A STACK MOULD SOLUTION FOR LONG-TERM SAVINGS

CASE STUDY

A STACK MOULD SOLUTION FOR LONG-TERM SAVINGS

CASE STUDY

When Growtivation – a British business offering unique products for the building, landscaping and growing sectors –required a specialist injection mould tooling solution, WSM INDUSTRIES was their service provider of choice.

Growtivation’s range includes Gravelrings, a gravel-retention product for achieving SuDS (sustainable drainage systems) compliance during the building of paths and driveways.

Gravelrings is manufactured in high-density polyethylene (HDPE) and comprises interlocking grid tiles made up of circular cells on a mesh base. The system helps surfacing specialists looking to achieve an elegant finish prevent issues such as stone migration, deep ruts and inconsistent coverage.

Prior to its partnership with WSM, Growtivation was importing Gravelrings from Europe and had recognised that long-term savings could be made by manufacturing the product in the UK. The Growtivation team calculated that by having tools and the end product made in Britain they could achieve ROI within 12 months and benefit from significant savings thereafter.

WSM INDUSTRIES, with its world-class engineers, state-of-the-art equipment and a reputation for helping customers reduce cost per part, was approached to develop a bespoke mould tool solution.

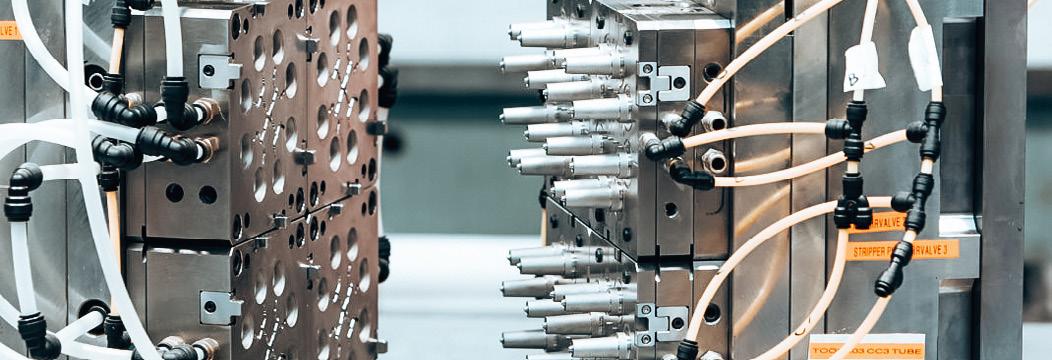

After evaluating the existing tooling and production process, the WSM technical team determined that, to achieve Growtivation’s target price of £2 per unit, two-impression tooling would be required. This meant that each mould tool would have two cavities, allowing two pieces

to be formed per shot of plastic. As well as increasing efficiency by doubling production capacity, this would save 25% compared to single-impression tooling.

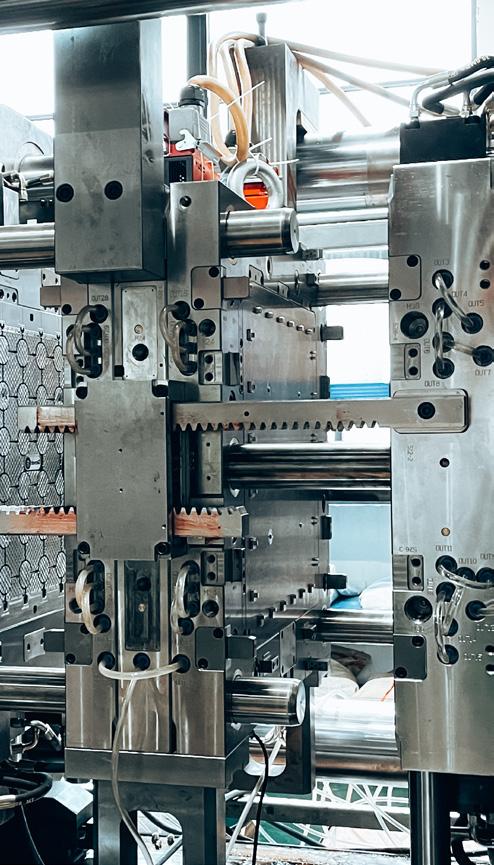

WSM identified that a conventional two-impression tool with adjacent parts would require a moulding machine with a 1,000-tonne clamp pressure. In order to reduce the client’s costs and help them achieve their target product price, WSM recommended a two-impression stack mould.

A stack mould is a series of interconnected single-face moulds of the same size that are stacked on top of one another. Stack moulds offer the benefit of doubling the number of cavities without increasing platen size or tonnage while fill, pack and cooling times remain the same.

The stack mould option enabled WSM to deliver a cheaper piece cost by doubling capacity which, with Growtivation forecasting 100,000 parts per annum, equated to a significant long-term saving. Meanwhile, WSM’s use of sustainable postconsumer recycled (PCR) material allowed Growtivation to reduce the environmental impact of its product without affecting performance or appearance.

Whether you require small or large components, recycled material, engineered polymers, single-component production or whole-product assembly, we offer the complete solution.

find out more find out more