemination.

Children‘s products

Accessories

With our products, we enable the healthy use of hammocks in various areas of life. Not only during travel and in the garden but also at home, in children‘s rooms, living rooms, or offices. That‘s why it is important for us to develop hammocks that are neither short-lived lifestyle products nor expensive niche products but rather offer noticeably high quality at a fair price. Our stands and smart suspension systems make it easy to use hammocks and hammock chairs in nearly any imaginable location – and all of this with great convenience. 20 % 29 % 11

Spreader bar hammocks

Travel hammocks

% 7 % 23 % 8 % 2 %

Percentage of sold products (LA SIESTA, Chillounge) in 2022.

Hammock chairs Hammocks

Stands 7

We strive for sustainability throughout the entire product life cycle, from materials and production to distribution and consumer use. In the end-of-life phase, our goal is to generate as much benefit and as little harm as possible.

8

Our strategy A world in balance

Sustainability is ingrained in the DNA of our products and our brand.

As a responsible family business, we understand the interconnectedness of economic success and its socio-environmental impacts. Dorothee and Alexander Grisar founded the company in 1991 with the idea of bringing the positive and healthy lifestyle associated with hammocks to Germany. Even then, sustainability played a central role at LA SIESTA, influenced in part by the report „The Limits to Growth“ by the Club of Rome and the global ecology movement.

Today, LA SIESTA is led by the second generation, consisting of the brothers Maximilian, Leonid, and Cornelius Grisar. What was once a startup has now become a global market leader, with materials and final products manufactured in nine production facilities across six countries. In 2021, we sold a total of 158,000 products in over 50 countries worldwide.

During these stages of development, it has been particularly important for us to not lose sight of sustainability and continuously reduce the negative social and environmental impacts of our business practices. Therefore, we have embedded sustainability in our mission statement, which not only shapes our brand identity but also guides our actions:

„Great Hammocks for a Balanced Life“ is the vision that drives us every day. It is infused in our products and serves as a guiding force for our business development. Living a balanced life is also our promise to our customers, our team, our suppliers, society, and our planet, which we strive to leave as intact as possible for our children and grandchildren.

9

This promise can be summarized in the following values:

Social corporate behavior

Ecological corporate behavior

Sustainable and socially responsible consumer behavior

10

Sustainability and fairness

We take responsibility for everything we do and don‘t do. In doing so, we have a holistic view that encompasses our customers, the people working along the LA SIESTA value chain, and our planet. We aim to leverage new insights and the innovation power of our teams to continually reduce the negative impacts of our value chains on people and the environment. To achieve this, we collaborate with trust and fairness with our workforce, partner companies, NGOs, and institutions.

Quality and simplicity

Less product means more quality of life - this is the principle by which we develop our hammocks and hammock chairs. The end result is simple and well thought out, characterized by its appealing design, high quality, comfort, and durability. We strive to eliminate anything that does not have a positive impact on the product‘s usefulness or its social and environmental footprint. In this way, we reduce materials, energy, and labor, and minimize waste. In our everyday business operations, we aim to simplify processes, promote equal treatment, and demonstrate clear and conscious communication.

Health and balance

Our goal is to enable people to lead healthier and more balanced lives. We consider the balance between rest and movement, the individual and the community, our company and its employees, and people and the planet to be essential.

Openness and transformation

As an open-minded company with flat hierarchies, we embrace new developments and drive meaningful changes forward.

Mindfulness and togetherness

As a family business, we see mindfulness and community as two sides of the same coin. Both values shape our everyday business operations, as well as our behavior towards society and the environment, and are reflected in our products.

11

Our Aspiration Achieving economic success through sustainability

Our philosophy is expressed through overarching goals and principles that combine healthy growth and sustainability in a future-oriented economic approach.

We align ourselves with the 17 Sustainable Development Goals (SDGs) of the United Nations:

12

Social corporate behavior

As an open-minded and diverse family business, we aim to provide people with safe, healthy, and fair workplaces and promote a partnership-based approach.

In selecting our supplier companies, we prioritize fair compensation, labor rights, employee participation, and gender equality.

SDG#5: Gender equality

SDG#8: Decent work and economic growth

SDG#10: Reduced inequalities

We seek to promote traditional production techniques in the countries of origin and actively contribute to their development.

SDG#1: No poverty

SDG#2: Zero hunger

SDG#8: Decent work and economic growth

SDG#9: Industry, innovation and infrastructure

We strive to further advance diversity and equality within our own company and among our partner companies.

SDG#5: Gender equality

SDG#10: Reduced inequalities

We support and empower our employees, fostering initiative and delegating responsibility.

SDG#8: Decent work and economic growth

We promote non-violent, open, and non-hierarchical communication.

SDG#8: Decent work and economic growth

SDG#16: Peace, justice and strong institutions

We support social projects such as the Centro LA SIESTA in Brazil.

13

CENTRO LA SIESTA

At first glance, Fortaleza in northeastern Brazil is a dream come true with its sun, beach, and sea. However, behind the beach promenades and leisurely strolls, the reality is different: poverty, domestic violence, and drugs are prevalent.

Since 2014, we have been working with José Expedito de Moura and the non-profit organization „Tor zur Hoffnung e.V.“ (Gateway to Hope) to open up opportunities for children from the Graviola favela in Fortaleza. At CENTRO LA SIESTA, they are taught values such as respect, diligence, and reliability.

CENTRO LA SIESTA is based on three pillars: sports, culture, and education, and it currently helps 85 children between the ages of 5 and 18 to have a better start in life.

Sports

At the centrally located beach promenade Praia de Iracema, Dito teaches children and teenagers beach soccer and beach volleyball every evening. Besides learning the skills of the sport, team sports teach them important values such as fairness, respect, and teamwork.

Culture

Additional activities such as board games, painting, and drawing lessons are offered. This allows less sports-oriented children to engage in enjoyable and meaningful activities and discover their talents. With the gradual expansion of CENTRO LA SIESTA, additional creative offerings will be created.

Education

Enrolled students receive extracurricular support at CENTRO LA SIESTA. In addition to practical homework assistance, they also have access to a small library. If needed, the children are provided with school notebooks, pens, and other supplies.

www.torzurhoffnung.de

facebook.com/centrolasiesta.ditoescolinha

instagram.com/ditobeach

Ecological business practices

Respectful and mindful treatment of our environment is at the core of our business operations. Central to the development of our products and value chains is the reduction of our ecological footprint and our consumption of natural resources.

We strive for carbon neutrality for all products, company locations, and value chains. In 2022, we took the first step by certifying our products from Colombia, our website, and our German headquarters as carbon neutral.

SDG#12: Responsible consumption and production

SDG#13: Climate action

Ultimately, we aim to use sustainable materials or materials from the circular economy for the production of all our products. Since 2022, we have discontinued the use of conventional cotton. Additionally, we exclusively use FSC®-certified wood.

SDG#12: Responsible consumption and production

SDG#13: Climate action

We have set the goal of establishing more transparent supply chains.

SDG#12: Responsible consumption and production

We encourage local stakeholders in Latin America to cultivate organic cotton and actively support them in doing so.

SDG#12: Responsible consumption and production

SDG#13: Climate action

SDG#17: Partnerships for the goals

We encourage our partner companies to adopt modern production processes that consume less energy and have a lower impact on natural cycles.

SDG#9: Industry, innovation and infrastructure

SDG#13: Climate action

We aim to reduce our water consumption, for example, through the use of organic cotton.

SDG#14: Life below water

SDG#15: Life on land

We promote and utilize the principles of the circular economy.

SDG#9: Industry, innovation and infrastructure

SDG#12: Responsible consumption and production

We support the transition to sustainable mobility through incentives within our own company and by transitioning to electric mobility.

SDG#13: Climate action

We prioritize shipping as the mode of transportation to avoid air transport in our logistics.

SDG#13: Climate action

15

Promoting sustainable consumption behavior

Our goal is to promote sustainable consumption behavior through our products. It is the desires and expectations of our customers that drive us in terms of sustainability.

We aim to develop high-quality, sustainable products for a wide range of customers and sell them at fair prices.

SDG#8: Decent work and economic growth

SDG#9: Industry, innovation and infrastructure

SDG#12: Responsible consumption and production

We design products that enhance well-being, provide high comfort, and support health. For this purpose, we collaborate with occupational therapists, for example.

SDG#3: Good health and well-being

SDG#12: Responsible consumption and production

We develop our products with a focus on long service life and promote durability through tips on maintenance and handling.

SDG#12: Responsible consumption and production

61 % of the materials we use in our products come from natural, renewable resources. We plan to further increase this proportion.

SDG#9: Industry, innovation and infrastructure

SDG#12: Responsible consumption and production

SDG#13: Climate action

We minimize the use of packaging as much as possible.

SDG#12: Responsible consumption and production

16

Healthy growth through values-based and fair business practices

Long-term economic thinking and values-based actions are important to us. Healthy growth for us always involves a balance between risk and benefit, between our values and market developments. In this process of weighing options, we consider the interests of our stakeholders as well as the environmental and social impacts of our actions.

Therefore, in recent years, we have successfully advanced the marketing of hammocks, particularly hammock chairs, for indoor use in the living area. We plan to continue pursuing this strategy in the future to achieve a more season-independent and stable business development, both for our company and our manufacturing partners.

To achieve healthy, values-based, and economically sustainable growth, we focus on the following factors:

• Meaningful product innovations (beneficial for people and the environment; e.g., organic cotton, ergonomic products, smart fastening systems)

• Expansion of usage and exploration of new lifestyles (e.g., indoor hammocks for the living area)

• Reduction of seasonal dependence

• Expansion into new markets and target groups

• Good partnerships

• Long-term financial independence

One particular economic challenge in recent decades has been the perception and marketing of hammocks as seasonal items for the garden season. As a result, both our company and our manufacturing partner companies experience significant fluctuations in capacity utilization throughout the year.

SDG#8: Decent work and economic growth

SDG#9: Industry, innovation and infrastructure

SDG#12: Responsible consumption and production

17

Fair partnerships, transparent supply chains, and certifications

We are privileged to collaborate with the world‘s best hammock manufacturers. Our supplier companies share common values and a sense of responsibility for people and nature.

We engage in responsible procurement. In collaboration with our suppliers, we source raw materials with consideration for social and environmental criteria. Alongside reliable supply of raw materials, technical goods, and services at competitive prices, our collaboration emphasizes shared value creation.

We place great importance on fair and long-term partnerships. In selecting our partner companies, we consider not only their professional qualifications, but also social aspects such as fair employee compensation, fair treatment, equal opportunities, and environmental factors. In partnerships, we see ourselves as drivers of sustainable transformation. We collaborate with NGOs such as GOTS and FSC® to work towards this goal. Certifications provide us and our customers with confidence regarding the origin, manufacturing processes, and materials used in our products.

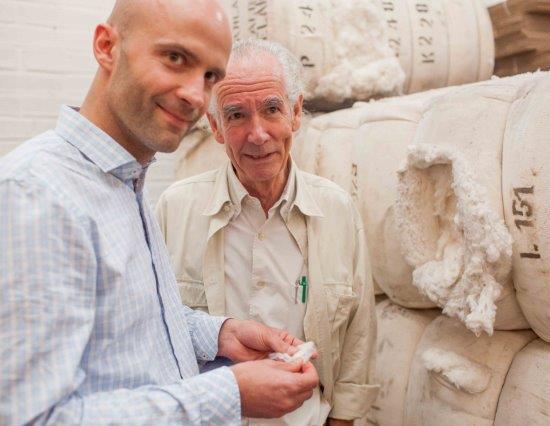

Our most important partner company, which generates approximately 50% of our total revenue, is Fatelares in Medellín, Colombia. As a result of our efforts, Fatelares became GOTS certified in 2014 through an extensive process. LA SIESTA became the world‘s first hammock brand to achieve GOTS certification, and Fatelares became the first company in Colombia to receive this certification. We also aim to promote the certification model with our other manufacturing partner companies.

Currently, we are working with Fatelares and other partner companies on the development of yarns made from recycled PET.

In addition, Climate Partner accompanies us on the path to carbon neutrality. In 2022, we successfully achieved carbon neutrality certification for our Colombian product range, our headquarters in Jugenheim, Germany, and our website.

SDG#17: Partnerships for the goals

18

GOTS

The Global Organic Textile Standard

GOTS (Global Organic Textile Standard) is the leading certification for sustainable textile production. This standard covers processing, manufacturing, labeling, packaging, and the trade and distribution of textiles made from at least 70% organically produced natural fibers. For GOTS-certified products in the „kbA/kbT - organic“ label category, at least 95% of the fiber material must come from certified organic agriculture that complies with the IFOAM (International Federation of Organic Agriculture Movements) Basic Standard.

All chemical additives, such as dyes and auxiliaries, must meet specific environmental and toxicological criteria. The handling of wastewater and waste is also strictly regulated within the GOTS certification.

Website of GOTS: www.global-standard.org/de

Certification proof: https://media.lasiesta.com/download/certificate/18-Cert-GOTS-V5-DE-LA-SIESTA-GMBH.pdf

19

FSC®

Responsible forest management

FSC® stands for Forest Stewardship Council®, which is the primary international institution for assessing environmentally and socially responsible forest management and wood processing.

The FSC® standards are based on 10 principles and 56 indicators. Forests that are managed according to these criteria can be certified by FSC®. LA SIESTA began the transition to FSC®-certified wood in 2008 and has steadily increased the proportion of certified wood. Today, our wooden stands as well as the bars of our hammock chairs and spreader bars carry the FSC® seal. They are marked with an FSC® tracking code that allows the origin of the product to be traced. Additionally, the wood species used and the type of certification can be verified.

Website of FSC®: www.fsc.org/en

Certification proof: https://media.lasiesta.com/download/certificate/FSC_Certificate.pdf

Platform of FSC® product trackings: www.connect.fsc.org/fsc-public-certificate-search

20

On the path to sustainability

2006

The Yayita baby hammock becomes LA SIESTA‘s first product made from organic cotton.

2008

Transition to FSC®-

21

2009

LA SIESTA launches the SOCiLA initiative to promote the cultivation of organic cotton.

2019

The Joki and Moki children‘s products are now made from organic cotton.

2009

The first line of hammocks and hammock chairs made from organic cotton is introduced: Casera

22

2010

LA SIESTA introduces the patented Rollitos a sustainable packag ing solution.

2014

The world‘s first GOTS-certified hammock is produced.

2014

The CENTRO LA SIESTA in Fortaleza, Brazil, is established.

2014

Fatelares becomes the first GOTS-certified hammock factory in South America.

23

2021

All hammock chairs are GOTS-certified.

2022

Products, locations, and website are certified as climate-neutral.

2022

LA SIESTA appoints Marcelo Zegarra as its first sustainability officer.

24

2022

All cotton products are exclusively made from organic cotton.

2023

LA SIESTA publishes its first sustainability report.

25

The year 2022 in numbers

By switching to organic cotton, LA SIESTA saved 782,977,417 liters of water, which is equivalent to the annual water consumption of 17,440 people.

48 % of textile products are made from renewable resources

75 % of products made from organic cotton are GOTS certified.

100 % of wood products and components are FSC certified

LA SIESTA manufactures its products in 9 production facilities across 6 countries and sells them in over 50 countries.

LA SIESTA sold 181,654 products and generated a revenue of 9.1 million euros.

26

Interview with Marcelo Zegarra, Sustainability Officer at LA SIESTA

When did your interest in sustainability begin?

My interest in sustainability started at home. These values were instilled in me by my parents. An exam ple of this is the ability to create something with lim ited resources while respecting the environment. In school, I was appointed as an environmentalist by the mayor of the city after organizing a large cleaning campaign for our school grounds and nearby play grounds. This gave me the opportunity to be a role model for other young people in society. Later, in uni versity, I learned that in professional life, one can be an agent of change, and I see it as the best way to drive sustainable change.

What motivates you to drive the sustainability agenda?

At LA SIESTA, I was given the opportunity to work on this topic, and I gladly take on this responsibility for four reasons that also serve as my motivation:

1. I identify with the values and vision of the company and have a strong affinity for the products we offer.

2. Due to my position in the company, I feel responsible not only for the materials and products but also for the people in our production facilities and their families. It particularly motivates me to carry the message of LA SIESTA to our production facilities, to be the driving force and role model for sustainable development.

3. Knowing that the entire team and all areas of the company are strongly involved in sustainability and that everyone is making their contribution excites me.

4. Last but not least, it motivates me to know that in my position, I can make changes that contribute to the sustainability of the company in all its aspects. It doesn‘t matter how small these changes are, as long as they represent a step in the right direction.

What are your expectations regarding sustainability in your personal and professional context?

I want to be a positive role model for my family and friends. In my professional position, I want to contribute to LA SIESTA being recognized not only for the quality and beauty of its products but also for their sustainability and positive impact on the community. Our motto, „great hammocks for a balanced life,“ reflects this goal. I hope that we can achieve a perfect balance between the three pillars of sustainability (social, economic, and environmental) and that our products are fair to everyone involved in the production and marketing process. Our hammocks and hanging chairs should provide consumers with a high-quality and relaxing product experience while being sustainable in ecological and social aspects.

27

Value Creation: At home in the world

Why LA SIESTA Relies on Global Supply Chains

It was not only the love for hammocks from Latin America but also the collaboration with the people living there that inspired us to establish the company LA SIESTA. This global orientation presents both significant opportunities and a multitude of ecological, economic, and social challenges.

To assess the fundamental impacts of our actions, we need to examine the following parts of our value chains in detail:

1. Raw materials and pre-products

2. Processing and production

3. Transportation routes

4. Distribution and shipping

5. Product usage and end-of-life phase

Raw materials and pre-products on their journey

28

1. Raw Materials and Pre-Products

For our products, we process a limited range of materials. Textile materials such as cotton (exclusively sourced from GOTS-certified organic farming since 2022), polypropylene, and nylon account for 60% of the materials used. Additionally, we use 40% non-textile materials, including wood (FSC®-certified), metals, polyester, and polyamide. 51.2% of our overall material mix consists of renewable resources (measured by sales volume in 2021). Let‘s take a closer look at the primary materials we use.

Percentage of individual raw materials in sales in 2022:

textile materials

29

non-textile materials 59 % 41 %

Textile materials:

GOTS-certified organic cotton

5% Conventional cotton

Organic Cotton

Non-textile materials:

bamboo

steel

2% stainless steel

glass fiber-reinforced polyamide 36

4% birch

2% pine

5% metal

1% aluminium

Siberian larch

34

9

12

38

3% polyamide polyester polypropylene 1% viscose

%

%

%

%

23 % 10 % 15 % 30

%

1.1 Textile materials

Textile materials account for 60% of our sales and 62% of our sold products. Our main material is cotton, and since 2022, we have focused exclusively on GOTS-certified organic cotton. Additionally, we use polypropylene for our products, as well as small amounts of other plastics such as polyamide, polyester, and viscose.

Percentage of individual raw materials in processed quantity (kg) in 2022:

4,7 % viscose

GOTS-certified organic cotton

conventional cotton

organic cotton

1,9%

51,9 % of the textile materials consist of renewable resources.

In 2022, 60 % of them were GOTS-certified.

51,9 %

polyamide polyester polypropylene

17,7

28,4

0,1 % polyurethane 31,2 % 10,3 %

%

% 5,7 %

31

Organic Cotton

From our perspective, cotton is the ideal material for our hammocks as it fully meets our quality standards in terms of comfort, texture, aesthetic appeal, functionality, and durability. However, cotton cultivation requires a significant amount of water and land.

Water consumption

12,703 liters

consumption

955 liters

By switching to organic cotton, the use of water is reduced by 11,748 liters per Habana Volcano Basic hammock compared to conventional cultivation. This is equivalent to the monthly water consumption of three people.

Calculation:

11,000 liters per kg of cotton cultivation (90% less for organic cotton) - 76.36 liters per kg for dyeing - 12% water reuse.

In 2022, we processed 90 tons of cotton. Of this, 66% was GOTS-certified organic cotton and 22% was non-certified organic cotton. Cotton products accounted for 47.1% of our textile sales in 2022. Since 2022, we exclusively use GOTS-certified organic cotton from Turkey and India in our cotton products.

Good to know

In conventional cotton farming, up to 11,000 liters of water are required to produce 1 kg of cotton. Less than half of this water amount is actually absorbed by the plants, while the rest evaporates or seeps into leaky channels. These socalled „thirsty crops“ have therefore become a focus of the work of the World Wildlife Fund (WWF).

for conventional cotton per hammock chair

32

Water

for organic cotton per hammock chair

The cultivation of organic cotton requires up to 90% less water than conventional cotton cultivation. By transitioning to organic cotton, we have saved approximately 783 million liters of water and 79.1 hectares of land, which is equivalent to 110 football fields, based on the annual volume of cotton processed.

The harvested organic cotton is processed into yarn on-site and shipped untreated to our production facilities in Medellín (Colombia) and Fortaleza (Brazil). Transporting yarns has the advantage that they do not need to be fumigated like unprocessed cotton fibers and they have a significantly lower transport volume. However, shipping organic cotton still has an impact on the climate (see transportation routes).

Our goal:

Using organic cotton from Latin America

Since 2008, LA SIESTA founder and partner Alexander Grisar has been driving the cultivation of organic cotton in Colombia through the non-profit initiative Socila („Support Organic Cotton in Latin America“). In 2015, the first organic cotton resulting from this initiative was harvested. In 2016, we were able to produce 235 anniversary hammocks „Aniversario“ made from Colombian organic cotton in our partner company Fatelares. Cotton cultivation in Colombia is now supported by the local government. Unfortunately, the support does not differentiate between organic and conventional cultivation.

33

SOCiLA, an initiative supported by LA SIESTA, is dedicated to promoting the sustainable cultivation of organic cotton. It was founded by Alexander Grisar, the founder of LA SIESTA.

The idea

The idea for SOCiLA came to Alexander Grisar in 2008 when he stepped back from the management of LA SIESTA. At that time, he had already introduced or-

However, when he wanted to have them produced in Colombia, he discovered that organic cotton was not being grown there. To manufacture the hammocks, he

34

The mission

Alexander Grisar took on the challenge of raising awareness about the ecological and economic prospects of organic cotton in Latin America. He advises farmers, industrial companies, interest groups, and governments on project development. He also assists them in obtaining the necessary expertise and financial resources from development aid organizations and brands.

Projects

SOCiLA has primarily focused on Colombia, the country where LA SIESTA produces more than half of its hammocks. Since 2009, Alexander Grisar has visited Colombia two to three times a year for SOCiLA. Initial experimental cultivation has already been conducted, laying the foundation for commercial organic cotton farming in the country.

Visit the website of SOCiLA: www.socila.eu

More about organic cotton: www.fairlyfab.com/de-DE/magazin/baumwolle-vs-bio-baumwolle

35

Polypropylene

Percentage of traditional hammocks from Colombia made of PP and organic cotton in 2022

For our outdoor hammocks, hammock chairs, and cushion covers, we use polypropylene, which is significantly more durable than organic cotton when subjected to intensive outdoor use.

The polypropylene is extruded into yarn in Bogotá, Colombia, and transported by truck to Medellín, located 412 km away. Since the color pigments are already present in the polypropylene yarn, the subsequent production steps do not require dyeing.

Our goal:

Sustainable material alternatives

The sales of outdoor hammocks made of polypropylene have significantly increased in recent years. The percentage of polypropylene in the textile material mix more than doubled from 17.3% in 2017 to 28.4% in 2022. In 2022, we processed 54 tons of polypropylene.

Polypropylene is non-toxic and skin-friendly, as it does not contain plasticizers or other additives suspected to be carcinogenic. Additionally, polypropylene can be recycled excellently and almost endlessly, being transformed into various different products. These characteristics have earned polypropylene a reputation for being environmentally friendly.

However, the production of the base material „propene,“ derived from petroleum and natural gas, is highly energy-intensive and generates large amounts of greenhouse gases. Like all plastics, polypropylene also causes long-term environmental damage as it mostly ends up in oceans or nature at the end of its life cycle. Although this issue can be reduced through efficient recycling processes, it cannot be completely prevented, as non-biodegradable plastic particles, known as microplastics, enter the environment during the use of textile plastics.

The use of native polypropylene is therefore a transitional solution for LA SIESTA to serve the market for robust outdoor hammocks. In the medium term, we aim to find more sustainable alternatives.

44 % 50 % Organic-Cotton (GOTS-certified)

5% conventional cotton

36

1% polyester polypropylene

Together with our Colombian partner company Fatelares and other external partners, we are working on developing suitable yarns made from recycled PET (Polyethylene terephthalate), a plastic from the polyester family, well-known for its use in beverage bottles. We produced initial hammock samples from this material at the end of 2021. Our goal is to offer a series of samples made from recycled PET by 2024. A successful market launch of PET hammocks would be a significant step towards a circular economy for us and our Colombian partner companies.

As described above, non-biodegradable plastic particles also enter the environment during the use phase of the hammock, such as during washing. For this reason, we are evaluating the use of additives that make the polyester biodegradable.

A hammock made from PET bottles

Additional textile plastics

In addition to polypropylene, we also use polyamide and polyester. Polyamide is used for our travel hammocks, while polyester is mainly used for our pillow fillings and padding. Polyamide accounts for 1.5% and polyester for 7.1% of our total sales. The shares of both materials in the material mix have decreased over the past 5 years.

Polyester and polyamide, like polypropylene, are products of the petrochemical industry, and their production requires a significant amount of energy and results in high CO2 emissions.

37

Therefore, we are also seeking sustainable alternatives for these materials.

1.2 Non-textile materials

Non-textile materials are primarily used at LA SIESTA for stands and suspension systems. They are also used in small quantities in the production of hammocks and hammock chairs.

Proportion of non-textile materials in the processed total quantity (kg) in 2022

0,14% aluminium

7,44 %

steel

0,67 % stainless steel

3,32 % polyamide (glass fiber-reinforced )

0,49 % polyamide (plastics)

0,12% nylon

6,01% metal

23,71 %

bamboo (FSC®-certified)

2,54 % birch (FSC®-certified)

0,23 % spruce (FSC®-certified)

1,19 % pine (FSC®-certified)

54,14 %

Sibirian larch (FSC®-certified)

65,5 %

65.5% of the non-textile materials consist of renewable resources such as wood and bamboo.

38

Wood and bamboo

We use bamboo from China for the spreader bars of our hammock chairs and spreader bar hammocks. For the Elipso and Calma stands, we process larch wood from Siberia.* Stands are experiencing the highest demand growth in the LA SIESTA product range, and wood is a trending material. However, forests worldwide are exposed to the impacts of climate change. Bamboo offers significant advantages in this regard: it is a grass that can be harvested after only 4 years, which is much faster than wood, which requires harvesting after 15 to 20 years. Our processed wood and bamboo materials come exclusively from FSC®-certified sources.

Metal

We mainly use metal for the production of our frames „Mediterráno,“ „Nautico,“ and „Romano,“ as well as for our fastening elements such as swivels and chains. The processed metals mainly come from production facilities in China. Metal offers functional and price advantages for frames. However, its production is energy-intensive and results in high CO2 emissions.

Polyamide (suspension systems)

We use polyamide and polyester for the ropes of our smart suspension systems. Both materials are products of the petrochemical industry, and their production requires a significant amount of energy and results in high CO2 emissions.

39

* FSC® has terminated its collaboration with Russia due to the war against Ukraine. Therefore, we have not been using larch wood from Siberia since mid-2022.

2. Processing and Production

Percentage of products (sales quantity) by country of manufacture in the year 2022.

50,4 % 11,8 % 23,2 % 12,5 % Germany India China 1,5% Italy 0,6% Brazil Colombia

40

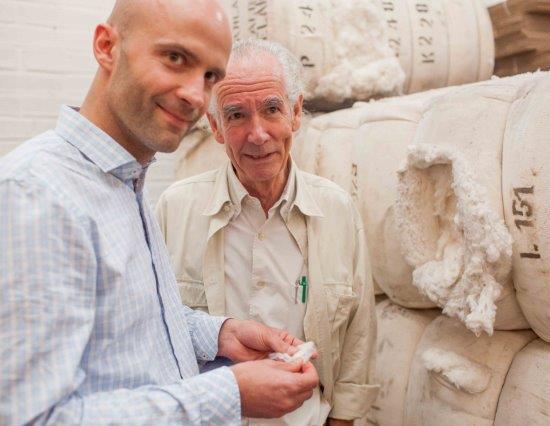

Production of Colombian hammocks in Medellín, Colombia

Production of Colombian hammocks in Medellín, Colombia

We have our classic hammocks made from organic cotton and polypropylene at our long-standing partner company, Fatelares, in Medellín, Colombia. Fatelares is known for its high-quality standards and is committed to continuously reducing its environmental impact through the introduction of new technologies and processes. Social corporate policies also hold great importance at Fatelares. In addition to fair wages, the company provides a company doctor, health programs, and a library for its employees.

In the administration of Fatelares, 47% of the workforce are women, who in most cases support their families with this income. There is a strong sense of identification with the company and with LA SIESTA as the contracting company at Fatelares. 25% of the employees have been with the company for more than 20 years, 23% have been employed for 10 to 20 years, and 41% have been part of the team for 5 to 10 years.

handmade wit h l o ev

Processing steps at Fatelares

Products made from organic cotton

Products made from polypropylene

Warping

Receipt of raw materials and quality control

Twisting

1 1

4 2

5 3

6 4 42

Weaving

2 Dyeing 3 Packaging and labeling 8 6 7 5 handmade wit h l o ev 43

Thread winding

In Colombia in general, and Medellín in particular, strict laws regarding social and environmental standards are in place and closely monitored.

Good to know

Medellín was included in the Green City Index in 2012. According to the Latin American Green City Index published by Siemens, Medellín currently contributes approximately 11% to Colombia‘s GDP. Among the seventeen cities in the index, its residents produce the lowest amount of waste per capita. Medellín also has the „longest mass transit network, the best wastewater treatment rate, and the highest percentage of people with access to sanitation facilities“ in its income class compared to other cities. The index also highlighted „green initiatives,“ including measures to improve water infrastructure, drastic actions to reduce traffic congestion and control, and the Integral Urban Project, which focuses on development efforts in low-income areas.

Furthermore, Fatelares has been GOTS certified since 2014, a certification that LA SIESTA has actively promoted. We aim to continue using our positive influence to drive social and environmental improvements at Fatelares, such as the use of renewable energy or the implementation of recycling systems.

The essential processing steps for LA SIESTA hammocks at Fatelares include dyeing, weaving, sewing, braiding the traditional Cadejos, and finishing. Dyeing the organic cotton fibers requires a significant amount of water and energy. As part of a project, Fatelares installed a new facility at the end of 2018 to significantly reduce both water and energy consumption. The water used in the dyeing process is intended to be recycled in a closed-loop system. The goal is to reuse 50% of the water used by 2025.

44

Production of Brazilian hammocks in Fortaleza, Brazil

In Brazil, we have our traditional hammocks made from organic cotton in Fortaleza. The manufacturing processes of our partner company there are based on an artisanal value chain that has evolved over the years. Many of the work steps are carried out by dif ferent suppliers, including several families.

In Fortaleza, our Brazilian Bossanova hammock is sewn together from several components that are meticulously crafted in different locations. The lying

45

Production of travel hammocks and children‘s products in India

In India, we have our hammocks from the travel category, mainly made through sewing. This includes our nylon travel hammocks, polypropylene hammocks, and GOTS-certified organic cotton children‘s products. The manufacturing company in India, like Fatelares in Colombia, is also GOTS certified.

As the client, LA SIESTA determines the design of the products and the requirements for the materials and quality of craftsmanship, while the manufacturing company is responsible for independently sourcing those materials. Therefore, we have less insight into the procurement process compared to our partner companies in Colombia and Brazil.

46

Wood processing

The wood is processed in China to make our Elipso and Calma stands. It is sawed, glued, bent, oiled, and assembled there. The spreader bars for our hammock chairs and hammocks are made from bamboo. The bamboo poles are first cut into small strips, then bonded under pressure to form rods, and further processed afterwards.

The mentioned products have high quality, and the raw materials used come from FSC®-controlled sources.

When evaluating our suppliers in Asia, we rely on BSCI reports (Business Social Compliance Initiative). These reports assess social, labor, and environmental criteria.

We actively monitor the development of our supplying companies to provide them with support and are pleased with the positive changes seen in the last three years.

Metal processing

The majority of metal is processed in China to make our metal frames. These frames are bent and powder coated.

A smaller percentage is used for the production of small parts such as swivels, hooks, and chains. These parts are mostly cast and then galvanized. The extraction, manufacturing, and processing of metals are not only highly energy- and resource-intensive but also result in significant negative environmental impacts throughout the entire value chain (source: Umwelt Bundesamt - German Environment Agency).

The companies in China that produce our frames are selected by us based on the criteria of the Business Social Compliance Initiative (BSCI).

47

Suspension systems

We have our smart suspension systems manufactured locally by ITM-Kunststofftechnik in Bad Kreuznach. The product, made of glass-fiber reinforced polyamide, is produced using the injection molding process. The specially developed plastic solutions offer significant advantages in terms of weight and energy consumption compared to metal solutions. We also source the polyester ropes locally from Liros in Upper Franconia.

48

3. Transportation routes

One major challenge in our global supply chain is transportation routes. Currently, we are still in the early stages of collecting and processing the necessary data for evaluation. Therefore, we would like to illustrate the topic using the example of a Habana hammock chair:

The organic cotton we process in Medellín, Colombia, comes from Turkey and India. It is initially spun into yarn in those countries, reducing the transportation volume and eliminating the need for fumigation. Raw cotton needs protection against pests and mold, which is typically done through fumigation of shipping containers. However, this process is harmful to health and the environment, so we do not engage in it.

For example, the yarn from Nhava Sheva Port in India is transported 18,110 km by ship and 471 km by truck to the production facility in Medellín. From Izmir Port in Turkey, the yarn is shipped 9,332 km by sea and 658 km by truck to Medellín.

The spreader bars made of FSC®-certified bamboo in China travel 18,066 km by sea from Shenzhen Port to Medellín, followed by 471 km by truck.

Similarly, the swivel hooks, also manufactured in China, are shipped 16,398 km by sea from Qingdao Port to Medellín and then transported an additional 471 km by truck.

Transportation routes of raw materials and intermediate products:

49

In total, in 2022, we shipped seven containers of materials and accessory products to our manufacturing companies in Medellín, China, India, and Turkey via sea freight and truck. These seven containers covered a total of 124,971 km by sea and 3,297 km by truck, resulting in a CO2 emission of 12.04 tons.

Our finished products are exclusively shipped to our warehouses and distribution partners via sea, rail, and road transport. We completely avoid using air freight for transportation.

When shipping to our end customers, we collaborate with climate-neutral partner companies whenever possible. This ensures that the emissions generated during the shipping process are offset or neutralized through various sustainability initiatives.

52.574 km

236 grams

18.110 km 471 km 471 km 471 km 18.066 km 16.398 km

Yarn (organic cotton) 1,69 kg

Bar (bamboo) 0,80 kg

155

73

8

Swivel hooks (stainless steel) 0,10 kg

g

g

g

50

4. Administration, Marketing, Sales, and Shipping

In Jugenheim, we utilize photovoltaic systems to generate electricity, and we provide our employees with the opportunity to charge their electric vehicles, making the transition to renewable transportation easier.

Additionally, we provide our team with JobBikes (company bicycles) as part of a meaningful and flexible home office policy, contributing to a reduction in CO2 emissions resulting from commuting. These commuting emissions constitute the majority of emissions at our German location.

At our headquarters in Jugenheim, located in the Rheinhessen region of Germany, we bring together the departments of product design, marketing, sales, and administration. These diverse tasks are handled by a team of 35 individuals from over 10 different nations.

Our products are sold through approximately 500 distributors worldwide and via our own website. In 2022, we sold a total of 181,654 products to customers in over 50 countries around the world, with 36.5% of the revenue coming from B2C sales.

15.542,48 kg CO2 saved 22.203,54 kWh generated 13.861,2 kWh delivered 8.920,89 kWh consumed 10.353 kWh procured 51

In 2022, 100% of our electricity consumption was covered by photovoltaic systems.

Employee commuting distances in 2022 from Jugenheim (headquarters) and Bingen (logistics center)

Distance traveled in km

CO2 savings in kg compared to car usage

CO2 emissions in kg

LA SIESTA supports the transition to electric mobility through initiatives such as charging stations and programs like JobRad, which promotes the use of bicycles for commuting.

Electric

Bicycle/walking

41.905 Kg 19 Kg 39 Kg 670 Kg 3.495 Kg 169 Kg 3.334 km 7.828 km 798 km 5.146 km 62.695 km 258 km 515 Kg 133 Kg 2.769 Kg 1.737 Kg 2.059 Kg Source: ClimatePartner

E-bike

car

Car Public transportation Train

52

Climate neutrality at LA SIESTA

Since 2022, our products from Colombia, our headquarters in Jugenheim, and our website have been climate-neutral.

Our goal:

Achieve climate neutrality for as many products as possible through significant CO2 reductions.

To be considered climate-neutral, companies, products, or processes should have no negative impact on the climate. This is primarily achieved through emission reduction measures and continuous optimization of climate protection initiatives within an organization and its network. However, it is not always possible to completely avoid emissions. In such cases, these emissions can be offset through internationally recognized climate protection projects.

Since the location of emission offsetting does not affect the overall CO2 balance, German companies can make their compensation contributions in other countries around the world.

LA SIESTA offsets a total of 1504.3 metric tons of CO2 through ClimatePartner, a provider of climate protection solutions. The selected offset project focuses on forest conservation in Mataven, Colombia.

53

BACKGROUND

Forest Conservation Project in Mataven, Colombia

Forests store large amounts of greenhouse gases, making them crucial in mitigating climate change. Additionally, forests support diverse ecosystems and serve as a vital resource for communities worldwide. However, factors such as illegal logging and resource extraction are leading to deforestation and a reduction in forested areas globally. To counter this problem, forest conservation projects aim to preserve forests for the long term. In Mataven, 1,150,200 hectares of tropical rainforest and its biodiversity are already protected, with LA SIESTA contributing to the conservation of 476.26 hectares. The initiative not only focuses on environmental sustainability but also implements measures to ensure food security, improve access to education for children, and promote health. The goal is to drive long-term change towards sustainable economic practices and nature conservation.

54

Climate neutrality –How does it work?

Leon Krieger, who has been part of the LA SIESTA team since 2018 and leads the Climate Neutrality project, explains what it means for LA SIESTA in an interview with Elena Gaber.

The concept of climate neutrality can encompass various aspects. In which dimensions is LA SIESTA currently implementing climate neutrality?

Leon: First and foremost, we focus on reducing emissions in our manufacturing, shipping, and office operations. All unavoidable emissions are measured and offset through a forest conservation project in collaboration with ClimatePartner, a provider of climate protection solutions. In our case, the offsets include emissions from our Colombian product range, including production and shipping, our headquarters in Jugenheim, and the use and operation of our website.

Various data serve as the basis for carbon offsetting. What are these data, and how are emissions measured?

Leon: In the case of location-based offsetting, such as for our office spaces in Jugenheim, the most important data include energy consumption and commuting. Additionally, we measure the amount of office supplies used and the fuel consumption for business trips and company vehicles. In the production of our Colombian hammocks and hanging chairs, emissions are attributed to factors such as material usage, transportation, and energy consumption during the production process.

55

And which type of emissions account for the largest share at LA SIESTA?

Leon: A significant portion of LA SIESTA‘s emissions from production is attributed to materials and their manufacturing, accounting for 70-75%. At the Jugenheim location, around 80% of the emissions are due to employee commuting.

LA SIESTA has chosen the compensation project in Mataven, Colombia. Why was this project selected?

Leon: When selecting the project, it was important for us to offset our emissions where they occur. Since we initially focused on our Colombian products, a project in Colombia was ideal for us. We were also impressed by the project‘s holistic approach to sustainability, contributing to a total of eight out of the 17 Sustainable Development Goals (SDGs), not only focusing on environmental sustainability. The project includes training and education programs, providing food for the elderly, strengthening local institutions, and more.

Does climate neutrality bring about real change?

There is also criticism of the concept of climate neutrality. What is your perspective on that?

Leon: The term is sometimes rightfully criticized. Before considering compensation measures, I believe it is crucial to focus on emission reduction to minimize our impact on the climate. However, as a consumer

goods manufacturer and online retailer, achieving climate neutrality without offset projects is challenging. Therefore, in my opinion, offsetting unavoidable emissions through an accredited project is a valuable complement. If all companies adopt this approach, it would make a significant positive impact on our planet.

Can you explain in more detail how LA SIESTA contributes not only to offsetting but also to emission reduction?

Leon: We strive to transport our products using the least environmentally harmful means possible. Whenever feasible, we avoid air freight and prioritize train and sea transportation over trucking. Sustainability is also a priority in the selection of our production materials. The cotton used for our hammocks and hanging chairs is organic, resulting in emissions savings. The wood for the spreader bars in our hanging chairs and hammocks comes from sustainable forestry, contributing to the health of forests.

To reduce CO2 emissions from employee commuting, LA SIESTA offers the option of using a JobRad (company bicycle) for commuting and working from home on certain days.

56

5. Use and End-of-Life Phase

As a manufacturer of a consumer good, we are committed to sustainability not only in terms of production and distribution but also in terms of product use and the end-of-life phase. Therefore, we design and develop our products in a way that minimizes harm to humans and the environment during their use and at the end of their life.

We place great importance on high quality and durability and therefore provide care and repair tips to our customers.

We also ensure that our products can be easily disassembled into their various components to facilitate proper and environmentally friendly disposal or recycling.

Furthermore, we strive to minimize packaging. For our Colombian hammocks, we have developed a patented non-packaging concept called „Rollito.“ The hammocks are held together solely by a cardboard banderole, which can be easily disposed of in the recycling bin.

57

Interview with Jean-Christophe Meillan, Creative Director at LA SIESTA

What can a designer improve and change in a hammock?

I believe that a hammock represents a counter-programming to the current consumerism. The beauty of a hammock lies in its simplicity and the craftsmanship that defines its production. I always strive to respect both aspects in my work. Good design, therefore, means strengthening the essential purpose of a hammock, improving its usability, that is, the way people interact with it, and participating in the more sustainable design of its production.

What are your goals when designing new products?

We believe that our products can bring great value to the lives of others. The products we develop aim to establish a connection between the person lying in the hammock and the place they are in.

This connection can lead to a deeper self-awareness and a new experience of the environment. We want to create an experience that is as simple, beautiful, and sustainable as possible, and there is still much that we can design in that regard.

How much influence do you think the design of a hammock has on its sustainability?

A designer bears a lot of responsibility for the sustainability of a product – they make decisions that have a significant impact. It starts with the selection of materials and continues with the product‘s construction. Hammocks must withstand strong forces, and we have high standards for durability. Every stitch must be in the right place, which needs to be considered in the design process.

58

If this is not done properly, tears can quickly appear, and tension on the fabric can strain the seams and the fabric more than necessary. A well-designed hammock distributes the forces evenly across the entire surface, preventing uneven stress. In addition to hammocks, hammock chairs, and accessories, we also design all of our packaging ourselves – at this point, the design team also has a significant influence on the sustainability of the final product. For us as a small company, packaging design is a particular challenge because we market our products through various distribution channels – from direct shipping to point-of-sale presentation. Solutions that are not fully thought out can be counterproductive in terms of sustainability, as they may require additional packaging. Due to the rapidly changing consumer world, we regularly subject our packaging solutions to sustainability checks. We always examine what makes sense and how we can save materials.

What have you achieved in terms of sustainability through design?

Over the years, we have been able to save a significant amount of material through our innovative product presentation. Our classic hammocks are compactly rolled into a so-called „Rollito“ and held together with a simple paper banderole. From my perspective, this is very sensible, provides a unique product experience, and has given LA SIESTA a distinctive feature and recognition. The fact that many other hammock brands have copied this type of „packaging“ shows that it was a good idea.

How do you try to counteract the fast pace of the consumer world?

Our hammocks are actually furniture pieces for homes and gardens, not fashion accessories or fast-fashion products. People usually buy furniture for many years. We focus on timeless designs with a tendency towards natural colors and untreated fibers. This is also sensible in terms of sustainability because it requires less water and chemicals.

Which designs are you personally most proud of?

I am proud of the designs of our Colombian products because we have managed to transform traditional colors and patterns into an elegant design that fits well in a modern living environment. I am also proud of the suspension systems we have developed. We have created a small universe of hanging elements that can all be combined with each other. They represent an evolution of the traditionally creative and playful approach to hammock suspension. They are fun, simple, and not overloaded.

59

What would you still like to improve?

For indoor use, I would like to develop hanging systems that blend even more seamlessly into the living environment. And in the area of logistics and packaging, we could save a lot by offering meaningful product bundles, such as a hammock and a matching hanging system combined. These are our challenges for the next two years.

As a brand manager, I am not only a hammock designer. What are your goals in this position?

I see myself as an ambassador of the hammock culture. I want to highlight the values of a shared hammock culture, such as openness, mindfulness, inspiration, and sustainability. And I want to prove that these are not just marketing terms for us.

In your opinion, what influence can the LA SIESTA brand have on consumer behavior in terms of sustainability?

We aspire to influence the habits and lifestyles of other people. Because when you surround yourself with products that last long and have a positive impact on health, togetherness, and family life, it also affects society as a whole, I believe. I call this positive effect „the power of the hammock.“ We have particularly emphasized this in our brand communication, creating a strong connection between our users and us.

Where do you want to lead the LA SIESTA brand in the next years?

Fortunately, I don‘t have to decide alone. However, I would like to consistently emphasize the topics of sustainability and quality. We aim to develop products that everyone can afford while offering high quality. I want to continue working on that.

Furthermore, I believe it is important to reconsider how and where we produce, how we transport and package our products, what materials we use, and where they come from. An essential question, for example, is how we can shorten transport routes or make transportation more sustainable when shortening them is not possible. Product design plays a significant role in this. It is our task to look for new ways and think outside the box.

Other significant topics include recycling, reuse, and repair. Due to the high stress hammocks endure, it is not easy to address these issues. However, we must engage with them more intensively in the coming years.

What hurdles need to be overcome, and what tasks need to be accomplished?

Current hurdles include the distances that materials and components travel during transportation. Additionally, there are long-standing partnerships that we highly value and cannot and do not want to change overnight. Therefore, it is important that we ask ourselves the right questions and always seek new solutions. The key is to preserve the good while also being unafraid to take radical steps. Many small steps are not enough.

Your ideas for more sustainability at LA SIESTA

61

Your ideas for more sustainability at LA SIESTA

62

LA SIESTA GmbH Im Wiesenweg 4 55270 Jugenheim Germany +49 6130 911919 info@lasiesta.com lasiesta.com in Imprint LA SIESTA GmbH Concept and editorial support: Joe Kaiser | www.re-nu.de Design: Ina Meillan | www.inameillan.com © LA SIESTA GmbH 2023