Where Quality Exceeds Expectation

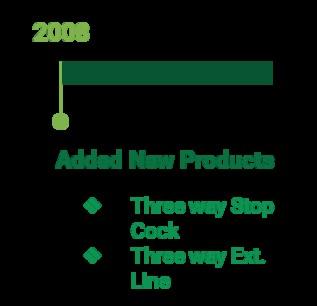

❖ Incorporated in 2005

❖ W ork force : 750 pax.

❖ Strength : Team of professional with 15 – 20 years of experience.

❖ Inhouse: Design and R&D department team working on Solidworks.

❖ Own in house sterilizer.

❖ Fully Equipped Lab.

❖ Assembly comprises of class 10,000 clean room.

❖ Injection molding is class 100,000 clean room, all fully electric & proportional hydraulic molding machine.

❖ Own tool Room : to make the confidential molds, gigs & fixtures in house.

❖ CNC – EDM From Chamiles enable us to achieve precision.

❖Verify that our products and services meet agreed requirements.

❖Monitor, benchmark and continuously improve our business, products, and services.

❖Enhance Organization and employees performance.

❖Endeavor to achieve our Mission and Goals.

❖We Lars Medicare Pvt

Ltd, Our dedicatedly on the way to the future for better Quality Healthcare Products to improve the quality of life.

Managing Director

Sakshi Goel

Global Sales

Sanjay Goel is the founde r and Managing Director of Lars Medicare.

Sanjay brings over 20 years of Entrepreneurial,Leadershi p Managemen t

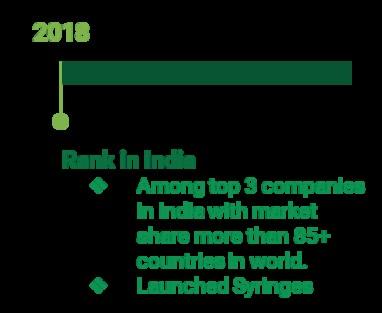

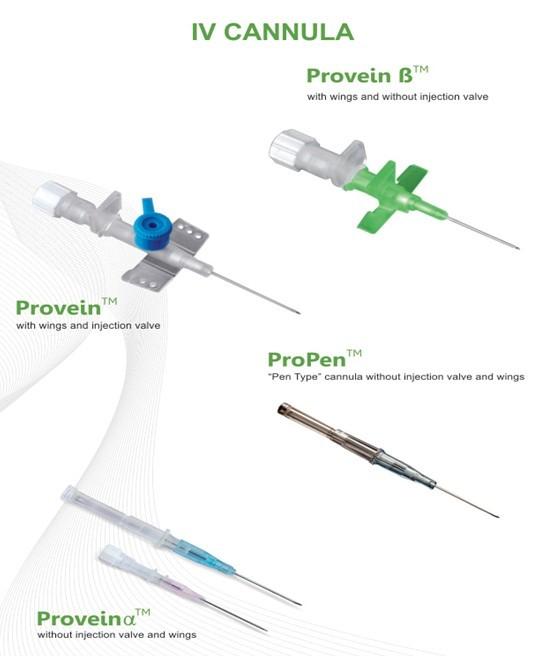

and Senior experience in Medical Technology manufacturing to Lars. Sanjay has been instrumental and a pioneer in envisioning IV Cannula manufacturing in India, that has since grown into a globally recognized industry.

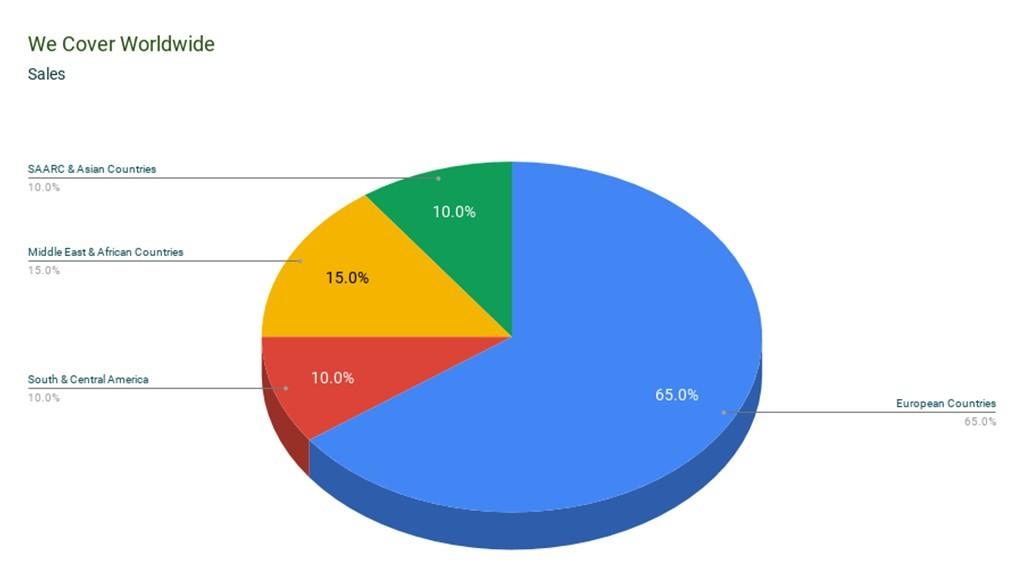

Goel heads the Sakshi Lars Sales Medicare’ s and global

Marke t initiative. Sakshi comes to Lars with over 15 years of experience in Medical Products distribution and relationship s the world. all across A results oriented, dynamic leader, Sakshi taking

has been key in Lars products to 60+ markets worldwide in a short span of time.

Sameer

Hingorani our North and

head s Sout h American operations out of our office near Toronto, Canada. Sameer brings in 15 years of International Sales and Marketing experience, working with global manufacturing companies in Telecom, HiTechnology and Healthcare.

Sanjay GoelThe first step of 5S, Sort, involves going through all the tools, furniture, materials, equipment, etc. in a work area to determine what needs to be present and what can be removed

The first step of 5S, Sort, involves going through all the tools, furniture, materials, equipment, etc. in a work area to determine what needs to be present and what can be removed

Once standard procedures for 5S are in place, businesses must perform the ongoing work of maintaining those procedures and updating them as necessary.

Once the first three steps of 5S are completed, things should look pretty good. All the extra stuff is gone, everything is organized, spaces are cleaned, and equipment is in good working order.

The Shine stage of 5S focuses on cleaning up the work area, which means sweeping, mopping, dusting, wiping down surfaces, putting tools and materials away, etc.

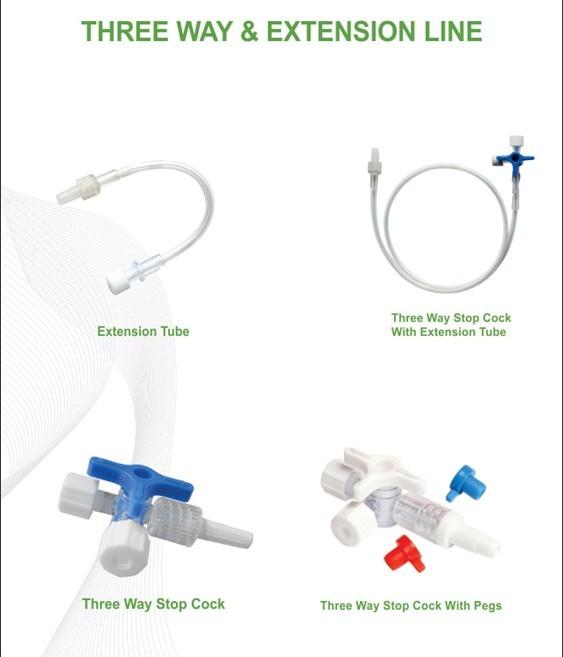

❖Infusion Therapy

❖Respiratory

❖Gloves

❖Personal Care Products

❖Diagnostics

❖Hypodermic Syringes

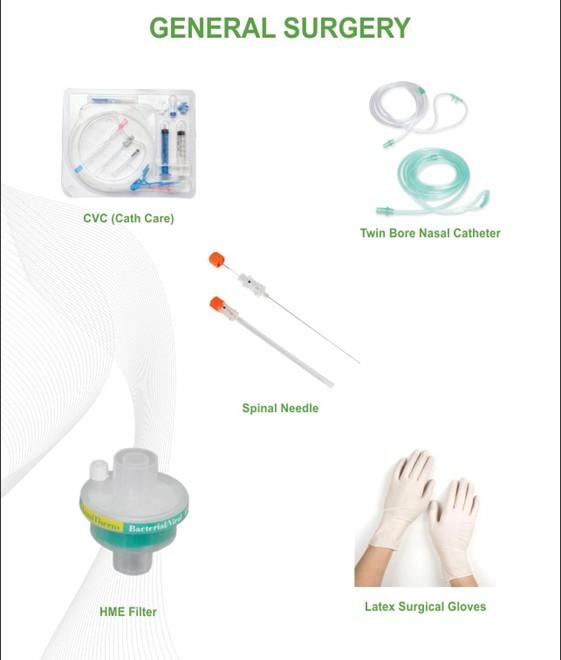

❖Central Venous Catheter

❖Anaesthesia

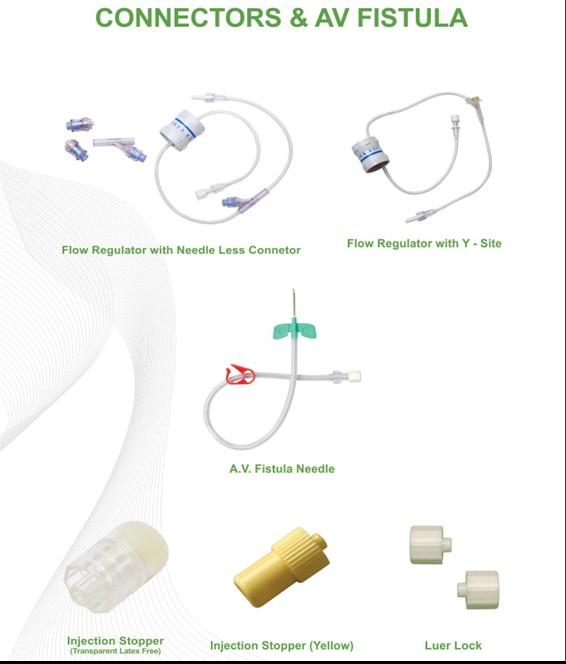

❖Dialysis

Consistent Product Quality .

❖ Customised Product .

❖ Packaging as per requirement *.

❖ OEM / OBM Facility available.

❖ Committed delivery .

❖ All production activities takes place under one roof . ❖ We offer Logistic arrangements, suits your need.