84129594

Issued August, 2008 1st Printing

Magnum 215, 245, 275, 305 and 335 Series Tractors

After P.I.N. Number Z8RZ06001

Operator’s Manual

Magnum 215, 245, 275, 305 and 335 Series Tractors

After P.I.N. Number Z8RZ06001

Operator’s Manual

84129594

Issued August, 2008 1st Printing

Magnum 215, 245, 275, 305 and 335 Series Tractors

After P.I.N. Number Z8RZ06001

Operator’s Manual

Magnum 215, 245, 275, 305 and 335 Series Tractors

After P.I.N. Number Z8RZ06001

Operator’s Manual

THIS SAFETY ALER T SYMBOL INDICA TES IMPOR T ANT SAFETY MESSAGES THIS MANUAL. WHEN YOU SEE THIS SYMBOL, CAREFULL Y READ THE MESSAGE THA T FOLLOWS AND ALER T T O THE POSSIBILITY DEA SERIOUS INJUR Y

Throughout this manual and the s safety you will find precautionary statements: DANGER< W ARNING CAUTION followed special instructions ISO two panel safety pictorial These tions are intended for your personal safety

Failure follow the W ARNING CAUTION instructions may result death serious bodily injury

W ARNING CAUTION are defined follows:

• DANGER: Indicates immediate hazardous situation not will result death serious injury

The color associated with Danger

• W ARNING: Indicates a potentially hazardous situation not could result death serious injury The color associated with W arning ORANGE.

• CAUTION: Indicates a potentially hazardous situation not could result minor moderate injury may also used alert against unsafe The color associated with Caution YELLOW

ISO two panel pictorial symbol decals are defined follows:

• The first panel indicates the nature the hazard.

• The second panel indicates the appropriate avoidance the hazard

• Background color YELLOW

• Prohibition symbols such and used are

W ARNING IMPROPER OPERA TION THIS MACHINE CAN CAUSE DEA SERIOUS INJUR Y BEFORE USING THIS MAKE CER T AIN THA T EVER Y OPERA T OR:

• instructed safe and proper use the

• Reads and understands the Manual(s) pertaining the

• Reads and understands ALL Safety Decals the

• Clears the area other

• Learns and practices safe use machine controls a clear area before operating this machine a job site.

your responsibility observe pertinent laws and regulations and follow CNH America LLC instructions machine operation and

Manuals are available from your Dealer for the operation, service and repair your machine. For prompt convenient contact your Dealer for assistance obtaining the manuals for your

Y Dealer can expedite your order for Operators Manuals, Parts Catalogs, Repair Manuals and maintenance records.

Always give the Machine Model and P (product identification number) your machine your Dealer can provide the correct manuals for your

The company continually striving improve its products and therefore reserves the right make improvements and changes when becomes practical and possible without incurring any obligation make changes additions the equipment sold previously

All data given this manual subject production IMPOR T ANT : OPERA TING AND SER VICE SAGES DISPLA YED THE ELECTRONIC OPERA TING P ANEL Y V Y FROM WHA T SHOWN THE ERA T OR’S SHOULD THIS OCCUR ADHERE T O THE TEST INSTRUCTION THE ELECTRONIC OPERA TING P ANEL.

Dimensions and weights are approximate only and the illustrations not necessarily show the machine standard For exact information about any particular please consult your dealer

Proposition

RCPH07CCH014F

This manual contains important information about the safe adjustment and routine maintenance your Magnum series tractor The manual divided into ten chapters outlined the table Refer the index the end this manual for locating specific items about your tractor .

NOT operate permit anyone operate service this machine until you the other persons have read this Use only trained operators who have strated the ability operate and service this machine rectly and safely .

This Operator ’ s Manual stored the manual partment equipped this Make sure this ual good Contact your dealer obtain ditional Contact your dealer for any further formation assistance about your Y our dealer has approved service parts. Y our dealer has technicians with special training that know the best methods repair and maintenance for your tractor

Magnum series tractors with standard equipment and thorized are intended used for customary farming, land leveling and related agriculture Installation utility (dozer) tile push bars the tractor not Any tractor damage resulting from the installation and / use such equipment not covered the tractor warranty

Consult authorized dealer CNH America LLC additions modifications that can required for this machine comply with various regulations and safety Unauthorized modifications will cause serious injury Anyone making such unauthorized modifications responsible for the

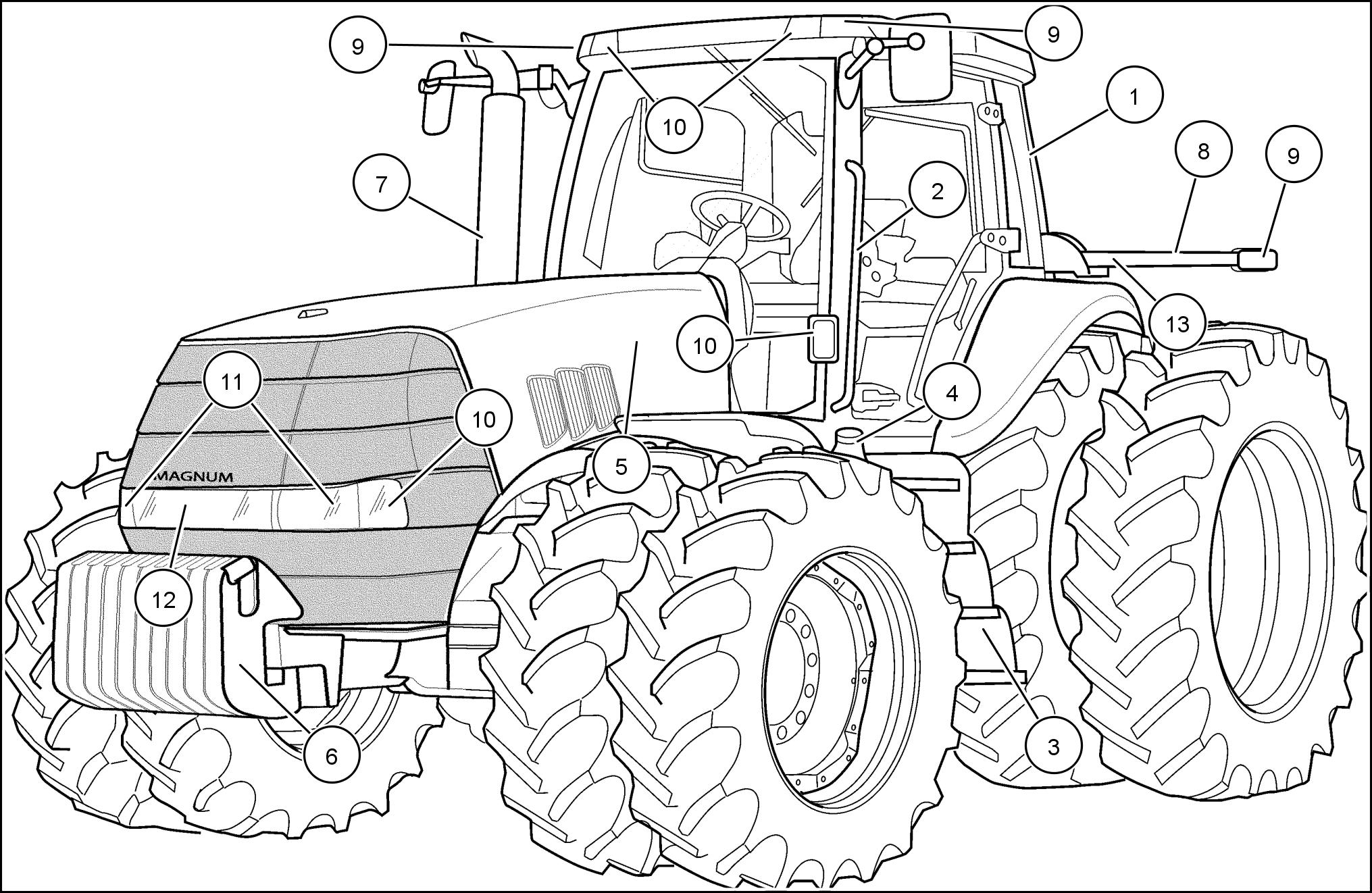

RCPH08CCH002F 1

Keep the Operator ’ s Manual the storage compartment provided your tractor The Operator ’ s Manual must available for use all

The right hand and left hand side the tractor used this manual are the same your right hand and left hand when sitting the tractor seat looking

GENERAL INFORMA TION - 1

T ractor model and product identification number

Model : PIN

NOTE: Located right hand front RCPH08CCH486AAB

Roll over protection system (ROPS) serial number

NOTE: Located the right hand cab floor RCPH08CCH482AAB

Engine serial number

NOTE: Located the front left hand side the engine.. RCPH08CCH479AAB

ransmission serial number

NOTE: Located the right hand side the transmission (speed housing) behind the fuel tank and the left the ground RCPH08CCH483AAB

Axle serial number

MFD axle: Located the rear right hand side the axle housing (1)

Saddle suspended axle: Located the rear right hand side the axle housing (not shown).

Scissors suspended axle: Located the front right hand side the axle housing (not shown).

Amber reflector

Understand that your safety and the safety other persons measured how you service and operate this machine. Know the positions and operation all controls before you try operate. MAKE SURE YOU CHECK ALL CONTROLS A SAFE AREA BEFORE TING YOUR

READ THIS MANUAL COMPLETEL Y and make sure you understand the All equipment has Make sure you understand the steering stability and load characteristics this machine before you start

The safety information given this manual does not replace safety codes, insurance state and local Make sure your machine has the correct equipment needed the local laws and CNH America LLC continuing work for your safety making tractors with better protection and providing these rules for safe

• Before starting the engine, sure all operating trols are neutral park lock This will eliminate accidental movement the machine start power driven (M106E)

• Operate controls only when seated the operators (M137A)

• Securely fasten your seat The seat belt can crease your safety used and maintained. Never wear a seat belt loosely with slack the belt Never wear the belt a twisted condition pinched between the seat structural Inspect seat belt buckle and retractors ensure they are not damaged. damage apparent, pair before operating the machine Failure comply could result death serious injury (M1284)

Failure comply could result death serious injury (M1219)

• Collision high speed road traf fic and slow moving machines can cause personal injury use flasher / lights according local Keep slow moving vehicle (SMV) emblem Pull over let faster traf fic Slow down and signal before turning (R1 10E)

• For speeds / h ( mph ) , make sure that the weight a trailed vehicle that not equipped with brakes does NOT EXCEED times the T ractor For speeds / h ( mph ) , make sure that the weight the trailed vehicle that not equipped with does NOT EXCEED the weight the T ractor Stopping distance increases with creasing speed the weight the towed load especially hills and (M814A)

• A frequent cause death serious injury persons falling f machinery and being run over Keep cab door closed. Instructional seat used only for structing service diagnosing only NOT permit others especially Seat belt must worn all (M488C)

• Brake pedals must locked together for road travel. This will insure uniform brake application and mum stopping ability Failure comply could result death serious injury (R1 12A)

• Stay f slopes too steep for safe Shift down before you start down a hill with a heavy A void wheeling.”

• not drive high speed with the dif ferential lock Dif ficult steering will occur , and can result field use the dif ferential lock for traction improvement, but release for turning row (M1 16A)

• Extra weight and bad traction conditions such mud ice increase your stopping distance. Remember that liquid the weights the machine tanks filled with fertilizer , herbicides secticides - all these add weight and increase the distance you need which (R138B)

• Before leaving the tractor , stop the put all trols neutral park lock remove the key from the key (R301B)

• T ravel speed should such that complete control and machine stability maintained all Where avoid operating near embankments and holes. Reduce speed when turning, crossing and muddy ure comply could result death serious injury (M109B)

• not exceed implement transport speed the speed rating the implement Review the implements Operator ’ s Manual for

• the tractor engine hydraulic pressure and the brake pedals can pushed the floor Activating BOTH pedals will engage the park (M768)

• O driven machinery can cause serious injury . fore working near the O servicing clearing the driven put the O lever the DISENGAGE position and the (R154A)

Suggest:

If the above button click is invalid.

Please download this document first, and then click the above link to download the complete manual.

Thank you so much for reading

• Whenever a O driven machine the O guard must place for most operations prevent injury the operator Where such are installed the O shaft (especially the tractor O guard moved ward extended shielding equivalent the O guard must installed with the Install the O guard its original position ately when the attachment (R273A)

• not pull with elastic tow Elastic tow rope stores energy Sudden release may cause injury (M425)

• Y oung children should not permitted operate ride the tractor under any circumstances. (M630)

• not tamper with the ballast the front rear High Intensity Discharge Lamps contains high voltage. Personal injury death can occur (M639)

• When doing stationary O work and dismounting from the tractor with the O keep clear all moving parts they are a potential safety (R127A)

• W A sound horn before starting the Make sure working area clear other before you start operating this chine. NEVER allow anybody work area during machine (M804)

• Never operate the engine a closed Proper ventilation required under all circumstances. (R142A)

• Never refuel the machine when the engine hot Never smoke while (R139C)

• T o prevent tractor always apply the park brake whenever the tractor parked with the engine The park brake applied automatically when the engine shut down. (M627)

• Always start the engine from the operator ’ s Never attempt bypass the tractor may denly start and move resulting serious fatal injury (M787)

• Check and service cooling system according the maintenance Hot coolant can spray out the deaeration tank cap removed while system hot. T o remove the deaeration tank cap, let system turn first then wait until all pressure Scalding can result from fast removal the cap. (R141C)

• Hydraulic oil diesel fuel leaking under pressure can penetrate the skin and cause infection other injury . T o Prevent Personal Injury:

• This tractor equipped with a spring applied ical front wheel drive (MFD) clutch and a front axle limited slip dif Even with the MFD engaging switch the f the front axle clutch can pel both front wheels any the following conditions occur:

The engine turned

• Relieve all pressure before disconnecting fluid

• Before applying make sure all tions are tight and components are good

• Never use your hand check for suspected leaks under

• Use a piece cardboard wood for this injured leaking see your doctor ately (R149B)

The engine stopped when the rear wheels are still

Any interruption the clutch operating hydraulic system flow pressure the electrical controls for clutch

Both brakes are

• For these the following service procedures must followed:

• Rear upset can result pulling from wrong location tractor Hitch only the drawbar Use three point hitch only with the implements designed for its usenot a drawbar

• not look directly into the front rear High Intensity Discharge Lamps. Eye damage can occur . (M638)

• Before rotating the rear wheels a MFD tractor (if you are using engine power with the rear wheels supported f the one the following cedures must done prevent accidental tractor movement.

• Jack and support BOTH front wheels completely f the

•

• the tractor hydraulic pressure and the brake pedals can pushed the floor . Activating BOTH pedals will engage the park (M768)

• Clean tractor field trash daily more frequently depending upon T rash accumulation the tractor can cause damage and (M791)

• Disconnect the front wheel drive Doing one these two procedures will insure that ment the MFD clutch will not result tractor movement. (R292B)

• T o avoid possible eye damage from microwave nals emitted the radar sensor , not look directly into the sensor (M788)

• Always keep the cab windows and rear view mirrors clean provide the best all around visibility while erating the tractor (R416)