Inside

FastBale: Non-stop baling

U-Drill: The drill of the future

SILOKING: Maximising production

2024 Edition

www.kverneland.ie

Welcome to the latest edition of the Kverneland Future of Farming Magazine! As we step into 2024, we find ourselves at the forefront of a new era in agriculture, where innovation, sustainability, and precision are shaping the future of our industry.

At Kverneland Group Ireland, our commitment to excellence in farming solutions continues to drive us forward. In these pages, you will discover the latest advancements in technology, insightful stories from the field, and expert perspectives that reflect our dedication to empowering farmers and contractors with the tools they need to thrive in an ever-evolving landscape.

In 2024, we celebrate not just the achievements of the past, but the limitless possibilities that lie ahead. As Managing Director, I am proud to witness the transformative impact our products and services have on the lives of farmers and contractors across Ireland. Through our relentless pursuit of innovation, we strive to contribute to a sustainable and prosperous future for agriculture.

I invite you to immerse yourself in the pages of this magazine, where the passion for farming meets the cutting edge of technology. Together, let's explore the Kverneland vision for the future of farming and the role we play in shaping the farming landscape.

Thank you for joining us on this journey. Here's to a fruitful and inspiring year ahead!

Managing Director, Kverneland Group Ireland

Managing Director, Kverneland Group Ireland

WHEN FARMING MEANS BUSINESS

Philip English

CONTENTS

We catch up with contractor, Alwyn Young, from Co. Tyrone on his butterfly mowers. Discover why reliability in tough conditions makes this mower a contractor's go-to choice.

Kverneland 6m u-drill: Alfie Byrne's Game-Changer. Versatile, efficient, and future-ready. Read how this universal seed drill revolutionizes agricultural contracting with precision, adaptability, and user-friendly automation.

WWW.KVERNELAND.IE 3 4 5 6-7 8 9 10 11 What’s New for 2024 FastBale Revolution 53100MT BX Seeding McConnel Siloking 4.0 Premium Finance & Parts

revolution

6 8 SEEDING

5 FastBale

53100MT BX

What’s New for 2024

Asagricultureevolvesrapidly,we remain one step ahead. We hear from our product managers, John and Leonard, as they unveil the latest advancements in Arable, Cropcare, and Harvest machinery,settingnewstandards forexcellenceinthefield.

LEONARD HOVENDEN

PRODUCT MANAGER ARABLE & CROPCARE

In the heart of Irish agriculture, where tradition meets innovation, Kverneland Group Ireland continues to pioneer solutions that not only ease the hard work of farming but also enhance the productivity and sustainability of our practices. As we embrace another season, I'm thrilled to introduce breakthroughs that are set to redefine our approach to cultivation, seeding, and weed control.

First up is our latest marvel, the Kverneland Plough Body No. 40. Designed with the challenges of Irish soil in mind, this plough body is a testament to our commitment to efficiency and performance.

Its innovative engineering ensures it glides through the soil with minimal effort, significantly reducing fuel consumption. This means not only savings at the fuel pump but also a lighter load on your tractor, extending its service life.

But it's not just about making ploughing easier. The Plough Body No. 40 is designed to improve soil turnover and aeration, laying the foundation for a bountiful harvest. By ensuring optimal soil health, we're not just working the land; we're nurturing it for future generations.

Next, let's talk about seeding – a critical step in the farming cycle where precision and flexibility can make all the difference. Our F-Drill CB F Coulter Bar, in combination with the Rotago F Power Harrow and front hopper F-Drill models, introduces a new level of precision and adaptability to seeding operations.

Customizable working widths and our renowned CXII coulters mean you can tailor your seeding to match your exact needs, ensuring every seed's placement is optimized for growth.

What's more, with easy adjustments for depth and pressure, controlled either manually or via ISOBUS, achieving perfect seeding conditions has never been simpler. And for those journeys between fields, we've added a supporting wheel to ensure safe transport on Irish roads.

In our quest for sustainable farming solutions, the Rotary Hoe Helios stands out for its innovative approach to weed control. This tool is designed to tackle weeds efficiently while preserving the integrity of your crops. Its ground-driven star wheels lift and remove weeds without disturbing the crop, performing multiple actions in one pass for the most effective weed control.

Precision adjustments allow for consistent performance across your fields, ensuring minimal crop disturbance and promoting healthy, sustainable growth. It's not just about removing weeds; it's about promoting an environment where your crops can thrive.

For more information, or to discuss how we can support your needs, feel free to reach out to me directlyatLeonard.Hovenden@kvernelandgroup.com

Arable & Cropcare Harvest

As we build upon the esteemed legacy of Taarup, known for pioneering agricultural machinery that has set industry standards, I am delighted to introduce Kverneland's latest contributions to the Irish market for 2024. These innovations not only pay homage to our rich heritage but are also designed with the modern farmer's needs at the forefront, ensuring that Kverneland remains synonymous with excellence and efficiency in agriculture.

The Kverneland 5387 MT BX triple mower combination represents a leap forward in mowing technology. Set to revolutionize our fields in 2024, this machine boasts an impressive 8.75-metre working width while maintaining a compact footprint. At its core is the innovative QuattroLink suspension concept, offering unmatched adaptability and performance across diverse terrains. This isn't merely about upholding the strengths of its predecessors; it's about redefining what's possible in mowing technology. Its efficiency is further enhanced by a belt merger in the BX version, making it a powerhouse in crop collection and setting new benchmarks for productivity.

In our continuous effort to cater to the broad spectrum of agricultural needs, we are excited to roll out the 85156 C tedder. This machine is a testament to Kverneland's commitment to improving productivity and crop quality for farmers and contractors. With a 15.6-metre working width and equipped with 14 rotors, the 85156 C is engineered for high output. The standout TerraFlow system ensures precise adaptation to ground contours, providing uniform crop flow and superior forage quality under almost any condition. Its design prioritizes user-friendly operation and maintenance, featuring a transport width of less than 3 metres for straightforward road transport and large tyres for enhanced stability and ground protection.

These innovations signify our dedication to advancing agricultural practices, offering solutions that meet the evolving demands of the industry. Yet, our commitment to enhancing the efficiency of farming operations doesn't stop there. When paired with the Kverneland FastBale, the world's only nonstop baler, the 5387 MT BX becomes part of an unstoppable duo that promises to transform foraging operations across Ireland. This synergy between cutting-edge technologies ensures that Irish farmers can achieve unparalleled efficiency and productivity in their harvesting efforts.

JOHN DOYLE

PRODUCT MANAGER HARVEST

As we look ahead to 2024, these new offerings from Kverneland are poised to become essential tools for farmers and contractors aiming to streamline their operations and enhance crop quality. It's a privilege to continue the legacy of innovation that Taarup began, providing the agricultural community with reliable, high-performance machinery.

For more details on how this innovative solution can revolutionize your foraging, don't hesitate to reach out to me at John.Doyle@kvernelandgroup.com.

4 WWW.KVERNELAND.IE

The art of round baling took a massive leap forward with the unveiling of FastBale – a revolutionary non-stop round baler wrapper combination that cleverly integrates a pre-chamber with a main chamber and a wrapper.

Gary Roe, a seasoned contractor hailing from Ballacolla Co. Laois, unveils the transformative power of the Kverneland FastBale.

"In my experience, I'd recommend a FastBale to farmers and contractors without hesitation," Gary asserts, his statement resonating with the challenges and demands of modern farming. "The efficiency, the quality of the bale it makes, compactness, and how well it travels the land – this year, it truly showed up," he adds, underlining the machine's performance that surpassed expectations.

Non-Stop Baling

Reflecting on his first year with the FastBale, Gary expresses his profound satisfaction with its efficiency and compactness. "From a point of efficiency and compactness as well, we find that it's a lot easier on the driver," he shares, emphasizing the seamless workflow facilitated by this innovative equipment. "You're constantly moving, you're not racing around the field," he explains, highlighting the machine's ability to streamline operations and enhance productivity.

Kverneland FastBale represents two world firsts: it is currently the World’s only non-stop fixed chamber baler and secondly, it is the World’s only non-stop fixed chamber baler-wrapper combination.

High-Quality Bales – Happy Farmer!

Gary commends the FastBale for its ability to produce highquality bales consistently. "It's making a very good bale as well," he remarks, attributing this achievement to the pre-chamber's unique design that ensures the formation of a hard center bale. "The pre-chamber makes like a hard center bale, so that's given us the good compact bale out the back, which the farmer seems to be happy with and like," Gary elaborates, illustrating the machine's ability to meet the demands of both contractors and farmers alike.

FastBale features two bale chambers – a full sized main chamber and a pre-chamber which is about two thirds of the size of the main chamber.

Baling starts in the conventional manner with the main chamber producing the first bale. However, once the bale is fully formed, instead of having to stop to apply the net, FastBale Premium diverts the crop flow to the pre-chamber.

This allows the net/film to be applied to the bale in the main chamber and for the bale to be ejected onto the wrapper. When the pre-chamber is full, the incoming crop flow, together with the pre-compressed crop are both then transferred into the main bale chamber. Here the bale is formed to its final size and density.

"Output-wise, we're very happy with, especially with silage," he adds, highlighting the FastBale's ability to keep pace with other equipment in the field. “It is keeping up with the rest of them,"

Gary's decision to invest in the FastBale was confirmed by a demonstration from the experts at Kverneland Group Ireland. "If it was ever a demo sold a machine, it was the day that the lads from Kverneland came up displaying the demo to us,"

Smart Wrapping Concept

In addition to its performance, Gary highlights the FastBale's film on film feature, which has garnered praise from farmers for its effectiveness and efficiency. "Film on film is also a very good thing,". Some of the benefits of this technique include improved silage quality, easier handling and feeding out of bales and simpler recycling of plastic waste.

Conventional baler-wrappers have to stop to apply net to the bale, which takes at least 5 seconds, plus more time to open/close the tailgate. Wrapping with net replacement film needs more wraps due to the ‘tail’ which has to be formed at beginning and end of cycle. This results in the binding cycle taking over 10 seconds – so at least 5 seconds extra spent stationary for every bale made. FastBale continues baling during binding so all of this time is saved.

Massive Intake Rotor with a Huge Appetite!

Huge 800 mm diameter intake rotor equipped with 50 Hardox® tines, gives unrivalled intake capacity. Close mounting of the pick-up to the rotor eliminates any dead areas when working in short crops while the 25-knife SuperCut chopping system features group selection giving a choice 6, 12, 13, 25 knives to match all conditions, all backed up with the security of a drop floor in case of blockage.

2.2m Wide Pick-up

FastBale Premium’s pick-up is equipped with 5 tine bars, with each bar supported by two intermediate bearings, while a cam track at both ends reduces cam loadings by 50%, giving assured long term durablity.

A unique internal drive system keeps overall width to a minimum, with the result that pick-up guide wheels do not need to be removed or folded for transport, reducing unproductive time between jobs.

A Contractors

Perspective

As a contractor striving to meet the demands of farmers, Gary sees the FastBale as a valuable asset that enables him to deliver exceptional service while ensuring operational efficiency. "So, from a contractor's point of view, that's great as you're trying to meet the demands from the farmer as a contractor," he concludes, underscoring the FastBale's role as a game-changer in the world of agricultural machinery.

Click here to watch the full video testimonial with contractor, Gary Roe.

WWW.KVERNELAND.IE 5

Gary Roe, Roe Agri Services, Co. Laois.

“We did try a few other makes but we always seem to end up back at Kverneland”

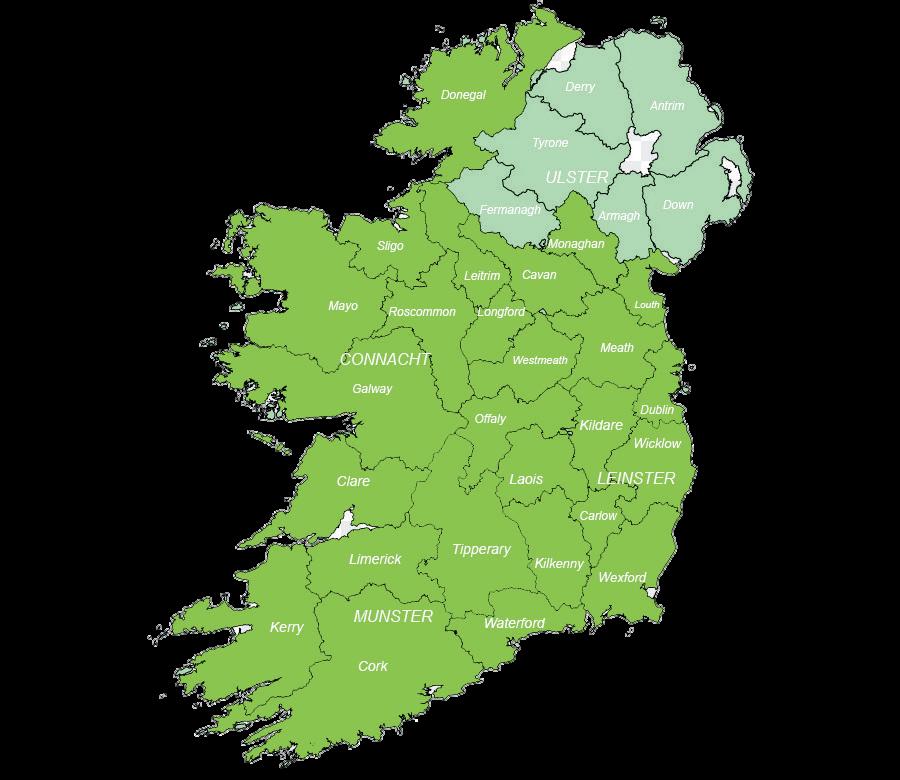

Alwyn Young, of WC Young & Sons Ltd., is a well-known contractor based in Castlederg, Co. Tyrone. Contracting has always been a way of life for Alwyn, who followed into the contracting business that his father Charlie established over 50 years ago.

Following the unprecedented weather this summer, Alwyn affirmed that 2023 will be remembered as a tough season for contractors.

“The rainfall’s held us back badly, I would say it’s nearly one of my worst years that I’ve ever experience. Everything just went totally against us; grass was early, all my customers were early and then it didn’t stop raining,” said Alwyn.

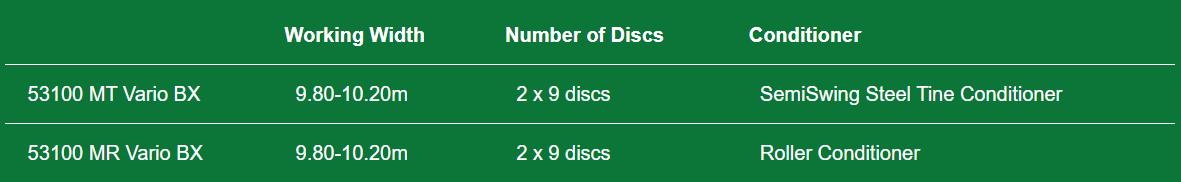

To get through such tough times and even tougher conditions, the quality and reliability of your mower is crucial. In his fleet, Alwyn has two sets of Kverneland 53100MT BX butterfly mowers, which have a 33 series front mower, two 3232MN rear mounted, and two 3532FT and 3632FT front mowers.

Discussing why he chose Kverneland, he said: “Our mowers of choice would tend to be Kverneland. The reason being is that we’d have challenging conditions. We did try a few other makes but we always seem to end up back at Kverneland”

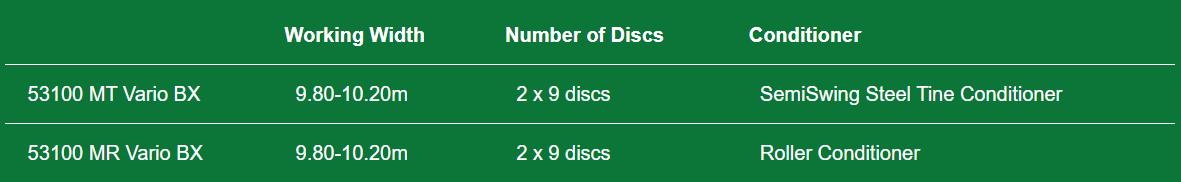

New triple-mowers

With the continued growth of the triple-mower market, Kverneland is expanding its product offering with two new triple-mower conditioner combinations.

Posing as a bridge between entry-level models and top of the range models, these two new 8.75m combinations, the 5387 MT and the 5387 MT, with belts featuring patented QuattroLink suspension, are specifically designed for long productive working days and will complete the company’s range of triple mowers.

The range starts from the entry-level model, 5087 MN, 8.7m nylon conditioner triple mower, which is an efficient yet uncomplicated mower purpose-built to lower power and fuel consumption costs.

John Doyle, product manager at Kverneland group Ireland sees this mower as being geared towards the self-sufficient farmer or entry-level contractor who may be looking to upgrade from a front and rear mower combination.

Alywn found that one of the main benefits to Kverneland’s mowers is their weight, particularly on heavy ground.

He said: “These mowers definitely now are a lot lighter and whenever the mowers are lifted and you’re turning, you’re not leaving the same imprints or the same damage to the ground.”

Additionally, the wider cutting width of 10.2m means less travel over challenging ground due to the ability of the patented Racecar QuattroLink four arm suspension of this flagship model.

Discussing this mower, John said: “We believe this mower is as robust and uncomplicated a triple mower as is in the market today, while offered at a very competitive price.“

“This model is particularly suitable for a medium-sized tractor which helps with lower fuel consumption.”

“Your next step in the butterfly range is our latest product offering, launching this summer, the 5387 MT, 8.7m mounted steel-tine mower conditioner.”

Racecar suspension

Kverneland’s newest model of triple mowers is equipped with patented ‘Racecar’ suspension, allowing for exceptional ground contour following with independent mower suspension resulting in increased productivity and superior performance in all crops.

....“These mowers really float, you can watch them, they really do,”

6 WWW.KVERNELAND.IE

Alwyn Young, Co. Tyrone.

“The Racecar suspension allows you to work at high speeds while ensuring both the tractor and mowers are at ease.

“We see this mower as bridging the gap between the entry level 5087MN and our flagship 53100 MT, 10m triple mower,” said John.

Kverneland sees this latest product offering completing its range of butterfly mowers on offer to the Irish market.

The 53100 MT, top-of-the-range butterfly mower, offers an impressive 10.2m working width, with ISOBUS controls, and Vario suspension arms allowing an overlap of 400mm on each mower, which is adjustable on the go. The two rear 3.6m mowers are Kverneland’s most powerful triple mowers which are made for high level uptime and productivity.

Saving time and money

Both the 5387 and the 53100MT are available with swath belts.

“For the customer who wants to go straight to harvesting, this is an extremely efficient operation,” commented John.

“Uniquely, we offer a quick coupling solution for the 53100MT, which allows you to remove the swath Belts within minutes.”

“The upshot means the contractor or farmer can adapt quickly to whatever customer requirements are, not only saving time but more importantly weight and fuel consumption.”

“You couldn’t fault them. We’ve always used Kverneland, and Kverneland with us has got a proven track record”....

Following last year’s dry weather, Alywn noted: “There wasn’t the same need for the BX belts. Very easy taken off the mowers. One pin set the mowers down and drive out.”

John continued: “We’re particularly enthusiastic about this new product launch as the 5387 model offers the main features of the 53100MT, specifically the Racecar suspension with a robust and compact build, at an extremely competitive price

and we’ve forged a proud reputation as a supplier of top quality reliable and efficient grass machines, so make sure to check out the latest addition,” concluded John.

For Alywn, as a busy contractor, being able to rely on the service and commitment of his local Kverneland Dealers is key.

Click here to watch the full video on YouTube with Alwyn and the

TECHNICAL SPECIFICATIONS

WWW.KVERNELAND.IE 7 New suspension concept for accurate tracking. The 4-arm suspension provide the mowing unit with an exceptional flexibility in adapting to demanding ground contours. QuattroLink® mowers provide protection across the full working width of the mower, including the part close to the tractor. No need to stop, the mower will automatically return to working position. Easy adjustment between swathing and wide spreading. Changing for wide spreading is virtually a one minute job. No tools are required. The new conditioner hood can be adjusted at both front and rear end to customise the conditioner to crop intensity. Vertical transport position with a 50/50% weight balance allows a higher transport speed. With the integrated vertical parking foot limited storage space is required. Hydraulic SideShift integrated into the carrying arm allows each mowing unit to move 400mm. Adjusting the overlap is done quickly from the tractor cab, on the go. 2 1 3 1 4 4 6 5 5 6 KVERNELAND QUATTROLINK® – RACECAR TECHNOLOGY APPLIED FOR MOWER CONDITIONERS 100% Non-Stop BreakBack QuattroLink® RaceCar SuspensionQuick Adjustment of Output Dual Adjustment of Conditioner Hood Vario Suspension Arm Vertical Transport Position 2 1

The Kverneland u-drill is a universal seed drill, for all crop establishment systems, planting a wide range of crops, including cereals, oilseeds, and legumes. It uses a unique drilling system that delivers the seed precisely and consistently, resulting in better crop emergence and more uniform plant growth. The focus in design has been especially given to high speed operation (10-18km/h) with low pulling requirement while ensuring a perfect seed placement.

Front Wheel Packer

Alfie particularly likes the levelling characteristics of the u-drill. “The front wheel packers is an absolutely super job, and the big wheel I think is a major plus with, this drill the wheel is higher and wider, which makes it easier to pull and floats the ground better”. For the best possible preparation, the front tyre packer levels the soil, crushes large clods and thus paves the way for the optimum depth control of the following tools. The front tyre packer has a diameter of 800mm. and when not needed can be lifted hydraulically, simply by pushing a button.

This system results in consistent seed-to-soil contact essential for optimal germination and plant growth. With the Kverneland CD-coulter, the narrow profile of the coulters with their slightly offset steel discs allow easy penetration into the soil. Thus, little pressure is required at this point with only little soil being displaced. The coulter pressure of 100kg can, therefore, be primarily used for the pressing by the integrated press wheels. The result is a uniform seeding depth even at high working speeds.

The “u” in u-drill stands for universal and not only refers to crop systems but also soil conditions.

Alfie maintains... “Especially in wet conditions. It's inclined to just float along the ground… and it gets through the wet spot easier”. With soil compaction always a concern for farmers with heavy conditions this is an important consideration.

Automated Headland Management

Designed with a fully automated headland management system, using just one button, the driver can initiate a headland sequence with wheels, discs and coulter bar all capable of automatic operation in timed stages. As the headland sequence starts, the metering device stops automatically – avoiding double seeding while the seed hoses are empty at the headland, saving valuable seed. “Everything is very user friendly, very clear”

TECHNICAL SPECIFICATIONS

folding to carry out seedbed preparation, levelling, reconsolidation, seeding and pressing in one pass. The drill is available as grain only or the grain and fertiliser application model, with split hopper functionality.

Alfie is so impressed with the drill he says. “I'd definitely recommend the drill to others, I'd actually think it’s the drill of the future”.

Click here to watch the full video on YouTube with Alfie and the 6m UDrill in action.

8 WWW.KVERNELAND.IE

70 & 75 SERIES

James Shine, a seasoned contractor hailing from South Tipperary, has spent decades in the field, navigating the landscapes of the “Golden Vale” in Ardfinnan, not far from Clonmel.

“We're contracting here for probably 45 or 50 years. It was hedge cutters when they started out first, and then moving along and doing hedge cutting, silage, bales, slurry, all that.”

JAMES SHINE ARDFINNAN, CO. TIPPERARY

“And then the revolution controls, if we have two or three people driving it and they like driving it different ways, you can set it up, change users, and it's quite precise and easy to use.”

For James, the journey with McConnel's Power Arms began with the acquisition of the PA6575. "Before the McConnel, we had a competitor machine, and when they were coming up for change, we saw the 6575, thought it was a good solid machine, and we purchased that in January of 2023," James recalls. The decision was driven by the machine's robust construction and advanced features.

"It has a real strong arm on it," James explains. "It's well-built. We've got quite a big cooling package on it which keeps the engine cool all day."

The ease of access for hooking on and off with the axle brackets and just lifting it up on the arms, and the stability of it is quite good. You can put it on and off in 10 minutes. And then also, this is the first telescopic machine that we bought. So, in wet conditions, we can vary the tracks quite a bit and get away when we wouldn't have been able to get away with the other makes.”

“On that machine, we have a 75 horsepower pump in it for encountering heavy bushes that haven't been cut for two or three years. Also, we put a tough cut head on it. We find that very userfriendly for changing flails. It's quite easy. You only need one socket and a spanner.”

Impressed by the performance of the PA6575T, James decided to expand the fleet with the addition of the PA6570T.

“"In September 2023, we were changing another one, and again, we looked around at different makes and models, and we went for the 6570," James recalls.

“It’s a slightly smaller horsepower compared to our other one. The arm is a small bit lighter but definitely more than adequate for what we want to do. “

“It has the Same 6.5-metre reach, different controls, but we have still got a tuffcut head on this, and it is a three linkage machine, but we put a sub-frame on it for stability and for cutting.“

James's experience with the PA6570T and PA6575T models exemplifies the dependability and versatility of McConnel Power Arms. "McConnels are a fantastic machine. They’re very fast and precise and make my job a lot easier," James remarks, his tone reflecting the confidence that comes from relying on equipment that consistently delivers.

Versatility is another key factor for James. With the ability to customize the machine to their specific needs, James and his team can tackle any task with confidence and efficiency. Both the 70-Series and 75-Series offer a choice of control systems and telescopic armset options, ensuring precise customization to individual requirements.

The technological advancements of both series further enhance their appeal. From the Easy Drive System (EDS) to McConnel's Variable Forward Reach armset, these machines offer the latest in hedge-cutting and verge-mowing technology, providing practical advantages in real-world scenarios.

Moreover, the comprehensive choice of flail heads and working attachments streamlines operations, making tasks like changing flails a breeze. James highlights the user-friendly nature of the tuffcut head, simplifying day-to-day operations and increasing efficiency.

In terms of maintenance, both series are designed for ease of use. The rugged Domex steel construction ensures durability, while features like the Hydraulic Power Slew and Hydraulic Safety Breakaway enhance safety during operation.

"Maintenance on these machines are quite easy, On our previous machines, you used to have to be taking off covers and guards to get in and make sure grease was going in, whereas on these, you don't. All the pins have two grease nipples either side, makes it very easy to grease." confirms James.

Reflecting on his purchasing experience, James acknowledges the importance of reliable support. "We purchased both machines off Sean and Abby retail. Their backup has been top class. No problem. We haven't had any issues with these," he explains, underscoring the significance of a dependable support system.

McConnel Power Arms represent the epitome of innovation in green maintenance equipment. With their robust construction, advanced technology, and unparalleled versatility, they continue to set the standard for professional contractors worldwide. And for James Shine and his team, they're not just machines—they're indispensable tools that make their work easier, faster, and more efficient.

70-series and 75-series machines offer a comprehensive choice of build options, control systems, and advanced features which enable customers to create a custom-spec machine that precisely meets their needs and offers outstanding reliability and performance. Operators can also choose from a wide range of working attachments including Multisaws, Ditch cleaners, Rotary Heads and Cutterbars.

To watch James Shine’s testimonial video on the McConnel PA6570T and PA6575T, click here.

+353 56 77 51597

General Enquiries Hebron Industrial Estate, Kilkenny, Co. Kilkenny

WWW.MCCONNEL.IE 9

Melvin Masterson on his SILOKING

TrailedLine 4.0 Premium 1814

In the world of dairy farming, efficiency is key. From optimizing feeding routines to ensuring the nutritional needs of the herd are met, every decision can have a profound impact on productivity and profitability. For Melvin Masterson, a dairy farmer based in Rathnure, Co. Wexford, the introduction of the Siloking diet feederhasrevolutionizedhisfarm'soperations.

"If you're in the market for a feeder, I'd definitely recommend considering Siloking. They're, in my opinion, one of the top choices," asserts Masterson. His statement stems from first-hand experience with the feeder's remarkable ease of use and exceptional performance. "You could show anyone within 5 minutes how to drive it," he adds, emphasizingthefeeder'suser-friendlydesign.

Beyond ease of use, Masterson highlights the crucial role Siloking feeders play in complementing thenutritionalneedsofhisherd,particularlyduring criticalperiodslikespringgrazing. "The consistency and the diet that Siloking feeders provide is massive," he notes, underscoring their ability to ensureoptimalnutritionyear-round.

Transitioning to Siloking feeders three years ago marked a significant turning point for Masterson's farm after purchasing from Donohoe Agri in Co. Wexford. "We were feeding a lot of bales at that time, and it just ate those up," he recalls, “and any questionsIhad,Donohue’swereonhand”.

The feeder's ability to handle various feed types seamlessly, even during challenging periods like droughts, has ensured consistent feeding throughouttheyear.

The size and capabilities of Siloking feeders were key factors in Masterson's decision-making process.

Maximizing Production on a dairy farm in Co. Wexford

"I wanted it big enough," he emphasized, recognizing the feeder's ability to meet the demands of his expanding operation. Unlike other options on the market, Siloking feeders are robust enough to handle large volumes of feed efficiently, makingthemidealforfarmsofallsizes.

Moreover, Masterson lauds the advanced technology integrated into Siloking feeders, particularly the DataE Control System (Bluetooth controls), which simplify the feeding process. "I love having it," he says, referring to the convenience it offers especially in comparison to the dial on the feeder and you’re not worrying about having the wrong pipes in or pressing the wrongspoolvalves.

In terms of maintenance and durability, Masterson attests to the reliability of Siloking feeders, stating, "After 1000 days of feeding, it's essentially like a new feeder still." The efficient feeding mechanism, facilitated by a conveyor system, minimizes waste andmaximizesfeedutilization.

Wrapping up his testimonial, Masterson expresses his satisfaction with Siloking feeders, crediting themfordrivingproductivityandprofitabilityonhis farm. "It's really helped us drive on our production," he concludes, highlighting the feeder's pivotal role in ensuring the long-term success of his dairy operation.

Masterson's journey with Siloking diet feeders serves as a testament to their transformative impactondairyfarmefficiencyandproductivity.As farming continues to evolve, investments in advanced technologies like Siloking feeders are essential for maximizing efficiency and ensuring thelong-termsustainabilityofdairyoperations.

For Masterson and many other farmers like him, Siloking is more than just a feeder—it's a partner in success.

Allan Hetherington, Kverneland Group Ireland’s product manager says “The German feeder manufacturer has really proven itself in the Irish market and continues to be innovative and adapt to the needs of the farmer, the professional farmer and also now industrial scale farms. Siloking concentrate on feeding business only and this really becomes obvious when end users get to use such a machine, or make an investment in Siloking machines. Taking the first step to invest in Siloking can be a game changer in the dairy or beef sector to really increase productivity and profitability.”

Efficiency by design for the Irish Market

The Kverneland Siloking TrailedLine 4.0 Premium range convinces with short mixing times and homogeneous mixing results thanks to the edged hopper shape. All models are equipped with SILONOXwearprotectionintheareaofthewedgeshaped hopper recesses and of the discharge door. The robust and torsion-free square-bar frame together with the powerful 4-planet gearbox ensureshighoperationalreliability.

Choosing from different hopper heights and tyres makes it possible to adapt the machine to the passage heights in the shed or to the maximum height of the loading vehicle. When reducing the hopper height, it is however important to adapt also the turbo auger in order to meet the quality requirementsofthehoppergeometry.Modelsfrom TrailedLine 4.0 Premium 3022-26 upwards are equipped with a tandem axle (with steering axle or steeringaxlewithpositivesteeringasoption).

www.kverneland.ie simply | intelligent | feeding

To watch Melvin’s testimonial video on his SILOKING feeder, click here. Contact Allan Hetherington SILOKING Product Specialist 0044 7826 544 630 Alan.Hetherington@kvernelandgroup.com “Diet and genetics I think are the two quickest ways you can improve the cows in your herd and the the profitability of the cow.” 10

XHD CARBIDE Payments Flat Rate VAT Inclusive Selling Price Machines 1+2 Annuals 0% 100% All Kverneland Equipment 1+4 Annuals 1.5% 100% All Kverneland Equipment The finance product offered under this promotion is a fixed rate Hire Purchase Agreement. Reference to ‘flat rate’ means flat rate interest only and excludes (i) a documentation fee of €100.00 collected on signing along with the first payment and (ii) an option-to-purchase fee of €50.00 collected with the final payment. All schemes subject to a maximum balance financed at 100% of VAT inclusive selling price. Promotion valid until 30th of June 2024. Available on new equipment only. Finance for Republic of Ireland business purposes only. Subject to acceptance and affordability checks. Images are for illustrative purposes only. Finance is provided by DLL Leasing DAC trading as DLL, Hyundai Construction Equipment Europe Finance, HP Integrated Financial Solutions Managed by DLL, and Apple Financial Solutions is regulated by the Central Bank of Ireland. Registered office: 7th Floor, 76 Sir John Rogerson’s Quay, Dublin 2.Registered No. 392788. Phone: +01 4814192 Warning: You may have to pay charges if you repay early, in full or in part, a fixed-rate credit facility. Terms and conditions apply. Valid until 30th of June 2024 Finance provided by Finance Special

McGinty Tractors LTD

Gervais

James

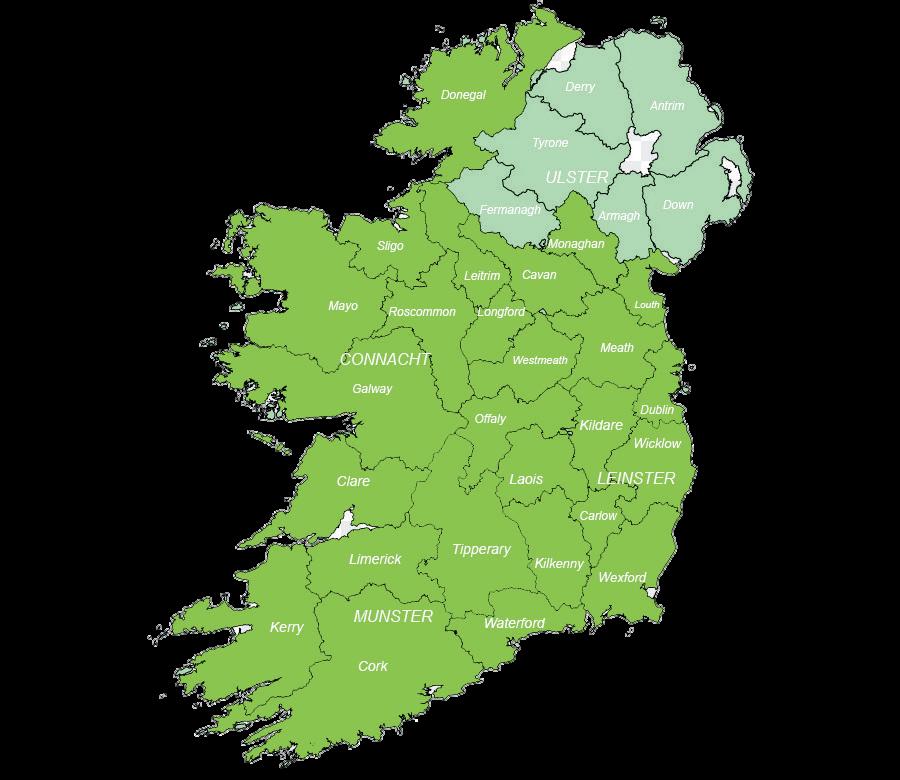

DEALER LOCATOR

LTD

Lynch & McCarthy

LTD

Lynch

& McCarthy

Agri Sales LTD Abbey Retail

West Waterford

Clerihan

LTD

Suir Garages

Agri LTD

Donohoe

Retail

Abbey

Nenagh

Agri Systems LTD

SAMCO

Castlebar Farm Machinery

of

Services LTD Lunney Tractors LTD D.A. Forgie D.A. Forgie Rea’s of Finvoy Armstrong Machinery LTD Mid Louth Garage LTD Clarkes of Kells Clarkes Machinery LTD D & E McHugh LTD Young’s Garage Delaneys (Ballaghmore) LTD Gordon Hegarty & Sons Gordon Hegarty & Sons Gordon Hegarty & Sons Swaine Farm Services LTD

Clarkes

Roscommon Ardagh Agri

LTD

Joe

Whelan

LTD Dealer TownTownCountyCounty PhonePhoneDealer D.A. FORGIE REAS OF FINVOY GORDON HEGARTY & SONS CLARKES MACHINERY LTD WHELANS GARAGE LYNCH & MCCARTHY LTD LYNCH & MCCARTHY LTD D.A. FORGIE MCGINTY TRACTORS ARMSTRONG MACHINERY WHELANS GARAGE SAMCO AGRI SYSTEMS LTD GORDON HEGARTY & SONS GORDON HEGARTY & SONS DELANEY (BALLAGHMORE) YOUNGS GARAGE LISBURN BALLYMONEY TULLOW BALLYJAMESDUFF KILRUSH LITTLE ISLAND ENNISKEANE LIMIVADY DONEGAL LUSK LOUGHREA TRALEE ATHY CLIFDEN PORTLAOISE PORTARLINGTON CO. ANTRIM CO. ANTRIM CO. CARLOW CO. CAVAN CO. CLARE CO. CORK CO. CORK CO. DERRY CO. DONEGAL CO. DUBLIN CO. GALWAY CO. KERRY CO. KILDARE CO. KILKENNY CO. LAOIS CO. LAOIS 02892677736 02829571232 0599151502 0498544353 0659051147 0214510050 0238822621 02877722375 0749723645 018431130 091880050 0667118331 0598673040 05677 26013 050521023 0578623177 LUNNEY TRACTORS LTD SAMCO AGRI SYSTEMS LTD D & E MCCUGH MID LOUTH GARAGE LTD CASTLEBAR FARM MACHINERY CLARKES MACHINERY LTD CLARKES MACHINERY LTD ARDAGH AGRI ABBEY RETAIL (Clerihan) ABBEY RETAIL (Nenagh) JAMES GERVAIS SUIR GARAGES LTD WEST WATERFORD AGRI. LTD DONOHOE AGRI LTD SWAINE FARM SERVICES SWAINE TRACTORS WALMSLEY TRACTORS LTD NEWTOWNGORE ADARE LONGFORD ARDEE CASTLEBAR KELLS ROSCOMMON BALLINA CLERIHAN NENAGH OMAGH WATERFORD TALLOW ENNISCORTHY GOREY RHODE KESH CO. LEITRIM CO. LIMERICK CO. LONGFORD CO. LOUTH CO. MAYO CO. MEATH CO. ROSCOMMON CO. SLIGO CO. TIPPERARY CO. TIPPERARY CO. TYRONE CO. WATERFORD CO. WATEFORD CO. WEXFORD CO. WEXFORD CO. OFFALY CO. FERMANAGH 0494333215 061396176 0433359002 0416853356 0949021307 0469241055 0906626771 09672803 0526135742 06733742 02880758262 051873689 0871960316 0539242526 040237147 0469737000 02868631393 SAMCO Agri Systems LTD Swaine Tractors Ballyheashill Walmsley Tractors LTD Kverneland Group Ireland Ltd, Hebron Industrial Estate, Co. Kilkenny R95 RT2A +353 56 77 51597 Follow us

Joe Whelan

Managing Director, Kverneland Group Ireland

Managing Director, Kverneland Group Ireland