2nd EDITION 2024

KEVIN DENNIS CEO

• Historic Achievement Recap - Krueger | Linfox

• Strengthening local business: The role of government support.

• 39 Years of Paintwork - Louis Coleiro retires

• Krueger “RENU” gains in popularity with fleet owners

• Supplier Spotlight: Calibre Steel

Welcome to the latest edition of Connect and what a busy few months it has been for us all, with so many milestones and achievements reached since our last edition.

The end of the 23-24 financial year is now behind us but I would just like to reflect on what we have achieved across the business.

In sales and production, we have just finished the largest order in the company’s history delivering over 200 units to Linfox including the 100 fully imported units from Schmitz CargoBull in Germany. This project took over 18 months to deliver but we did it on time and to the immense satisfaction of Linfox who had specific operational dates to meet. A very big thank you to the many people across the company who worked on this project. Based on this successful delivery we have just received another large order from Linfox.

Our industry leading Laser Cutter has just celebrated its first birthday and its performance has revolutionised our material handling process with greatly improved efficiency, speed, quality, and cost reduction. We

now do 95% of our cutting needs in house compared to less than 40% with the plasma cutter. We have cut 90,000 components using a total of 1000 tons of steel. Our wastage has dropped from 40% to less than 10% with improved cutting and nesting. In addition to this, We have now commenced performing laser cutting services for 3rd parties, giving an additional income stream to the business.

In HR our International recruitment policy has enabled us to fill vital roles in manufacturing, helping us build 584 new trailers last year. We are now actively recruiting for our retail branches to fill the skills gaps.

Around the market our promotional and marketing campaigns have set us apart from everybody else and have set new standards for the industry. However, we are starting to see a very real softening of activity with all our customers reporting a drop in freight movements as the impact on interest rate increases start to bite hard which will bring new challenges to FY25.

In closing, I would just like to welcome the newest member of the senior management team, Mark Poswiat, our new CFO to the company.

Stay Safe.

Krueger Connect is your magazine about all things Krueger. Learn more about the business and activities through all parts of the Krueger Business. We hope you all enjoy the read.

Editor: James Tamanika (james_tamanika@krueger.com.au)

STEVEN TEOFILO DIRECTOR OF ENGINEERING & SUPPLY CHAIN

The Swinburne project team at Krueger comprised students from the Master of Professional Engineering program at Swinburne University. The focus of the project was to provide these students with a real-world final year capstone project, allowing them to apply their academic knowledge in a practical setting.

The team consisted of three students and was supervised at Krueger by Jesse Pouw and myself, alongside an academic supervisor from Swinburne University, Mr. Mariadas Roshan. The project spanned the first academic semester of 2024, lasting a total of 12 weeks.

The primary objective of the project was to investigate and develop concepts for the efficient and safe collection of waste metals from a laser machine. In laser cutting operations, many small items fall between the slats of the laser bed, especially when the beds are in motion. This movement can cause parts in the sheets to dislodge. Due to the large

size of Krueger’s laser cutting beds and the high volume of cut parts, the bottoms of these beds quickly accumulate waste metal, necessitating frequent manual cleaning.

Accessing the underside of these large cutting beds is both challenging and time-consuming, given the volume of waste material. The goal of the student project was to explore various methods for the safe and efficient collection and disposal of this waste material.

Initially, the project team proposed several concepts. One concept was selected for further analysis and development. The team then detailed the design possibilities and identified constraints that would need to be addressed during implementation. The project concluded with a firm design concept, which Krueger’s engineering department has since advanced to the next stages of detailed design, simulation, structural analysis, and prototype manufacture.

“Krueger’s partnership with Swinburne school of Engineering is a great way for us to ensure the future of our business by working with some of the smartest minds as they transition from school to real world business..”

KEVIN

DENNIS CEO

GRANT KRUEGER NATIONAL SALES DIRECTOR

As we roll into July, we look back on our historic achievement in Krueger’s 45-year history. The project began with high-level meetings between Krueger and Linfox, focusing on the specific requirements of the order. Linfox required over 250 trailers to fulfil a new corporate contract, demanding a versatile fleet capable of handling a wide range of cargo types, including temperature-sensitive goods and bulk commodities. Additionally, Linfox’s dedication to sustainability necessitated ecofriendly features in the trailer designs.

Krueger’s project scope involved closely collaborating with Linfox to define a detailed trailer specification tailored for a retail dock loading application, essential for servicing a long-term contract.

Among Linfox’s requirements were a substantial quantity of curtain-sided and temperature-controlled freezer trailers, including B Doubles. Krueger responded by purpose-designing and constructing numerous curtain siders through its cuttingedge local manufacturing facility.

Leveraging our partnership with Schmitz Cargobull, Krueger designed and built a significant number of B Double chassis equipped with the Schmitz Cargo Bull freezer boxes. Furthermore, Krueger facilitated the importation of over 150 German-built, worldclass S.KO Cool body box semi trailers into Australia.

In March, our Victorian teams went above and beyond to not only manufacture within a very

tight timeline but also take delivery of over 75 Schmitz Cargobull Freezer vans fresh off the boat from Germany and ready to roll.

In May, we repeated this success in Queensland, successfully completing the largest single order in the company’s history. Despite the challenges, Krueger was tasked with meeting a fixed timeline for trailer delivery to ensure Linfox could meet their client’s expectations. This milestone marks a significant achievement and showcases the collaborative effort and dedication of everyone involved in the project.

LAUREN BAXTER

NATIONAL MARKETING MANAGER CALIBRE STEEL

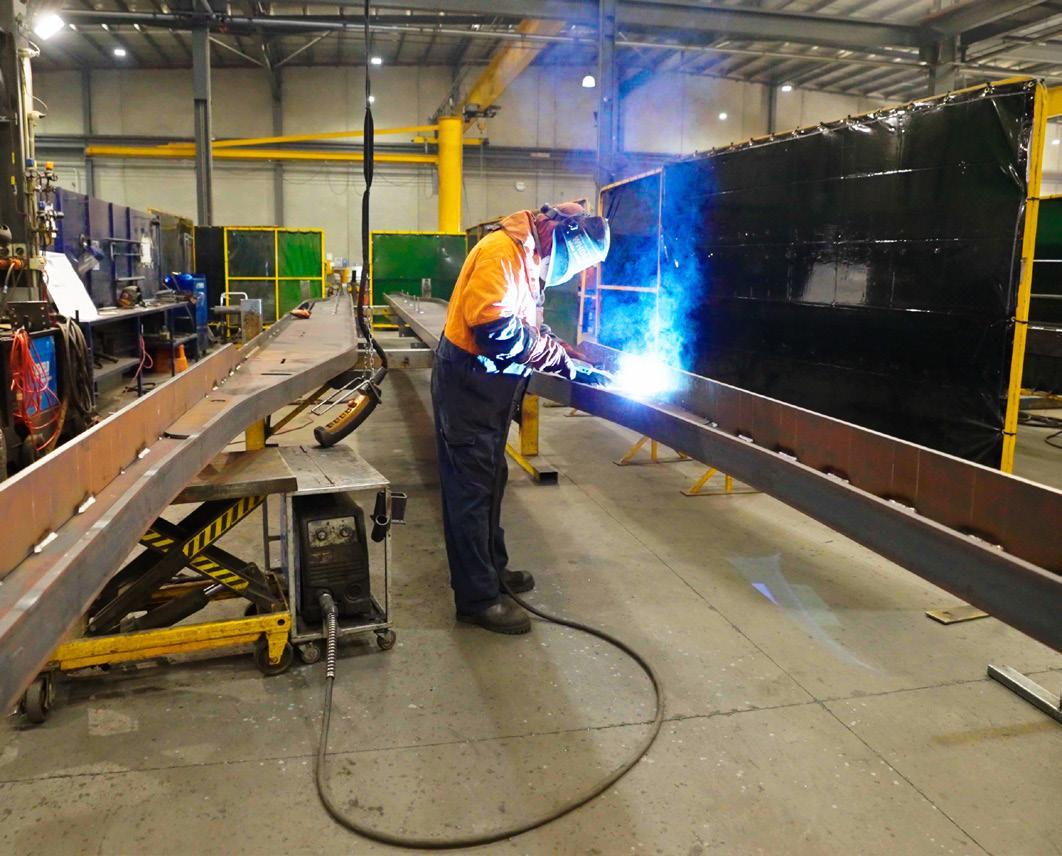

Krueger Transport are happy to celebrate their partnership with leading steel supplier Calibre Steel to increase efficiency for Krueger while allowing the company to access the industry’s best products and personalised steel supply. A key benefit of the arrangement is Calibre Steel’s close proximity to Krueger’s manufacturing facility, which results in reduced material transportation costs and greater on-call access to Calibre Steel’s specialist account service team. All this while still enabling Krueger to source the same high-quality Australian-made steel plate products the company has utilised for decades.

The partnership sees Calibre Steel supply Australian-made plate TRUSPEC® steel to Krueger in various dimensions for use across all of

Krueger’s product lines, ensuring consistency and reliability. TRUSPEC® steel is stretch-levelled to remove internal stresses and for excellent flatness. This consistency has provided many benefits for Krueger Transport’s manufacturing processes. Krueger can also call on Calibre Steel’s in-house secondary processing capabilities, including plasma and oxy cutting. Once a delivery arrives on-site, less handling and processing is required, resulting in more efficient manufacturing. Calibre Steel provides ‘just in time’ delivery, project management, and forecasting as required, and all supplied steel is quality assured with full traceability.

Krueger Director of Engineering and Supply Chain, Steven Teofilo said “Calibre Steel is based in an adjoining suburb to us, meaning that transportation is greatly reduced, with as little as 10 minutes’ travel. Multiply these time savings across a schedule of regular deliveries, and the efficiency gains really add up,” Steven explained. “As a manufacturer, it’s important to continuously identify processes and techniques that grow our competitiveness. Efficiencies could come through new technologies, such as our new state-of-the-art Fiber Laser cutting machine, or via logistics and supply chain improvements, such as those provided by Calibre Steel.”

A Relationship Built on Quality and Trust.

Calibre Steel Customer Relationship Manager, Maddie Dharmapala said the company was excited to be a partner of Krueger Transport Equipment. “Krueger is well known and highly regarded in the road freight industry,” Maddie said. “It’s extremely rewarding for Calibre Steel to partner with such an operation and assist the company in reaching its corporate goals.”

Serving our truck body, trailer and tipper manufacturing customers with reliable and robust steel plate solutions, Calibre Steel are proud to be a supply partner for Krueger Transport.

Calibre Steel offers a wide range of high-quality plate products and grades including structural, laser, boiler and quench and tempered steel plate. Complemented by value-add processing services, and backed by expert technical support and flexible supply. Our team are experienced in handling the varying needs of our customers steel requirements, and tailor our steel supply to suit each project. We understand our customers need a reliable supply partner who guarantees high-quality products, backed with availability, traceability, and on-time delivery.

Our steel plate range includes TRU-SPEC® steel, XLERPLATE® steel and Bisalloy Steel products. Matched with the industry expertise, technical support and customer service you can rely on, we prioritise your success.

Over the past 45 years, Krueger has consistently delivered trailers that meets the needs of Australian logistics companies and withstand the rigors of the Australian environment. Our unwavering dedication to innovation and advanced engineering techniques has positioned us as a leader in the Australian Transportation Industry for many years to come.

DAVID GRANT GENERAL MANAGER OF MANUFACTURING

In our constantly changing local economy, Krueger Transport remains a strong and reliable presence. Recently, our CEO Kevin Dennis invited five local and state representatives to visit our manufacturing facility. Having them take time from their busy schedule gave us a clear direction of how they recognise how important government support is for businesses like ours.

The COVID-19 pandemic brought many challenges, but Krueger Transport stayed stable in the transport sector. Despite the chaos, we played a key role in sustaining local, state, and federal economies by ensuring the continuous flow of essential goods and services. This commitment helped support the resilience of our communities and economies.

The visits by elected representatives during this recovery period highlight the crucial relationship between government support and local businesses. As we and other businesses come out of the pandemic and face potential economic downturns, the interest shown by parliamentarians demonstrates their dedication to collaboration between the public and private sectors. These visits boost our confidence and encourage the broader business community.

The connection between local governments and businesses like Krueger is vital. Government support through regulatory guidance and financial incentives helps local enterprises grow and succeed.

From my perspective as Head of Manufacturing, the engagement from our local and state government has been exceptional. Their visits and interactions with our staff have infused our operations with renewed energy and optimism. These visits highlight the importance of strong partnerships between sectors, especially after the COVID-19 pandemic. Working together is essential for creating policies and initiatives that address the unique challenges faced by local manufacturers.

As we navigate the post-pandemic landscape, the visit to Krueger Transport serves as a reminder of the vital role of government support in fostering economic growth and prosperity. To each parliamentarian who visited our facilities, we extend our heartfelt appreciation for your interest and support. Let’s continue to create an environment where businesses like Krueger Transport can thrive, ensuring sustained prosperity for our industry and community.

CHRISTINE SAMUEL HR CO-ORDINATOR

In 1984, a fresh-faced painter named Louis Coleiro stood in front of John Krueger asking for a job. “I remember it,” Louis recalls. “It was John Krueger who actually interviewed me, and he said, ‘G’day mate, so you can paint, can you?’

To which I replied, ‘Yeah, I think I can. If you like, John, I can give it a shot!’ He then replied, ‘OK, you got two days then, and we’ll see how you do.’” As we chuckle at the memory, it hits us that 39 years later, Louis is finally hanging up his overalls.

Many of Krueger’s long-term employees have similar stories, often staying in the roles they started. “I think it’s because we all wanted to do our best back then,” says Louis. “Krueger as a company was just beginning to find its feet in the marketplace, and we were all in to make the best of what we could for John and his

family. And if I was to look at then to now, I just really loved my job.”

Louis worked closely with Gary Krueger, John’s brother and factory manager for many years. “Gary was great to work with, such a character, and we had such a laugh. He would call me all sorts of names in playful banter and even once asked me if I was stealing black paint as I used to dye my hair jet black.”

Louis has painted more than 15,000 trailers, mastering his craft as the facilities evolved. “I remember back to when we had the pits at St Albans, oh my god, the early days,” Louis reminisces. “We used to have to crawl underneath the trailers, and now we have the best facilities you could ask for with our stands, different techniques, different pumps, and hi-tech spray booth setups. Yeah, a lot has changed and made it so much easier.”

David Grant, General Manager of Manufacturing, remarked, “Louis’s input over the past four years I have been in the manufacturing side of the business has been critical to the success of what you see on the road. His work in implementing and educating younger painters and apprentices will live on as a legacy to Louis’s career. He’s been a great part of the business, and we wish him all the best.”

“Louis was a very talented painter and one day I thought he might leave to focus on automotive painting which was a passion. 39 years later I bid him farewell on what has been a huge career at Krueger. One of the best we have ever had and I wish Louis all the very best in retirement.”

At Krueger, we take great pride in our tradition of long-term staff members celebrating significant employment milestones across various departments. This year, we are thrilled to acknowledge four remarkable milestones: three celebrating 10 years and one celebrating an impressive 30 years with the company.

We extend our heartfelt congratulations to Ben Raudino and Ryan Kaio from our National Spare Parts division for their 10 years of dedicated service. Additionally, we celebrate Andrew Barmby from our Paint Shop for his 10 years of commitment. Finally, we are honoured to recognize Bill Dzumkovski from our Manufacturing Maintenance division for his incredible 30 years as part of the Krueger family.

Introducing our new CFO - Mark Poswiat

Krueger is excited to welcome some new staff members. Mark Poswiat joins us as the new CFO, bringing with him 7 years of experience from RYCO Hydraulics where he served as Group CFO. Mark shared his enthusiasm, stating, “I am excited about this new endeavour. Having worked at Ford at the beginning of my career, I am aware of what it’s like to be part of a large manufacturing company, but I am excited to learn more about being in the transport industry and how Krueger has been such a huge player for so many years”.

Additionally, we are pleased to welcome Masayuki Yamaguchi, Angelo Asombrado, Gerard Canedo and Aron Cequena, our latest arrivals under the Visa 482 employment program. Krueger has a long history of working with this program, and with these four new additions, the total number of employees under the program now stands at 20, with another 8 expected to join in the coming months. Gerard, Masayuki, Arron, and Angelo all share a passion for basketball and represent Krueger as part of the Krueger Komets in the Filipino basketball league in Melton.

We also welcome Jordan Dejumo, Jordan Perez, Adonis Pitoy, and Francisco Gepitulan to our National Service team in Derrimut. These four have transferred to us from another engineering company in the area, as we take over their 482 visa arrangements. Brett Tweedly, National Service Manager for Victoria, states, “It’s great having some new guys on the team as our workload ramps up. Having already been working in the industry, they have settled in nicely as part of the team.”

Please join us in welcoming our newest employees.

"Dependable and durable which is synonymous with the Krueger name."

John Krueger, Founder

The Krueger KVan offers the flexibility for customisation to suit dedicated freight tasks. This level of adaptability empowers fleets to invest in technology and equipment that is purpose built to drive productivity and efficiency gains. Available in various lengths from 40-foot to 33-foot, we can tailor to your specifications.

Whether it’s catering to specific cargo requirements, optimising loading and unloading processes, or enhancing overall operational efficiency, Krueger’s dry freight KVans provide a platform for tailoring solutions to meet the unique demands of various freight tasks.

Krueger’s Renu offering is experiencing significant growth as owneroperators increasingly seek to renew and update their existing trailers. This surge in demand is largely driven by the desire to enhance the longevity and performance of their assets, ensuring that their fleets remain competitive and reliable in the dynamic Australian freight and logistics industry.

The quality of work provided by Krueger’s National Service team has been exemplary, particularly through their branches in New South Wales (NSW) and Victoria. The team’s commitment to excellence is evident in the meticulous attention to detail and the superior craftsmanship that go into every trailer renewal project. This dedication has not only helped in meeting the specific needs of owner-operators but has also played a crucial role in reinforcing Krueger’s reputation as a trusted service provider across all brands.

In NSW, the National Service team has tackled a variety of challenging projects, including working on trailers for major clients like Toll/Team Global. Despite these trailers not being originally manufactured by Krueger, the team’s skill and expertise have enabled them to restore and upgrade these units to meet high standards. This demonstrates the team’s versatility and ability to handle a diverse range of trailers, further establishing their credibility and capability.

Our Victorian National Service team has been incredibly busy with refurbishing and refitting over 100 gates to existing trailers for Toll/Team Global. They have also undertaken major refurbishments and refits for clients such as Trainion Transport, Cannys, Matino Brothers, and Transmo. Additionally, they completed a very special piece of work for Mark Tuckerman, a volunteer driver for Need for Feed, showcasing their ability to handle unique and meaningful projects. The Victorian team’s proficiency in handling these complex updates and renewals has set a new benchmark for service standards. Their collaborative approach ensures that every project is completed on time and within budget, providing owner-operators with trailers that are not only refreshed but also optimised for better performance.

Krueger’s Renu offering is flourishing thanks to the exceptional work of the National Service teams in NSW and Victoria. Our unwavering dedication to quality and customer satisfaction has solidified Krueger’s position as a leader in the trailer renewal market, offering owner-operators a reliable partner in maintaining and enhancing their fleets no matter big or small.