Link Product / Engine

Product Market Product Engine

F5HFL463D*F005

580N T - Wheel Drive (2WD)

T ier (final) [NHC740227 - ] North America

F5HFL463D*F005

580N Four - Wheel Drive (4WD)

T ier (final) [NHC740227 - ] North America

INTRODUCTION

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[10.001] Engine and crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.1

[10.103] Crankshaft and flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.2

[10.202] Air cleaners and lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.3

[10.206] Fuel filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.4

[10.216] Fuel tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5

[10.218] Fuel injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.6

[10.304] Engine lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.7

[10.400] Engine cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.8 [10.414] Fan and drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.9 [10.501] Exhaust Gas Recirculation (EGR) exhaust treatment . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.1 [55.201]

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.2 [55.301] Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.3

[55.302] Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.4

[55.404] External lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.6 [55.510]

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine hood and panels

[90.1 14] Operator protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.2

[90.124] operator seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.3

[90.150] Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.4

[90.151] Cab interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.5

[90.154] Cab doors and hatches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.6

[90.156] Cab windshield and windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.7

Foreword - Important notice regarding equipment servicing

All repair and maintenance work listed this manual must carried out only qualified dealership strictly complying with the instructions and whenever the special

Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall responsible for any subsequent

The manufacturer and all the organizations its distribution chain, including - without limitationnational, regional, local reject any responsibility for damages caused parts and / components not approved the facturer , including those used for the servicing repair the product manufactured marketed the manufacturer any case, warranty given attributed the product manufactured marketed the manufacturer case damages caused parts and / components not approved the manufacturer

The manufacturer reserves the right make improvements design and changes specifications any time without notice and without incurring any obligation install them units previously and illustrative material herein are accurate known time publication but are subject change without notice.

case refer your CASE CONSTRUCTION Sales and Service

Safety rules

Personal safety

This the safety alert used alert you potential personal injury Obey all safety messages that follow this symbol avoid possible death injury

Throughout this manual you will find the signal words W and CAUTION followed special These precautions are intended for the personal safety you and those working with

Read and understand all the safety messages this manual before you operate service the

DANGER indicates a hazardous situation not will result death serious injury

W ARNING indicates a hazardous situation not could result death serious injury

CAUTION indicates a hazardous situation not could result minor moderate injury

Machine safety

NOTICE: Notice indicates a situation that, not avoided, could result machine property damage.

Throughout this manual you will find the signal word Notice followed special instructions prevent machine property damage. The word Notice used address practices not related personal safety .

Information

NOTE: Note indicates additional information that clarifies other information this

Throughout this manual you will find the word Note followed additional information about a step, other information the The word Note not intended address personal safety property

Safety rules - Personal safety

Unless otherwise instructed, always perform these steps before you service the machine:

Park the machine a level

Place the backhoe the transport position with the swing lock pin installed for transport.

Place the loader bucket the with the bottom the loader bucket parallel the

Place the direction control lever and the transmission you need open the hood perform raise the loader arms and install the support

Shut down the Place a Not tag the key switch that visible other workers remove the key

Safety rules - Ductile iron

DANGER

Altering cast ductile iron can cause weaken Before you weld, cut, drill holes any part this machine, make sure that the part not cast ductile iron. Failure comply will result death serious injury .

Altering cast ductile iron can cause weaken

Unauthorized modifications cast ductile iron parts can cause death serious injury not repair , attach items cast ductile iron parts this

Before you drill holes any part this make sure the part not cast ductile See your dealer you not know a part cast ductile

The following items are examples cast ductile iron There may also other parts made cast ductile iron that are not the list below

• two - wheel drive steering link

• dump links

• front axle

• stabilizers

• extend - a - hoe

• swing tower

• bucket linkage

• Air - Conditioning / compressor mounting bracket not make any unauthorized Consult authorized dealer before making any modifications this

Engine - Prepare - Stall tests

the stall test find the cause poor

The main relief valve must set within specifications achieve accurate readings when performing the following stall

The engine run full throttle and the transmission and hydraulic systems are engaged separately , and then gether .

Comparing the engine speeds from the stall test with the check sheets this section will help find the cause the problem. can necessary check a separate system find the exact cause the problem.

Use a photo tachometer other tachometer equal accuracy get accurate results from the stall

The transmission and hydraulic system must operating temperature before doing the stall Heat the oil according instructions this

Machines with standard transmission

Apply the parking

Move the transmission gear selector into fourth gear

Lock the brake pedals together Put your foot the service brakes and hold the machine with service

Release the parking

With the engine running low move the direction control lever

Slowly increase the engine speed full the machine begins move any decrease the engine speed low idle and stop the

Machines with S - T ype and H - T ype transmissions

Apply the parking Place the automatic / manual switch the manual

Select fourth gear the range selector .

Lock the brake pedals together Put your foot the service brakes and hold the machine with service

Release the parking

With the engine running low move the direction control lever

Slowly increase the engine speed full throttle. the machine begins move any decrease the engine speed low idle and stop the Refer sections Parking brake discs - Inspect (33.1 10) , Parking brake discs - T est (33.1 10) and Parking brake discs - Check 10)

Procedure heat the torque converter and the hydraulic oil

Apply the parking

Start and run the engine low

Run the engine full throttle, hold the loader control lever the rollback position for

Return the loader control lever neutral for

Return the boom control lever neutral for Repeat steps 3 and 4 until the temperature the oil ( 126 ) The side the reservoir will very warm this

With the engine running low move the mission control fourth gear and the direction control lever

Run the engine full throttle for seconds.

Decrease the engine speed low idle and move the direction control lever neutral for

10. Repeat steps 6 through 8 until the pointer the gauge for transmission oil temperature the center the green zone the gauge for transmission oil ature.

Stall test procedure

Prepare the machine for the stall test according structions this

Heat the oil according instructions this

Apply the parking brake and start the engine.

With the engine running full hold the loader control lever the lift position and read the tachometer Record the reading line 1 the check

With the engine running full throttle and boom travel hold the dipper lever the position and read the tachometer Record the reading line 2 the check

Decrease the engine speed low

Move the transmission control lever fourth gear .

NOTE: For machines with S - T ype and H - T ype place the automatic / manual switch the manual sition.

Lock the brake pedals together Put your foot the service brakes and hold the machine with service

Release the parking brake.

Move the direction control lever

1 Slowly increase the engine speed full throttle and read the tachometer Record the reading line 3 the check sheet.

12. With the transmission control lever fourth gear , the direction control lever and the engine ning full hold the loader control lever the lift position and read the tachometer Record the ing line 4 the check

Decrease the engine speed low move the directional control lever neutral.

Run the engine low idle for two minutes and then stop the

See the check sheet understand the results the stall test.

Engine - Remove

Prior operation: Remove the engine See Engine hood - Remove (90.105)

Prior operation: Remove the Diesel Oxidation Catalyst (DOC) tray See Diesel Oxidation Catalyst (DOC) - Remove Prior operation: Drain the engine cooling See Radiator - Drain fluid Prior operation: Remove the engine cooling system. See Radiator - Remove (10.400) . Prior operation: evacuate the air - conditioning See Air conditioning - Charging Air conditioner system evacuation and recharging

disconnect electrical connectors (1) and (2)

disconnect the A / C high pressure disconnect the A / C low pressure disconnect the A / C condenser voltage

Disconnect fuel lines (1) and (2)

Disconnect the water sensor electrical connector (not shown).

NOTE: W ater sensor located the bottom the primary fuel filter

Disconnect the glow plug control unit electrical tor (1)

RAPH1 1TLB0021BA 3

Remove the supporting bracket (1) and hanging barrier curtain (2)

RAIL14UTL0095BA 4

Disconnect the heater hose (1)

RAPH1 1TLB0039BA 5

NOTE: For assembly identify and label all trical

Disconnect the wires from the air restriction indication

Remove the air filter assembly and cap all

RAIL14FRK0104BA 8

RAIL14FRK0122BA 9 14. Disconnect the wiring harness connector (1) and the positive battery cable (2) from the rear the tor RAPH12FRK0163AA

15. equipped, remove the battery disconnect switch bracket from the frame and set

RAIL14TLB0403AA 1 1

Remove the nut (3) , disconnect the wire harness (4) and positive battery cable (2) from the terminal the starter (1) .

RAIL14TLB0403AA

Disconnect the ground

RAIL14FRK0129BA

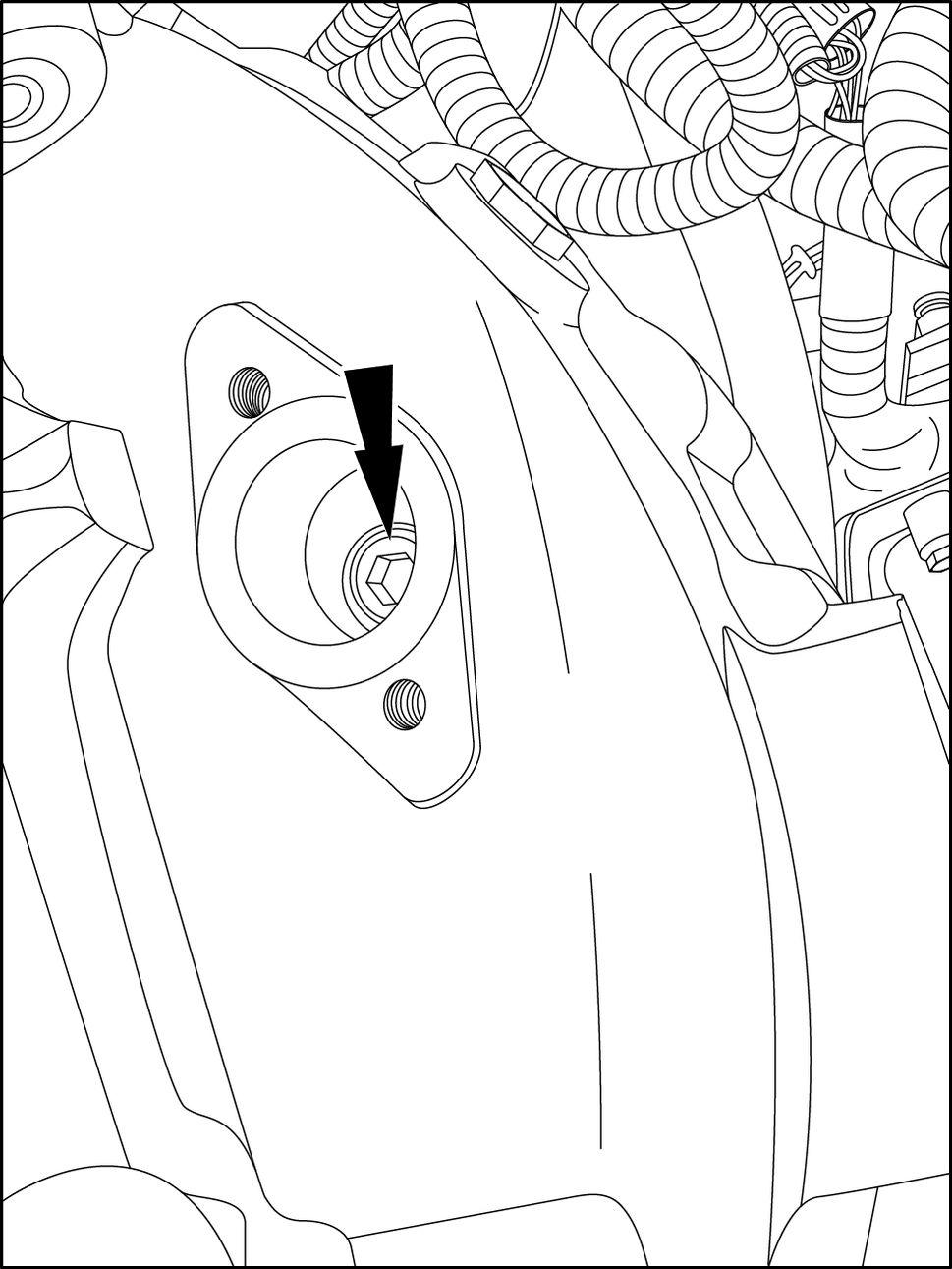

Insert the engine turning tool 380003372 into the lower opening and rotate the flywheel until the flex plate bolt visible the top opening.

23. Loosen the motor mount - - frame bolts both sides the Remove all motor mount - - engine bolts both sides the engine.

NOTICE: A void machine Maintain adequate clearance between the engine and machine Make sure the engine components NOT come contact hang the frame frame components during engine

Carefully raise and remove the engine from the Place the engine the repair stand and repair replace necessary

Engine - Install DANGER

Heavy objects! Lift and handle all heavy components using lifting equipment with adequate capacity . Always support units parts with suitable slings hooks. Make sure the work area clear all bystanders. Failure comply will result death serious injury

Specification

Engine weight (approximate) 363 ( 800 ) Attach appropriate lifting device the three engine lift eyelets (1) the engine

NOTICE: A void machine Maintain adequate clearance between the engine and machine Make sure the engine components NOT come contact hang the frame frame components during engine

Carefully raise and position the engine the Install all the bolts and washers that fasten the mission the flywheel housing (only two not tighten this time.