SLUDGE MEASUREMENT SOLUTION

When an Italian wastewater treatment plant required a solution for the measurement of two types of sludge with a single probe, water-monitoring expert Chemitec was approached to provide bespoke instrumentation.

The project, based at a site in Sant’Antonino Ticino just outside Milan, was being carried out by industrial plant specialist F.lli Bari on behalf of water services operator Alfa Varese.

The plant, which has been operational for 40 years, is responsible for the collection of domestic and industrial sewage from 25 municipalities – including Milan Malpensa Airport – and is designed to handle 5,500-6,000 m3 of wastewater per hour.

The operator was facing the challenge of having only a single collector for digested and excess effluent at the inlet of the sludge centrifuge.

Because these two sludges have different concentrations of suspended solids, optimal dewatering within the centrifuge could not be achieved and individual measurement was required.

Chemitec, with four decades’ experience designing and manufacturing instrumentation for global wastewater treatment processes, was commissioned to devise a customised solution.

The initial phase of the project saw the technical team from Chemitec visit site and perform a comprehensive assessment of the application alongside their counterparts from F.lli Bari.

Having considered the process’s unique requirements and challenges, Chemitec returned with a multiinstrument solution.

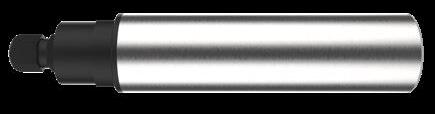

This included a dedicated S461ST suspended solids sensor, which was installed on the pipeline at the centrifuge inlet to allow the measurement of both the digested and excess sludge matrices.

Meanwhile, at the heart of the process was Chemitec’s intelligent 50 Series controller, which allowed the logic of the sensor to communicate with the operating logic of the centrifuge.

The 50 Series controller was cabinet mounted complete with a manual selector to enable recognition of the two sludge types, which the operator had the option of upgrading to automatic mode.

During system start-up, a calibration was performed with the two sludge samples taken and analysed on site to ensure optimal system performance.

The team at F.lli Bari were fully satisfied with Chemitec’s customised solution, the quality of the instrumentation and its integration with the existing system.

As part of Chemitec’s comprehensive after-sales service, the operator will continue to be supported with periodic probe calibration to ensure repeatable results over the long term.

50 SERIES FEATURES

• Multi-parametric controller for up to 8 digital sensors

• Sensor self-recognition with plug & play system

• Data storage and graphic display of measurement trends

• Control outputs and Modbus RTU serial interface

• Panel and wall-mounted versions

S461ST FEATURES

• Ultra-reliable infrared optical concentration measurement

• Pulsed infrared light absorption method

• Sensor body in AISI 316 stainless steel

• Free of moving parts for low maintenance

• High sensitivity in low signal transmission

• Ready to install

WORLDWIDE DISTRIBUTOR NETWORK

Thanks to flexible and reliable instruments, user-friendly solutions, outstanding technical skills and continuous improvement, we are selected as an ideal partner and continue to increase our international presence.

CHEMITEC SRL

Via Isaac Newton, 28 50018 Scandicci (FI) Italy

Phone +39 055 7576801

Fax +39 055 756697

sales@chemitec.it • www.chemitec.it CHEMITEC LTD SALES SUBSIDIARY Room 901, Floor 9 108, Yuyuan Road Shanghai (PRC)

Phone +86 021 3331 1193

Fax +86 021 3331 1193-808

info@chemitec.asia • www.chemitec.asia

Chemitec reserves the right to amend and change specifications without prior notice. All pictures shown are for illustration purpose only. Actual product may vary due to product enhancement. Published data may be subject to change.

© 2024 Chemitec