Do you experience slow production ramp up, low yields or variation in product quality?

Tough and out-of-round cables require you to deploy your most skilled operators to use hand tools, leading to bottlenecks.

Bonded enamel wires have to be dipped in dangerous hot caustic – a health & safety nightmare.

Variations in pressure and alignment can lead to uneven strips or micro-cuts affecting the performance of the end product.

When faced with challenging wire constructions, up to now, there has been no alternative than to use human skill to strip wires. Lasers require no human skill – no matter how small or tough the wire.

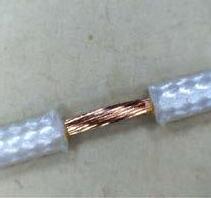

A minimum of two laser beams are used to give a 360 degree ablation.

The laser selectively removes the required material, reflecting from the next layer. This creates a very stable process.

Laser stripping can be achieved with vaporizing (ablating) an area of insulation, cutting across the wire or cutting across and slitting.

• Non-operator dependent

• Increases product quality and yield

• Low maintenance equipment

• Self-limiting process

• Safe to use

• No nick, no scrape

• Non-contact

Experience the assurance of having a dedicated ally in advanced medical devices.

From micro fine catheter wires to MRI enamel coils, we partner with the world’s leading medical device manufacturers to implement laser wire stripping technology that handles their wires and cables with ease.

• Laser stripping of wires pre-welding can increase bond strength to 100%.

• Laser stripping enables micro-coax stripping down to 56 AWG.

• Suitable for manufacturers specializing in cardiovascular ablation, mapping catheters, neurovascular pull wires, bone ablation.

Suitable Wires:

Electrodes

• Enamel

• Polyimide

• Polyester – sizes 0.0200.20mm (<40 AWG)

Draw Wires:

• Stainless Steel

Thermocouples:

• Bonded Enamel Wires

• Bifilar, Multifilar

All conductors including:

• Copper

• Monel

• Gold Coated

Neurovascular Pull Wire

iFR/FFR Pressure Wire

IVUS / ICE Catheter

Balloon Catheters

Oncology RF

Ultrasound Cables

Endoscopic

Cochlear Implant RF &

Ablation & Mapping

Electrode Bone Ablation Brain Mapping

The rapid evolution of modern vehicles—driven by electrification, autonomous technology, and connectivity—is fueling a surge in high-speed data cables. From advanced driver-assistance systems (ADAS) to in-vehicle infotainment and battery management, reliable data transmission is critical.

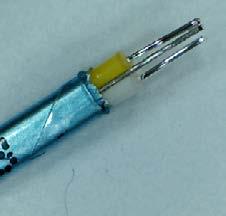

Traditional wire stripping methods risk damaging delicate shielding and conductors, but laser wire stripping ensures precision and integrity.

• Clean cutting of thick insulation on wires that are not rounded.

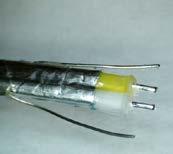

• Clean removal of delicate foil shielding in data cables without tearing or damaging underlying conductors.

• Busbars

• Magnet wires and coils

• High-voltage isolation wires

• Charging cables

• Shielded twisted pairs

• Camera wiring

• Brake wear indicators

• Central information display

• Charging cables

• Data transfer cables

• In-vehicle infotainment

From non-round cables where mechanical methods struggle, to tough insulations like fibreglass, laser technology provides precise results each time.

Our laser solutions precisely remove the insulation without causing any damage to the conductor, offering unmatched accuracy in stripping various types of aircraft wires.

• By using lasers, wires and cables are AIR6894A standardand IPC compliant.

• Suitable for high temperature wires with multi-layer insulations including kapton and fibre-glass such as BMS1358.

• Jackets of twisted shielded multiconductors are handled with ease.

• Shielded twisted pairs

• Thin PTFE insulations

• Kapton coatings

• Theromocouples

• Coaxial wires

• Temperature-resistent cables

• Thin magnet wires

• General wire harness

• Engine theromocouples

• Mission critical electronics

• Cockpit display systems

• Data transmission wiring

• Test and measurement equipment

Data centers are the backbone of our digital world, enabling seamless connectivity, cloud computing, and AI-driven advancements. As demand for faster data transmission grows, precision in cable processing becomes critical.

Laser wire stripping ensures the integrity of high-speed data cables, minimizing signal loss and optimizing performance for the next generation of data infrastructure.

• No bending of conductors to achieve precise strips.

• Manual operation, semi-automatic, and fully automatic configurations available.

• No residue left by lasers allow for the minimum gap required from the dielectric.

• Single drain wire

• Two drain wires

• Twisted pairs

• Twin Ax shields

• Twin Ax jackets and dielectrics

• Infiniband cables

• Coaxial cables

• High speed data centers

• Storage area networks

• High-performance computing

• Broadband infrastructure

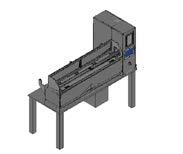

The Odyssey range of laser wire strippers is a state-of-the-art solution designed and manufactured specifically for precision applications.

These strippers excel in handling medical fine wire and enamel wire down to 54AWG. They offer single, bifilar, and trilfilar capability, ensuring versatility across various wire types.

With recipe driven processing, this technology provides consistent, high-quality results that are operator independent.

Suitable Materials

Suitable Wire Types

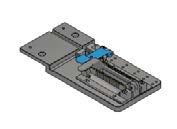

• Single wire insert

• Auto wire detect

• Recipe controlled HMI

• Compact footprint

• Suitable for low wire count

Polyurethane Enamel, Polyester Enamel PEW, Polyester-imide EIW, Polyamide-imide, Kapton, ML

Single conductors, twisted pairs, bifilar, and trifilar wires

Processing Speed < 10 second cycle for a typical 2mm strip (material dependent)

Processing Length Up to 6 mm (0.2”)

Breakout Length 18 mm (0.7”)

Max. Wire Diameter < 0.2 mm (0.007”), 0.4 mm on request (0.015”)

Dimensions (LxWxH), Weight 180 x 340 x 480 mm, 6 kg

Suitable Materials

Suitable Wire Types

• Multi-wire stripping

• Micro-coax shield cutting

• Fixture loaded

• Suitable for high wire count

• Highly customizable

Polyurethane Enamel, Polyester Enamel PEW, Polyester-imide EIW, Polyamide-imide, Kapton, ML

Single conductors, twisted pairs, bifilar, and trifilar wires

Processing Length Up to 70 mm (2.7”)**

Processing Area Up to 70 mm (2.7”)**

Max. Wire Diameter

<0.2 mm (0.007”)

Dimensions (LxWxH), Weight 1180 x 800 x 1470 mm, 220 kg

**Larger working area available on request (Odyssey-4E) with a working area of 100 x 100 mm.

Alternative Die blade Mechanical stripper, exacto knife

Challenges Worn blades, downtime, nicks, scrapes, tags

Power Options*

Application

30 W / 55 W

Risk of nicks, scrapes, inconsistent

20 W / 30 W / 50 W

Data Twin-Ax, Mechanical Alternate Mechanical Alternate, Data Centers Aerospace, Electronics

Max. Wire Diameter 6 mm / 0.23" 6 mm / 0.23" Max.

Inline Yes Yes **

Wire Loading Fixture plate, inline Fixture plate, single wire insert, inline

*The higher the power wattage the faster the processing time. Please note that a higher wattage is not suitable for all applications. Discuss with a key account manager the best wattage for your application. **Larger working area available on request (Mercury-4E) with a working area of 100 x 100 mm, but this is not available as an inline system

Materials

• PTFE

• ETFE

• PVC (special extraction)

• PU

• Silicone

• Kapton

• Polyimide

• Polyester

• Fiberglass

• Polyethylene

• Nylon

• and more

Not fully automated line Mechanical stripper, exacto knife, not fully automated Alternative

Time consuming process Time consuming process damaged conductors Challenges

2 x 55 W 25 W / 50 W / 150 W Power Options*

Data Twinax, Dielectric, Data Centers Mechanical Alternate, Automotive Application

6

The Gemini laser wire strippers are a versatile solution for a wide range of wire stripping needs. They are perfectly suited for scribing and cutting cable shields, aero thermocouples, and enamel.

These strippers are capable of performing a variety of cuts, including end-strips, window cuts, slits, and area vaporization.

Suitable Materials

• Suitable for shield cutting and enamel ablation

• Aerospace thermocouples or medical grade enamel

• Fixture plate loading

Polyimide type insulations, enamels, magnet wire, microcoax, no fluropolymers

Processing Length Up to 100 mm (3.93”)

Processing Width Up to 100 mm (3.93”)

Max. Wire Diameter Up to 2 mm (0.07”)

Dimensions (LxWxH), Weight

Laser Processing Unit: 860 x 430 x 975 mm, 95 kg

Power Supply Unit: 250 x 540 x 430 mm, 31 kg

Suitable Materials

Suitable Wire Types

Scribe Length

• Large fixture area

• Suitable for scribing and cutting cable shields

• Tinned micro-coax and aluminized foils

Scribing of tinned micro-coax shield

Micro-coax

Up to 127 mm (5”)

Scribe Width Up to 177 mm (7”)

Max. Wire Diameter Up to 0.5 mm (0.01”)

Dimensions (LxWxH), Weight 510 x 654 x 997 mm, 100 kgs

If we don’t have a ready-made solution from our existing range to suit your requirements, we draw on our process knowledge and technical expertise to create a solution that is customized to address the requirements of a particular application.

We can tailor machines offering custom guards and tooling for unique shapes and configurations.

Custom modules designed to complement your current automation workflow. Integrated Systems

Fixtures to hold your wires precisely where they’re meant to be to achieve the best possible results.

We tackle complex wire processing challenges with bespoke solutions built around your needs.

For some medical device manufacturers, investing in the capital equipment for stripping wires in-house isn’t possible for manual production for cost issues, and outsourcing to a third-party is more feasible.

By using our suite of automated Odyssey manufacturing solutions, we can offer full production to meet our medical device manufacturing partners laser wire ablation requirements, shipped and ready to be used.

ISO 9001 certified service Automated lights out manufacturing Medical component manufacture

Supplier to major OEM companies

Spool to spool, Spool to cut Full analytical laboratory

A leading medical device manufacturer producing RF ablation catheters struggled with stripping 42 AWG copper-clad 316L stainless steel wire. Their vertical abrasion process caused inconsistencies, leading to a high failure rate in continuity tests.

Once implemented, they saw a 1.5% yield increase, saving $200k per line across lines in total.

The Solution: Odyssey-8

• UV laser technology ensures clean, precise stripping.

• 6mm strip length with complete insulation removal.

• Contact-free process eliminates mechanical damage.

• Zero insulation residue –perfect surface for welding.

• Processing time: <10 seconds per wire.

• Improved yield & production

A world leading electric vehicle manufacturer faced issues with mechanical processing of foil under coroplast insulation.

Cutting errors resulted in damaged shield strands and foil tags, compromising quality.

Required a more precise and reliable stripping solution.

The Solution: Mercury-9

• Specialized for shielded coroflex cables (20mm OD).

• Ring cut and slit performed on both outer and inner jackets.

• Precision processing eliminates strand damage.

• Clean, accurate cuts with zero damage to inner layers.

• Processing time: ~18 seconds per end.

• More efficient and scalable

A customer manufacturing ultrasound devices needed precise removal of the outer jacket on 128 micro-coax wire at 42 AWG.

Required preparation of the braid for soldering without damage.

Their current methods involved a rotary stripper that produced 30% scrap with manual rework needed with a tweezer.

The Solution: Cassini-10

• Automated system for the full preparation of micro-coax.

• Fixture plate based for high repeatability.

• Processing time: under 10 seconds for multiple wires.

• Clean, precise jacket removal with intact braid for soldering.

• No mechanical damage.

• Fast turnaround, ideal for highvolume production.

A leading cable manufacturer required precise exposure of inner dielectric from twinax cables.

Needed minimal melt and swelling to maintain integrity.

The cable manufacturer now has over 100 fully automated Mercury-4 OEM units installed.

• Laser-based processing ensures accurate, clean cuts.

• Optimized recipe to cut while minimizing heat impact.

• Cycle time: <5 seconds per wire.

• Precision stripping with minimal deformation.

• Multiple wires processed simultaneously for fixture plate for higher efficiency.

• Ideal for automation.

A robotic motors manufacturer required precise removal of outer insulation from 20 AWG HGP magnet wires.

Needed a clean conductor surface for soldering. As the wires were visible on the end-product they also needed a clean strip for cosmetic purposes.

Existing mechanical stripping methods caused micro-cuts, fatigue, and wire breakage.

The Solution: Gemini-4E

• Fiber laser technology ensures clean, precise stripping.

• Maintained conductor integrity for optimal solderability.

• Zero micro-cuts.

• Clean, distinct edge between insulation and copper core.

• Eliminated micro-cuts and fatigue

• Superior positioning control, precise, repeatable results.

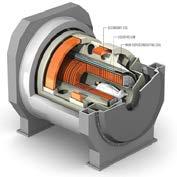

A sealed MRI technology manufacturer needed efficient enamel removal from rectangular copper magnet wire.

Their previous process of using hot caustic was slow, labor-intensive, and posed EHS (Environmental, Health, and Safety) risks.

Inconsistent quality led to variability in product performance.

The Solution: Viking-4

• Eliminated manual labor and improved speed.

• No physical contact, reducing risk of wire damage.

• Consistent, high-quality stripping.

• Faster and safer production with automated processing.

• Eliminated EHS risks, making the workplace safer. Customer operates 3 Viking-4

Our commitment to your success doesn’t end at delivery. At Laser Wire Solutions, we offer dedicated service and support to keep your machines operating at peak efficiency.

Whether it’s remote troubleshooting, preventative maintenance, spare parts, or on-site support, our experienced engineers are here to help you minimise downtime and maximise productivity.

System upgrades and troubleshooting support provided on-site and remote.

Installing ready for use and keeping your operations running smoothly.

We can provide introductory and customized training package on installation.

At the completion of the 12-month warranty period we offer two routes for customers to ensure we continue to provide ongoing support.

Laser Wire Solutions, located in Cardiff, in the United Kingdom, serves the world wide market for laser wire stripping equipment and contract laser ablation services.

This non-contact, high precision method is revolutionizing the connection of mission critical wiring systems from medical devices to jumbo jets.

If you have a wire connection challenge – speak to our experts.

in partnership with

We are the laser wire stripping experts. Our solutions ablate the coating without damaging the conductor.

As pioneers of laser microsoldering we understand the requirement for efficiency and accuracy in soldering your wires.

Using our suite of automated solutions, we can offer full production to meet your requirements, shipped and ready to be used.