Washington University School of Medicine

Washington University School of Medicine

Asset Name & Number B012 McDonnell Medical Sciences Building

Address 320 South Euclid Avenue; St. Louis, MO 63110

Date of Original Construction 1968 ( Murphy and Mackey-Architects )

Gross Area

Primary Use + Function

Current Replacement Value

317,341 GSF

Medical Classroom, Lab and Office Building

$221,952,839 (WUSM FY24 CRV Report)

It is the goal of the team to conduct a limited Facilities Condition Assessment of Building B012 MMSB reviewing the condition of all identified spaces utilizing a grading scale provided by Washington University School of Medicine (WUSM). The team will also provide Site, Building Envelope, MEPFP system, Accessibility and Code analysis for all spaces identified and create a cost estimate for any upgrades and revisions identified and needed to upgrade any space to current building code and the School of Medicine standards.

All structural items shall reference the 2002 FCA B009 report, 2021 B012 MMSB Building Profile and supplemental Washington University School of Medicine input.

This report was prepared by Lamar Johnson Collaborative, Inc.

Architecture & Interiors

Lamar Johnson Collaborative, Inc.

Cost Estimating Moss Construction Cost Management

Structural n/a*

Envelope TAG

MEP/FP Bernhard

Accessibility & Code

Lamar Johnson Collaborative, Inc.

*Supplemental information provided by Operations & Facilities Management Department at Washington University School of Medicine

This report was generated in good faith through a compilation of visual site observations, existing document review, user interviews and previously generated reports, components and information provided by others. Comments, recommendations & identified building deficiencies from previous reports that had not been addressed or remedied at the time of this report have been carried over to this report. These primary documents include, but may not be limited to:

B012-MMSB Building.doc

Referred to in this document as the “2002 FCA”

Building Scan

02.B

Testing, intrusive observations and exploratory demolition were out of the scope of this report. While ASTM E2018-15 provided guidance on the scope and organization of this report, this report shall be considered a Facilities Conditions Report as opposed to a Property Conditions Report due to the request that recurring as well as non recurring costs have been included through the year 2034. In addition, this property conditions assessment has been conducted under the assumptions that major interior renovations would be completed as part of any remediation activities. While all reasonable effort has been made to capture the full breadth of scope to bring this building up to Washington University School of Medicine standards & code enforced regulations, it should be noted that previous studies were completed to address renovations, demolition & rebuild, and decommissioning. The cost associated with maintaining the building to function as is, with no extensive renovations cannot fully address all issues. Items may appear in multiple sections as some items’ impact is greater than one discipline.

At the time of this report’s writing, the City of St. Louis (who is the Authority Having Jurisdiction) has adopted the 2018 ICC suite of building codes as well as ANSI 117.1 2009 pertaining to accessibility. The comments and recommendations within this report use these codes and standards as the reference point. At this time, there is no known date for adoption of future codes nor known impacts to the recommendations within this report.

These costs are cyclical and include major repairs or replacement of major building systems that can be predicted and planned. An example of this type of item is a roof that has reached the end of it’s normal and useful life.

These costs include repairs or modifications necessary to comply with Accessibility or Fire and Life Safety code requirements. They also may address non recurring deficiencies that could negatively affect the facilities structure or building systems.

(1) A “path of travel” includes a continuous, unobstructed way of pedestrian passage by means of which the altered area may be approached, entered, and exited, and which connects the altered area with an exterior approach (including sidewalks, streets, and parking areas), an entrance to the facility, and other parts of the facility.

(2) An accessible path of travel may consist of walks and sidewalks, curb ramps and other interior or exterior pedestrian ramps; clear floor paths through lobbies, corridors, rooms, and other improved areas; parking access aisles; elevators and lifts; or a combination of these elements.

(3) For the purposes of this document, the term “path of travel” also includes the restrooms, telephones, and drinking fountains serving the altered area.

(1) Alterations made to provide an accessible path of travel to the altered area will be deemed disproportionate to the overall alteration when the cost exceeds 20% of the cost of the alteration to the primary function area.

(2) Costs that may be counted as expenditures required to provide an accessible path of travel may include:

(i) Costs associated with providing an accessible entrance and an accessible route to the altered area, for example, the cost of widening doorways or installing ramps;

(ii) Costs associated with making restrooms accessible, such as installing grab bars, enlarging toilet stalls, insulating pipes, or installing accessible faucet controls;

(iii) Costs associated with providing accessible telephones, such as relocating the telephone to an accessible height, installing amplification devices, or installing a text telephone (TTY);

(iv) Costs associated with relocating an inaccessible drinking fountain.

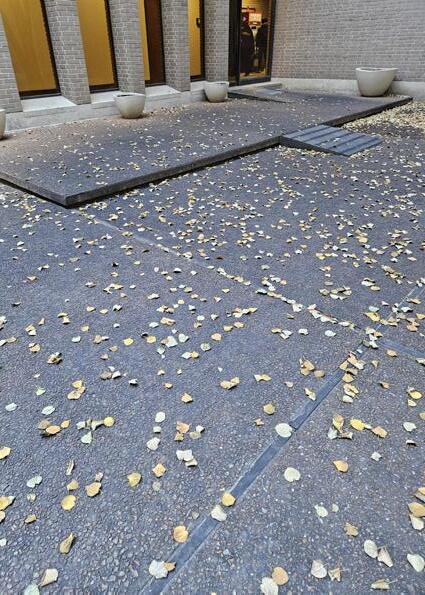

The McDonnell Medical Sciences Building sits along the North side of Mckinely Ave and is bounded by the South Building, CRB, and North building along the West side, Olin and the Shell Cafe along the North East side, and Scott Avenue to the North. There is a drop off drive through to the East along with street parking directly along McKinely. Between Mckinely and Scott there are 80+ stalls including 5 ADA stalls with an additional 11 stalls across from Couch to the East which are all accessed by an ADA curb cut with proper markings. The property has a concrete curb and sidewalk to the South with poured concrete entry steps and a hand railing in good condition. The ADA entry along the East is at grade. The North side has 3 covered truck lanes to allow for loading and unloading at the dock. The West side has an interior courtyard that is 2 steps lower than the first floor.

The landscape consists of planting pots along the South, planting beds with mulch and shrubs to the East tucked in between the vertical shafts with centered planting bed in the middle of the drive through featuring a bosk of trees along with shrubs and potted plantings. The interior courtyard features several planting beds with a mixture of shrubs, planting pots, and ornamental trees. Access to the center courtyard could be improved with the addition of a more permanent ramp and hand railing in lieu of the wood ramps without any railings.

A - Site

Category Location Items to be Addressed

012-A-01 Walkways 01 Replace horizontal sealant joints x

012-A-02 Truck Dock 02 Repaint Guard railing x

012-A-03 Truck Dock 03 Replace horizontal sealant joints x

012-A-04 Truck Dock 04 Repair concrete crack X

012-A-05 Courtyard 05 Replace wood ramps with wider architectural concrete and handrailing X

The McDonnell Medical Sciences Building (#012) is a 9-story structure constructed in 1968 of approximately 300,818 sf. The primary use is for office, labs, and classroom spaces. Directly adjacent to the West are buildings #001, #002 and #003 which each encompass 2 shared courtyards. The main entrance is via a grade level paved plaza on the East off McKinley Ave. Grade level planting beds are in good condition. The South entry concrete steps and railing are also in good condition, but access panels at this entrance are rusting and painted finish cracking. Building #012 was primarily observed from the South and East as well as from the rooftops of adjacent buildings. (See Photo 1)

The exterior façade is predominately face brick with a limestone horizontal band, limestone or precast at the window sills, and a limestone base. A series of circular vertical brick clad piping and mechanical shafts highlight the East and West facades. Windows are an aluminum framed system with a medium bronze finish, some windows being operable. The South and North faces have multistory vertical windows while the East and West are predominately punched window openings. Entry doors on the East and South are a similar aluminum system. Level 6 has a series of mechanical louvers with a finish to match the aluminum windows. No signs of structural settlement or distress were observed.

The connection between building #012 and #003 to the West, mostly comprised of brick and sealant, appears in good condition. This joint should be monitored to avoid water or air intrusion. (See Photo 2)

The building’s stone base has deteriorated in many areas which may be a result of winter salt applications over time. Chipping and flaking of the stone was observed as well as the degradation of sealant joints. Stone used on the upper-level horizontal bands and windowsills shows severe staining, mostly below windows where water flow is high. (See Photos 3-7)

The exterior brick walls are in fair to average condition. Mortar joints are raked, show signs of severe weathering, and in some cases segments of mortar are missing. Several areas along the West and East have severely deteriorated brick faces and should be replaced, primarily at the SE and SW corners. Also at these corners, a waviness was observed in the brick when looking from the ground and up the building face. This inconsistency should be monitored to ensure misalignment does not worsen. Brick is also used at the horizontal return at window head openings. Brick in these locations should be monitored for any open joints. (See Photos 8-13)

The aluminum window systems generally appear in good form. Most mullions show a lighter appearance than the original finish due to typical mineral build-up and wear on the surface over time. Some sealants are beginning to show signs of weathering and should be monitored. Several open joints in the framing system were observed, at both entries and at Level 1 windows. Hollow metal doors are integrated into the framing system and should be refinished because they are losing their original finish. (See Photo 14-17)

Building #012 roof was not inspected as it was indicated by the University that the roof would be replaced in the near term.

Generally, it is recommended to continue to monitor the condition of all exterior sealant joints between face brick and adjacent materials. At the ground level it is recommended that all existing stone joints at the base should be removed, and new sealants applied. It is also recommended that a clear permeable sealer be applied to help protect the stone surface. Existing upper-level stone should be cleaned, and sealant joints removed and replaced, especially horizontal joints. Rusted access panels at the South entry need a new coat of paint.

A re-pointing of the brick mortar joints throughout should be scheduled in the near term. Future brick work should match the existing joint tooling. Tuck-pointing should not be used to treat the joints in lieu of re-pointing. Upon re-pointing, investigate locations of brick alignment issues by selective demolition to examine back-up wall conditions and condition of brick wall anchors.

It is also recommended that a cleaning of the window system is scheduled every so often to remove built-up sediment and resulting color variation and faded appearance. Open joints at window mullions should be monitored and sealed to prevent water intrusion. The broken window glazing on the East side should be replaced in the near term (See Photo 18). Hollow metal doors within the window system need to be refinished to prevent further rust accumulation.

The existing structural system consists of a concrete basement foundation poured concrete structural framing systems. In the original building a concrete column + beam system supports concrete floor framing. Based on discussions with WUSM, there is no future change of use anticipated and the current loading capacity should be sufficient. No seismic upgrades have been completed to date and should be evaluated by a structural engineer if revision of the defined building use changes.

None

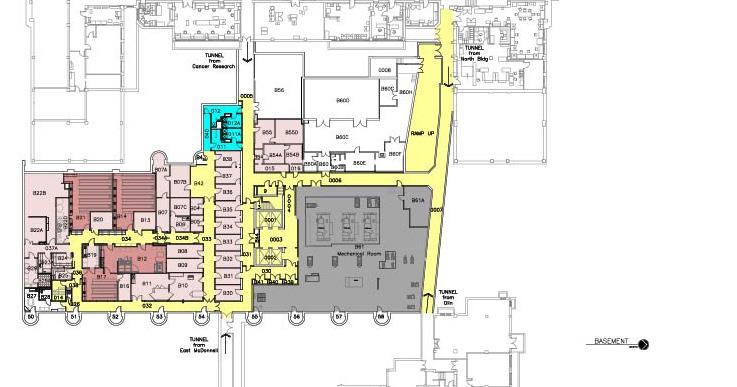

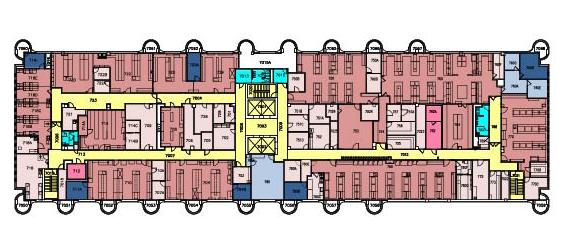

MMSB has 9 occupied levels within it’s 11 floors. Primary use including the basement and Levels 02-09 is laboratory space and lab support and offices. The first floor has 3 larger active learning classrooms, food service, and an office suite. Level 06 and the penthouse are dedicated to Mechanical spaces, along with portions of the basement and first floor. There are interior connections to CRB and Shell Cafe on the first floor along with the South Building on Levels 01-04 to the West. It is also connected to the North building on Levels 02,03, and 04. In addition, the basement has connections through tunnels to CRB, East McDonnell, and Olin. The floor to floor of the building varies from 14’-0” (Basement to Level 01); 16’-4” ( Level 01 to 02) and 13’-1”(Level 02 to Level 06), 14’-2” on Level 06 to the roof in the original 1968 build, then continues with 13’-1” floor to floors up to the roof completed in 1974. The ceiling height in the building is varied in some in the building but is predominantly 7’-11” in the corridors with up to 8’-4” in the newer renovated floors with ACT. With the exception of open ceilings, the only deviation is on Level 01 where the corridor is set at 9’-2” along the classrooms and 12’-4” in the main entry lobby ( and newer Active Learning Classrooms). The exterior grade changes around the building, as well with the East side entry at the first floor grade, the south entry is approximately 20” lower with access via stairs. The truck dock along the North is approximately 3’-0” below grade and slopes away to the North.

The interior finishes in the corridors consist of Ceramic Tile and wood base on the First floor corridor spaces and carpet tile with wood base in the Active Learning Classrooms. Levels 02-05/ 07-09 corridors have VCT in the corridors and labs and carpet in the offices and conference areas. The lower level is a mixture of painted concrete, epoxy flooring, and VCT. There is newer LVT in the renovated kitchen areas along with the entry to shell cafe and ceramic tile in all the restrooms. The walls are either painted drywall or plaster and the ceilings are a combination of painted plaster, gypsum, hung acoustic ceiling tiles, or exposed concrete structure above that has been painted. The first floor along with most of the elevator lobbies feature the original brick work as a wall finish.

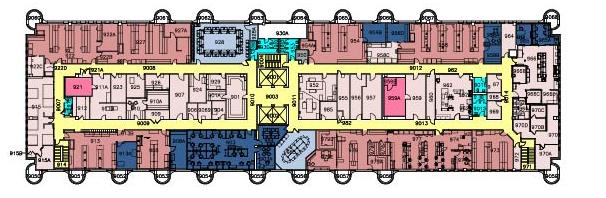

The basement currently consists of Laboratory and MEPFP support space. The First Floor includes the main entrance lobby, offices, Cori and Erlanger Active Learning Classrooms, a Testing Room, the food service area and 2 entry vestibules. Level 02-06, along with Levels 07-09 contains labs, offices, support space, conferencing, and some mechanical support. Level 06 and the penthouse contains MEPFP support spaces along with storage. Most of the 1st floor along with areas of Floors03, 04, and 08 have been recently updated. WUSM plans to upgrade finishes on Levels 04, 05, 07, and 09 along with the basement lab.

Cold Rooms were observed throughout Levels 02-09 and only 3 are noted as needing finish upgrades. WUSM noted that most of the compressors have been recently upgraded.

D - Interior Finishes & Layout

012-D-01

012-D-02

012-D-03 Exit Stairwells 03 New flooring X

012-D-04 B55, 55A, 55b, 55D 04 Replace VCT flooring X

012-D-05 Basement 05 Repaint interior double doors at Dock X

012-D-06

012-D-07

012-D-08

012-D-09

012-D-09 RR 468 09 New ACT X

012-D-10 10 X

012-D-11 478 11 Finish space X

012-D-12 CR712 12 Replace Flooring and casework X

012-D-13 CR921 13 Update finishes X

012-D-14 CR959A +B 14 Update finishes X

012-D-15 15 X

012-D-16 9th Floor 16 New ACT X

012-D-17 9th Floor 17 New VCT X

012-D-18 18 X

D2- Interior Finishes & Layout-Renewal

Category Location Items to be Addressed

012-D2-01 Level 00 Basement 01

012-D2-02 Level 1 FirstFloor 02

012-D2-03 Level 2 SecondFloor 03

012-D2-04 Level 3 ThirdFloor 04

012-D2-05 Level 4 FourthFloor 05

012-D2-06 Level 5 FifthFloor 06

Repaint Walls, Door Frames. Replace Carpet in Offices. Replace VCT+ ACT throughout X

Repaint Walls, Doors, Door Frames. Replace Carpet in Offices. Refinish Wood Trim Base X

Repaint Walls, Door Frames + Carpet in Offices and Conference Rooms, Replace VCT + ACT throughout X

Repaint Walls + Carpet in Offices and Conference Rooms, Replace VCT + ACT throughout X

Repaint Walls, Door Frames + Carpet in Offices and Conference Rooms, Replace VCT + ACT throughout X

Repaint Walls, Door Frames + Carpet in Offices and Conference Rooms, Replace VCT + ACT throughout X

012-D2-07 Level 6 SixthFloor 07 X

012-D2-08 Level 7 SeventhFloor 08

Repaint Walls, Door Frames + Carpet in Offices and Conference Rooms, Replace VCT + ACT throughout X

012-D2-09 Level 8 EigthFloor 09 Repaint Walls. X

012-D2-10 Level 9 NinthFloor 10 Repaint Walls, Door Frames X

Domestic water enters the basement chiller room where two (2) booster pumps distribute it to the rest of the building. Domestic hot water is supplied from the Euclid Power Plant. Two (2) domestic hot water pumps in the basement draw from the plant and serve the building. Additional plumbing systems – including control air, lab vacuum, lab air, and deionized water – are located on the 6th floor. The major lab vacuum and lab air equipment appears to have recently been updated, and components to update the deionized water system were being staged while Bernhard was on site.

Though the waste piping from the Shell Café was partially replaced in a 2007 renovation, it is all cast iron pipe and known to be in poor condition. Its condition, combined with its unfortunate location above AHU-4 has caused numerous disruptive issues. Equally concerning is the glass acid waste and vent piping throughout the building. It is fragile and difficult to replace when damaged. Acid waste systems in more recent buildings on campus utilize Polypropylene (PP) or Polyvinylidene Fluoride (PVDF) as a lower maintenance alternative. The glass piping in the floors is best replaced during floor level renovations; however, risers would benefit from a dedicated replacement project.

The domestic water booster pumps are anticipated to reach their expected end of life within the next 10 years. A handwritten note was observed next to DCWP-1, prohibiting it from being shut off. This suggests an issue in the system that requires further study before the pumps are replaced. The domestic hot water pumps are also expected to reach end of life within the next 10 years.

Due to recent renovations, only limited pneumatic controls remain in the building. Steam control valves at the heat exchangers still utilize high pressure pneumatic actuators and a few pneumatic terminal units in unrenovated spaces may remain. When the existing control air compressors reach end of life, also anticipated in the next 10 years, there may be an opportunity to downsize the equipment.

E - Plumbing

012-E-01 Domestic Water 01

012-E-02 Domestic Hot Water 02

012-E-03 Control Air 03

to be Addressed

Replace (2) domestic water booster pumps DCWP-1 & DCWP-2 at end of life. When replaced, investigate system issues preventing pump from turning off. X

Replace (2) domestic hot water pumps DHP-1 & DHP-2 at end of life. X

Replace (3) control air compressors CA-1, CA-2, & COM-03 at end of life. Consider right-sizing to match reduced pneumatic load. X

012-E-04 Kitchen Waste 04 Replace all kitchen waste piping including under slab piping. X

012-E-05 Acid Waste 05

Replace (40) 4" glass acid waste risers & (40) 3" glass acid vent risers with PVDF. X

012-E-06 X

012-E-07 X

012-E-08 X

The McDonnell Medical Sciences Building is cooled by chilled water at approximately 44°F. The building is equipped with three (3) chillers configured in a variable primary-variable secondary system with two independent secondary loops. Booster pumps downstream of the secondary pumps serve fan coil unit risers as well as AHU-13. In addition to its chillers, the building is connected to the WUSM district chilled water loop. Depending on conditions, the building could be served by its own chillers or the district loop. The MMSB basement also contains secondary pumps serving North Medical Building and the Cancer Research Building; however, these pumps pull from the campus loop, rather than the MMSB chilled water system.

As a result of these chilled water complexities, the building has 20 chilled water pumps – compared to 7-9 pumps in a typical design. 15 of these pumps will reach their expected end of life in the next 10 years. Unfortunately, there is limited opportunity to simplify the system and reduce this capital renewal burden. Past projects have already reduced the number of pumps by 13, but further reduction is anticipated to be cost prohibitive.

Nearly all components of the condenser water system are also at or beyond their expected end of life, including the cooling towers, pumps, and tower freeze protection system. WUSM is already planning to replace the cooling tower in its FY27 capital plan. Given that a large number of service valves in this system are known to leak, that project may prove the optimal time to drain down the entire system, replace all equipment, and replace all service valves. Finally, in keeping with WUSM’s maintenance pattern, all the Trane chillers will be due for an R’NEWAL within the next 10 years.

The building is heated by 100-psig steam from the Euclid Power Plant. The building is loop-fed steam, so a distribution failure between the building and the EPP would not disable the heating system. Condensate is returned via a condensate return unit in the basement. The building uses steam for both direct and indirect heating. Direct heating is done by steam coils at the hot decks of the large dual duct AHUs. Indirect heating is performed via hydronic heating systems fed from steam heat exchangers. There are five hydronic systems independently serving preheat, radiant heat, basement reheat, 7th floor reheat, and 5th/8th floor reheat loads. All the systems were designed around 180°F to 200°F temperatures. The preheat and radiant systems utilize glycol to prevent freezing. Steam is also used for a few unit heaters in the building and for cooling tower freeze protection.

The building’s main utility chases are located on its exterior. These chases are exposed on 3 sides and appear to be uninsulated. Some are also exposed from below by architectural overhangs. This has led to repeated issues with pipes freezing. The original design heated these chases with short fin-tube radiators in the chases on floors 1 through 6. This configuration had limited overall capacity and particularly low effectiveness at the lower floors. Over time, renovations removed fin-tube radiators from the labs, unintentionally impairing this system by cutting off flow to certain chases. A recent project removed all the radiators in the labs and reconfigured the system to return the chase heating system to its original performance. Today, the radiant heating system exclusively serves the chases and electric unit heaters have been added to heat the overhangs; however, the limitations of the original design remain unaddressed.

Like the chilled water system, the heating water systems in the McDonnell Medical Sciences Building were originally more complex. Past projects have simplified the building down to 5 systems with 2 pumps each. There is one further opportunity for simplification. The 5th/8th floor reheat system has been sized to take on the 7th floor reheat loads in the future. When the 7th floor reheat heat exchanger and pumps reach end of life, anticipated within the next 10 years, we recommend this equipment be removed and the system tied into the provided connection on the 5th/8th floor reheat system. Within the next 10 years, all heat exchangers, pumps, and the condensate return unit will reach their expected end of life.

Space conditioning in the building varies by floor. The 1st through 4th floors, the 7th floor (except as noted below), the laboratory portion of the 8th floor, and the 9th floor are served by dual duct terminal boxes. The basement, 5th floor, a region on the south end of the 7th floor, and the office portion of the 8th floor are served by single duct VAV terminal boxes with hot water reheat. The AHUs are located in the basement, on the 2nd floor roof, on the 6th floor, and in the 9th floor penthouse. Most of the AHUs are at or near 100% outdoor air owing to the ventilation requirements of the laboratory spaces. Exceptions include AHU-11 & AHU-12, which serve offices on the 8th floor. Many laboratories are equipped with chilled water fan coil units to assist with cooling. Exhaust is performed by fans on the 6th floor, on the roof, and in the penthouse. Except for the 8th floor and portions of the basement, the building exhaust is hard-balance constant volume.

AHUs and exhaust fans were added gradually via different shell build-outs and renovations. As a result, there is no cohesive pattern to their layout or spaces served. Detailed information on which floors each AHU serves can be found in the appendix. For similar information regarding the exhaust fans, please see the drawings from the 2015 Exhaust Fan Locations study performed by 8760 Engineering.

AHUs -1 through -3 are unusual in that they are architectural elements of the building. Their casings consist of cinderblock walls from slab to slab. Most other AHUs in the building are high-quality custom Air Enterprises or Marcraft AHUs. As a result of the quality, and in some cases permanence, of the construction, the University has historically upgraded components within the existing AHUs due to age or issues. Current AHU concerns include:

• Stratification and control of the steam heating coils serving the hot decks of AHU-1 and AHU-3.

• Pressure drop and inability to clean the reclaim coils serving AHUs -1 through -3.

• Toshiba VFDs that no longer meet the campus standard at AHUs -7, -10, -13, and -15.

• Fans in AHUs -1 through -4 are anticipated to require replacement within the next 10 years.

• Regular sealing of AHUs -1 through -3 to prevent condensate leakage to 5th floor.

Downstream of the AHUs, many of the dual duct terminal units are original to the building. Past issues with the pressure of the hot deck on AHUs -1 & -3 have damaged the damper seals of these terminal units. Other terminal units throughout the building are also fit for replacement, but these are less critical and would be well suited for replacement during larger architectural renovations of the spaces served. The University should ensure any architectural renovation of this building includes funding for terminal unit renewal. The planned renovation of the 9th floor is the ideal time for renewal of terminal units on that floor and AHU-9, which serves that floor exclusively.

Additional HVAC systems in the building include three reclaim/heat recovery systems with run-around coils that capture heat from the exhaust and reuse it to pre-treat outside air at the major AHUs. Similar to the cooling system, the pumps in the reclaim systems are anticipated to reach their expected end of life in the next 10 years.

The exhaust fans serving the 5th floor BSL3 lab are currently located inside the 6th floor mechanical room. This conflicts with the current campus standard that prohibits positive pressure exhaust ductwork from a BSL3 inside a building.

The building has two building automation systems. The JCI Metasys BAS controls the chilled water system, including all chillers, pumps, and cooling towers. This allows the system to be integrated with the larger campus district cooling loop, which is also controlled by JCI. The JCI system also controls the single BSL3 suite on the 5th floor. The Schneider EcoStruxure system is responsible for controlling all other systems including AHUs, terminal units, heat exchangers, etc.. Both systems have had recent upgrades, are equipped with up-to-date controllers, and primarily utilize the BACnet protocol for communication.

012-F-01

012-F-04

012-F-05

012-F-06

Remove (2) heat exchangers and (2) pumps serving the 7th floor south reheat at end of life. Reconnect piping to taps available taps on the main building reheat system. HX-1, HX-2, RHP-1, & RHP-2.

Replace preheat system at end of life including PREHX-1, PREHX-2, PREHX-3, HWP-01, & HWP-02.

Replace radiant heating system at end of life including RADHX-1, RADHX-2, HWP-03, & HWP-04.

Replace 6th floor reheat system at end of life including REHX-01, REHX02, HWP-05, & HWP-06. X

012-F-07

07

012-F-08 Cooling 08

012-F-09 09

012-F-10 10

012-F-11 11

012-F-12 12

012-F-13 13

012-F-14 Airside 14

012-F-15 15

012-F-16 16

012-F-17 17

012-F-18 18

Replace basement reheat system at end of life including RHHX-03, RHHX04, HWP-07, & HWP-08. X

Rebuild chillers CH-1, CH-2, & CH-3. X

Replace all components of tower water system due to age. Includes CT-1A, CT-1B, CT-2A, CT-2B, CT-3, CNP-1, CNP-2, CNP-3, CTBP-1, & HX-CT. X

Replace primary, secondary, and loop chilled water pumps due to age. Includes CWP-01, CWP-02, CWP-21, CWP-27, CWP-28, CWP-29, CWP30, & CWP-31. X

Replace FCU booster chilled water pumps at end of life. Includes CWP-17, CWP-18, & CWP-32. X

Replace Cancer Research chilled water pumps due to age. Includes CWP-25 & CWP-26. X

Replace North Building chilled water pumps due to age. Includes NORCWP-1 & NORCWP-2. X

Remove steam hot deck heating coils in AHUs -1 & -3 and replace with heating water coils. X

Replace fans in AHUs -1, -2, -3, and -4 with fan walls with N+1 redundancy. X

Replace all internals (coils, fans, dampers, etc.) for AHU-9 as part of 9th floor renovation. Replace reclaim pump RCP-03. X

Replace Toshiba VFDs at AHU-07, -10, -13, and -15 with ABB VFDs matching campus standard. X

Replace dual duct boxes on floors 01, 02, 03, & 04 due to failed hot deck seals. X

012-F-19 Reclaim 19 Replace reclaim pumps RCP-1 & RCP-2 at end of life. X

012-F-20 20 Replace reclaim coils serving AHU-1, -2, & -3. X

012-F-21 Exhaust 21 Replace Exhaust Fans #5A & #5B. X

012-F-22 Other 22

Seal the perimeter of and all penetrations in the slab beneath AHU-1, -2, & -3.

012-F-23 23 X

There are adequate egress paths, stair & door widths meet code, and quantity of access points within the building indicate no additional exits are required. In stairwells, however, the guard railings and hand railings do not meet current code and should be upgraded with any major building renovation.

It appears that the egress doors are rated doors + hardware is up to code. In stairwells, there seems to be proper ratings for the exiting.

The McDonnell Medical Sciences Building is equipped with a fully sprinklered wet system. The fire pump is located in the chiller room in the basement. It was replaced in 2001 along with its jockey pump and control panel. These components are in good condition but are near their expected end of life. The fire alarm panel is located in the CRB courtyard electrical room. It is a Simplex 4100ES panel, which is still the most up-to-date offering from Simplex.

Electricity is fed to the McDonnell Medical Sciences Building at 4,160V via two buried feeds from the McKinley substation. The first feed powers the basement equipment loads, while the other serves the 4,160V distribution switchgear located in the McDonnell Sciences Loading Dock. This switchgear feeds unit substations on the 6th floor, as well as several other buildings including: South Building, Cancer Research Building, North Building, Becker Medical Library, Olin Residence Hall, and the Farrell Learning & Teaching Center. The McDonnell Science Loading Dock Switchgear was installed in 2001, but its location exposed to the elements in the loading dock has caused premature wear and damage. Its tie switch has failed, reducing its redundancy. The University is currently making plans to replace this switchgear in an indoor location within North Building.

The basement 4,160V feed serves the chillers and USS-3, which steps it down to 480V to serve mechanical equipment in the basement. A set of 5KV switches are configured to allow either load to be served redundantly. Major renovations occurred to the basement electrical systems in 1998 and 2001 and all components appear to be in good condition.

On the 6th floor, a similar set of 5KV switches provide redundancy before the voltage is stepped down to 480V and 208V by USS-1 and USS-2, respectively. Both USS-1 and USS-2 are double ended with a tie switch. USS-1 feeds equipment loads on the 6th floor, 9th floor, and the penthouse. The panels and motor control centers it serves date from a 2001 renovation and are in good condition. Due to the pump renovations discussed above, there are many spare circuits in these panels, providing ample flexibility for future projects. USS-2 partially dates from 2001, but the central component called USS-2 (NORTH & SOUTH) appears to be original to the building. The original design of the electrical system called for a very flat configuration with most lab panels served directly from USS-2, rather than through floor level distribution panels. As a result, this central component is critical to more than 100 lab panels and cannot be replaced without a lengthy outage. As floors are renovated, we recommend adding floor level distribution panels to build a deeper tree and allow for a less disruptive future replacement of USS-2. Until that occurs, it is not feasible to replace the original portion of USS-2. During the build out of the shell spaces on the 7th, 8th, and 9th floors, distribution panels were more common. Some of these original panels have reached their expected end of life including LDP7-1 on the 7th floor and DP-9A & DP-9B on the 9th floor. Replacement of the 9th floor panels should be coordinated with the forthcoming renovation of that floor.

Two (2) generators provide emergency power to the building. The generators serve independent circuits. Major renovations to the emergency power system are believed to have occurred in 1994, 2001, and 2012. EMG1 was installed in the 1994 renovation. It is located indoors and has a capacity of 375 kW. It serves only ATS-2 which in turn serves optional standby loads on the lower floors. EMG2 was installed in the 2012 renovation. It is located outdoors on the 6th floor roof and has a capacity of 515 kW. It serves ATS-1, ATS-3, ATS-4, and the fire pump, which cover a variety of life safety and non-life safety loads.

Components from the 1994 renovation including EMG1, ATS-1, and ATS-2 are approaching their expected end of life within the next 10 years.

012-H-02

012-H-04

Four passenger elevators were observed to service all levels and appeared to be in good working condition with updated finishes. The elevators are all sized to meet ADA.

None

The building appears to lack true MDF and IDF spaces for telecom and low voltage distribution throughout the majority of the floors. Telecom is distributed to racks located within the electrical rooms of each floor. Proper telecom spaces will need to be developed to distribute fiber and cat cabling and meet campus standards. The exceptions include 100 A on Level 01, and 8035 on Level 08 which have new IT spaces that meet campus standards.

- Telecom / Data / AV

012-K-01 01

Provide dedicated MDF and IDF spaces throughout the building, current data infrastructure spread out through the building sharing space with existing electrical infrastructure, lacking adequate space to meet WUSM standards. This would occur with major project renovations on the floor X

Site + Building Arrival

The entry to B012 has a Vestibule on the ground floor with doors equipped with ADA operators leading into the main lobby. It also has accessible routes to the West into CRB and North and out through Becker Library and FLTC. The pathway is NOT visually clear from the ADA stalls on the street.

The main accessible building entrance above grade and has access to on street parking from an existing curb ramp at the sidewalk. Vertical Circulation

Current accessibility legislation requires that any building over two stories in height and currently serving the professional office of a health care provider is required to provide wheelchair access to all floors within the building. The current elevators are sized adequately for wheelchair access, lacks accessible call controls and a hands-free phone.

Existing Egress stair handrails and guardrails do meet current code requirements. Existing handrails and guardrails are grandfathered in until a major renovation occurs.

Accessible Routes

Current accessibility legislation outlines Maneuvering Clearances at Manual Swinging Doors, Doorways without Doors, Recessed Doors and Doors in Series. Most of the interior doors do meet these current maneuvering clearances.

Current accessibility legislations outline guidelines for operable parts as they relate to doors, handsets should not require tight grasping, pinching, or twisting of the wrist; and doors should not require more than 5 pounds of force to operate. Most of the interior doors are currently equipped with Levers that do meet these requirements.

The newer Lab renovations do meet ADA. The remaining existing Lab casework/ sinks does not meet current accessibility standards, but could be brought up to current accessibility standards when casework is altered. Sinks at public restrooms do meet current accessibility standards with the height and should also have pipe wrap installed if the sink meets all other accessible requirements, full replacement if not. The exception includes the sinks in the restrooms recently renovated on Levels 02, o4, Restrooms

All restrooms in the building are not compliant with current accessibility guidelines, however alterations of the existing restrooms to bring them up to current standards may not be feasible based off available adjacent space required for expansion. Level 02 and Level 04 both have recently renovated restrooms with signage marked ADA accessible, the remainder of the restrooms throughout the building including the rest of Levels 02 and 04 does not meet the current standard with regards to size, clearance, or grab bar placement. Directional signage, that meets current accessible code guidelines, should be located at all existing inaccessible restrooms indicating the location of the new unisex accessible restroom on each floor.

All water coolers meet current accessibility standards.

Most Signage existing within the building is not currently ADA compliant. It is recommended that all signage should be upgraded to current ADA standards regarding size/graphics, height, braille and location requirements.

L - Accessibility & Code

It is recommended that a risk assessment and abatement be done prior to any future renovation work or demolition.

It is our understanding that buildings constructed before 1978 typically have lead based paint. Because the buildings last major renovation was in 1985, it is recommended that a risk assessment or inspection for possible lead-based paint hazards is recommended prior to any future renovation.

**It has been observed that the building’s plumbing system may contain asbestos, which is covered in the plumbing section of this report.

The overall building has been reviewed and categorized by “use type” categories that include Public Spaces & Circulation, Office, Office Support, Classroom, Classroom Support, Lab Space, Lab Support, Coldrooms, Restrooms, and Building Systems.

Each space is measured against individual criteria to rank it from a Class A to Class C space in respect to overall quality and condition. The total number of points for each category varies as some spaces will hold more value from a renewal prioritization perspective, i.e. exam rooms vs. office support space.

Each criterion under the use type gets a score of A (100% of possible points), B (67% of possible points) or C (33% of possible points). The totals are then added together and divided by total possible points to give each use type category an A, B or C score. In the building summary, the use type categories are averaged together to give the building an overall score.

The final A-C grading scale for the overall building is determined by the following:

• A = 85-100% | Recommendation: No work to minimal upgrades necessary ($)

• B = 60-84% | Recommendation: Medium upgrades necessary ($$)

• C = 0-59% | Recommendation: Large and expansive upgrades necessary ($$$+)

Note: Breakdown of Spaces based on OSIS report from WUSM and revised per observations made during this reporting.

*Notes: Accessibility Descriptor criteria is defined as:

• A = Building is in line with current Accessibility Standards or requires minimal upgrades

• B = Building is moderately in line with current Accessibility Standards, but requires significant upgrades

• C = Building is minimally in line with current Accessibility Standards and requires extensive building upgrades

Washington University School of Medicine

2024 Facility Condition Assessment

Building 012 Cost Report R1

McDonnell Medical Science Building

Prepared: May 17, 2024 by: Cost Report 1 of 31

Introduction

Moss Construction Cost Management Incorporated (“MossCost”), as part of the LJC design team, has been tasked to provide third party/independent cost modeling and estimates for the Washington University School of Medicine 2023/24 Facility Condition Assessment (“FCA”). This report contains estimates of the likely probable cost of correcting such existing deficiencies as were identified during the site inspection by LJC team members, together with estimates of future renewal costs.

This report should be read in conjunction with the document “Standard Notes / Guide to the Cost Report” 1 which provides guidance on understanding the cost report and includes pricing notes, exclusions and assumptions.

Basis of Estimate(s)

Draft FCA spreadsheet and inspection report of 26 January 2024

LJC Navvis Ivion capture (360 degree site walkthrough)

Archival drawings received from WUSM

MEPFP report and summary of 31 January 2024

Updated MEPFP report and summary of 12 February 2024

Query responses/team comments of 15 March 2024

Updated summaries received 9,12 & 25 January 2024, 12 February 2024

Review meeting of 28 March 2024

Estimate Issue

This issue: Revisions following final review

Previous issues: Initial report 25 March 2024

Draft Costs, 26 February 2024

Summary of Costs2 3

1 Current edition dated 14 February 2024

2 For further summaries and supporting data, refer to “Corrective Cost Details” section later in this report.

3 Escalated cost based upon 10 year lookahead

Deferred costs exclude approximately $163,000 of mechanical corrections (items F-12 & F-13) relating to replacement of hydronic pumps serving building 001(North) and 002 (CRB). Costs for these items are included with the building that the relevant equipment serves.

For this asset the following items potentially overlap:

(1) costs relating to ceiling & other access work ($202,085)

(2) finishes updates that fall part of renewal costs dependent upon timing ($127,357)

A total adjustment of $329,442 is made in the calculation of the facility indices to allow for these non-unique costs.

Based upon the cost estimates attached, the preliminary indices are as follows, indicating a building that is currently in good condition. Significant investment is required now in coming years to correct deficiencies and avoid deterioration. Exclusion of item 012-H-01 (Loading Dock Switchgear Replacement) has distorted these calculations, leading to each index value being understated.

Disclaimer

Purpose and use of estimate: The intent of any estimate contained in the cost reports is to reflect fair market value for the correction of deficiencies noted. It is not a prediction of lowest, or any, bid. It is an opinion of probable cost intended as a tool for cost control for budgeting purposes. The estimator can not and does not guarantee that bids, proposals or actual construction costs will not vary from any estimate or study.

Scope of work: The line items included in the estimate represent the estimators understanding of the scope of work as communicated by the documents identified in the basis of estimate. Any apparent discrepancies and/or significant differences in understanding should be brought to the estimators’ attention as soon as possible so that interpretation of scope can be clarified.

2

3 - Recommended

012-M-01R - Abate Flooring & Mastic (with 127,949.0SF

Row

#Item Description

371 replace pumps, CWP-21, 60HP (loop)

372 replace pumps, CWP-1 & 2, 50HP (2y 7F-9F)

373 replace pumps, CWP-27, 28 & 29, 25HP (1y Bst-5F)Moderate

374 replace pumps, CWP-30 & 31, 125HP (2y Bst-5F)Moderate

375 replace VFD, 125HP w/bypass

376 replace VFD, 25HP w/bypass

replace VFD, 50HP w/bypass

378 replace VFD, 60HP w/bypass

F20 Selective Demolition

381 mechanical demolition, pump, 125HP

Selective

012-F-15 - AHU1/2/3/4 Fanwalls

D30 HVAC

416 fanwall, assumed 2x3 24" array (AHU-2)

417 fanwall, assumed 2x4 24" array (AHU-4)

418 fanwall, assumed 2x6 24" array (AHU-1 & 3)

419 fanwall, controls/VFD's (AHU-1 & 3)

420 fanwall, controls/VFD's (AHU-2)

421 fanwall, controls/VFD's (AHU-4)

422 fanwall, modify fan discharge/plenum (AHU-01 & 03)High

fanwall, modify fan discharge/plenum (AHU-02)

fanwall, modify fan discharge/plenum (AHU-04)

Row

#Item Description

442 supply fans, assume 15,500CFM each

443 heating coils, 1 section/2 row, 90x27

444 heating coils, 2 section/2 row, 90x30

445 preheat coils, 4 section/2 row, 102x36

446 reclaim coils, 4 section/8 row, 102x36

447 cooling coils, 3 section/10 row, 114x33

448 replace pumps, RCP-03, 7.5HP

449 replace drain pans/accessories, allow

450 replace VFD, 7.5HP w/bypass

451 replace VFD, 80HP w/bypass

F20 Selective Demolition 454 mechanical demolition, drain pans/accessories

711 replace DCW booster pump DCP-1 & 2, 40HP (2027)Moderate

Consultants

F - HVAC/Mechanical 012-F-02 - CRU COND-4A

D30 HVAC

012-F-03 - Heat Exchangers, Pumps & Piping

D30 HVAC

40HP (HWP1&2)

012-F-05 - Radiant Heating System

D30 HVAC

767 heat exchanger, shell & tube, 2932MBH

replace HW pumps, 10HP (HWP3&4)

012-F-06 - 6F Reheat System

modify electrical feeders to chillers, allowance

822 EOL 2038 (but planned for next 10 years)

D30 HVAC

830 heat exchanger, shell & tube, 466MBH

831 replacement cooling towers, crossflow (5 total)

832 chillers/piping/fittings

833 cooling tower, riser pipe & fittings

834 replace pumps, CNP-1,2,3, 50HP

835 replace pumps, CTB-1, 7.5HP

836 replace valves, 10" butterfly

837 replace VFD, 50HP w/bypass

838 replace VFD, 7.1/2HP w/bypass

D50 Electrical Systems

841 modify electrical feeders to cooling plant, allowanceHigh

F20 Selective Demolition 844

D30 HVAC

(AHU-10)

Row

012-F-19 - Replace Reclaim Pumps

D30 HVAC

898 replace pumps, RCP-01, 20HP

899 replace pumps, RCP-02, 10HP

900 HVAC, VFD, 10HP w/bypass

901 replace, VFD, 20HP w/bypass

H - Electrical

012-H-02 - Distribution Panels 9A & 9B

D50 Electrical Systems 916 distribution panels, 120/208-3-4, DP-9A, 800A

917 distribution panels, 120/208-3-4, DP-9B, 800A

& 9B

012-H-03 - Replace Panel LDP7-1

012-H-04 - Replace Generator EMG1

generator set,

modifcations 943 generator set, replacement project, additional scopeModerate

per WUSM

Lookahead

1

(1) Current costs are 1Q24 dollars.

(2) Escalated costs reflect a 3% annual rate.

(3) Non-recurring required renewal costs are averaged over a 5-year period unless specific replacement dates are known.

(4) Non-recurring recommended renewal costs are averaged over a 10-year period unless specific replacement dates are known.

(5) Recurring costs are assigned based upon anticipated life cycle of building systems and components.

(6) Some minor rounding issues may be apparent when compared to estimate detail.

$60,000,000

$50,000,000

$40,000,000

$30,000,000

B012 envelope is in good shape for a building that is 55 years old and with the planned replacement of the roof and tuckpointing should continue to be viable building for the campus . The interior spaces on Level 01 and parts of 04 and most of 08 are in good to excellent condition, while the remaining portions of the building needing a refresh soon along with full upgrading on 09 planned. The majority of the costs in the MEPFP are related to the age of the buildings infrastructure with the major projects in the HVAC category. Plumbing and Electrical upgrades make up the minority of the cost, in addition to some accessibility and code upgrades.

Prepared: February 14, 2024 by:

MossConstructionCostManagementIncorporated(“MossCost”),aspartoftheLJCdesignteam,hasbeen taskedtoprovidethirdparty/independentcostmodelingandestimatesfortheWashingtonUniversitySchoolof Medicine2023FacilityConditionAssessment(“FCA”).Thesenotesareintendedasaguideforunderstanding thecostreportsproducedforeachbuilding/asset.

Theintentofthecostreportistosupportstrategicandbudgetaryplanningforagivenasset.Itachievesthisby providingkeyperformancemetrics(inthiscase,thefacilitiesindices)thatcanbeusedtoquicklyascertainthe stateofagivenbuildingandenablecrosscampuscomparisonofthebuildingstock.

Thereportsummarizesthecostdatarelatingtotheanticipatedcostofrepairorreplacementofthevarious buildingcomponentsidentifiedbytheinspectionteamasbeingdefectiveandrequiringcorrection,orsoonto requirecorrection.

Thecostreportcomprises:

1) Summaryofcostsbytype&priority

2) Descriptionofnon-unique/overlappingcosts,ifany

3) ThecalculatedFacilityConditionIndices

4) Correctivecostdetails

5) Summaryofdeficiencybypriorityclassification

6) 10Yearlookahead

Thecostreportcontainsestimatesofthelikelyprobablecostofcorrectingsuchdeficienciesaswereidentified duringthesiteinspection.CostestimatespreparedaspartoftheFCAeffortarepreliminaryopinionsand subjecttovariationwhentheworkisplanned,designed,andexecuted.Each itemistypicallytreatedasa standalonetask.Thiscanleadtodisproportionatelyhighercoststhanifitemswerebundledintoprojects(for exampleanentirefloorrefurbishment)whichwouldrealizeeconomiesofscale.

Thecostassessmentspreadsheetistheprimarybasisfordeterminingthescopeandextentofagivencorrection, andcategorizationintonon-recurringandrecurringcosts.Followingcompletionofthebuildingwalkthrough and360-degreescan,draftreportsgeneratedbytheinspectionteamareusedasthebasisfordeveloping estimatesofthelikelyprobablecostofcorrectingexistingandanticipatedfuturedeficiencies.Reference materialincludingarchivaldrawingsandequipmentreportsareusedtofurtherinformtheseestimates. Followingreviewbydiscipline,thescopeofeachlineitemisconfirmed,andcostsrefinedandcategorizedas deferredorfutureanda10yearlookaheadproduced.

ConstructionCost: Estimatedprobableconstructioncostofthosecomponentsnormallyincludedwithinthe hardconstructionbudget,togetherwiththeappropriateestimatingriskfactor.

CostTypes: Costsfallintotwomaincategories:Non-recurringandRecurring.Furtherclassificationincludes deferred,future,andnon-unique.

CurrentReplacementValue(CRV): TheCRVofafacilityistheestimatedprojectcosttoreplaceafacility withoneofsimilarfunction,appearance,buildingsystems,buildingmaterials,architecturalandsitedetail includingdesignfeesandprojectmanagementcosts.Currentreplacementvaluesforthisstudywereprovidedper WUSM(6November2023).

Escalation:Thechangeinexpectedcostovertime,forwhichprovisioncanbemadeasacontingency allowanceinestimation.Estimateswithinthecostreportexcludesuchallowance.Thelookaheadaddsa3% annualescalationtofuturecosts.

FacilityConditionIndex(FCI): Aratioofthecostofrequiredcorrectivemeasurestothecurrent replacement valueforafacility.Itisderivedbydividingdeferredrenewalcostsbythereplacementvalue.

FacilityNeedsIndex(FCNI):Aratioofthesum ofallnonrecurringandrecurringcoststothereplacement valueofafacility.

Lookahead:Ascheduleofthefuturecorrectivecosts(bothnon-recurringandrecurring)overadefinedperiod. Thelookaheadperiodforthisstudyis10years.Timingisbasedupontheexpectedendoflifeofbuilding componentswhereknownand/orthecyclicalrenewalofsystems.Fornon-recurringdeferredcosts,item priorityclassificationisusedtoinformschedule.Typically,priority1isassumedtobeexpendedinthecurrent year,priority2inyears1-5andpriority3inyears1-10.Non-criticalitems(priority4)areplacedinyear10.

Non-RecurringCosts: Correctivecoststhatarenormallyone-timeonlywithintheanticipatedlifeofthe buildingasset.Suchcostsareassociatedwithbringinganassetbacktoasatisfactoryconditionandincludeall deferredrepairstogetherwithnecessarylifesafetyandothercodecorrections.Theymaybefurtherclassifiedas deferred(pastdue)orfuture(comingdueduringthe1ookaheadperiod). Example; replacing a non-functional or failing supply fan would be classified as a deferred cost. Replacing the entire AHU at its expected end of life 8 years from now would be a future cost.

Non-UniqueCosts:Correctivecoststhatduplicateorotherwiseoverlapworkcoveredbyotherestimates.Costs insuchcaseareprovidedforinformationpurposesshouldOwnerelecttonotperformagivencorrective measure,orwherethetimingoftheworkisnotoptimal.Forexample,acorrectioncallsforthereplacementof sprinklerpiping.Aseparateitemcallsforcommunicationcablingtobeupdated.Bothitemsrequireceiling accessandallowancesareincludedinthecostsforthis.Ideally,thecorrectionworkwouldbeperformedasa combinedprojectallowingtheoptimizationofceilingremovalandreplacementandavoidingcostduplication.

ProjectCost: Estimatedconstructioncostsplusdesignfeeandprojectmanagementallowance.

PriorityClass:Deficienciesareclassifiedintermsofurgencyintooneoffourrenewalcategories; Immediate, Necessary,RecommendedandNon-Criticalappliedasfollows:

1 ImmediateRenewal Immediatecorrectionrequiredtoeither(a)correctasafetyhazard(b)prevent accelerateddeteriorationand/or(c)returntonormaloperation.

2 Required(Necessary)Renewal Short-tomid-termactionrequiredtopreventfurtherdeteriorationortocorrectnonlife-threateningcodeissues(e.g.accessibility).

3 RecommendedRenewal Suggestedbutnotessentialimprovementstothebuildingtoincreaseefficiencyand/or usability.

4 Non-CriticalRenewal Noactionrequiredunlessuseoroccupancychanges,ortocomplywithcodeas grandfatherclausesexpire(forinstance,duetoexpansionorremodeling).

RecurringCosts:Manybuildingsystemsandcomponentshaveausefullifeshorterthanthatofthe building/structureitself. Recurring costsrepresent thenormalrepairandreplacementcostofsuchbuilding systemsandcomponentsastheyreachtheendoftheirusefullife.Forthepurposesofthisstudy,suchrecurring costswereidentifiedfora10yearlookaheadonly.

RenewalCosts:Renewalcostsarethosecostsassociatedwiththecyclicalrefreshingoftheinteriorfinishesof aspace,regardlessofwhethersuchitemshavebeenclassifiedasadefectbytheinspectionteam.Where refreshingthefinishesisoverduethesearecategorizedasdeferredcosts,otherwisetheyareshownasrecurring futurecosts.Thefollowingtableshowstherenewalcycleofvariousfinishesasappliedtothisstudy.

TheFCIandFCNIareusefulmetricsthatcanbeusedtoquicklyascertainthestateofagivenbuildingand, whenappliedconsistently,enablecrosscampuscomparisonofthebuildingstock.Theindicescanbeappliedto anysubsetofanassetportfolioandusedtocomparewithcompetingfacilities.

Inreviewingtheindices,itisimportanttonotethatthehighertheindexvalue,themoredeficientabuildingor groupofbuildingsis.AsFCIincreases,theassetswillexperience:

•Increasedriskofcomponentfailure

•Increasedfacilitymaintenanceandoperatingcosts

•Greaternegativeimpactstooccupantsandusers

Thefollowingchartisaguidetointerpretingdifferentindexvaluesasappliedtoabuildingasawhole.Tiers aresomewhatsubjectiveandarbitrary,andwerecommendthatthesebereviewedincontextofthepresent studyanduser(WUSM)specifictablebedeveloped.

Whatdoestheindexsayaboutyourbuildngcondition?

0.10•ExcellentCondition(likenew)

0.20•GoodCondition(wellmaintained)

0.30•FairCondition(normalrenovationrequired)

0.40•PoorCondition(significantrenovationrequired)

0.50•Deficient(extensiverenovationrequired)

0.60•Critical(totalrenovation/replacementindicated)

Allestimatedcostsareincurrentdollars(pertheeffectivedateofeachreport)1 . Laborandequipmentratesarelocationspecificwithproductivitybasedonnationalaverages. Materialscostsarebaseduponnationalaveragesadjustedforlocation. Competitivebidprocurementassumed.

Adequatebidcoveragefromgeneralcontractorsandsubcontractorsassumed. Allworkisperformedduringnormalworkinghours. Estimatesincludesallowancesforthefollowing,asappropriate: Accesstoitemstoberepaired/replaced.

1 Anescalationallowanceisincludedonthe10yearlookahead,atarateof3%.

Disturbanceorremovalofadjacentelements

Temporarysupports

Servicedisconnections&reconnections

Restorationofelementsaffectedbythework

Difficultyofaccess

Safetyrequirements

Thefollowingmarkupsareincludedintheestimates:

1) EstimatingRiskfactor.Itemshaveariskratingasfollows:

a) Low:Requirementsareself-evident anduncomplicated.Riskofunforeseen conditionsislow;factorof 10%added.

b) Moderate:Extentofdeficiencymayextendsomewhatbeyondwhatcanreadilybeobserved. Unforeseenconditionsarelikelytobeencounteredbutnotexpectedtobeextensive;factorof20%.

c) High:Extentofdeficiencyandrequirementforcorrectionaredifficulttoascertainwithoutextensive investigation. Riskofunforeseenconditionsandunanticipatedworkishigh;factorof35%.

2) Constructioncostmarkupof30%isaddedtonetcoststocovergeneralcontractor’sstaging/general requirements/OH&P

3) Locationaladjustmentasappropriate

4) Designfees@7%

5) WUSMprojectadministrationandcontingency@20%

Inthecostreport,“ConstructionTotal”includesmarkups(1),(2)and(3).ProjectTotalincludesmarkups(1) through(5).Allothermarkupsareexcluded.

Correctivecostitemsareanestimateofprobableconstructioncostofthosecomponentsnormallyincluded withinthehardconstructionbudgetandlimitedtothoseitemsidentifiedbythesiteinspectionteams. Estimationofotherdisciplinesandprojectcosts,notlimitedtothefollowing,isexcluded.

Furnishings,appliances&movableequipment

Artwork

SupplycostofOwnerFurnished,ContractorInstalled(OFCI)items

Supply&InstallationcostofOwnerFurnished,OwnerInstalled(OFOI)items

Itemsmarked"FFE","NIC",“EXCL”orotherwisespecificallyexcludedwithintheestimatedetail

Systemdevelopmentchargesorutilitycompanysurcharges

Operational&indirectimpact/disruptioncosts

Escalation(exceptasallowanceincludedin10Yearlookahead)

Futuremarketconditionchanges

Routineandcontractmaintenance,annualinspections/certification

SwingSpace,temporaryhousingorparking

Premiums/allowancesforspecificprocurementmethods(e.g.8A/SDVOSB)

Space,functional,securityissuesrelatedtothecorrectivemeasure

Project“softcosts”exceptasstatedunder“Markups”

Consultingfeesexceptdesignfeesandsuchstudiesascalledoutinreport

Constructionadministrationcosts,and/orowner’srepresentativefees

Projectlevelcontingencies

Constructioncontingencies

LEEDapplication/certifyingfees,ifappropriate

Independenttesting,inspection,orthird-partycommissioningagents

Thelookaheadislimitedtothoseitemsidentifiedbythesiteinspectionteamsandexcludesupdatesof expendituresforecastbypriorFCAstudies2

Allworkwillbeperformedbyoutsidecontractors,competitivelyprocured.

Unlessexplicitlystatedotherwise,eachFCAitemisassumedtobeaself-containedpieceofwork,performed independentlyofothercorrections.

Whereaccessworkforbuildingservicesandrelatedsystemsrequiresdemolition,reinstatementand/or abatement,itisassumedthattheseeffortswillnotbecoordinated/optimized.Anyduplicationofeffortis, however,recognizedinthenon-unique/overlappingcostsummaryofeachreport.

Itmaybeunrealistictocutout,patch,andrepairpartofanassembly. Inthatcase,estimateincludesforfull replacement.

2 Perprojectdescription“whilethecurrentISESreportincludescostnarrativesoffuturecapitalexpendituresupto10years,forthepurposesof thisproject,theconsultantwillnotbeincludingupdatedre-occurringexpenditures.”

CostsarepresentedusingthefacilityconditionreportitemcodewithaUniformatlevel2breakdownperthe examplebelow.Deficiencieshavebeenprovisionallyallocatedapriorityclass,howeverwithintheclassitems arenotsortedbycriticality.

AssetID

B064 4511ForestParkRADOC

CostType 1 Non-Recurring(Deferred)

FCACategory/System A Site

FCA Item#

064-A-01A Mill&overlayparking

UniformatL2Code G10 SitePreparations

Cost/RiskFactor 1 Low

Standard Abbreviations

Atableofstandardabbreviationsusedintheestimatesisappended.

Disclaimer

Purposeanduseofestimate:Theintentofanyestimatecontainedinthecostreportsistoreflectfairmarket valueforthecorrectionofdeficienciesnoted.Itis notapredictionoflowest,orany,bid. Itisanopinionof probablecostintendedasatoolforbudgetingpurposes. Theestimatorcannotanddoesnotguaranteethatbids, proposalsoractualconstructioncostswillnotvaryfromanyestimateorstudy.

Scope: NodesignsolutionsarepresentedaspartoftheFCA. Theestimatorhasthereforeusedhisbest judgementtodeviseaworkingsolutionforthedeficienciesnoted. Estimatorisnot,however,adesigner, architect, engineerorcodeofficial.

BDFT Board Feet

BGSF Building Gross Square Feet

CF Cubic Foot

CFM Cubic Feet per Minute

CRV Current Replacement Value

CSF 100 SF

CY Cubic Yard

DAY Workday

DGSF Departmental Gross Square Feet

LVS Leaves

NA Not Applicable

NASF Net Assignable Square Feet

NB Important note3

NIC Not in Contract

NSF Net Square Feet

OFCI

OFOI

Owner Furnished Contractor Installed

Owner Furnished &Installed

OPG Opening

EA Each PR Pair

EOL End of Life

ETR Existing To Remain

EXCL Excluded

FCA Facility Condition Assessment

FCI Facility Condition Index

FFE Furnishings, Fixture & Equipment

PTS Points

R&R Remove & Replace

RM Room

RMS Rooms

RSF Renovated Square Feet

SET Group of Items

FLR Floor SF Square Feet

FLRS Floors

SFFA Square Foot Surface Area

FXT Fixture SQ Square (100SF)

GSF Gross Square Feet

STN Station

HR Hour STOP Elevator Stop

INCL Included in another item

LF Linear Foot

LFR Linear Foot (of) Riser

LOCN Location

LOT Group of Items

LS Lump Sum

3 FromtheLatin “NotaBene”meaningnotewell.

SY Square Yard

TBD To Be Determined

TON 12,000 BTUH- Heating& Cooling

TON Short Ton (2,000 pounds) - Steelwork

VLF Vertical Linear Feet

YRS Years