Resiliency in Electrical Systems

What is resiliency?

The Merriam-Webster Dictionary defines resilience as “an ability to recover from or adjust easily to misfortune or change.” Although this definition might seem to be more human-centered, the same definition can be applied to non-human ideologies such as building systems. In the case of building systems, the definition can be reworded to “the ability of a building system to recover from or adjust easily to disaster, manmade or natural.” In our day and age, a building system is liable to be exposed to different kinds of disasters ranging from equipment malfunction, user error, or natural disasters like flooding. Thus, when incorporating resiliency into MEP systems, we are attempting to design these systems to recover from or adjust to a disaster as quickly and with as little difficulty as possible.

Why design resilient systems…

We are all familiar with the phrase, “Time Is Money” and understand that the meaning behind the aphorism is to suggest that a waste of time will inevitably lead to less money earned. That being said, I would like to provide a slight reword of the expression to “[Down] time is money.” What I mean by this is that the amount of time a building system is out of service, the more money is wasted. This is most evident when you think about the flooding associated with the most recent storm Elsa which caused subway cancellations, utility shutdowns, and building evacuations. All those interruptions led to downtime which led to the inability of business continuity for countless different entities and eventually a lot of monetary losses. One of the paramount goals, then, of a resilient

system is to minimize the downtime and allow for expedient recovery of building systems with the goal of minimizing overall monetary losses.

Continuing the narrative of a flooding event, central to the building owner’s post-flood efforts is resuming building operations as quickly as possible, while also attempting to achieve this recovery in the most affordable manner possible. So, is there an emphasis on ensuring that all efforts are economical? Is the owner replacing equipment that had just recently been purchased with capital and operating costs sunk into them? In general, when a new building is constructed, the hope is to purchase equipment once, attempt to use that equipment up to its useful life, and only have to purchase new equipment after the lifetime of the original equipment has been expended. However, when a disaster strikes, the useful life of equipment is diminished or eliminated. Avoiding wasted investment on equipment supporting building systems is another reason why designing a resilient system is very beneficial.

How to make building electrical systems more resilient…

One of the first steps in determining how to implement resilient design into your electrical systems is to understand the threat. Focusing on flooding as our case study, the threat is flood water damaging and rendering equipment unusable as described in the paragraphs above. After the presumed threat is understood, the next step is understanding what building systems will be impacted by the threat. In the case of building flooding, electrical service equipment located at the lowest level of a building is particularly

vulnerable because it interconnects equipment within the building with utility services outside the building. Thus, our focus for applying resiliency measures would be on the utility service connection boxes, switchboards, panelboards, and any conduit and wire that exists below the Design Flood Elevation (DFE) level.

As soon as we have identified the equipment most vulnerable to a flood, we can either design resiliency into those systems and keep them in place or remove them from the threat entirely. For the service switchboards and panelboards, for example, is it necessary that the switchboards remain in the basement level? Perhaps, they can be relocated to a level above the DFE and kept away from the threat. However, achieving this is easier said than done as various codes or requirements from Authorities Having Jurisdiction (AHJ) might not allow for a complete relocation of service equipment. If they do not, then sacrificial service equipment could be placed below the DFE with main distribution equipment placed above the DFE. In the event that the AHJ permits the equipment to be relocated to a higher level, then all service and distribution equipment (including equipment that “Resiliency in Electrical Systems” continued on page 2

VISION ISSUE THIRTEEN | SPRING 2022 ALL TEXT ©2022 KOHLER RONAN, LLC

Resiliency in Electrical Systems 1 Approach to Historic Structures 3 Revit ® Corner Net-Zero Buildings 4 Project Highlight 6 IN THIS ISSUE

“Resiliency in Electrical Systems” continued from page 1

might serve the level below the DFE) should be relocated higher. Despite relocating equipment above the DFE,

the fact remains that the equipment has to tie into services that are located below the DFE. One example could be the utility to building connection point which typically occurs at the building façade just below grade. Unfortunately, such situations cannot be avoided if the utility is unable to be relocated or the building owner does not wish to move the services above the DFE. As such, the engineer is forced to design for resilience in place. For example, the conduit and wire that connects the utility to the service switchboards, even with the switchboards moved to an upper level, will still require that a portion of the run be installed below the DFE. How then do we build resiliency in place for the conduit and wire? One solution includes specifying wire and conduit that is listed to sustain some level of water ingress without failure. For the conduit we can design water/ weather resistant conduit with watertight fittings to prevent as much water ingress into the conduit as possible while also allowing for the ability to reuse the

conduit after the event. One option would be utilizing Fiber Reinforced Conduit (FRC) in lieu of Electrical Metallic Tube (EMT) conduit for the service entrance as the FRC is more resilient to water, chemicals, dirt, and the like.

It is important to note that a vital part of resiliency is dependability. Selecting manufacturers and vendor equipment

MEP 2040 Challenge

that are reliable and dependable in times of need is very important. Ensuring that equipment specifications reference the appropriate manufacturer and call out the specific requirements as pertain to waterproofing or weatherproofing and listing will help ensure that not only is resiliency being incorporated into the system design, but that the equipment itself is inherently resilient. The vendor or manufacturer contact for the replacement equipment, if required, is also especially beneficial, as is making sure that the manufacturer’s representative is available as needed for quick procurement and replacement of equipment. Adding such language to the specifications about availability of a manufacturer within a certain timeframe helps to ensure that the bidding contractors are including reputable manufacturers with offices and staff within the vicinity of the project who will be able to help building owners achieve their resiliency goals.

Summary

Although the focus of this article has been flooding, it is easy to imagine other resiliency measures. Depending on the threat, a standby generator could be

“Resiliency in Electrical Systems” continued on page 3

Approved Technical Consultant in NY & CT –Incentive and Rebate Assistance

Kohler Ronan is an approved Technical Consultant providing valuable assistance to clients interested in accessing incentives in both New York and Connecticut. In New York, we are approved under NYSERDA’s Commercial New Construction Program and also serve as an Independent FlexTech Consultant. As part of the Energize Connecticut initiative, Kohler Ronan is approved for projects within Eversource and United Illuminating territory. Under each of these programs, our professionals provide technical support in the form of energy modeling and controls commissioning to assess and identify appropriate energy efficiency opportunities for new construction and substantial renovation projects. For details, please email Madhav Munshi at mmunshi@kohlerronan.com.

2

Kohler Ronan is pleased to join a growing number of MEP/FP industry leaders in accepting the Carbon Leadership Forum (CLF)’s MEP 2040 Challenge. As signatories, we are committed to “advocate for and achieve” net-zero operational and embodied carbon by 2030 and 2040 respectively, across all our projects.

Figure 1: Relocated Service Equipment Above the Design Flood Elevation (DFE)

Approach to Historic Structures

Kohler Ronan is part of a partnership that builds, restores, and transforms buildings to improve their functions and prolong their life cycles. We seek to become an extension of the architect’s office in the pursuit of a common goal. Our collaboration is not just with the historic and design architects for the current building project but with the architects throughout the history of the building.

We begin a historic building project with research into the historical perspective of the existing architecture and the complementing mechanical, electrical, plumbing, and fire protection systems. This process requires extensive field investigation to thoroughly understand the MEP/FP system configurations, how they are operated, and their routings within the building.

Determining the current equipment routings, along with researching existing architectural and structural documents, informs and guides the selection process for new equipment locations while limiting the impact on the building’s historic fabric. As the structure of a building typically is designed in concert with equipment location and pipe and conduit routings, we often uncover brick and stone cavities expressly constructed to house these utilities.

Atypical of new construction, the interior walls of historic buildings are often masonry. It is important that any new penetrations through existing walls or any routing of pipe and conduit below existing slabs and structure be assessed by the structural engineer on the project team.

Pipe and equipment hanging methods will require pullout tests as several types of structures are often found; Flat arch terracotta and Guastavino tile are common discoveries. Again, a structural engineer will be needed to review the possible locations of any new equipment going to into the building.

the coordination of multiple locations for new utilities, ductwork, pipes, and conduits. There is a specific SOI standard to address each of the possible treatments a property may undertake: preservation, rehabilitation, restoration, and reconstruction. Adhering to these standards will help realize a successful end result for historic structures.

“Resiliency in Electrical Systems” continued from page 2

specified even if one is not required per code. Similarly, a temporary generator connection box might be included if a permanent generator is too costly. Resiliency can also be understood in terms of redundancy. Designing systems with few to no single points of failure so that building systems remain operational, even when a switchboard receives damage due to a fault, is such an example. In any case, the aim of resilient design is to ensure that building systems are as they were before the catastrophic event, and that such remediation happens as quickly as possible, as seamlessly as possible, and as cost effectively as possible.

The Secretary of the Interior’s Standards for the Treatment of Historic Properties are the guiding principles regarding

REVIT® CORNER

BEST PRACTICES FOR MODEL MAINTENANCE IN REVIT

It is imperative to the health of a Revit project to continually keep up with model maintenance in order to ensure continual workflow without interruption. Below are some steps to follow...

Once the home page loads, you can find the applicable version and build number in the upper right hand corner under the question mark.

many times as necessary until Revit can no longer find elements to purge.

• Review and resolve warnings (as many as possible). Excessive warnings can increase file size and greatly impact performance.

• Remove extra views that are not needed in Project Browser; extra views will affect load times for models.

• Save the file with Compact selected (if saving over the same file). If this is a workshared file, it is recommended that you archive the original central file and its backup folder before saving in the same location with the same name.

We work closely with the project team to establish space requirements for new and/or reconfigured MEP/FP systems to efficiently utilize either new or repurposed spaces.

• Open the file with Audit selected (If the file is workshared, select Audit and Detach from Central). Do this on a regular basis (weekly or bi-weekly).

• Purge unused families and views. Do this as

• Save the file with a new name. Compact will automatically be selected and this will compact the file further than just selecting Compact.

3

Image 1: Brick cavities used for gravity heating can be utilized for ductwork.

Image 2: Terracotta Structure

Net-Zero Buildings

Introduction and Definitions

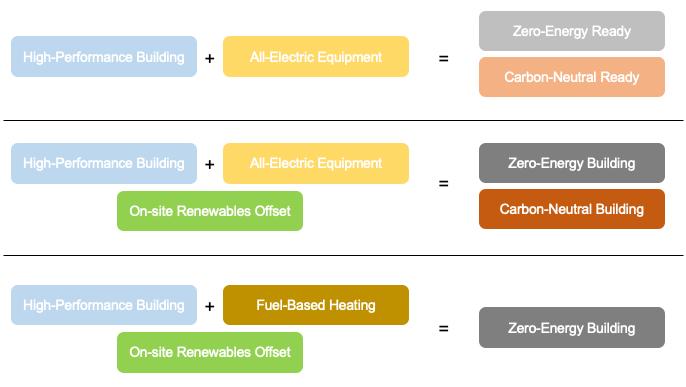

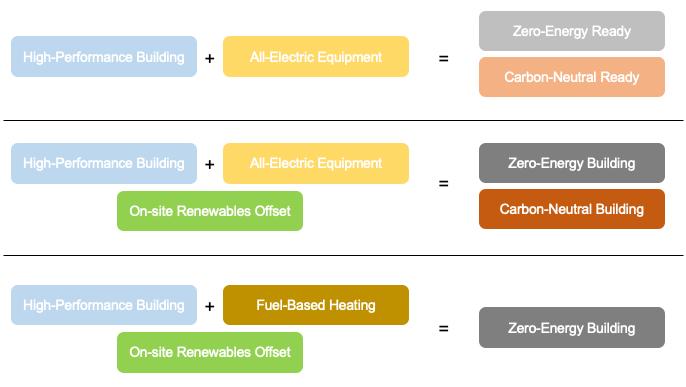

The building construction industry has pivoted from focusing only on energy efficiency towards a more holistic goal of achieving zero-carbon emissions in the built environment. Every year, we see transformations and improvements in policy, energy codes, and technology, as well as design as they relate to carbon neutralization in the building construction industry. A few years ago, only projects of significance even considered zero-energy level performance; now, it is commonly expressed as a requirement in RFPs for schools, affordable housing, and public buildings. While it might be hard for all projects to install their own energy generation systems, due to the lack of space (especially in urban settings), it is possible to achieve a high-performance building with the capability of connecting to a green grid when that becomes available in the future. It is important that the definition of a net-zero building be clarified for owners, architects, engineers, and other stakeholders to ensure that the correct decisions are made on projects with these ambitious goals.

There are multiple definitions that we need to understand to determine the appropriate path for each project.

Carbon-Neutral Building (NYSERDA 2021)

“A carbon neutral building is one where the design, construction, and operations do not contribute to emissions of greenhouse gases that cause climate change.”

Carbon-Neutral Ready (NYSERDA 2022)

“An energy efficient project that excludes all fossil fuels from the building systems and equipment qualifies as Carbon NeutralReady.”

Zero-Energy Building (DOE 2015/ ASHRAE Zero Energy Guides)

“An energy-efficient building where, on a source energy basis, the actual annual delivered energy is less than or equal to the on-site renewable exported energy.”

Balancing Design, Technology, and Operations

The main requirement of net-zero buildings is to design a high-performance building with low energy demands. These buildings will typically have low energy consumption on a per-squarefoot basis, also known as EUI, than the average code compliant building. The ‘average’ high-performance, all-electric building has an energy use intensity (EUI), which is energy consumed on a squarefoot basis, of less than 25 kBtu/sf/year excluding buildings that have high energy usage such as labs, hospitals, museums, data centers, and the like.

This level of high performance requires a close-knit collaboration between the design team, building owners, and building operators. A design with complex systems and controls can become a burden from an operations standpoint, so sometimes it is beneficial to scale back on complexity and provide a simpler system that is easy to trouble shoot and maintain. Passive house has shown us a method of designing airtight buildings, with heat pump and superefficient ventilation systems. While not all buildings can be passive house, it is possible to borrow passive house principles and technology to design

high-performance buildings. Projects may find it useful to establish an ‘energy budget’ early in the design process and determine how it can achieve that target using an energy analysis process. Energy simulation can help balance first cost, operating costs, and carbon emissions and enable the design team to make the appropriate decisions regarding projects. High-performance codes such as the International Green Construction Code or ASHRAE standards 189.1 have provided systematic approaches to the design, construction, and operations of highperformance buildings.

High-performance and carbon-neutral buildings also need to be operated in an optimal manner. Operational emissions cannot be controlled if users and facility managers have no training or understanding of building systems, controls, and maintenance schedules. Building commissioning processes that encompass functional performance testing, systems manuals, and training of staff ensure a proper handoff after construction. Ongoing commissioning and measurement & verification for the first year of occupancy can further ensure that the building operates in the manner consistent with its design intent and the data collected.

4

Figure 2: Visual Representation of Definitions

“Net-Zero Buildings” continued from page 4

Design

world to tackle carbon emissions, will require its existing buildings over 25,000 square feet to reduce their operational emissions to meet the city’s goal of 80% emissions reduction by 2050 as compared to 2005 levels. As the state’s grid becomes cleaner, these low energy requirements will facilitate a faster transition to a low and zero-carbon future.

construction, demolition, and disposal of buildings and building materials, constitutes half of the total emissions of a building. This means that embodied carbon is as equally critical as operational carbon in the process of decarbonization. The current industry-wide parameters that help to quantify the environmental impacts of products are described below:

Certifications for zero-carbon and zeroenergy are offered by both LEED and the International Living Futures Institute (ILFI). These certifications go beyond the design and construction of the building and rely on actual operation data of the building’s energy consumption and the generation of the renewable components. On-site combustion is forbidden unless it is for emergency power only. Kohler Ronan’s project portfolio includes the ILFI Certified Net-Zero Energy Kohler Environmental Center at Choate Rosemary Hall in Wallingford, CT.

Connecticut has also signaled its intention towards decarbonization and is looking to detail a long-term strategy of reducing greenhouse gas emissions in its 2022 Comprehensive Energy Strategy. The final goals are yet to be determined, but there is a clear focus on energy efficiency, resiliency, and climate.

The Next Big(ger!) Challenge: Embodied Energy

LCA: Life Cycle Assessment is the industry methodology for assessing environmental impacts associated with the various stages of a product’s life cycle. The amount of environmentally harmful by-products released from the extraction stage to the product’s ultimate disposal are quantified.

GWP: Global Warming Potential is a metric used to capture the relative potency of all the compounds (CFCs, Methane, etc.) that contribute to global warming, measured in kgCO2e units. Specifically, it is a measure of how much energy the emissions of one ton of a gas will absorb over a given period, relative to the emissions of one ton of carbon dioxide (CO2).

EPD: Environmental Product Declarations are third-party verified objective reports that communicate what a product is made of and how it impacts the environment across its entire life cycle.

Kohler Ronan’s Efforts

A Tale of Two States

New York State is leading this transformational change in buildings and infrastructure using its three-year energy code cycles which are increasing in stringency with each iteration. The state has also made commitments to transform its electrical grid and make it carbon neutral by the year 2040. New York City, which has the most ambitious plan in the

It is estimated that embodied carbon, which is carbon emissions because of extraction, transportation, manufacturing,

Kohler Ronan’s firmwide sustainability initiative seeks to make technically informed, practical, environment-friendly, and holistic design decisions. As part of the Carbon Leadership Forum’s MEP 2040 Challenge, we have made a commitment to reduce operational and embodied carbon to zero by 2040.

Kohler Ronan remains dedicated to our collective, low-carbon future, and sustainability is at the center of our engineering practice.

5

Operations Technology

Continued

Figure 3: Visual Representation of Definitions

Figure 4: Upfront Embodied Carbon

Image 3: Choate Rosemary Hall, Kohler Environmental Center, Wallingford, CT

Extraction

Figure 5: End-of-Life Embodied Carbon

Refurbishment

Construction Transpor t to Factor y Transpor t to Site Manufacturing

Landfill Demolition Waste Processing Transpor tation

Project Highlight — Rock and Roll Hall of Fame Museum

Originally designed by I.M. Pei, the iconic Rock and Roll Hall of Fame is currently undergoing a significant expansion and renovation, representing a combined 86,100 square feet. Kohler Ronan has been invited by Practice for Architecture and Urbanism (PAU) to join their team in providing comprehensive mechanical, electrical, plumbing, and fire protection designs. For decades, the culturally acclaimed museum has provided a space for education, family events, and performances by some of the world’s most popular rock artists. Challenged with creating a structure that would complement the original signature design of I.M. Pei, PAU conceived “the Clash.” This triangular addition creates a new entrance for the museum where the point of the pyramid collides with the main structure. The building will be made of galvanized steel and will include a rooftop deck overlooking Lake Erie. Rather than upstaging the addition, the lighting design supports the new structure in similar fashion to stage lighting. The hope for this obtrusive addition is to bring more of what is characteristically and historically Cleveland to the heart of the museum and bridge the gap between the city, the lake, and the pyramid.

Author Credits

Resiliency in Electrical Systems, Pearl Odu, PE, LEED AP, Senior Associate Approach to Historic Structures, Robert V. Hedman, PE, LEED AP BD+C, Well AP, CPHD, Principal Revit® Corner, Victor Alves, BIM Coordinator Net-Zero Buildings, Madhav Munshi, LEED AP BD+C, BEMP, Associate

Figure & Image Credits

Figures and Images are courtesy of Kohler Ronan, LLC unless otherwise indicated. Image 3: © Anna Wesolowska/www.photographerhedman.com

About the Firm

From our offices in Danbury, Connecticut and New York, New York, our diverse team of approximately 70 professionals collaborates with prominent architectural firms on a wide array of regional and nationally recognized project assignments. Commissions include those for world-renowned museums, fine and performing arts centers, prestigious universities, state-of-the-art educational and healthcare facilities, luxury residences, and premier recreation establishments. Additionally, we have the privilege of designing specialty systems for landmark sites and historically significant buildings across the country. Regardless of project type, sustainability and environmentally responsible, forward-looking design are at the center of our work.

For more information, please visit our website at kohlerronan.com or connect with us on social media.

New York

171 Madison Avenue, New York, NY 10016

T 212.695.2422

Danbury

93 Lake Avenue, Danbury, CT 06810

T 203.778.1017

Connect kohlerronan.com

marketing@kohlerronan.com

6

Rendering Courtesy of Practice for Architecture and Urbanism (PAU)