Chassisandcounterweight2

Jacking up the fork truck3

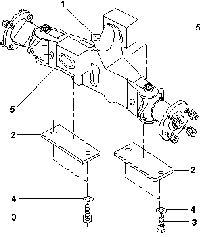

Chassis and counterweight

Chassis

The vehicle chassis is a welded construction with bolted on counterweight.

The fuel tank is arranged in the right chassis half and the hydraulic tank in the left chassis half..

Counterweight

The counterweight is fastened to the welded chassis construction with four bolts, see diagram.

1 - Hexagon bolt M24x130 / 8.8

Tightening torque = 710 Nm

2 - Spherical washer

3 - Cone pan

Weight of counterweight: 2407 kg

Jacking up the fork truck

ATTENTION Before jacking up the fork truck, apply the parking brake.

For various servicing routines, the fork truck must be jacked up.

When jacking up the fork truck, suitable measures must be taken to prevent the fork truck slipping or tilting, e.g. using wooden blocks.

Always ensure that only jacks with sufficient bearing capacity are used and that the fork truck is jacked up only on level ground and secured to prevent it rolling.

Only jack up the vehicle at the points shown in the photos, i.e. at the mast on the left or right and at the chassis at the front or rear.

Do not jack up the fork truck at the counterweight!

When jacking up the fork truck at the mast, the safety regulations for working on the mast must be observed.

Chassis and counterweight

Workshop manual 7084 - 86

Steering axle

Lubricant

bearings hub Wheel

litthium -20, DIN51825-KP2K to acc F Grease saponified

litthium -30, DIN51825-KP2K to acc F Grease saponified

bearings axle Sub lithium -20, DIN51825-KPF2N to acc FL Grease saponified

148659 No - Ident STILL

Design of the steering axle

The steering axle is mounted with 2 buffer elements on the counterweight. The stub axlesare supported in taper roller bearings in the axle body.Steer angle limitation takes place via stop bolts on the stub axle

1Axle body

2Fixing plates

3Hexagon bolt

4 Lockwasher 5Bufferelements

Removing the steering axle

CAUTION: Only remove the steering axle with the mast mounted! Risk of tilting!

-Apply the handbrake.

-Place wooden blocks under the front wheels to preventthevehiclerolling.

-Loosen the steering axle wheel nuts.

-Jack up the vehicle in the precribed manner. (SeeGroup01)

-Removethewheels.

-Unscrewthehydraulicconnectionsfromthesteering cylinder.

CAUTION: Hydraulicoilwilldischargewhenthe hydraulic connections are unscrewed. Collect hydraulic oilanddispose of ina proper manner.

-Place a hand pallet truck or similar with blocks of wood underthe steering axle.

-Unscrewthefourcheese-headscrewsforfixingthe steering axle.

Fitting the steering axle

- Fitting takes place in reverse orderto removal.

- Tightening torque of 4cheese-head screws: MA = 195 Nm

CAUTION: Do not interchange left and right hydraulicconnections!

Workshop manual 7084

Steering axle

Removing the wheel hub

5

7

8

9

10

11

12

-Loosen nuts(11)and removewheel.

-Removedustcap (7).

-Loosen hexagonnut (8).

-Removewasher(9)withpin (6).

-Removewheelhub.

-Removetaperrollerbearings(4)and(10)fromwheel hub; for this purpose, the radial seal (3) must be removed..

-If necessary, remove outer rings of taper roller bearings (4)and (10).Fitting the wheel hub

-Thoroughly grease sealing lips ofradial seal.

-FilltaperrollerbearingswithgreaseFbetweeninner ring and cage.

-Fill bearing spaces at the points marked (x) with grease F.

-Fitting takes place in reverse order to removal.

-Tighten hexagonnut(8)constantly turning the wheel hub.

Tightening torque: MA = 470 Nm

Checking the steer angle

The steer angle a must be 80° - 82°. To facilitate measurement, the supplementary angle b can be used. This must be 98° - 100°.

ATTENTION:It must be ensured that the steer angle is definitely limited by the stop bolts (1). The stop must not take place in the steering cylinder.

Adjusting the steer angle

The steer angle is limited by one stop bolt (1) on each side respectively.

-Adjustthe leftandrightsteerangles(1) to 80°-82° with the stop bolts (1).

-Check the opposite angle.

- Check the free space at full steering wheel lock.

-Checkthatthe steerangle stop doesnottakeplace in the steering cylinder.

turn right

turn left

steering angles

Workshop manual 7084 - 86

Steering axle

Removing the stub axle

1Hexagon bolt

2Washer

3Kingpin

4Plug

5Stub axle

6Hexagon bolt

7Hexagonnut

8Spacer

9Scraperring

10Taperrollerbearing

11Spacer

12Nipple

13Taperrollerbearing

14Scraperring

15O-ring

16Spacer

-Removewheel.

- Press out bolt between tie rod and stub axle.

- Loosen hexagon nut(1).

-Removewasher(2).

- Press out king pin (3) downwards.

- Remove stub axle from axle.

-Removespacers,O-ring,scraperrings,taper roller bearings and spacers (8 - 16)fromstub axle.

Fitting the stub axle

1 Hexagon nut

2 Washer

3 King pin

4 Plug

5 Stub axle

6 Spacer

7 Scraper ring

8 Taper roller bearing

9 Spacer

10 Taperrollerbearing

11 Scraper ring

12 O-ring

13 Spacer

14 Bolt

-Fit spacer (9) in stub axle.

-Fit both taperroller bearings (8+10). Grease both bearings well with grease FL!

-Thoroughly grease sealing lips of scraper rings (7+11) with grease FL

-Fit scraper rings (7+11), both spacers (13, 6 ) and O-ring(12).

-Fit sub axle in axle.

-Insert king pin (3) from below; lightly oil pin.

-Fit washer (2).

-Fit a new hexagon nut (1) and tighten with a torque of: MA = 310 Nm.

-Press in bolt (14) of tie rod and secure with pins.

-Fit wheel.

-Grease steering axle with grease FL. Greasing the steering axle

-Operate steering while greasing steering axle.

- Grease eight nipples of steering axle with grease FL until fresh grease discharges at the bearing points (see diagram on page 8)

Steering axle

Workshop manual 7084 - 86

Steering axle

Removing the tie rods

The steering axle has two tie rods seated between the steering cylinder and both stub axles.

1 Sub axle

2 Piston rod

3 Seals

4 Pins

5 Bolt

6 Tie rod

7 Ball socket

Removepins(4)

Press out bolt (5)

Fitting the tie rods

Fitting takesplace in reverse order to removal.

Bolt press-in force on cylinder side: max. 29 kN

Bolt press-in force on stub axle side: max. 38 kN

3 4 4 5

Removing the steering cylinder

-Remove tierods.

- Unscrew hydraulic connections and mark.

ATTENTION: Discharginghydraulic oil.

- Loosen fourbolts (1).

Fitting the steering cylinder

- Tighten bolts (1).

Tightening torque: MA= 295 Nm

- Screw on hydraulic connections.

ATTENTION:Donotinterchangehydrauliclines.

- Fit tie rods.

NOTE: Instructions for removing and fitting the steering cylinder are given under Group 06.

Greasing the steering axle

-Relievethesteeringaxlewhilstgreasingandoperate the steering.

- Grease the eight nipples (2) of the steering axle, starting from the upper nipples until fresh grease discharges atthe bearing points.

NOTE: When greasing the upper bearing, it is unnecessaryforgreaseto dischargefromthe upper seal. It can also deviate downwards.

Steering axle

Technicalservice data2

Geardrive3+4

Spurgearing withdifferential5

Fittingthegear drive6

Geardrive/tubularshaft7

Axle shaft8

Wheel hub9

Workshop manual 7084 - 86

Technical service data

03 Group drive ear G2 0 - 40 AE Type

torque ightening Tm N 1000 = MA axle Drive Chassis/

torque Tightening Nm 295 = MA Transmission housing/ Axle clearance Axial mm 06 0 - to mm 03 0 + shaft tubular Gear

torque Tightening 10.9 18 x M8 ZS hub Wheel flange/ Centering Nm 135 = MA

torque ightening Tm N 70 = MA plug drain Oil

torque Tightening Nm 120 = MA 9 10 35 x M12 ZS shaft Axle oil ransmission Te litr 5 9 = Capacity

type rease Ge additiv EP with grease soap Lithium

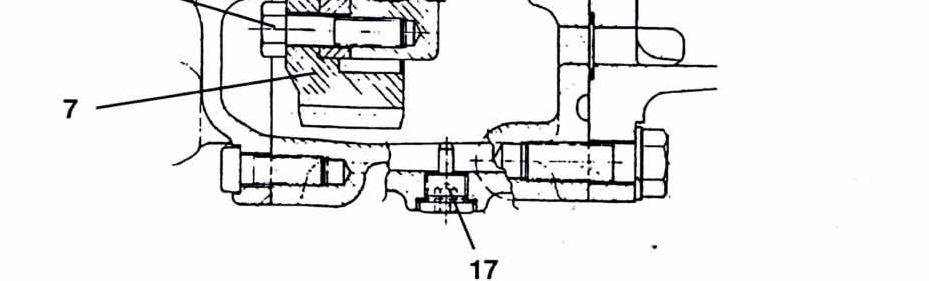

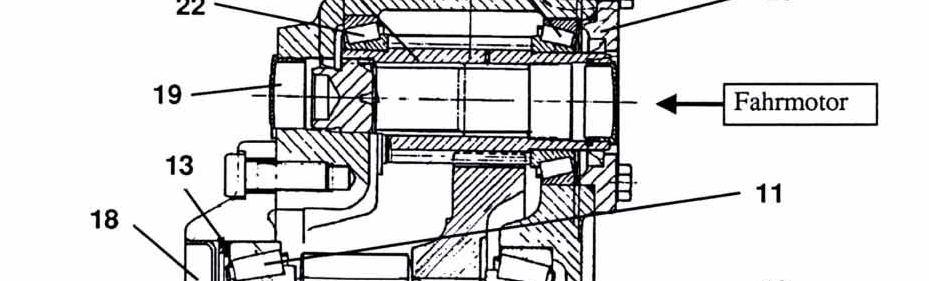

Gear drive Description

The gear drive consists of two-speed spur gearing withdifferential(1)anddoublesupporteddrivepinion aswell asflange-mounted d.c.motor(2),a long axle housing(3)andanaxlehousing(shortside) integrated in the transmission case (1).

Thelongaxlehousing(3)isboltedtothespurgearing. Both are bolted to the chassis and simultaneously serve for accommodating themastbearing.

Gear drive

1Transmissioncase

2

Spur gearing with differential

3Dowel pin

4Cheese-headscrew

5Taperrollerbearing

6Differential

7Gear

8Pin

9Hexagon bolt

10Washer 145 x 130 x 0.5 - 0.9

11Taperrollerbearing

12Gearwith shaft

13Washer 160 x 85 x 0.5 - 0.9

14Lock ring

15Reducingpipe

16Seal

17Plug

18Cover

19Plug

20Catch

21Shaft seal

22Taperrollerbearing

23Gear

24O-ring

25Washer 75 x 65 x 0.5 - 0.8

26O-ring

27Shaft seal

28Cover

29Lock washer

30Hexagon bolt M8 x 20 8.8

Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL.NOWAITING

NOTE:

If there is no response to click on the link above, please download the PDF document first and then clickonit.

Workshop manual 7084 - 86

Gear drive

Removing the gear drive

Removemast

Jackup vehicle

Drain oil (2) and collect

Loosenwheels/mounting

Removewheels

DisconnectE-motorcables (mark!)

Disconnect brake line at main brake cylinder

Removebrake linefromparking brake

Support gear drive with acraneorrope winch

Unscrew bolts (3) left and right

Fitting the gear drive

Position gear drive in chassis with a crane or rope winch

Drawgeardriveagainstchassiswith16boltsand16 washers

Tighten all bolts (3)

Tightenting torqueMA =1000Nm

Removecrane orropewinch

ConnectE-motorcables

Connect brake lines at main cylinder

Fit brake lines in parking brake

Fit wheels (see Group 04)

Mount mast (see Group 20)

Measure oil level with dipstick

Oil capacity: 9.5 litre

Transmission oil: SAE 90 EP - 51512

Gear drive/tubular shaft

Housing = B

Gear tubular shaft = A mm

Instructions for adjusting gear tubular shaft bearing

1. Measureboth taper rollerbearings complete on thegeartubularshaftuptothestopinthevertical positionAover outer rings.

2.Measurehousing mountingdimension B

3.Measure centring collar length C on cover

4.Packing thickness D=B-(A+C+0.06)

5.RoundpackingthicknessDupordownaccording to actual dimension = D + 0.03mm (initial tension)to 0.06mm(clearance).

Cover = C

6.Bothtaperrollerbearingsmustbefittedwith50% greasefilling. Transmission oilSAE140 EPcan be used as a substitute.

7.Prefittaperrollerbearing outer ring (tacho) with fitting mandrel about 20 mm.

8.Fit geartubularshaft.

9.Prefittaperrollerbearing outer ring (cover) with fitting mandrel about 20 mm.

10.Insertpackingandbringtaperrollerbearingouter ring into its final position by evenly tightening the bolts.