SPACE FRAMES

span= 20 m

Ht = more than 10 m

Definition

Types of space frames

1 case study

Connections/support/joinery material

span= 20 m

Ht = more than 10 m

1 case study

Connections/support/joinery material

• Space frames are essentially three dimensional trusses able to span in two directions.They may be flat for use as roofs, walls or inclined walls, or may be curved to form continuous barrel type roof geometries. Flat frames used as roofs sometimes have slight cambers to direct water to appropriate roof outlets. Space frames allow for easy service distribution within their depth and can provide light elegant structural solutions.

• Depth: Span/40

• Typical maximum length: 100 m

• Independently developed by Alexander graham bell around 1900 and Buckminster fuller in the 1950s Buckminster fuller's focus was architectural structures.

• It was developed in California during the 1960s and introduced to the South African market in 1982, specifically developed for unstable soil conditions, the panels form a monolithic structure offering superior wall strength in which no cracking will occur

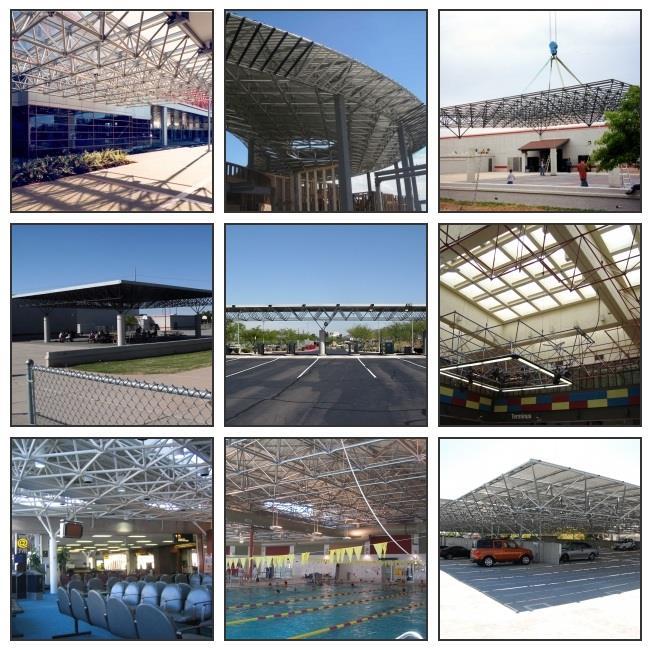

• Steel space frame structures is used for commercial and industrial buildings, auditoriums, airport hangers, sport stadium, sky lights, mosque, lighting towers, petrol pumps, canopies, exhibition hall, atrium,Toll Plaza

• Factory Sheds, Hotels,Vehicle Stand, Community Halls, Poultry Sheds, Dairy Farm Structures Etc.

• Malls,TransportTerminals, Schools, Pools,Arenas, Entertainment, Hospitals, Hotels, Corporate & Commercial Buildings, Convention Centers

1. Flat covers

2. Spherical domes

3. Barrel vaults

• Single Layer -All elements are located on the surface to be approximated.

• Double Layer - The elements are organized in two parallel layers with each other at a certain distance apart. The diagonal bars connecting the nodes of both layers in different directions in space.

• Triple layer -Elements are placed in three parallel layers, linked by the diagonals. They are almost always flat. This solution is to decrease the diagonal members length.

A space frame is strong because of :

• The inherent rigidity of the triangle;

• Flexing loads (bending moments) are transmitted as tension and compression loads along the length of each strut.

•Designed using a rigidity matrix.

• The special characteristic of the stiffness matrix in an architectural space frame is the independence of the angular factors.

•If the joints are sufficiently rigid, the angular deflections can be neglected, simplifying the calculations.

• Nodus connector

• Triodetic connector

• Tuball node connector

• Hemispherical dome connector

Types of tubes

1. Nodus connector:

WELDED CONNECTION BOLTED CONNECTION THREADED CONNECTION

2.Triodetic connector:

Consists of a hub, usually an aluminum extrusion, with slots or key ways.

3.Tuball node connector:

It can accept both rectangular and circular hollow sections and that the cladding can be fixed directly to the chords. Chord connectors have to be welded to the ends of the hollow members on site.

Hollow sphere made of spheroid graphite. End of the circular hollow section member to be connected is fitted at its ends by welding connection from inside the cup is done using bolt and nut.

4.

Usually use for double layer domes. Has a span more than 40m.More economical for long span.The jointing is connect by slitting the end of the tube or rod with the joint fin.Two types of joint: Pentagonal joint and Hexagonal joint.

Hemispherical dome connector:

Hemispherical dome connector:

The method chosen for erection of a space frame depends on:

• Its behavior of load transmission

•Constructional details

•Scale of the structure, method of jointing, and strength and rigidity of the space frame

•The whole space frame is assembled at ground level so that most of the work can be done before hoisting.This will result in increased efficiency and better quality. For short and medium spans, the space frame can be hoisted up by several cranes.

• For long-span space frame, temporary posts are used as the support and electric winches as the lifting power.The whole space frame can be translated or rotated in the air and then seated on its final position.This method can be employed to all types of double-layer grids.

•Individual elements are assembled in place at actual elevations, members and joints or prefabricated subassembly elements are assembled directly on their final position.

•Full scaffoldings are usually required for this type of erection. Sometimes only partial scaffoldings are used if cantilever erection of space frame can be executed.The elements are fabricated at the shop and transported to the construction site, and no heavy lifting equipment is required.

•The space frame is divided on its plan into individual strips or blocks.These units are fabricated on the ground level, then hoisted up into its final position and assembled on the temporary supports.

•With more work being done on the ground, the amount of assembling work at high elevation is reduced.This method is suitable for those double layer grids where the stiffness and load-resisting behavior will not change considerably after dividing into strips or blocks, such as two-way orthogonal latticed grids, orthogonal square pyramid space grids, and the those with openings.The size of each unit will depend on the hoisting capacity available.

Types

Vashi railway station, navi mumbai

The fixing arrangement consists of:

Bolted Arrangement

Spaceframes from McCoy are available in various types:

Screwed Arrangement

Clamped Arrangement

Horizontal

Pyramid

Inclined

Geodesic (Dome)

Vault Ridge

Spaceframes are available in options of double or tripled layered grid:

Square-on-square grid

Triangle-on-triangle grid

Rectangle-on-rectangle grid

Features

Carries loads along both axis.

High aesthetic appeal.

Enormous spanning capacity.

High resale value.

Additional services like lightings, ducting can be easily incorporated.

Pre-fabricated structure reduces site activities.

McCoy uses nodes of high quality and precision forged components.

Cladding

The different cladding materials used by McCoy for Spaceframes are:

Metal Sheet

Glass

Safety Glass

High performance

Fabric

PVC Polyester

Glass PTFE

Insulated Safety Glass

Polycarbonate Solid Sheet

Polycarbonate Multi-Walled Sheets

Insulated Puff Panels

Space Frame support is located at Panel points

Space Frame support is located at Panel points

Light -Minimum structure weight

Elegant & Economical

Carry load by three dimensional action

High Inherent Stiffness

Easy to construct

Save ConstructionTime & Cost

Services (such as lighting and air conditioning) can be integrated with space frames.

Offers the architect unrestricted freedom in locating supports and planning the subdivision of the covered space.

Simple modification or dis-assembly for re-use

Space Frame can be a feature without ceiling

Accommodates concentrated loads

Suit irregular support or plan geometry

Variable depth for roof drainage is built-in

Minimum structure weight

Long clear spans & cantilevers

• One major disadvantage is that they can be difficult to engineer.

• It's not straightforward to determine how forces will distribute throughout a structure that has a lot of redundant pieces.

Designed as space frame in reinforced concrete; the 'Hall of Nations' provides an uninterrupted exhibition area of approximately 6,700 sq m in a 82m x 82m x 27m high truncated pyramid supported on eight points.