621F

721F

Tier 4

Wheel Loader

OPERATOR’S MANUAL

Part number 84474094

2nd edition English

December 2011

Replaces part number 84376871

Contents 1GENERALINFORMATION Notetotheowner...........................................................................1-1 Operator'smanualstorage.................................................................1-3 Right,left,front,andrearofthemachine...................................................1-4 Notetothe wner ..........................................................................1-7 Productidentification.......................................................................1-8 2SAFETYINFORMATION Safetyrules.................................................................................2-2 Personalsafety.............................................................................2-3 Safetyrules.................................................................................2-5 Safetyrules.................................................................................2-7 Safetyrules-Operatingprecautions......................................................2-8 Safetyrules-Maintenanceprecautions..................................................2-10 Safetyrules-Fuelhandling...............................................................2-11 Safetyrules................................................................................2-13 Safetyrules-Supportstrutandservicelink..............................................2-15 Safetysigns...............................................................................2-17 3CONTROLS/INSTRUMENTS ACCESSTOOPERATOR'SPLATFORM OPERATOR'SSEAT FORWARDCONTROLS Steeringcolumn........................................................................3-8 Pedalcontrols.........................................................................3-10 LEFT-HANDSIDECONTROLS Transmissioncontrols.................................................................3-13 Joysticksteering.......................................................................3-15

STOPPINGTHEUNIT MOVINGTHEUNIT

RIGHT-HANDSIDECONTROLS Twofunctionvalve.....................................................................3-19 Threefunctionvalve...................................................................3-23 Fourfunctionvalve....................................................................3-27 Wristrest..............................................................................3-29 EXTERIORCONTROLS INSTRUMENTCLUSTER Displaysettings........................................................................3-43 Keypad................................................................................3-45 Operatorpreferences..................................................................3-53 SIDECONSOLE Overview..............................................................................3-58 Climatecontrols.......................................................................3-64 CLIMATECONTROLS Cabairlouvers........................................................................3-66 Windows...............................................................................3-68 4OPERATINGINSTRUCTIONS COMMISSIONINGTHEUNIT Runinperiodofanewmachine........................................................4-2 STARTINGTHEUNIT Startingtheengine.....................................................................4-3 Coldtemperatureoperation............................................................4-6

Ridecontrol............................................................................4-14 Automaticmode.......................................................................4-24

Loaderfunctions.......................................................................4-25 5TRANSPORTOPERATIONS RECOVERYTRANSPORT Transportingthemachine..............................................................5-2 6WORKINGOPERATIONS LOADEROPERATIONS Operatingtips.......................................................................6-1 Couplingtotheattachment.........................................................6-6 Joystickoperation.................................................................6-12 7MAINTENANCE GENERALINFORMATION Supportstrutforloaderliftarm.........................................................7-3 Releasingpressureinthehydraulicsystem............................................7-5 Fluidsandlubricants...................................................................7-7 SelectiveCatalyticReduction(SCR)system..........................................7-13 MAINTENANCECHART MaintenanceChart....................................................................7-16 Dailyinspection General................................................................................7-18 Every10hours Engineoil..............................................................................7-22 Every50hours Bucket/attachmentgreasefittings.....................................................7-23 Hydraulicoillevel......................................................................7-25 Enginecoolant.........................................................................7-27

Initial100hours Changeengineoilandfilter(Initial)...................................................7-29 Cleanin-lineDieselExhaustFluid(DEF)supplyfilter(Initial).........................7-32 Fuelfilter(Initial).......................................................................7-34 Every100hours Greasefittings.........................................................................7-35 Every250hours Cabairfilter-Recirculationfilter......................................................7-39 Wheelsandtires.......................................................................7-41 Every500hours Engineoilandfilter....................................................................7-43 Replacefuelprefilter..................................................................7-45 Replacefuelfilter......................................................................7-46 Fueltanksediment....................................................................7-47 Rolloverprotectivestructure..........................................................7-49 Every1000hours Articulationfittings.....................................................................7-53 Drivebelt..............................................................................7-55 Replacingtheenginebreatherfilter...................................................7-59 Every1500hours Changefrontandrearaxleoil.........................................................7-60 Transmissionfluidandfilter...........................................................7-62 Selectivecatalyticreductionsystem-Replacesupplymodulefilter..................7-65 Calibratingthegearbox...............................................................7-66 Transmissiondeclutchpressureadjustment4-speedtransmissiononly.............7-68 Every2000hours Hydraulicoilandfilters................................................................7-69 Engineairfilters.......................................................................7-73

Enginevalveclearance................................................................7-75 Every3000hours Selectivecatalyticreductionsystem-Replacesupplymodulefilter..................7-76 Asrequired Fuelpre-filter..........................................................................7-78 Selectivecatalyticreductionsystem-Cleantankfilter................................7-79 Heightcontrolandreturntotravel.....................................................7-82 Parkingbrake..........................................................................7-88 Cabservice............................................................................7-93 ELECTRICALSYSTEM Batteryservice.........................................................................7-96 Auxiliarybatteryconnections.........................................................7-100 Fusesandrelays.....................................................................7-103 Drivinglights..........................................................................7-110 Rotatingbeaconlight.................................................................7-111 STORAGE Preparationforstorage...........................................................7-112 Every30days....................................................................7-113 Removal..........................................................................7-113 8SPECIFICATIONS Generalspecifications......................................................................8-1 Generalspecifications......................................................................8-8 Z-Bardimensions621FGeneralSpecifications..........................................8-17 Z-Bardimensions-721FGeneralSpecifications.........................................8-34 Materialweights...........................................................................8-53 9ACCESSORIES

Notetotheowner

RCPH11WHL418FAH 1

Readthismanualbeforeyoustarttheengineoroperatethemachine.Ifyouneedmoreinformation,seeyourCase

Thismanualcontainsimportantinformationaboutthesafeoperation,adjustment,andmaintenanceofyourmachine.

causeseriousinjuryordeath.Anyonemakingsuchunauthorizedmodificationsisresponsiblefortheconsequences.

Theinformationinthismanualisprovidedonthebasisofinformationthatwasavailableatthetimethemanualwas written.Settings,procedures,partnumbers,softwareandotheritemscanchange.Thesechangescanaffectthe

ATTENTION:

untilreworktooriginalconditioniscompleted.Engineserviceand/orrepairsmustbedonebyacertifiedtechnician only!

1-GENERALINFORMATION

RCPH11WHL416FAH 2

DONOTOPERATEorpermitanyonetooperateorservicethismachineuntilyouortheotherpersonshavereadand demonstratedtheabilitytooperateandservicethismachinecorrectlyandsafely.

movingpurposessuchaslandleveling,truckloading,andmaterialrehandling.Thismachineisnotintendedtobe

DONOTusethismachineforanyapplicationorpurposeotherthanthosedescribedinthismanual,decals,orother productsafetyinformationprovidedwiththemachine.Thesematerialsdefinethemachine'sintendeduse. causeseriousinjuryordeath.Anyonemakingsuchunauthorizedmodificationsisresponsiblefortheconsequences.

•

CaseCustomerAssistancecanbereachedat: 1–866–54–CASE6(1–866–542–2736ore-mail:casecustomerassistance.na@cnh.com.

•

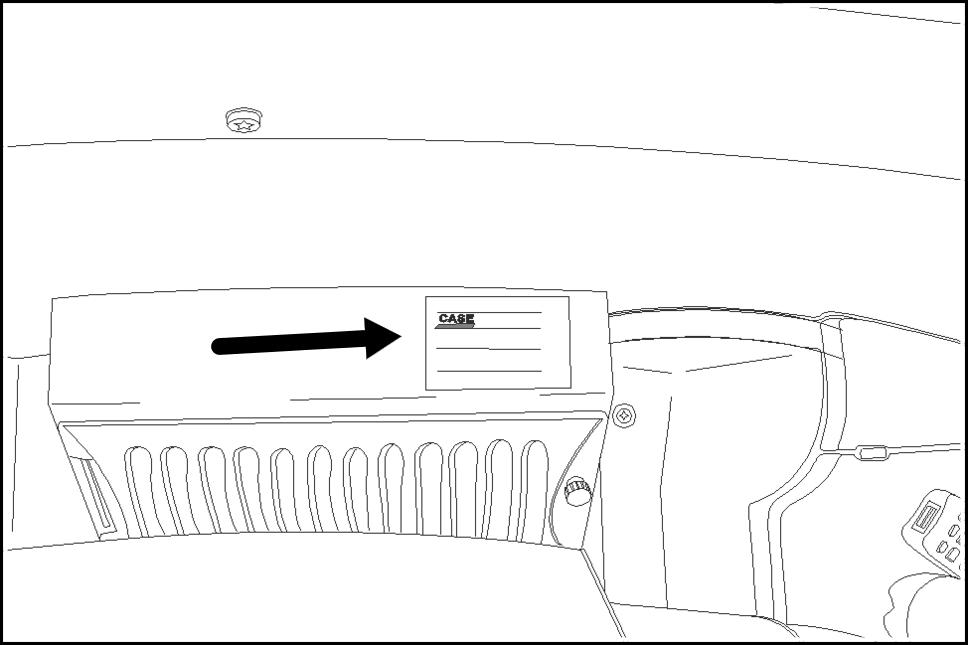

Toaccesstheoperatormanualstoragearealocatedon thebackoftheoperator’sseat,releasethelatchontopof

READTHISMANUALCOMPLETELYandmakecertain stabilityandloadcharacteristicsofthismachinebefore youstarttooperate. DONOTremovethismanualorthesafetymanualfrom storagecompartmentprovidedonthemachine.TheOpWhenyouseethissymbolreadyour operator'smanual.

RCPH11WHL0030AA 1

Whenyouseethissymbolrefertoyour

Right,left,front,andrearofthemachine inthismanualtoindicatethesidesastheyareseenfrom theoperator'sseat. RCPH10WHL003BAH 1

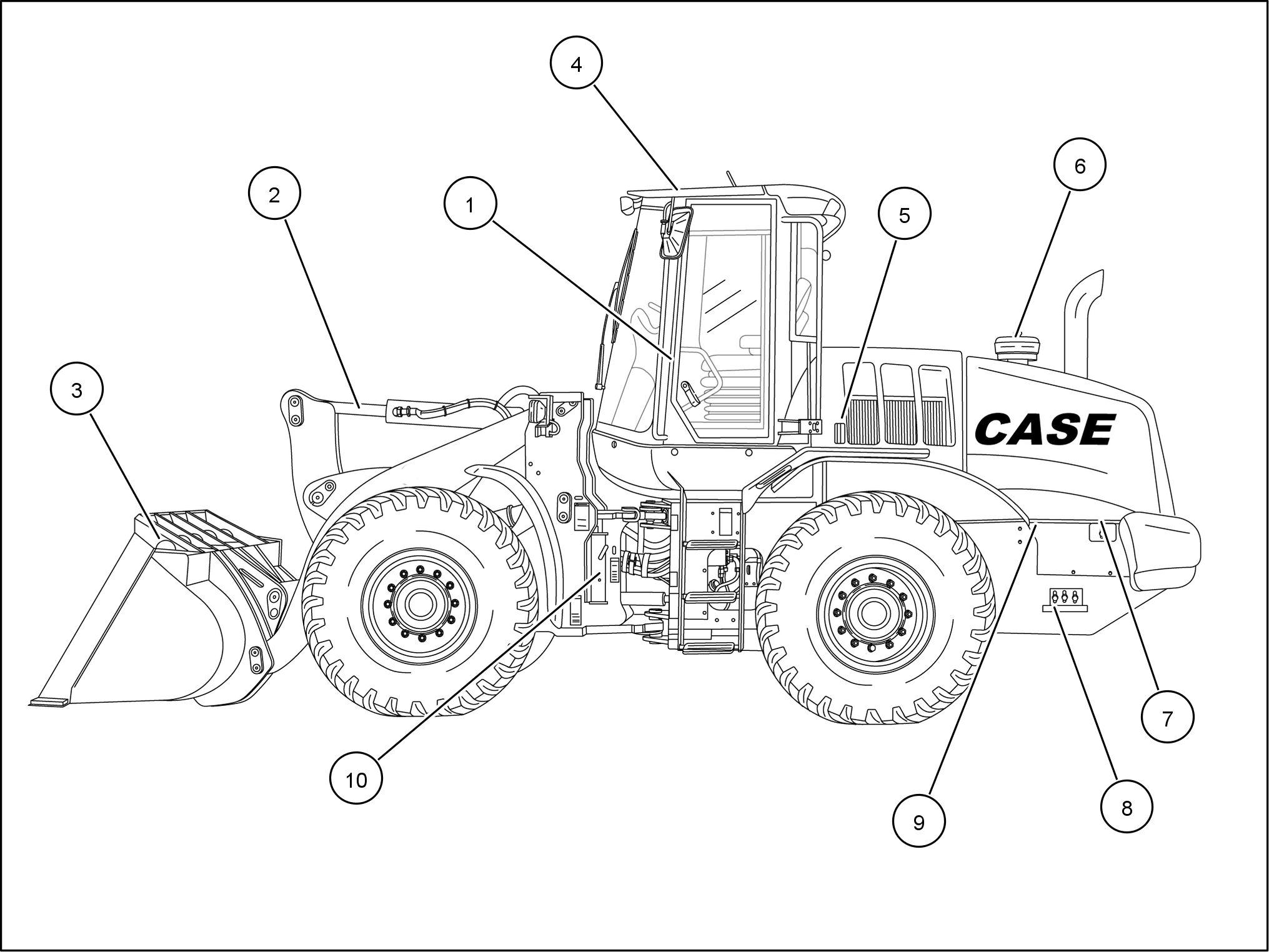

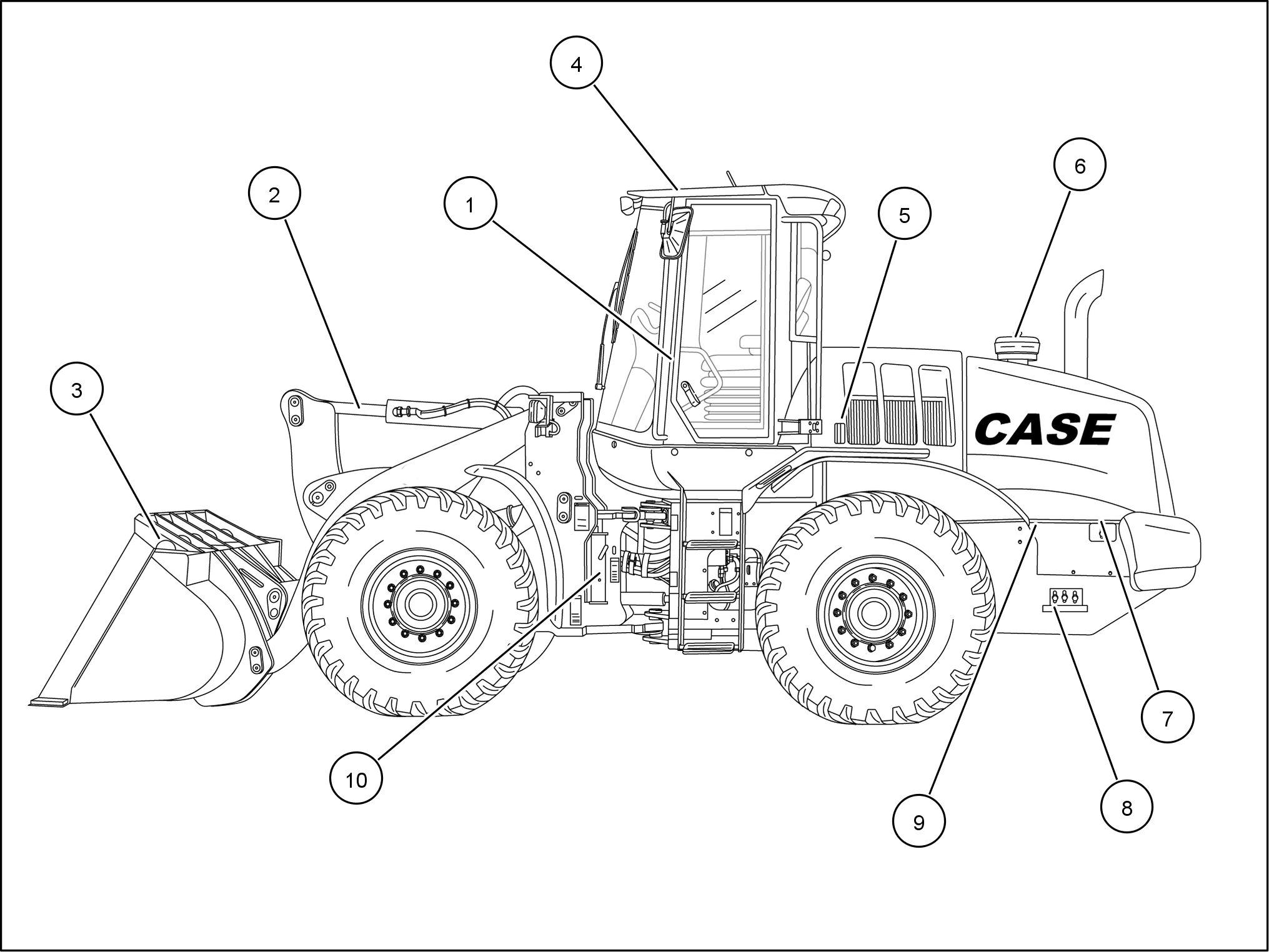

Machinecomponents RCPH11WHL418FAH 1 5.Hydraulicfluidsightgauge 10.Liftarmsupportstrut

RCPH11WHL416FAH 2

Notetothe wner Thismanualcontainsinformationconcerningtheadjustmentandmaintenanceofyournewequipment.Youhave Yourauthorizeddealerwillinstructyouinthegeneraloperationofyournewequipment.Yourdealer'sstaffoffacnumbersnowandrecordthembelow.Refertothe'GeneralInformation'sectionofthismanualforthelocationofthe PLEASERECORDTHEFOLLOWINGINFORMATION Model DatePurchased WARNING Illustrationsinthismanualmayshowprotectiveshieldingopenorremovedtobetterillustrateaparticularfeatureoradjustment. Failuretocomplycouldresultindeathorseriousinjury. W0012A IMPROVEMENTS CNHAmericaLLCiscontinuallystrivingtoimproveitsproducts.Wereservetherighttomakeimprovementsor

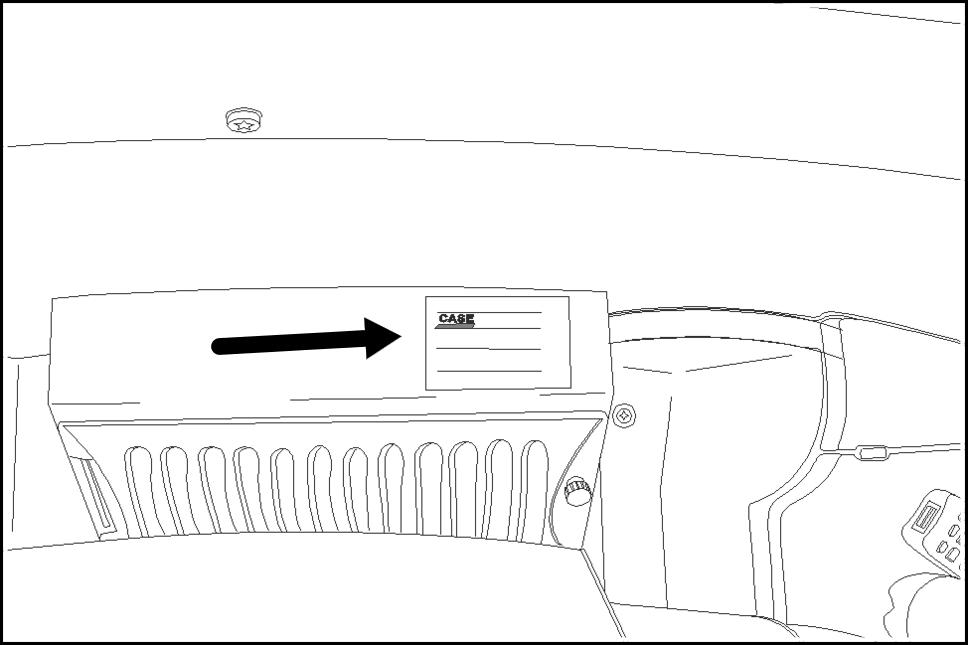

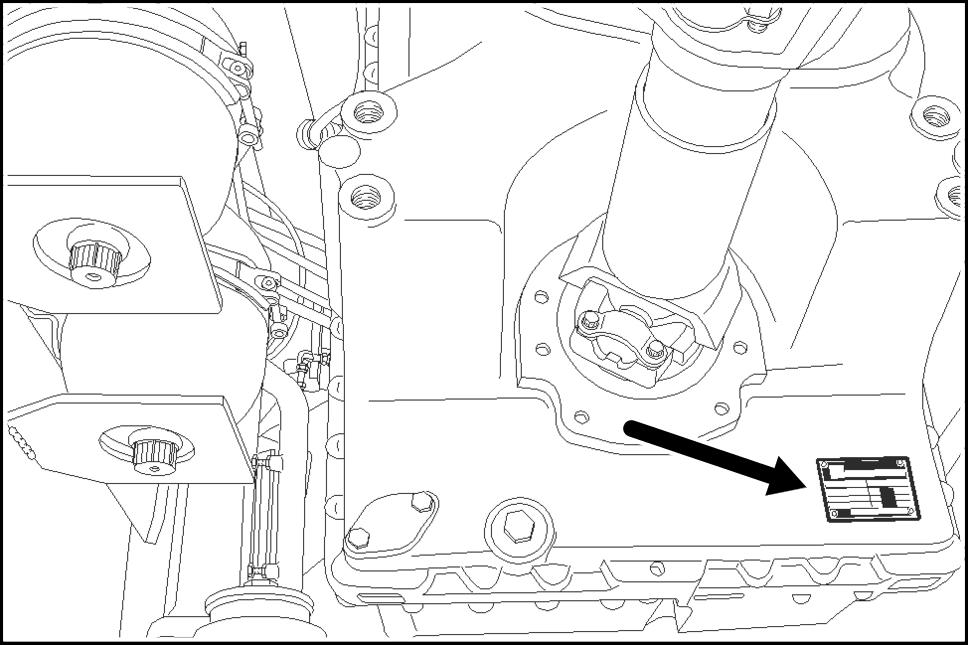

Productidentification Model,serialnumber,andyearofmanufacture andyourManufacturer’sStatementofOrigininasafeplace.Ifthemachineisstolen,reportthenumberstoyourlocal Machineidentification Modelname PIN Modelyear TheProductIdentificationNumber(PIN)plateislocated RCIL10WHL014AAL 1 Roll-OverProtectiveStructure(ROPS) RCIL10WHL013AAL 2 Enginemakeandmodel Engineserialnumber RCIL10WHL015AAL 3

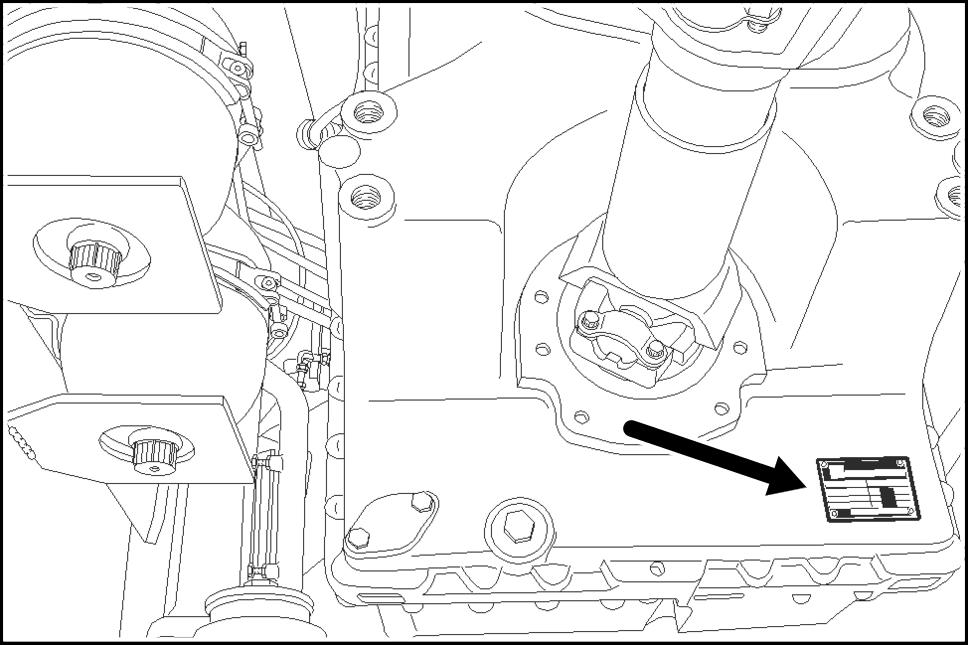

Transmission RCPH10WHL004BAH 4 Axle RCPH10WHL081AAH 5

Suggest:

If the above button click is invalid.

Please download this document first, and then click the above link to download the complete manual.

Thank you so much for reading

Electro-MagneticCompatibility(EMC)

• • Theelectromagneticfieldgeneratedbytheaddonsystemshouldnotexceed 24V/m atanytimeandatany •

following: