Experience the assurance of having a dedicated ally in advanced medical devices.

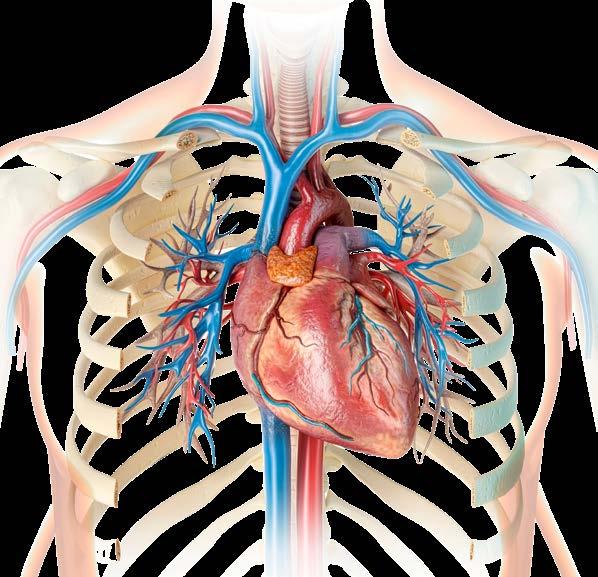

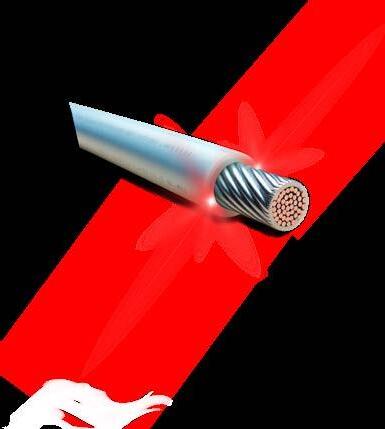

From micro fine catheter wires to MRI enamel coils, we partner with the world’s leading medical device manufacturers to implement laser wire stripping technology that handles their wires and cables with ease.

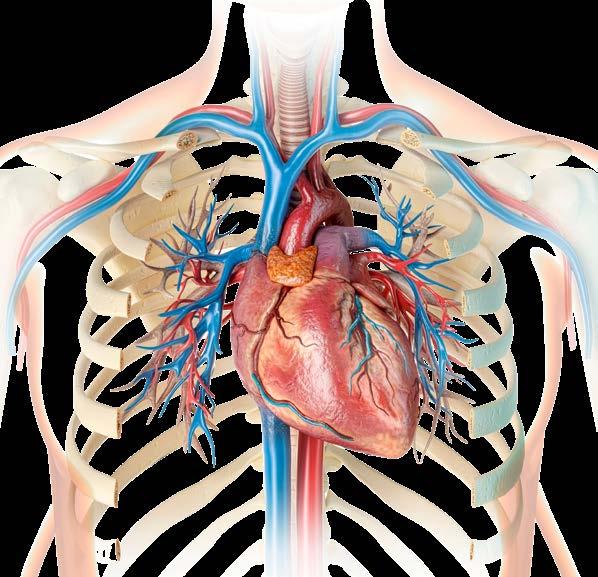

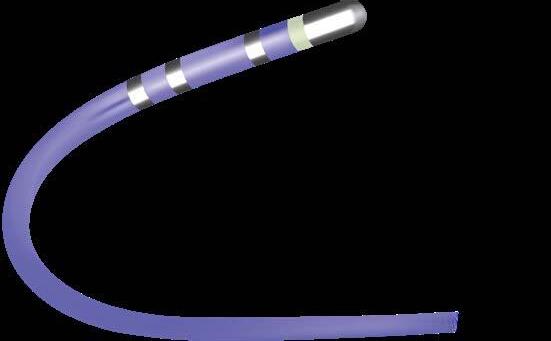

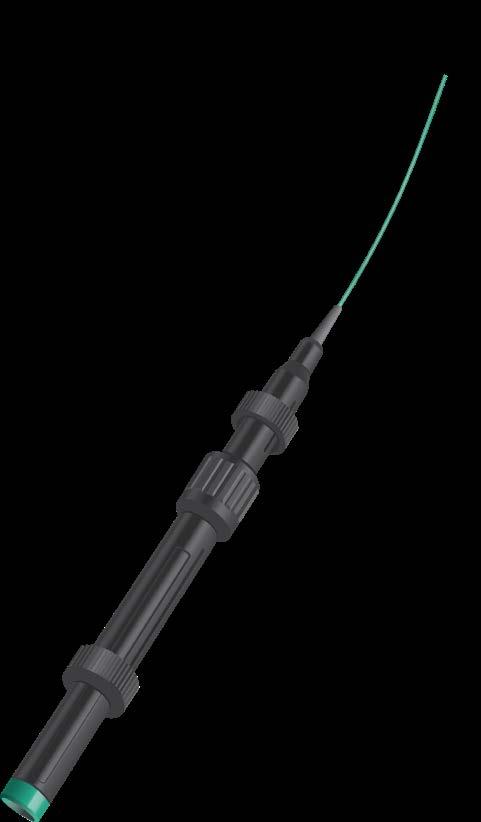

Neurovascular Pull Wire

iFR/FFR Pressure Wire

IVUS / ICE Catheter

Balloon Catheters

Oncology RF

Electrode

Suitable Wires:

Electrodes

• Enamel

• Polyimide

• Polyester – sizes 0.0200.20mm (<40 AWG)

Draw Wires:

• Stainless Steel

Thermocouples:

• Bonded Enamel Wires

• Bifilar, Multifilar

All conductors including:

• Copper

• Monel

• Gold Coated

Trifilar wire <52 AWG with stripped insulation for soldering.

Nitinol, stainless steel, or polymer

Coper wires with enamel/ polyimide coating, single, bifilar, or ribbon arrangements sizes <40 AWG.

Thermocouples for measuring temperature with soldered bifilar, multifilar, or twisted pair wires

Fine polyimide-coated wires in high-density configurations.

Do you experience slow production ramp up, low yields or variation in product quality?

• Inconsistent resistence welding process

• Signal transmission variation

• Wire attachment breaking off

• Soldering has voids or inclusions

• Batch or lot variation

• Inherent health & safety risks

• Unsuitable for all wire configurations

• Operator skill dependent

• Contamination due to residue

• High tool wear and maintenance

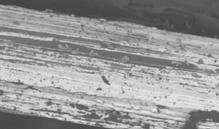

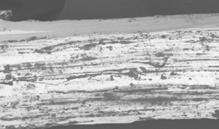

Tiny defects from wire processing often go unnoticed until final testing—after full assembly. By then, the cost isn’t just the scrap wire, but wasted labor, components, and lost production time.

Hidden wire scrap can quietly drain thousands of dollars from your bottom line and delay critical deliveries.

Laser wire stripping eliminates hidden damage by providing precise, contact-free insulation removal.

• Eliminates the need for operator skill

• Increases product quality

• Increases yield

• Safe to use on production floor, no PPE

• No nick, no scrape process

• Laser reflects from conductors

• Suitable for all wire types & sizes

• Highly repeatable process

• No operator fatigue

• Fast process time

• Minimal working parts, low maintenence

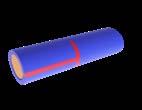

Our laser stripping technology utilizes a minimum of two laser beams to create a 360-degree ablation around the wire.

This advanced process offers unparalleled precision, ensuring that only the required material is removed while maintaining the integrity of the surrounding layers.

The laser selectively removes the required material, reflecting from the next layer. This creates a very stable process.

Laser stripping can be tailored for various manufacturing needs:

• Suitable for assembly lines

• Suitable for small batches or R&D

• Low wire count

Fixture Based

• Batch production

• Multi-process operations

• High wire count

Integrated / Automated

• Lights out production

• Seamless integration

Perfect for high wire count

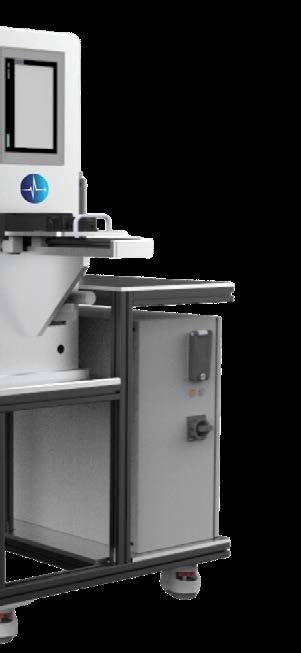

General Features

• Highly customizable

• Fixture loaded

• Recipe controlled touch screen HMI

• Internal QC camera

• Multi-wire stripping

• Micro-coax shield cutting

• Suitable for high wire count

Suitable Materials

Suitable Wire Types

Polyurethane Enamel, Polyester Enamel PEW, Polyester-imide EIW, Polyamide-imide, Kapton, ML

Single conductors, twisted pairs, bifilar, and trifilar wires

Processing Length Up to 70 mm (2.7”)**

Processing Area Up to 70 mm (2.7”)**

Max. Wire Diameter

<0.2 mm (0.007”)

Dimensions (LxWxH), Weight 1180 x 800 x 1470 mm, 220 kg

**Larger working area available on request (Odyssey-4E) with a working area of 100 x 100 mm.

Perfect for low wire count

General Features

• Compact footprint

• Single wire insert

• Automatic wire detect

• Recipe controlled touch screen HMI

• Fast recipe changeover

Suitable Materials

Suitable Wire Types

Processing Speed

Polyurethane Enamel, Polyester Enamel PEW, Polyester-imide EIW, Polyamide-imide, Kapton, ML

Single conductors, twisted pairs, bifilar, and trifilar wires

< 10 second cycle for a typical 2mm strip (material dependent)

Processing Length Up to 6 mm (0.2”)

Max. Wire Diameter

< 0.2 mm (0.007”), 0.4 mm on request (0.015”)

Dimensions (LxWxH), Weight 180 x 340 x 480 mm, 6 kg

Perfect for micro-coax

General Features

• Onboard vision system

• Carbon dioxide and UV lasers in one system

• Compact footprint

• Recipe controlled touch screen HMI

• Variety of configurations available

Suitable Materials

Suitable Wire Types

All polymer insulations and all metals

Micro-coax wire stripping, electrode coating removal, fine wire stripping

Processing Speed < 10 second cycle

Processing Length

Max. Wire Diameter

Dimensions (LxWxH), Weight

Up to 2” (50 mm) as standard, custom lengths available

<0.015” (0.4 mm) as standard

321 x 540 x 565 mm, 40 kg

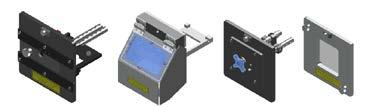

Single Wire Option

Wire/cable inserted through ceramic guide

Automatic wire detection and gripping

Optional wire rotation for increased quality

Cassini-10 Fixtured Option

Multiple wires/cables mounted in custom fixture plate.

Allows high productivity and wire pitch alignment for downstream connection.

Cassini-8 Inline Option

Wire/cable passed through the unit to be automatically stripped in combination with a spool to spool or spool to cut wire automation.

Cassini-OEM Integrated Option

Supplied with or without laser guarding and control interface for integration into larger systems.

Perfect for a wide range of applications

General Features

• Simple UI HMI

• Recipe loaded

• Variety of configurations available

• Benchtop system

• Suitable for high wire count

PTFE, ETFE, PVC, PU, Silicone, Kapton, Polyimide, Polyester, Fiberglass, Polyethylene, Nylon, more. Single conductors, twisted pairs, bifilar, and trifilar

**Larger working area available on request (Mercury-4E) with a working area of 100 x 100 mm.

For some medical device manufacturers, investing in the capital equipment for stripping wires in-house isn’t possible for manual production for cost issues, and outsourcing to a third-party is more feasible.

By using our suite of automated Odyssey manufacturing solutions, we can offer full production to meet our medical device manufacturing partners laser wire ablation requirements, shipped and ready to be used.

ISO 9001 certified service Automated lights out manufacturing Medical component manufacture

Supplier to major OEM companies

Spool to spool, Spool to cut Full analytical laboratory

A leading medical device manufacturer producing RF ablation catheters struggled with stripping 42 AWG copper-clad 316L stainless steel wire. Their vertical abrasion process caused inconsistencies, leading to a high failure rate in continuity tests.

Once implemented, they saw a 1.5% yield increase, saving $200k per line across lines in total.

The Solution: Odyssey-8

• UV laser technology ensures clean, precise stripping.

• 6mm strip length with complete insulation removal.

• Contact-free process eliminates mechanical damage.

• Zero insulation residue –perfect surface for welding.

• Processing time: <10 seconds per wire.

Improved yield & production

A customer manufacturing ultrasound devices needed precise removal of the outer jacket on 128 micro-coax wire at 42 AWG.

Required preparation of the braid for soldering without damage.

Their current methods involved a rotary stripper that produced 30% scrap with manual rework needed with a tweezer.

The Solution: Cassini-10

• Automated system for the full preparation of micro-coax.

• Fixture plate based for high repeatability.

• Processing time: under 10 seconds for multiple wires.

• Clean, precise jacket removal with intact braid for soldering.

• No mechanical damage.

• Fast turnaround, ideal for highvolume production.

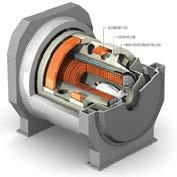

A sealed MRI technology manufacturer needed efficient enamel removal from rectangular copper magnet wire.

Their previous process of using hot caustic was slow, labor-intensive, and posed EHS (Environmental, Health, and Safety) risks.

Inconsistent quality led to variability in product performance.

The Solution: Viking-4

• Eliminated manual labor and improved speed.

• No physical contact, reducing risk of wire damage.

• Consistent, high-quality stripping.

• Faster and safer production with automated processing.

• Eliminated EHS risks, making the workplace safer. Customer operates 3 Viking-4

Our commitment to your success doesn’t end at delivery. At Laser Wire Solutions, we offer dedicated service and support to keep your machines operating at peak efficiency.

Whether it’s remote troubleshooting, preventative maintenance, spare parts, or on-site support, our experienced engineers are here to help you minimise downtime and maximise productivity.

System upgrades and troubleshooting support provided on-site and remote.

Installing ready for use and keeping your operations running smoothly.

We can provide introductory and customized training package on installation.

At the completion of the 12-month warranty period we offer two routes for customers to ensure we continue to provide ongoing support.

Laser Wire Solutions, located in Cardiff, in the United Kingdom, serves the world wide market for laser wire stripping equipment and contract laser ablation services.

This non-contact, high precision method is revolutionizing the connection of mission critical wiring systems from medical devices to jumbo jets.

If you have a wire connection challenge – speak to our experts.

in partnership with

We are the laser wire stripping experts. Our solutions ablate the coating without damaging the conductor.

As pioneers of laser microsoldering we understand the requirement for efficiency and accuracy in soldering your wires.

Using our suite of automated solutions, we can offer full production to meet your requirements, shipped and ready to be used.