walls 4

THE ART AND FRAMING MAGAZINE FOR PROFESSIONALS

THE ART AND FRAMING MAGAZINE FOR PROFESSIONALS

Welcome to Issue 48 of 4walls as we celebrate 50 years in business with a festival of framing! Pages 4 & 5 summarise where we are now, along with current trends and more recent innovations, with pages 16 & 17 dedicated to our story from 1975 through to 2025.

The whole Larson-Juhl team wishes to say a huge thank you to all of you, our customers, for your part in our success – we couldn’t have done it without you.

On Sunday 29 June, we will be holding an event to mark our Golden Anniversary – and you are all invited. On the opposite page, you can see more details, but we very much hope that you and your families will join us.

Also in this issue of 4walls, we feature some excellent customer stories: The Framemaker in Cork (pages 6 & 7), Wilson Images in Chatteris, Cambridgeshire (pages 12 & 13), Wrexham-based Beckett Framing and artist Geoff Beckett (pages 14 & 15), Hang It Framing in Bristol (pages 18 & 19), Thou Art in Hampstead (pages 24 & 25) and Watling Street Galleries in Towcester (30 & 31). Then Larson-Juhl Scholars Janine Bailey of Arlais Framing and Hayley Bell of Frameworks Picture Framing are profiled on page 23.

Jo and Alec Palmer give us an expert view on sub-frames on pages 20 to 22 and Jon Price’s Masterclass lays out some best practice around selling bespoke picture framing on pages 8 to 10.

Pages 26 & 27 showcase some of our favourite posts that customers have recently created on their social channels, with a lovely selection of our mouldings taking centre stage.

We had a fantastic trip to FamaArt in Bologna last autumn and we give a summary of the exhibition on pages 28 & 29. Finally, some recent additions to our product portfolio feature on page 11.

Thank you to all our contributors for their words and images – this is a very special edition. I hope you agree and do let me have your thoughts and feedback, or suggestions for future issues of 4walls.

Wishing you a successful spring and summer and I hope to see you in June! If you would like any help with product or business advice, please contact your area sales manager or call the customer service team on 01234 852777.

Matt George, Editor mgeorge@larsonjuhl.com

4. 50 Years of Framing Celebrating Larson-Juhl’s Golden Anniversary

6. The Framemaker Meet Paddy and Sarah Costigan and their talented team

8. Selling Bespoke Picture Framing The latest Masterclass from Jon Price

11. New products

@Larson-Juhl UK @larsonjuhluk

Showcasing EcoWood and Naturale

12. Creative Showcase

Featuring the highly creative Jon Wilson and his partner Pauline Scullion

14. Beckett Family Framing

A hugely successful ‘framer sister’ and ‘artist brother’ partnership

16. 50 Years of Larson-Juhl Larson-Juhl’s historic timeline

18. Hang It Framing

A fantastic story with innovation at its heart

20. Ask the Experts

Jo and Alec Palmer provide a professional view on sub-frames

23. Larson-Juhl Scholarship winners Meet Janine Bailey and Hayley Bell

24. Antonio Yepes Perez’s Thou Art From Barcelona to Hampstead!

26. Customer social media content

Showcasing our latest round of favourites

28. Back at Bologna A review of FamaArt

30. Watling Street Galleries Mike Novakovic’s inspiring story

The Larson-Juhl UK story started back in 1975 when the world was a very different place – most framing techniques were done by hand, there was no internet or social media and all documentation was paper-based.

As we celebrate our Golden Anniversary, first of all, the entire Larson-Juhl team wants to say a massive thank you to our customers – many of whom have been with us for decades!

In this issue of 4walls, we will be reflecting on the milestones and the changes, but we also want to focus on our enduring commitment to service, range and quality, which we believe is at the heart of our longevity, and to look forward to what we believe to be a very exciting future for the industry.

One of the most significant changes the framing industry has seen over the last 50 years has been the introduction and advances of various technologies and equipment, which has allowed many manual tasks to become more automated and/or digitised – saving time and bringing consistency.

The underpinner was a particularly useful piece of equipment that was developed back in 1976. It allowed framers to join mouldings from the bottom, instead of having to drill nail holes that would be on show.

A significant innovation in the nineties was the computerised mount cutter. Cutting mountboards by hand is a highly skilled task and it is also very time-consuming. With technology, all that is required is the push of a few buttons on the computer and perfect, well-cut mountboards are produced instantly.

The introduction of computers and subsequently the internet, of course, changed everything. And today, alongside the ability for those who wish to, to trade online exclusively, this has brought innovations like virtual framing software, for example, that has transformed the selling process.

Back in the seventies, the sales team created letters and invoices on a typewriter, ready to be posted, and customer orders were handwritten into an order book. Warehouse inventory lists were also handwritten, although customers could, of course, visit the showroom and pay cash!

Today, the business is totally paperless and 80% of sales transactions are done online.

Sales director Simon Flavill comments: “It’s not surprising that so many customers are now ordering online. The website makes selection and checking stock levels so accessible and convenient. The fact that framers can be serving a customer, they chose their moulding, and its availability can be checked instantly, makes closing a deal so much easier - whatever device you have to hand!”

Simon adds:

“The digital revolution has of course brought many opportunities to our customers - with some enjoying huge success with their e-commerce offers. The publishers have invested in highly impressive websites to help sell their artwork; and entrepreneurial small businesses, for little outlay in reality, are using Instagram and Facebook as an extension of their shop window to showcase their services and skills and also to sell.”

A great example of adapting to new trends is the introduction of float frames. To start with, canvas artwork was not framed. Larson-Juhl then launched a range of float mouldings and over the last 10 years has seen a huge growth in demand. Simon says: “I’m really proud that we have the biggest range of float frames on the market, with nearly 150 different mouldings, from design-led options like Eiffel to the ever-popular Coastal Woods range.”

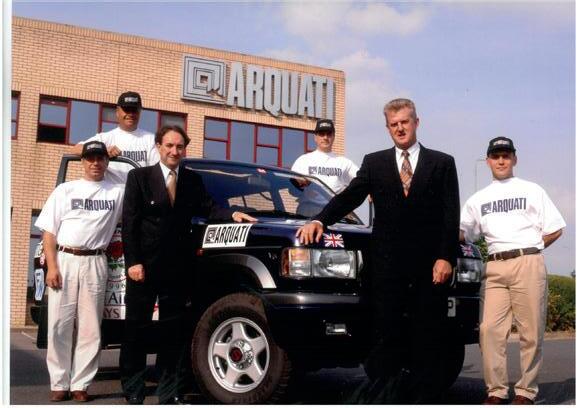

Founder Derek Masters commented: “The company has come a long way since I made that first trip to Italy to view the Arquati range of products and then began knocking on framers’ doors to sell the mouldings we had chosen. It has evolved over the years and grown into an industry-leading position, which is an amazing achievement.”

Managing Director Mike Brown is rightly proud of the company’s achievements and observes: “To have retained our place as market leader shows incredible commitment and hard work from the whole team, but we must say a huge thank you to our customers, without whom we would not be celebrating this 50 year milestone.”

Reflecting on how the industry has changed over the last 50 years, Mike makes a number of key points. He says: “50 years ago, there were many more high street framers but, of course, there was no online trading or any virtual businesses.

“Like many other retailers, the decline of the traditional high street has hit framing hard, with less footfall making some businesses unprofitable and the property costs associated with high street units has not helped. Not surprisingly, as a result of this, there has been a rise in framers taking out-of-town premises – with benefits including cheaper rent, facilitating more space for less cost, and much better parking facilities for customers.

“The popularity of minimalist interior design in some markets has limited the scope of framed art in the decoration of houses and apartments but other opportunities have opened up. The commercial sector, for example, like hotels, bars, cruise ships, offices and care homes.

Paulo Botrugno is Larson-Juhl’s longest serving employee, having joined the business in 1980. Today, he is Vice President of Procurement and Product Management and in his 45th year with the company, he makes some interesting observations about the enduring importance of quality

“Another big change in the business is the move from ornate mouldings in framing to simpler, cleaner black and white products. This is a consequence of the gradual modernisation of housing stock with open plan living and the use of simpler colour palettes in decoration. 25 years ago, 50% of Larson-Juhl’s top 100 products were ornate, traditional mouldings, now it is more like 10% although there are signs that the trend is reversing slightly.

“The rapid development of technology has made big differences to the industry even though you would not think that framing was a particularly tech-heavy sector. Some examples of change are:

• Website development – this has forever changed how we communicate with our customers. From digital catalogues and online ordering to stock information available online.

• Warehouse management systems have automated how we purchase, track and ship products to customers. This has shortened the time before an order is despatched and allows endto-end tracking of the order.

• Another great example of technological change in the last 50 years is in the selling sphere. Larson-Juhl sales people have all the information they need to do their jobs at their fingertips. We would like to think this makes their visits to customers more effective for the client.

“It’s really interesting to reflect on where we are now and while so much has changed in terms of technology and progress around logistics and communications, the core values of putting customers first, always, offering the best possible range with new products that reflect industry trends and consumer demand, the strictest possible quality control and a first-class sales and service team has not changed at all!”

and having a commitment to continual improvement:

“Maintaining healthy relationships with vendors and service providers is ever important as the best possible quality of product continues to be in high demand from our customers.

“Customer service also remains a very high priority from a logistics perspective, particularly with regard to picking, packing and shipping customer orders. We have invested heavily in our internal IT-aided processes, assisting the development of a large, single storage facility.”

The Framemaker, based in County Cork, is owned by Paddy and Sarah Costigan and comprises two busy retail spaces serviced by one large workshop at the Carrigaline premises - all run by a top team of experienced, creative and talented individuals. Having been in business for 39 years, The Framemaker has built up a reputation for excellent quality bespoke framing, while also servicing the needs of customers looking for large scale production. The Framemaker team strives to be friendly, helpful and focused on the detail. They are a fine example of best practice.

Paddy originally worked in the clothing trade but always had an interest in carpentry and a love of art. When an opportunity arose to start framing in 1986, he took it. Initially, he worked out of his garage, but soon realised he needed more space. He moved first to a workspace/shop in Douglas on the outskirts of Cork but after a short time he moved again to Cook Street, in the heart of Cork city. This proved to be a great choice of location and The Framemaker is still there today. As well as offering a bespoke framing service, the shop on Cook Street also sells a wide selection of framed prints and readymade frames. From the beginning, Paddy committed to delivering a top-quality service and now The Framemaker has expanded to a team of 11, maintaining high standards is still a core principle of the business.

Paddy opened the purpose-built facility in Carrigaline in 2004. It includes a 3,500 square foot showroom, 4,000 square foot framing workshop, a printing studio and three artists’ studios. There is a team of eight, many of whom have been with The Framemaker for a long time. James, who runs the workshop, joined over 20 years ago, having graduated from the Cork School

of Art, specialising in Sculpture. Over the years, James has built up a reputation as a brilliant craftsman, both creative and highly skilled from a technical perspective. Working closely with James is Sam, who has a Masters from the Cork School of Art and who also places high value on attention to detail. Cian specialises in large framing contracts. Ryan manages the print room, photography and front-of-house responsibilities. Lucy, Sarah and part-timer Ciara, assist with assembling and finishing off frames, which must of course pass Paddy’s high standard of quality control!

Cook Street comprises a team of three and is managed by the very capable and highly respected Louise. Louise, like James, has been with The Framemaker for over 20 years and has vast knowledge of all aspects of picture framing.

Paddy firmly believes, that the overall experience for the customer should be helpful, informative and also enjoyable! He says: “Positive, face-to-face staff/customer interaction, is of huge importance. One should never underestimate the value of personal engagement and a bit of chat! It is the key aspect of our business which separates us from the impersonal alternative that is shopping online!”

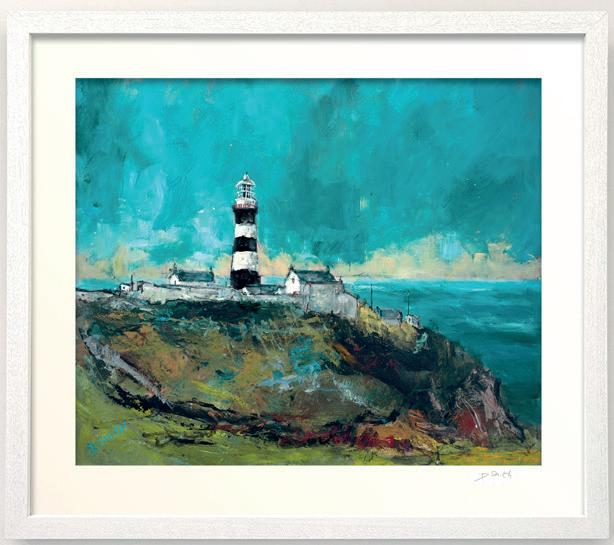

In both locations, The Framemaker stocks a wide range of framed artists’ prints and Paddy particularly likes to support local Irish talent. Danny Smith is one of Paddy’s favourites (see separate profile).

When it comes to framing, Paddy is passionate about the role it plays. A phrase he uses to describe framing is:

“The frame is the frontier between the real and imagined world.” Consequently, he puts a lot of thought into moulding choices.

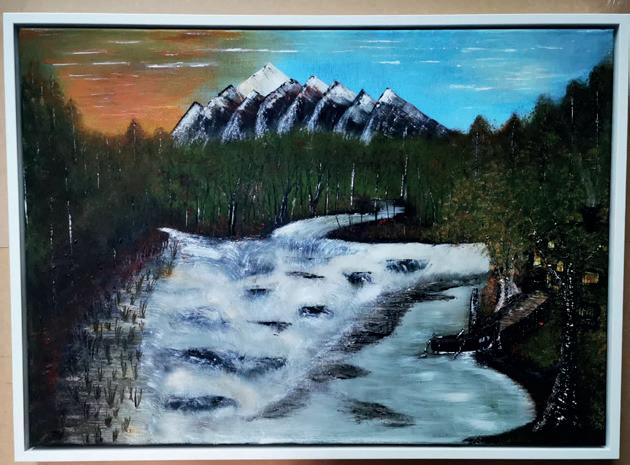

Danny Smith’s work is regularly framed in white Coastal Woods with a Hayseed mount – which really complements his style and looks fantastic. Square white-lined frames may be stylish and timeless, but Paddy is also pleased to see an increasing trend for more colour. Larson-Juhl’s Confetti and Andover being a couple of examples. When it comes to art, Paddy is also seeing a change, with a move away from abstract art to more realism, like landscapes, and a revival in popularity for old classics like the Impressionists.

Orin Forshaw is Paddy’s area sales manager and they have been working together since 2016. Paddy told 4walls: “Orin is very helpful and is always professional in his approach to business. He gives the Framemaker great service.

“Our business with LarsonJuhl increases year on year because the quality of the product is excellent and the service is also excellent. Orin’s regular visits along with his market knowledge and understanding of The Framemaker’s needs, play an important role in our business relationship.”

The Framemaker has a high number of commissions that include artwork but they also frame sports and other memorabilia. Among other things, this has ranged from a full army uniform to a two-foot ponytail of human hair, a pair of skis, shoes and a glass walking stick!

Using state-of-the-art printers and editing technology, the team also produces high-quality photographic and art prints onto a range of papers and canvas.

As well as bespoke framing, The Framemaker receives a considerable number of commercial contracts from hotels, offices and other business-to-business sectors.

Danny Smith was born in 1972 in the West Cork town of Bantry. He still lives there today, with wife Ursula and daughters Milly and Molly.

Danny is entirely self-taught. While he started drawing and painting from a very early age, it was in the year 2000 that he got serious. A postman by trade, Danny takes advantage of his short, early working day, spending the afternoons traveling around Ireland in his campervan, seeking inspiration from landscapes, seascapes and the people and animals he meets along the way. Danny is driven by a desire to capture the variety of light, tone, colour and atmosphere. Danny also receives a lot of commissions.

Danny has a long-standing relationship with Paddy. “Framing is very important, bringing an extra dimension to the artwork,” he told 4walls, “and it finishes the painting. I get very excited whenever I take work up to Paddy and can’t wait to pick it up!”

Running a bespoke framing business involves wearing a lot of hats. One is that of a sales person; a hat that doesn’t always sit comfortably. Perhaps because we see sales people as pushy, which doesn’t align with the way we want to interact with our customers. Many of us don’t have any sales experience and don’t know where to start. However, our customers need information and advice (even if they don’t always know it!) and that is a key part of being a good sales person. I’m sure that the role of informed advisor, which is how I think of selling bespoke framing, sits more comfortably with most of us than that of a pushy sales person.

You probably think that you slip your sales hat on when a customer walks through the door, but the sales process starts the moment the customer has any contact with your business. That might be through your website, social media pages, via your shop front or by word of mouth. When you first meet a customer, they will have preconceived ideas about who you are and what you do. Giving out the right message, via your marketing and follow-up communications, will help to attract the type of customers that want what you offer. This, in turn, will make your sales role easier. Think hard about the message that you give out, how it ties in with your USP and exactly which customers you are aiming at.

When a customer comes in to my shop I want to help them feel at ease and build a rapport. So, I often start off with a chat about the weather or where they’ve come from. This takes time, especially with a new customer, but I think it’s worth it. As we go through the sales/design process it’s important that the customer feels comfortable enough to express their opinions. Besides, taking time with a customer shows that you value them.

Having got a feel for the customer, I ask open-ended questions about the item they’d like framed: how they got it, its history, etc. This gives me an indication of the intrinsic and sentimental value of the piece (both equally important) as well how much emphasis the customer is likely to place on framing. At this stage it is important to prompt and listen. I always complement the item, in whichever ways I can, to subtly reassure the customer that it is worth framing.

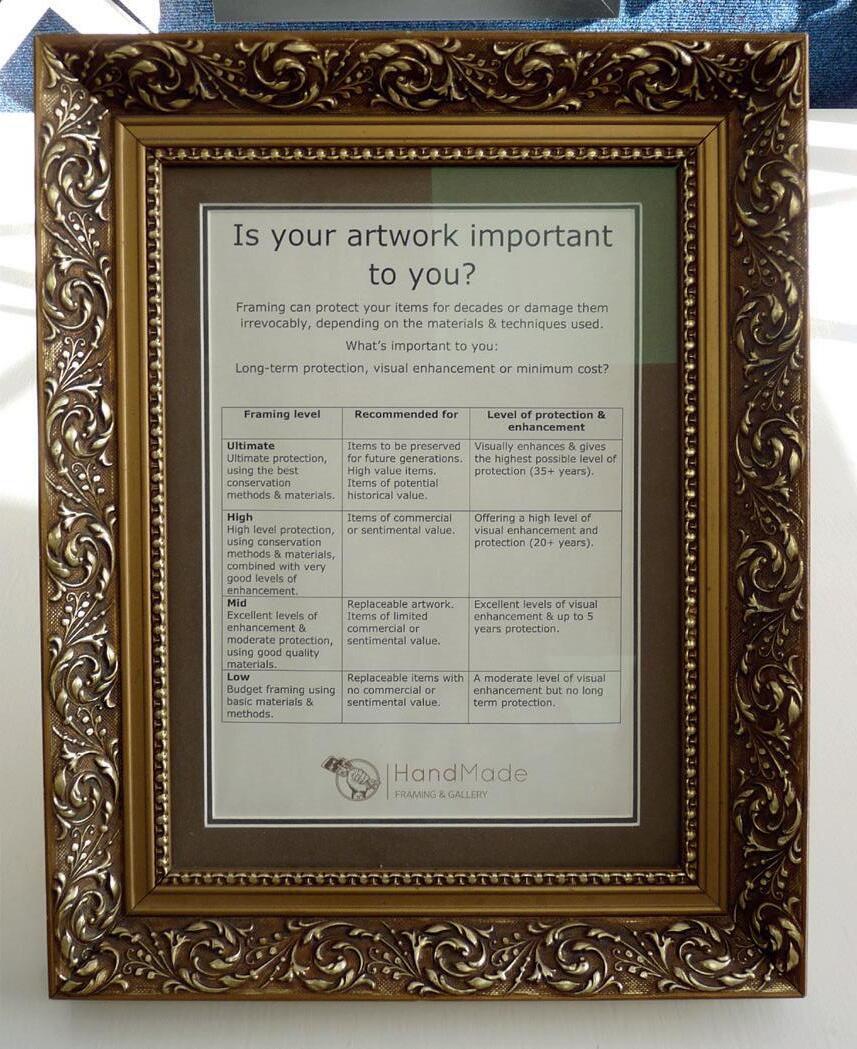

My business emphasises conservation framing, so I start the frame design process by explaining that different framing materials and techniques offer different levels of long-term protection. I explain why protection might be needed and give examples, often citing the difference between non-conservation and conservation mountboard. I then introduce the Fine Art Trade Guild’s ‘Four levels of framing’, showing the customer a table which explains the levels and asking which level they’d like for their item. If the customer asks the price difference, I explain that the price will be affected by the overall design. I suggest that they choose their ideal level and that this can be reduced at a later stage, if necessary, to decrease price. This reassures the customer whilst giving me the potential to down sell, if required.

I’ve now set the pattern for the whole sale: I provide expert information, explaining the advantages and disadvantages of each option and then ask my customer to choose.

I use this sales tool to help my customers decide on the level of framing they would like.

By the time I meet the customer face-to-face, it is likely that I have already established a level of expertise; through the marketing that led to the customer’s enquiry and the shop displays that customers see as they approach and enter my premises. However, as I go through frame design options, starting by selecting mountboard chevrons, I aim to gently assert my design knowledge. As before, I do this by providing expert information. I might start off by explaining that often the best way to enhance an item is to choose framing materials that match the colours within it. Once I’ve selected the mount colours that work best, I’ll demonstrate and explain that a single mount is the simplest option but a neutral single mount doesn’t do much to enhance, while a stronger coloured single mount often detracts from the artwork. I’ll then demonstrate how a double mount can be used to enhance by adding a small amount of colour that matches aspects of the artwork. I always go on to show more complex design options (upsells), for example, multiple mounts, a double mount with a V-groove or a shadow mount, as long as they enhance the design.

I gently assert my design expertise by explaining and demonstrating what I am doing and why.

Frame selection follows the same pattern: offer mouldings that match and enhance both the artwork and the selected mounts. Again, as long as they enhance, always offer upsells such as premium mouldings, stacked mouldings and fillets on the inside of the rebate lip. When a customer is uncertain, don’t be afraid to reassure with your expert opinion.

When it comes to more complex frame designs, it’s amazing how many framers have told me that they don’t offer them because there’s no demand or because customers can’t afford them. It’s equally amazing how many customers will choose, and pay for, complex designs when they are presented in the right way.

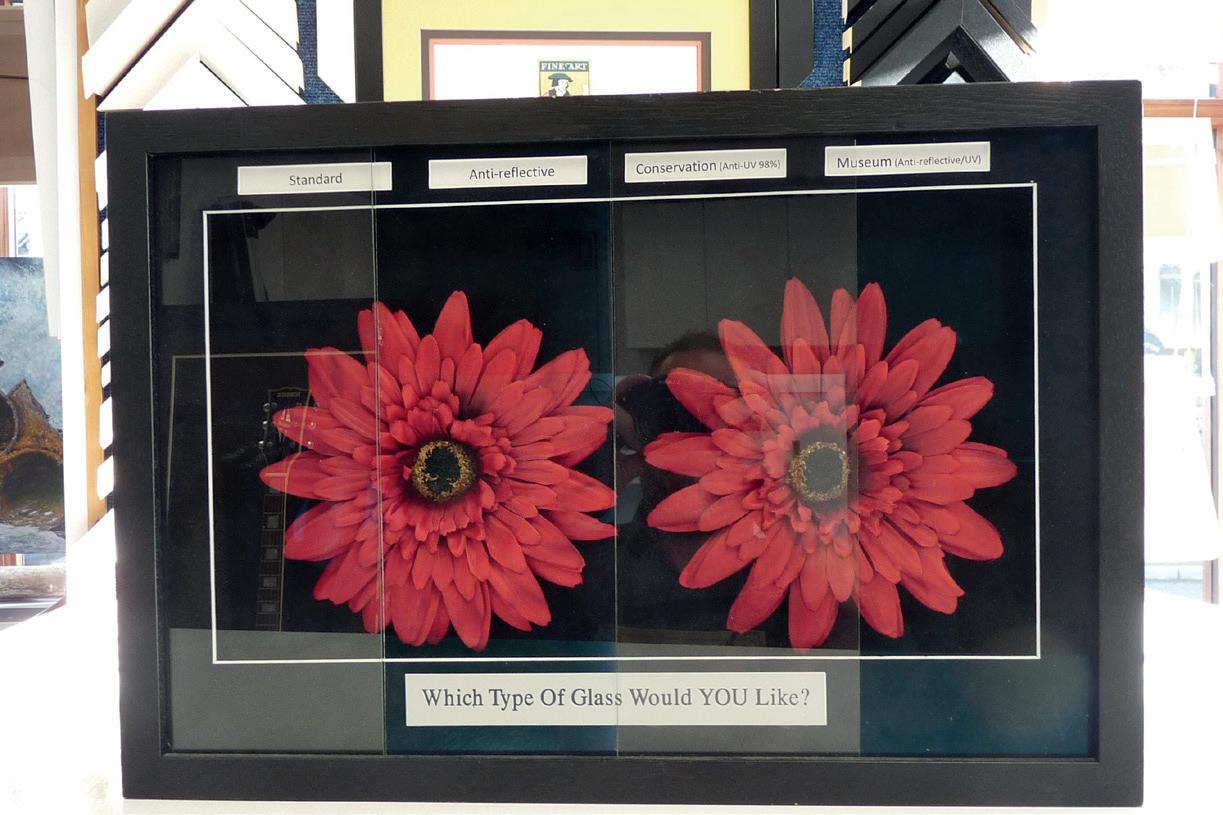

If you offer specialist glass you already know the right way because you are already making sales by providing expert advice and a range of options, including upsells: “This glass protects your artwork by blocking 98% of the ultraviolet light that causes fading. This anti-reflective glass is virtually invisible in the right lighting conditions and really lets the colour and detail of your painting stand out, and this museum glass does both, giving very high UV protection and stunning clarity. Which would you prefer?” Why not sell frame design in the same way?

Let’s also consider how we sell AR glass: we use sales aids; point of sale displays which show our customers AR glass and compare it directly to float glass. These displays sell AR glass so well that we often don’t need to do more than put them in front of our customers. This is exactly how to sell frame design; show our customers a standard design and then show them something special in comparison. To do this you need to make more sales aids: mount chevrons with V-grooves, key lines, deep bevels and shadow mounts, and stacked moulding chevrons. Offer them at every suitable opportunity. Make a selection of display frames with the types of designs you want to sell. Of course, this takes up valuable time. Think of it as speculating to accumulate.

Let’s finish off by addressing the ‘Elephant in the workshop’: pricing. It’s all well and good promoting enhanced design options but, if you’re not making a decent profit, what’s the point? You cannot offer complex frame designs without charging for your time. However, if you are clearly offering more, customers will expect to pay more. As a skilled professional you deserve to make a decent living. So, work out a fair and reasonable hourly rate based upon your business overheads and cost of materials, plus a mark-up for profit. Then look your customer in the eye and give them your fair and reasonable price. There will always be some refusals, no matter how little you charge, but there will also be plenty of customers that say ‘yes’. If you only offer single and double mounts that’s what your customers will choose. Why not offer them more complex design options and let your customers decide?

Jon Price runs Picture Framing Tuition, offering industry-leading framing tuition and business consultation to framers of all levels. He has over 25 years’ professional training experience and is a Fine Art Trade Guild Accredited Trainer. Jon has owned a bespoke framing business for more than a decade, during which time he has framed for world-renowned museums and exhibition spaces, as well as the works of internationally recognised artists, photographers, designers and musicians.

www.pictureframingtuition.uk

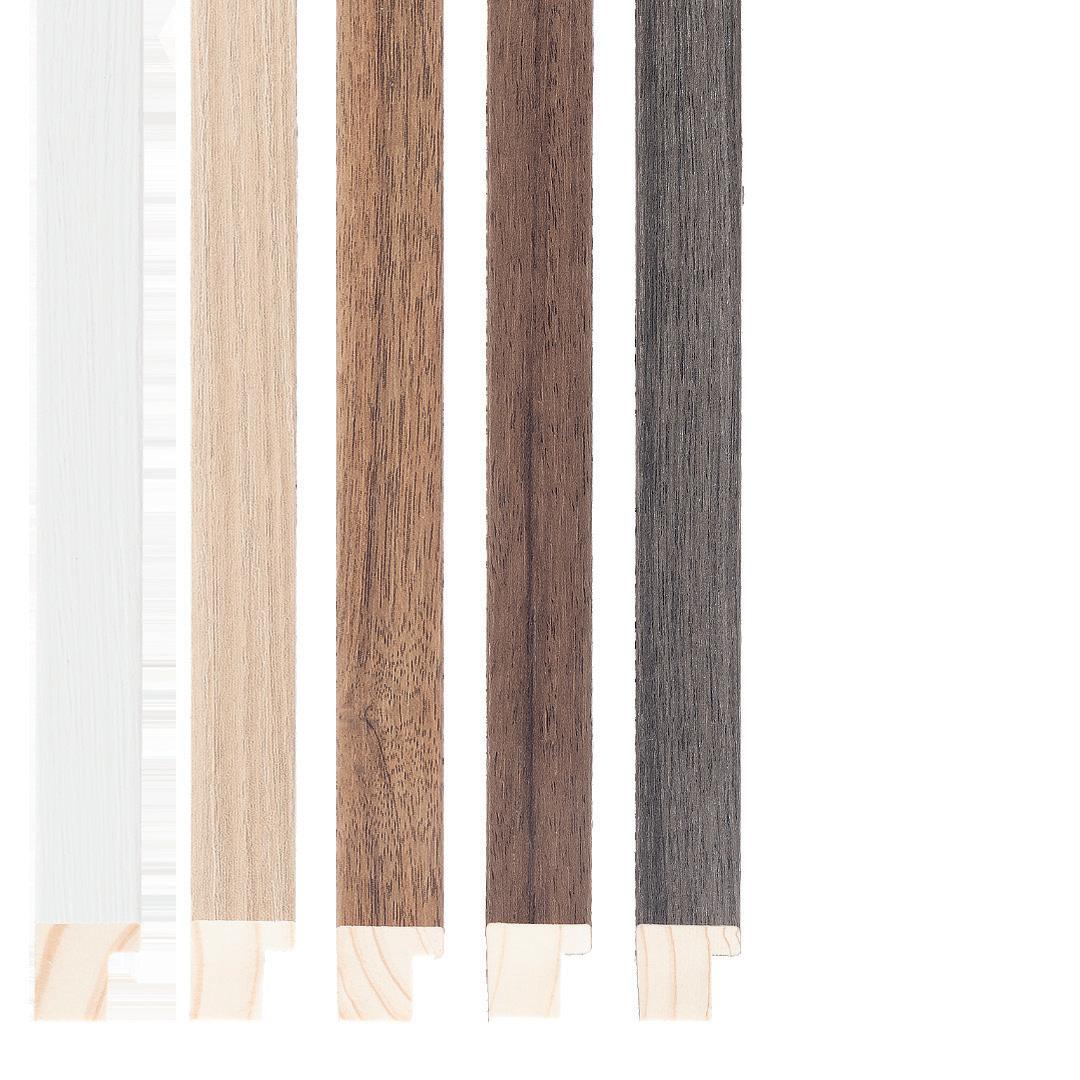

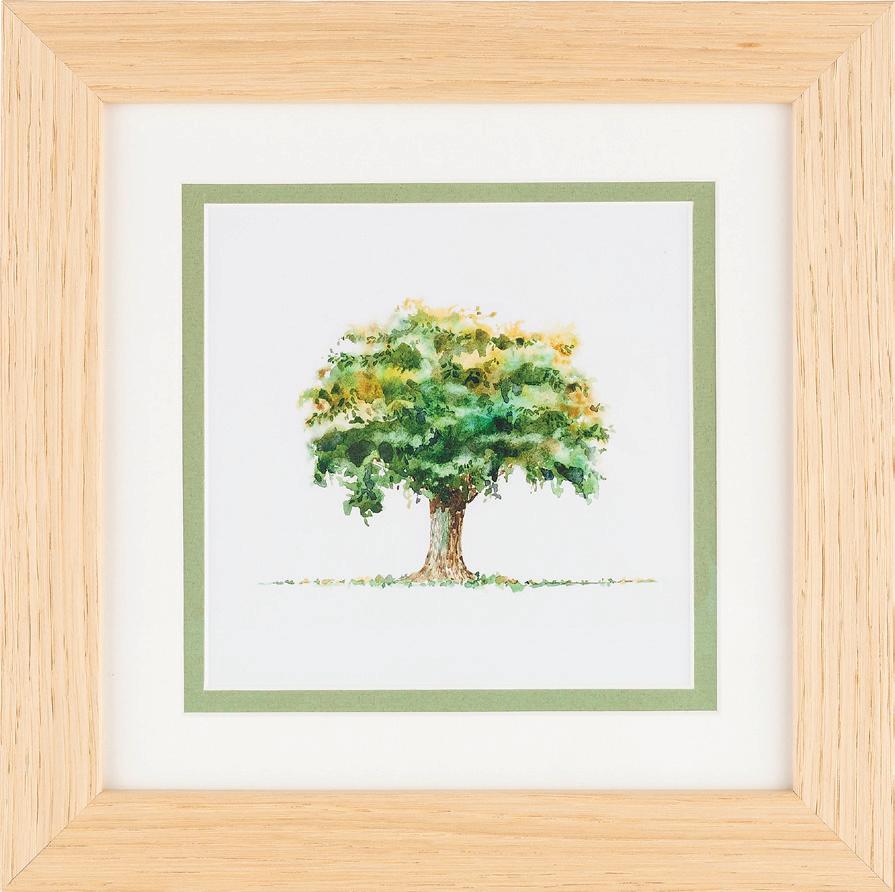

The two latest additions to the mouldings rangeNaturale and EcoWood – both have a sustainability aspect to their offer.

The Naturale Collection combines craftmanship with nature. Featuring a luxurious real wood veneer of oak and walnut, this range offers a timeless, organic beauty. With seven stunning colours and a variety of profiles to choose from, each moulding is FSC® accredited, perfect for those who seek both elegance and sustainability.

Our EcoWood Collection is also crafted with the environment in mind. Available in three stylish colours and two profiles, these mouldings add a sophisticated touch to any space. Made from responsibly sourced materials, our EcoWood range is FSC® accredited, ensuring eco-friendly craftmanship without compromising on quality.

Wilson Images Ltd specialises in the dry mounting and printing of limited-edition photographic prints, framing and consultancy services.

Based in Chatteris, Cambridgeshire, Jon Wilson and his partner Pauline Scullion work with artists, galleries, museums, photographers and other framers, both nationwide across the UK and overseas.

Although the business has been trading since 2016, it is only latterly that framing has become such a key part of their plans for growth with it now accounting for around 50% of their sales. On the back of this, Jon and Pauline have recently become Larson-Juhl customers as they look to focus on premium mouldings.

Jon fondly reminisces about his early career, when he worked with his brother in Hatton Garden, producing photographic images for exhibitions and with contracts for iconic brands like Nina Ricci, Alfred Dunhill, the Bank of England and the BBC.

From there he went traveling before joining John Jones in the year 1999. It was here that he developed his skills for dry mounting photography and artwork, with handfinished silk overmounts being just one example of his many specialisms.

Jon very much enjoyed these times and says: “We worked for every gallery you

can think of over the years and we worked with ‘celebrity’ photographers including David Bailey, Mario Testino, Nick Knight and Rob and Nicky Carter – some of whom are still customers today.”

In 2016, Jon decided it was time for a new challenge and so Pauline and he got their heads together to produce a business plan, found a site in Chatteris, Cambridgeshire, and launched Wilson Images. They continue to have a number of highprofile customers. For example, they received a commission for 200 David Hockney pieces towards the end of last year through Darbyshire Frames. Flowers Gallery is another long-time loyal customer with a reputation for beautiful art who Jon loves to work with. Edward Burtynsky and Nadav Kander being two of his particular favourite artists.

Further developing the framing side of their business is a top priority for Jon and Pauline, and given they focus on high-end images, it is important that they have a range of highend mouldings. They recently redesigned their Larson-Juhl chevron display as they know it helps them to sell premium mouldings. Jon says: “The Larson-Juhl range looks superior – the products are superior! Everyone who comes in falls in love with these mouldings. They also cut beautifully and don’t chip.”

He adds: “I remembered area sales manager John Green from my London days, so it was great to meet him again at our factory and studio. He’s a great guy and really understands our business.”

Some of Jon and Pauline’s favourite products include Spoleto and Metalia. The 4walls team was delighted to hear that Jon and Pauline are planning to use more and more Larson-Juhl mouldings going forward.

Jon’s consultancy work covers the science behind the materials used and he advises on all aspects of the handling of artwork from printing through to conservation and storage.

With a background in theatre ticket sales and administration, Pauline also has a natural understanding of what works visually and creatively so their skills are very complementary. The pair met almost 30 years ago at The Clockhouse in Dulwich, often frequented by actors and musicians back then. Today, they have a thriving business that is evolving in many different ways. For example, in the future, Jon and Pauline have ambitious

plans to build a mezzanine floor and to open a gallery to showcase local talent. This will include Jon’s own work as he is a photographer and artist too - and has started to develop a portfolio that features nature. Larson-Juhl’s colourful Zen range is perfect for Jon’s paintings and photography. 4walls looks forward to hearing how all aspects of Wilson Images develop!

They also cut beautifully and don’t chip.

In 1988, the Beckett Framing Company started as a bespoke picture framing business on the Cheshire/Shropshire/Welsh border. Skip forward to 2025, and they’re now fully settled in a new workshop and gallery, purpose-built back in the autumn of 2023 at owner Elaine’s home. Thanks to their excellent reputation and long-standing relationships, their loyal customer base has followed them on their five-mile move out into the beautiful countryside.

Over 30 years ago, Elaine Beckett had just finished her A levels and started an apprenticeship for a picture framer close to home – GTM Crafts in Overton-on-Dee, near Wrexham. Elaine got on really well with the owner, George Mysal, and after a couple of years when he decided to retire, she bought the business from him and continued its success.

“It’s changed names a few times, but the equipment is all the same, especially the original Morso which has really stood the test of time!” Elaine told 4walls.

And now in the present day, a few more things have changed – even the premises –but the quality and dedication to framing has certainly never wavered. The new workshop built next to Elaine’s house was created for a couple of reasons, from framing efficiency to a shortened commute! Everything was moved across in the early months of 2024 and by autumn, the business was fully functioning as usual.

“Our customers trust us and know we’ll get the work done on time for them,” says Elaine, “I’ve gotten to know our bespoke customers really well and they know I’ll always accommodate them.”

Elaine has chosen to really harness the

power of social media to build her brand. With over 800 followers on Instagram, she uses it as a way to get the Beckett name out there, but also as a great means of documenting work and favourite commissions that have gone through the workshop. “Lots of people find us on Instagram. People come in and say ‘I saw this’ and want something similar, so it’s a nice way to showcase moulding options,” says Elaine.

Although it’s time consuming to do properly, Elaine feels it’s important to put the hours into social media and you’ll certainly see the benefits from it. It’s also a great way to tag and feature artists, to

Our customers trust us and know we’ll get the work done on time for them.

support each other and get them some valuable and deserved recognition.

The Beckett Framing Company has used Larson-Juhl for a very long time, so much so that Larson-Juhl is now the main supplier. The business stocks a great mix of the range and their fantastic chevron display consists of almost solely LarsonJuhl mouldings.

Beckett’s area sales manager, Richard Clayton, has visited the new workshop and gallery and was really impressed with the space. “Richard is one of our favourite

reps,” says Elaine, “although all reps from Larson-Juhl have been good actually, we’ve got a really strong relationship.”

Geoff Beckett

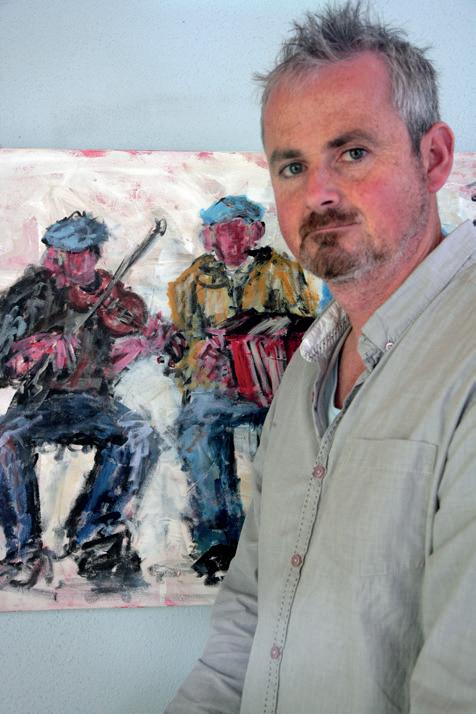

4walls also managed to catch up with artist Geoff Beckett, Elaine’s brother, to learn about how the two have been working in partnership for an incredible 17 years, with Geoff still occasionally supporting on the framing side of things.

Despite doing a maths degree, Geoff has been an artist for most of his life. “I’d always painted, but never planned for it to be an actual career,” he told 4walls, “I got my degree back in 2004, spent a couple of years in finance and then went to help Elaine when she bought the workshop. It definitely helped me at the start of my art career to meet people in the industry and get in with some galleries.”

With the framing business booming, the two split the work a few years ago so that Elaine concentrates on framing, and Geoff has more time to focus on his art.

Geoff pointed out the importance of having multiple income streams. As well as selling his original pieces through galleries and art fairs, and licensing his artwork, he also built up online sales through the pandemic lockdowns on his own website.

A further sideline is running the publishing business, Beckett & Green, together with his illustrator partner Sophie, where they sell prints and greeting cards of their own designs to the trade. “It’s been a tough few years in the art

It definitely helped me at the start of my art career to meet people in the industry and get in with some galleries.

business, but by diversifying and not relying too much on any one sector it’s all kept ticking over nicely,” says Geoff.

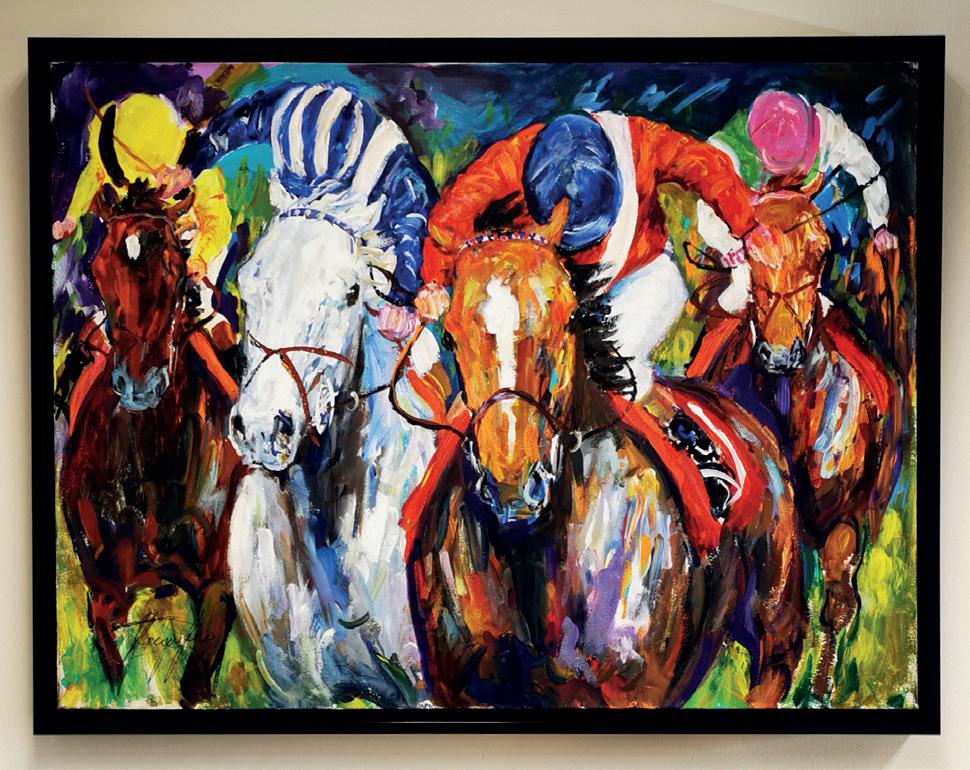

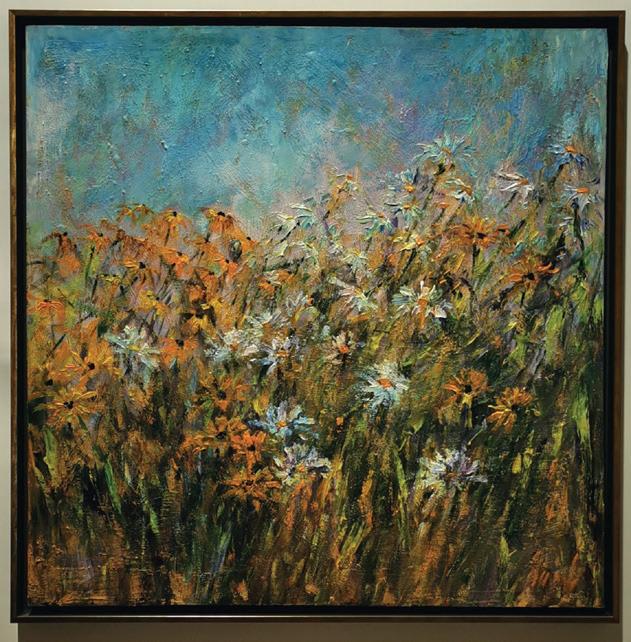

Thanks to his experience and skill set, Geoff frames all of his own pieces, regularly using Larson-Juhl mouldings to complement his art - such as 241000107 and 241000127 from the Coastal Woods range and 756287000 from the Essentials range.

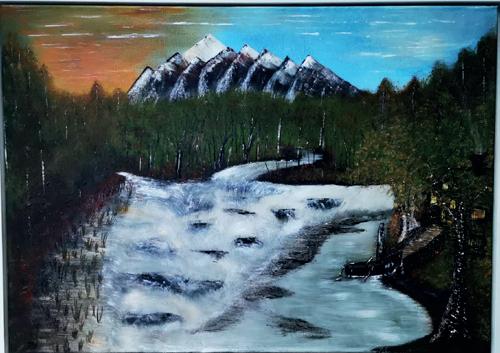

His main style is textured landscape paintings, created using sculpted paint and resin that gives a 3D effect often leaving people questioning whether it’s ceramic! This unusual style really grabs attention and has seen his business soar. “Standing out from the crowd is half the battle,” explains Geoff, “and making sure the art is well framed really helps!”

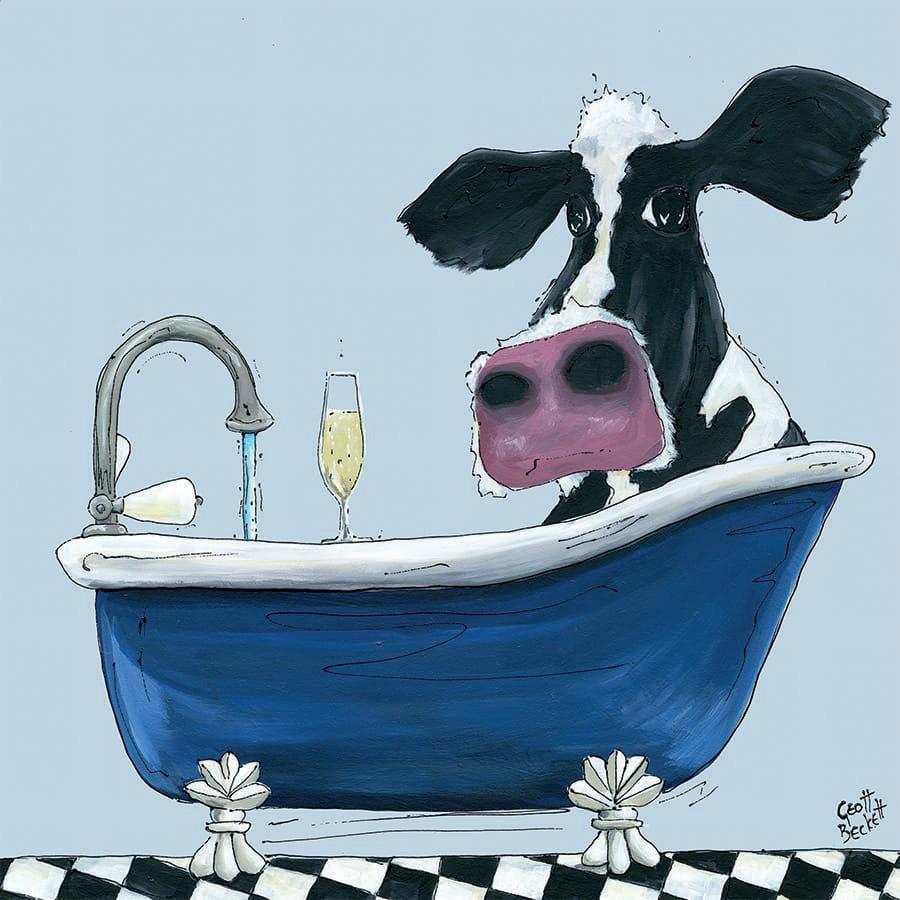

Another style of Geoff’s is his range of quirky cow paintings which you can find on his website. These light-hearted pieces reflect his farming roots and complement the countryside landscapes.

www.beckettframing.co.uk

www.geoffbeckett.co.uk

www.beckettandgreen.co.uk

1978

The company moved to a unit at the Manton Industrial Estate in Bedford. Arquati’s portfolio was focused around dark woods with a gold sight edge or gold and silver leaf.

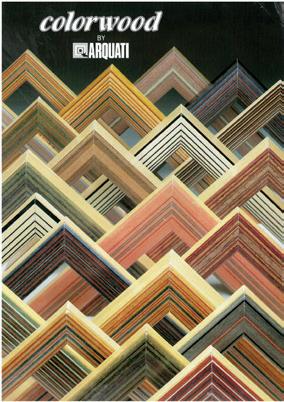

Derek commented: “The brown furniture finish style was the most popular type of moulding in the seventies; they were successful straightaway. We also offered a range of coloured wood mouldings that had an aluminium insert added. These were ‘way out there’ for the time! However, it was something framers had never seen before, so they went down well.”

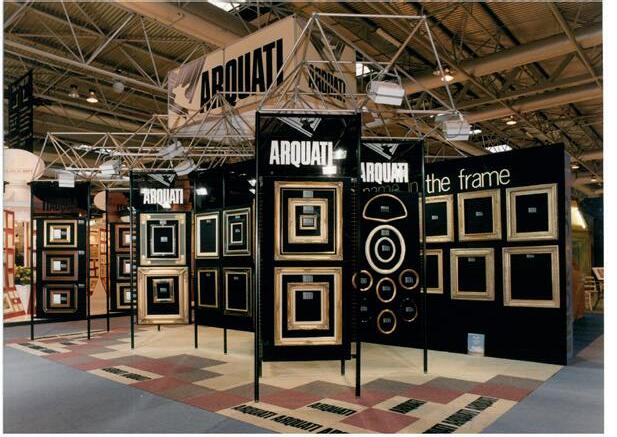

The company was originally known as Arquati UK, founded by Derek Masters and Denis Ballinger in Flitwick, selling a range of around 110 mouldings and with five staff. The company was backed by Italian businessman Franco Arquati.

Arquati was one of the original companies to exhibit at the first Spring Fair.

Mountboard was introduced with a choice of around 20 colours.

Arquati produced its first catalogue, having previously used suppliers’ materials to showcase products. This involved all the mouldings being laid out in page order on the meeting room floor and photographed! The company name changed to Arqadia - which involved major celebrations as well as all the logistics around signage, stationery, etc.

The business moved to Woburn Industrial Estate in Bedford to accommodate the growing product range.

Arquati was sold to Larson-Juhl.

2004 took director.

2005 was introduced newly James Sullivan of James Frames was one of Arquati’s first customers and said: “I remember when Derek first turned up at my Reading workshop. He just had a small case with a selection of moulding samples that they would then get delivered from Italy.”

While Larson-Juhl bought Arqadia in 1996, the name did not change until 2019. Although a relatively new name to the UK framing industry, Larson-Juhl has an impressive heritage that can be traced back to 1893 and the launch of Pacific Picture Frame in Seattle!

Over the next half century, the custom framing industry took off as a commercial opportunity with

PEFC and FSC™ Chain of Custody accreditations were achieved for a significant number of mouldings.

2014 - Whitecore and conservation standard mountboard were introduced.

2015 - The warehouse became paperless. Facebook page went live.

2016 - Larson-Juhl Scholarship was launched with the Fine Art Trade Guild.

2017 - Instagram page went live.

2018 - Chop service was introduced – a first for the industry.

- Mike Brown over as managing director.

- Online ordering introduced via the newly created website.

4walls was launched with 16 pages showcasing products, best practice, Ask the Experts, ‘how to’ features and industry news. Issue 2 featured The Rolling Stones and many subsequent issues have included celebrities from the world of art and music. The focus on providing advice, support and relevant news has been a constant throughout.

many new inventions speeding up the process. By 1957, Roger Larson had formed frame manufacturer Larson Picture Frame in Minnesota, and Tom Juhl had founded the frame shop Juhl Inc, in nearby Minneapolis. In 1968, Juhl Inc merged with Pacific Picture Frame to form Juhl-Pacific. Major investment in distribution and logistics from both businesses

The company moved to Bedford Link Logistics Park.

The challenges of the Covid19 pandemic dominated everyone’s agenda through to 2021.

The first series of LarsonJuhl webinars launched to help framers stay connected during the pandemic.

Happy 50th Birthday Larson-Juhl. Our commitment to quality and service is as strong as ever. We do what we do to give your customers the best product and let you focus on framing!

Arqadia changed its name to Larson-Juhl and 4walls got a new look.

Power Bi and CRM were introduced to the sales and customer service teams. With customer and product data available in realtime, the focus on service remains as important today as it was in 1975!

resulted in rapid expansion across the United States. Twenty years later, Larson Picture Frame and Juhl-Pacific merged to become Larson-Juhl, and by 2002 was clearly an impressive, thriving concern with international reach across 17 countries, as it was then acquired by American entrepreneur Warren Buffet.

Throughout the years, the core values of delivering excellent customer service, breadth of range and premium quality have remained paramount, which is a huge part of the brand’s longevity and global success. Despite its presence around the world, however, the focus on local service has been a priority in every region and country.

The furthest one, which I thought was a joke when she first phoned up, was from Australia!

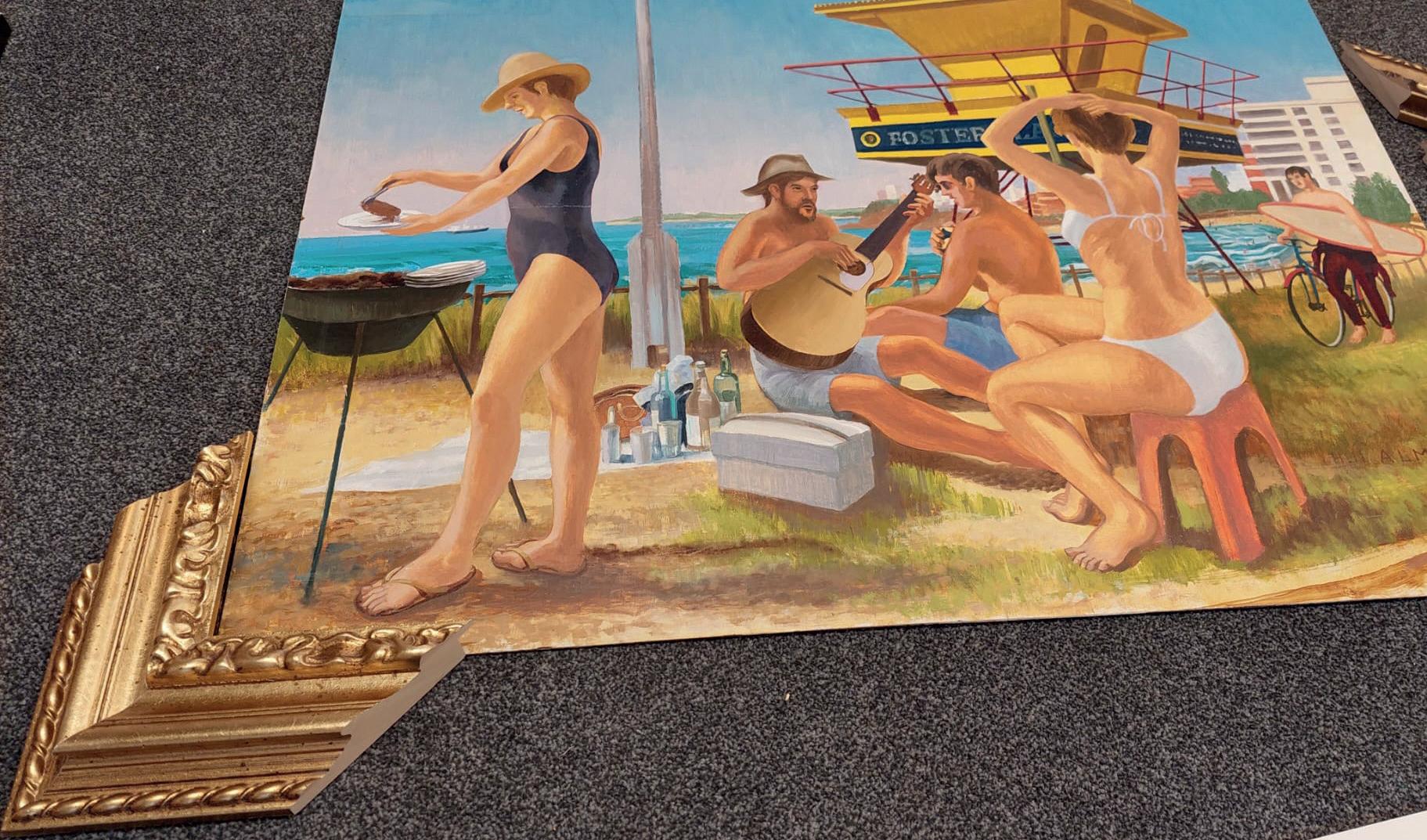

The selection process using Larson-Juhl Prague 869077 for the Loungers contract

Hang It Picture Framing opened its doors in Totterdown, Bristol, back in January of 2020 – a date that most will remember as the start of a very turbulent time for businesses of any age, but especially a new one. Despite the following pandemic, John Marsh and his wife, Sharon were not set back on their mission to build up their framing business. Today, they typically have over 80 jobs to complete in a week with orders coming in from as far afield as Australia, so it’s safe to say there’s a success story to tell!

John’s first taste of the framing industry was working at Art Original in central Bristol. He worked there for 29 years with owners, Paul and Jenny, and eventually built up his skill set to run the workshop himself. “In the end, I got to know everything and dealt with all the suppliers, so it was just Jenny and I running it really,” John told 4walls.

Although the couple wanted John to take over Art Original, he had dreams of setting up his own framing workshop, so that’s exactly what he did.

“I’d never done anything like that before, so I started off as just me, thinking it would be nice and easy,” explained John, “but from the day I started, it’s not let up from there – there’s never been a quiet day!”

Luckily, John was soon joined by his wife Sharon who mainly does all the bookkeeping and serving customers. “She used to work as a theatre nurse handing surgeons tools, now she hands me tools!” John jokes.

Hang It Picture Framing sadly had to temporarily close almost as soon as it opened, shutting for two lockdowns and then opening back up properly just before Christmas of 2021. “When we finally opened back up, we were just unbelievably busy – people were working from home and wanting to update their interiors,” says John.

Although the volume of orders caused a six to seven-week wait, that still didn’t stop the constant flow of customers

who were so pleased to have such a shop in their local area – and it’s not just the locals who appreciate John’s work. “People easily travel 20 miles to get to us,” he says, “the furthest one, which I thought was a joke when she first phoned up, was from Australia!”

Situated on a busy main street, John has noticed a trend in people spotting something they like in the window as they sit in traffic on their morning commute, then when they arrive at work, they call in and enquire about it.

“We get lots of repeat customers,” says John, “there’s no need for us to advertise.” Although drive time has become the perfect sales tool for the business, Hang It Picture Framing has outstanding online reviews and they are heavily and effectively marketed by their loyal customers’ word of mouth.

“I’ve been doing it a really long time,” says John, “people rely on my experience and generally take my opinion on how to frame something.” Despite the high amount of orders coming through, John and Sharon know exactly how to tackle the workload.

When we finally opened back up, we were just unbelievably busy – people were working from home and wanting to update their interiors.

up with over 40 samples to use – Derrick’s fantastic and has such a huge amount of framing knowledge,” John explains. They’ve just recently changed over to a new area sales manager, Joel Marr, who has supplied John with a huge sample collection of ornate mouldings so that he’s set up for success with the Loungers contract.

www.hangitpictureframing.co.uk

“We also owe a lot of custom to our third member of staff – and a very important one at that,” Sharon told 4walls. “Our Boxer puppy Loki started to work with us from just nine-weeks old and is now 18 months. He is a firm favourite with our customers who have watched him grow with us. Our regular postman comes in daily to say ‘hello’ to him, even if we don’t have any post!”

Lots of people don’t want to lose John and Sharon and lucky for them, they’ve just taken out a 10-year lease, so they won’t be going anywhere! 4walls is so pleased to hear this and looks forward to seeing the business thrive.

Alongside the bespoke orders, John has also secured some top contracts across the UK. Loungers has around 280 café bars and are looking to almost triple that number over the next 10 years. “I do stacks of framing for their interior decor – they usually choose gilt frames from Larson-Juhl,” explains John.

Loungers send through around 90 canvases at a time and they like to have a variety of detailed, ornate-style mouldings so that each one is different. John has found that the Larson-Juhl Signature collection is perfect for them, regularly using products like LJS Prague 869077, 869075 and 869079, LJS Intermezzo 771560, LJS Sevilla Brown 750542 and many more!

“At the start, I only had about four samples from Larson-Juhl, but my area sales manager, Derrick got in contact with me, took me through the catalogue and set me

By Alec Palmer GCF(APF)

ADV

and Jo Palmer GCF(APF) ADV

“I just want the skinniest black frame on this.”

We’ve all faced that awkward conversation at the design desk with a customer. They request an unrealistically narrow wood frame on a large piece of work. You suggest options that are more substantial and size appropriate. It goes back and forth between the customer’s request and the practicalities of making the frame.

As a framer, you know all the downsides to that skinny moulding on bigger frames. These might include the lack of support and integral strength, the pressure on mitres due to weight of the glazing and the inherent overall weakness of the finished piece when it is being transported. Will it even make it home safely?

Of course, we’re not just framers, we are problem solvers. In most cases, we’re able to take some time and think about how to adapt what we do to meet our customers’ expectations. So how do we problem solve that skinny moulding on a large piece?

The easiest way could be to reduce the weight of the package within the frame. Changes to the board materials or glazing options can have a bit of an impact. But in many cases, those mitigating decisions really won’t be enough or even be appropriate. So how can we strengthen the frame itself?

The most obvious solution is to use a sub-frame. The main criteria should be that the depth of the moulding can fit the artwork package (glazing, mounts and backing boards) as well as the depth of a sub-frame.

The sub-frame becomes the structural strength – supporting the weight and allowing fixings to be securely attached so that it can be hung safely. The customer’s choice of a skinny moulding then becomes a decorative rim visible from the front. The sub-frame can be made from any appropriately sized timber and the idea is for it to be hidden away at the back.

You could use a suitable length of prepared timber – creating a rim with lap joints (other woodworking joints are available!) strengthened corners and even brace bars if it is very oversized. A handy bare-wood moulding can also easily be utilised. But these days many suppliers stock dedicated sub-frame mouldings. Larson-Juhl offers two sizes: 596 500 000 which is 51mm wide and 15mm deep and 594 500 000 which is 38mm wide and 10mm deep in finger jointed pine. There is also a flat slip option 151 400 000 which is 67mm wide and 9mm deep.

3

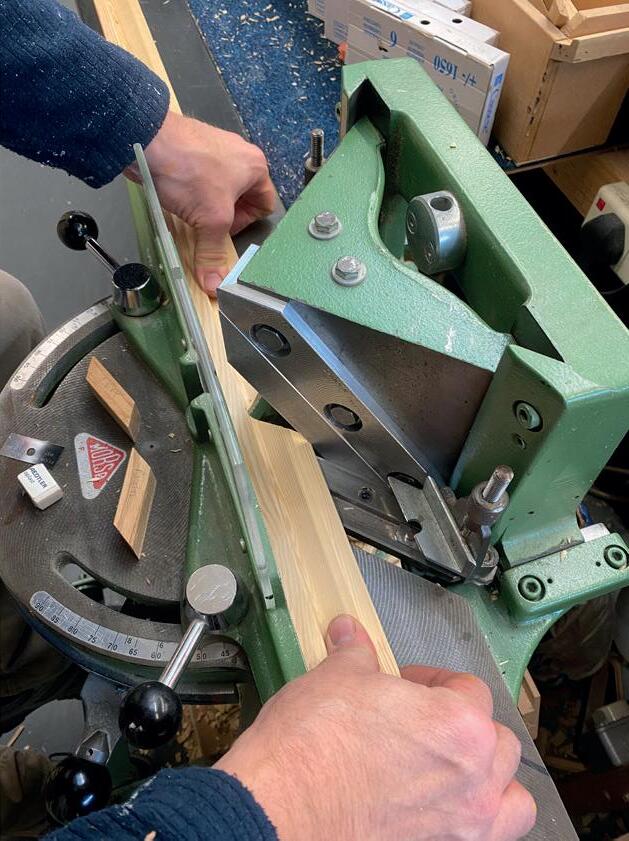

The first step is to make your frame using the skinny moulding. Once this is made and the glue on the mitres has cured or the frame is being securely held in clamps, you start cutting the sub-frame. (Photo 1) Measure carefully so that the sub-frame fits snugly, but not so tight that it is in any way forcing against the mitres. Glue and pin the subframe as normal. (Photo 2)

Obviously, you need to fit the artwork into the frame BEFORE you install your sub-frame! If using glazing, you may find it easier to seal the glazing and mount package around the edges with tape before fitting to avoid dust ingress. Fit the backing board, framers points or other fixing tabs and seal with brown tape as normal.

Next prepare the sub-frame for fitting. If you are using a specially designed sub-frame moulding these have a handy channel that allows you to easily fit fixing screws. If you are using prepared timber or similar, then

you may need a pocket hole jig to create the same angle.

Using a drill, carefully drill pilot holes using the angle of the channel as a guide and staying parallel to the bevel line. (Photo 3) Once the pilot holes have been drilled it is time to fit the sub-frame into the frame itself. Select appropriate length screws and carefully screw through the sub-frame and into the outer frame. How many screws will depend on the size of the frame, but make sure to have them at regular intervals along all four sides. (Photo 4)

Once the sub-frame is secured you can, of course, cover that with brown tape if preferred and this is also where you can secure any hanging fixings.

The advantage of either the dedicated subframe moulding or the flat slip option is that they can also be utilised as an integral French cleat, also known as a split batten style fixing.

With their own successful bespoke framing business, drawing on over 50 years combined industry knowledge and expertise, Alec and Jo Palmer are also Guild Accredited Trainers and Guild Certified Examiners. They have both achieved the “full house” of the Guild’s GCF and three Advanced qualifications. They serve as current members of the Guild’s Framers Committee and Jo is a past Chair & Master of the Guild.

To use this style of hanging, the back edge of the sub-frame must be flush with the back of the moulding – so add additional layers of foamboard or other backing if necessary underneath it. (Photo 5) The advantages of using this type of hanging fixing is the distribution of the weight of the overall piece along a longer section. Especially useful for long panoramic images where there can be a tendency for the top rail of the moulding to bow. This type of fixing has the advantage of being flatter to the wall and if installed correctly, being extremely secure. You simply need to provide your customer with an additional piece of the right length that they can secure to their wall, for the frame to lower down onto. (Photo 6)

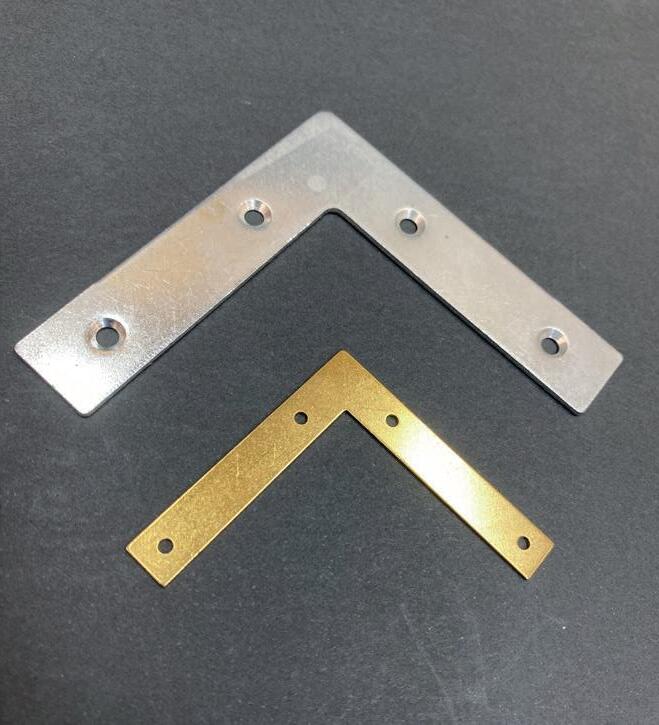

If you are using prepared timber or other flat wood for a sub-frame, then you can purchase metal versions of French cleat/split batten fixings which allow you to still incorporate that type of hanging system. (Photo 7)

Alongside other fully qualified framing professionals, they offer industry specific training and business consultation via www.pictureframingtraining.com.

Invariably with picture framing, there is more than one way to achieve an outcome. Which method you use will depend on the circumstances on the design desk in front of you. The final choice can sometimes become clearer as you are making up the frame. Knowing the available resources allows you to reassure your customer at the design stage and then decide and engineer the final product in your workshop later.

The structural help could be as simple as attaching the backing board to the back of the frame itself. It does seal the frame firmly shut, so is only suitable if the customer doesn’t want to swap out the artwork. Whether you use MDF or kraftboard, you cut the backing board to just short of the external frame dimensions and glue/staple the board (Photo 8) around all four edges. This prevents bowing of the moulding and reduces the flex of the frame. It gives instant strength, and is a finish which is widely used in continental Europe. It can be less effective though, as the frame dimensions increase.

Metal corner braces (Photo 9) are a manufactured product that could also be

used. They don’t help with any bowing of the moulding, but may offer some helpful support across the mitres. They are also only useful where the moulding to be supported is wider than the corner brace. Therefore, they have clear limitations.

Corner braces can be very effective for older frames which need a bit of extra support in the mitres. As an example, an antique frame with mitres gaping open, but which needs to be retained because it is age-appropriate would be an ideal candidate for this type of support. The corner braces won’t close the mitre, but they may give it enough support to enable the customer to continue to safely enjoy the frame on their wall.

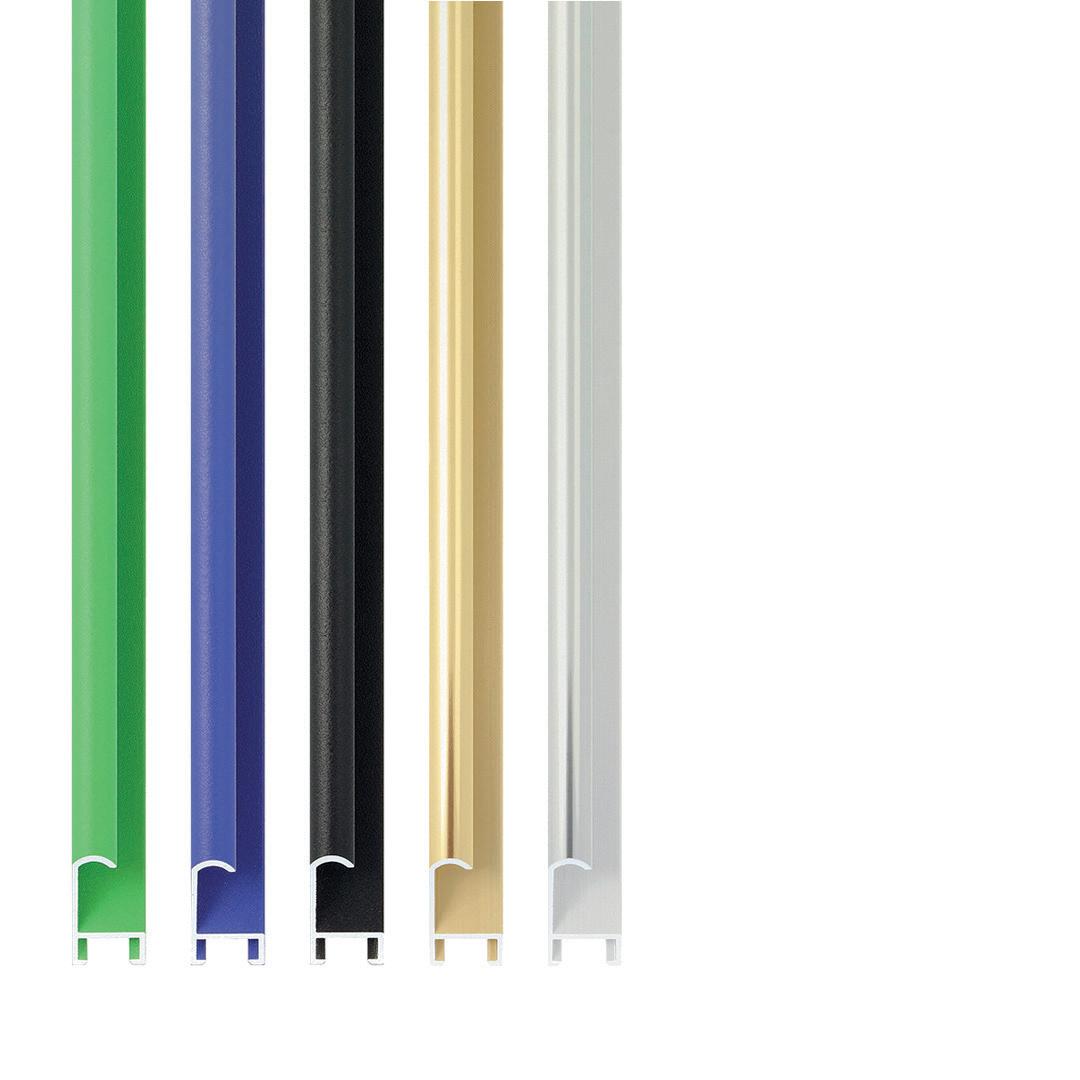

Aluminium frames can also be an option when a skinnier look is needed. They offer

more robust support than their equivalent size in wood. The Larson-Juhl Clark range of aluminium mouldings is available in a wide choice of profiles and colours. But even some aluminium frames, if deep enough, can be boosted with the addition of a wooden sub-frame (Photo 10). Whereas on wide panoramic styles where a sub-frame won’t fit, you may instead want the support of bracing straps to prevent flex and bowing (Photo 11).

Finally, there are the jobs where even the chunkiest of mouldings can need a bit of extra help and support, particularly for when they are being moved and transported. On wider mouldings a subframe may not be appropriate, but fitting wooden corner braces can avoid awkward mitre flex and the danger of closed-corner frame mitres cracking. (Photo 12)

There will be times where your professional knowledge will caution you against agreeing to use a very skinny frame. But where it is appropriate, having various solutions available to you can alleviate some of the concerns about meeting customer expectation. Safe in the knowledge that the frame’s structural integrity won’t be comprised, because you’ve added that all-important additional support.

As a market-leading supplier to the framing industry, Larson-Juhl is totally committed to supporting emerging talent, which is very much evident in the Larson-Juhl Scholarship.

4walls caught up with two of the 2024 winners: Janine Bailey of Arlais Framing and Hayley Bell of Frameworks Picture Framing.

Janine Bailey is relatively new to the sector. She has a background in graphic design and wanted to get back into the creative industries. She started framing in 2022, initially trading from home, then moved into a dedicated workshop in the spring of 2023. Today, Arlais Framing, which is located in Llandrindod Wells, is thriving. Janine’s favourite commissions are textiles and cross-stitch – which she regularly frames in Larson-Juhl’s Metalia and Elegante.

Janine is a big fan of Larson-Juhl’s chop service as she holds limited stock, but likes to offer customers a wide choice of mouldings. Added to this, free carriage makes it great value for her.

Janine applied for the Scholarship because she has a thirst for learning. She told 4walls: “Whenever I start something new, I want to progress. And I want validation!” Janine will be attending her two-day training session with Jo and Alec Palmer and then taking her GCF exam later in the year.

www.arlaisframing.co.uk

With 16 years in the framing industry under her belt as an employee, Hayley Bell launched her own gallery and framing workshop business called Frameworks Picture Framing, in Paignton in 2023.

While Hayley was already a very competent framer, when she attended the two-day workshop with Jo and Alec Palmer of The Framing Lot in Dawlish, she reached a whole new level of confidence and passion for the sector.

Hayley says: “I call Jo and Alec ‘the gurus’! Their set-up is absolutely amazing. It was really hard work trying to absorb everything! I didn’t want to miss a single thing and I felt so lucky to learn from them first-hand. This was exactly what I had hoped to achieve from this element of the scholarship when I applied.

“While I’d got 16 years’ experience to reference, I was only taught by a single person. Now, as a scholar, not only have I benefitted from a wonderful and intense training course with Jo and Alec, I also have access to all the Guild’s

resources and huge pools of knowledge. I can check out whether there is another way of dealing with a particular framing challenge – not only relying on my own experiences. It has given me a real boost and I am really excited about the future growth of my business.”

Hayley is already using her Guild membership in her marketing activity and her GCF exam is imminent, adding: “Having a professional accreditation will really make a difference, building reassurance and trust with new customers and helping to differentiate myself as a professional.”

Hayley is a big fan of Instagram and Facebook, particularly to promote initiatives like Artist of the Month – which features local talent in her gallery window.

When it comes to mouldings, Hayley’s Larson-Juhl favourites include Komodo and Anvil – which is featured here, framing African spears.

You can find out more about Hayley on her social channels at @frameworks_picture_framing and www.frameworkspictureframing.co.uk

Framers can apply for the 2025 Larson-Juhl Scholarship at https://www.fineart.co.uk/ larson-juhl-scholarship.aspx

Round 1 opens on 1st April.

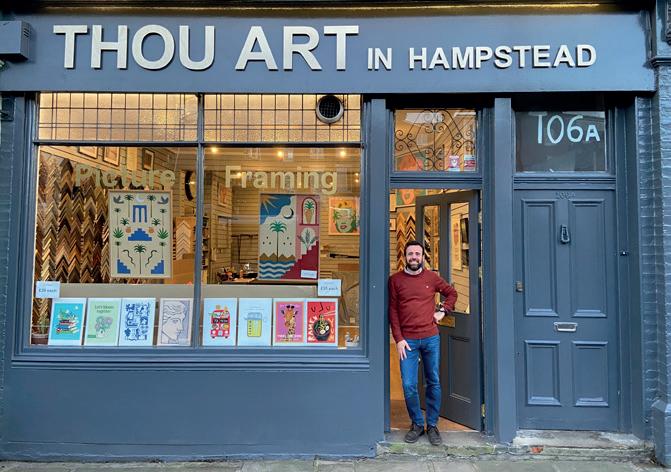

Antonio Yepes Perez truly was born into the framing industry. His parents, the proud owners of Turo Marc based in Barcelona, have been running their successful framing business for over 50 years. It’s no surprise that Antonio spent a huge amount of his childhood at the workshop, becoming increasingly involved as he grew older, leading him all the way to his current position as owner of Thou Art in Hampstead Limited, based in North London.

Coming from a family of picture framers, Antonio certainly gained the base of his framing knowledge from the team at Turo Marc, but down the line has realised there’s always more to learn and continuous room for growth in his skill set.

“My Dad (also called Antonio) is still doing it now – he’s 76 but he just loves it,” says Antonio. “When I was younger, I started going to the workshop to do my homework and I would help out wherever I could.”

As he watched the framers work, they would gradually let him try more and more things until he was old enough to use some of the workshop machinery.

“I then started going in the school summer holidays and by the time I was at university, I was working there part time,” he explains. In the end, Antonio actually decided to leave university as his responsibilities rapidly increased at the family business.

When Antonio turned 22, he took a break from the business and moved to the UK. “Originally it was just for a month, then it was six months, now it’s been almost 20 years,” he laughs. Although both himself and his parents always thought it would be a temporary move, Antonio met his girlfriend (now wife, and co-owner of Thou Art), Teresa, soon after moving to the UK.

The UK was a daunting place for Antonio when he first moved. “I didn’t speak any English back then and I was constantly reaching out to people for random, lowqualification jobs,” he told 4walls. But when he decided to contact picture framers, he was delighted to get a call back straight away and started the very next day. “It’s a fairly rare profession, so people really appreciate it if you have the skills.”

Antonio worked at three different framing businesses in London before starting his own, and after a while, Thou Art’s previous owner, Leon Portnoi, offered him his shop in 2015.

“At the time, it was just me and one other employee, but now I’ve got a team of three who I absolutely couldn’t do without,” he says.

When Antonio first started his business in the UK, he reached out to various suppliers but was disheartened to either not hear back from them, nor have a visit from them.

“Simon Davies, Larson-Juhl’s area sales manager, was one of the only representatives to come and visit me. He came back a few times, always bringing along a huge range of samples which was a really nice, proactive way of approaching someone who was just starting out,” says Antonio.

“Larson-Juhl has been there for me since day one and now that my business is much bigger, I really do appreciate that Simon has been with me from the start.”

I want customers and employees alike to feel like they’re at home.

The Thou Art workshop is small, but mighty. “We are super busy,” says Antonio, “I always joke that we’re at 200% capacity!”

He prides himself on offering a huge range of mouldings and has found that using the Larson-Juhl chop service allows him to do this. With over 1,000 samples on the walls and a tight workshop space, there simply isn’t the room to keep stock of everything they have to offer. However, Antonio is keen for customers to be able to find

something different when they come to him, so shopping chop means he can use a wide variety of products from the cost-effective ranges, all the way up to premium on a weekly basis.

A large majority of Thou Art customers are local, usually looking to get bespoke artwork or memorabilia framed for their homes. “I don’t have corporate clients but I think that’s nice,” explains Antonio, “it’s a family atmosphere here, I like people to come in and feel like they know us and trust us.”

The ethic at Thou Art is to be completely honest with customers and prioritise giving out sound advice. Antonio promotes this by always reminding his team that the sales side of the business is of equal importance to the smooth running of the workshop, so they must ensure to deliver toplevel customer service.

My Dad (also called Antonio) is still doing it now – he’s 76 but he just loves it...

4walls was so pleased to hear that Antonio’s parents have visited the shop a few times and were both proud and impressed by how the business runs. Turo Marc in Barcelona is a large premises with masses of equipment, so it functions in a completely different way to Thou Art.

Antonio is confident that by taking care of his customers, he can thrive from just their recommendations and wordof-mouth alone to market his business.

“I want customers and employees alike to feel like they’re at home. If they’re happy with how they are treated, then we’ve started out on the right foot – this is something I learnt from my family’s business and I’ve always made sure to continue it in mine,” says Antonio.

“My business is now actually more profitable than theirs and they wonder how I’m doing it. When they first saw it, they said: ‘Is this it?!’” he jokes.

“For me, it’s all about being efficient, wellorganised and, most importantly, feeling passionate about what you do and taking pride in it.”

thouartframing.co.uk

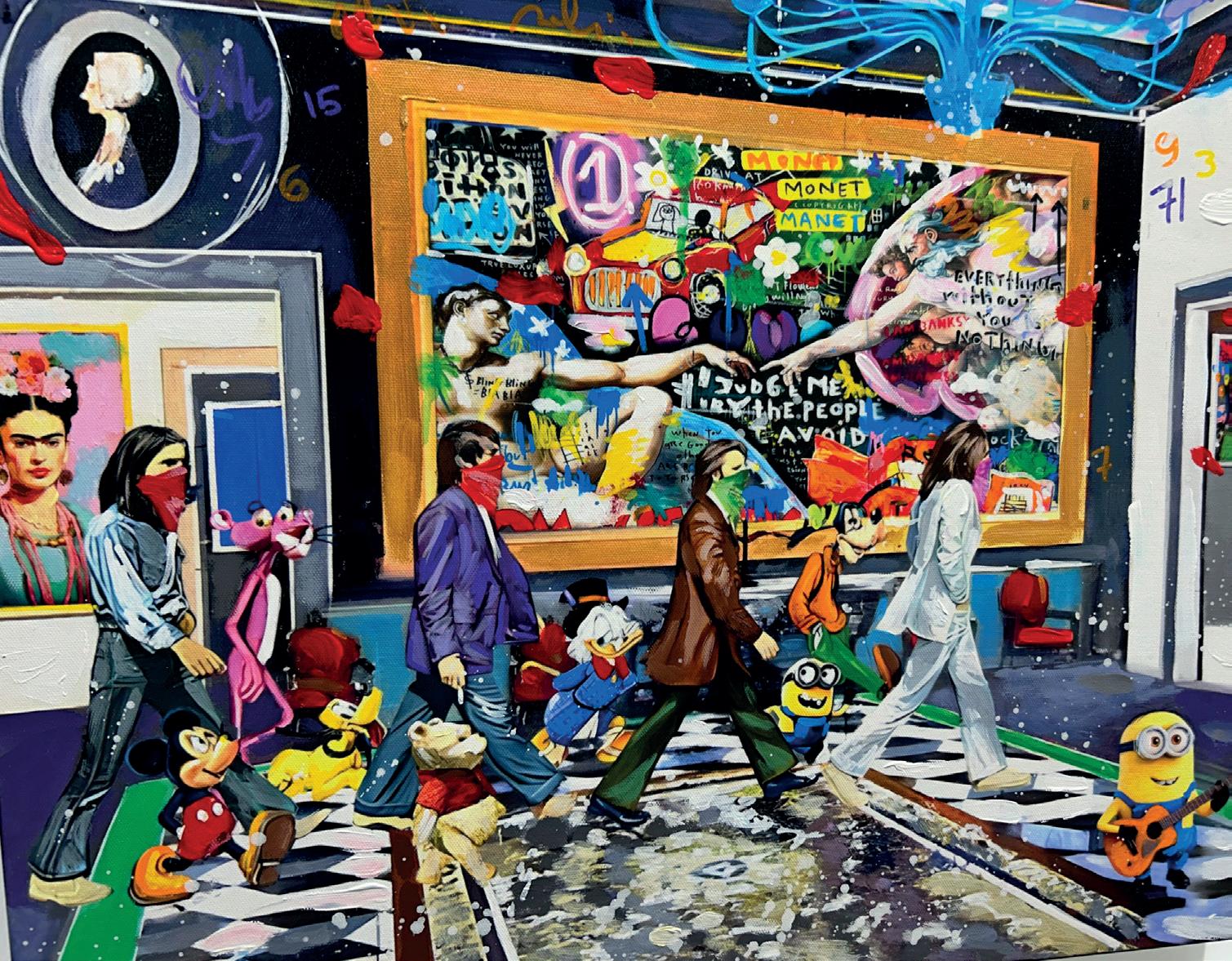

4walls loves to celebrate customers using Larson-Juhl in their everyday work to frame fantastic artwork and customer commissions. This issue’s product showcase has a great range of pieces with a variety of mouldings from Larson-Juhl customers all across the UK!

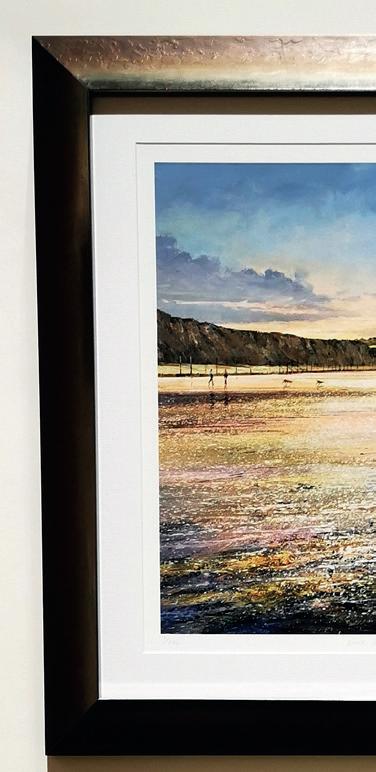

Holt’s Framing (Holt’s Framing on Facebook)

This pastel-on-paper piece, titled ‘An evening stroll, Whitehaven harbour’ was created by Cumbrian artist William Bell. Framed in a black and silver, Italian moulding, LJ 415301 – Canaletto with a gutter mount that allows for any loose pastel to fall behind the bevel.

The team at EasyFrame jumped at the chance to frame these eight Kris Barras Band vinyls and, although it was a challenging commission, they’ve definitely pulled it off with double mounting and using LJ 440227000 – Essentials 53mm-wide black moulding.

This beautiful autumnal print has been framed using LJ 432900 – Foundry, in a warm antique brass finish to perfectly match the tones of falling leaves, crafted by artist Samuel Thomas Art.

If you look closely, you’ll see that this is actually a jigsaw puzzle! One of many similar types of commissions completed lately by Sebastian Warner. LJ 804290 – Aurora moulding is a perfect pairing for this unique artwork.

Moon Base Two Framing @moonbasetwo_framing

This ‘Skeletor’ piece by artist Mike Mitchell has been framed using purple LJ 140639 - Confetti moulding with a painted yellow spacer and finished with Artglass to do it justice.

Berkshire Bespoke Picture Framing @berkshirebespokepictureframing

This original oil painting has been framed using LJ 283502653 - Andover. A distressed silver moulding that suits the piece perfectly.

Edge Bespoke Picture Framing @edge_bespoke_picture_framing

This wonderfully happy piece has been created in acrylic on board by artist Helen Glee, highlighted with a gilded ground making a lovely contrast between styles and techniques. A modern painting framed in a traditional style using large black/brown distressed LJ 756287000 moulding.

the Picture Framer @davidthepictureframer

This is a stunning use of the new LJ Metalia 254908, floated on a luxurious deep green, accentuating the softened industrial metallic style of the collection with a subtle etched surface. This is a signed print using the latest non-reflective glass.

Last October, Larson-Juhl was back at FamaArt, an internationally renowned event which takes place at Italy’s BolognaFiere exhibition centre every two years.

Larson-Juhl had last attended in 2018. The pandemic meant 2020 was cancelled and even in 2022 there was still some reservations about the sector’s appetite for face-to-face events. FamaArt 2024, however, was a resounding success!

The Larson-Juhl contingent included representatives from the UK, France, Germany, Japan, the Czech Republic and the Netherlands and the exhibition was an opportunity for the business to showcase its breadth and quality of range and service levels.

Flagship products on display included Signature, Coastal Woods, LJ Collections, Barefaced, Essentials and Aluminium, attracting considerable attention from visitors from across the globe.

International marketing director Matt George was hugely impressed with the energy and innovation that was evident from the organisers and the venue, commenting: “FamaArt is the only international exhibition of its kind for our sector and following the uncertainty of recent years, it was brilliant to be part of such a dynamic collection of exhibitors. The organisers at FamaArt and BolognaFiere were clearly determined to create a feel that had a new impetus, and were very much looking to fuel the market with new ideas and innovation. Their efforts really paid off. There is clearly still a real demand for events like FamaArt with well over 2,000 visitors over the three days (10% up on 2022), and 55% of whom were international.

“Attending exhibitions is a big commitment, especially as if we are going to be there, we need to have a significant presence that gives us some real visibility and impact, and brings visitors onto the stand. A lot of thought was put into the stand and we

Nothing beats face-to-face communication with our customers, potential customers, industry experts and other stakeholders.

were actually really pleased with both the number and profile of visitors.

“In addition to suppliers like ourselves, the exhibition showcased equipment, a selection of wood options for moulding production and ran a programme of ‘meet the artist’ events. We noticed some really interesting emerging trends. For example, developments around framing software.

We saw what’s going on in the sector first hand. And there were so many inspiring people to talk to. We collected ideas and saw lots of new products, like shiny metallics and neon colours.

“Three-day exhibitions are hard work, but nothing beats face-to-face communication with our customers, potential customers,

industry experts and other stakeholders. And being in the beautiful, historic city of Bologna was certainly an added bonus!”

Dunbar Picture Framing is owned by Colin Bain, who is hugely experienced and runs a picture framing studio and gallery.

Passionate about art and creativity, Colin was hugely enthusiastic about his visit to FamaArt: “FamaArt was a total sensory overload! Bologna is a beautiful city and the FamaArt organisers had embraced the vivid, vibrant colours from the surroundings into the exhibition itself. It really was a very impressive and inspirational show.

“The Larson-Juhl stand showcased all their ranges so it was great to see their entire collection in one place and to feel the mouldings up close in real life! Not just online or in the paper catalogue.

“It was also good to see the trends in moulding shapes and colours. We’ll definitely be going back in 2026!”

Richards is a premium framing business in Groningen, The Netherlands. Owner Richard van den Berg and his colleagues Mercedes Folkerts, Petra Kok and Machteld Pennekamp all absolutely loved their trip to Bologna. The team told 4walls that it was the first time in 40 years that they had closed on a Friday and Saturday so expectations were high! But it was absolutely worth it. Comments included: “We saw what’s going on in the sector first hand. And there were so many inspiring people to talk to. We collected ideas and saw lots of new products, like shiny metallics and neon colours. We have incorporated many things learnt from FamaArt into our store.”

Richard added: “The Larson-Juhl stand looked very good. The team was very welcoming and super friendly. Super professional too.”

The Senelar range particularly impressed the Richards’ team and they placed an order straight away!

In a number of export territories, the BARTH range of readymade picture frames is hugely popular. The collection is available in a choice of European-made aluminium or sustainably sourced wood. All of which are available with CLARITY glass which reduces reflections to less than 1% and is durable and scratch resistant. The special coating also provides radiation protection to help prevent artworks from fading over time. There is also an acrylic option.

If you take a stroll down Towcester high street, you’ll find a four-storey, 300-year-old, Grade II listed building that is the proud home of Watling Street Galleries. Owner Mike Novakovic bought the workshop and gallery nearly 35 years ago and the business has seen a constant stream of happy customers ever since.

Buying Watling Street Galleries was a big step to take for Mike, and it all happened to go through on the very same day that his son, Louis, was born.

Mike had worked at the gallery for several years and was offered the business when the current owner retired. So, he bought the business, sold his home and planned to move into the flat above the shop – but of course, moving house is never that simple.

On the day of the move, the solicitors had made an error with the exchange meaning that Mike and his wife spent their first three days of parenthood with their belongings in a removals lorry and no place to live. “It all worked out in the end,” Mike told 4walls, “Louis is all grown up now and works as a robotic engineer!”

The three of them lived above the shop for several years before moving out and expanding the workshop upwards. The business currently spans four floors, with wonderfully winding staircases to take you between them.

Glass cutting takes place in the basement – as this is the only route with a straight staircase to carry the sheets of glass down, the gallery is on the ground floor, the framing workshop (the primary space) is on the first floor, and the top floor is used as an office area with a large-format printer.

We were one of the first framers in the country to have visualising tech.

Although this layout has served them well for many years, there are some key efficiency-focussed changes in the pipeline to reduce the gallery space, move the workshop down to the ground floor and convert the top floor into an apartment.

The framing side of the business is the key element, so moving the workshop down to the ground floor is the most logical solution.

The plans are in the works to take place this year, so 4walls looks forward to catching up again with Mike to see the updates!

100% Larson-Juhl moulding and mountboard

“There’s really no need for me to go anywhere else, Larson-Juhl has got it all,” says Mike, pleased with his recent decision to simplify his processes down and use just one single supplier rather than ordering from multiple providers.

“They’ve got more than enough variety and I don’t even need to change my sample range often, what I’ve got really works for me,” he says. A few of his favourite, go-to Larson-Juhl mouldings include 229901973 from the Barranda collection, 229901982 from Pedraza, and 302736127 from Essentials.

Mike orders mountboard as well as mouldings from Larson-Juhl and loves the fact that he can order a week’s material,

At one time, Watling Street Galleries was a team of four people, but Mike decided to streamline his processes, make it more cost-efficient and go it alone, which was made more appealing by the prospect of using Larson-Juhl’s chop service.

“I don’t need anyone here chopping the frames. Larson-Juhl providing that has been of massive value to me,” he told 4walls. Although he does still stock

all from one place, for it to arrive with him in a couple of days so he can complete the work and get orders finished.

The business really does run like clockwork, with a schedule that allows him to turn around orders in one week, whereas some competitor framers can quote up to one month to complete an order.

“While the customer is with me, we’ll have the Larson-Juhl website open to check the stock because then I know they can have it fairly quickly. If they want something that isn’t in stock, they’re always happy to wait a little longer.”

This devotion to using Larson-Juhl has been strongly supported by Mike’s area sales manager, Dustin Little, who has seamlessly continued the relationship built up by Watling Street’s previous representative, John Green. “They’re both lovely guys – there’s little to complain about!” says Mike.

a selection of regularly used moulding lengths and cuts them in-house, Mike has found that the chop service allows him to offer much more elaborate and unusual styles that he wouldn’t necessarily keep in stock, giving customers even more freedom to choose the style they want.

“I think it’s always important to be efficient with your materials,” explains Mike, who has been consistent over the years in ensuring that the business runs smoothly. Changing the flooring layout, using 100% Larson-Juhl and exercising the chop service are just a few of the ways in which Mike has ensured this happens.

There’s really no need for me to go anywhere else, Larson-Juhl has got it all.

“I’ve also always had a lot of tech on the go and around 20 years ago, we were one of the first framers in the country to have visualising tech,” says Mike. This piece of software allows the customer to see on a screen at the counter how their completed job will look and has proved invaluable for Mike and his business – still using the same original software to this day!

Another important investment in Mike’s workshop was machinery such as a computerised mount cutter, computerised underpinner and mitre cutting machinery, all of which heavily contribute to the quality and efficiency of the service that customers receive at Watling Street Galleries. www.picture-shop.co.uk