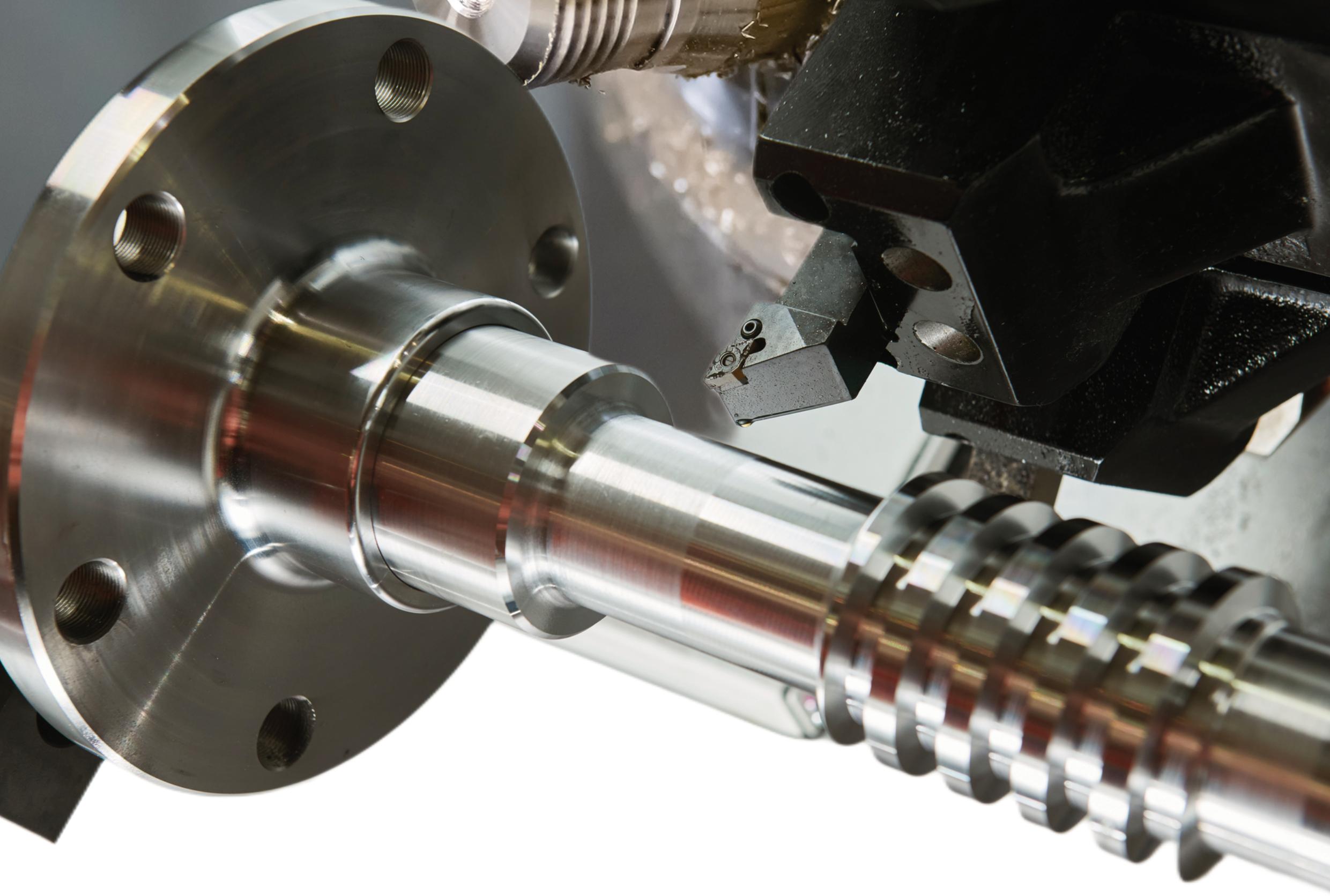

4-TITANIUM is; A metal cutting lubricant in paste form for all machining operations including reaming, tapping and drilling on all metals.

It has been specially formulated to cling to the tool thus providing the ultimate in cutting performance. 100% BioBased Lubricant using natural plant esters as the base oil, is readily biodegradable, is an Environmentally Acceptable Lubricants (EALs).

There are NO SOlveNTs Or PeTrOCHeMICAl products used in the manufacturing of this products

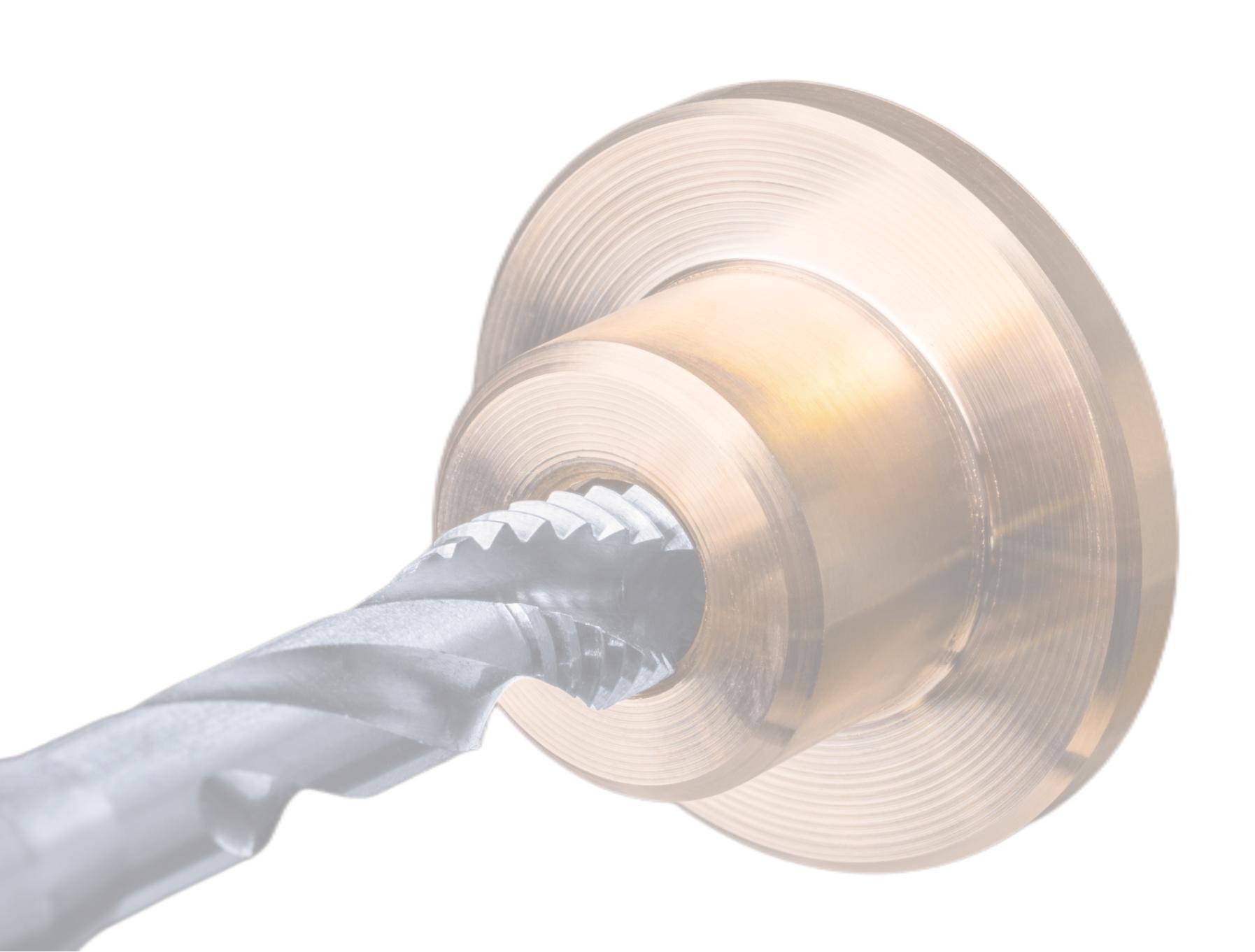

Combined with a unique cooling effect provides dramatic increases in precision cutting and tool life due to less heat stress on tools and parts being worked. The increase in tool life on tough super alloys is approximately 300% above current metalworking lubricants. Expect superior threading with fewer broken parts or tools. Drills, mills, taps and performs any other cutting application with precision. Produces minimal smoke with no noxious vapours or unpleasant odour.

However, there are more advantage to using biobased 4-Titanium compounds.

Some of these advantages include:

FeATUres AND BeNefITs

•Greater control in heat transfer (tool cooling when drilling)

•Controls a wider temperature range (over 365deg C)

•Prolongs tool and die life (300% above standard performance)

•Increased production rates (Less machining downtime)

•Improves thread and surface finish

•Compound adheres to working surfaces

•Hydrophobic (water resistance)

•Melting Point (Extreme 0C does not burn)

•Stays in Position (does not run)

•Leaves a corrosion protective coating after drill finishing

•Electromagnetically treated oil. (Product stability, no carcinogens or allergens )

•100% Solvent Free

•Easy surface cleaning,

•Clean up using Hot Soap and Water

AreAs Of APPlICATION

•Reaming

•Tapping

•Drilling

•Metal forming

FIT fOr PUrPOse ( DrIllING AND TAPPING)

Biodegradable and water-washable tapping compound used to facilitate tapping of holes and rod threading.

PRODUCT USES:

Tapping and machining hard metals and alloys to include hardened stainless steel, any alloy, or super alloy: anodized aluminium to including, but not limited to:

TYPES OF METALS: Hastelloy, Inconel, titanium, cobalt, nickel alloys or combination of these alloys. Also used to mill, drill and perform all machining cutting work where a paste is appropriate.

CUsTOMer RefereNCING;

SUCCessfUl Use Of 4-TITANIUM TAPPING AND MACHINING PAsTe

Quote “ On 304L Stainless Steel machinery, 4-Titanium paste has a successfully improved; Tool Life > 1 hole with a Cycle Time < 145 seconds per hole.

4-Titanium lubricating paste performs, 30 holes at 30 seconds per hole with no heat in the tap or part, a heat test was conducted after the 1st hole showed no additional heat elevation.

CUsTOMer RevIew APrIl 2022:

We machine a substantial amount of 304 and 316 stainless. We recently had a recurring job that has 48 blind 10-32 tapped holes in the flange. Using Tapit all, we ran the entire lot of 12 parts, 576 holes, with same tap. Part 12 was the same as part 1. We use Tapit all for all of our tapping needs!

Momentum Manufacturing Group (mmg1982.com)

4-TITANIUM MACHINING COMPOUND (wHAT Is IT?)

Seed oil-based, biobased machining compound.

MATerIAls COMPATIbIlITy

4-Titanium Tapping and Machining Paste is outstanding for super alloys and is compatible with everything from aluminium, CRS, HRS, SST’s titanium and titanium alloys. The paste is a hydrophobic mixture that contains only non-hazardous and non-corrosive ingredients. Washes off with soap and hot water or steam. Cleaning is a MUsT before heat treating parts machined with 4-Titanium Tapping and Machining Paste.

NOrMAl CleANING

If heat treatment is not going to follow you will find most of the paste will be consumed in use. Any remaining residue is wiped off easily with a cloth or paper towels.

Note – Permanently stains cloth/clothing but is easily removed from metal and painted surfaces

PRODUCT

APPEARANCE: Silver/Gray paste

ODOUR: Mild vegetable oil odour

PHYSICAL STATE: Semi-solid with a grease like consistency

SOLUBILITY IN WATER: Compound is extremely hydrophobic

FLASH POINT ASTM D92 = 608oF (320oC) ASTM D92 = 669oF (350oC)

NOTe:

FLASH POINT: ASTM D92 315°C (599°F) is the Lowest Flashpoint Registered in testing. The product inventors are confident the actual flash point will be much higher (approximately 15%) of the ingredients do not burn but will melt at approximately 260°F. All ingredients exceed 599°F (315oC) Flash point and are evenly distributed in the lubricant.

TOXICOLOGICAL INFORMATION

U.S. FEDERAL REGULATIONS TSCA (TOXIC SUBSTANCE CONTROL ACT): All components are listed or are exempt.

MEDICAL CONDITIONS WHICH MAY BE AGGRAVATED BY EXPOSURE: Repeated or prolonged exposure to this compound is not known to aggravate existing medical conditions by any route of entry into human body. Nothing in this product is listed in the National Toxicology Program (NPT). Nothing in this product has been found to be a potential carcinogen in the International Agency for Research on Cancer (IARC Monographs (latest editions) or found to be a potential carcinogen by OSHA.