Established in 2012, Kyocera Hardcoating Technologies provides premium PVD coating solutions to a broad spectrum of industries in the UK and across Europe. We also have a facility in North America with dedicated coating scientists and a laboratory.

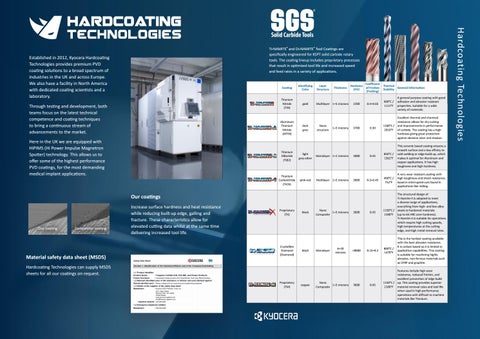

Coating Titanium Nitride (TiN)

Through testing and development, both teams focus on the latest technical competence and coating techniques to bring a continuous stream of advancements to the market.

Aluminum Titanium Nitride (AlTiN)

Here in the UK we are equipped with HiPIMS (Hi Power Impulse Magnetron Sputter) technology. This allows us to offer some of the highest performance PVD coatings, for the most demanding medical implant applications.

Titanium DiBoride (TiB2)

Titanium Carbonitride (TiCN)

Identifying Color

gold

dark grey

light grey-silver

pink-red

Layer Structure

Thickness

Multilayer 1–5 microns

Nano structure

1–5 microns

Monolayer 1–2 microns

Multilayer 1–5 microns

Coefficient Hardness of Friction (HV) (Fretting)

2200

3700

4000

3000

0.4–0.65

0.30

Our coating

Competitor coating

Material safety data sheet (MSDS)

Proprietary (TX)

Crystalline Diamond (Diamond)

black

black

Nano 1–5 microns Composite

Monolayer

6–20 microns

3600

>8000

Kyocera SGS Precision Tools Europe Ltd | www.kyocera-sgstool.co.uk | +44 (0) 1189 795 200

copper

Nano 1–5 microns Composite

3600

A general purpose coating with good adhesion and abrasion resistant properties. Suitable for a wide variety of materials.

Excellent thermal and chemical resistance allows for dry cutting 1100°C / and improvements in performance 2010°F of carbide. The coating has a high hardness giving great protection against abrasive wear and erosion.

0.45

850°C / 1562°F

0.3–0.45

400°C / 752°F

A very wear resistant coating with high toughness and shock resistance. Good in interrupted cuts found in applications like milling.

0.45

0.15–0.2

Hardcoating Technologies can supply MSDS sheets for all our coatings on request. Proprietary (TM)

600°C / 1112°F

This ceramic based coating ensures a smooth surface and a low affinity to cold welding or edge build up, which makes it optimal for Aluminum and copper applications. It has high toughness and high hardness.

Our coatings Increase surface hardness and heat resistance while reducing built-up edge, galling and fracture. These characteristics allow for elevated cutting data whilst at the same time delivering increased tool life.

Thermal General Information Stability

0.45

Hardcoating Technologies

Ti-NAMITE® and Di-NAMITE® Tool Coatings are specifically engineered for KSPT solid carbide rotary tools. The coating lineup includes proprietary processes that result in optimized tool life and increased speed and feed rates in a variety of applications.

The structural design of Ti-Namite-X is adapted to meet a diverse range of applications; everything from high- and low-alloy 1150°C / steels to hardened materials 2100°F (up to 65 HRC core hardness). Ti-Namite-X is suitable for operations which require high cutting speeds, high temperatures at the cutting edge, and high metal removal rates.

800°C / 1470°F

This is the hardest coating available with the best abrasion resistance. It is carbon based so it is limited in application capabilities. This coating is suitable for machining highly abrasive, non-ferrous materials such as CFRP and graphite.

Features include high wear resistance, reduced friction, and excellent prevention of edge build 1150°C / up. This coating provides superior 2100°F material removal rates and tool life when used in high performance operations with difficult to machine materials like Titanium.

Kyocera SGS Precision Tools Europe Ltd | www.kyocera-sgstool.co.uk | +44 (0) 1189 795 200

51