New York City’s New Electrical Code

After Over a Decade, New York City Adopts a New Electrical Code. At the end of 2024, Local Law 128 brought into force a new electrical code for NYC, bringing it under Title 28 with the other NYC construction codes. The last update to the electrical code was in 2011 and this updates NYC to the 2020 National Electrical Code (NEC) from the 2008 version.

The 2025 NYC Electrical Code will apply to all applications for electrical work filed on or after December 21, 2025. In the meantime, depending on the work to be completed, it may be completed under the 2011 or 2025 code, per Figure 1 [Buildings Bulletin 2024-008].

New York Building Code. For nonresidential buildings, it is permitted for equipment to be located below the DFE when dry floodproofing is provided [110.11(B)].

• For systems not exceeding 1000V, Limited Level Coordination is required when the service overcurrent protective device is 1200A or greater. For Systems exceeding 1000 volts, full selective coordination is required [230.96].

• The previous NYC amendment that permitted overcurrent protection of the fire pump between 300% and 600% of the full load motor current has been removed. The overcurrent protective device is now required to

adapting to new and improved technologies. Over the years there have been numerous changes to the NEC that are now applicable in NYC, below are some of the most notable.

Safer Installations for Workers

Some of the code updates are intended to make electrical installations safer for the workers who repair and maintain them:

Electrical Rooms

Personnel doors are now required to open out and be provided with panic hardware when a panelboard 800A or more is installed, rather than 1200A [110.26(C)(3)].

Arc Energy Reduction

When fuses and circuit breakers are raed 1200A or higher, a means shall be provided to reduce the clearing time [240.67 and 240.87]. The intent of this section is to reduce the arc energy, thus reducing the potential hazard faced by a worker.

Safer

Installations for Users

Several code updates make electrical installations safer for users:

GFCI

The requirements for ground-fault circuit-interrupter (GFCI) protection have also been greatly expanded in the new code; refer to Supplement [210.8].

Arc-Fault

Circuit-Interrupter Protection

Figure 1: Code Compliance Based on Filing Type [Buildings Bulletin 2024-008]

NYC Specific Amendments

NYC extensively amends the NEC; some of the new amendments include:

• The definition of “Electrical Equipment Room” replaces “Electrical Closet” [Article 100].

• Metering equipment, panelboards, load centers, main disconnect switches, all service disconnecting means, and all circuit breakers shall be located at or above the design flood elevation (DFE) specified in Appendix G of the

carry indefinitely the sum of the locked rotor current of the largest fire pump motor and the pressure maintenance pump motor and the full-load current of all the other pump motors and associated fire pump accessory equipment when connected to this power supply [695.4(B)(2)(a)(1)].

NEC Updates

The NEC seeks to make installations safer for workers, users and occupants while

The requirements for Arc-Fault CircuitInterrupter protection were expanded from

dwelling units to include dormitory units, guest rooms, guest suites, and patient sleeping rooms in nursing homes and limited-care facilities [210.12].

Tamper-Resistant Receptacles

Tamper-resistant receptacles have shutters to ensure that insertion of an object in one side of a receptacle does not open the shutter, protecting children from electrocution. The new code expands this requirement from just dwelling units to now include:

1. Guest rooms and guest suites of hotels motels, and their common areas

2. Child care facilities

3. Preschools and education facilities

4. Business offices, waiting rooms, corridors and similar in medical and dental offices, clinics, and outpatient facilities.

5. Subset of assembly occupancies which includes places of awaiting transportation, gymnasiums, skating rinks, and auditoriums

6. Dormitory units

7. Assisted living facilities [406.12]

Meeting Rooms

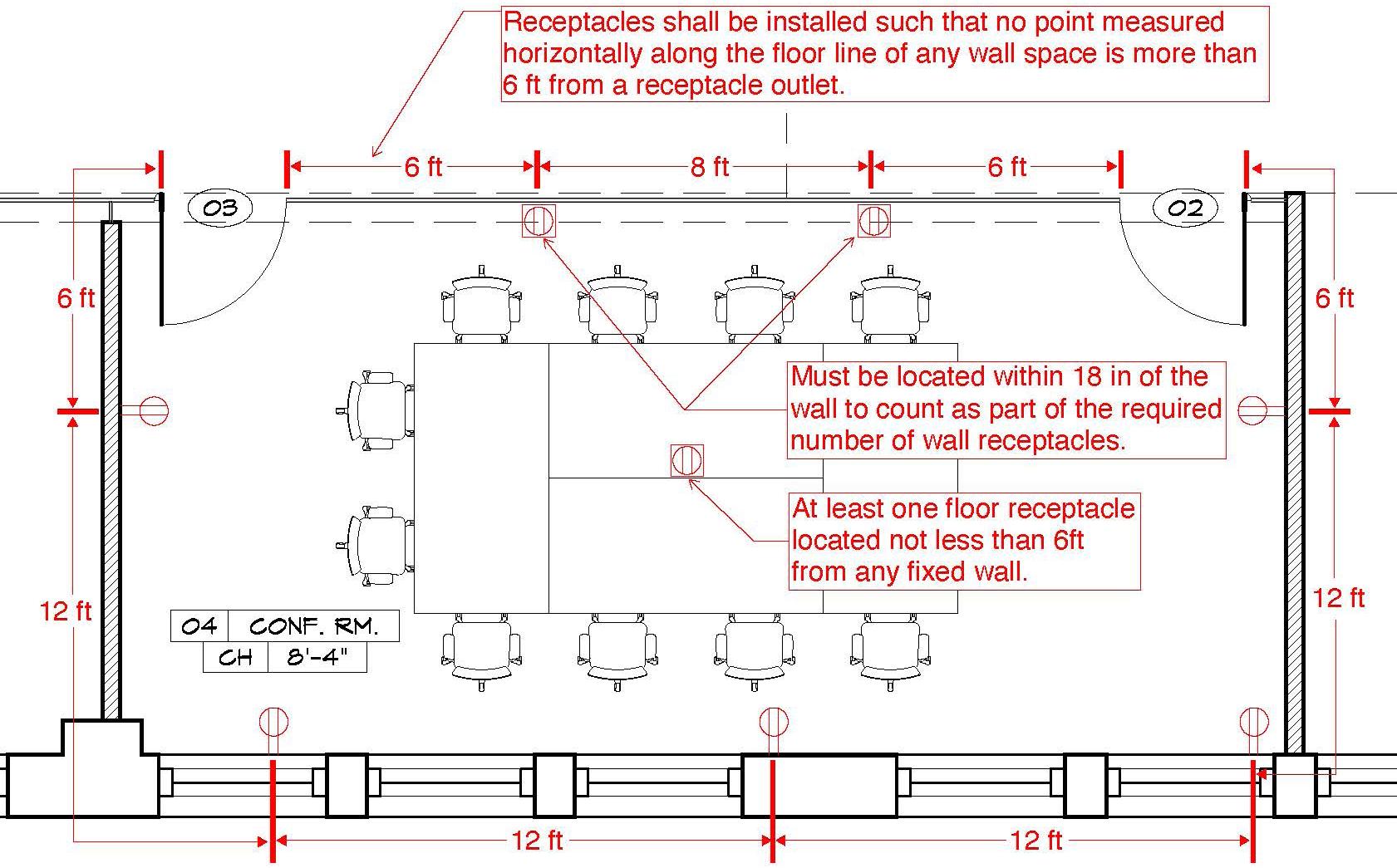

To prevent potential tripping hazards created by cords and cables spread across floors in meeting rooms, the NEC now defines the receptacle placement required in meeting rooms. Refer to Figure 2

No point measured horizontally along the floor line of any wall space is more than 6 ft from a receptacle outlet.

AND

A meeting room with any floor dimension that is 12 ft or greater in any direction and that has a floor area of at least 215 ft2 shall have at least one floor receptacle outlet, or at least one floor outlet to serve receptacle(s), located at a distance not less than 6 ft from any fixed wall for each 215 ft2 or major portion of floor space [210.65].

Surge Protection for Dwelling Units

All new services supplying dwelling units shall be provided with a surge-protective device (SPD). This protects sensitive electronics and systems found in modern appliances [230.67].

Increased Emergency System Requirements

Article 700 Emergency Systems includes a number of updated and new sections to improve occupant safety:

Temporary Source of Power

If the emergency system relies on a single alternate source of power, which will be disabled for maintenance or repair, the emergency system shall include permnent switching means to connect a portable or temporary alternate source of power, which shall be available for the duration of the maintenance or repair [700.3(F)]. This is commonly provided by a portable

MEP 2040 Challenge

generator docking station mounted at the exterior of the building.

Surge Protection

Surge protective devices shall now be installed in or on all emergency system switchboards and panelboards [700.8].

Feeder-Circuit

Wiring

The requirements for feeder-circuit wiring were expanded to include educational occupancies with more than 300 occupants. In addition, where the cables or equipment are not installed in areas protected by an automatic fire suppression system, feeder circuit cables for emergency systems must “

page 3

Kohler Ronan is pleased to join a growing number of MEP/FP industry leaders in accepting the MEP 2040 Challenge posed by the Carbon Leadership Forum (CLF). As signatories, we are committed to “advocate for and achieve” net-zero operational and embodied carbon by 2030 and 2040, respectively.

Approved Technical Consultant in NY & CT –

Incentive and Rebate Assistance

Kohler Ronan is an approved Technical Consultant providing valuable assistance to clients interested in accessing incentives in both New York and Connecticut. In New York, we are approved under NYSERDA’s Commercial New Construction Program and also serve as an Independent FlexTech Consultant. As part of the Energize Connecticut initiative, Kohler Ronan is approved for projects within Eversource and United Illuminating territory. Under each of these programs, our professionals provide technical support in the form of energy modeling and controls commissioning to assess and identify appropriate energy efficiency opportunities for new construction and substantial renovation projects. For details, please email Madhav Munshi at mmunshi@kohlerronan.com.

now be rated for a minimum of 2 hours (increased from 1 hour) and equipment installed in spaces with a 2-hour fire resistance rating (increased from 1 hour). This is intended to provide an additional margin of safety for occupant movement to a safe location in the event of a fire [700.10(D)].

Generator Control Wiring

Generator remote start circuits shall be monitored for broken, disconnected, or shorted wires. Loss of integrity shall start the generators [700.10(D)(3)].

New and Improved Technology

Finally, a number of the code updates are for new technology, which required new articles:

646 Modular Data Centers

691 Large-Scale Photovoltaic (PV) Electric Supply Stations

694 Wind Electric Systems

706 Energy Storage Systems

710 Stand-Alone Systems

712 Direct Current Microgrids

750 Energy Management Systems

Significantly updated articles to align with technology advancements:

625 Electric Vehicle Power Transfer System

690 Solar Photovoltaic (PV) Systems

Lighting & Energy Code

The requirements for lighting load calculations have also been updated. A number of new occupancy types have been added to the lighting load table [220.12] and the loads for the existing occupancy types in general have been reduced as lighting technology has improved. In addition, a new section permits the lighting loads to follow the energy code applied to the building (with a continuous load multiplier of 125%).

Looking to the Future

The new code incorporates expanded safety measures and the latest technology; but to remain up to date, the city plans to launch its next code revision cycle this year.

Impacts of Refrigerant Changes: What You Need to Know

As the HVAC industry continues its push toward sustainability, a major shift is on the horizon: the transition to A2L refrigerants. This change is driven by regulatory updates aimed at reducing global warming potential (GWP) and improving environmental safety. Whether you are a building owner, engineer, or contractor, understanding these refrigerant changes is critical for planning future installations and equipment maintenance.

Understanding A2L Refrigerants

Until 2021, A2L refrigerants were not permitted for human comfort applications due to fire safety concerns. However, after further UL testing, these concerns have been addressed, allowing for the phased trans-

ition away from high-GWP refrigerants like R-410A. The key differences between A2L and previous refrigerants include:

• Lower GWP: A2L refrigerants significantly reduce environmental impact compared to R-410A which is an A1 refrigerant.

• Same Toxicity Levels: A2L refrigerants maintain the same toxicity classification as R-410A, ensuring continued safety.

• EPA Approval: Six A2L refrigerants (R32R-452B, R-454A, R-454B, R-454C and R-457A) have been approved for residential and light commercial applications. Among these, R-32 and R-454B are expected to be the most commonly used for heat pump applications.

THE CORNER

AUTODESK® BIM RECOMMENDATIONS

Every successful project begins with a strong foundation. In 2025, that foundation is Building Information Modeling (BIM). At Kohler Ronan, we believe that a shared, coordinated model is essential to guiding smart, efficient design from start to finish. That’s why we promote BIM as the framework from which every discipline can build with confidence throughout the life of a project. Here are a few of our recommendations:

Utilizing the features of BIM Collaborate Pro, users can…

• Publish/Consume vs Live Linking.

• Allows one to consume the model on a set schedule, review the model for updates, and work through changes/ coordination.

• Establish model coordinates from the beginning.

• Establish administrative rights.

• Team members can be added freely.

• Clash detection can be instituted.

• Bridge hubs/projects when necessary.

“Impacts of Refrigerant Changes” cont. on page 4

“Impacts of Refrigerant Changes” cont. from page 3

Key Timelines for the Transition

The EPA has established a clear timeline for the phase-out of high-GWP refrigerants:

• Starting January 1, 2025, the EPA prohibits new manufacturing and importing of R-410A refrigerant for chillers in the United States. There will be a one year grace period to enact this change for new residential and commercial installations; some exceptions may apply for projects permitted on earlier dates, based on your local code.

• Starting January 1, 2026, the EPA will prohibit the use of R-410A refrigerant on VRF (Variable Refrigerant Flow) systems. Refrigerants are continuously developing to lower GWP, so it is important to stay informed on code developments.

• 2036: R-410A is expected to be completely phased out.

Additionally, the 2024 International Mechanical Code includes significant refrigerant -related updates. While most states have yet to adopt these changes, it is crucial to refer to local codes for compliance before proceeding with HVAC upgrades.

Equipment Selection: Replace vs. Repair

The transition to A2L refrigerants impacts

Author Credits

how owners decide between repairing or replacing their systems. While R-410A will remain available for servicing, parts for older equipment will become increasingly difficult to source. When an HVAC system reaches its life expectancy, owners will need to weigh the costs and benefits of upgrading to a system compatible with the new refrigerants.

Owner Preparation

• Stay informed about the useful life of HVAC systems and plan financially for refrigerant changes.

• Schedule regular maintenance to help minimize environmental impact and ensure efficient system performance.

Design Considerations & Industry Impact

Refrigerant changes are not just affecting equipment selection—they are also reshaping project design and schedules.

Project Schedules

• Designs must incorporate A2L refrigerants to comply with upcoming restrictions.

• Delays in manufacturer selection data are causing last-minute adjustments.

Architectural Impacts

• Fire-rated shafts are required for refrigerant piping chases spanning more than two floors.

• Changes in equipment capacity may alter system sizing.

Engineering Impacts

• Manufacturers are integrating additional refrigerant sensors on equipment exteriors.

• Refrigerant pipe shafts now require mechanical venting to comply with safety regulations.

• Infrastructure originally designed for older refrigerants cannot be recharged with newer A2L refrigerants (i.e. piping, compressors, branch selectors, etc.).

Conclusion

The shift to A2L refrigerants represents a significant industry change, influencing everything from equipment selection to mechanical and architectural design. While the last decade has seen a surge in VRF (Variable Refrigerant Flow) systems, it will be interesting to observe how these refrigerant updates impact future HVAC trends. Staying informed and preparing well in advance will be crucial for a smooth transition to the next generation of refrigerants.

New York City’s Electrical Code — Caitlin Ronan, PE, LEED AP BD+C, Associate Impacts of Refrigerant Changes: What You Need to Know — Kaitlyn Nelson, PE, LEED AP BD+C, Senior Engineer, and Gabriella Black, PE, Project Engineer

The Corner Kevin Czarnecki, CFPS, Senior Associate

Figure & Image Credits

Figures and Images are courtesy of Kohler Ronan, LLC, unless otherwise indicated.

Figure 3: Understanding A2L Refrigerants. [Figure]. Retrieved April, 2025 from https://www.achrnews.com/articles/153195-understanding-a2l-refrigerants.

About the Firm

From our offices in Danbury, Connecticut, and New York, New York, our diverse team of approximately 70 professionals collaborates with prominent architectural firms on a wide array of regional and nationally recognized project assignments. Commissions include those for world-renowned museums, fine and performing arts centers, prestigious universities, state-of-the-art educational and healthcare facilities, luxury residences, premier recreation establishments, and collaborative workspaces and ever-changing corporate campuses. Additionally, we have the privilege of designing specialty systems for landmark sites and historically significant buildings across the country. Regardless of project type, sustainability and environmentally responsible, forward-looking design are at the center of our work.

For more information, please visit our website at kohlerronan.com or connect with us on social media.

New York City’s Electrical Code - Updated GFCI Requirements

LOCATION

DWELLING

All 125V, 1ph, 15 and 20A receptacles in the following locations:

1. Bathrooms

2. Garages, and also accessory buildings that have a floor located at or below grade level not intended as habitable rooms and limited to storage areas, work areas, and areas of similar use

3. Outdoors

4. Crawl spaces – at or below grade level

5. Unfinished basements

6. Kitchens – where the receptacles are installed to serve the countertop surfaces

7. Laundry, utility, and wet bar sinks – where the receptacles are installed with in 6 ft of the outside edge of the sink

8. Boathouses

Outlets not exceeding 240V that supply boat hoists

All 125V, 1ph, 15 and 20A receptacles in the following locations:

1. Bathrooms

2. Kitchens

3. Rooftops

4. Outdoors

5. Sinks – where receptacles are installed within 6 ft of the outside edge of the sink

All 125V – 250V receptacles supplied by 1ph branch circuits rated 150V or less to ground in the following locations:

1. Bathrooms

2. Garages, and also accessory buildings that have a floor located at or below grade level not intended as habitable rooms and limited to storage areas, work areas, and areas of similar use

3. Outdoors

4. Crawl spaces – at or below grade level (plus lighting outlets not exceeding 120V)

5. Basements

6. Kitchens – where the receptacles are installed to serve the counter top surfaces

7. Sinks – where receptacles are installed within 6 ft from the top edge of the bowl of the sink

8. Boathouses

9. Bathtubs or shower stalls – where receptacles are installed within 6 ft of the outside edge of the bathtub or shower stall

10. Laundry areas

11. Indoor damp and wet locations

All 125V – 250V receptacles supplied by 1ph branch circuits rated 150V or less to ground, 50A or less, and all receptacles supplied by 3ph branch circuits rated 150V or less to ground, 100A or less, installed in the following locations:

1. Bathrooms

2. Kitchens or areas with a sink and permanent provisions for either food preparation or cooking

3. Rooftops

4. Outdoors

NONDWELLING

SPECIFIC APPLIANCES

Commercial Garages, Repair and Storage, Motor Fuel Dispensing Facilities – in areas where electrical diagnostic equipment, electrical hand tools, or portable lighting equipment are to be used

5. Sinks – where receptacles are installed within 6ft of the outside edge of the sink

6. Indoor damp and wet locations

7. Locker rooms with associated showering facilities

8. Garages, accessory buildings, service bays, and similar areas other than vehicle exhibition halls and showrooms

9. Crawl spaces — at or below grade level (plus lighting outlets not exceeding 120V)

10. Unfinished areas of basements

11. Laundry areas

12. Bathtubs and shower stalls — where receptacles are installed within 6 ft of the outside edge of the bathtub or shower stall

EQUIPMENT REQUIRING SERVICING [210.63]

Appliances below:

1. Vending machines manufactured prior to 2005

2. Electric drinking fountains

3. Cables installed in electrically heated floors of bathrooms and in hydromassage bathtub locations [424.44(G)]

4. Fixed outdoor electric deicing and snow-melting equipment [426.28]

5. Electric heat tracing and heating panels[427.22]

Appliances below rated 150V or less to ground and 60A or less, 1ph or 3ph:

1. Automotive vacuum machines

2. Drinking water coolers and bottle fill stations

3. Cord-and-plug-connected high-pressure spray washing machines

4. Tire inflation machines

5. Vending machines

6. Sump pumps

7. Dishwashers [422.5(A)]

8. Cables installed in electrically heated floors of bathrooms, kitchens, and in hydromassage bathtub locations [424.44(E)]

9. Fixed outdoor electric deicing and snow-melting equipment [426.28]

10. Electric heat tracing and heating panels [427.22]

Receptacles provided for servicing:

1. Heating, Air-conditioning, and Refrigeration Equipment

2. Indoor Service Equipment

3. Indoor Equipment Requiring Dedicated Equipment Spaces